MITSUBISHI ECLIPSE 1990 Service Manual

Manufacturer: MITSUBISHI, Model Year: 1990, Model line: ECLIPSE, Model: MITSUBISHI ECLIPSE 1990Pages: 391, PDF Size: 15.27 MB

Page 381 of 391

EMISSION CONTROL SYSTEMS - Exhaust Car Recirculation (EGR) System25-7Duty ratio

I .,

ON e-_-m-L--l

T2L1.TlOFF---

m

1c1-i1e2100260 msec. 60 msec.

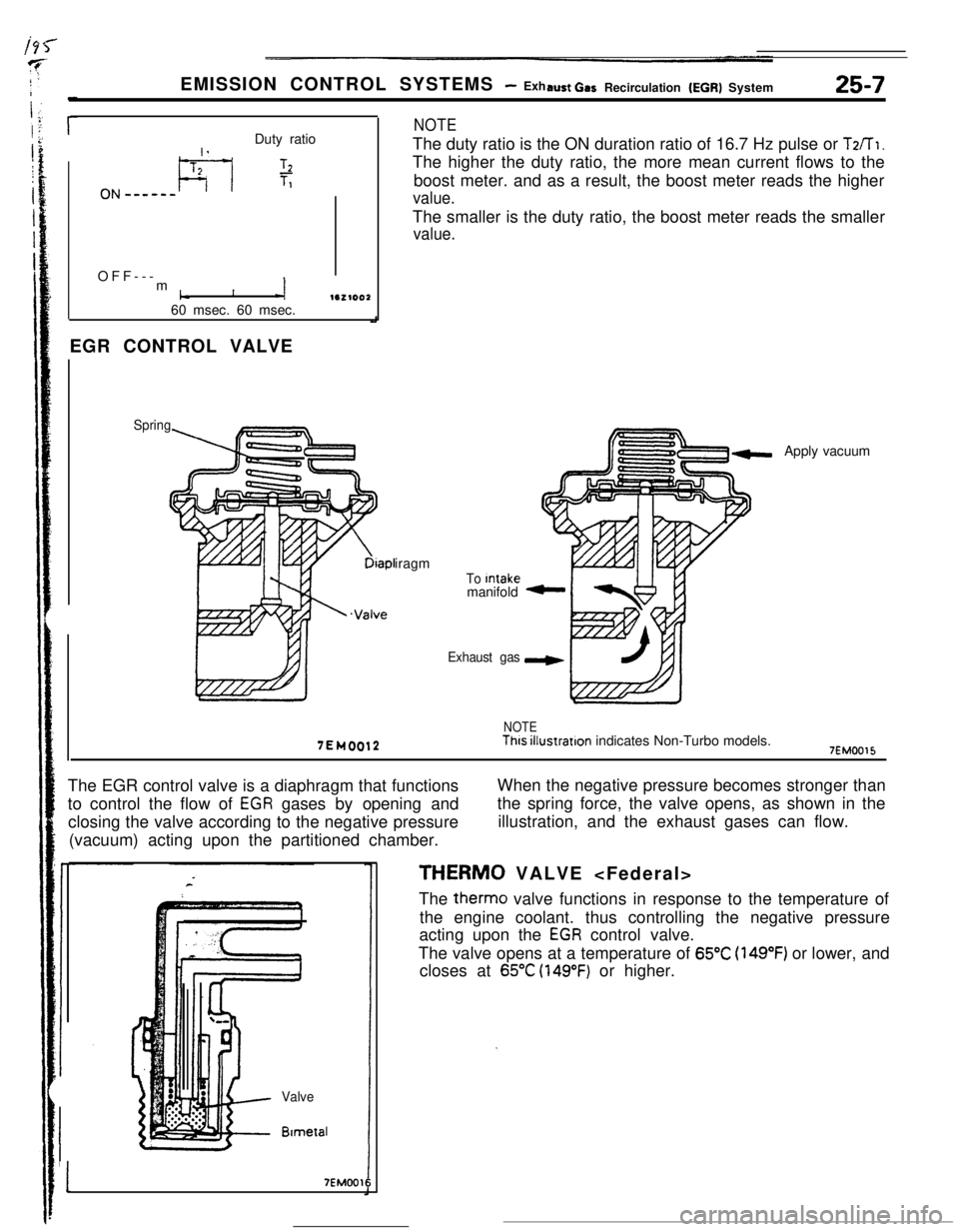

EGR CONTROL VALVE

Spring

NOTEThe duty ratio is the ON duration ratio of 16.7 Hz pulse or

T2/T1.The higher the duty ratio, the more mean current flows to the

boost meter. and as a result, the boost meter reads the higher

value.The smaller is the duty ratio, the boost meter reads the smaller

value.

Diapl

.Valveiragm

To Intakemanifold

Exhaust gasApply vacuum

7EM0012

NOTEThis illustration indicates Non-Turbo models.7EMOO15The EGR control valve is a diaphragm that functions

to control the flow of

EGR gases by opening and

closing the valve according to the negative pressure

(vacuum) acting upon the partitioned chamber.When the negative pressure becomes stronger than

the spring force, the valve opens, as shown in the

illustration, and the exhaust gases can flow.

Valve

BlmetzII

17EMOO16

THERM0 VALVE

The therm0 valve functions in response to the temperature of

the engine coolant. thus controlling the negative pressure

acting upon the

EGR control valve.

The valve opens at a temperature of

65°C (149°F) or lower, and

closes at

65°C (149°F) or higher.

Page 382 of 391

25-8EMISSION CONTROL SYSTEMS- Exhaust Gas Recirculation (EGR) System

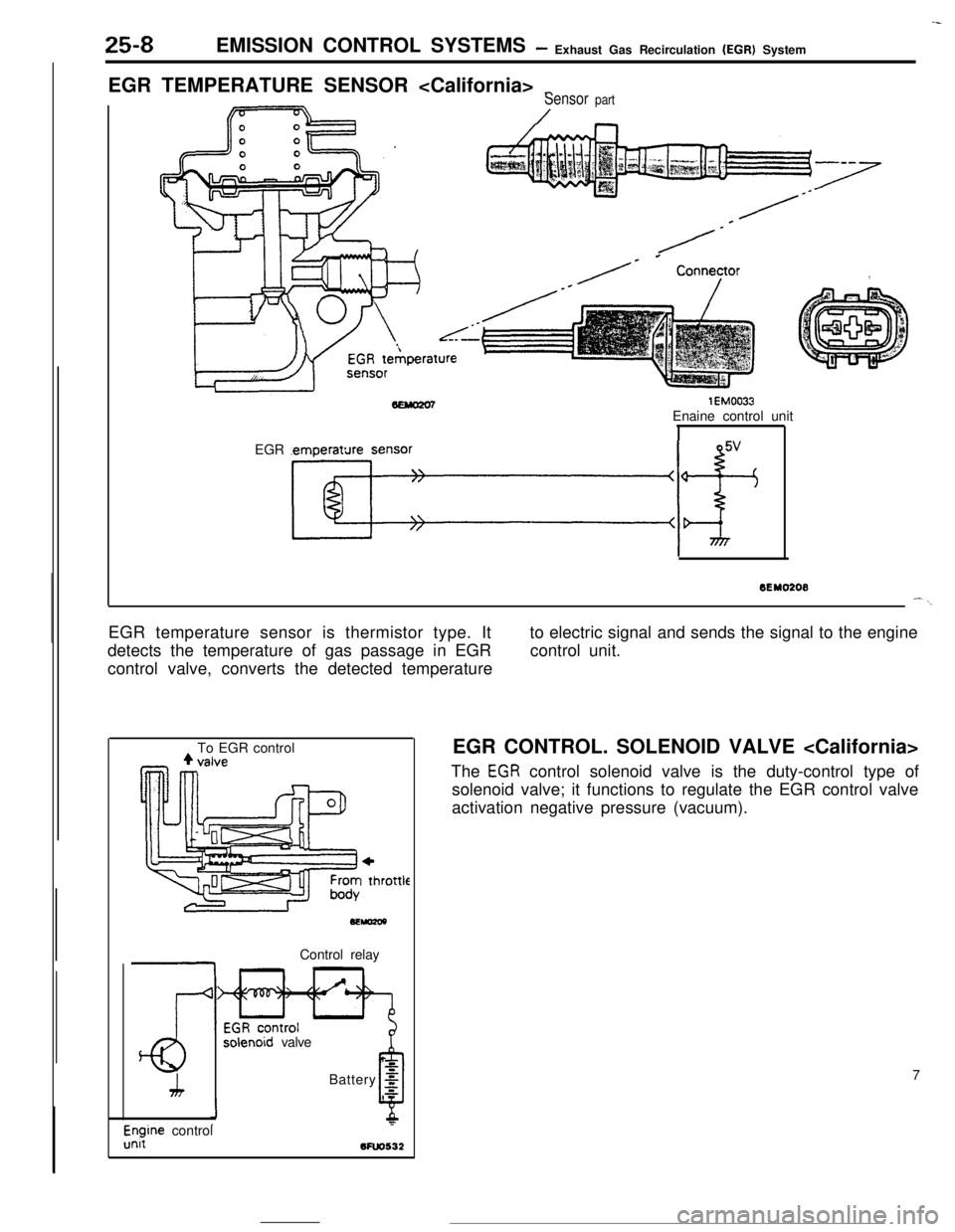

EGR TEMPERATURE SENSOR

_Sensor part

/

/-

/* * Conneyor,

lEM0033Enaine control unit

EGR temperature sensor

Kf+

--

6EY0208--\EGR temperature sensor is thermistor type. It

detects the temperature of gas passage in EGR

control valve, converts the detected temperatureto electric signal and sends the signal to the engine

control unit.

To EGR control

+I thl

.ottleControl relay

solenoid valve

h

LBattery

g

0s

l$ine control5FW532EGR CONTROL. SOLENOID VALVE

The

EGR control solenoid valve is the duty-control type of

solenoid valve; it functions to regulate the EGR control valve

activation negative pressure (vacuum).

7

Page 383 of 391

---- .~ _ _EMISSION CONTROL SYSTEMS

- Catalytic Converter I Air-fuel Mixture Ratio Control System25-9

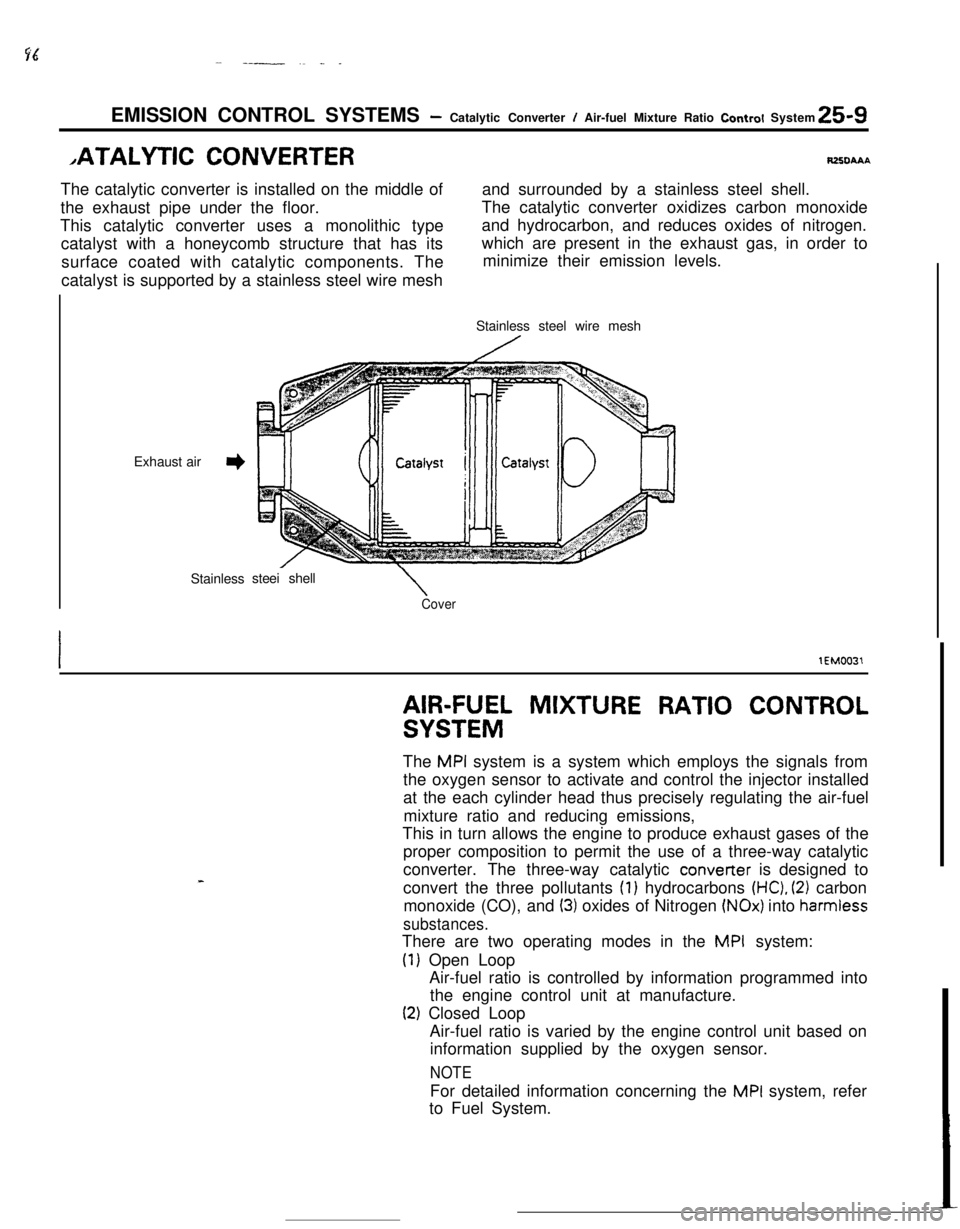

,ATALYTlC CONVERTERRZXIAAAThe catalytic converter is installed on the middle ofand surrounded by a stainless steel shell.

the exhaust pipe under the floor.The catalytic converter oxidizes carbon monoxide

This catalytic converter uses a monolithic type

catalyst with a honeycomb structure that has itsand hydrocarbon, and reduces oxides of nitrogen.

surface coated with catalytic components. Thewhich are present in the exhaust gas, in order to

minimize their emission levels.

catalyst is supported by a stainless steel wire mesh

Exhaust air

3Stainlesssteei shell

\CoverStainless steel wire mesh

lEM0031

AIR-FUEL MIXTURE RATIO CONTROL

SYSTEMThe

MPI system is a system which employs the signals from

the oxygen sensor to activate and control the injector installed

at the each cylinder head thus precisely regulating the air-fuel

mixture ratio and reducing emissions,

This in turn allows the engine to produce exhaust gases of the

proper composition to permit the use of a three-way catalytic

converter. The three-way catalytic converter is designed to

convert the three pollutants

(1) hydrocarbons (HC), (2) carbon

monoxide (CO), and

(3) oxides of Nitrogen (NOx) into harmiess

substances.There are two operating modes in the

MPI system:

(1) Open Loop

Air-fuel ratio is controlled by information programmed into

the engine control unit at manufacture.

(2) Closed Loop

Air-fuel ratio is varied by the engine control unit based on

information supplied by the oxygen sensor.

NOTEFor detailed information concerning the

MPI system, refer

to Fuel System.

Page 384 of 391

25-10EMISSION CONTROL SYSTEMS - Crankcase Ventilation Svstem-

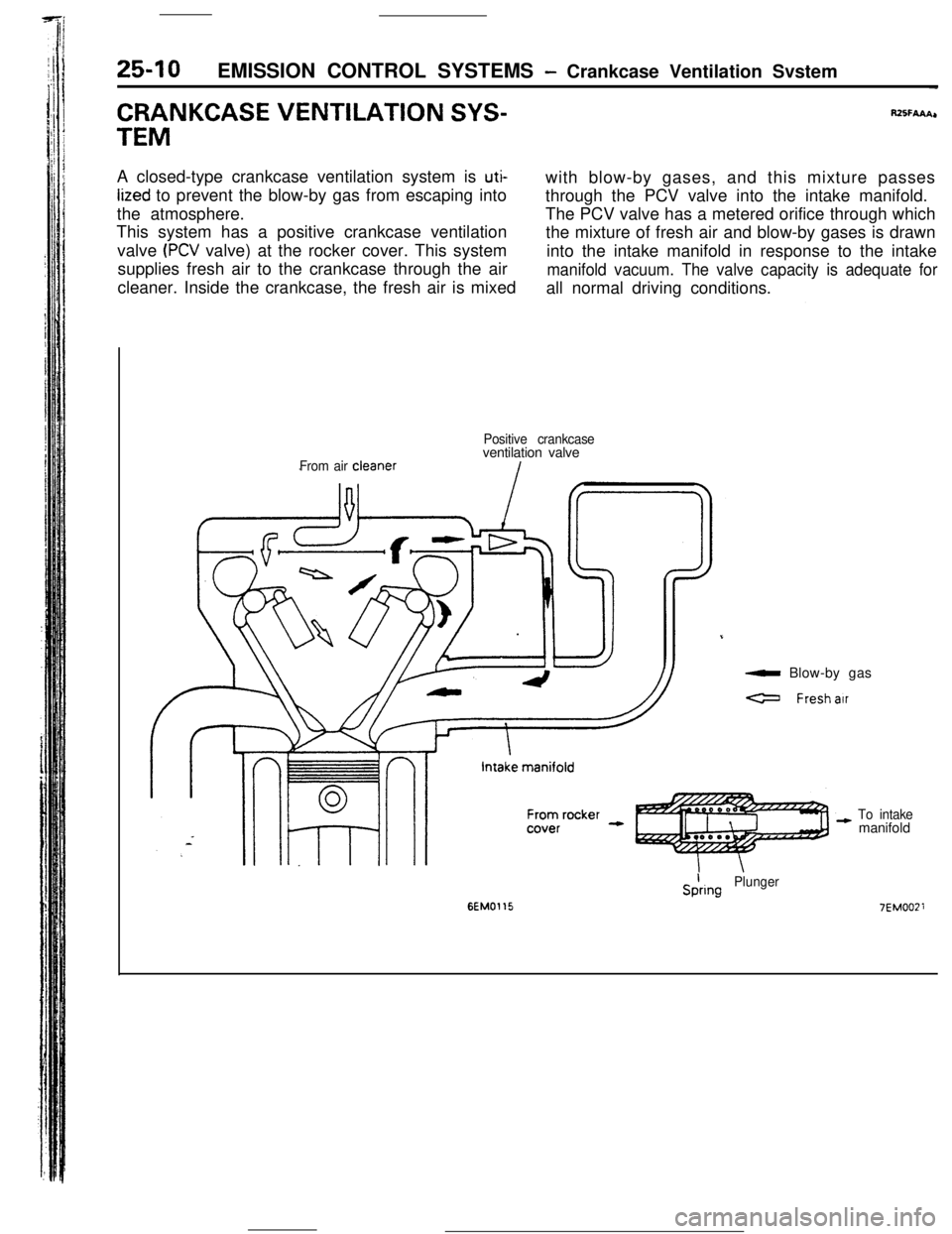

CRANKCASE VENTILATION SYS-fUSFAAA,r

TEMA closed-type crankcase ventilation system is

uti-with blow-by gases, and this mixture passes

lized to prevent the blow-by gas from escaping into

through the PCV valve into the intake manifold.

the atmosphere.The PCV valve has a metered orifice through which

This system has a positive crankcase ventilation

the mixture of fresh air and blow-by gases is drawn

valve

(PCV valve) at the rocker cover. This system

into the intake manifold in response to the intake

supplies fresh air to the crankcase through the air

manifold vacuum. The valve capacity is adequate forcleaner. Inside the crankcase, the fresh air is mixed

all normal driving conditions.

From air cleanerPositive crankcaseventilation valve

a Blow-by gas

a Freshair

To intakemanifold

6EM0115

SiringPlunger

7EMOOZi

Page 385 of 391

__..--. -._ _^__. __--- -._ _..EMISSION CONTROL SYSTEMS

- Evaporative Emission Control Svsvem25-l 1

,VAPORATlVE EMISSION CON-

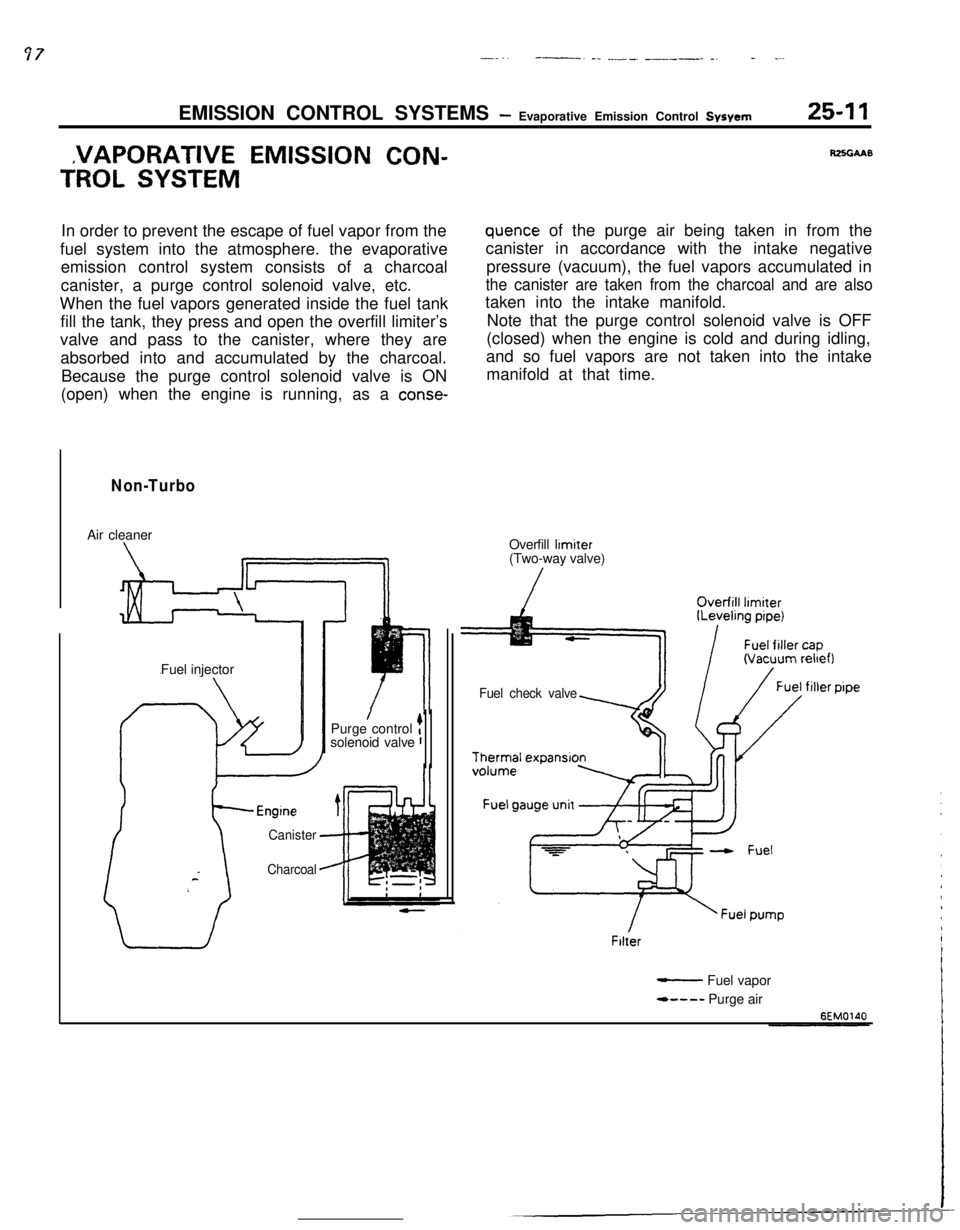

TROL SYSTEMIn order to prevent the escape of fuel vapor from the

fuel system into the atmosphere. the evaporative

emission control system consists of a charcoal

canister, a purge control solenoid valve, etc.

When the fuel vapors generated inside the fuel tank

fill the tank, they press and open the overfill limiter’s

valve and pass to the canister, where they are

absorbed into and accumulated by the charcoal.

Because the purge control solenoid valve is ON

(open) when the engine is running, as a

conse-

Non-TurboAir cleaner

Fuel injector

Canister

Charcoal

/Purge control tsolenoid valve r

RZSGAAB

quence of the purge air being taken in from the

canister in accordance with the intake negative

pressure (vacuum), the fuel vapors accumulated in

the canister are taken from the charcoal and are alsotaken into the intake manifold.

Note that the purge control solenoid valve is OFF

(closed) when the engine is cold and during idling,

and so fuel vapors are not taken into the intake

manifold at that time.

Overfill

limiter(Two-way valve)

Fuel check valveFilter

- Fuel vapor

*---- Purge air

Page 386 of 391

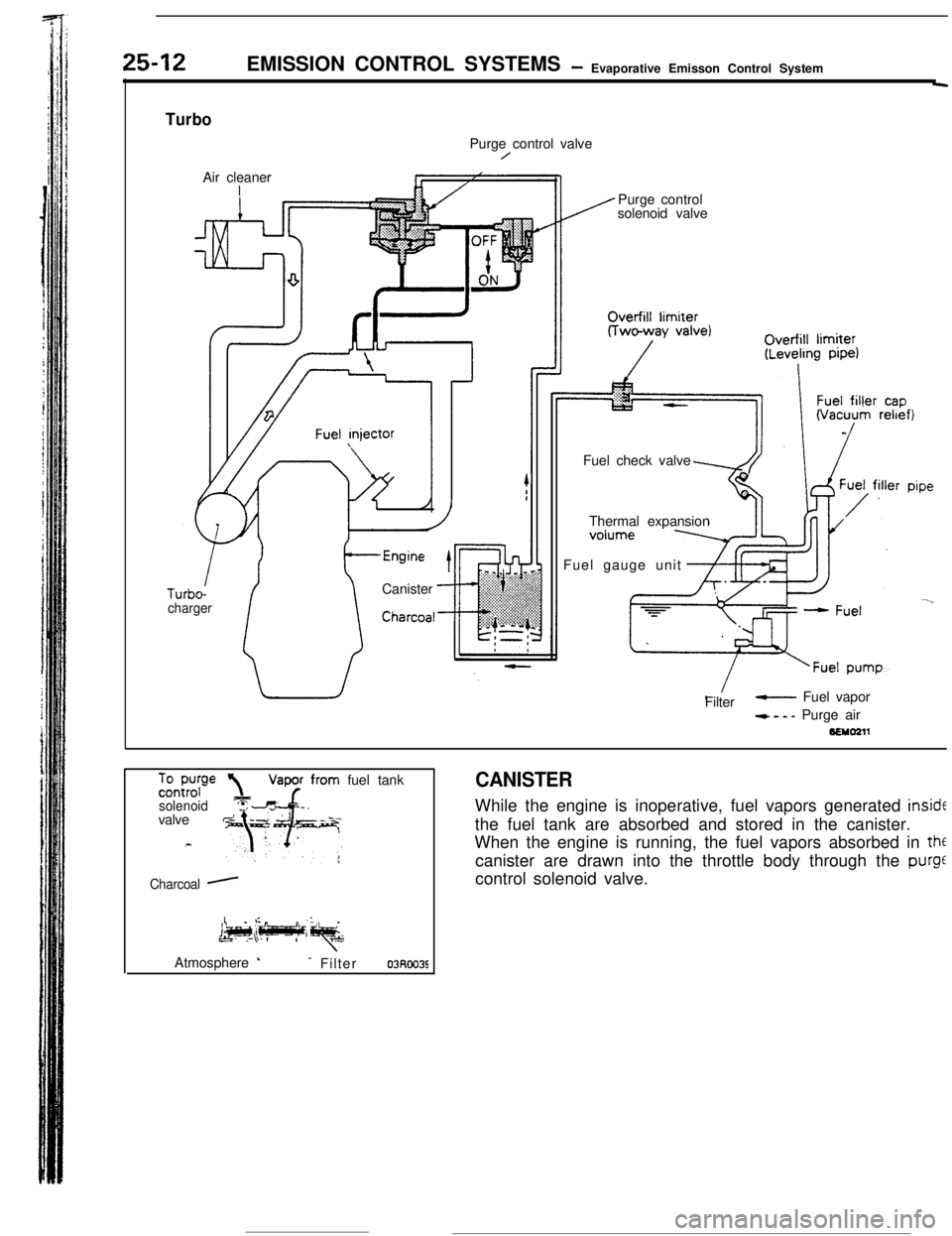

25-12EMISSION CONTROL SYSTEMS- Evaporative Emisson Control System-

TurboPurge control valve

/Air cleaner

Canister

-Charcoal-ITurbo-

chargerPurge control

solenoid valve

Fuel check valve

Thermal expansion

Fuel gauge unit

Filter

- Fuel vapor

- - - - Purge air

BEMO211

%-E?”solenoidvalve

Charcoal -fuel tank

CANISTERWhile the engine is inoperative, fuel vapors generated

insidEthe fuel tank are absorbed and stored in the canister.

When the engine is running, the fuel vapors absorbed in

thfcanister are drawn into the throttle body through the

purgecontrol solenoid valve.

Atmosphere

L- Filter03Roo3E

Page 387 of 391

EMISSION CONTROL SYSTEMS- Evaporative Emission Control System25-13

IFrom canister1

,To intake air plenum or throttle body

7EMOlPControl

relavPurge control

solenoid valve

Battery

g

6

,zEngine control

unit

From throttle body

4To purge

control

valve

SEMo2laControl relay

3:

1.

Purge control

solenoid valve

zBattery g

Engtne controlunii

bfuo532JPURGE CONTROL SOLENOID VALVE

The purge-control solenoid valve is the ON/OFF control type of

solenoid valve; it functions to control the introduction of purge

air to the intake air plenum from the canister.

PURGE CONTROL SOLENOID VALVE

The purge-control solenoid valve is the ON/OFF control type of

solenoid valve; it functions to control the activation of the

purge-control valve.

ITo throttle body11PURGE CONTROL VALVE

The purge-control valve functions to control the introduction of

purge air to the air-intake hose from the canister.

0 From canister

Page 388 of 391

--.25-14EMISSION CONTROL SYSTEMS

- Evaporative Emisson Control System

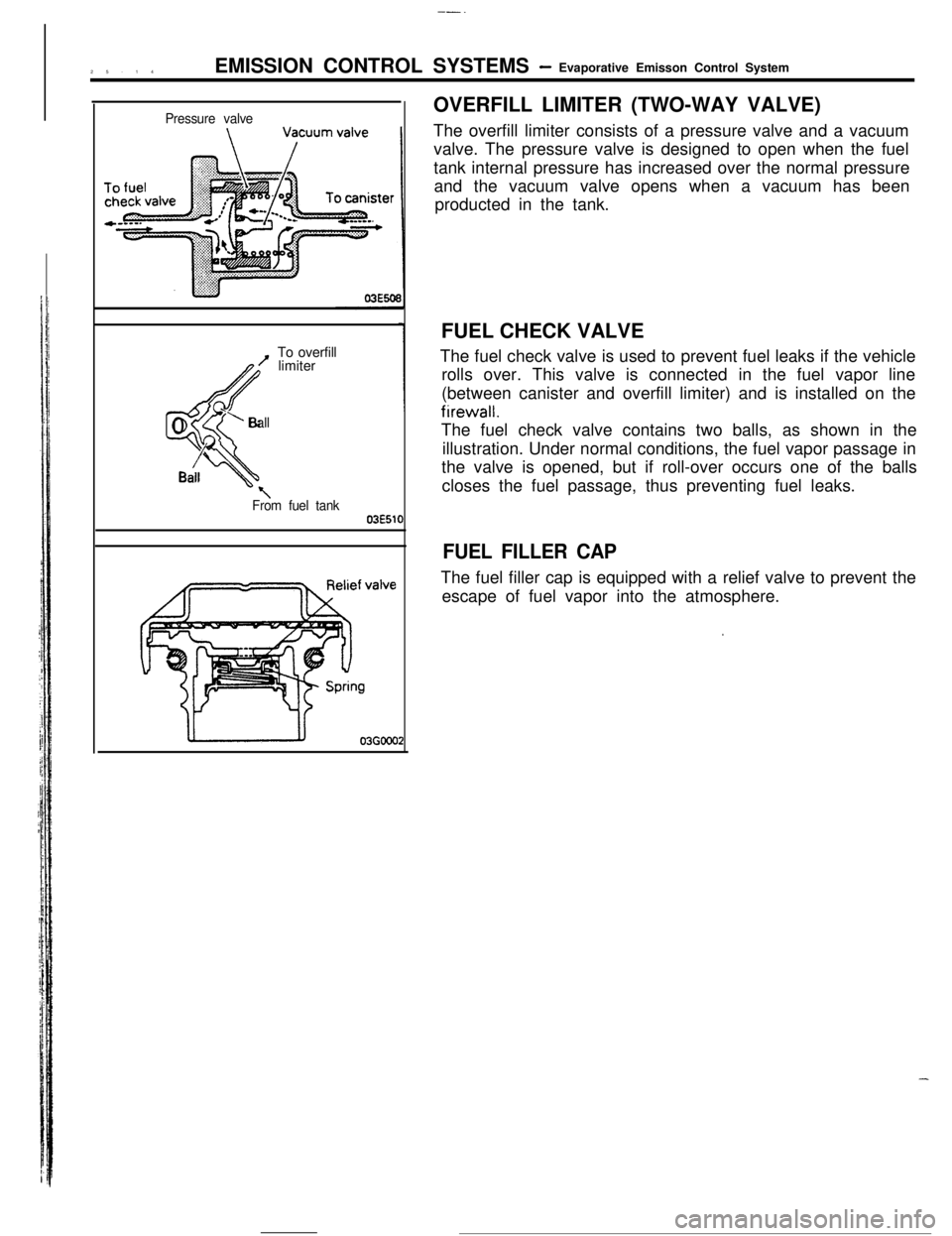

Pressure valveTo overfill

’ limiter

40

” Ball

Bail

\From fuel tank03E51fOVERFILL LIMITER (TWO-WAY VALVE)

The overfill limiter consists of a pressure valve and a vacuum

valve. The pressure valve is designed to open when the fuel

tank internal pressure has increased over the normal pressure

and the vacuum valve opens when a vacuum has been

producted in the tank.

FUEL CHECK VALVE

The fuel check valve is used to prevent fuel leaks if the vehicle

rolls over. This valve is connected in the fuel vapor line

(between canister and overfill limiter) and is installed on thefirewall.

The fuel check valve contains two balls, as shown in the

illustration. Under normal conditions, the fuel vapor passage in

the valve is opened, but if roll-over occurs one of the balls

closes the fuel passage, thus preventing fuel leaks.

FUEL FILLER CAPThe fuel filler cap is equipped with a relief valve to prevent the

escape of fuel vapor into the atmosphere.

.

-

Page 389 of 391

-_--

NOTES

Page 390 of 391

-_--

NOTES