torque MITSUBISHI ECLIPSE 1991 Service Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1991, Model line: ECLIPSE, Model: MITSUBISHI ECLIPSE 1991Pages: 1216, PDF Size: 67.42 MB

Page 685 of 1216

STEERING - Power Steering Gear Box

13A017EI

\Silicon grease

Lip

Sealant131564-r-MB990776-A

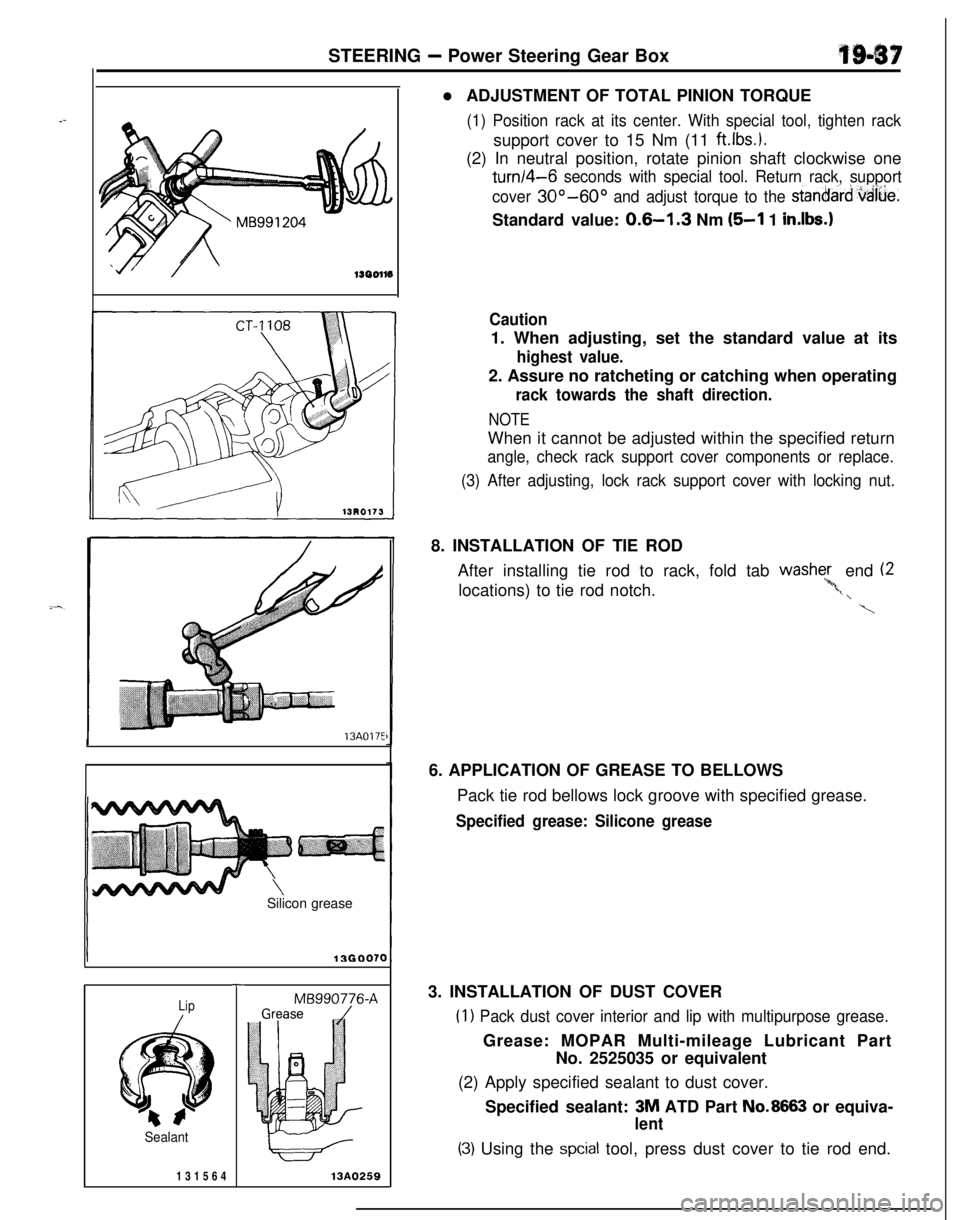

13A0259l ADJUSTMENT OF TOTAL PINION TORQUE

(1) Position rack at its center. With special tool, tighten racksupport cover to 15 Nm (11

ftlbs.).(2) In neutral position, rotate pinion shaft clockwise one

turn/4-6 seconds with special tool. Return rack, support

cover

30°-60° and adjust torque to the stanoard,vaiue.Standard value:

0.6-l .3 Nm (5-l 1 in.lbs.1

Caution1. When adjusting, set the standard value at its

highest value.2. Assure no ratcheting or catching when operating

rack towards the shaft direction.

NOTEWhen it cannot be adjusted within the specified return

angle, check rack support cover components or replace.

(3) After adjusting, lock rack support cover with locking nut.8. INSTALLATION OF TIE ROD

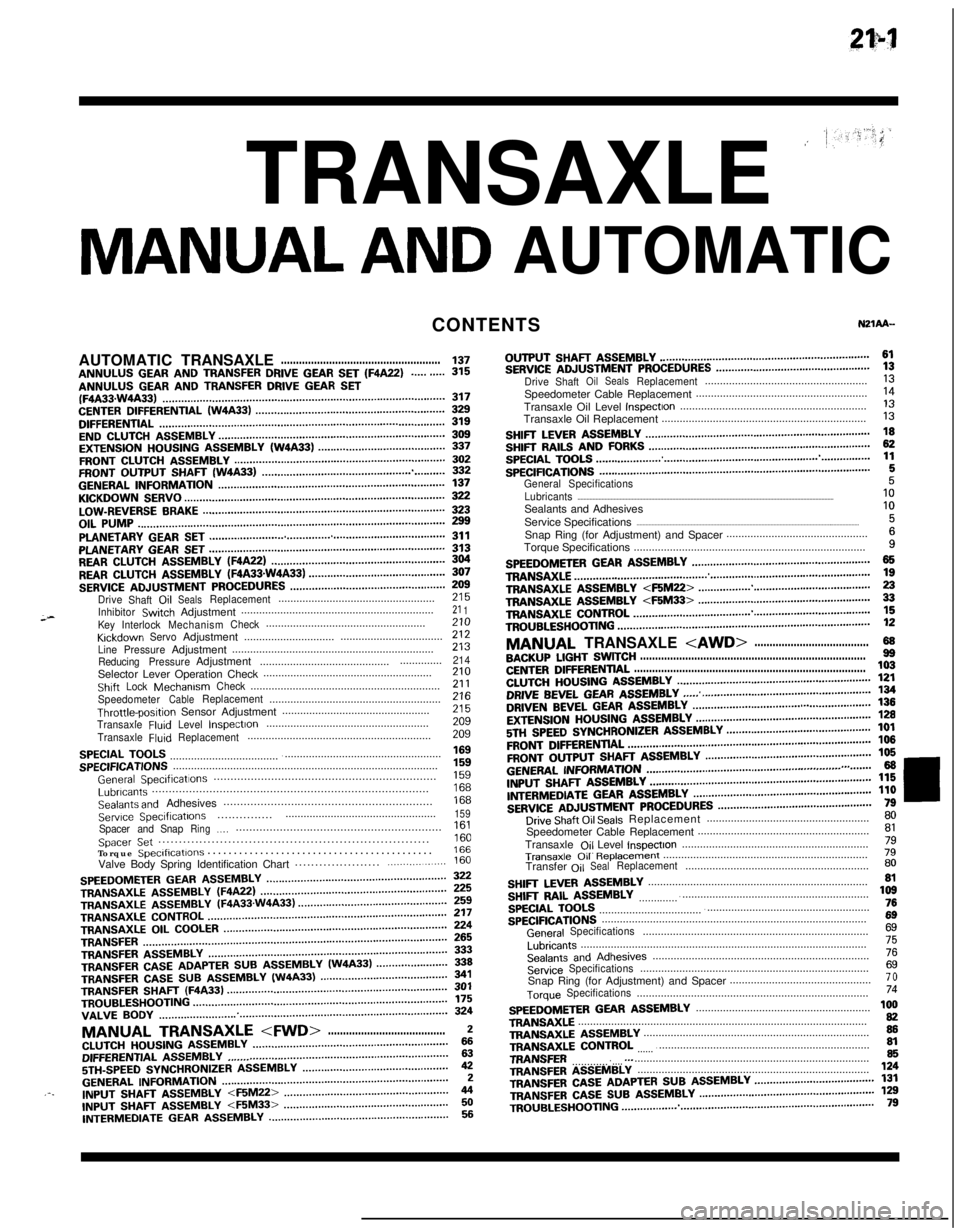

After installing tie rod to rack, fold tab washe;, end (2

locations) to tie rod notch.

‘*,t, \

\6. APPLICATION OF GREASE TO BELLOWS

Pack tie rod bellows lock groove with specified grease.

Specified grease: Silicone grease3. INSTALLATION OF DUST COVER

(1) Pack dust cover interior and lip with multipurpose grease.Grease: MOPAR Multi-mileage Lubricant Part

No. 2525035 or equivalent

(2) Apply specified sealant to dust cover.

Specified sealant: 3M ATD Part

No.8663 or equiva-

lent

(3) Using the spcial tool, press dust cover to tie rod end.

Page 695 of 1216

TRANSAXLE ’

MANUAL AND AUTOMATICCONTENTS

;-AUTOMATICTRANSAXLE

.....................................................137ANNULUS GEAR AND TRANSFER DRIVE GEAR SET (F4A22)..........315ANNULUS GEAR AND TRANSFER DRIVE GEAR SET(F4A33.W4A33)...........................................................................................317CENTERDIFFERENTIAL(W4A33).............................................................329DIFFERENTIAL............................................................................................319ENDCLUTCHASSEMBLY.........................................................................309EXTENSIONHOUSINGASSEMBLY(W4A33).........................................337FRONTCLUTCHASSEMBLY....................................................................302FRONTOUTPUTSHAFT(W4A33)...........................................................332GENERALINFORMATION.........................................................................137KICKDOWNSERVO....................................................................................322LOW-REVERSEBRAKE..............................................................................323OILPUMP...................................................................................................299PLANETARYGEARSET............................................................................311PLANETARYGEARSET............................................................................313REARCLUTCHASSEMBLY(F4A22)........................................................304REARCLUTCHASSEMBLY(FQA33sW4A33)............................................307SERVICEADJUSTMENTPROCEDURES..................................................Drive

Shaft,OilSealsReplacement....................................................;;;

InhibitorSwtchAdjustment................................................................21 1KeyInterlockMechanismCheck.....................................................KrckdownServoAdjustment..................................zii..............................

LinePressureAdjustment...................................................................213

ReducingPressureAdjustment.........................................................214Selector Lever Operation Check........................................................210ShiftLockMechanismCheck...............................................................21 1SpeedometerCableReplacement.........................................................Throttle-posltipn Sensor Adjustment.................................................z2:

TransaxleFluIdLevelInspectIon......................................................209

TransaxleFluidReplacement.............................................................209

SPECIALTOOLS.........................................................................................SPECIFICATIONS........................................................................................;“5”9

GeneralSpeclficatlons..................................................................1%Lubricants..................................................................................Sealants and Adhesives..............................................................izi

Serwce Speclflcatlons..................................................159...............Spacer andSnapRing.,.,.............................................................Spacer Set..................................................................1::Torque Speclflcatlons...........................................166Valve Body Spring Identification Chart.....................

.................160

SPEEDOMETERGEARASSEMBLY..........................................................TRANSAXLEASSEMBLY(WA22)............................................................zTRANSAXLE

ASSEMBLY(F4A33.W4A33)................................................TRANSAXLECONTROL.............................................................................;;;TRANSAXLE

OILCOOLER........................................................................TRANSFER..................................................................................................fg

TRANSFERASSEMBLY.............................................................................333TRANSFERCASEADAPTERSUBASSEMBLY(W4A33).......................339TRANSFER CASE SUB ASSEMBLY (W4A33)341TRANSFER SHAFT (F4A33)TROUBLESHOOTING..................................................................................................................................................................................................f;;VALVE

BODY.............................................................................................324

MANUAL TRANSAXLE

5TH-SPEEDSYNCHRONIZERASSEMBLY...............................................42GENERALINFORMATION.........................................................................2.-.INPUTfj,-,A,TASSEMBLY

INTERMEDIATE GEAR ASSEMBLY..........................................................56OUTPUT

SHAFT ASSEMBLY....................................................................61SERVICEADJUSTMENTPROCEDURES..................................................DriveShaftOilSealsReplacement......................................................;;Speedometer Cable Replacement.........................................................

Transaxle Oil Level

InspectIon..............................................................‘liTransaxle Oil Replacement....................................................................

I3

SHIFTLEVERASSEMBLY.........................................................................SHIFTRAILSANDFORKS........................................................................g

SPECIALTOOLS.........................................................................................SPECIFICATIONS........................................................................................1:

General Specifications5Lubricants..........................................................................................................................................................................10Sealants and Adhesives

Service Specifications

....................................................................................................................................................1:Snap Ring (for Adjustment) and Spacer...............................................

Torque Specifications.............................................................................

i

SPEEDOMETERGEARASSEMBLY..........................................................TRANS&G.E................................................................................................zTRANSAXLEA!jSEMBLY

TROUBLESHOOTING..................................................................................12

MANUAL TRANSAXLE

CENTERDIFFERENTIAL.............................................................................103CLUTCHHOUSINGASSEMBLY...............................................................DRIVE BEVEL GEAR ASSEMBLY;g

...... .......................................................DRIVENBEVELGEARASSEMBLY...................................a......................EXTENSIONHOUSINGASSEMBLY.........................................................;g

5Tf.jSPEEDSYNCHRONIZERASSEMBLY...............................................101

FRONTDlFFERENTlAL...............................................................................106

FRONTOUTPUTSHAFTASSEMBLY......................................................106

GENERALI~~~~MATN)N...............................................................,.,.......66INPUTSHAFTASSEMBLY........................................................................l~ER,“,EDlATEGEARASSMBLY..........................................................;;i

SERVICEADJUSTMENTPROCEDURES..................................................Drive Shaft Oil Seals Replacement......................................................;;Speedometer Cable Replacement.........................................................

Transaxle

Ojl Level lnspectlon..............................................................;l

Transaxle 011 R~pb33ment....................................................................79Transfer

OilSealReplacement.............................................................80

SHIFTLEVERASSEMBLY.........................................................................SHIFTRAILASSEMBLY............................................................................,z

SPECIALTOOLS.........................................................................................76

SPECIFICATIONS........................................................................................6g

GeneralSpecifications...........................................................................6g

Lubricants...............................................................................................75

SealantsandAdhesives........................................................................76

ServiceSpecifications............................................................................6gSnap Ring (for Adjustment) and Spacer...............................................7 o

TorqueSpecifications.............................................................................74

SPEEDOMETERGEARASSEMBLY..........................................................TRANSAXLE................................................................................................1:TRANSAXLEASSEMBLY...........................................................................86TRANSAXLE

CONTROL

.............................................................................TRANSFER...............................................................................................

g.._TRANSFERA!333lBLY.............................................................................,24

TRANSFERCASEADAPTERSUBASSEMBLY.......................................131TRANSFERCASESUBASSEMBLY.........................................................TR,,UBLES,,OO,,NG..................................................................................1;;

Page 703 of 1216

MANUAL TRANSAXLE

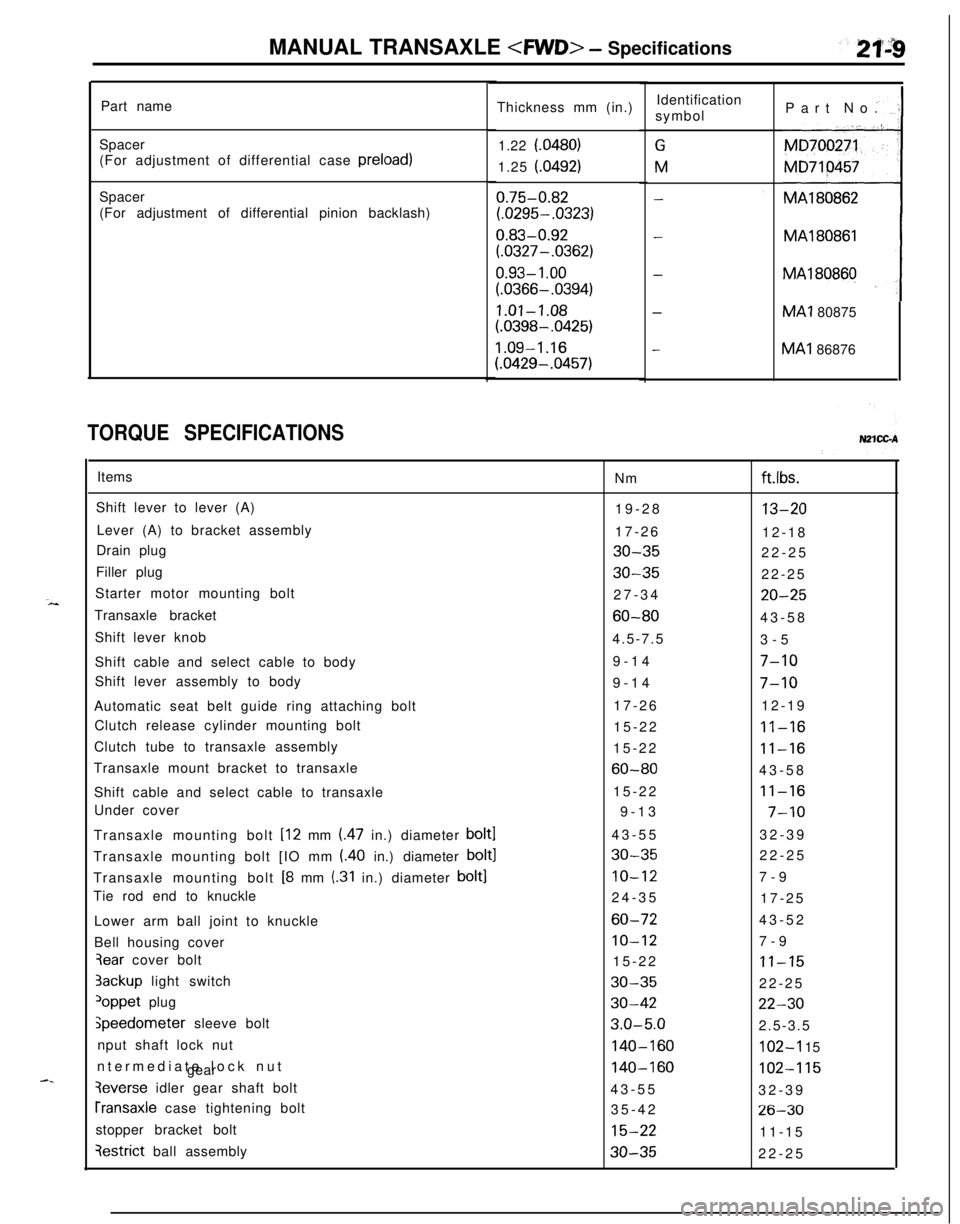

Part name

Spacer

(For adjustment of differential case preload)

Spacer

(For adjustment of differential pinion backlash)

TORQUE SPECIFICATIONSThickness mm (in.)

1.22 f.0480)

1.25 (.0492)

0.75-0.82

(.0295-.0323)

0.83-0.92

(.0327-.0362)

0.93- 1 .oo

(.0366-.0394)

1.01-1.08

(.0398-.0425)

1.09-1.16

(.0429-.0457)Identification

symbol

GM

-

-

-

-Part No.

MA180862MA1

80866MA1 80875MA1 86876

Items

Nm

Shift lever to lever (A)

19-28

Lever (A) to bracket assembly

17-26

Drain plug

30-35Filler plug

30-35Starter motor mounting bolt

27-34

Transaxle bracket

60-80Shift lever knob

4.5-7.5

Shift cable and select cable to body9-14

Shift lever assembly to body

9-14

Automatic seat belt guide ring attaching bolt17-26

Clutch release cylinder mounting bolt

15-22

Clutch tube to transaxle assembly

15-22

Transaxle mount bracket to transaxle

60-80Shift cable and select cable to transaxle15-22

Under cover

9-13

Transaxle mounting bolt [12 mm (.47 in.) diameter

bolt143-55

Transaxle mounting bolt [IO mm (.40 in.) diameter

bolt130-35Transaxle mounting bolt

[8 mm (.31 in.) diameter bolt]IO-12Tie rod end to knuckle

24-35

Lower arm ball joint to knuckle

60-72Bell housing cover

IO-123ear cover bolt

15-223ackup light switch

30-35

loppet plug30-42

jpeedometer sleeve bolt3.0-5.0nput shaft lock nut

140-160ntermediate lock nut

gear

140-160

3everse idler gear shaft bolt

43-55

rransaxle case tightening bolt

35-42

stopper bracket bolt

15-22

qestrict ball assembly30-35

ft.lbs.

13-2012-18

22-25

22-25

20-2543-58

3-5

7-10

7-1012-19

11-16

11-1643-58

11-16

7-1032-39

22-25

7-9

17-25

43-52

7-9

11-1522-25

22-302.5-3.5

102-I 15

102-11532-39

26-3011-15

22-25

Page 723 of 1216

MANUAL TRANSAXLE

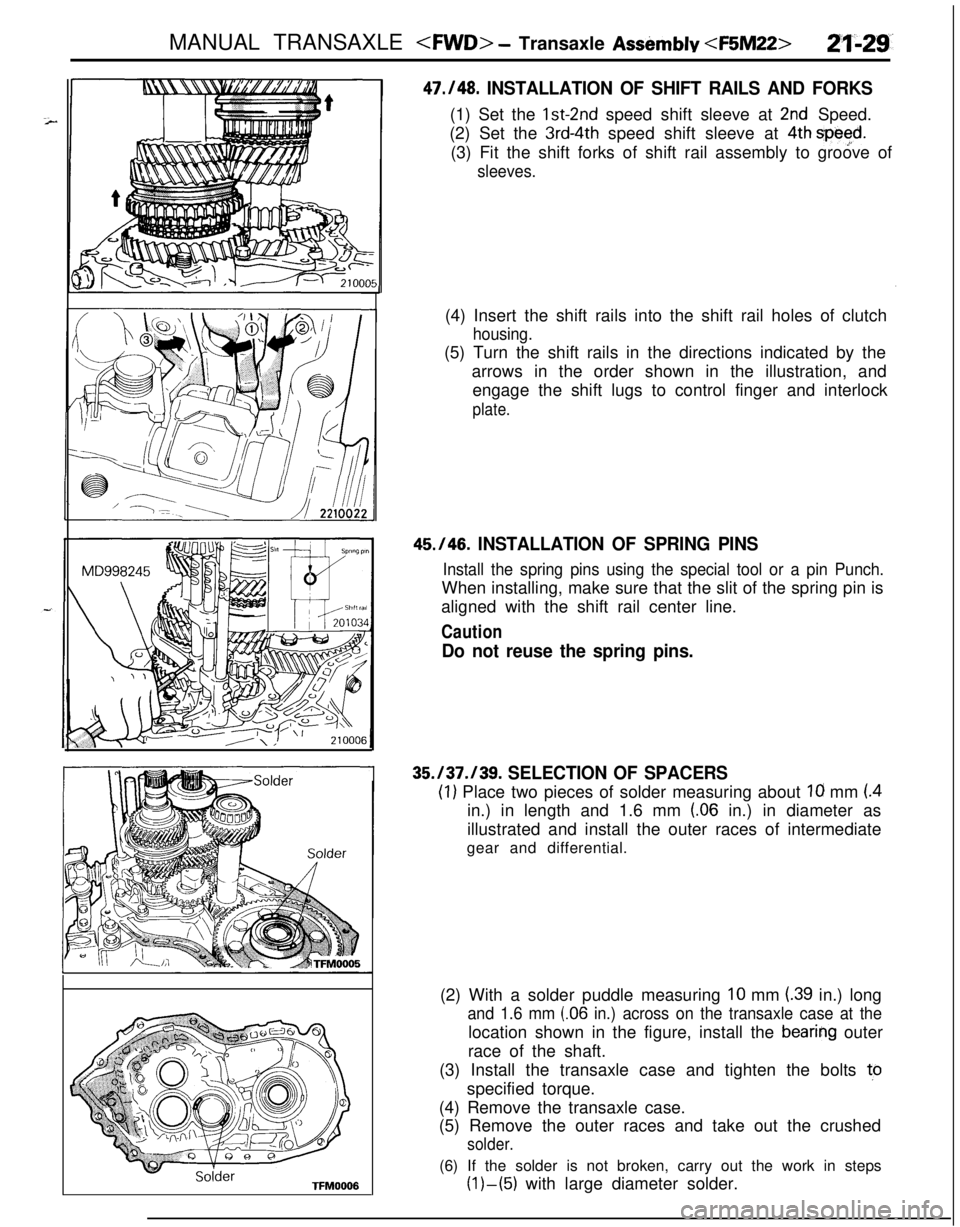

47./48. INSTALLATION OF SHIFT RAILS AND FORKS(1) Set the

lst-2nd speed shift sleeve at 2nd Speed.

(2) Set the

3rd-4th speed shift sleeve at 4th spe$d.(3) Fit the shift forks of shift rail assembly to groove of

sleeves.(4) Insert the shift rails into the shift rail holes of clutch

housing.(5) Turn the shift rails in the directions indicated by the

arrows in the order shown in the illustration, and

engage the shift lugs to control finger and interlock

plate.

45.146. INSTALLATION OF SPRING PINS

Install the spring pins using the special tool or a pin Punch.When installing, make sure that the slit of the spring pin is

aligned with the shift rail center line.

Caution

Do not reuse the spring pins.

35.137.139. SELECTION OF SPACERS

(1) Place two pieces of solder measuring about Ia mm (.4in.) in length and 1.6 mm

(.06 in.) in diameter as

illustrated and install the outer races of intermediate

gear and differential.

(2) With a solder puddle measuring

10 mm (.39 in.) long

and 1.6 mm (.06 in.) across on the transaxle case at thelocation shown in the figure, install the

bearing outer

race of the shaft.

(3) Install the transaxle case and tighten the bolts to

specified torque.

(4) Remove the transaxle case.

(5) Remove the outer races and take out the crushed

solder.(6) If the solder is not broken, carry out the work in steps

(l)-(5) with large diameter solder.

Page 725 of 1216

![MITSUBISHI ECLIPSE 1991 Service Manual MANUAL TRANSAXLE <WD> - Transaxle Assembly <F5M22>2%3T

IMD998245(5)

Insert a Phillips screwdriver [8 mm (.32 in.) shaft

diameter] into the bolt hole in the case, as shown in thefigure, and use it to MITSUBISHI ECLIPSE 1991 Service Manual MANUAL TRANSAXLE <WD> - Transaxle Assembly <F5M22>2%3T

IMD998245(5)

Insert a Phillips screwdriver [8 mm (.32 in.) shaft

diameter] into the bolt hole in the case, as shown in thefigure, and use it to](/img/19/57104/w960_57104-724.png)

MANUAL TRANSAXLE

IMD998245(5)

Insert a Phillips screwdriver [8 mm (.32 in.) shaft

diameter] into the bolt hole in the case, as shown in thefigure, and use it to align the threaded hole of the

reverse idler gear shaft with the bolt

hole in the

transaxle case.

(6) Install the reverse idler gear shaft bolt and tighten the

bolt by fingers.

(7) Tighten the all transaxle tightening bolts to specified

(8)

E$r& the reverse idle gear shaft bolt to specified

torque.

15./ 16. INSTALLATION OF LOCK NUTS(1) Install the special tool to the splined end of input shaft.

(2) Screw a bolt

(10 mm) into the hole on the periphery of

clutch housing and attach a spinner handle to the

special tool.

(3) Shift the transmission in reverse using control lever andselect lever.

(4) Tighten the lock

nut,to specified torque, while ‘using the

bolt attached in the above step as a spinner handle

stopper.(5) Loosen the lock nuts.

(6) Retighten the lock nuts to the specified torque.

(7) Stake the lock nut.

14. INSTALLATION OF SPRING PIN(1) Install the spring pin using the special tool or a pin

punch.

Caution

Do not reuse the spring pins.

Page 733 of 1216

MANUAL TRANSAXLE

/Shift rail

11-t201034er

2150008

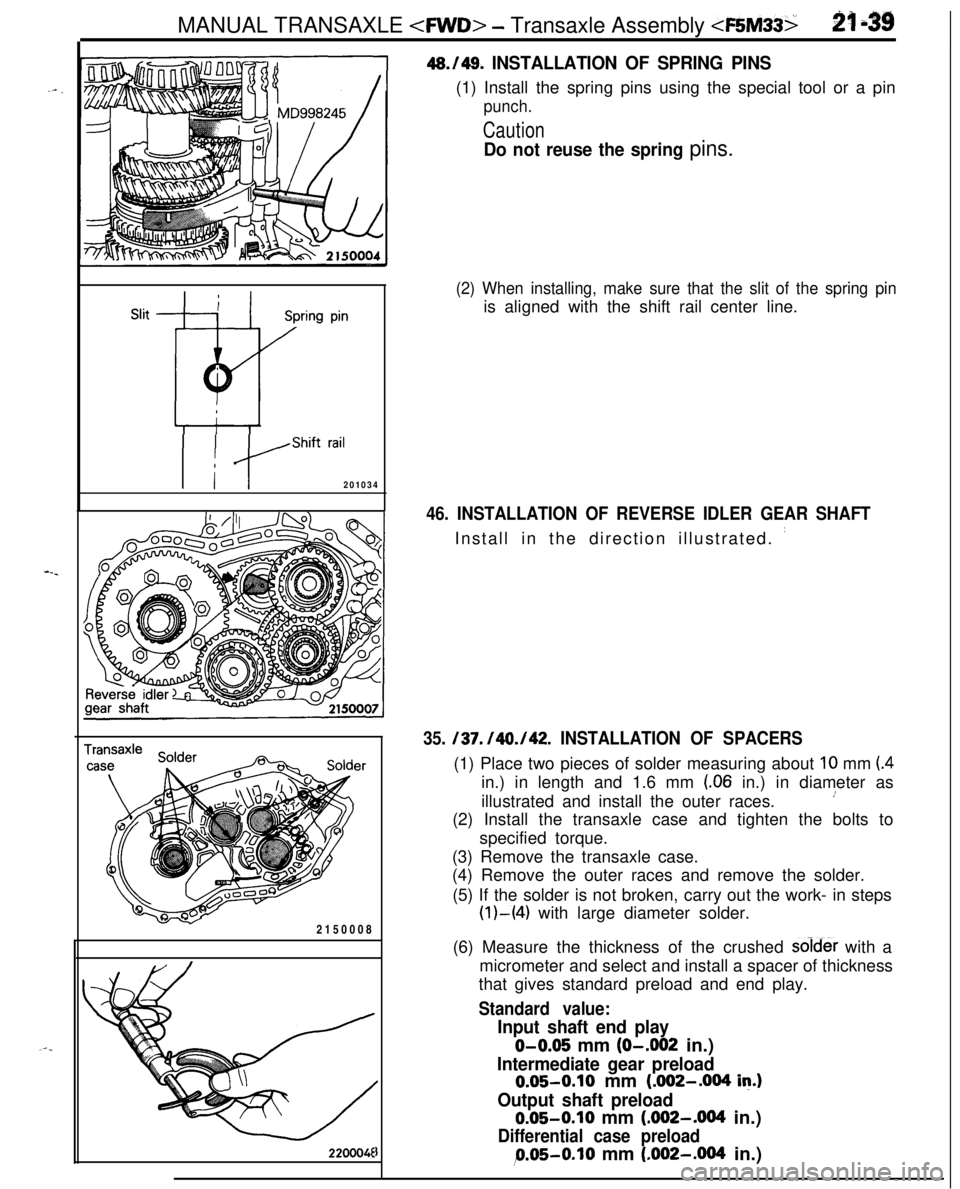

220004E46./49.

INSTALLATION OF SPRING PINS(1) Install the spring pins using the special tool or a pin

punch.

Caution

Do not reuse the spring pins.

(2) When installing, make sure that the slit of the spring pinis aligned with the shift rail center line.

46. INSTALLATION OF REVERSE IDLER GEAR SHAFTInstall in the direction illustrated.

’

35. /37. /40./42. INSTALLATION OF SPACERS(1) Place two pieces of solder measuring about

10 mm (4in.) in length and 1.6 mm

(.06 in.) in diameter as

illustrated and install the outer races.

’(2) Install the transaxle case and tighten the bolts to

specified torque.

(3) Remove the transaxle case.

(4) Remove the outer races and remove the solder.

(5) If the solder is not broken, carry out the work- in steps

(l)-(4) with large diameter solder.

(6) Measure the thickness of the crushed soid& with a

micrometer and select and install a spacer of thickness

that gives standard preload and end play.

Standard value:

Input shaft end play

O-0.05 mm (O-.002 in.)

Intermediate gear preload0.05-0.10 mm (.002-.004

in.)

Output shaft preload0.05-0.10 mm (.092-.004 in.)

Differential case preload

9.05-0.10 mm (.002-.004 in.)

Page 734 of 1216

21-40 MANUAL TRANSAXLE

1-2 mm

J

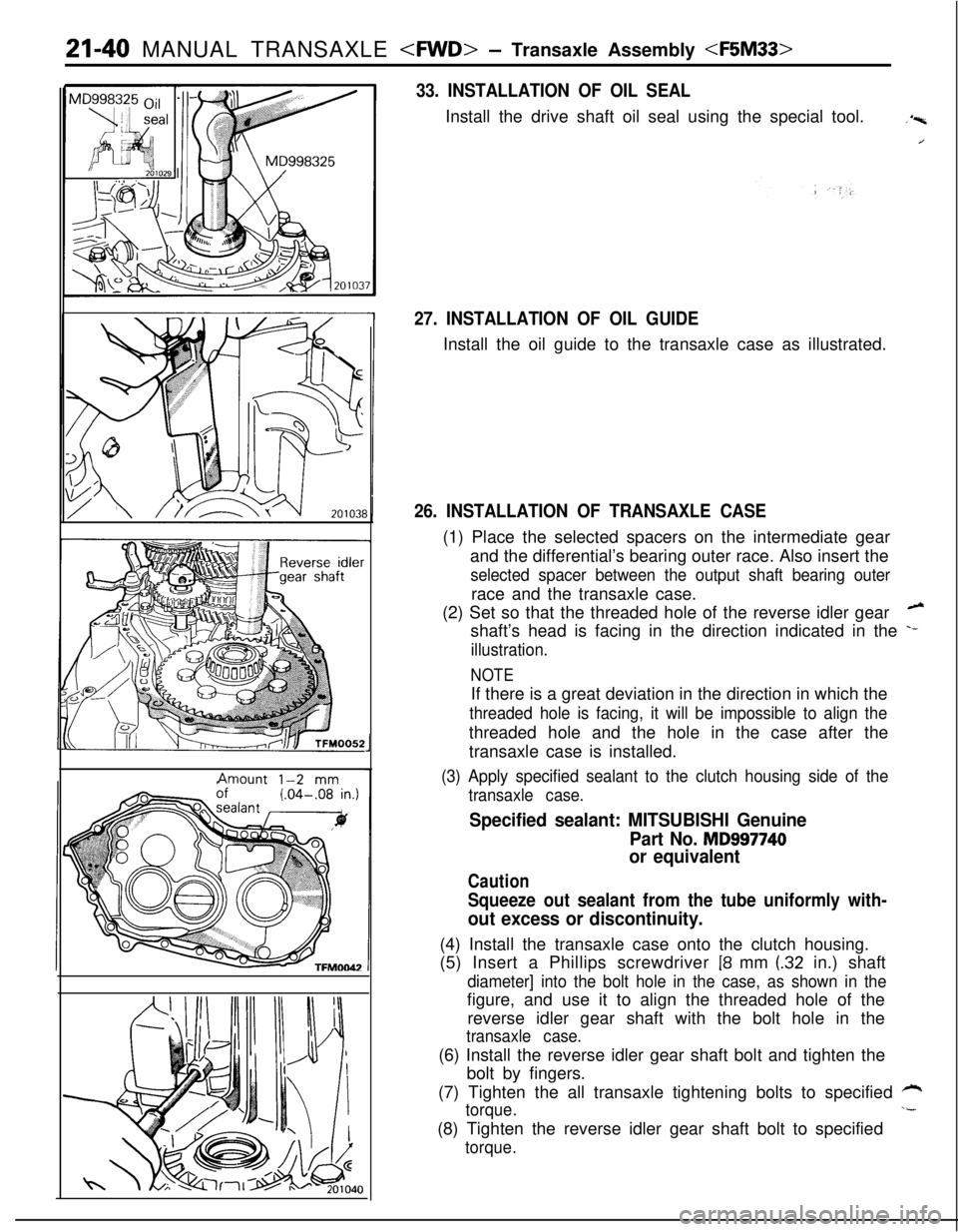

33. INSTALLATION OF OIL SEALInstall the drive shaft oil seal using the special tool.

.‘p,

/

27. INSTALLATION OF OIL GUIDEInstall the oil guide to the transaxle case as illustrated.

26. INSTALLATION OF TRANSAXLE CASE(1) Place the selected spacers on the intermediate gear

and the differential’s bearing outer race. Also insert the

selected spacer between the output shaft bearing outerrace and the transaxle case.

(2) Set so that the threaded hole of the reverse idler gear

hshaft’s head is facing in the direction indicated in the

.-

illustration.

NOTEIf there is a great deviation in the direction in which the

threaded hole is facing, it will be impossible to align thethreaded hole and the hole in the case after the

transaxle case is installed.

(3) Apply specified sealant to the clutch housing side of the

transaxle case.

Specified sealant: MITSUBISHI Genuine

Part No.

MD997740

or equivalent

Caution

Squeeze out sealant from the tube uniformly with-

out excess or discontinuity.(4) Install the transaxle case onto the clutch housing.

(5) Insert a Phillips screwdriver

18 mm (32 in.) shaft

diameter] into the bolt hole in the case, as shown in thefigure, and use it to align the threaded hole of the

reverse idler gear shaft with the bolt hole in the

transaxle case.(6) Install the reverse idler gear shaft bolt and tighten the

bolt by fingers.

(7) Tighten the all transaxle tightening bolts to specified

*

torque.,-(8) Tighten the reverse idler gear shaft bolt to specified

torque.

Page 735 of 1216

MANUAL TRANSAXLE

10 mm (.40 in.)

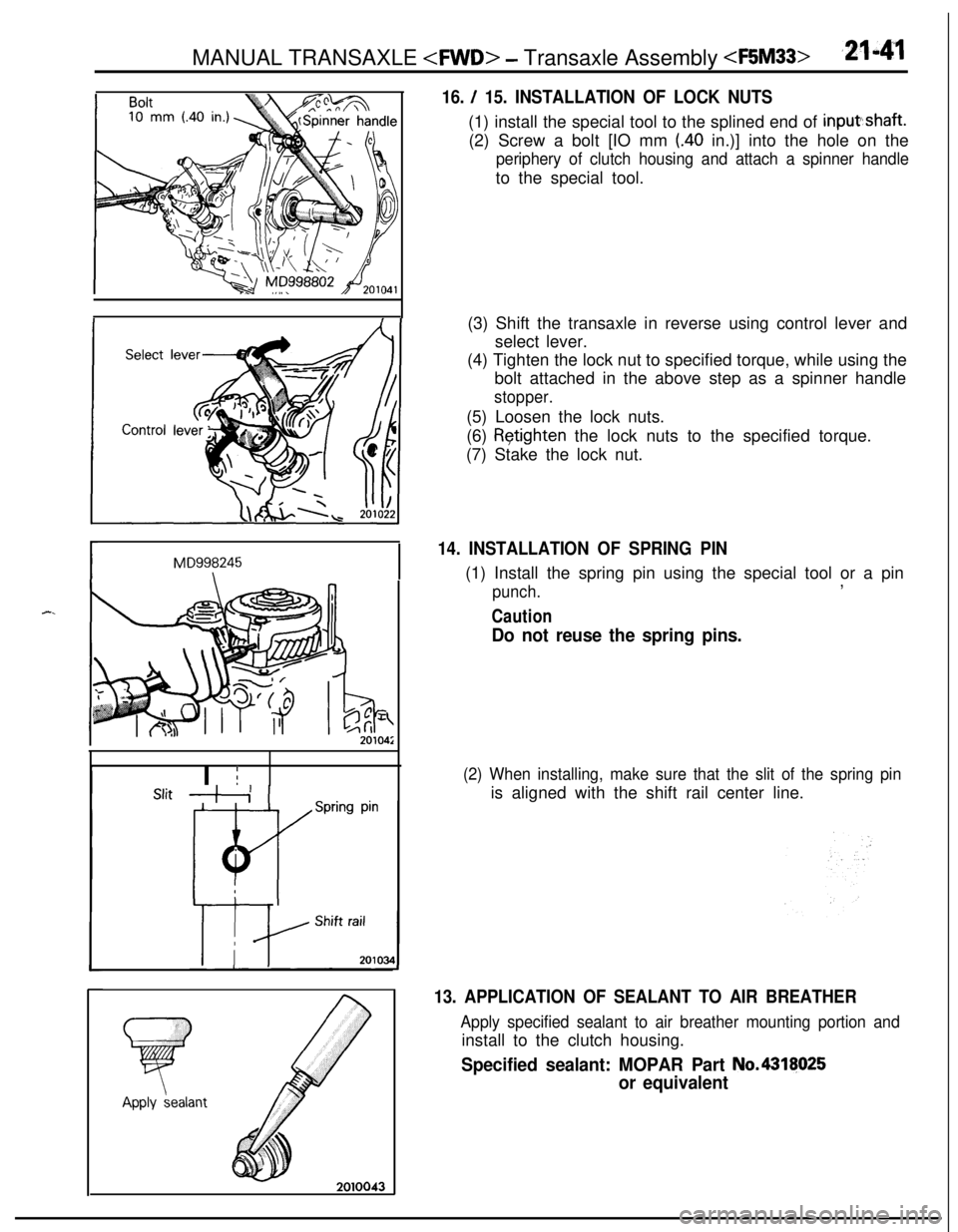

16. / 15. INSTALLATION OF LOCK NUTS(1) install the special tool to the splined end of inputshaft.

(2) Screw a bolt [IO mm

(.40 in.)] into the hole on the

periphery of clutch housing and attach a spinner handleto the special tool.

MD998245\ISlit

,+i 1I I

r

Spring pin

, Shift rail(3) Shift the transaxle in reverse using control lever and

select lever.

(4) Tighten the lock nut to specified torque, while using the

bolt attached in the above step as a spinner handle

stopper.(5) Loosen the lock nuts.

(6)

&tighten the lock nuts to the specified torque.

(7) Stake the lock nut.

14. INSTALLATION OF SPRING PIN(1) Install the spring pin using the special tool or a pin

punch.,

Caution

Do not reuse the spring pins.

(2) When installing, make sure that the slit of the spring pinis aligned with the shift rail center line.

13. APPLICATION OF SEALANT TO AIR BREATHER

Apply specified sealant to air breather mounting portion andinstall to the clutch housing.

Specified sealant: MOPAR Part No.4318025

or equivalent

Page 759 of 1216

bierential Assembl /MANUAL TRANSAXLE

, .Bearing

TFYOOIO

The numerals 0 to (8 indicate1 the tiqhtening Gequeice.210029I

SPEEDOMETER GEAR ASSEMBLY

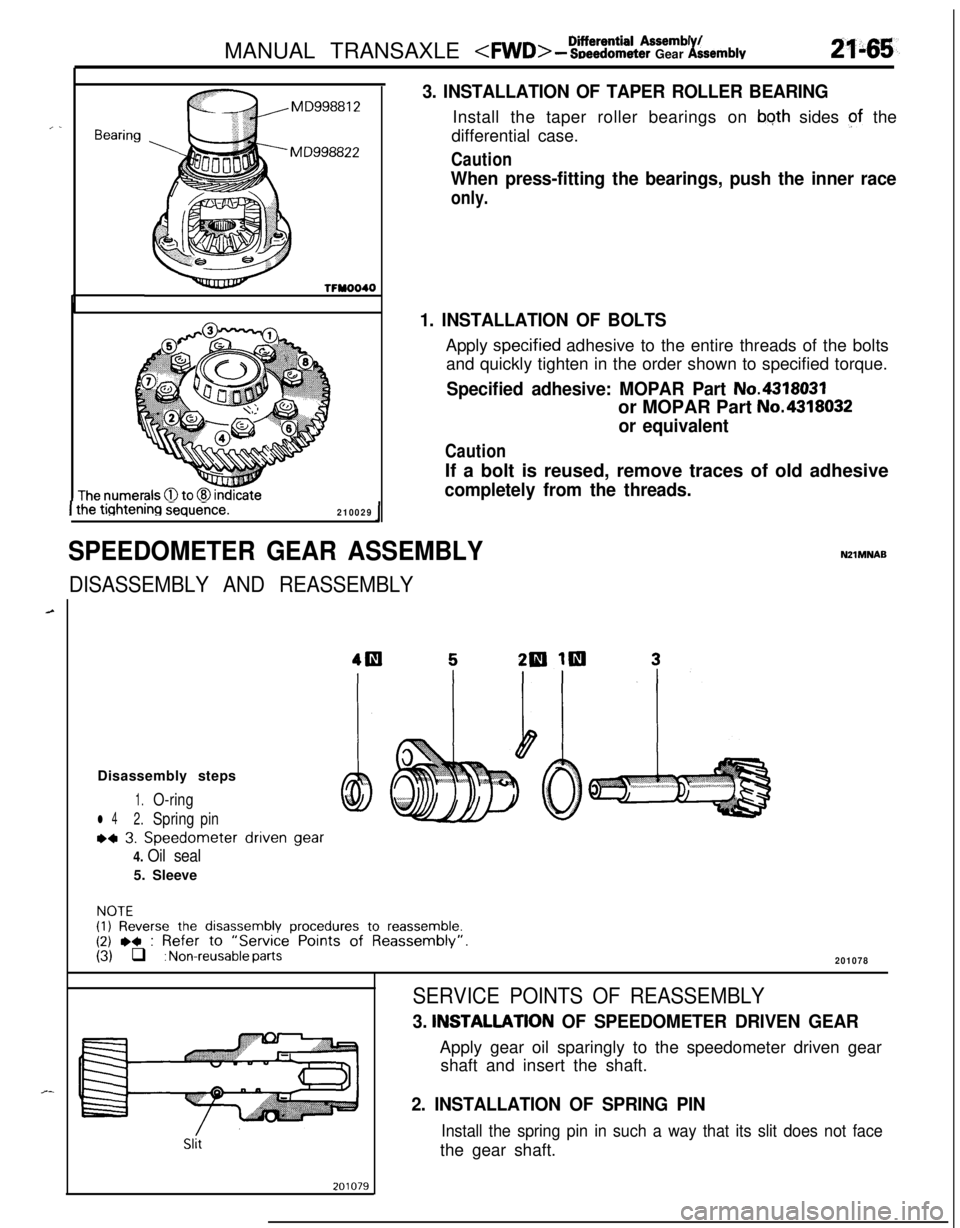

3. INSTALLATION OF TAPER ROLLER BEARINGInstall the taper roller bearings on

bqth sides of the

differential case.

Caution

When press-fitting the bearings, push the inner race

only.

1. INSTALLATION OF BOLTSApply

spec.ified adhesive to the entire threads of the bolts

and quickly tighten in the order shown to specified torque.

Specified adhesive: MOPAR Part No.4318031or MOPAR Part

No.4318032

or equivalent

CautionIf a bolt is reused, remove traces of old adhesive

completely from the threads.

DISASSEMBLY AND REASSEMBLY

NZlMNABDisassembly steps

1.O-ring

l 42.Springpin

~4 3. Speedometer driven gear

4. Oil seal5. Sleeve

NOTE(1) Reverse the disassembly procedures to reassemble.(2) ,+ : Refer to “Service Points of Reassembly”.(3) q : Non-reusable parts201078

Slit

SERVICE POINTS OF REASSEMBLY

3. INSTALLATlON OF SPEEDOMETER DRIVEN GEARApply gear oil sparingly to the speedometer driven gear

shaft and insert the shaft.

2. INSTALLATION OF SPRING PIN

Install the spring pin in such a way that its slit does not facethe gear shaft.

Page 763 of 1216

MANUAL TRANSAXLE

2f.46g

\ ,...,

,,, .,

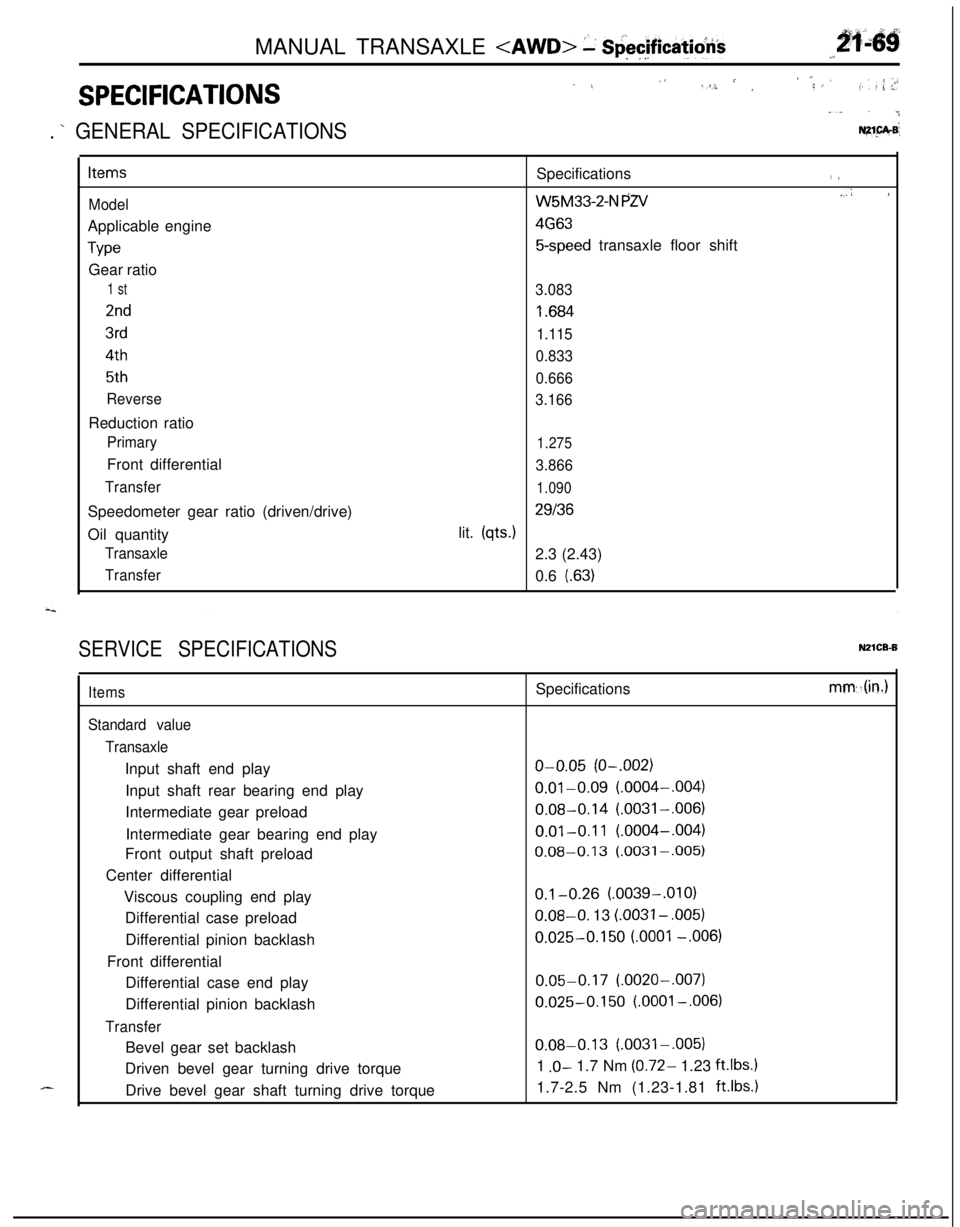

SPECIFICATIONS

1 L,‘S. / ,‘; ,< ’,f. : ,: ; .>r

“. . ..&

. ’ GENERAL SPECIFICATIONSNZ1.pA.B’

Items

ModelApplicable engine

TypeGear ratio

1 st

2nd

3rd

4th

5th

ReverseReduction ratio

PrimaryFront differential

TransferSpeedometer gear ratio (driven/drive)

Oil quantity

Transaxle

TransferSpecifications

(I

W5M33-2-N PZV.,A I

4G63

5-speed transaxle floor shift

3.083

I .684

1.115

0.833

0.666

3.166

1.275

3.866

1.090

29136lit.

(qts.)2.3 (2.43)

0.6

l.63)

SERVICE SPECIFICATIONSN21CB-B

d-...

Items

Standard value

TransaxleInput shaft end play

Input shaft rear bearing end play

Intermediate gear preload

Intermediate gear bearing end play

Front output shaft preload

Center differential

Viscous coupling end play

Differential case preload

Differential pinion backlash

Front differential

Differential case end play

Differential pinion backlash

TransferBevel gear set backlash

Driven bevel gear turning drive torque

Drive bevel gear shaft turning drive torqueSpecifications

o-0.05 (O-.002)

0.01-0.09 (.0004-,004)

0.08-0.14 (.0031-,006)

0.01-0.11 (.0004-,004)

0.08-0.13 (.0031-,005)

0.1-0.26 (.0039-.OlO)0.08-O. 13

LOO31 - ,005)

0.025-0.150 LOO01 -.006)

0.05-0.17 (.0020-,007)

0.025-0.150 (.OOOl-,006)

0.08-0.13 (.0031-.005)

1

.O- 1.7 Nm (0.72- 1.23 ft.lbs.11.7-2.5 Nm (1.23-1.81

ft.lbs.1

mm,.(in.)