MITSUBISHI DIAMANTE 1900 Manual PDF

Manufacturer: MITSUBISHI, Model Year: 1900, Model line: DIAMANTE, Model: MITSUBISHI DIAMANTE 1900Pages: 408, PDF Size: 71.03 MB

Page 71 of 408

3-10 ENGINEANDENGINEOVERHAUL

2. Disconnect the battery negative cable.

3. Drain the cooling system.

Never open, service or drain the radiator or

cooling system when hot; serious burns can

occur from the steam and hot coolant. Also,

when draining engine coolant, keep in mind

that cats and dogs are attracted to ethylene

glycol antifreeze and could drink any that is

left in an uncovered container or in puddles

on the ground. This will prove fatal in suffi-

cient quantities. Always drain coolant into a

sealable container. Coolant should be reused

unless it is contaminated or is several years

old.

4 Disconnect the accelerator cable and air in-

take hose.

5. Disconnect the upper radiator hose, heater

hose and water bypass hose.

6. Unplug the vacuum connection at the power

brake booster and the PCV valve if still connected.

Disconnect all remaining vacuum hoses and pipes as

necessary.

7. Disconnect the high pressure fuel line, fuel

return hose and remove throttle control cable brack-

ets

8. Tag and detach the electrical connectors from

the oxygen sensor, coolant temperature sensor,

therm0 switch, idle speed control assembly, EGR

temperature sensor, distributor, fuel injectors and

spark plug wires. Position the engine wiring harness

aside.

9. Matchmark the distributor housing to the in-

take manifold, and remove the distributor.

10. Remove the intake manifold bracket and the

engine hanger.

11. If the thermostat housing is preventing re-

moval of the intake manifold, remove it.

12. Remove the intake manifold mounting bolts

and remove the intake manifold assembly. Drsassem-

ble manifold from the Intake plenum on a work bench

as required

To install: 13. Clean all gasket material from the cylinder

head intake mounting surface and intake manifold as-

sembly. Check both surfaces for cracks or other dam-

age. Check the intake manifold water passages and

jet air passages for clogging. Clean if necessary.

14 Assemble the intake manifold assembly using

all new gaskets. Torque air intake plenum bolts to

11-14ff. Ibs. (15-19 Nm).

15. Install a new intake manifold gasket to the

head and install the manifold. Torque the manifold in

a crrsscross pattern, starting from the inside and

working outwards to 11-14 ff. Ibs. (15-19 Nm).

16. Install the fuel delivery pipe, injectors and

pressure regulator to the engine. Torque the retaining

bolts to 4 ft. Ibs (6 Nm).

17. install the thermostat housing, intake mani-

fold brace bracket, and engine hanger bracket.

18 Connect or install all hoses, cables and elec-

trical connectors that were removed or disconnected

during the removal procedure.

19. Align the distributor matchmarks and install

the distributor.

20. Fill the system with coolant,

21. Connect the negative battery cable, run the

vehicle until the thermostat opens, fill the radiator

completely. 22. Adjust the accelerator cable. Check and ad-

just the idle speed and ignition timing.

23. Once the vehicle has cooled, recheck the

coolant level.

1.6L and 2.OL DDHC Engines

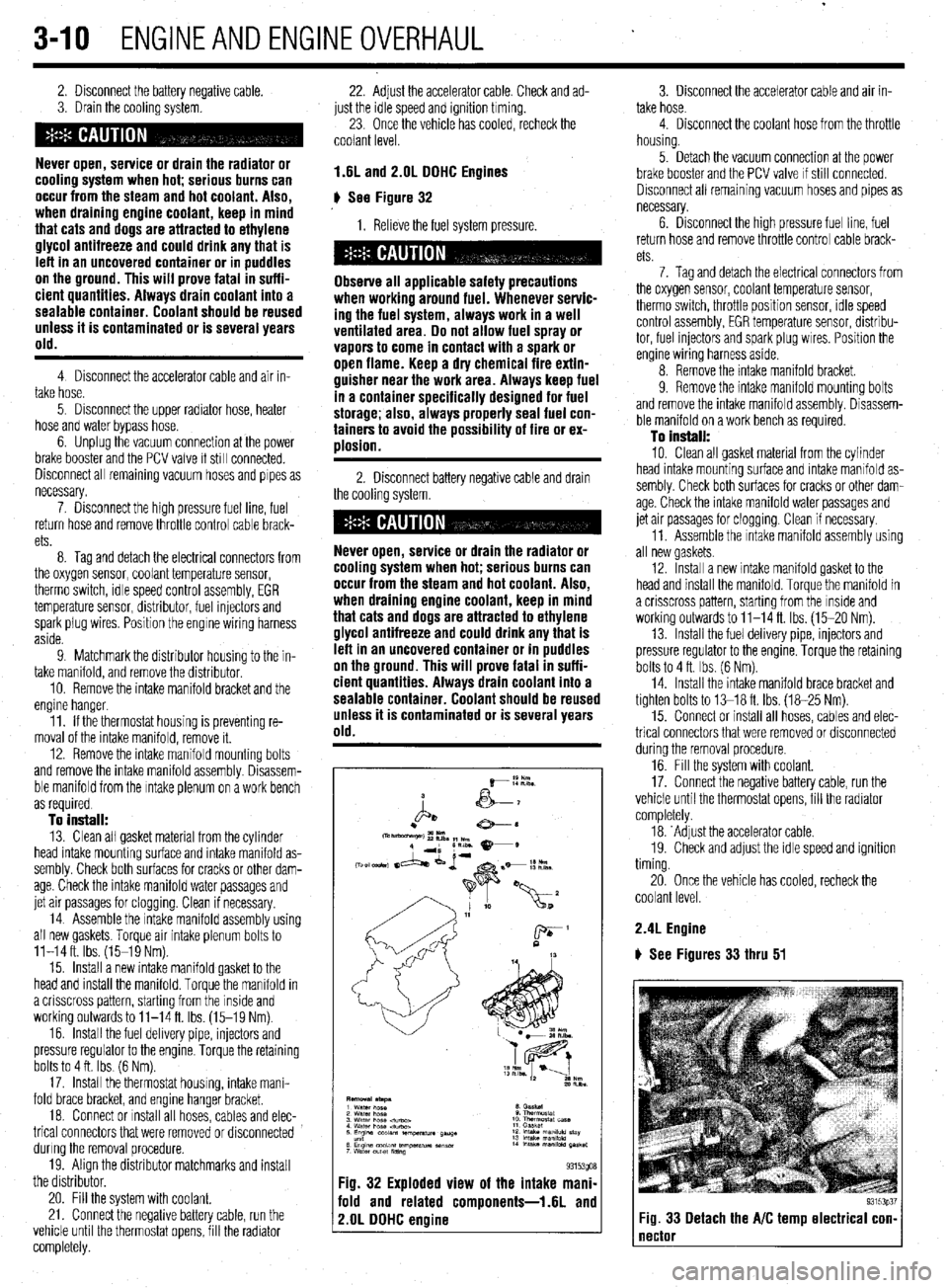

# See Figure 32

1. Relieve the fuel system pressure.

Observe all applicable safety precautions

when working around fuel. Whenever servic-

ing the fuel system, always work in a well

ventilated area. Do not allow fuel spray or

vapors to come in contact with a spark or

open flame. Keep a dry chemical fire extin-

guisher near the work area. Always keep fuel

in a container specifically designed for fuel

storage; also, always properly seal fuel con-

tainers to avoid the possibility of fire or ex-

ulosion.

2. Disconnect battery negative cable and drain

the cooling system.

Never open, service or drain the radiator or

cooling system when hot; serious burns can

occur from the steam and hot coolant. Also,

when draining engine coolant, keep in mind

that cats and dogs are attracted to ethylene

glycol antifreeze and could drink any that is

left in an uncovered container or in puddles

on the ground. This will prove fatal in suffi-

cient quantities. Always drain coolant into a

sealable container. Coolant should be reused

unless it is contaminated or is several years

old.

Fig. 32 Exploded view of the intake mani-

fold and related components-1.6L and

2.OL DDHC engine

3. Disconnect the accelerator cable and air in-

take hose.

4. Disconnect the coolant hose from the throttle

housing.

5. Detach the vacuum connection at the power

brake booster and the PCV valve If still connected.

Disconnect all remaining vacuum hoses and pipes as

necessary.

6. Drsconnect the high pressure fuel line, fuel

return hose and remove throttle control cable brack-

ets

7. Tag and detach the electrical connectors from

the oxygen sensor, coolant temperature sensor,

therm0 switch, throttle position sensor, rdle speed

control assembly, EGR temperature sensor, distribu-

tor, fuel injectors and spark plug wires. Position the

engine wiring harness aside.

8. Remove the intake manifold bracket.

9. Remove the intake mamfold mounting bolts

and remove the intake manifold assembly. Disassem-

ble manifold on a work bench as required.

To install:

10. Clean all gasket material from the cylinder

head intake mounting surface and intake manifold as-

sembly. Check both surfaces for cracks or other dam-

age. Check the intake manifold water passages and

jet air passages for clogging. Clean if necessary.

11. Assemble the Intake manifold assembly using

all new gaskets.

12. Install a new intake manifold gasket to the

head and install the manifold. Torque the manifold in

a crisscross pattern, starting from the inside and

working outwards to 11-14 ft. Ibs. (15-20 Nm).

13. Install the fuel delivery pipe, injectors and

pressure regulator to the engine. Torque the retaining

bolts to 4 ft. Ibs. (6 Nm).

14. Install the intake manifold brace bracket and

tighten bolts to 13-18 ft. Ibs. (18-25 Nm).

15. Connect or install all hoses, cables and elec-

trical connectors that were removed or disconnected

during the removal procedure.

16. Fill the system with coolant.

17. Connect the negative battery cable, run the

vehicle until the thermostat opens, fill the radiator

completely.

18. ‘Adjust the accelerator cable.

19. Check and adjust the idle speed and ignition

timing.

20. Once the vehicle has cooled, recheck the

coolant level.

2.4L Engine

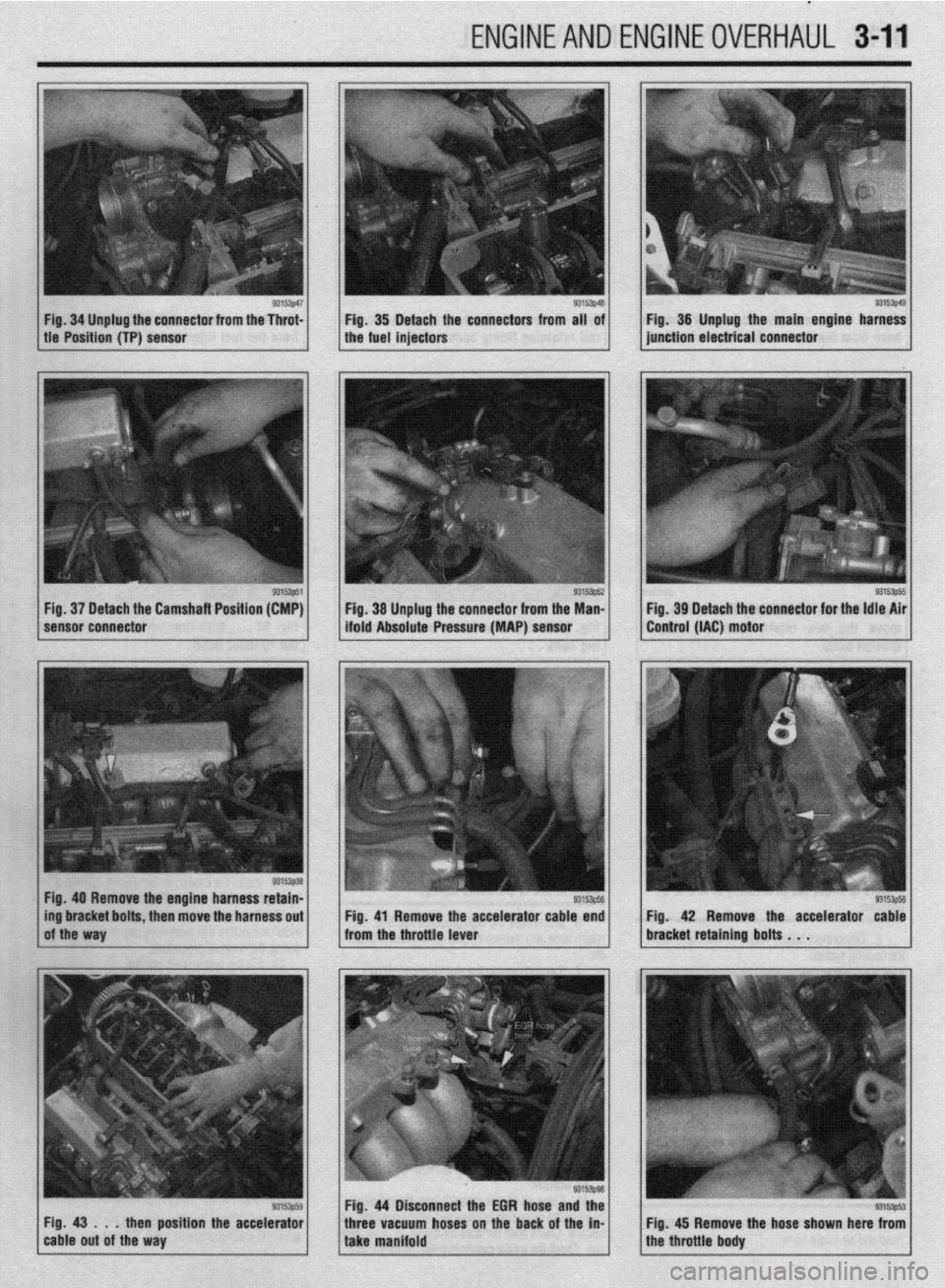

) See Figures 33 thru 51

93153p37 Fig. 33 Detach the A/C temp electrical con- 1

Page 72 of 408

.

ENGINEAND,ENGINEOVERHAUL 3-11

Fig. 34 Unplug the connector from the Throt-

tle Position (TP) sensor Fig. 35 Detach the connectors from all of

the fuel injectors

93wp3a Fig. 40 Remove the engine harness retain-

ing bracket bolts, then move the harness out

of the way Fig. 38 Unplug the connector from the Man-

ifold Absolute Pressure (MAP) sensor 93153p5a Fig. 41 Remove the accelerator cable end

from the throttle lever

93153p59 Fig. 43 . . . then position the accelerator

cable out of the way

93i53p9a Fig. 44 Disconnect the EGR hose and the

three vacuum hoses on the back of the in- take manifold Fig. 39 Detach the connector for the Idle Air

Control (IAC) motor

93153p5a Fig. 42 Remove the accelerator cable

bracket retaining bolts . . .

93153p53 Fig. 45 Remove the hose shown here from

the throttle body

Page 73 of 408

.

3-12 ENGINEANDENGINEOVERHAUL

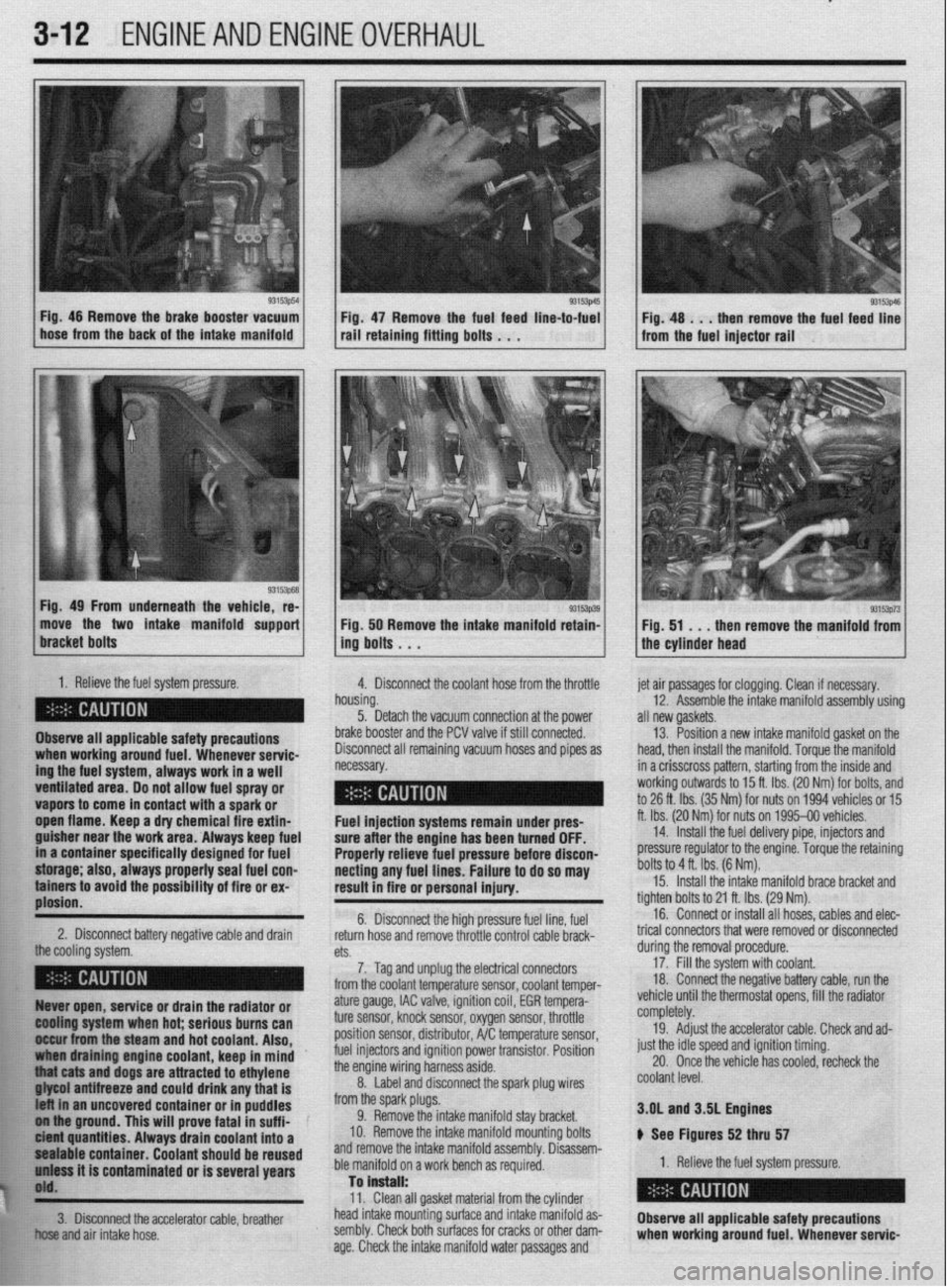

93153p54

1

L Fig. 46 Remove the brake booster vacuum

hose from the back of the intake manifold Fig 47 Remove the fuel feed line-to-fuel rail’retaini”g fitti”g bo,ts . . .

Fig. 49 From underneath the vehicle, re-

move the two intake manifold support

1. Relieve the fuel system pressure.

4. Disconnect the coolant hose from the throttle

Observe all applicable safety precautions

ing the fuel system, always work in a well when working around fuel. Whenever servic-

ventilated area. Do not allow fuel spray or - __.

vapors to come in contact with a spark or

._

open flame. Keep a dry chemical fire extin-

guisher near the work area. Always keep fuel

in a container specifically designed for fuel

storage; also, always properly seal fuel con-

tainers to avoid the possibility of fire or ex-

plosion.

2. Disconnect battery negative cable and drain

the cooling rtfctnm 93153p39 Fig. 50 Remove the intake manifold retain-

ing bolts . . .

h

n ousing.

5. Detach the vacuum connection at the power

b

rake booster and the PCV valve if still connected.

C lisconnect all remaining vacuum hoses and pipes as

ecessary. et air passages for clogging. Clean if necessary.

12. Assemble the intake manifold assembly using

III new gaskets.

13. Position a new intake manifold gasket on the

lead, then install the manifold. Torque the manifold

n a crisscross pattern, starting from the inside and

vorking outwards to 15 ft. Ibs. (20 Nm) for bolts, and

o 26 ft. Ibs. (35 Nm) for nuts on 1994 vehicles or 15

t. Ibs. (20 Nr$ for nuts on 1995-00 vehicles.

14. Install the fuel delivery pipe, injectors and

xessure regulator to the engine. Torque the retaining

)olts to 4 ft. Ibs. (6 Nm). Fuel injection systems remain under pres- f

sure after the engine has been turned OFF.

Properly relieve fuel pressure before discon-

necting any fuel lines. Failure to do so may [

result in fire or personal injury.

t 6. Disconnect the high pressure fuel line, fuel

return hose and remove throttle control cable brack- t

n+C.

cm. durino the removal orocedure. 15. Install the intake manifold brace bracket and

ighten bolts to 21 ft. Ibs. (29 Nm).

16. Connect or install all hoses, cables and elec-

rical connectors that were removed or disconnected

7. Tag and unplug the electrical connectors

from the coolant temperature sensor, coolant temper- 17: Fill the system with coolant.

18 Connect the negative battery cable, run the

, . : .., ,, ., , ,

,,,, ,. ,.

93153p73 Fig. 51 . . .

then remove the manifold from

the cylinder head

Ruver open, service or drain the radiator or

@Ming system when hot; serious burns can

II&ur from the steam and hot coolant. Also,

draining engine coolant, keep in mind ’

j “thiat cats and dogs are attracted to ethylene

. . . ..____ “..” 11_,1 -...... any that is

t uncovered container or in puddles

FE ol iha ground. This will prove fatal in suff i-

k ici?M quantities. Always drain coolant into a

$1 pealable container. Coolant should be reused

h’ uniass it is contaminated or is several years

j$O'd.

**w

ature gauge, IAC valve, ignition coil, EGR tempera-

ture sensor, knock sensor, oxygen sensor, throttle

position sensor, distributor, A/C temperature sensor,

fuel injectors and ignition power transistor. Position

the engine wiring harness aside.

8. Label and disconnect the spark plug wires

from the spark plugs.

9. Remove the intake manifold stay bracket.

IO. Remove the intake manifold mounting bolts

and remove the intake manifold assembly. Disassem-

ble manifold on a work bench as required.

Tan is”.+..ll. vemcle unrn me mermosrar opens, ml tne raalaror

completely.

19. Adjust the accelerator cable. Check and ad-

just the idle speed and ignition timing.

20. Once the vehicle has cooled, recheck the

coolant level.

3.OL and 3SL Engines

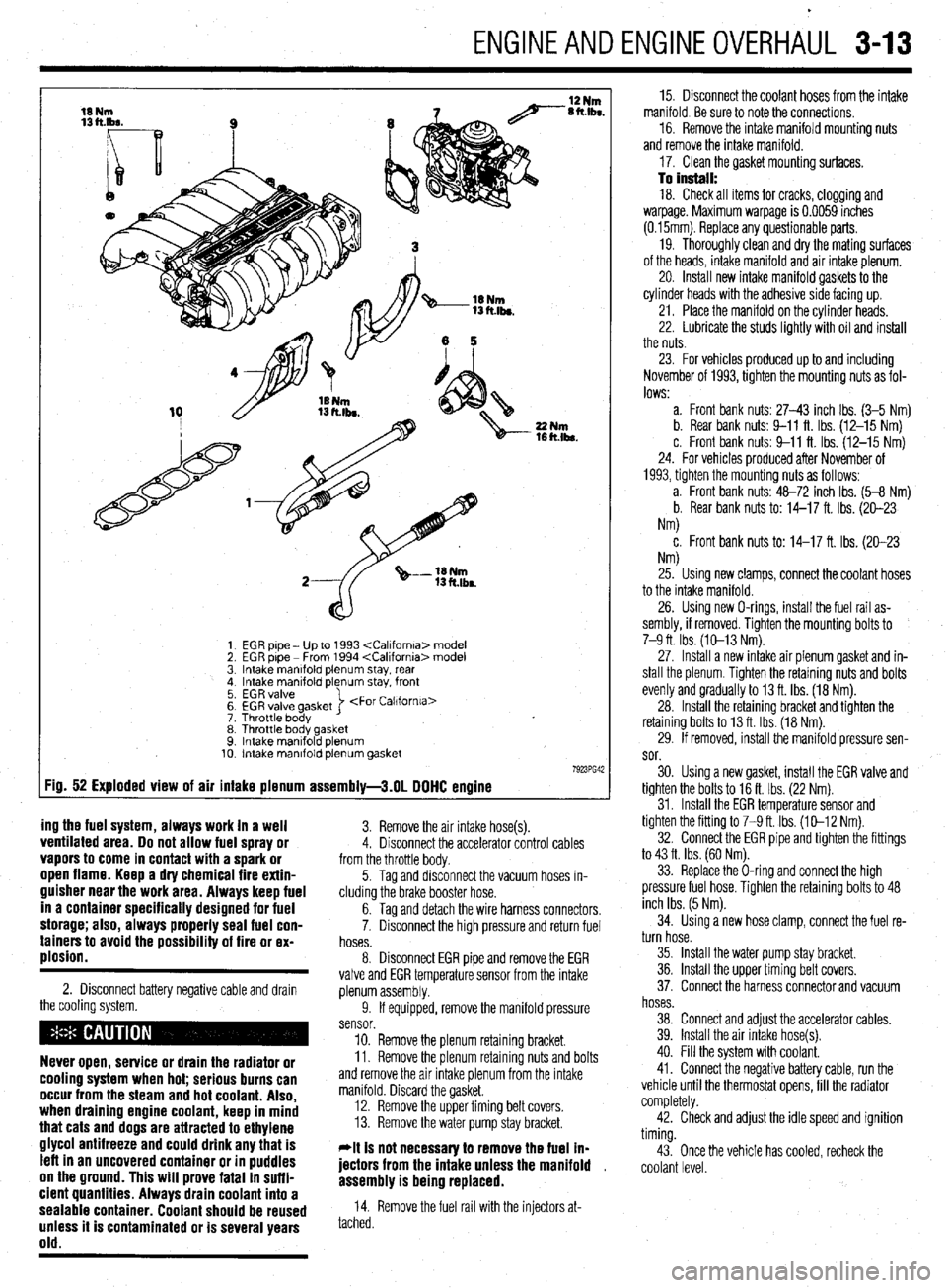

ti See Figures 52 thru 57

1. Relieve the fuel system pressure.

W.>. Clean all gasket material from the cylinder

!&S head intake mounting surface and intake manifold as-

fir!: 3. Disconnect the accelerator cable, breather

Observe all applicable safety precautions

El .;,

+w..” and air intake hose. sembly. Check both surfaces for cracks or other dam-

age. Check the intake manifold water passages and when working around fuel. Whenever servic-

Page 74 of 408

ENGINEANDENGINEOVERHAUL 3-13

EGR pipe - Up to 1993

EGR pipe - From 1994

Intake manlfold plenum stay, rear

Intake manifold plenum stay. front

EGR valve

EGR valve gasket

Throttle body >

Throttle body gasket

Intake mantfold plenum

Intake manifold plenum gasket

:ig. 52 Exploded view of air intake plenum assembly-3.01 DOHC engine

ing the fuel system, always work in a well

3. Remove the air intake hose(s). ventilated area. Do not allow fuel spray or 4. Disconnect the accelerator control cables vapors to come in contact with a spark or from the throttle body. open flame. Keep a dry chemical fire extin-

guisher near the work area. Always keep fuel

in a container specifically designed for fuel

storage; also, always properly seal fuel con-

tainers to avoid the possibility of fire or ex-

plosion.

2. Disconnect battery negative cable and drawn

the cooling system.

Never open, service or drain the radiator or

cooling system when hot; serious burns can

occur from the steam and hot coolant. Also,

when draining engine coolant, keep in mind

that cats and dogs are attracted to ethylene

glycol antifreeze and could drink any that is

left in an uncovered container or in puddles

on the ground. This will prove fatal in suffi-

cient quantities. Always drain coolant into a

sealable container. Coolant should be reused

unless it is contaminated or is several years

old.

5. Tag and disconnect the vacuum hoses in-

cluding the brake booster hose.

6. Tag and detach the wire harness connectors,

7. Disconnect the high pressure and return fuel

hoses.

8. Disconnect EGR pipe and remove the EGR

valve and EGR temperature sensor from the intake

plenum assembly.

9. If equipped, remove the manifold pressure

sensor.

10. Remove the plenum retaining bracket.

11. Remove the plenum retaining nuts and bolts

and remove the air intake plenum from the intake

manifold. Discard the gasket.

12. Remove the upper timing belt covers.

13. Remove the water pump stay bracket.

*It is not necessav to remove the fuel ln-

jectors from the intake unless the manifold ,

assembly is being replaced.

14. Remove the fuel rail with the injectors at-

tached. 15. Disconnect the coolant hoses from the intake

manifold. Be sure to note the connections.

16. Remove the intake manifold mounting nuts

and remove the intake manifold.

17. Clean the gasket mounting surfaces.

To install: 18. Check all items for cracks, clogging and

warpage. Maximum warpage is 0.0059 inches

(0.15mm). Replace any questionable parts.

19. Thoroughly clean and dry the mating surfaces

of the heads, intake manifold and air intake plenum.

20. Install new intake manifold gaskets to the

cylinder heads with the adhesive side facing up.

21. Place the manifold on the cylinder heads.

22. Lubricate the studs lightly with oil and install

the nuts.

23. For vehicles produced up to and including

November of 1993, tighten the mounting nuts as fol-

lows:

a. Front bank nuts: 27-43 inch Ibs. (3-5 Nm)

b. Rear bank nuts: 9-11 ft. Ibs. (12-15 Nm)

c. Front bank nuts: 9-11 ft. Ibs. (12-15 Nm)

24. For vehicles produced after November of

1993, tighten the mounting nuts as follows:

a. Front bank nuts: 48-72 inch Ibs. (5-8 Nm)

b. Rear bank nuts to: 14-17 ft. Ibs. (20-23

Nm)

c. Front bank nuts to: 14-17 ft. Ibs. (20-23

NM

25. Using new clamps, connect the coolant hoses

to the intake manifold.

26. Using new O-rings, install the fuel rail as-

sembly, if removed. Tighten the mounting bolts to

7-9 ft. Ibs. (10-13 Nm).

27. Install a new intake air plenum gasket and in-

stall the plenum. Tighten the retaining nuts and bolts

evenly and gradually to 13 ft. Ibs. (18 Nm).

28. Install the retaining bracket and tighten the

retaining bolts to 13 ft. Ibs. (18 Nm).

29. If removed, install the manifold pressure sen-

sor.

30. Using a new gasket, install the EGR valve and

tighten the bolts to 16 ft. Ibs. (22 Nm).

31. Install the EGR temperature sensor and

tighten the fitting to 7-9 ft. Ibs. (10-12 Nm).

32. Connect the EGR pipe and tighten the fittings

to 43 ft. Ibs. (60 Nm).

33. Replace the O-ring and connect the high

pressure fuel hose. Tighten the retaining bolts to 48

inch Ibs. (5 Nm).

34. Using a new hose clamp, connect the fuel re-

turn hose.

35. Install the water pump stay bracket.

36. Install the upper timing belt covers.

37. Connect the harness connector and vacuum

hoses.

38. Connect and adjust the accelerator cables.

39. Install the air intake hose(s).

40. Fill the system with coolant.

41. Connect the negative battery cable, run the

vehicle until the thermostat opens, fill the radiator

completely.

42. Check and adjust the idle speed and ignition

timing.

43. Once the vehicle has cooled, recheck the

coolant level.

Page 75 of 408

.

3-14 ENGINEANDENGINEOVERHAUL

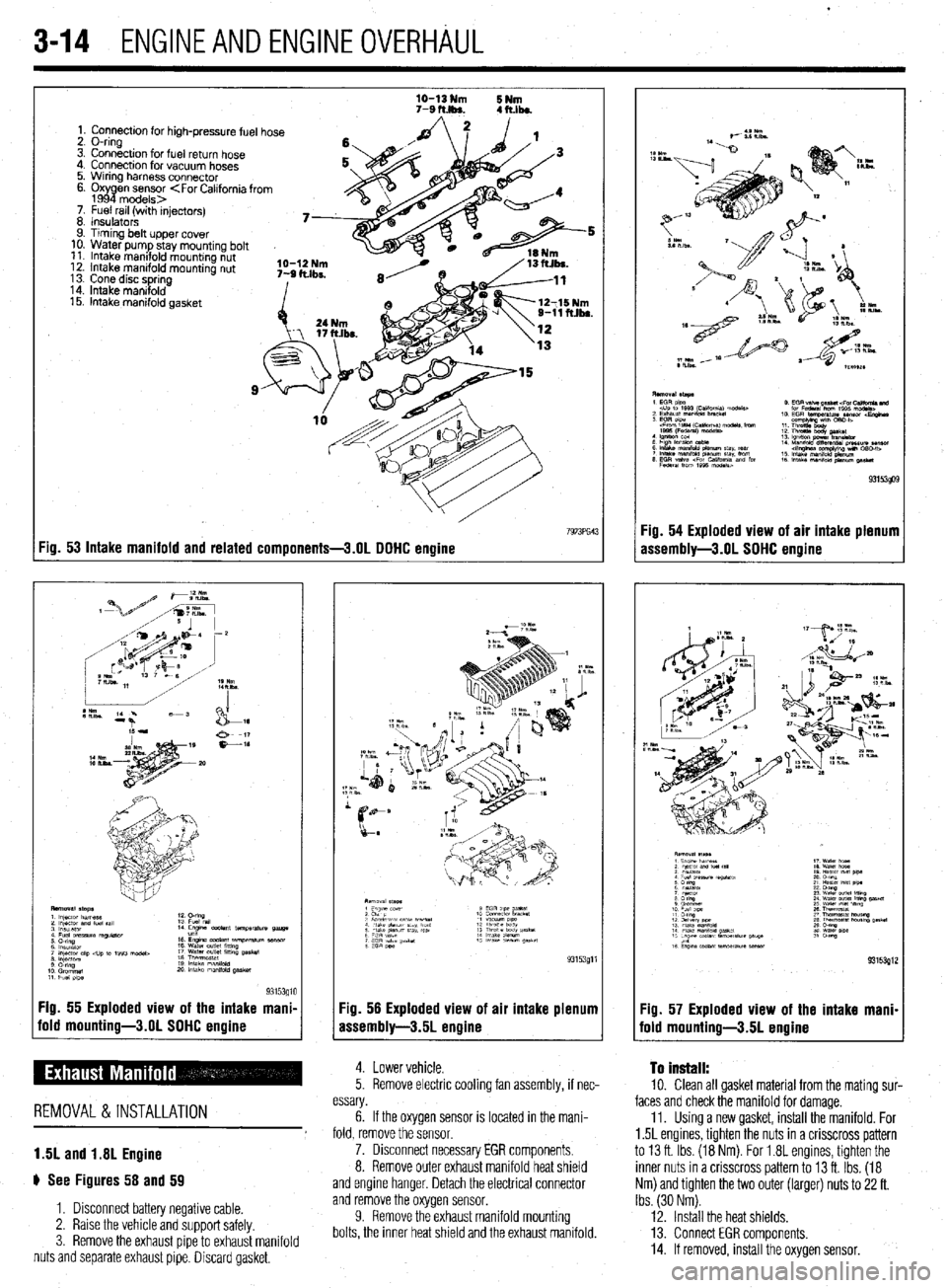

1. Connection for high-pressure fuel hose

2. O-ring

3. Connection for fuel return hose

4. Connection for vacuum hoses

5. Wrring harness connector

6. Oxy

P en sensor

7. Fuel rail (with injectors)

8 Insulators

9. Timing belt upper cover

10. Water pump stay mountrng bolt

11. Intake manifold mounting nut

12. Intake manifold mounting nut

13 Cone disc spring

14. Intake manrfold

15. intake manifold gasket

:ig. 53 Intake manifold and related components-3.01 DDHC enaine

Fig. 55 Exploded view of the intake mani- :ig. 56 Exploded view of

fold mounting-3.01 SDHC engine

Issembly-3.5L engine air intake plenum

5. Remove electric cooling fan assembly, if nec- 4. Lower vehicle. To install: 10. Clean all gasket material from the mating sur-

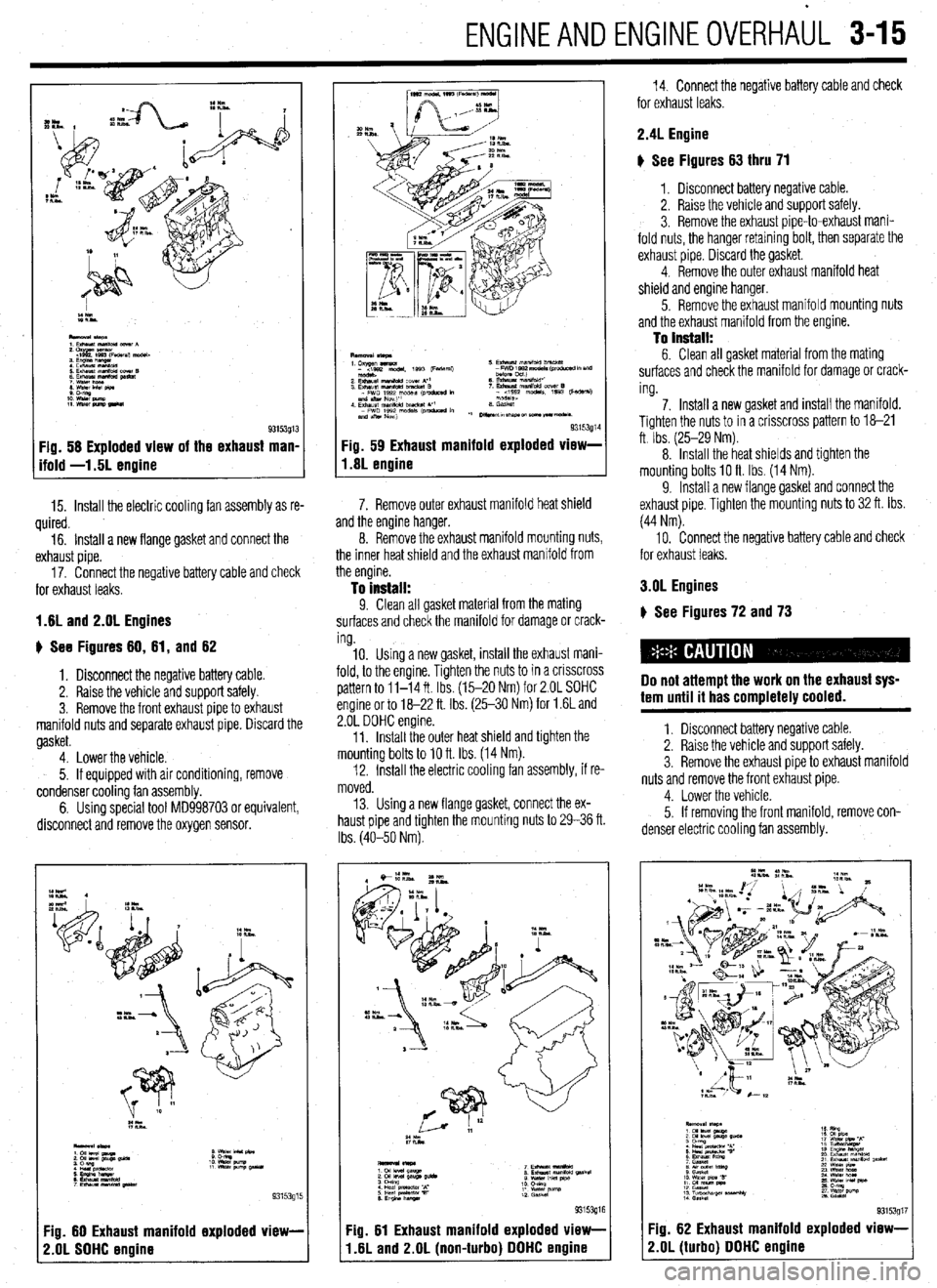

REMOVAL &INSTALLATION

1.5L and 1.8L Engine

# See Figures 58 and 59 essary. faces and check the manifold for damage.

6. If the oxygen sensor is located in the mani- 11. Using a new gasket, install the manifold. For

fold, remove the sensor. 1.5L engines, tighten the nuts in a crisscross pattern

7. Disconnect necessary EGR components. to 13 ft. Ibs. (18 Nm). For 1.8L engines, tighten the

8. Remove outer exhaust manifold heat shield inner nuts in a crisscross pattern to 13 ft. Ibs. (18

and engine hanger. Detach the electrical connector Nm) and tighten the two outer (larger) nuts to 22 ft.

1. Disconnect battery negative cable.

2. Raise the vehicle and support safely

3. Remove the exhaust pipe to exhaust manifold

nuts and separate exhaust pipe. Discard gasket, and remove the oxygen sensor.

9. Remove the exhaust manifold mounting

bolts, the inner heat shield and the exhaust manifold. Ibs. (30 Nm).

12. Install the heat shields,

13. Connect EGR components.

14. If removed, install the oxygen sensor.

Page 76 of 408

ENGlNEANDENGlNEOVERHAbL 3-15

Fig. 58 Exploded view of the exhaust man,

ifold -1.5L enoine

15. Install the electric cooling fan assembly as re-

quired.

16. Install a new flange gasket and connect the

exhaust pipe.

17. Connect the negative battery cable and check

for exhaust leaks.

1.8L and 2.OL Engines

u See Figures 80, 81, and 62

1. Disconnect the negative battery cable.

2. Raise the vehicle and support safely.

3. Remove the front exhaust pipe to exhaust

manifold nuts and separate exhaust pipe. Discard the

gasket.

4. Lower the vehicle.

5. If equipped with air conditioning, remove

condenser cooling fan assembly.

6. Using special tool MD998703 or equivalent,

disconnect and remove the oxygen sensor.

:z**

::EEWl

93153915

:ig. 60 Exhaust manifold exploded view-

!.OL SOHC engine

93153g1 Fig. 59 Exhaust manifold exploded vlew-

1.8L engine

7. Remove outer exhaust manifold heat shield

and the engine hanger.

8. Remove the exhaust manifold mounting nuts,

the inner heat shield and the exhaust manifold from

the engine.

To install: 9. Clean all gasket material from the mating

surfaces and check the manifold for damage or crack-

ing.

10. Using a new gasket, install the exhaust mani-

fold, to the engine. Tighten the nuts to in a crrsscross

pattern to 11-14 ft Ibs. (15-20 Nm) for 2.OL SOHC

engine or to 18-22 ft. Ibs. (25-30 Nm) for 1.6L and

2.OL DOHC engine.

11. Install the outer heat shield and tighten the

mounting bolts to 10 ft. Ibs. (14 Nm).

12. Install the electric cooling fan assembly, if re-

moved.

13. Using a new flange gasket, connect the ex-

haust pipe and tighten the mounting nuts to 29-36 ft.

Ibs. (40-50 Nm).

:ig. 81 Exhaust manifold exploded view-

I .8L and 2.OL (non-turbo) DOHC engine

14. Connect the negative battery cable and check

for exhaust leaks.

2.4L Engine

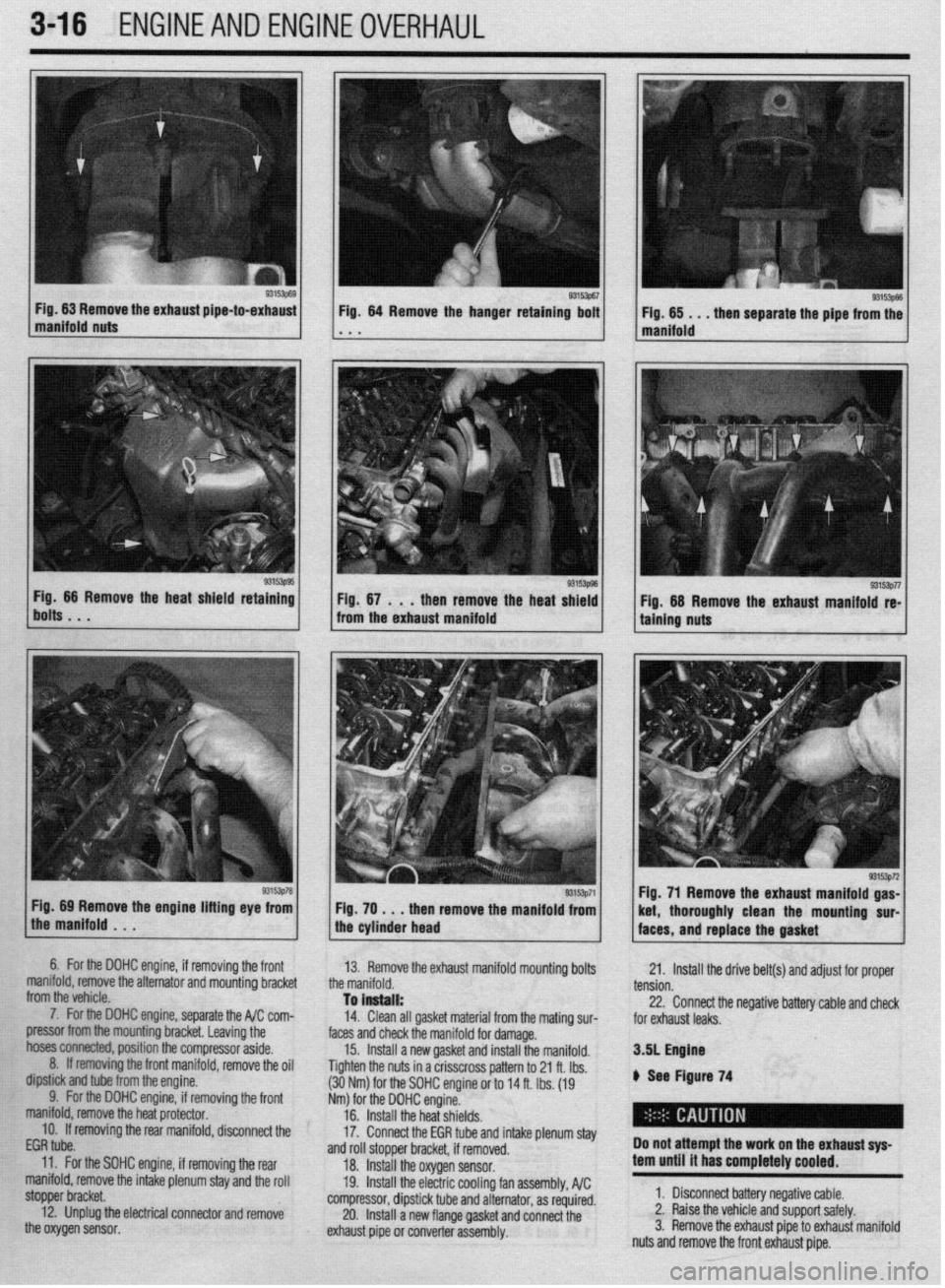

g See Figures 63 thru 71

1, Disconnect battery negative cable.

2. Raise the vehicle and support safely.

3. Remove the exhaust pipe-to-exhaust mani-

fold nuts, the hanger retaining bolt, then separate the

exhaust pipe. Discard the gasket.

4. Remove the outer exhaust manifold heat

shield and engine hanger.

5. Remove the exhaust manifold mounting nuts

and the exhaust manifold from the engine.

To install: 6. Clean all gasket material from the mating

surfaces and check the manifold for damage or crack-

ing.

7. Install a new gasket and install the manifold.

Tighten the nuts to in a crisscross pattern to 18-21

ft Ibs. (25-29 Nm).

8. Install the heat shields and tighten the

mounting bolts IO ft Ibs. (14 Nm).

9. Install a new flange gasket and connect the

exhaust pipe. Tighten the mounting nuts to 32 ft. Ibs.

(44 Nm).

10. Connect the negative battery cable and check

for exhaust leaks.

3.OL Engines

) See Figures 72 and 73

Do not attempt the work on the exhaust sys-

tem until it has completely cooled.

1. Disconnect battery negative cable.

2. Raise the vehicle and support safely.

3. Remove the exhaust pipe to exhaust manifold

nuts and remove the front exhaust pipe.

4. Lower the vehicle.

5. If removing the front manifold, remove con-

denser electric cooling fan assembly.

9315391; -ig. 82 Exhaust manifold exploded view-

!.OL (turbo) DOHC engine

Page 77 of 408

3-16 ,ENGlNEANDENGlNEOVERHAUL

Fig 66 Remove the heat shield retaining

bolts. . . g3’~‘51 Fig. 64 Remove the hanger retaining bolt

* . I(

Fig, 67 . . .

then remove the heat shield

from the exhaust manifold

Fig. 69 Remove the engine lifting eye from

the manifold . . . Fig. 70 , . . then remove the manifold from

the cylinder head Fig. 71 Remove the exhaust manifold gas-

/ faces, and replace the gasket ’ 93’53p72 ket, thoroughly clean the mountmg sur-

6. For the DOHC engine, if removing thr

a front

manifold, remove the alternator and mountin!

from the vehicle. 3 bracket

7. For the DOHC engine, separate the I$,, I.vIII- /r nnm

pressor from the mounting bracket. Leaving the

hoses ~~~, position the compressor aside,

8. ff removing the front manifold, remove the oil

dipstick and tube from the engine.

9. For the DOHC engine, if removing the front

manifold, remove the heat protector. 13. Remove the exhaust manifold mounting bolts

the manifold.

To install:

-4” PI,*, -11 rm.A.^L -,‘&^-:-I f-e.- IL- -_-I!-- - .-

17. lrlMll dll yWK1 Illdlell~l 110111 LIle lKWi~ SIN- faces and check the manifold for damage.

15. Install a new gasket and install the manifold.

Tighten the nuts in a crisscross pattern to 21 ft. Ibs.

(30Nm). .’ --.._

Nm) for 1

16. II 21. Install the drive belt(s) and adjust for proper

tension.

to1 the SOHC engine or to 14 ft. Ibs. (19

he DOHC engine.

Wall the heat shields. 22. Connect the negative battery cable and check

I- L- L, #

ror exnausr leaks.

3.51 Engfne

A Sam Finnwn 74

17. c

“IIII”“IUI” L”ll L”“““ll” IIIlu#lb p,““l~,aa~

and roll stopper bracket, if removed.

18. Install the oxygen sensor.

19. Install the electric cooling fan assembly, A/C

compressor, dipstick tube and alternator, as required.

20. Install a new flange gasket and connect the

exhaust pipe or converter assembly. Do not attempt the work on the

exhaust sys-

tern until it has completely coo

led.

1. Disconnect battery negative cable.

2. Raise the vehicle and support safely.

3. Remove the exhaust pipe to exhaust manifold

nuts and remove the front exhaust pipe. IO. If removing the rear manifold, disconnect the

EGR tube.

11. For the SOHC engine, if removing the rear

manifold, remove the intake plenum stay and the roll

stopper bracket.

12. Unplug the electrical connector and remove

the oxygen sensor.

Page 78 of 408

ENGlNEANDENGlNEOVERHAiJL 3-17

Fig. 73 Exploded view of the exhaust man

ifold -3.OL DOHC engine

9315392c Fig. 74 Exhaust manifold exploded view-

3.5L engine

4. Lower the vehicle.

5. If removing the front manifold, remove the ra-

diator and cooling fan assembly.

6. If removing the front manifold, remove the al-

ternator.

7. Remove the heat protector(s). 8. If removing the rear manifold, disconnect the

EGR tube.

9. Remove the exhaust manifold mounting bolts

the manifold.

To install:

10. Clean all gasket material from the mating sur-

faces and check the manifold for damage.

11. Install a new gasket and install the manifold.

Tighten the nuts in a crisscross pattern to 21 ft. Ibs.

(30 Nm).

12. Install the heat protector(s).

13. If installrng the rear manifold, replace the

gasket and connect the EGR tube.

14. If installing the front manifold, install the ra-

diator and cooling fan assembly.

15. If installing the front manifold, install the al-

ternator.

16. Install the drive belt(s) and adjust for proper

tension.

17. Raise and safely support the vehicle securely

on lackstands.

18. Install a new flange gasket and connect the

exhaust pipe or converter assembly.

19 Lower the vehicle

20. Connect the negative battery cable and check

for exhaust leaks.

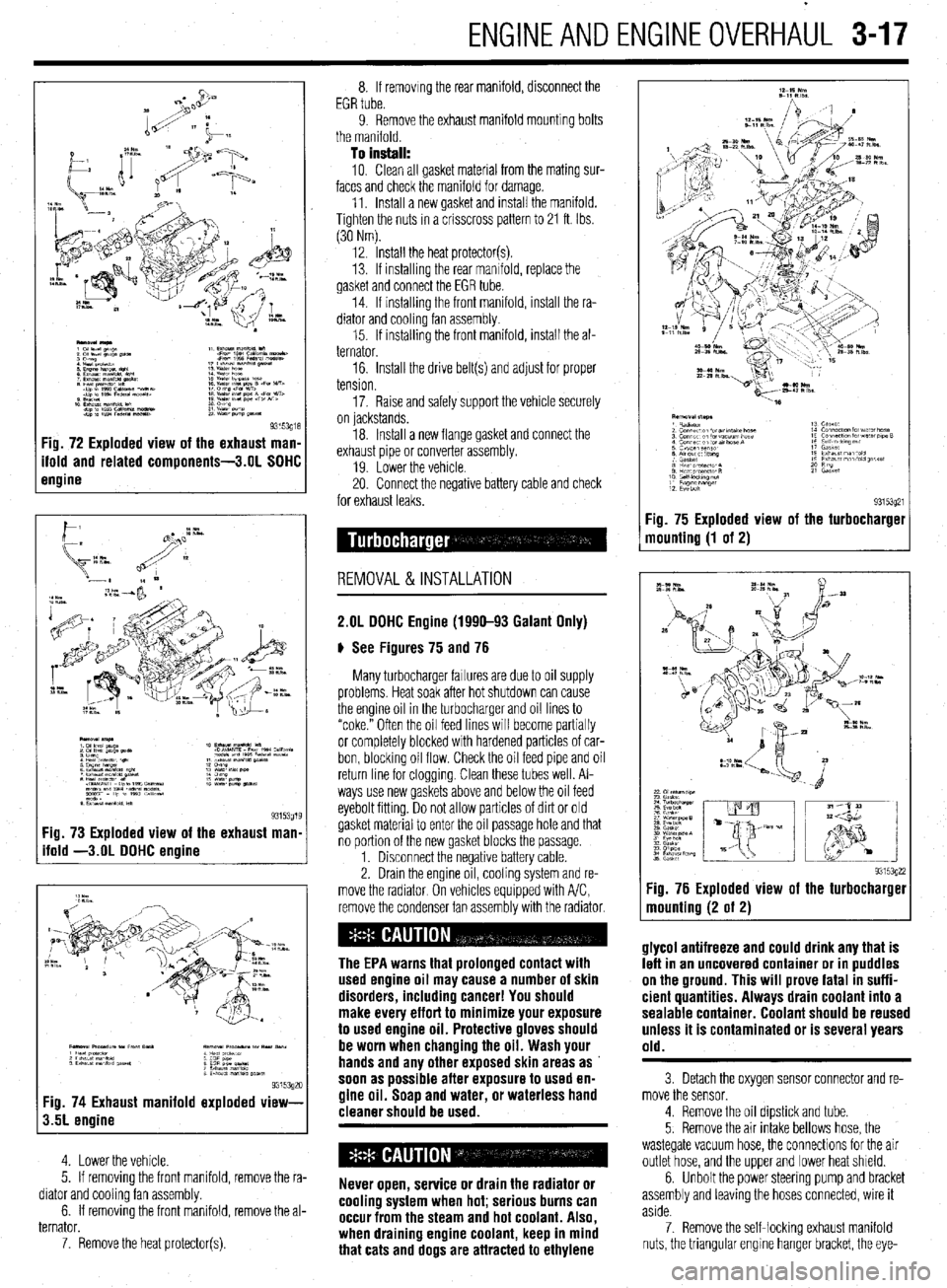

REMOVAL&INSTALLATION

2.OL DOHC Engine (1990-93 Galant Only)

# See Figures 75 and 76

Many turbocharger failures are due to oil supply

problems. Heat soak after hot shutdown can cause

the engine oil in the turbocharger and oil lines to

“coke.” Often the oil feed lines will become partially

or completely blocked with hardened particles of car-

bon, blocking oil flow. Check the oil feed pipe and oil

return line for cloggrng. Clean these tubes well. Al-

ways use new gaskets above and below the oil feed

eyebolt fitting. Do not allow particles of dirt or old

gasket material to enter the oil passage hole and that

no portion of the new gasket blocks the passage.

1. Disconnect the negative battery cable.

2. Drain the engine oil, cooling system and re-

move the radiator On vehicles equipped with A/C,

remove the condenser fan assembly with the radiator.

The EPA warns that prolonged contact with

used engine oil may cause a number of skin

disorders, including cancer! You should

make every effort to minimize your exposure

to used engine oil. Protective gloves should

be worn when changing the oil. Wash your

hands and any other exposed skin areas as

soon as possible after exposure to used en-

gine oil. Soap and water, or waterless hand

cleaner should be used.

Never open, service or drain the radiator or

cooling system when hot; serious burns can

occur from the steam and hot coolant. Also,

when draining engine coolant, keep in mind

that cats and dogs are attracted to ethylene Fig. 75 Exploded view

mounting (1 of 2)

93153q21 the turbocharget

9315392: :ig. 76 Exploded view of the turbocharger

nounting (2 of 2)

glycol antifreeze and could drink any that is

left in an uncovered container or in puddles

on the ground. This will prove fatal in suffi-

cient quantities. Always drain coolant into a

sealable container. Coolant should be reused

unless it is contaminated or is several years

old.

3 Detach the oxygen sensor connector and re-

move the sensor.

4. Remove the oil dipstick and tube.

5. Remove the air intake bellows hose, the

wastegate vacuum hose, the connections for the air

outlet hose, and the upper and lower heat shield.

6. Unbolt the power steering pump and bracket

assembly and leaving the hoses connected, wire it

aside.

7. Remove the self-locking exhaust manifold

nuts, the triangular engrne hanger bracket, the eye-

Page 79 of 408

l

3-18 ENGINEANDENGINEOVERHAUL

bolt and gaskets that connect the oil feed line to the

turbo center section and the water cooling lines. The

water line under the turbo has a threaded connection.

8. Remove the exhaust pipe nuts and gasket and

lift off the exhaust manifold. Discard the gasket,

9. Remove the 2 through bolts and 2 nuts that 16. If removed, install the power steering pump

and bracket.

17. Install the heat shields, air outlet hose, waste-

gate hose and air intake bellows.

18. Install the oil dipstick tube and dipstick. In-

stall the oxyqen sensor. cient quantities. Always drain coolant into a

sealable container. Coolant should be reused

unless it is contaminated or is several years

old.

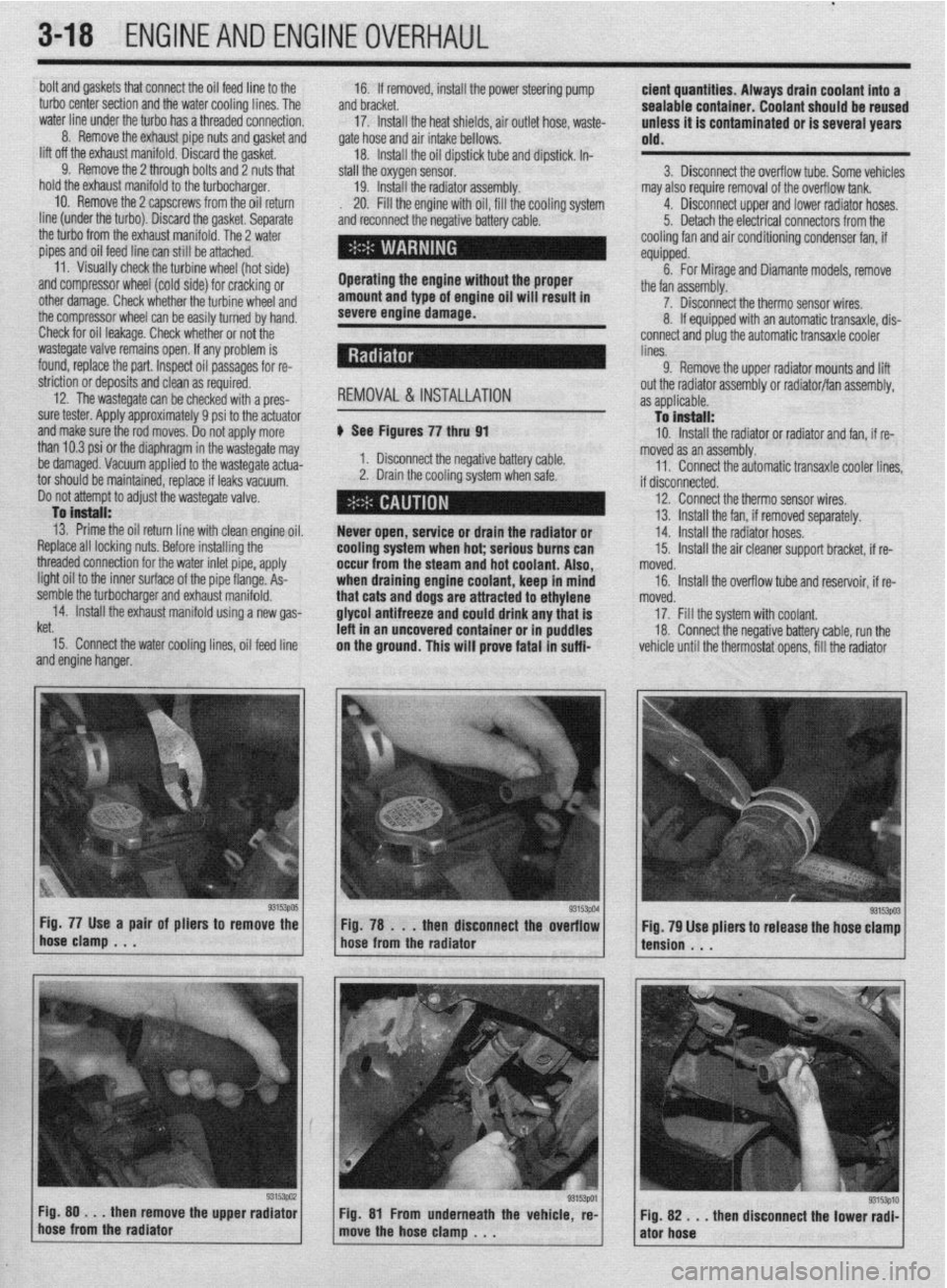

3. Disconnect the overflow tube. Some vehicles

hold the exhaust manifold to the turbocharger,

10. Remove the 2 capscrews from the oil return

line (under the turbo). Discard the gasket. Separate

the turbo from the exhaust manifold. The 2 water

pipes and oil feed line can still be attached. 19. In&h the radiator assembly.

20. Fill the engine with oil, fill the cooling system

and reconnect the negative battery cable.

11. Visually check the turbine wheel (hot side)

and compressor wheel (cold side) for cracking or

other damage. Check whether the turbine wheel and

the compressor wheel can be easily turned by hand.

Check for oil leakaae. Check whether or not the Operating the engine without the proper

amount and type of engine oil will result in

severe engine damage.

wastegate valve remains open. If any problem is .

found, replace the part. Inspect oil passages for re- #I , I

striction or deposits and clean as required,

12. The wasteaate can be checked with a ores-

REMOVAL & INSTALLATION sure tester. Apply approximately 9 psi to the&h&or

and make sure the rod moves. Do not apply more

than 10.3 psi or the diaphragm in the wastegate may

be damaged. Vacuum applied to the wastegate actua-

tor should be maintained, replace if leaks vacuum,

Do not attempt to adjust the wastegate valve. $ See Figures 77 thru 91

I. Disconnect the negative battery cable.

2. Drain the cooling system when safe.

To

install: 13. Prime the oil return line with clean engine oil.

Replace all locking nuts. Before installing the

threaded connection for the water inlet pipe, apply

light oil to the inner surface of the pipe flange. As-

semble the turbocharger and exhaust manifold.

14. Install the exhaust manifold using a new gas-

ket.

15. Connect the water cooling lines, oil feed line

and engine hanger. Never open, service or drain the radiator or

cooling system when hot: serious burns can

occur from the steam and hot coolant. Also,

when draining engine coolant, keep in mind

that cats and dogs are attracted to ethylene

glyeol antifreeze and could drink any that is

left in an uncovered container or in puddles

on the ground. This will prove fatal in suffi-

Fig. 77 Use a pair of pliers to remove the

Fig. 78 . . .

then disconnect the overflow

hose clamp . . .

hose from the radiator may also require removal of the overflow tank.

4. Disconnect upper and lower radiator hoses.

5. Detach the electrical connectors from the

cooling fan and air conditioning condenser fan, if

equipped.

6. For Mirage and Diamante models, remove

the fan assembly.

7. Disconnect the therm0 sensor wires,

8. If equipped with an automatic transaxle, dis-

connect and plug the automatic transaxle cooler

lines.

9. Remove the upper radiator mounts and lift

out the radiator assembly or radiator/fan assembly,

as applicable.

To install:

10. Install the radiator or radiator and fan, if re-

moved as an assembly.

11. Connect the automatic transaxle cooler lines

if disconnected.

12. Connect the therm0 sensor wires,

13. Install the fan, if removed separately.

14. Install the radiator hoses.

15. Install the air cleaner support bracket, if re-

noved.

16. Install the overflow tube and reservoir, if re-

noved.

17. Fill the system with coolant.

18. Connect the negative battery cable, run the

vehicle until the thermostat opens, fill the radiator

93153003 Fig. 79 Use pliers to release the hose clamp

tension . . .

Fig. 80 . . .

then remove the upper radiator

hose from the radiator Fig. 81 From underneath the vehicle, re-

move the hose clamp , . . ”

then disconnect the lower radi- Fig. 82 . . .

ator hose

Page 80 of 408

![MITSUBISHI DIAMANTE 1900 Manual PDF ENGINEANDENGINEOVERHA~L 3-19

93153po3 93153P29 Fig. 87 Detach the connectors for the elec-

radiator to prevent contamination

/..: g3’Bpz] lFig.PO,..thenremovethemo”n~;~~ Fig 89 Remove the radi MITSUBISHI DIAMANTE 1900 Manual PDF ENGINEANDENGINEOVERHA~L 3-19

93153po3 93153P29 Fig. 87 Detach the connectors for the elec-

radiator to prevent contamination

/..: g3’Bpz] lFig.PO,..thenremovethemo”n~;~~ Fig 89 Remove the radi](/img/19/57096/w960_57096-79.png)

ENGINEANDENGINEOVERHA~L 3-19

93153po3 93153P29 Fig. 87 Detach the connectors for the elec-

radiator to prevent contamination

/..: g3’Bpz] lFig.PO,..thenremovethemo”n~;~~ Fig 89 Remove the radiator mount bolts

the radiator and radiator support panel

completely and check the automatic transaxle fluid

level, if equipped.

79. Once the vehicle has cooled. recheck the

coolant Ievel.

Except Diamante

6 See Figures 77 thru 93

1. Disconnect the negative battery cable.

2. Drain and recycle the engine coolant. Fig. 92 The fans are retained to the radla-

tor by four retaining bolts. Remove the re-

taining bolts . . .

93153px Fig. 91 Carefully grasp the radiator and fan

assembly and lift St out of the vehicle

n153p23 Fig. 93 . . . then carefully lift the fan from

the radiator