torque MITSUBISHI ECLIPSE 1991 Repair Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1991, Model line: ECLIPSE, Model: MITSUBISHI ECLIPSE 1991Pages: 1216, PDF Size: 67.42 MB

Page 509 of 1216

FUEL SYSTEM - Service Adjustment Procedures <2.0L Engine>14-55

(18)Connect the high-pressure fuel hose,,to the delivery pipe

and tighten the screws to the specified torque.

(19)Check for fuel leaks.

@I Apply battery voltage to the fuel pump check terminal

to operate the fuel pump.

@ With fuel pressure acting, check the fuel line for leaks.

A

E2li:>

/ )

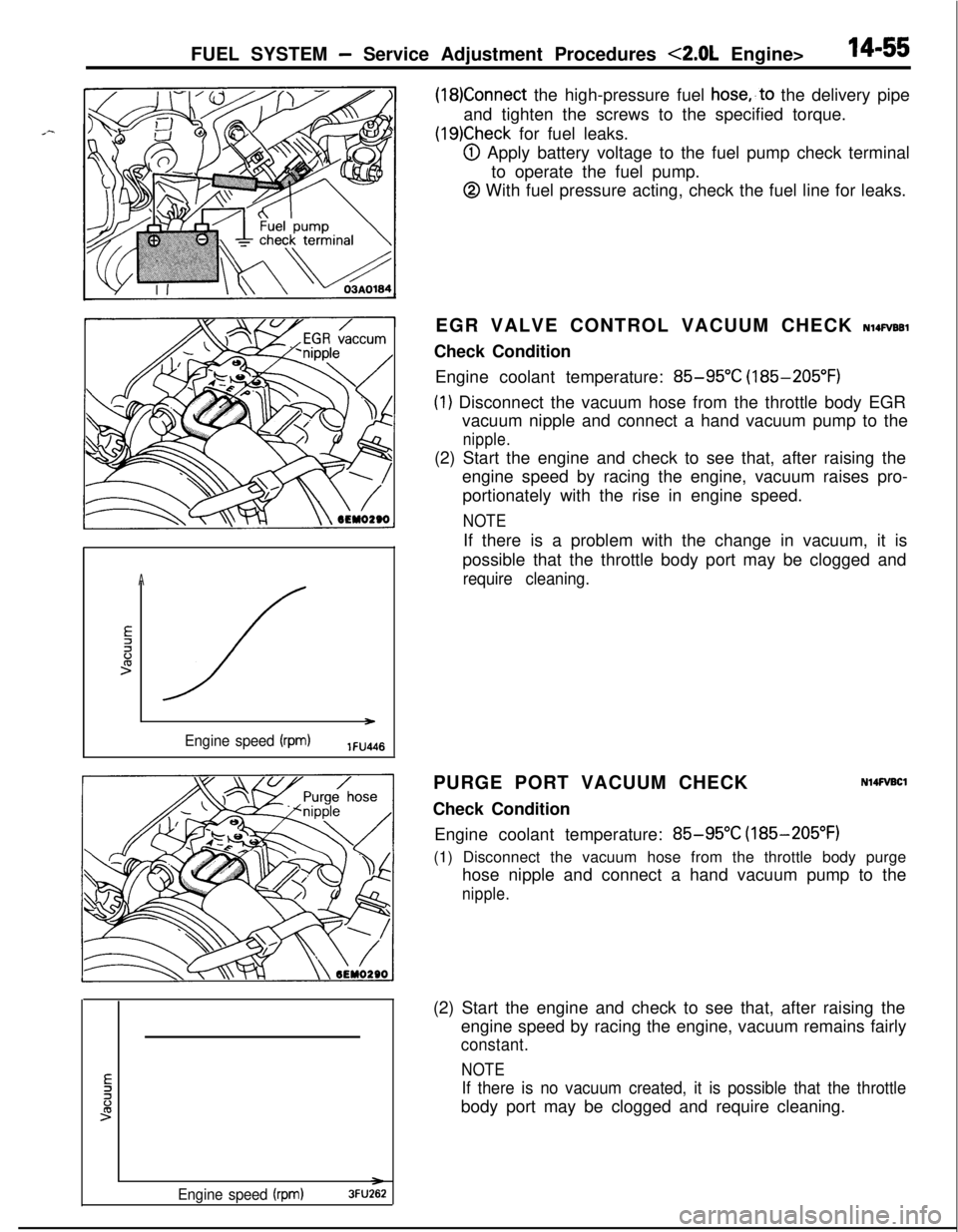

Engine speed (rpm)lFU4l6EGR VALVE CONTROL VACUUM CHECK

NlQFVBBlCheck Condition

Engine coolant temperature:

85-95°C (185-205°F)

(1) Disconnect the vacuum hose from the throttle body EGR

vacuum nipple and connect a hand vacuum pump to the

nipple.(2) Start the engine and check to see that, after raising the

engine speed by racing the engine, vacuum raises pro-

portionately with the rise in engine speed.

NOTEIf there is a problem with the change in vacuum, it is

possible that the throttle body port may be clogged and

require cleaning.PURGE PORT VACUUM CHECK

Check Condition

N14FVBClEngine coolant temperature:

85-95°C (185-205°F)

(1) Disconnect the vacuum hose from the throttle body purge

hose nipple and connect a hand vacuum pump to the

nipple.

Engine speed (rpm)3FU262(2) Start the engine and check to see that, after raising the

engine speed by racing the engine, vacuum remains fairly

constant.

NOTE

If there is no vacuum created, it is possible that the throttlebody port may be clogged and require cleaning.

Page 516 of 1216

14-62FUEL SYSTEM - MPI System Inspection <1.8L Engine>

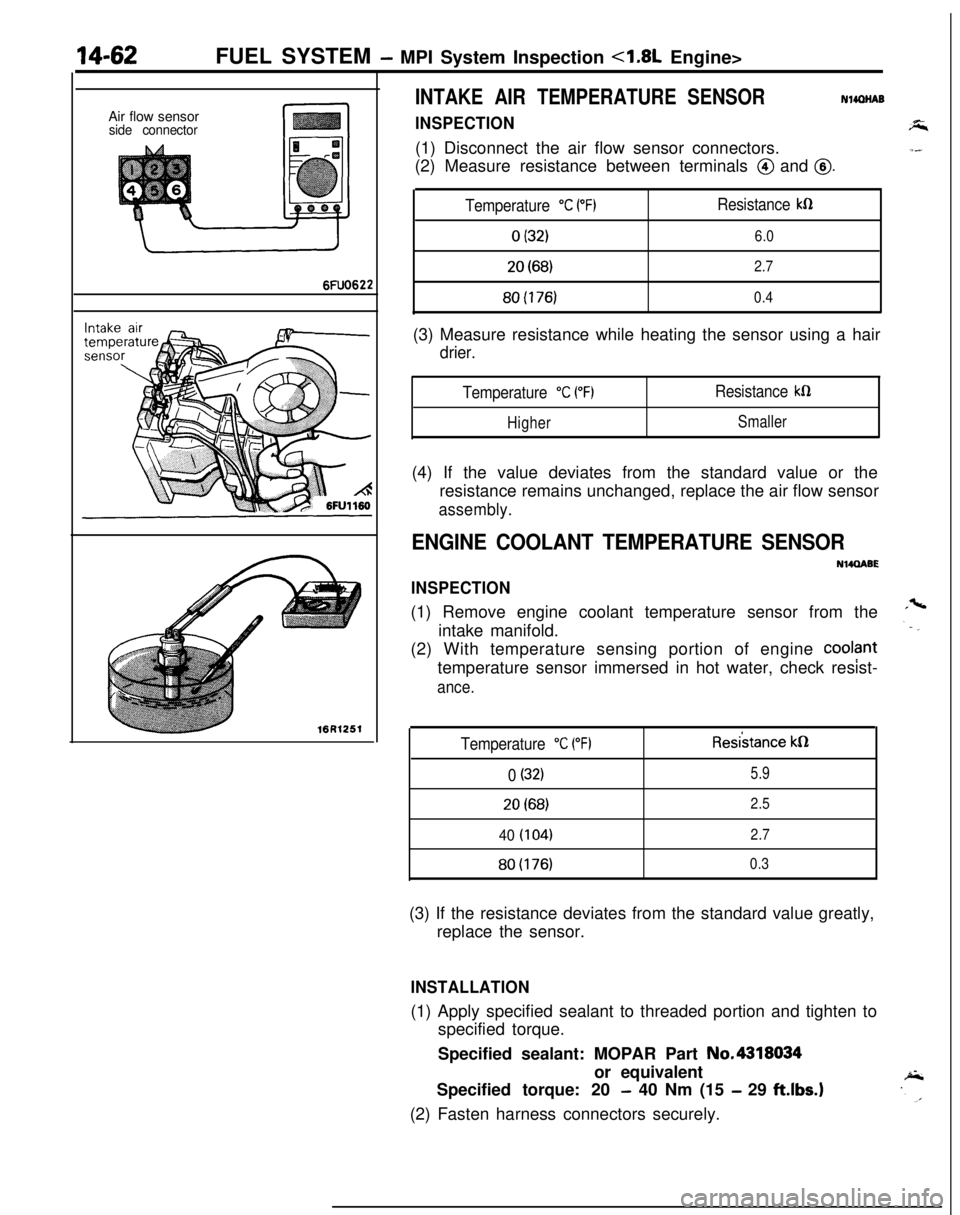

INTAKE AIR TEMPERATURE SENSORNlmNABAir flow sensor

side connectorINSPECTION(1) Disconnect the air flow sensor connectors.

(2) Measure resistance between terminals

@ and @.

6FUO622

Temperature “C PF)Resistance kR

0 (32)6.0

20(68)2.780(176)

0.4(3) Measure resistance while heating the sensor using a hair

drier.

Temperature “C (“F)Resistance kfi

HigherSmaller(4) If the value deviates from the standard value or the

resistance remains unchanged, replace the air flow sensor

assembly.

ENGINE COOLANT TEMPERATURE SENSOR

NWQABE

INSPECTION(1) Remove engine coolant temperature sensor from the

intake manifold.

(2) With temperature sensing portion of engine

cool?nttemperature sensor immersed in hot water, check resist-

ance.16R1251

Temperature “C (“F)Resi’stance kQ

0 (32)5.920(68)

2.5

40 (104)2.7

80(176)0.3(3) If the resistance deviates from the standard value greatly,

replace the sensor.

INSTALLATION(1) Apply specified sealant to threaded portion and tighten to

specified torque.

Specified sealant: MOPAR Part No.4318034

or equivalent

Specified torque: 20

- 40 Nm (15 - 29 ftlbs.)(2) Fasten harness connectors securely.

Page 517 of 1216

FUEL SYSTEM - MPI Svstem Inspection <1.8L Engine>18-63

Throttle position sensor

Groundoutput

Sensorpower

SUPPlY(5V)

1 FUO507

6FU1244Motor

Dosition sensor connector

(motor ‘side, front view)

T

6FU1247Motor position sensor

connector(motor side, front view)

6FU1252

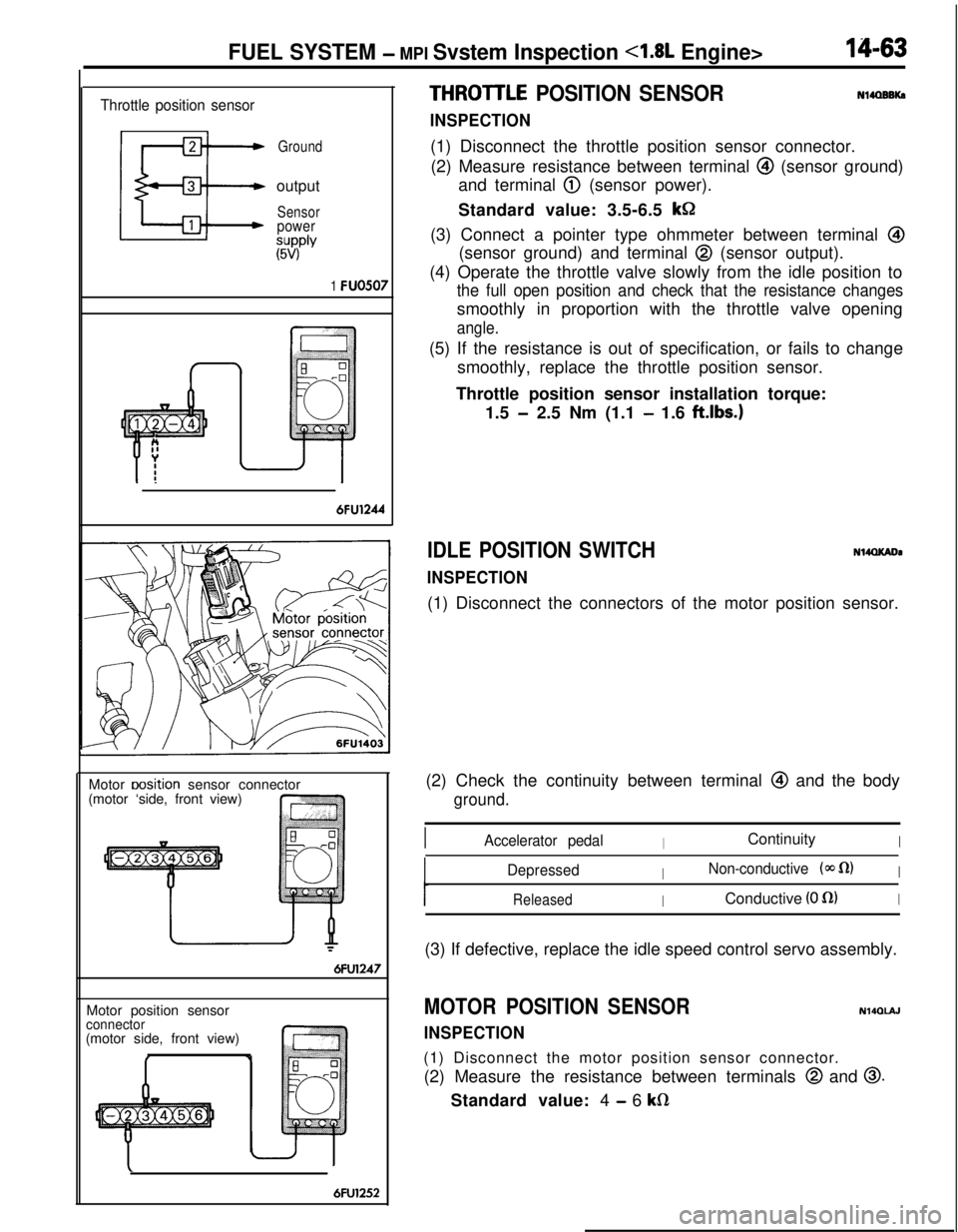

THROITLE POSITION SENSOR

INSPECTION

Nl4OBBKa(1) Disconnect the throttle position sensor connector.

(2) Measure resistance between terminal

@I (sensor ground)

and terminal

@ (sensor power).

Standard value: 3.5-6.5

kGI(3) Connect a pointer type ohmmeter between terminal

@(sensor ground) and terminal

@ (sensor output).

(4) Operate the throttle valve slowly from the idle position to

the full open position and check that the resistance changessmoothly in proportion with the throttle valve opening

angle.(5) If the resistance is out of specification, or fails to change

smoothly, replace the throttle position sensor.

Throttle position sensor installation torque:

1.5

- 2.5 Nm (1.1 - 1.6 ftlbs.)

IDLE POSITION SWITCH

INSPECTION

N14QKADa(1) Disconnect the connectors of the motor position sensor.

(2) Check the continuity between terminal

@ and the body

ground.

IAccelerator pedalIContinuityI

DepressedINon-conductive (@J fl)I

ReleasedIConductive (0 fl)I(3) If defective, replace the idle speed control servo assembly.

MOTOR POSITION SENSOR

INSPECTION

N140lAJ(1) Disconnect the motor position sensor connector.

(2) Measure the resistance between terminals

@ and 0.Standard value: 4

- 6 kfi

Page 518 of 1216

14-64FUEL SYSTEM -MPI System Inspection <1.8L Engine>

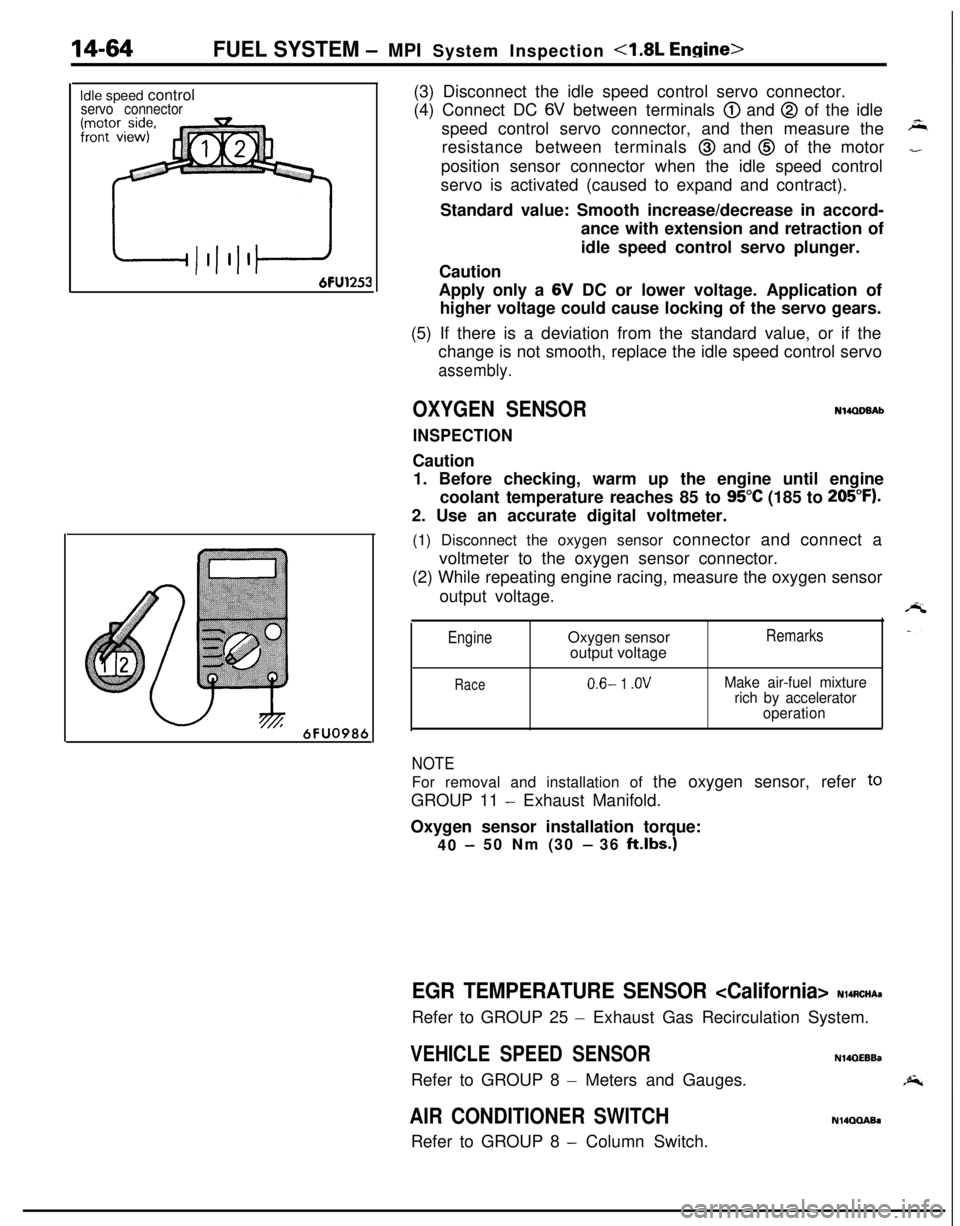

Idle speed controlservo connector

6FU098t(3) Disconnect the idle speed control servo connector.

(4) Connect DC

6V between terminals @) and @ of the idle

speed control servo connector, and then measure the

resistance between terminals

@ and @ of the motor

position sensor connector when the idle speed control

servo is activated (caused to expand and contract).

Standard value: Smooth increase/decrease in accord-

ance with extension and retraction of

idle speed control servo plunger.

Caution

Apply only a 6V DC or lower voltage. Application of

higher voltage could cause locking of the servo gears.

(5) If there is a deviation from the standard value, or if the

change is not smooth, replace the idle speed control servo

assembly.

OXYGEN SENSORN14QDBAb

INSPECTIONCaution

1. Before checking, warm up the engine until engine

coolant temperature reaches 85 to

95°C (185 to 205°F).2. Use an accurate digital voltmeter.

(1) Disconnect the oxygen sensor connector and connect a

voltmeter to the oxygen sensor connector.

(2) While repeating engine racing, measure the oxygen sensor

output voltage.

EngineOxygen sensor

output voltageRemarks

Race0.6- 1 .OVMake air-fuel mixture

rich by accelerator

operation

NOTEFor removal and installation of the oxygen sensor, refer

toGROUP 11

- Exhaust Manifold.

Oxygen sensor installation torque:

40

-50 Nm (30 - 36 klbs.)

EGR TEMPERATURE SENSOR

- Exhaust Gas Recirculation System.

VEHICLE SPEED SENSORN14QEEBaRefer to GROUP 8

- Meters and Gauges.

AIR CONDITIONER SWITCHRefer to GROUP 8

- Column Switch.

N14QQABa

Page 531 of 1216

FUEL SYSTEM - MPI Svstem InsDection <2.0L DOHC Engine>14-77INSTALLATION

(1) Apply specified sealant to threaded portion and tighten to

specified torque.

Specified sealant: MOPAR Part No.4318034 or

equivalent

Specified torque: 20

- 40 Nm (15 - 29 ft.lbs.1(2) Fasten harness connectors securely.

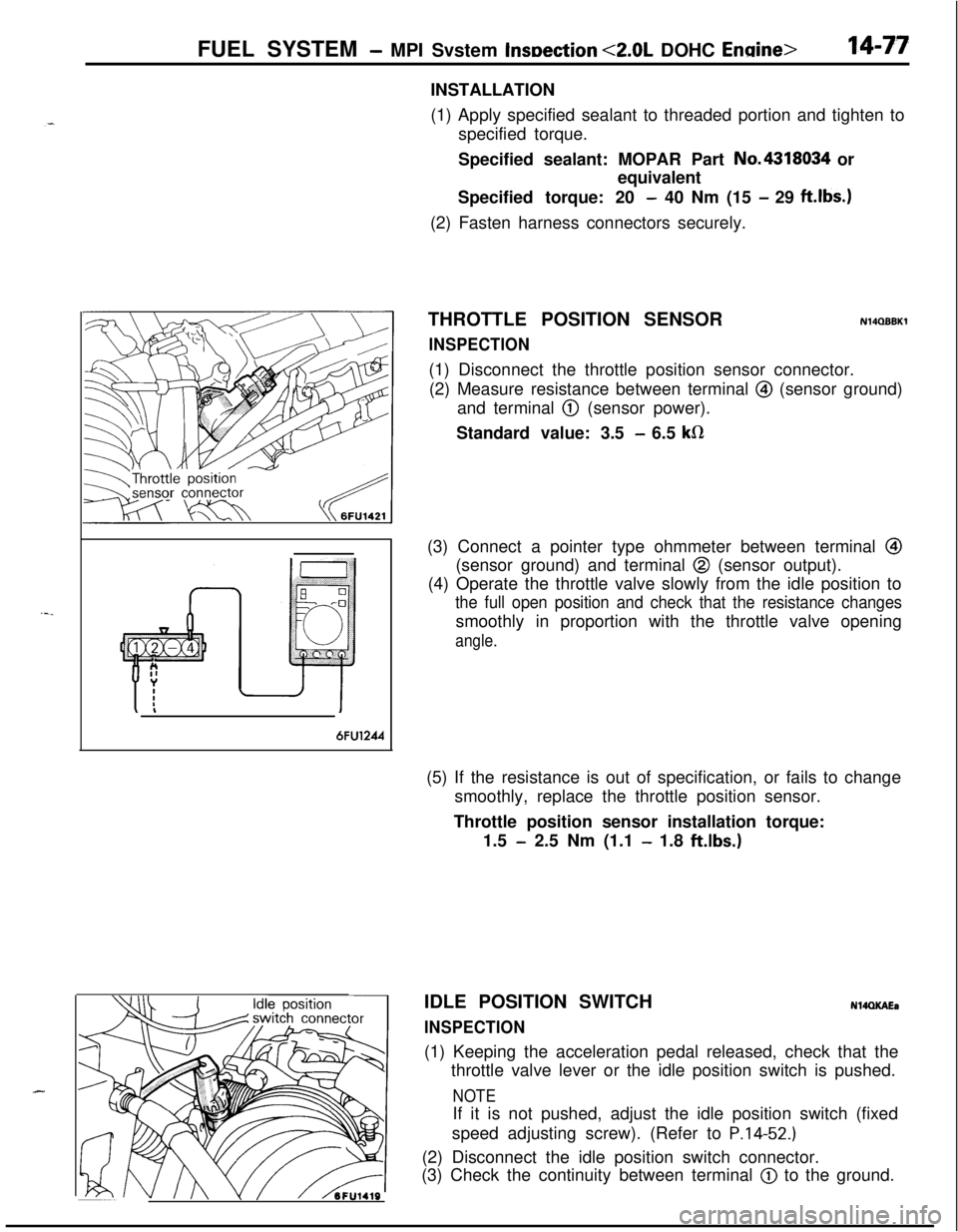

THROTTLE POSITION SENSOR

INSPECTION

N14QBBKl(1) Disconnect the throttle position sensor connector.

(2) Measure resistance between terminal

@I (sensor ground)

and terminal

@ (sensor power).

Standard value: 3.5

- 6.5 kR(3) Connect a pointer type ohmmeter between terminal

@I(sensor ground) and terminal

@ (sensor output).

(4) Operate the throttle valve slowly from the idle position to

the full open position and check that the resistance changessmoothly in proportion with the throttle valve opening

angle.

6FU1244(5) If the resistance is out of specification, or fails to change

smoothly, replace the throttle position sensor.

Throttle position sensor installation torque:

1.5

- 2.5 Nm (1.1 - 1.8 ft.lbs.)

J II\/ hFU1419IDLE POSITION SWITCH

INSPECTION

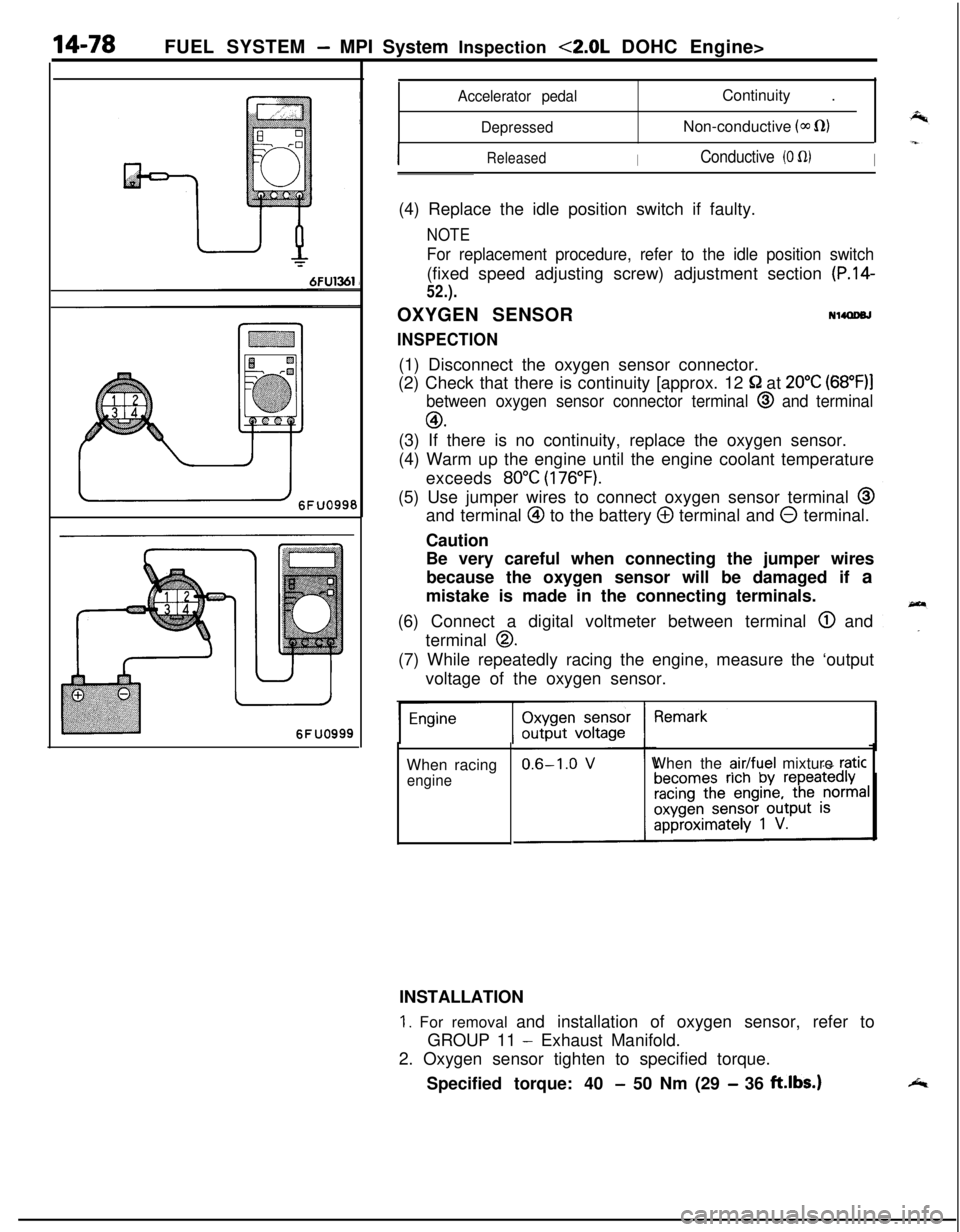

N14QKAEa(1) Keeping the acceleration pedal released, check that the

throttle valve lever or the idle position switch is pushed.

NOTEIf it is not pushed, adjust the idle position switch (fixed

speed adjusting screw). (Refer to

P.14-52.)(2) Disconnect the idle position switch connector.

(3) Check the continuity between terminal

@) to the ground.

Page 532 of 1216

FUEL SYSTEM - MPI System Inspection <2.0L DOHC Engine>

6FUO999

Accelerator pedal

DepressedContinuity .

Non-conductive

(03 fl)

ReleasedIConductive (0 fl)I(4) Replace the idle position switch if faulty.

NOTE

For replacement procedure, refer to the idle position switch(fixed speed adjusting screw) adjustment section

(P.14-

52.).OXYGEN SENSOR

NllQDeJ

INSPECTION(1) Disconnect the oxygen sensor connector.

(2) Check that there is continuity [approx. 12

52 at 20°C (68”F)l

between oxygen sensor connector terminal @ and terminal

GO.(3) If there is no continuity, replace the oxygen sensor.

(4) Warm up the engine until the engine coolant temperature

exceeds

80°C (176°F).(5) Use jumper wires to connect oxygen sensor terminal

@and terminal

@ to the battery @ terminal and 0 terminal.

Caution

Be very careful when connecting the jumper wires

because the oxygen sensor will be damaged if a

mistake is made in the connecting terminals.

(6) Connect a digital voltmeter between terminal

@ and

terminal

0.(7) While repeatedly racing the engine, measure the ‘output

voltage of the oxygen sensor.

When racing

engineWhen the

air/fuel mixture raticINSTALLATION

1. For removal and installation of oxygen sensor, refer to

GROUP 11

- Exhaust Manifold.

2. Oxygen sensor tighten to specified torque.

Specified torque: 40

- 50 Nm (29 - 36 ft.lbs.)

Page 550 of 1216

FUEL SYSTEM- Fuel Tank

Flare nut

Se&e side 03~043

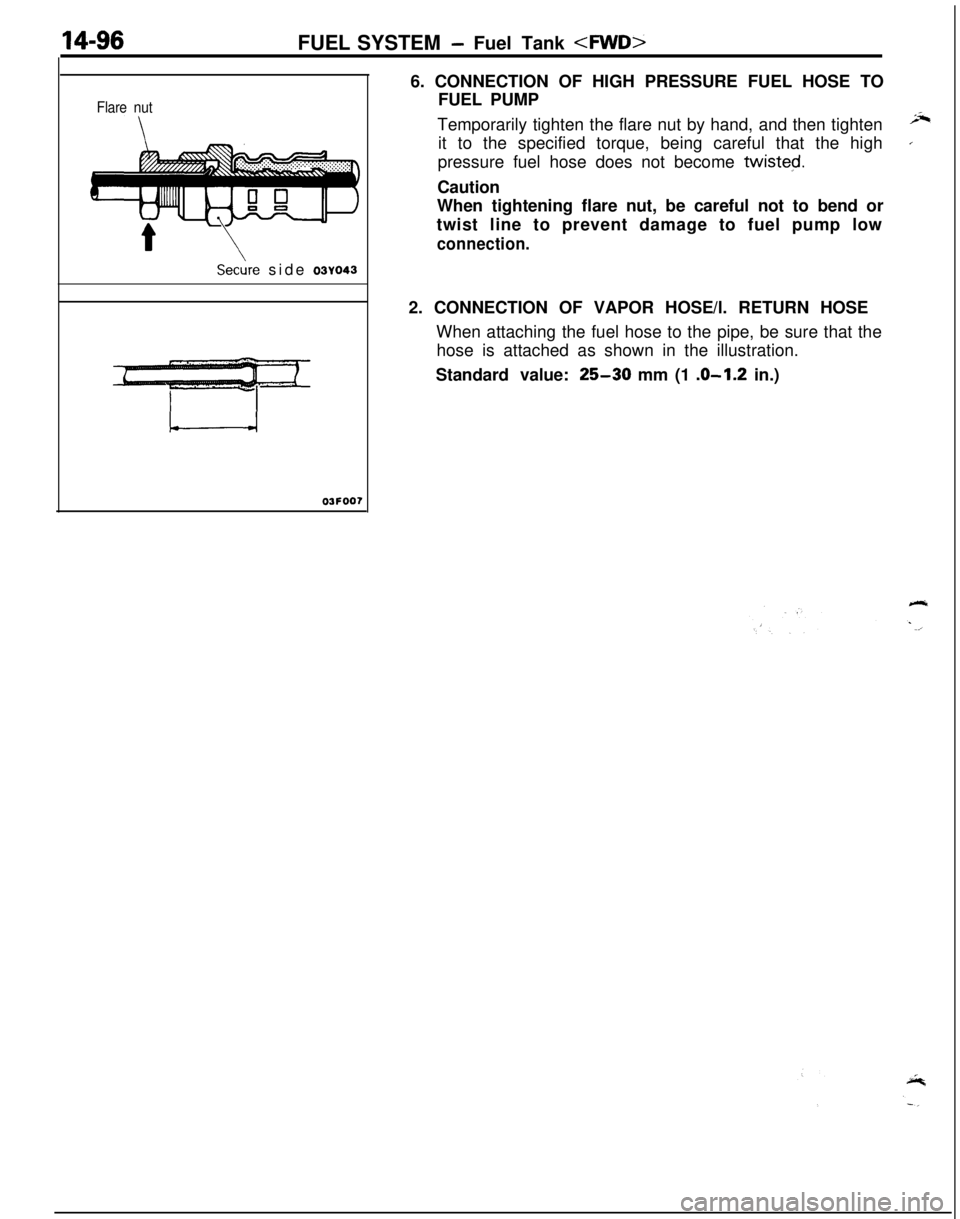

03FOO76. CONNECTION OF HIGH PRESSURE FUEL HOSE TO

FUEL PUMP

Temporarily tighten the flare nut by hand, and then tighten

;Jtit to the specified torque, being careful that the high

’pressure fuel hose does not become twisted.

Caution

When tightening flare nut, be careful not to bend or

twist line to prevent damage to fuel pump low

connection.2. CONNECTION OF VAPOR HOSE/l. RETURN HOSE

When attaching the fuel hose to the pipe, be sure that the

hose is attached as shown in the illustration.

Standard value:

25-30 mm (1 .O-1.2 in.)

Page 558 of 1216

FUEL SYSTEM - Fuel Line and VaDor Line/Fuel Filter

High-pressur

hose

f+-----Eye bolt

Gasket

Fuel filter

Flare nut

Fuel main

pipe

\-Apply engine

&ring Oi’

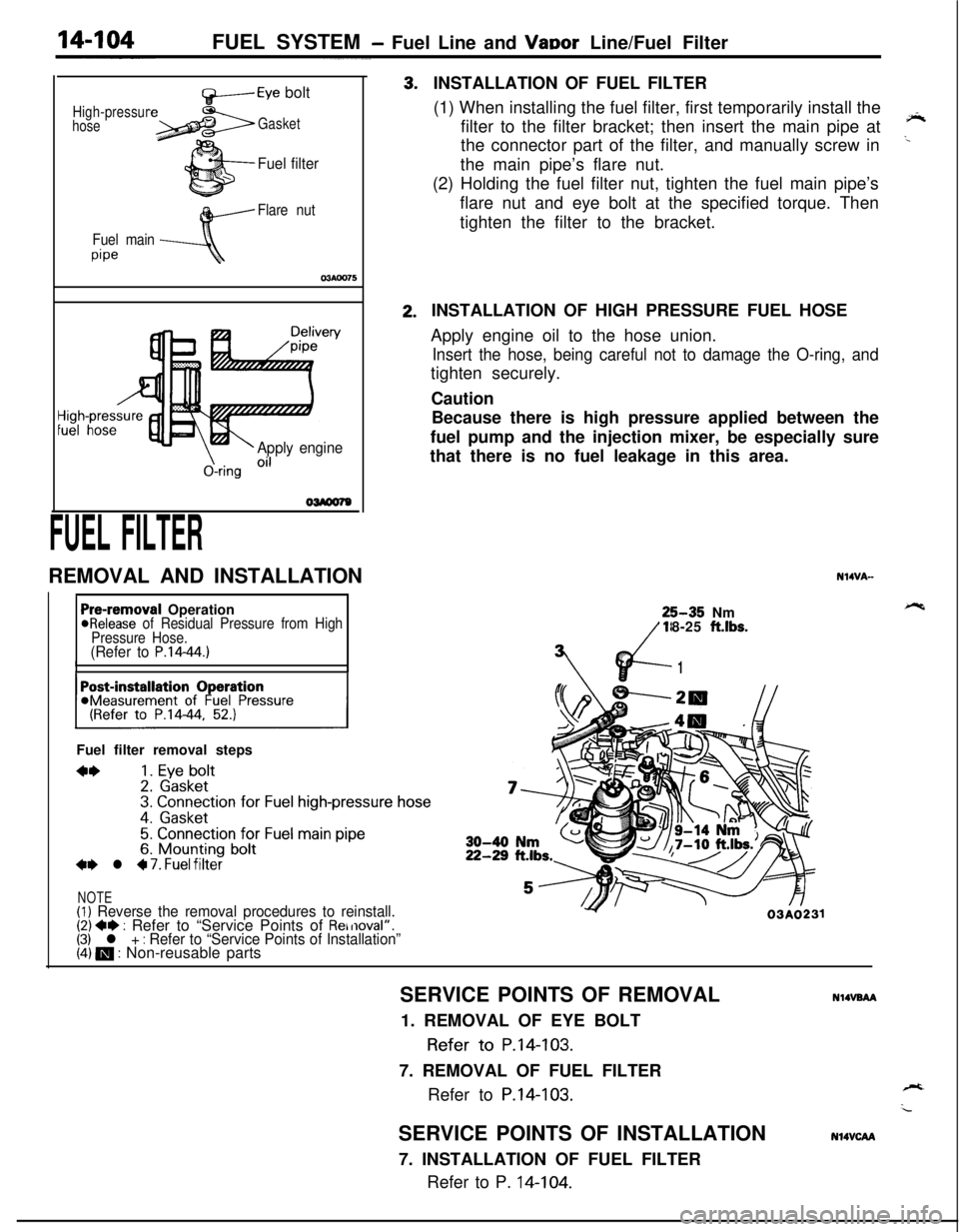

FUEL FILTERREMOVAL AND INSTALLATION3.2.INSTALLATION OF FUEL FILTER

(1) When installing the fuel filter, first temporarily install the

filter to the filter bracket; then insert the main pipe at

‘*the connector part of the filter, and manually screw in

..the main pipe’s flare nut.

(2) Holding the fuel filter nut, tighten the fuel main pipe’s

flare nut and eye bolt at the specified torque. Then

tighten the filter to the bracket.

Pre-removal Operation@Release of Residual Pressure from High

Pressure Hose.

(Refer to P.14-44.)IIFuel filter removal steps

**1. Eye bolt2. Gasket3. Connection for Fuel high-pressure hose

4. Gasket

5. Connection for Fuel main pipe6. Mounting bolt+e l 4 7. Fuel filter

NOTE(1) Reverse the removal procedures to reinstall.(2) +e : Refer to “Service Points of Removal”.(3) l + : Refer to “Service Points of Installation”(4) m : Non-reusable partsINSTALLATION OF HIGH PRESSURE FUEL HOSE

Apply engine oil to the hose union.

Insert the hose, being careful not to damage the O-ring, andtighten securely.

Caution

Because there is high pressure applied between the

fuel pump and the injection mixer, be especially sure

that there is no fuel leakage in this area.

N14VA-25-35 Nm

18-25

ft.lbs.

vd-

7’

1

Y03A0231SERVICE POINTS OF REMOVAL

NlIVBAA1. REMOVAL OF EYE BOLT

Refer to P.14-103.

7. REMOVAL OF FUEL FILTER

Refer to

P.14-103.SERVICE POINTS OF INSTALLATION

7. INSTALLATION OF FUEL FILTER

Refer to P. 14-104.

N14VCAA

Page 559 of 1216

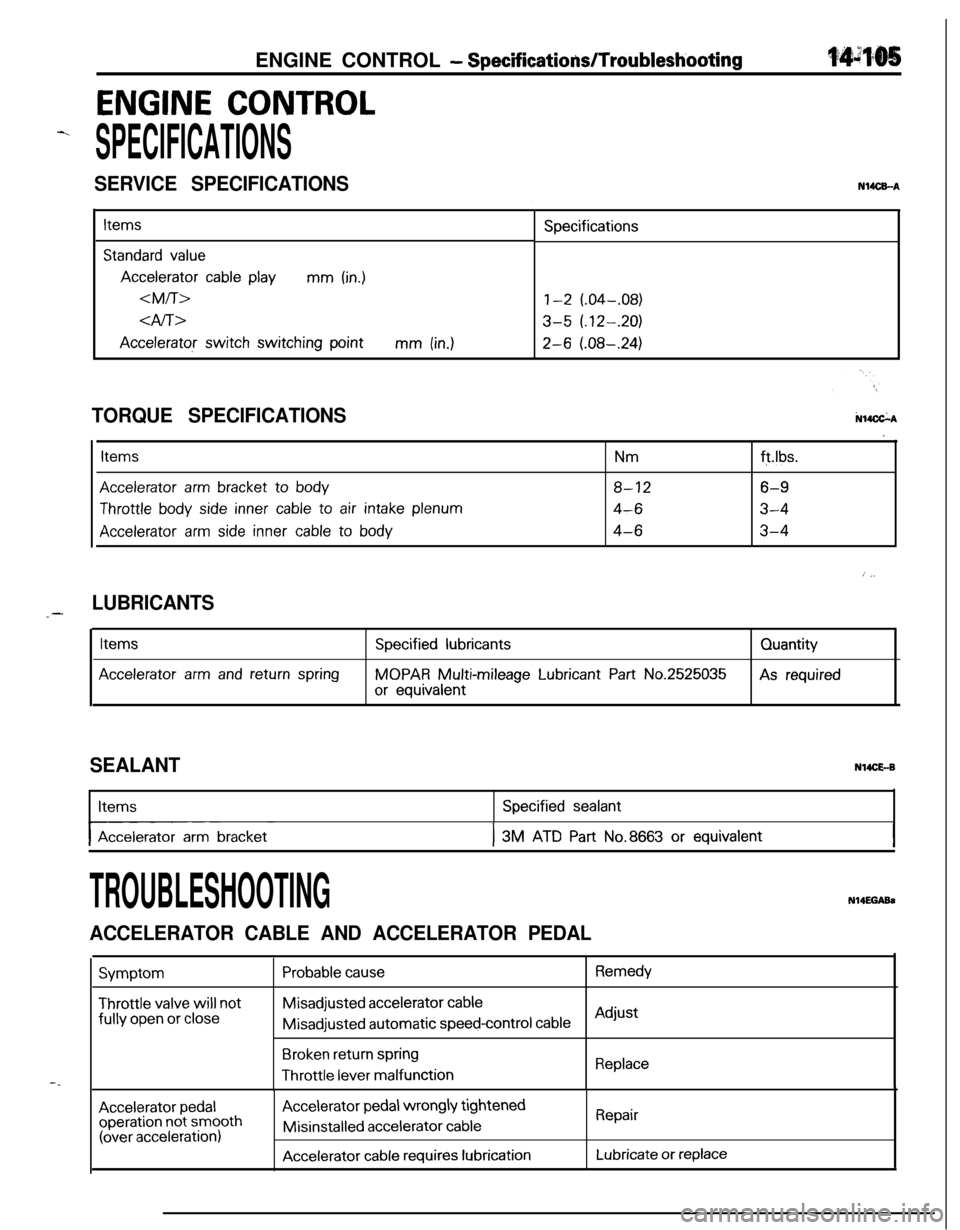

ENGINE CONTROL - SpecificatiodTroubleshooting

ENGINE CONTROL

-.

SPECIFICATIONS

SERVICE SPECIFICATIONSN14CEA

Items

Standard value

Accelerator cable playmm (in.)

dfi>

Accelerator switch switching pointmm (in.)Specifications

1-2 (.04-.08)

3-5 (.12-.20)

2-6 (.08-.24)

N14CkATORQUE SPECIFICATIONS

Items

Accelerator arm bracket to body

Throttle body side inner cable to air intake plenum

Accelerator arm side inner cable to body

Nmft.lbs.

8-126-9

4-63-4

4-63-4

I

: j,

LUBRICANTS_-

Items

Accelerator arm and return spring

Specified lubricants

MOPAR Multi-mileage Lubricant Part No.2525035

or equivalentQuantityAs required

SEALANTN14CE.-BItems

I-- ~Accelerator arm bracket

Specified sealant

I3M ATD Part No.8663 or equivalentI

-.

TROUBLESHOOTINGN14EGABa

ACCELERATOR CABLE AND ACCELERATOR PEDAL

Symptom

Throttle valve will notfully

open or close

Probable causeRemedyMisadjusted

accelerator cableMisadjusted automatic

speed-control cableAdjust

Broken return springThrottle

lever malfunctionReplace

Accelerator pedaloperation not smooth(over acceleration)

Accelerator pedal wrongly tightenedMisinstalled

accelerator cable

Accelerator cable requires lubrication

Repair

Lubricate or replace

Page 563 of 1216

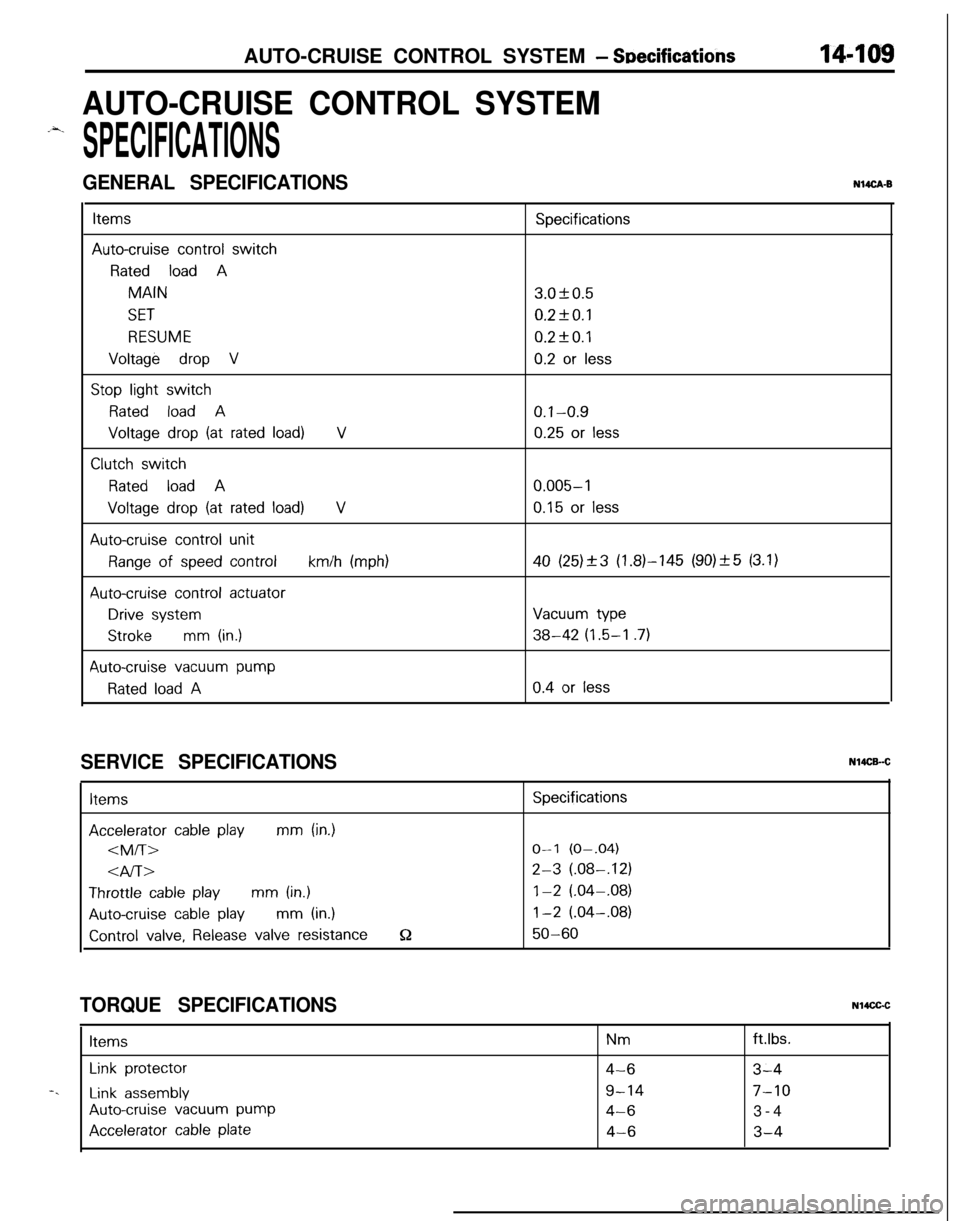

AUTO-CRUISE CONTROL SYSTEM - Snecifications14-109

AUTO-CRUISE CONTROL SYSTEM

.-4.

SPECIFICATIONS

GENERAL SPECIFICATIONSNUCA-B

ItemsSpecifications

Auto-cruise control switch

Rated load AMAIN3.OkO.5

SET0.2fO.l

RESUME0.2kO.l

Voltage drop V0.2 or less

Stop light switch

Rated load A0.1-0.9

Voltage drop (at rated load)V0.25 or less

Clutch switch

Rated load A0.005-l

Voltage drop (at rated load)V0.15 or less

Auto-cruise control unit

Range of speed controlkm/h (mph)40 (25)_+3 (1.81-145 (90)_+5 (3.1)

Auto-cruise control actuator

Drive systemVacuum type

Strokemm (in.)38-42 (1.5-I .7)

Auto-cruise vacuum pump

Rated load A0.4 or less

SERVICE SPECIFICATIONSItems

Accelerator cable playmm (in.)

4l-bThrottle

cable playmm (in.)

Auto-cruise cable playmm (in.)

Control valve, Release valve resistanceQ

Specifications

O-l (O-.04)

2-3 (.08-,121

1-2 (.04-.08)

1-2 (.04-.08)

50-60

TORQUE SPECIFICATIONSN14CGCItems

Nmftlbs.

Link protector4-63-4-.

Link assembly9-147-10

Auto-cruise vacuum pump4-63-4

Accelerator cable plate4-63-4