MITSUBISHI ECLIPSE 1991 Service Manual

Manufacturer: MITSUBISHI, Model Year: 1991, Model line: ECLIPSE, Model: MITSUBISHI ECLIPSE 1991Pages: 1216, PDF Size: 67.42 MB

Page 1091 of 1216

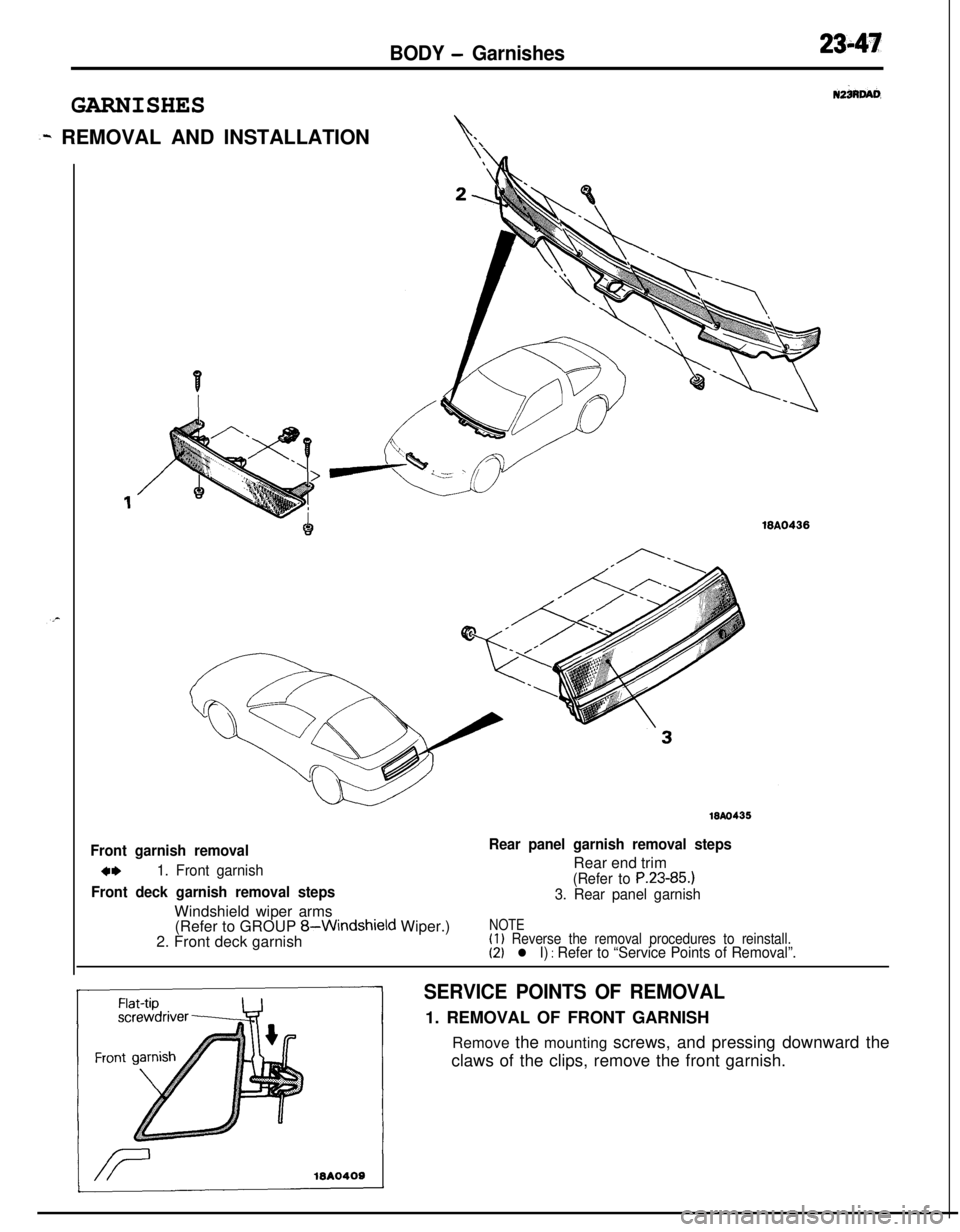

BODY - Garnishes2347

GARNISHES

N2iRW

~w REMOVAL AND INSTALLATIONi‘\

18Ao435

Front garnish removal

4m1. Front garnish

Front deck garnish removal stepsWindshield wiper arms

Rear panel garnish removal stepsRear end trim

(Refer to P.23-85.)

3. Rear panel garnish(Refer to GROUP

8-Windshield Wiper.)

2. Front deck garnishNOTE(1) Reverse the removal procedures to reinstall.(2) l I) : Refer to “Service Points of Removal”.

SERVICE POINTS OF REMOVAL1. REMOVAL OF FRONT GARNISH

Remove the mounting screws, and pressing downward the

claws of the clips, remove the front garnish.

Page 1092 of 1216

23-48

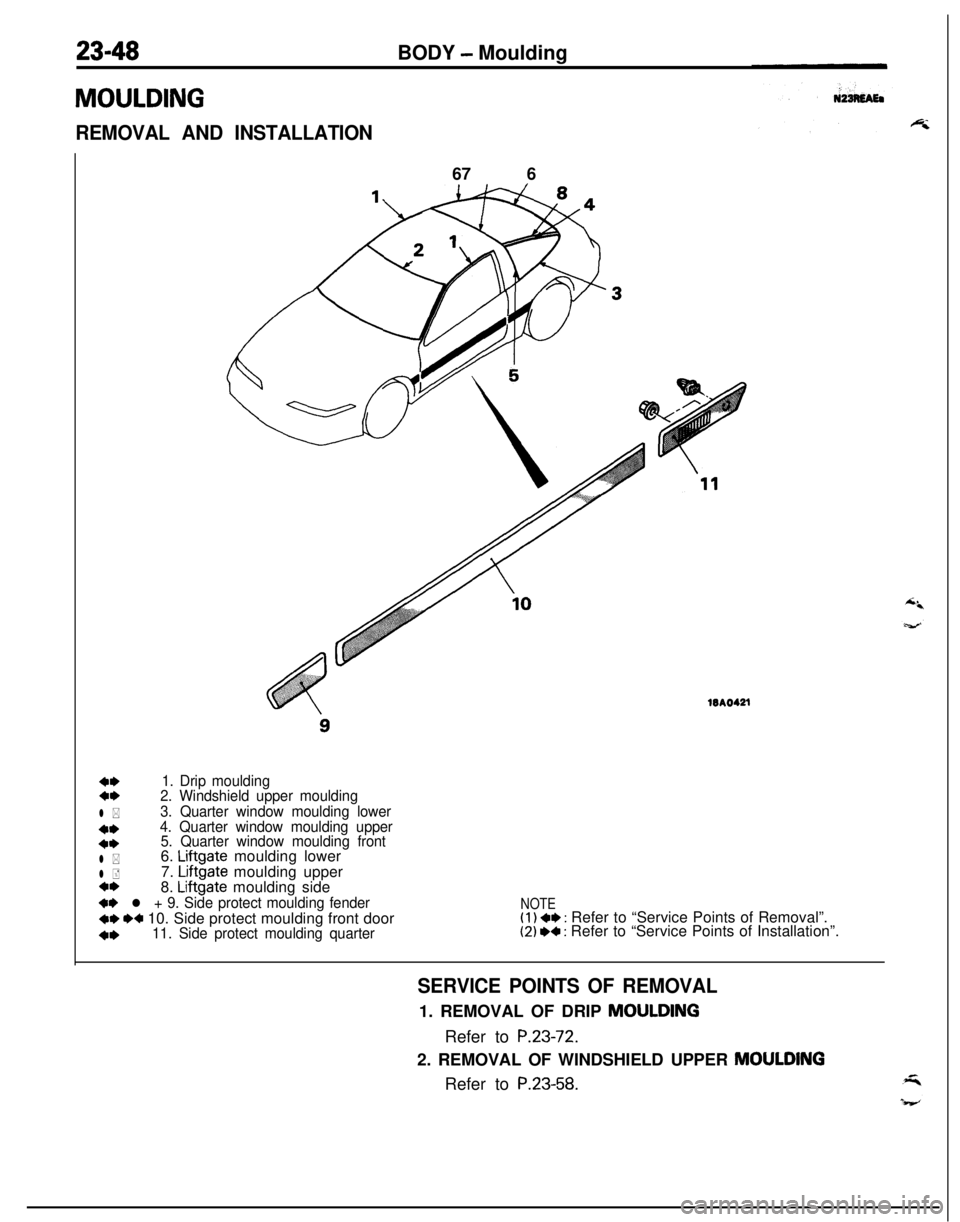

MOULDINGBODY

- Moulding

REMOVAL AND INSTALLATION67 6WA0421

4,1. Drip moulding4,2. Windshield upper moulding

l *3. Quarter window moulding lower

**4. Quarter window moulding upper

4*5. Quarter window moulding front

l *6. Liftgate moulding lower

l +7. Liftgate moulding uppera*8. Liftgate moulding side

+* l + 9. Side protect moulding fender

+e I)+ 10. Side protect moulding front door

4,11. Side protect moulding quarter

NOTE(1) ** : Refer to “Service Points of Removal”.(2) I)+ : Refer to “Service Points of Installation”.

SERVICE POINTS OF REMOVAL1. REMOVAL OF DRIP MOULDING

Refer to

P.23-72.2. REMOVAL OF WINDSHIELD UPPER

MOULDINGRefer to

P.23-58.

Page 1093 of 1216

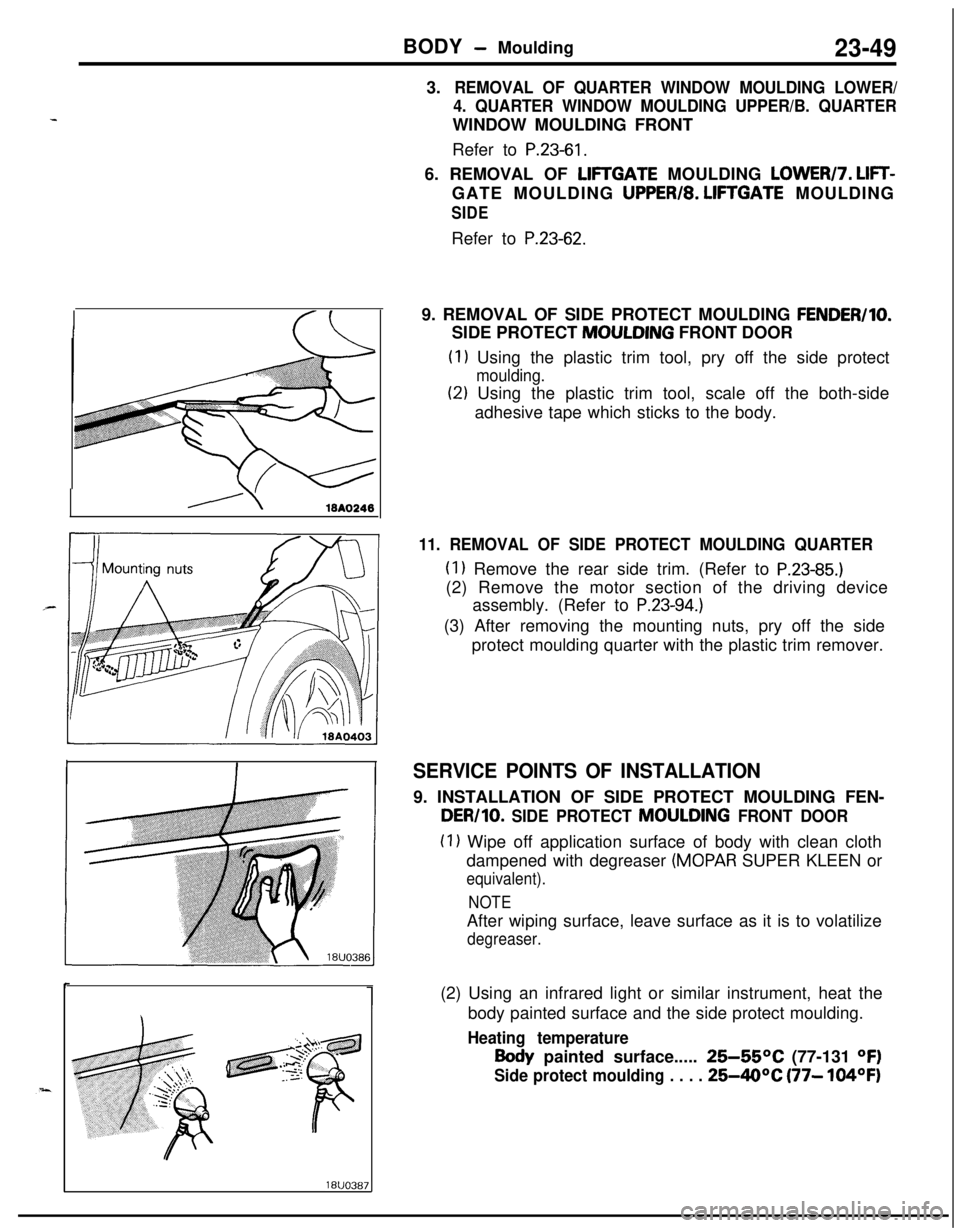

BODY - Moulding23-493.

REMOVAL OF QUARTER WINDOW MOULDING LOWER/

4. QUARTER WINDOW MOULDING UPPER/B. QUARTERWINDOW MOULDING FRONT

Refer to

P.23-61.6. REMOVAL OF

LIFTGATE MOULDING LOWERI7. LIFT-GATE MOULDING

UPPER/8. LIFTGATE MOULDING

SIDERefer to

P.23-62.

19. REMOVAL OF SIDE PROTECT MOULDING

FENDER/IO.SIDE PROTECT MOULDING FRONT DOOR

(1) Using the plastic trim tool, pry off the side protect

moulding.

(2) Using the plastic trim tool, scale off the both-side

adhesive tape which sticks to the body.

11. REMOVAL OF SIDE PROTECT MOULDING QUARTER

(1) Remove the rear side trim. (Refer to P.23-85.)(2) Remove the motor section of the driving device

assembly. (Refer to

P.23-94.)(3) After removing the mounting nuts, pry off the side

protect moulding quarter with the plastic trim remover.

SERVICE POINTS OF INSTALLATION9. INSTALLATION OF SIDE PROTECT MOULDING FEN-

DER/10. SIDE PROTECT MOULDING FRONT DOOR

(1) Wipe off application surface of body with clean cloth

dampened with degreaser

(MOPAR SUPER KLEEN or

equivalent).

NOTEAfter wiping surface, leave surface as it is to volatilize

degreaser.(2) Using an infrared light or similar instrument, heat the

body painted surface and the side protect moulding.

Heating temperature

Body painted surface..... 25-55OC (77-131 OF)

Side protect moulding . . . . 25-40°C (77- 104OF)

Page 1094 of 1216

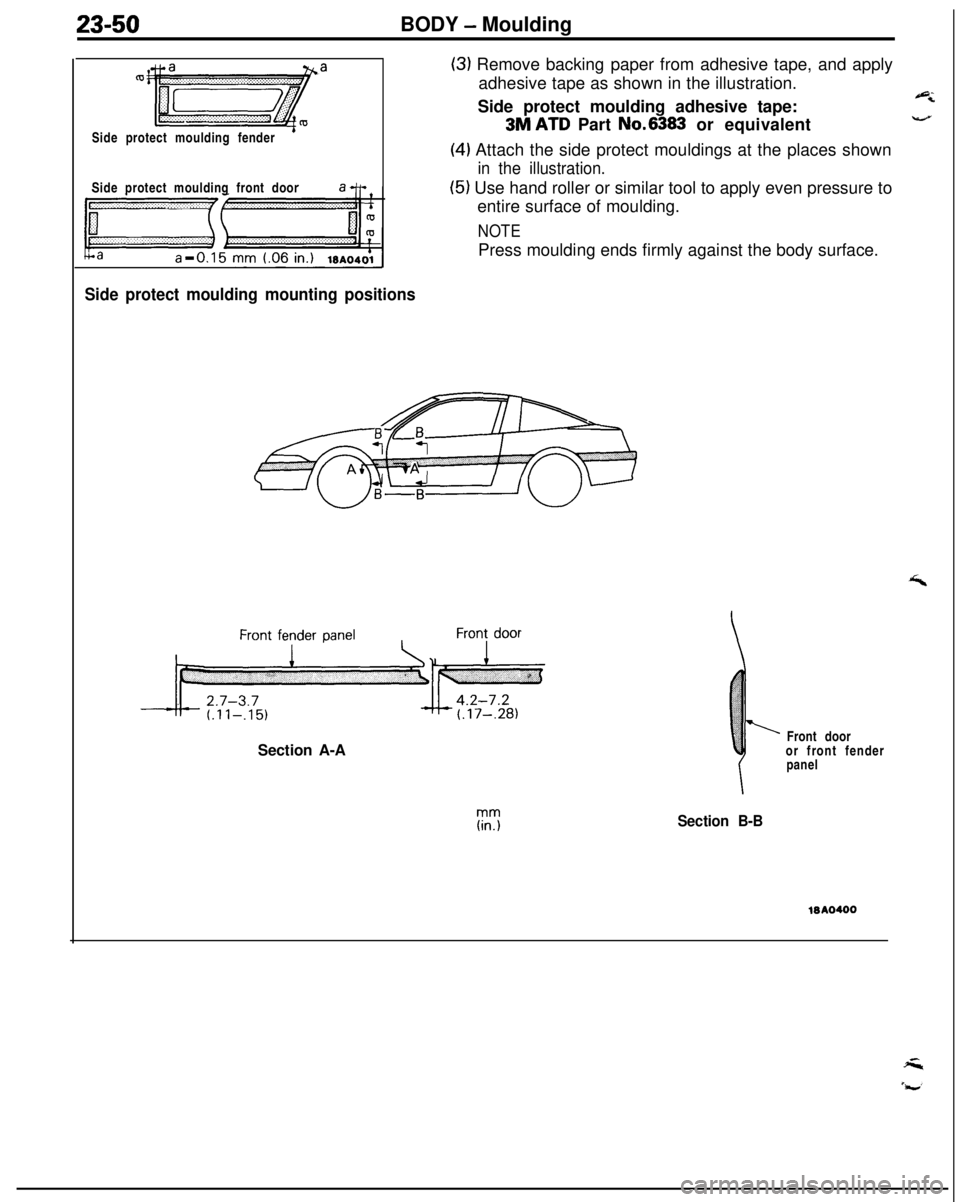

23-50BODY - Moulding

Side protect moulding fender

’Side protect moulding front door

Side protect moulding mounting positions

(3) Remove backing paper from adhesive tape, and apply

adhesive tape as shown in the illustration.

Side protect moulding adhesive tape:

6

3M ATD Part No.6383 or equivalentV

(4) Attach the side protect mouldings at the places shown

in the illustration.

(5) Use hand roller or similar tool to apply even pressure to

entire surface of moulding.

NOTEPress moulding ends firmly against the body surface.

Section A-AFront door

or front fender

ipanel

Section B-BWA0400

Page 1095 of 1216

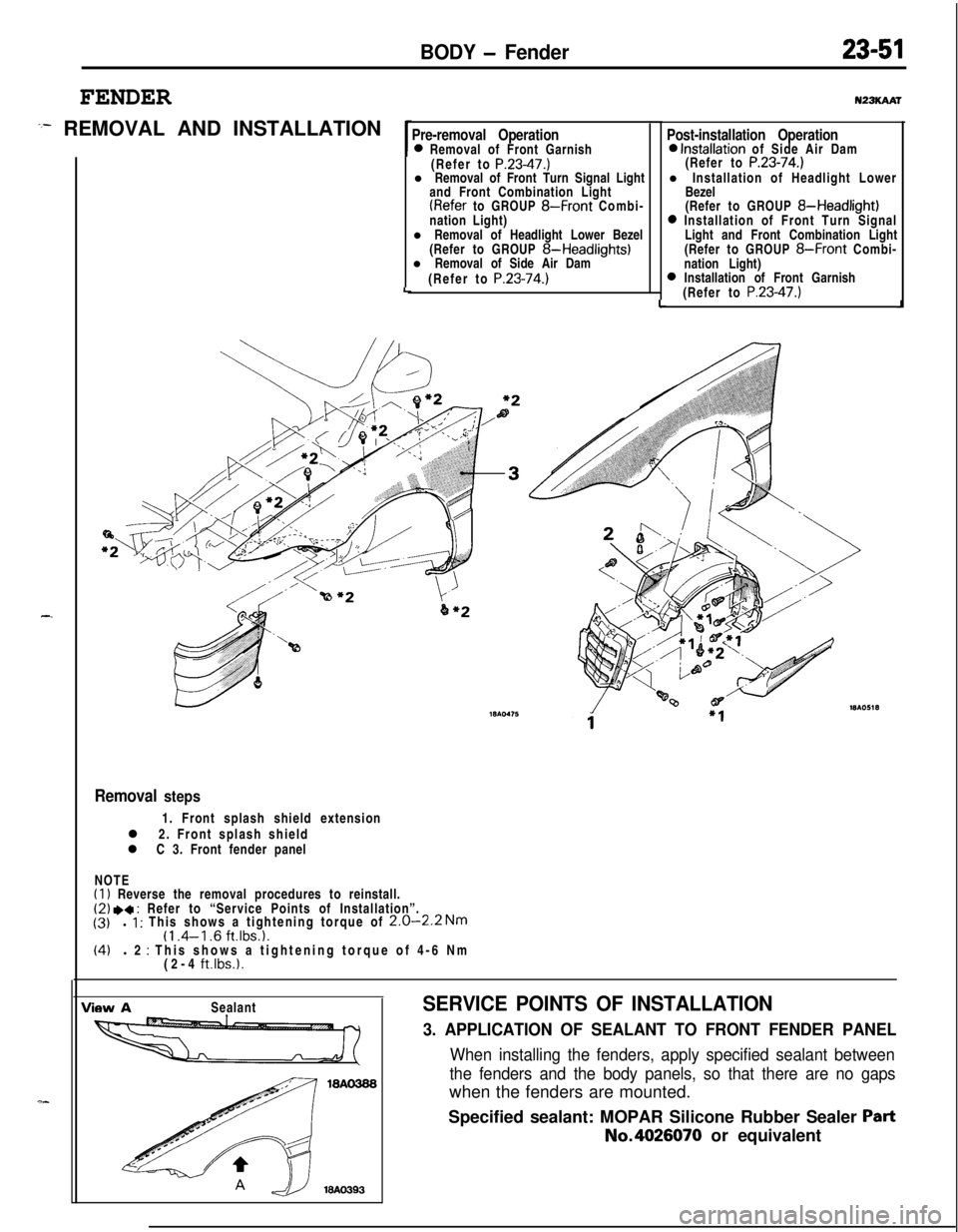

BODY - Fender

FENDER

:- REMOVAL AND INSTALLATION

-.

Pre-removal Operation0 Removal of Front Garnish

(Refer to P.23-47.)l Removal of Front Turn Signal Light

and Front Combination Light

(Refer to GROUP 8-Front Combi-

nation Light)

l Removal of Headlight Lower Bezel

(Refer to GROUP

8-Headlights)l Removal of Side Air Dam

(Refer to

P.23-74.)LLu23KAAr

Post-installation Operation0 Installation of Side Air Dam

(Refer to P.23-74.)l Installation of Headlight Lower

Bezel

(Refer to GROUP

8-Headlight)0 Installation of Front Turn Signal

Light and Front Combination Light

(Refer to GROUP

8-Front Combi-

nation Light)

0 Installation of Front Garnish

(Refer to P.23-47.)J

Removal steps1. Front splash shield extension

l 2. Front splash shield

l C 3. Front fender panel

NOTE

(1) Reverse the removal procedures to reinstall.(2) .a : Refer to “Service Points of Installation”.

(3)l 1 : This shows a tightening torque of 2.0-2.2 Nm(1 .4-l .6 ft.lbs.1.(4)l 2 : This shows a tightening torque of 4-6 Nm

(2-4 ft.lbs.1.

View ASealantSERVICE POINTS OF INSTALLATION

3. APPLICATION OF SEALANT TO FRONT FENDER PANEL

When installing the fenders, apply specified sealant between

the fenders and the body panels, so that there are no gapswhen the fenders are mounted.

Specified sealant: MOPAR Silicone Rubber Sealer

PartNo.4026070 or equivalent

Page 1096 of 1216

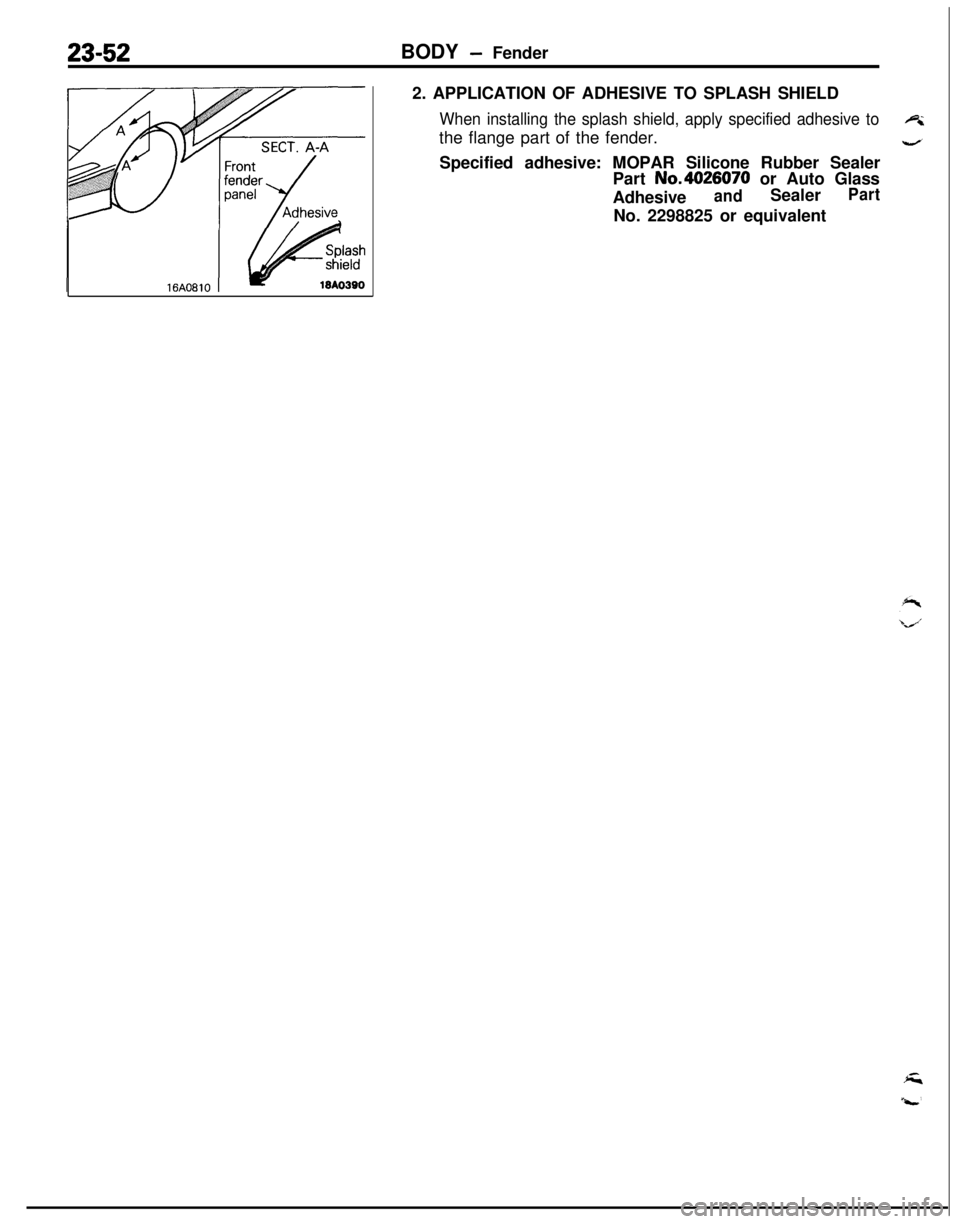

23-52BODY - Fender

2. APPLICATION OF ADHESIVE TO SPLASH SHIELD

When installing the splash shield, apply specified adhesive toethe flange part of the fender.

4Specified adhesive: MOPAR Silicone Rubber Sealer

Part No.4026070 or Auto Glass

Adhesive

andSealerPartNo. 2298825 or equivalent

Page 1097 of 1216

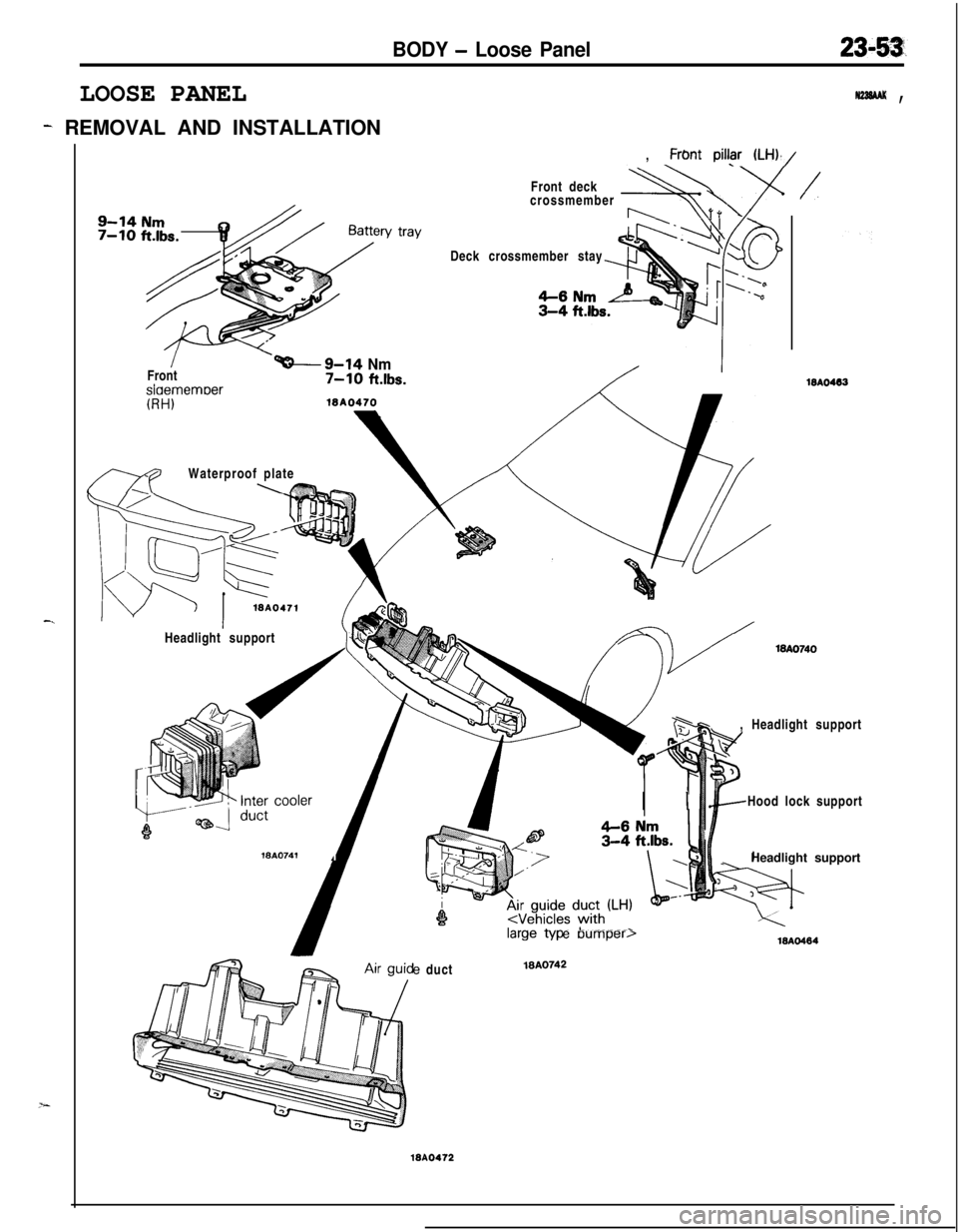

BODY - Loose Panel

LOOSE PANEL

- REMOVAL AND INSTALLATION

, Frbnt

piI@ (LH),/

N22SAAK ,

-.

v trayFront deck

crossmember

+ADeck crossmember stay

/Front

I

‘-9-14 Nm7-10 ftlbs.slaememoer

mWaterproof plate\K?%--

(RH)

WA0471Headlight supportWA.0741

,

/

WA0463, Headlight support

/-c---x/

I IHood lock support

_Headlight supporte duct

MA0742

WA0472

e Dumper,18AO484

Page 1098 of 1216

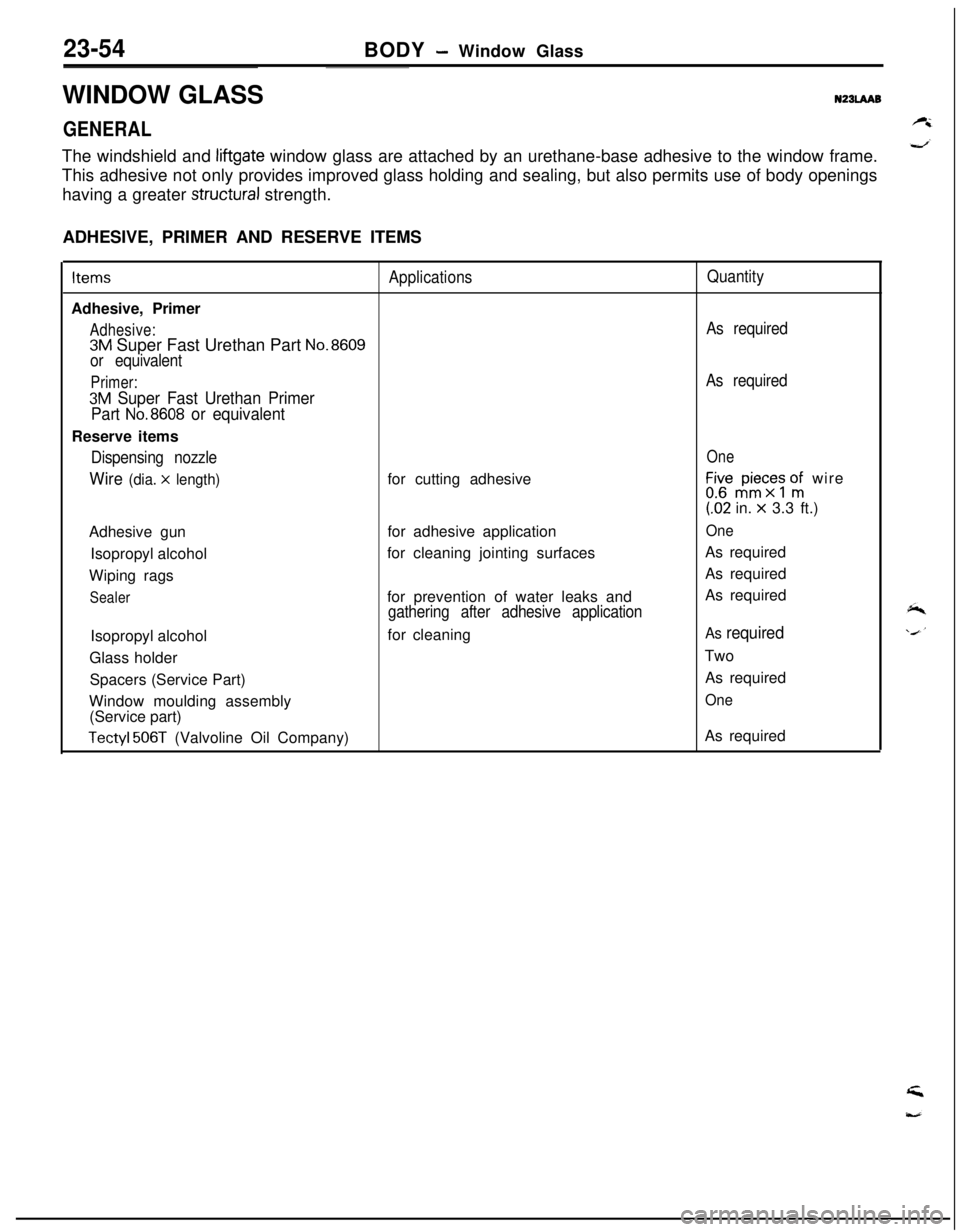

23-54BODY - Window Glass

WINDOW GLASS

N23LAAB

GENERALThe windshield and

liftgate window glass are attached by an urethane-base adhesive to the window frame.

This adhesive not only provides improved glass holding and sealing, but also permits use of body openings

having a greater

structural strength.

ADHESIVE, PRIMER AND RESERVE ITEMSItems

ApplicationsQuantityAdhesive, Primer

Adhesive:As required

3M Super Fast Urethan Part No.8609

or equivalent

Primer:As required

3M Super Fast Urethan Primer

Part

No.8608 or equivalentReserve items

Dispensing nozzleOne

Wire (dia. x length)for cutting adhesiveLir,“$c;s onfi wire(62 in.

x 3.3 ft.)

Adhesive gunfor adhesive application

OneIsopropyl alcoholfor cleaning jointing surfacesAs required

Wiping ragsAs required

Sealerfor prevention of water leaks andAs requiredgathering after adhesive applicationIsopropyl alcoholfor cleaning

As requiredGlass holderTwo

Spacers (Service Part)As required

Window moulding assembly

One(Service part)

Tectyl 506T (Valvoline Oil Company)As required

Page 1099 of 1216

BODY - Window Glass23-55

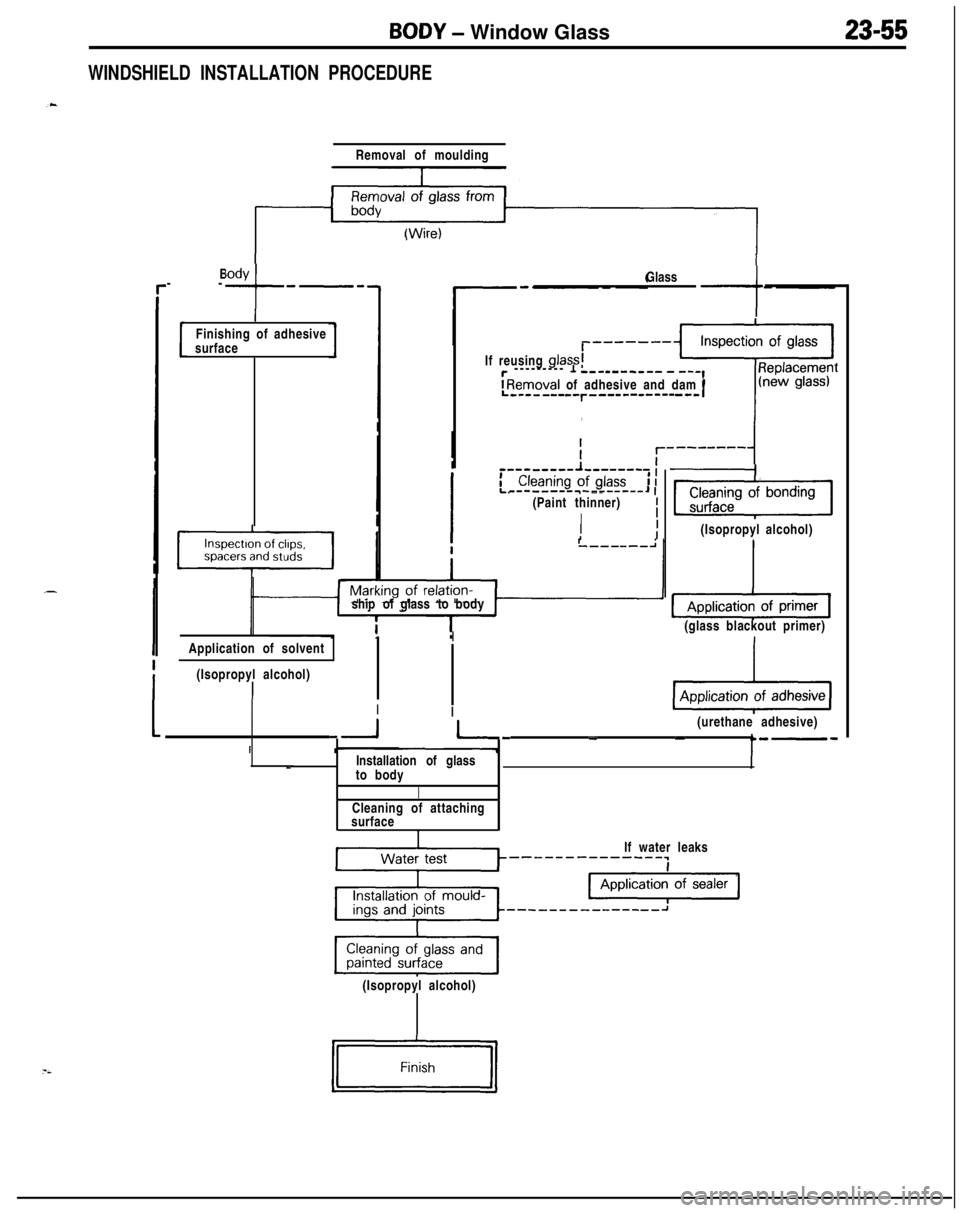

WINDSHIELD INSTALLATION PROCEDURE

_-Body

--

+

e-eRemoval of moulding

(Wire)

IFinishing of adhesive

surfaceGlass-tIf reusing glass;

r --------- 1 ---s------ - -‘-,

IRemoval of adhesive and dam rL---------r---s---------- I

e-e _---mm,- __-_--_ 1,(Paint thinner)

II

IIIship ofglass tobody

IApplication of solvent

(Isopropyl alcohol)

III

-*I(Isopropyl alcohol)

(glass blackout primer)

pi&g(urethane adhesive)

-1 I- - -Installation of glass

_to body

ICleaning of attaching

surface

1If water leaks

--------------~

p%zG&pJ(Isopropyl alcohol)

Page 1100 of 1216

23-56BODY - Window Glass

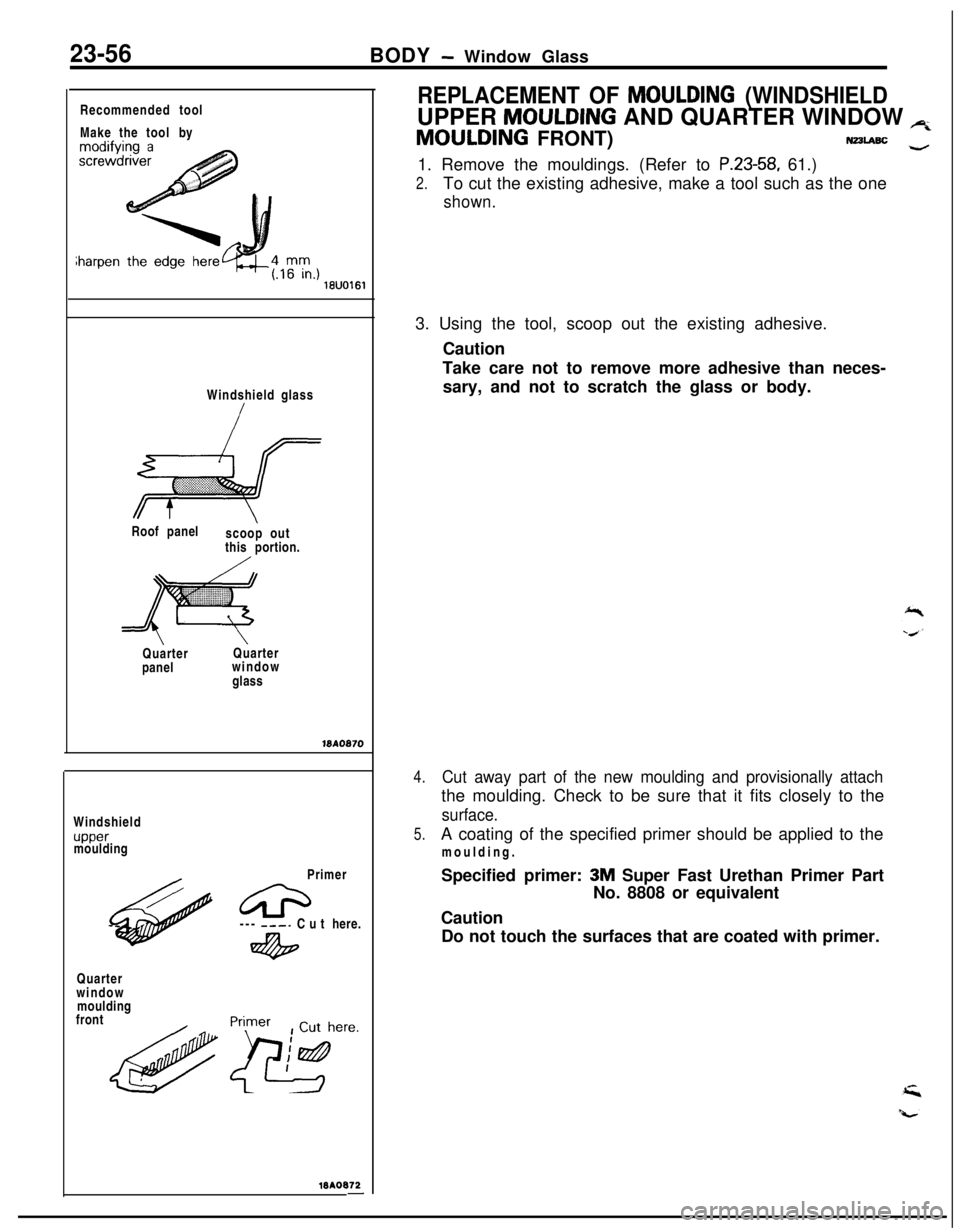

Recommended tool

Make the toolby

Windshield glass

Roof panel

scoop out

this portion.

iiiii- ,.:::i:::::::::::i.p:://jiiiig;iiiijjiiij

I&

::::::::::iiiiiii.::;QuarterQuarter

panelwindow

glass

WA0870Windshield

uppermoulding

Primer

Quarter

window

moulding

front---

---. Cuthere.

4%

>/yere.

MAO672-

REPLACEMENT OF MOULDING (WINDSHIELDUPPER

MOULDING AND QUARTER WINDOW p;MOULDING FRONT)

N22LABc -1. Remove the mouldings. (Refer to

P.23-58, 61.)

2.To cut the existing adhesive, make a tool such as the one

shown.3. Using the tool, scoop out the existing adhesive.

Caution

Take care not to remove more adhesive than neces-

sary, and not to scratch the glass or body.

4.Cut away part of the new moulding and provisionally attachthe moulding. Check to be sure that it fits closely to the

surface.

5.A coating of the specified primer should be applied to the

moulding.

Specified primer:

3M Super Fast Urethan Primer Part

No. 8808 or equivalent

Caution

Do not touch the surfaces that are coated with primer.