MITSUBISHI ECLIPSE 1991 Service Manual

Manufacturer: MITSUBISHI, Model Year: 1991, Model line: ECLIPSE, Model: MITSUBISHI ECLIPSE 1991Pages: 1216, PDF Size: 67.42 MB

Page 1121 of 1216

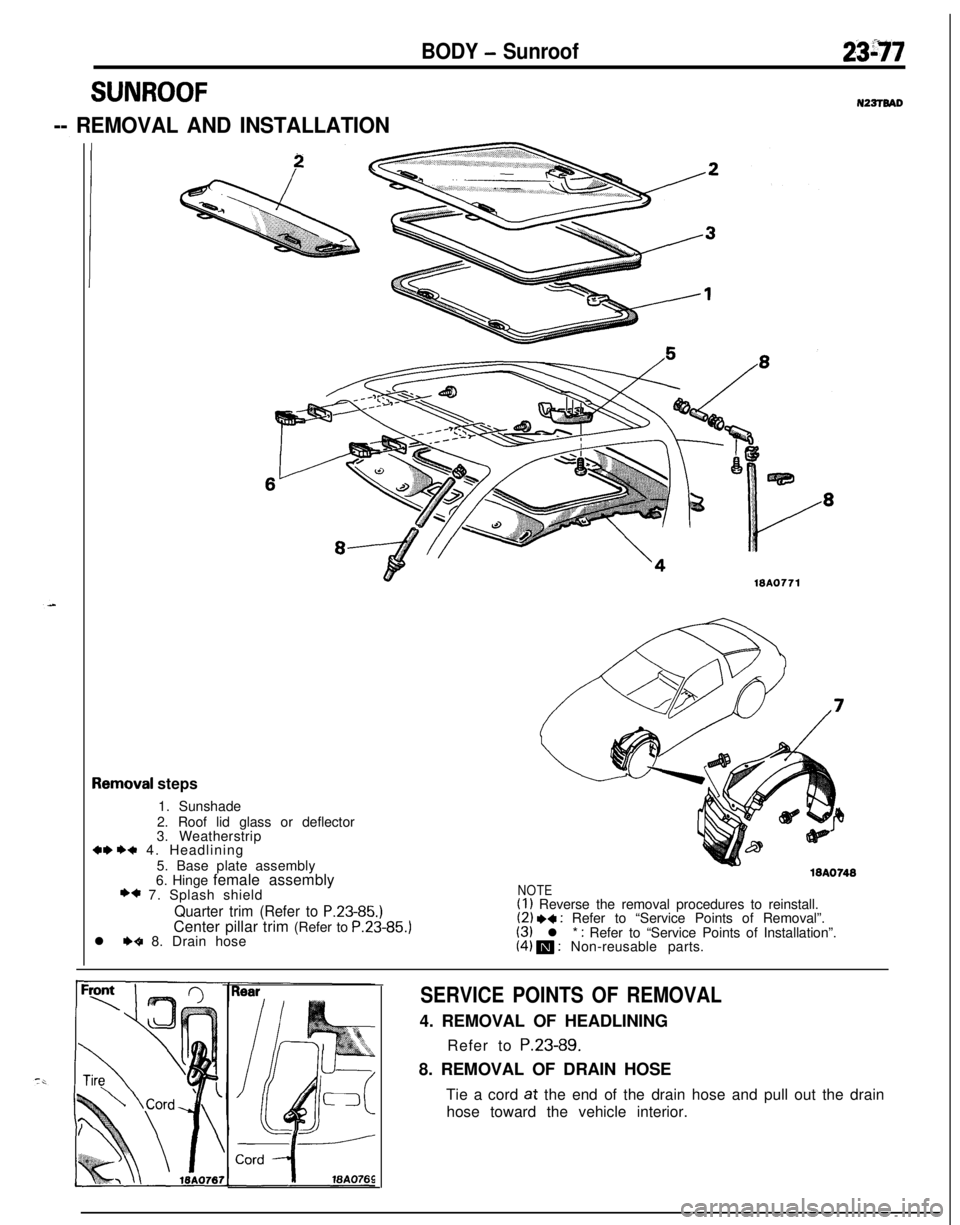

BODY - Sunroof2397

SUNROOFN22TTBAD

-- REMOVAL AND INSTALLATION

demoval steps

1. Sunshade

2. Roof lid glass or deflector

3. Weatherstrip

+w ++ 4. Headlining

5. Base plate assembly

6. Hinge female assembly

+* 7. Splash shield

Quarter trim (Refer to P.23-85.)Center pillar trim (Refer to P.23-85.)

l

++ 8. Drain hose

NOTE(I 1 Reverse the removal procedures to reinstall.(2) ** : Refer to “Service Points of Removal”.(3) l * : Refer to “Service Points of Installation”.(4) m : Non-reusable parts.

SERVICE POINTS OF REMOVAL4. REMOVAL OF HEADLINING

Refer to P.23-89.

8. REMOVAL OF DRAIN HOSE

Tie a cord

at the end of the drain hose and pull out the drain

hose toward the vehicle interior.

Page 1122 of 1216

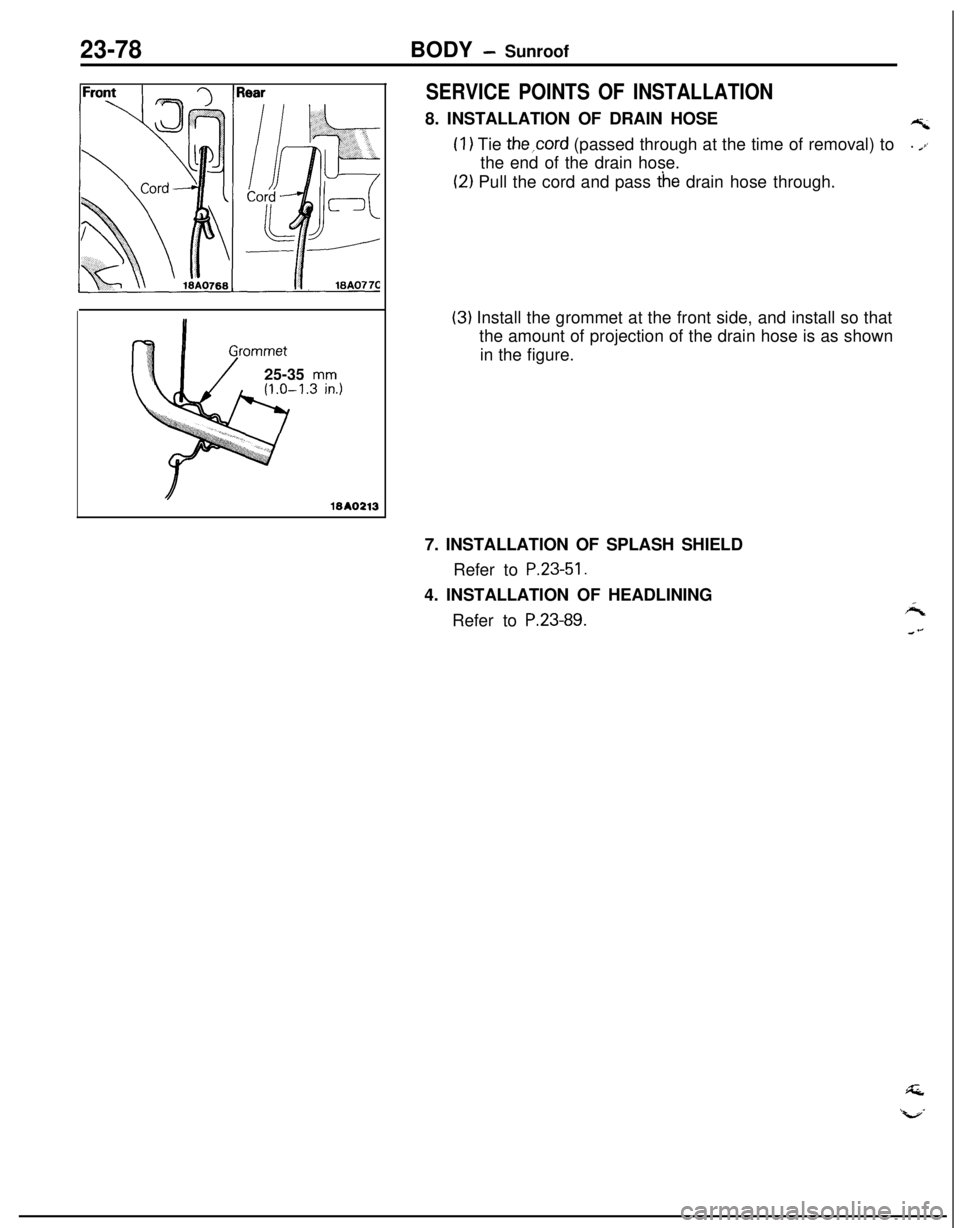

23-78BODY - Sunroof

25-35

mm

SERVICE POINTS OF INSTALLATION8. INSTALLATION OF DRAIN HOSE

AZ

(I) Tie the,cord (passed through at the time of removal) to. .ithe end of the drain hose.

(2) Pull the cord and pass t’he drain hose through.

(3) Install the grommet at the front side, and install so that

the amount of projection of the drain hose is as shown

in the figure.

7. INSTALLATION OF SPLASH SHIELD

Refer to

P.23-51.4. INSTALLATION OF HEADLINING

Refer to

P.23-89.

Page 1123 of 1216

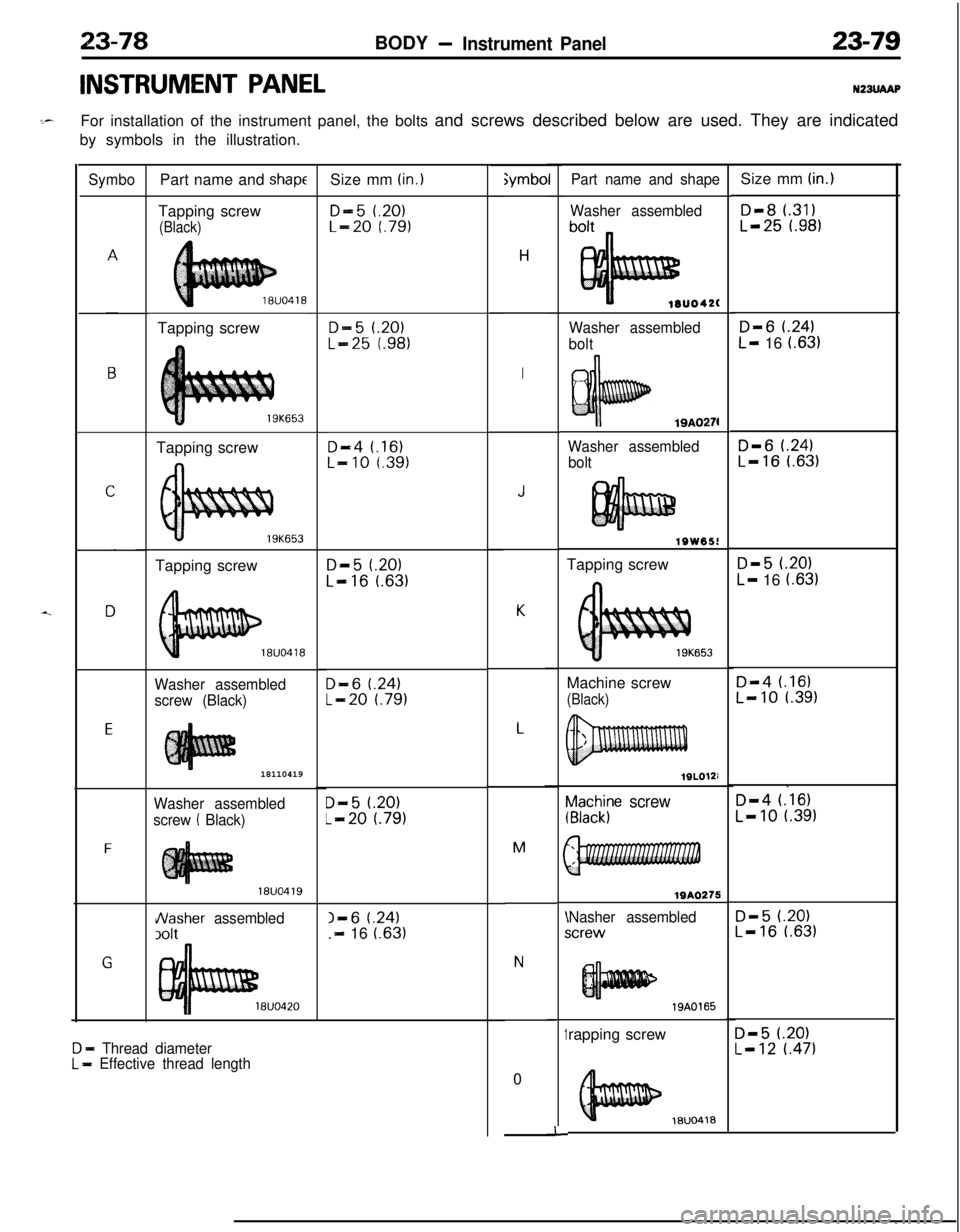

23-78BODY -Instrument Panel23-79

INSTRUMENT PANELNZBUAAPI_-

For installation of the instrument panel, the bolts and screws described below are used. They are indicated

by symbols in the illustration.

Symbo

E

F

GPart name and

shapeTapping screw

(Black)Tapping screw

Tapping screw

19K653Tapping screw

Washer assembled

screw (Black)18110419

Washer assembled

screw

! Black)

18UO419

Nasher assembled

3olt

8UO420

D - Thread diameterL = Effective thread lengthSize mm

(in.)

D-5 t.20)L-20 f.79)

D-5 1.20)

L-25 t.98)

D-4 t.16)L-10 r.391

D-5 f.20)

L-16 l.63)

D-6 t.24)

L-20 l.79)

D-5 t.20)

L-20 t.791

I-6 t.24)-=- 16 i.63);ymbo

H

I

J

K

L

M

N0

~a2h$e screw

WA0275

Nasher assembledicrew\I

1

-I-rapping screw

Part name and shape

Washer assembled

lOUO42(

Washer assembled

bolt

19A0274

Washer assembled

bolt

lSW65!Tapping screw

653Machine screw

(Black)

19A0165

18UO418Size mm

(in.)

D-8 l.31)L-25 t.98)

D-6 t.24)

L- 16 (.63)

D-6 f.24)L-16 l.63)

D-5 (.20)

L- 16 i.631

D-4 t.16)L-10 l.39)

D-4 (.‘16)

L-10 t.391

D-5 t.20)L-16 l.63)

D-5 l.20)L-12 t.471

Page 1124 of 1216

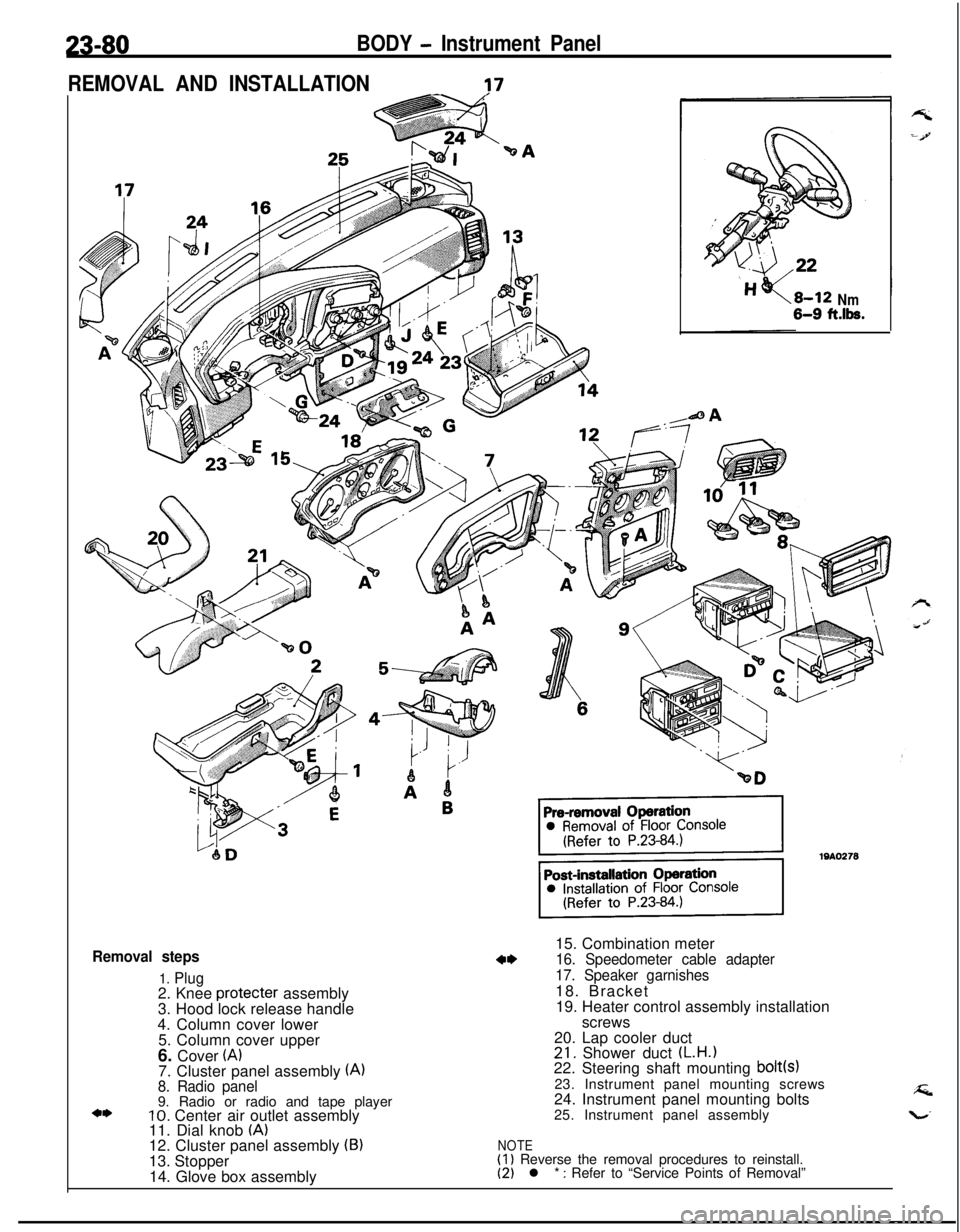

23-80BODY - Instrument Panel

REMOVAL AND INSTALLATION

-?7

Removal steps

1. Plug2. Knee protecter assembly

3. Hood lock release handle

4. Column cover lower

5. Column cover upper

6. Cover

(A)7. Cluster panel assembly (A)8. Radio panel9. Radio or radio and tape player

10. Center air outlet assembly

11. Dial knob (A)12. Cluster panel assembly (B)13. Stopper

14. Glove box assembly

Nm6-9 ft.lk.15. Combination meter

16. Speedometer cable adapter

17. Speaker garnishes18. Bracket

19. Heater control assembly installation

screws

20. Lap cooler duct

21. Shower duct (L.H.122. Steering shaft mounting bolt(s)23. Instrument panel mounting screws

24. Instrument panel mounting bolts

25. Instrument panel assembly

NOTE(1) Reverse the removal procedures to reinstall.(2) l * : Refer to “Service Points of Removal”

Page 1125 of 1216

BODY - Instrument Panel23-81

SECT. A-A

Flat-tip

( - ) screwdriver19A0274

1910267

SERVICE POINTS OF REMOVAL

10. REMOVAL OF CENTER AIR OUTLET ASSEMBLY

Removing the paw1 of the center air outlet assembly with aflat-tip

( - 1 screwdriver,remove the center air outlet

assembly with the plastic trim tool.

16. REMOVAL OF SPEEDOMETER CABLE ADAPTER

(1) Disconnect the speedometer cable at the transaxle endof the cable.

(2) Pull the speedometer cable slightly toward the vehicle

interior, release the lock by turning the adapter to the leftor right, and then remove the adapter.

Page 1126 of 1216

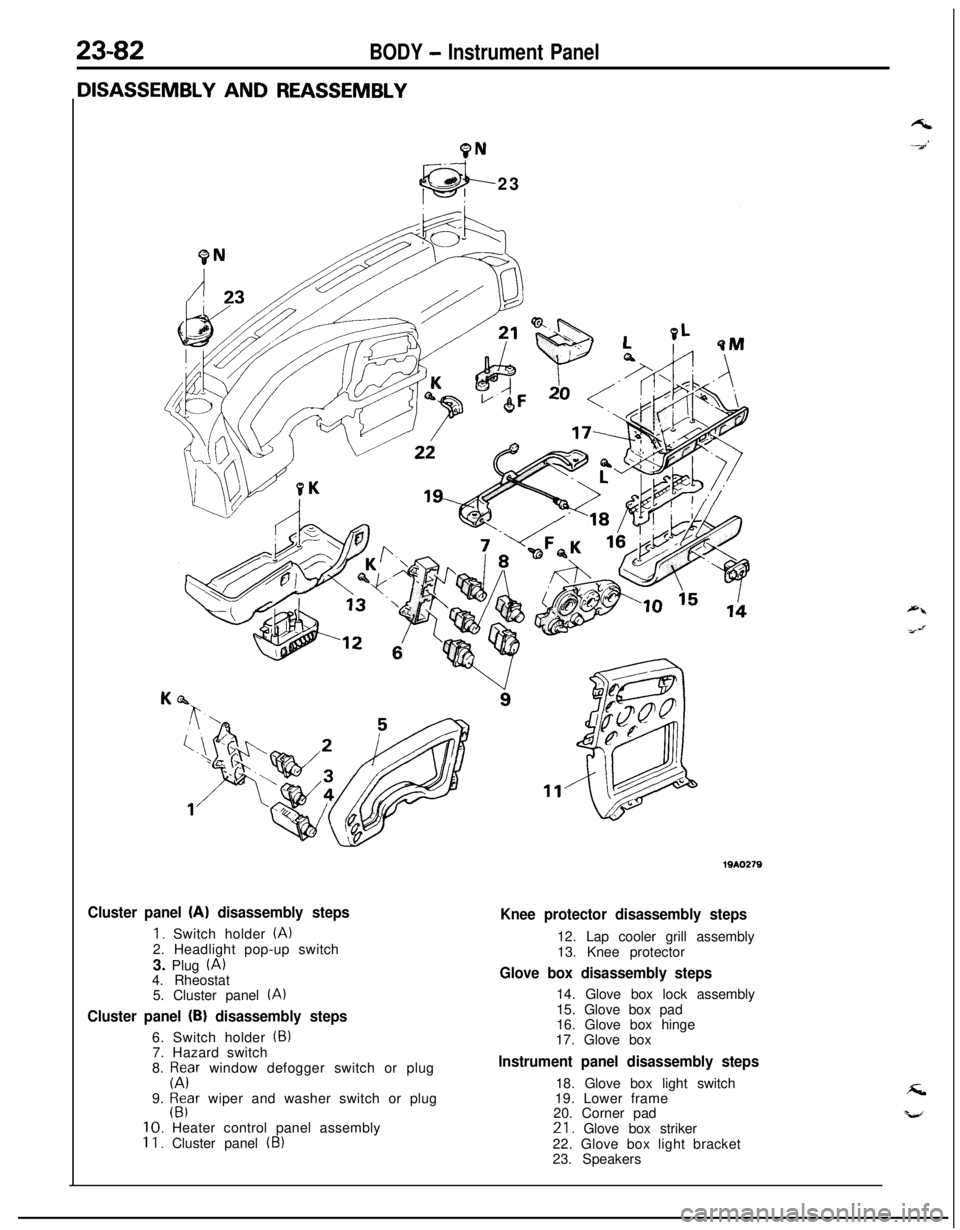

23-82BODY - Instrument Panel

9N23

Cluster panel (A) disassembly steps

1. Switch holder (A)2. Headlight pop-up switch

3. Plug

(A)4. Rheostat

5. Cluster panel

(A)

Cluster panel (B) disassembly steps6. Switch holder

(5)7. Hazard switch

8.

p;Fr window defogger switch or plug

9.

$far wiper and washer switch or plug10. Heater control panel assembly

II. Cluster panel (B)

Knee protector disassembly steps12. Lap cooler grill assembly

13. Knee protector

Glove box disassembly steps14. Glove box lock assembly

15. Glove box pad

16. Glove box hinge

17. Glove box

Instrument panel disassembly steps18. Glove box light switch

19. Lower frame

20. Corner pad21. Glove box striker

22. Glove box light bracket

23. Speakers

Page 1127 of 1216

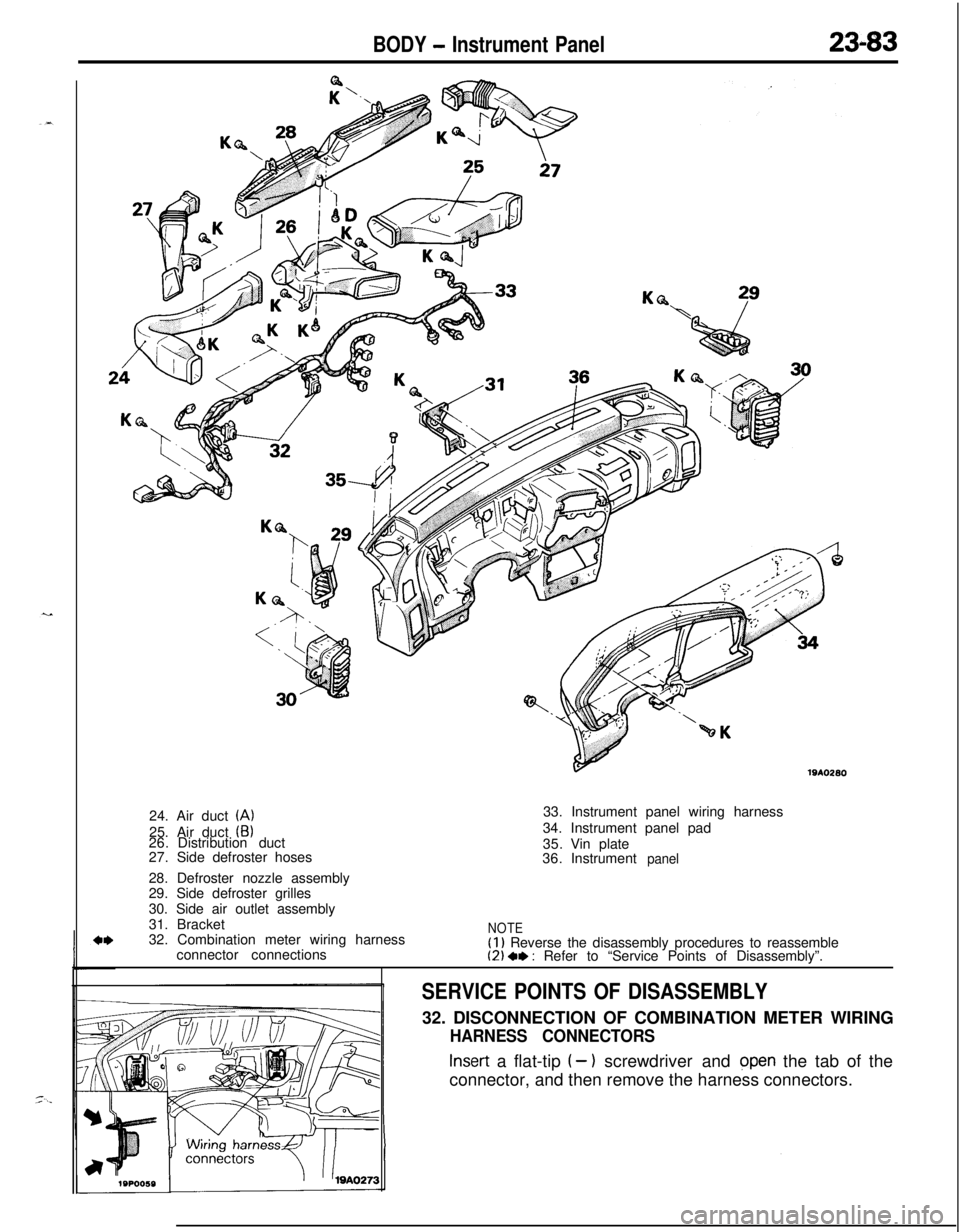

BODY - Instrument Panel23-83

191026024. Air duct

(A)25. Air duct

(B)26.Distribution duct

27.Side defroster hoses

28. Defroster nozzle assembly

29. Side defroster grilles

30. Side air outlet assembly

31. Bracket

32. Combination meter wiring harness

connector connections33. Instrument panel wiring harness

34. Instrument panel pad

35.Vin plate

36.Instrument

panel

NOTE(I) Reverse the disassembly procedures to reassemble(2) 4, : Refer to “Service Points of Disassembly”.

SERVICE POINTS OF DISASSEMBLY32. DISCONNECTION OF COMBINATION METER WIRING

HARNESS CONNECTORS

Insert a flat-tip I- 1 screwdriver and open the tab of the

connector, and then remove the harness connectors.

Page 1128 of 1216

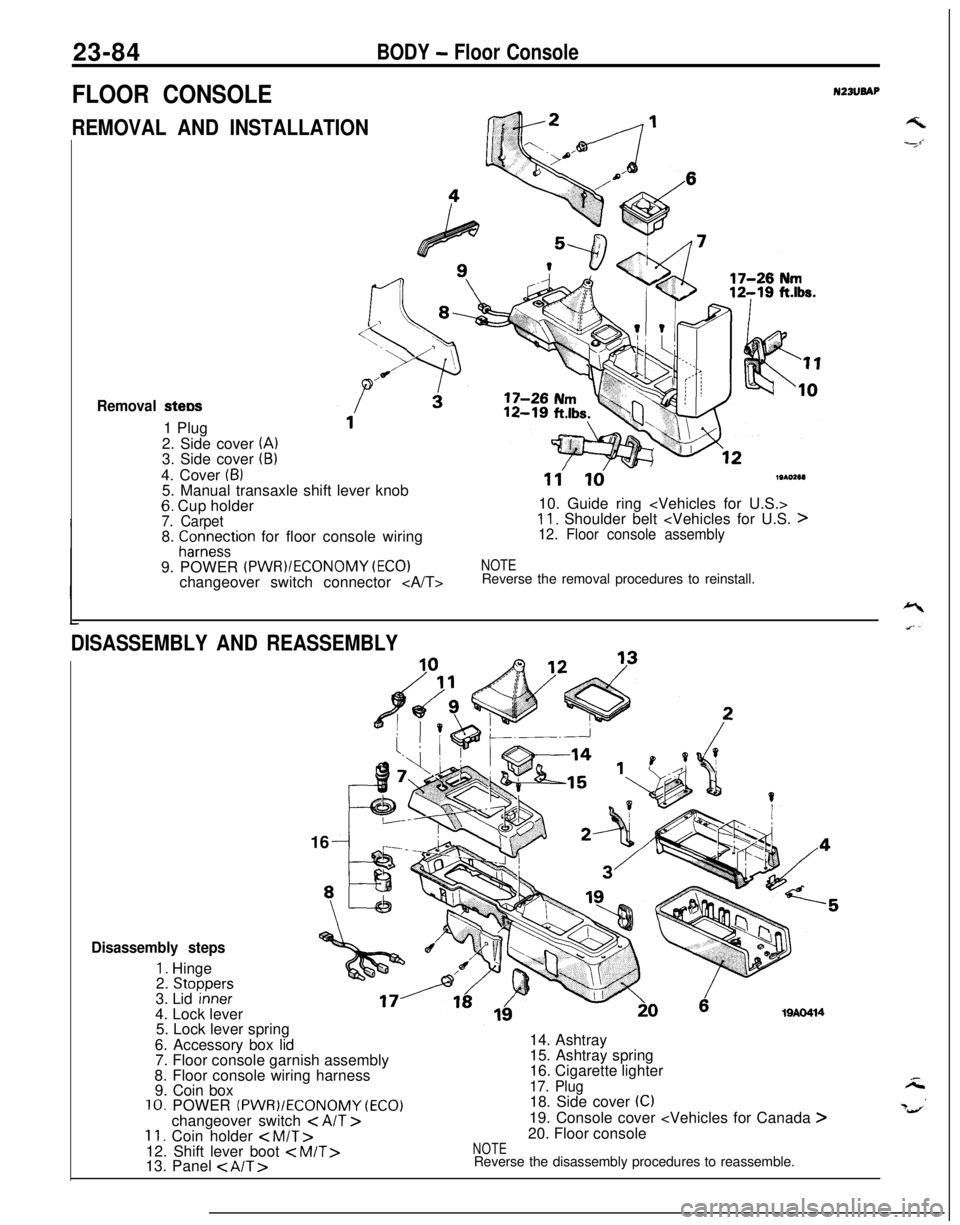

23-84BODY - Floor Console

FLOOR CONSOLEN23lJBAP

REMOVAL AND INSTALLATIONGk2 /---I

Removal stew1 Plug

2. Side cover

(A)3. Side cover (B)4. Cover

(6)5. Manual transaxle shift lever knob

6. Cup holder7. Carpet8. fCor;e~tion for floor console wiring

9. POWER

(PWR)/ECONOMY (EC01changeover switch connector

11'ld19102e1)10. Guide ring

11. Shoulder belt

NOTEReverse the removal procedures to reinstall.

DISASSEMBLY AND REASSEMBLY16

19AO414

Disassembly steps

1. Hinge

2. Stoooers3. Lid ‘inneF4. Lock lever

5. Lock lever spring

6. Accessory box lid

7. Floor console garnish assembly

8. Floor console wiring harness

9. Coin box

10. POWER (PWR)/ECONOMY (ECO)changeover switch < AIT >11. Coin holder < M/T>12. Shift lever boot

15. Ashtray spring

16. Cigarette lighter

17. Plug18. Side cover (C)19. Console cover

NOTEReverse the disassembly procedures to reassemble.

Page 1129 of 1216

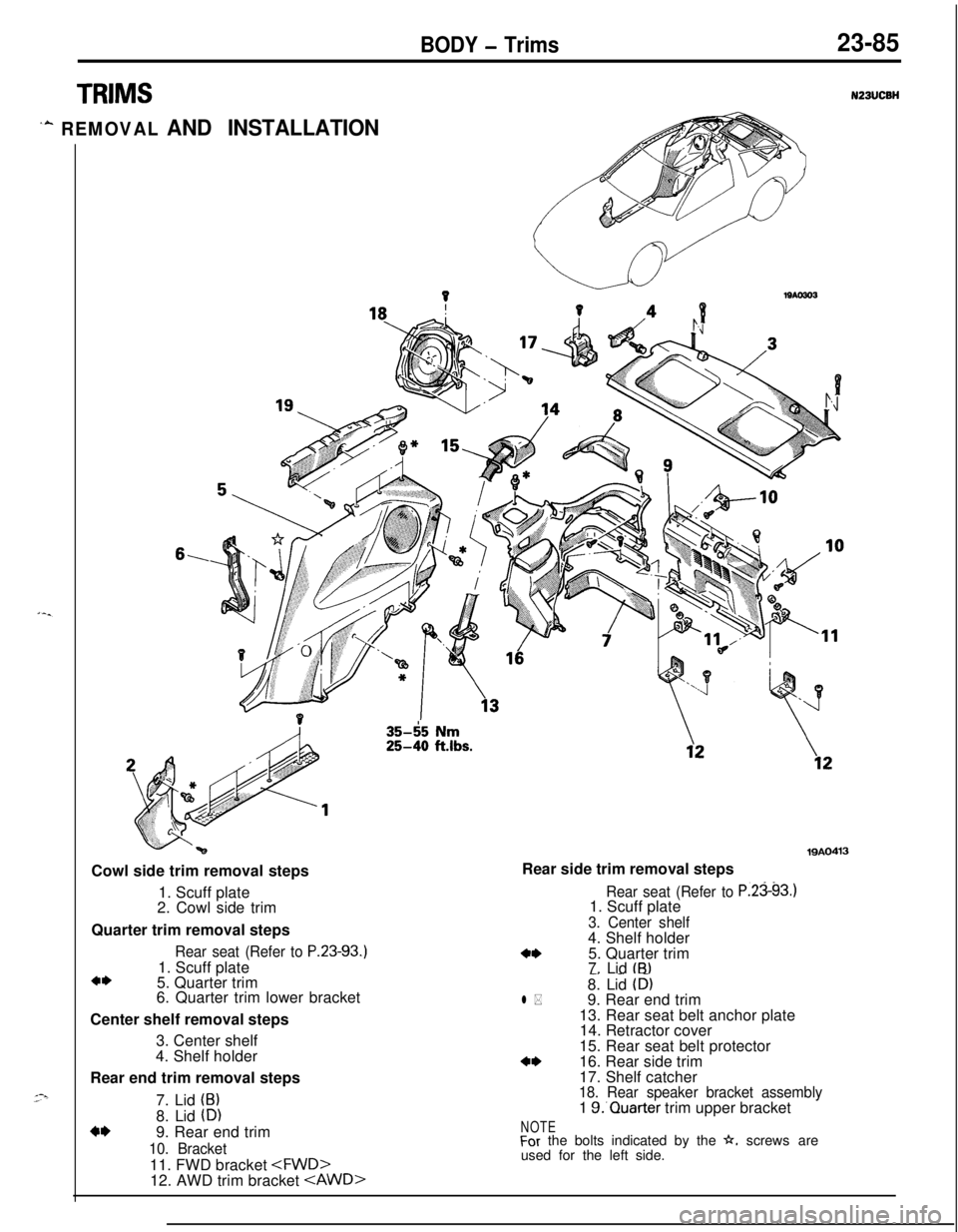

BODY - Trims23-85

TRIMS

‘A REMOVAL AND INSTALLATION

6,Cowl side trim removal steps

1. Scuff plate

2. Cowl side trim

Quarter trim removal steps

Rear seat (Refer to P.23-93.1. Scuff plate

a*5. Quarter trim

6. Quarter trim lower bracket

Center shelf removal steps

3. Center shelf

4. Shelf holder

Rear end trim removal steps

7. Lid

(B)8. Lid

(D)4*9. Rear end trim

10. Bracket11. FWD bracket

35-65 Nm25-40 ftlbs.

19AO413Rear side trim removal steps

Rear seat (Refer to P.2393.11. Scuff plate

3. Center shelf4. Shelf holder

4*5. Quarter trim

7. Lid tB)-. _ -8. Lid (D)l *9. Rear end trim

13. Rear seat belt anchor plate

14. Retractor cover

15. Rear seat belt protector

a*16. Rear side trim

17. Shelf catcher

18. Rear speaker bracket assembly1 S.‘Quarter trim upper bracket

NOTEFor the bolts indicated by the h. screws are

used for the left side.

Page 1130 of 1216

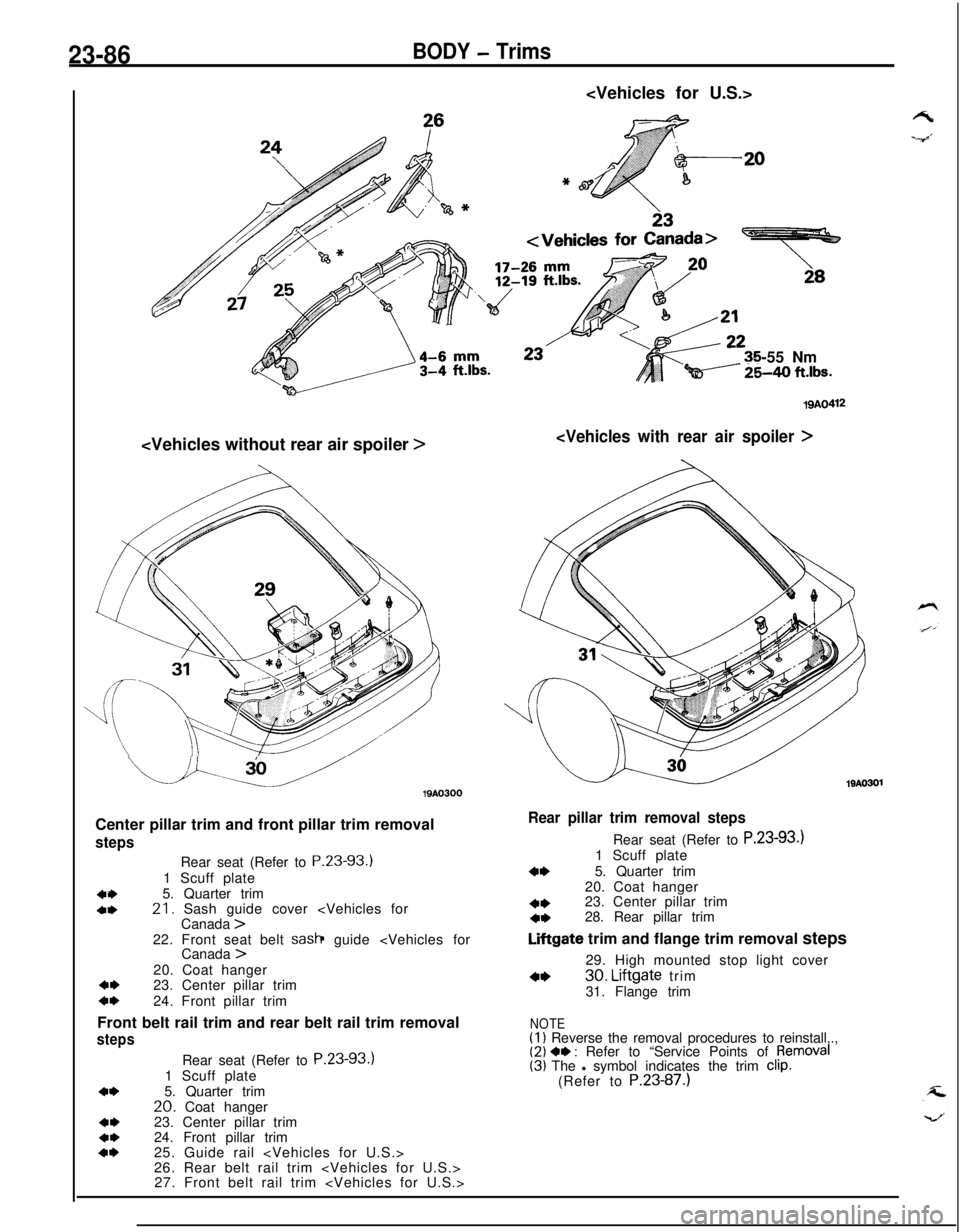

23-86BODY - Trims

-55 Nm

Qi----- %40 ft.lbs.

u.u19AO300

Center pillar trim and front pillar trim removal

steps

404,Rear seat (Refer to P.23-93.)

1 Scuff plate

5. Quarter trim21. Sash guide cover

4,23. Center pillar trimc*24. Front pillar trim

Front belt rail trim and rear belt rail trim removal

steps

4*

4,4*4*Rear seat (Refer to P.23-93.)

1 Scuff plate

5. Quarter trim

20. Coat hanger

23. Center pillar trim

24. Front pillar trim

25. Guide rail

26. Rear belt rail trim

27. Front belt rail trim

19AO412

19AO301

Rear pillar trim removal stepsRear seat (Refer to P.23-93.)

1 Scuff plate

4*5. Quarter trim

20. Coat hanger

4*23. Center pillar trim4*28. Rear pillar trim

Liftgate trim and flange trim removal steps

29. High mounted stop light cover

4*30. Liftgate trim

31. Flange trim

NOTE(1) Reverse the removal procedures to reinstall,.,(2) 4, : Refer to “Service Points of pemoval(3) The l symbol indicates the trim clip.(Refer to P.23-87.)