MITSUBISHI ECLIPSE 1991 Service Manual

Manufacturer: MITSUBISHI, Model Year: 1991, Model line: ECLIPSE, Model: MITSUBISHI ECLIPSE 1991Pages: 1216, PDF Size: 67.42 MB

Page 1111 of 1216

BODY - Door Glass and Reaulator/Power Window23-67

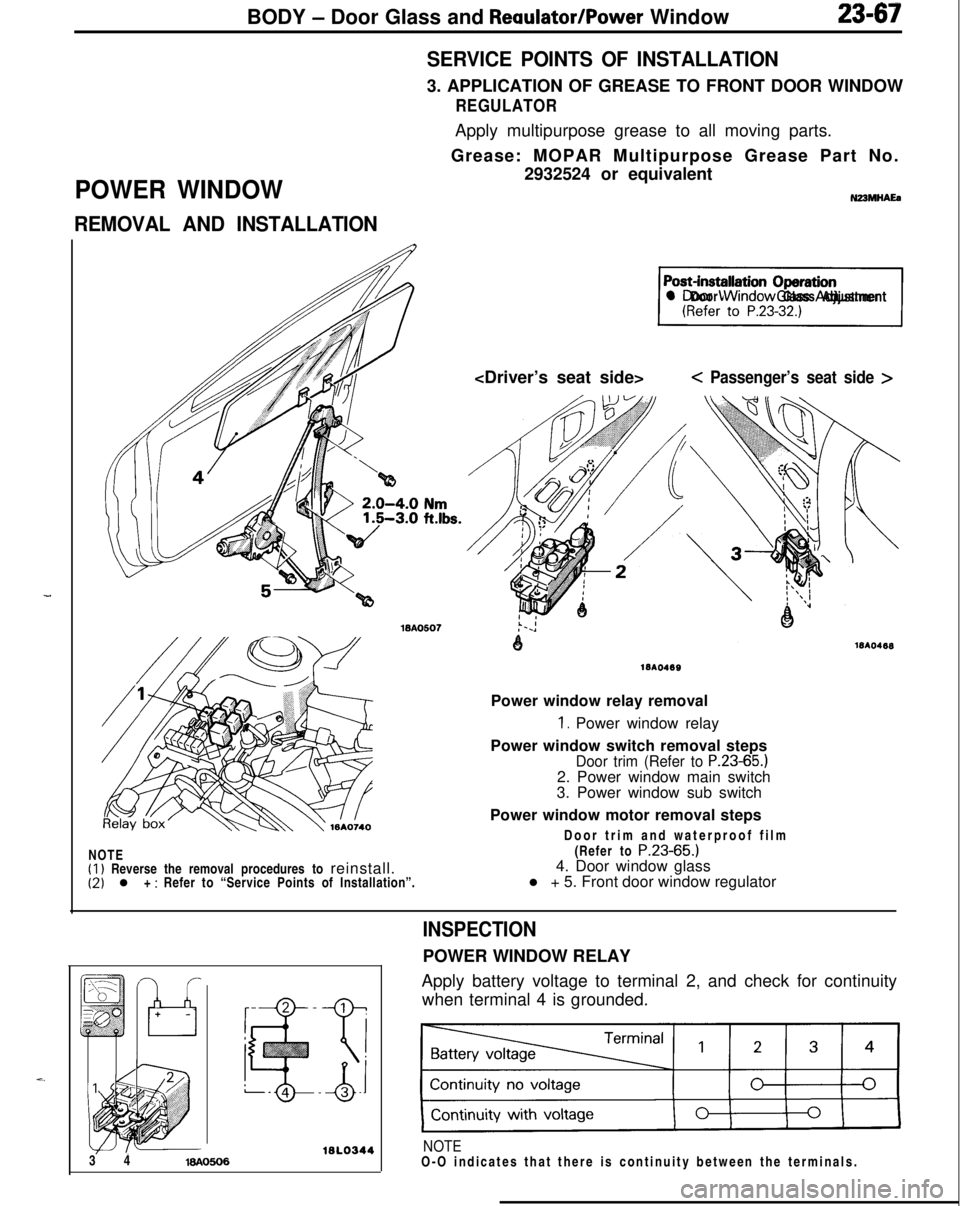

POWER WINDOW

REMOVAL AND INSTALLATIONSERVICE POINTS OF INSTALLATION3. APPLICATION OF GREASE TO FRONT DOOR WINDOW

REGULATORApply multipurpose grease to all moving parts.

Grease: MOPAR Multipurpose Grease Part No.

2932524 or equivalent

N23MHAEa

71l Door Window Glass Adjustment

< Passenger’s seat side >NOTE

(1) Reverse the removal procedures to reinstall.(2) l + : Refer to “Service Points of Installation”.

1810469Power window relay removal

1. Power window relay

Power window switch removal steps

Door trim (Refer to P.23-65.)2. Power window main switch

3. Power window sub switch

Power window motor removal steps

Door trim and waterproof film

(Refer to

P.23-65.)4. Door window glass

l + 5. Front door window regulator

16l.03443 416AO606

INSPECTIONPOWER WINDOW RELAY

Apply battery voltage to terminal 2, and check for continuity

when terminal 4 is grounded.

NOTEO-O indicates that there is continuity between the terminals.

Page 1112 of 1216

23-68BODY - Power Window

Power

window

lock

switch

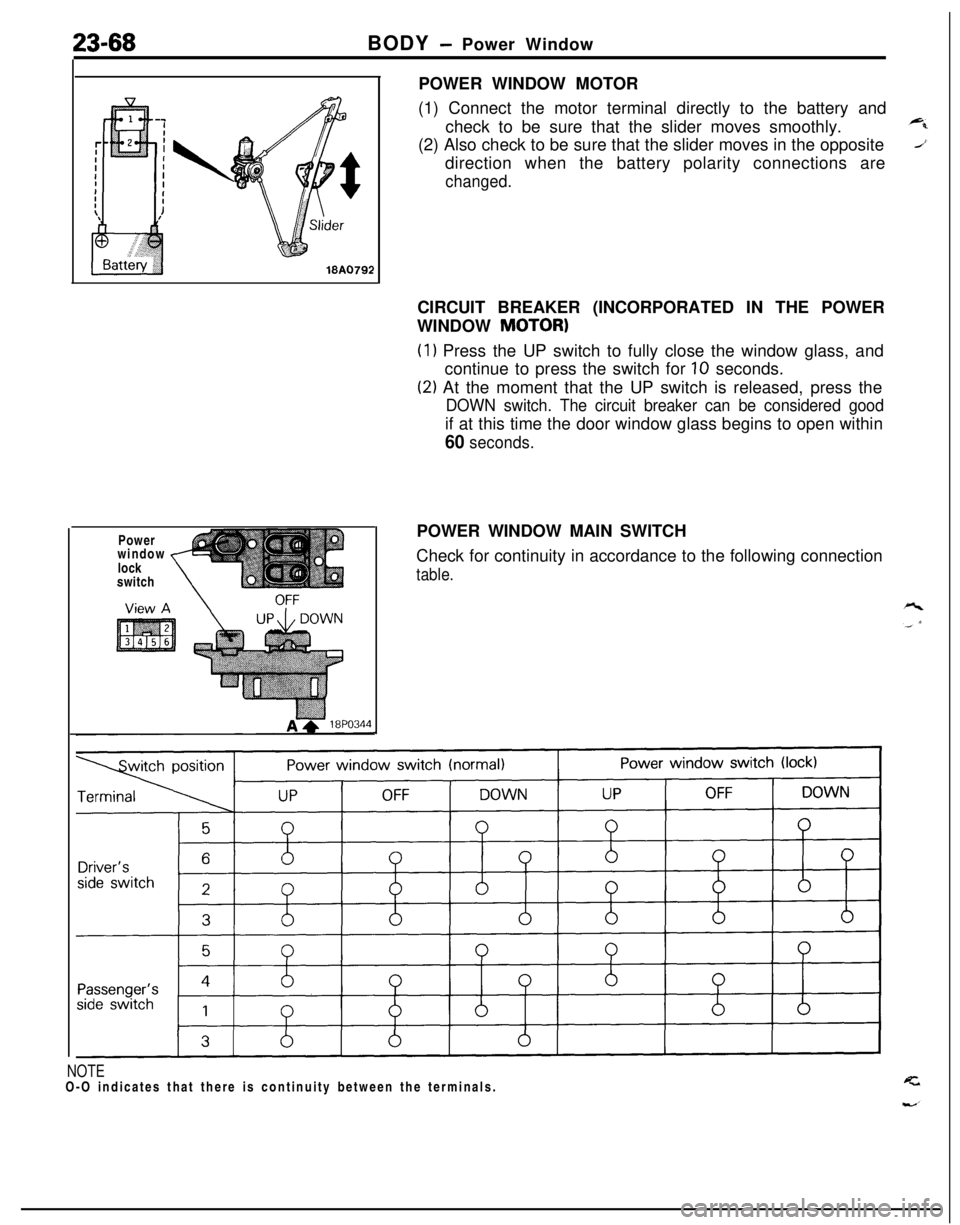

,POWER WINDOW MOTOR

(1) Connect the motor terminal directly to the battery and

check to be sure that the slider moves smoothly.

(2) Also check to be sure that the slider moves in the opposite

direction when the battery polarity connections are

changed.CIRCUIT BREAKER (INCORPORATED IN THE POWER

WINDOW

MOTOR)

(1) Press the UP switch to fully close the window glass, and

continue to press the switch for

10 seconds.

(2) At the moment that the UP switch is released, press the

DOWN switch. The circuit breaker can be considered goodif at this time the door window glass begins to open within

60 seconds.POWER WINDOW MAIN SWITCH

Check for continuity in accordance to the following connection

table.

NOTEO-O indicates that there is continuity between the terminals.

Page 1113 of 1216

BODY - Power Window/Door Handle and Latch23-69

I-

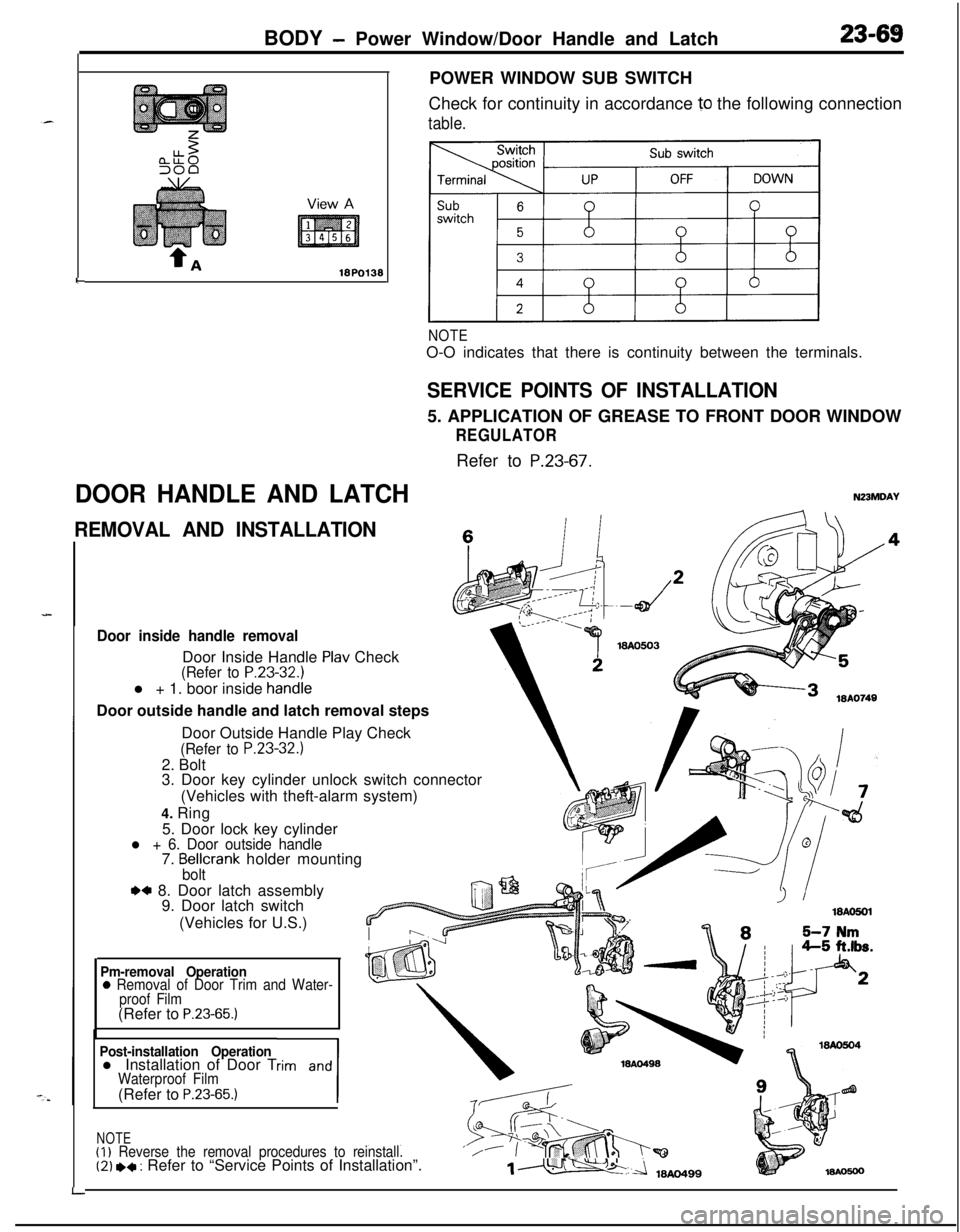

DOOR HANDLE AND LATCHPOWER WINDOW SUB SWITCH

Check for continuity in accordance

10 the following connection

table.

NOTEO-O indicates that there is continuity between the terminals.

SERVICE POINTS OF INSTALLATION5. APPLICATION OF GREASE TO FRONT DOOR WINDOW

REGULATORRefer to

P.23-67.

N23MDAY

REMOVAL AND INSTALLATIONc

Door inside handle removalDoor Inside Handle

Plav Check(Refer to P.23-32.1l + 1. boor inside

handieDoor outside handle and latch removal steps

LDoor Outside Handle Play Check

(Refer to P.23-32.)2. Bolt

3. Door key cylinder unlock switch connector

(Vehicles with theft-alarm system)

4. Ring

5. Door lock key cylinder

l + 6. Door outside handle7. Bellcrank holder mountingbolt

.a 8. Door latch assembly

9. Door latch switch

(Vehicles for U.S.)

Pm-removal Operation0 Removal of Door Trim and Water-

proof Film(Refer to

P.23-65.)

Post-installation Operationl Installation of Door Trim and

1

Waterproof Film(Refer to P.23-65.)

NOTE(I)

Reverse the removal procedures to reinstall.‘/(2) *+ : Refer to “Service Points of Installation”.1m

Page 1114 of 1216

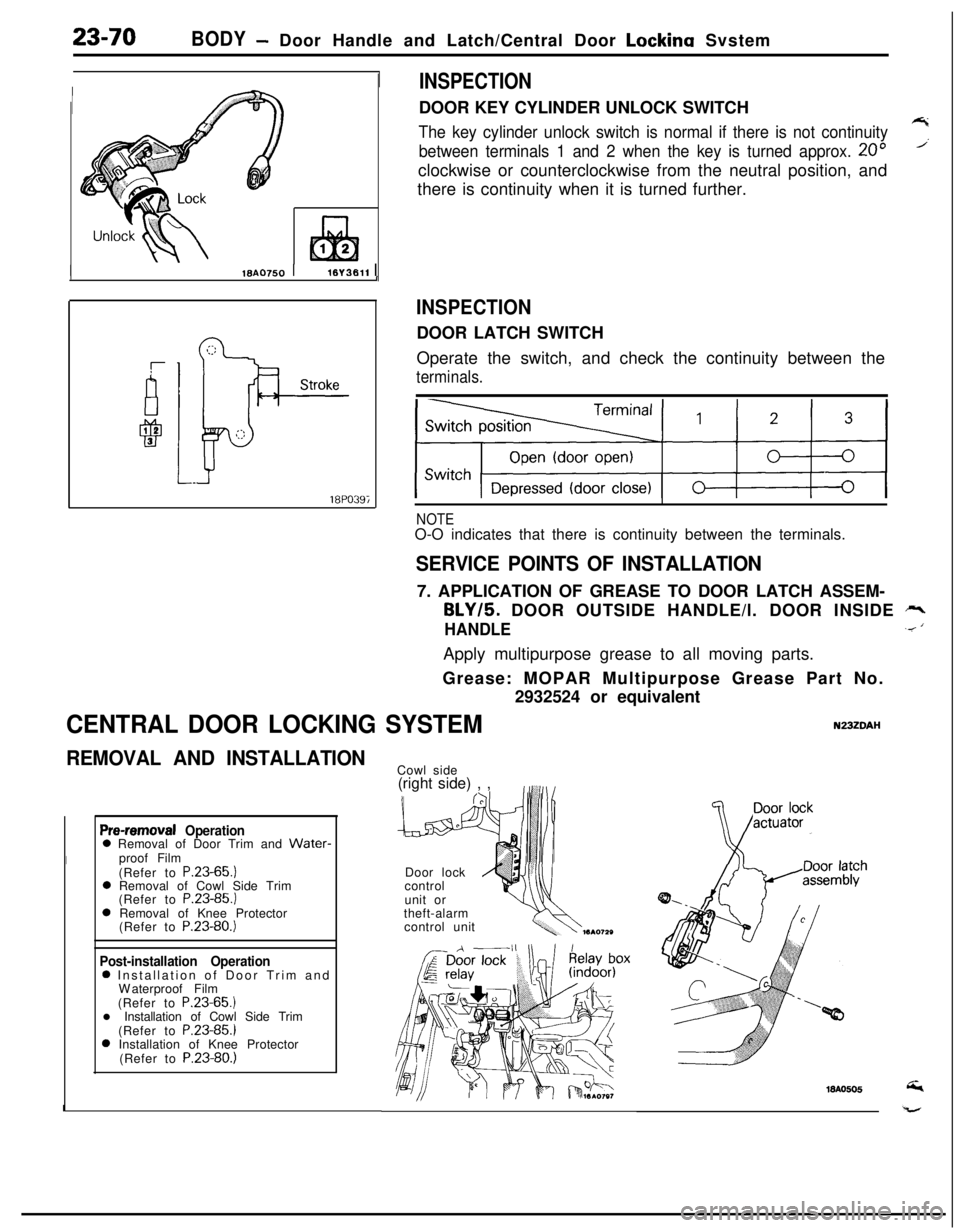

23-70BODY- Door Handle and Latch/Central Door Lockina Svstem

I18AO750 1lBY3611 I.- .--,

!-

II

T!3123

18PO39i

INSPECTIONDOOR KEY CYLINDER UNLOCK SWITCH

The key cylinder unlock switch is normal if there is not continuity7

between terminals 1 and 2 when the key is turned approx. 20”’clockwise or counterclockwise from the neutral position, and

there is continuity when it is turned further.

INSPECTIONDOOR LATCH SWITCH

Operate the switch, and check the continuity between the

terminals.

NOTEO-O indicates that there is continuity between the terminals.

SERVICE POINTS OF INSTALLATION7. APPLICATION OF GREASE TO DOOR LATCH ASSEM-

BLY/5. DOOR OUTSIDE HANDLE/l. DOOR INSIDE rr,

HANDLE.< ‘Apply multipurpose grease to all moving parts.

Grease: MOPAR Multipurpose Grease Part No.

2932524 or equivalent

CENTRAL DOOR LOCKING SYSTEMN23ZDAI-I

REMOVAL AND INSTALLATION

Pre-removal Operation0 Removal of Door Trim and Water-

Iproof Film

(Refer to P.23-65.)

0 Removal of Cowl Side Trim

(Refer to P.23-85.)

0 Removal of Knee Protector

(Refer to P.23-80.)

Post-installation Operation0 Installation of Door Trim and

Waterproof Film

(Refer to P.23-65.)

l Installation of Cowl Side Trim

(Refer to P.23-85.)

0 Installation of Knee Protector

(Refer to P.23-80.)

ICowl side

(right side) , ,

Door lock

control

unit or

theft-alarm

control unit

Page 1115 of 1216

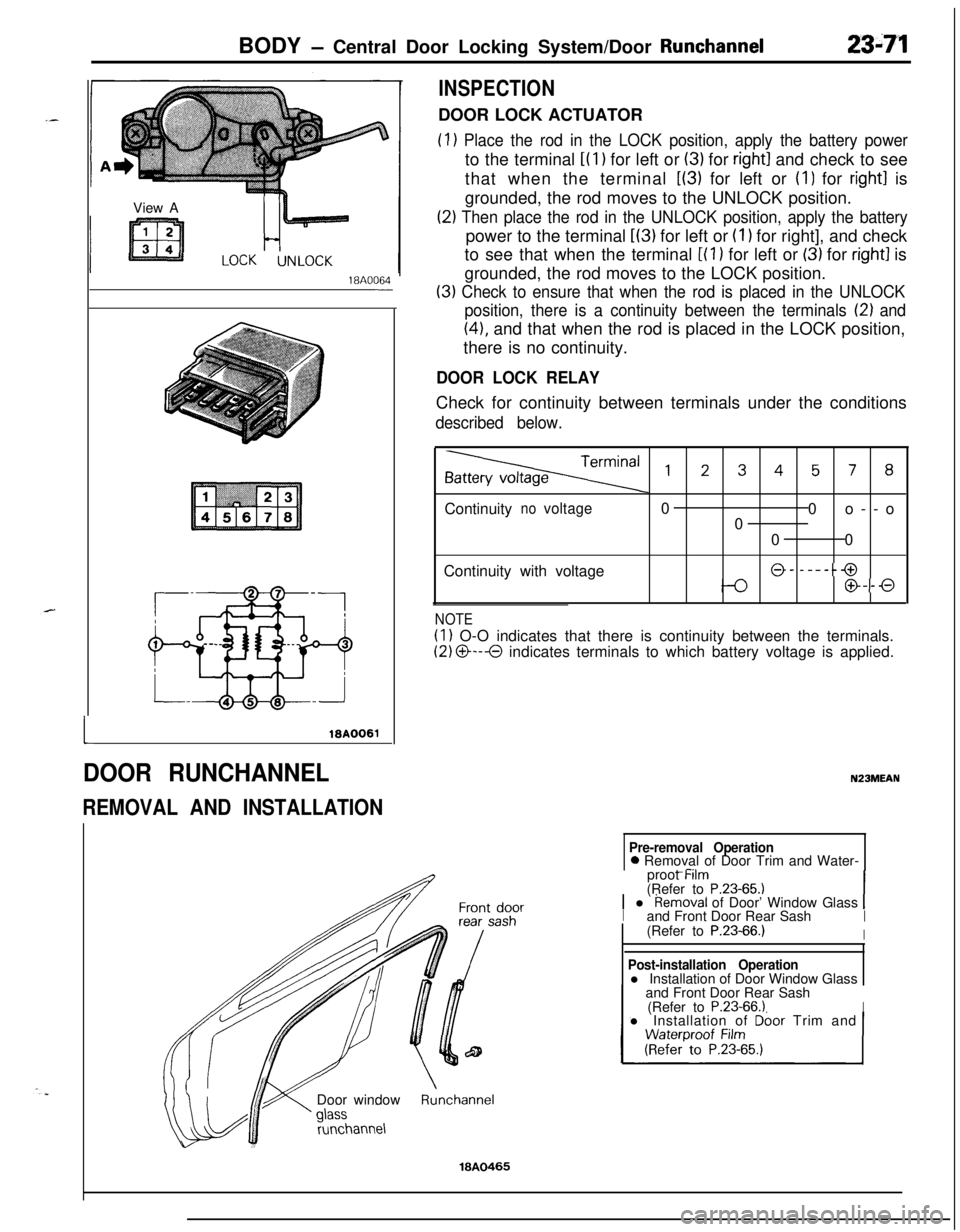

BODY - Central Door Locking System/Door Runchannel23-71View A

18A0064-

L

DOOR RUNCHANNEL

REMOVAL AND INSTALLATION

INSPECTIONDOOR LOCK ACTUATOR

(1) Place the rod in the LOCK position, apply the battery powerto the terminal

i(l) for left or (3) for right1 and check to see

that when the terminal

L(3) for left or (I) for right1 is

grounded, the rod moves to the UNLOCK position.

(2) Then place the rod in the UNLOCK position, apply the batterypower to the terminal

L(3) for left or (I 1 for right], and check

to see that when the terminal

[(l ) for left or (3) for right1 is

grounded, the rod moves to the LOCK position.

(3) Check to ensure that when the rod is placed in the UNLOCK

position, there is a continuity between the terminals

12) and

(41, and that when the rod is placed in the LOCK position,

there is no continuity.

DOOR LOCK RELAYCheck for continuity between terminals under the conditions

described below.

,2345, 8Continuity

novoltage0

0o--o

0

00

Continuity with voltage

@- -----@

@--0

NOTE

(1) O-O indicates that there is continuity between the terminals.

(2) O---O indicates terminals to which battery voltage is applied.

N23MEAN

Pre-removal Operation0 Removal of Door Trim and Water-

_ -..proot Mm

(Refer to

P.23-65.11 l Removal of Door’ Window Glass 1Iand Front Door Rear SashI(Refer to P.23-66.)IDoor window

runchannel

Post-installation Operationl Installation of Door Window Glass

and Front Door Rear Sash

(Refer to

P.23-66.1Il Installation of Dbor Trim and

Runchannel

18A0465

Page 1116 of 1216

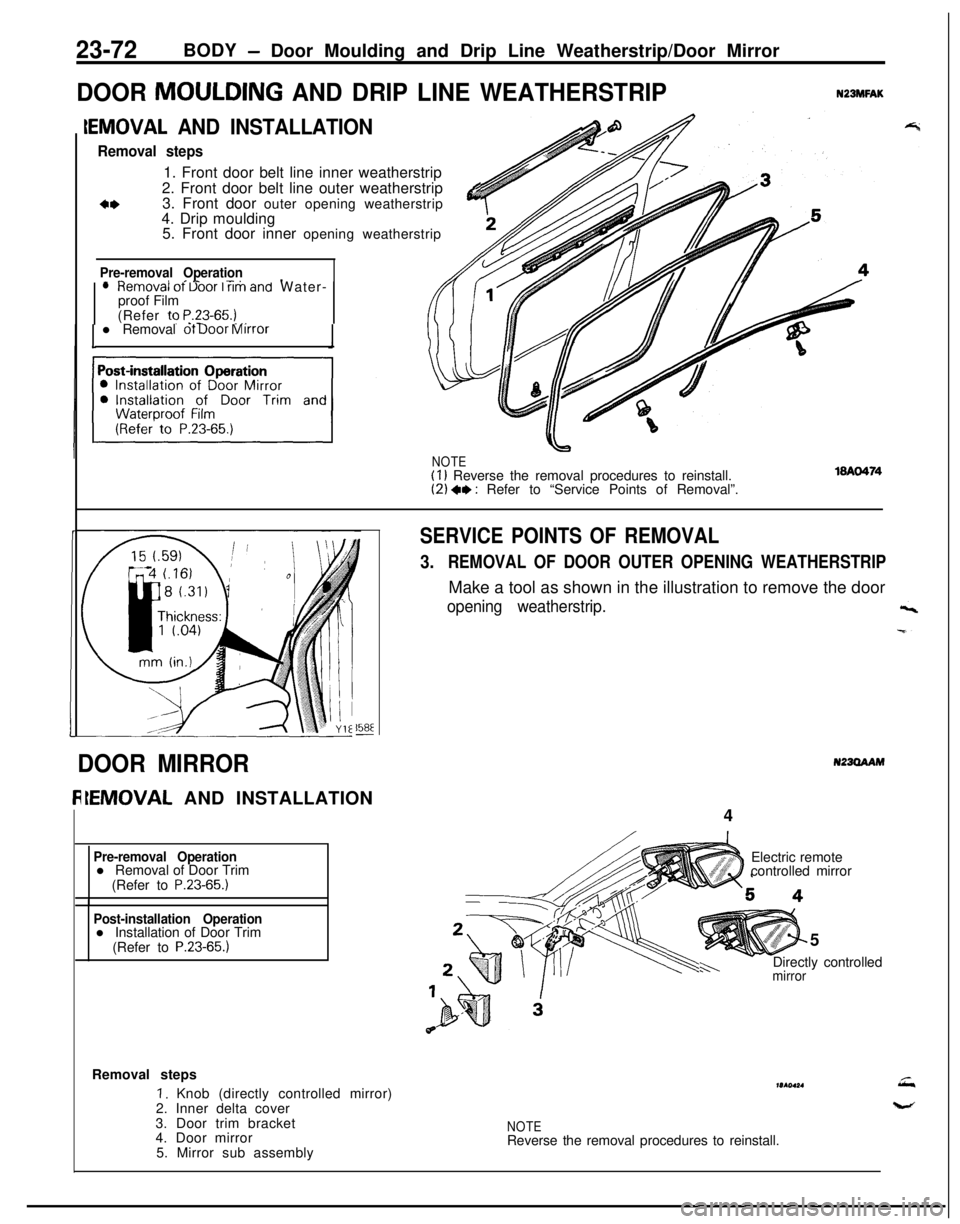

23-72BODY -Door Moulding and Drip Line Weatherstrip/Door Mirror

DOOR MOULDING AND DRIP LINE WEATHERSTRIPNZBMFAK

IEMOVAL AND INSTALLATION

Removal steps1. Front door belt line inner weatherstrip

2. Front door belt line outer weatherstrip

3. Front door outer opening weatherstrip

&4. Drip moulding

5. Front door inner opening weatherstrip

Pre-removal Operation- ^II_ -..lHemOVal ot Uoor I rim and Water-

proof Film

(Refer to

P.23-65.) _,. -l Removal ot Door Mirror

NOTE(I 1 Reverse the removal procedures to reinstall.(2) +, : Refer to “Service Points of Removal”.

158E-

SERVICE POINTS OF REMOVAL

3.REMOVAL OF DOOR OUTER OPENING WEATHERSTRIPMake a tool as shown in the illustration to remove the door

opening weatherstrip.

N23OAAMDOOR MIRROR

IEMOVAL AND INSTALLATION

4

Pre-removal Operationl Removal of Door Trim

(Refer to

P.23-65.)

Post-installation Operationl Installation of Door Trim

(Refer to

P.23-65.)5

mirrorh-.Directly controlled Electric remote

controlled mirror

Removal steps

I. Knob (directly controlled mirror)

2. Inner delta cover

3. Door trim bracket

4. Door mirror

5. Mirror sub assemblymr(ol*.

NOTEReverse the removal procedures to reinstall.

Page 1117 of 1216

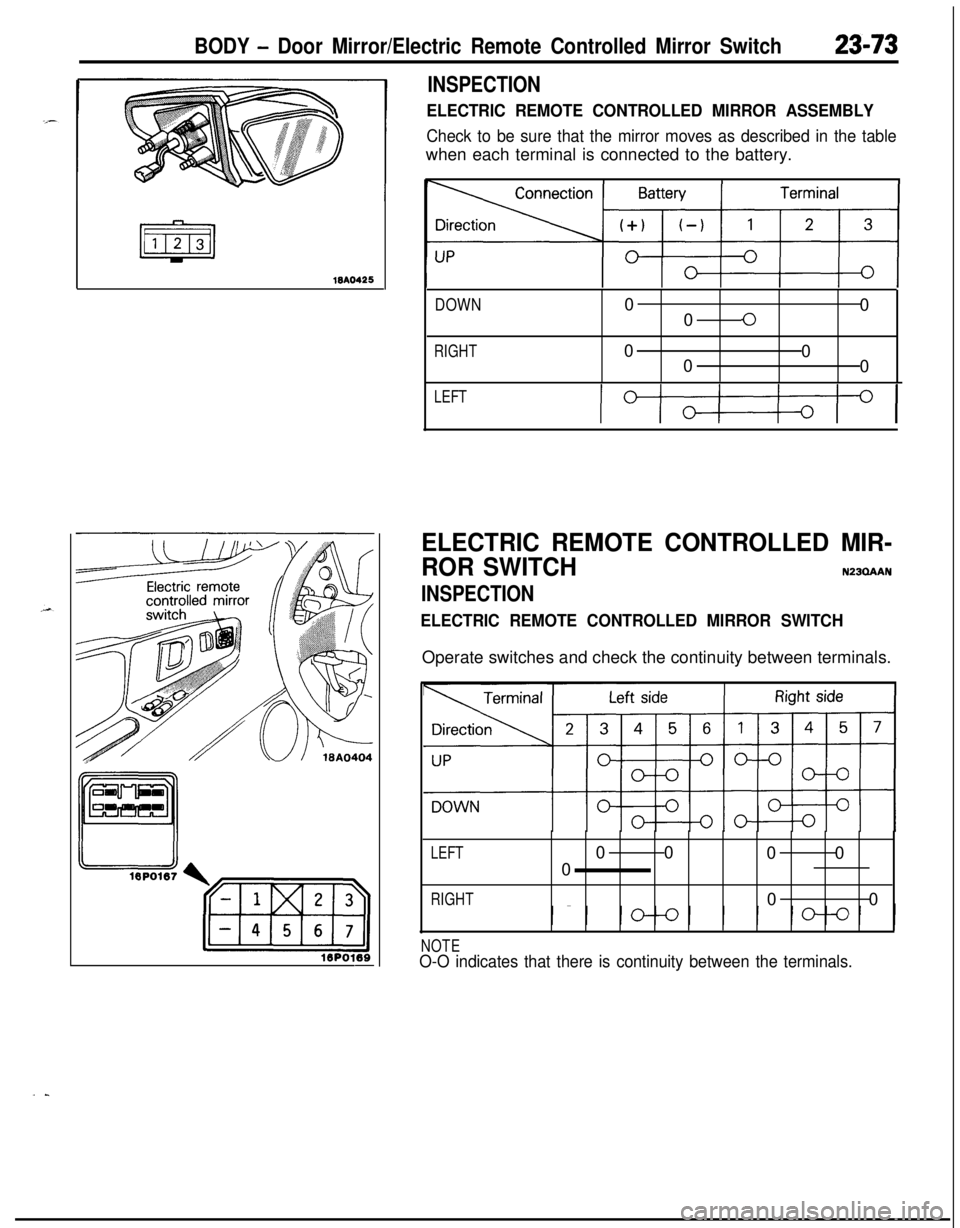

BODY - Door Mirror/Electric Remote Controlled Mirror Switch23-73

18AO425

16P0109-

INSPECTION

ELECTRIC REMOTE CONTROLLED MIRROR ASSEMBLY

Check to be sure that the mirror moves as described in the tablewhen each terminal is connected to the battery.

DOWN0

0

00

RIGHT0

0

0

0

LEFT

IOI

ELECTRIC REMOTE CONTROLLED MIR-

ROR SWITCH

N23QAAN

INSPECTION

ELECTRIC REMOTE CONTROLLED MIRROR SWITCHOperate switches and check the continuity between terminals.

LEFT00

00

0

RIGHT00

NOTEO-O indicates that there is continuity between the terminals.

..

Page 1118 of 1216

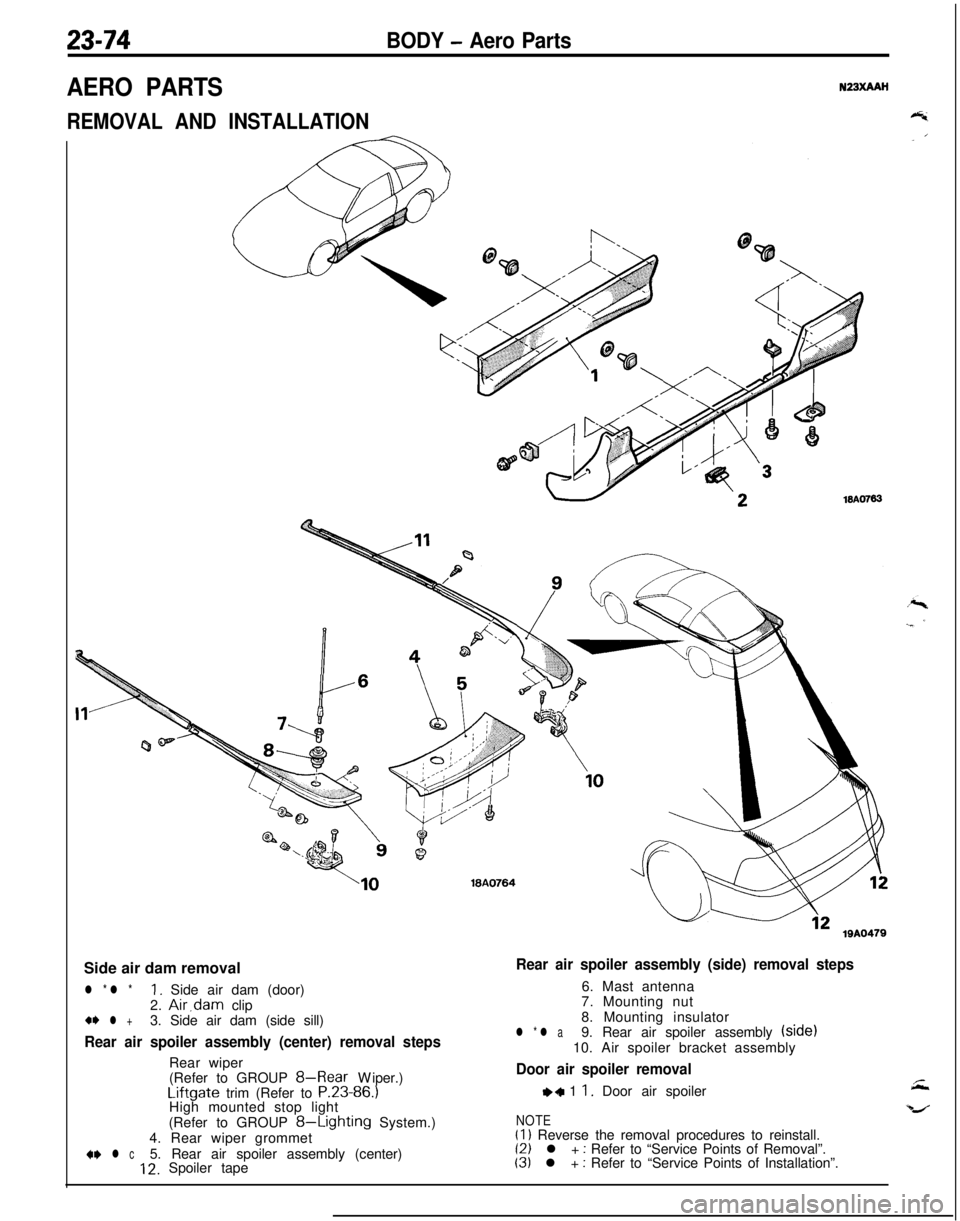

23-74BODY - Aero Parts

AERO PARTSN23XAAH

REMOVAL AND INSTALLATION

WA076318A0764

lQA0479Side air dam removal

l * l *1. Side air dam (door)

2. Air,dam clip+* l +3. Side air dam (side sill)

Rear air spoiler assembly (center) removal stepsRear wiper

(Refer to GROUP

8-Rear Wiper.)Liftgate trim (Refer to P.23-86.)

High mounted stop light

(Refer to GROUP

8-Lighting System.)

4. Rear wiper grommet

+w l c5. Rear air spoiler assembly (center)12. Spoiler tape

Rear air spoiler assembly (side) removal steps6. Mast antenna

7. Mounting nut

8. Mounting insulator

l * l a9. Rear air spoiler assembly (side)

10. Air spoiler bracket assembly

Door air spoiler removal

,+ 1 1. Door air spoiler

NOTE(1) Reverse the removal procedures to reinstall.(2) l + : Refer to “Service Points of Removal”.(3) l + : Refer to “Service Points of Installation”.

Page 1119 of 1216

BODY - Aero Parts23-75

\18A0245

16A0765

18A041618A041C

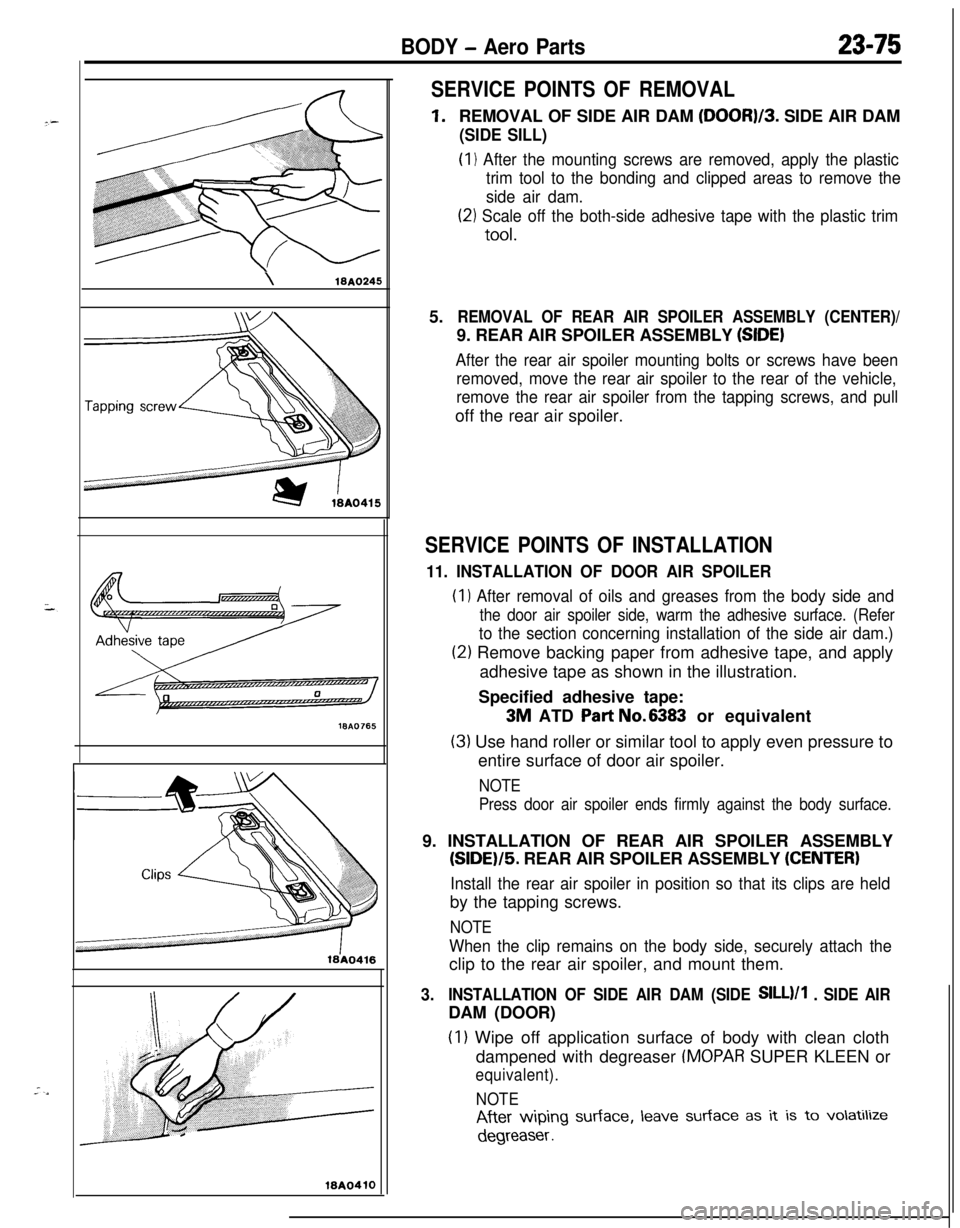

SERVICE POINTS OF REMOVAL

1.REMOVAL OF SIDE AIR DAM (DOOR)/3. SIDE AIR DAM

(SIDE SILL)(I

1 After the mounting screws are removed, apply the plastic

trim tool to the bonding and clipped areas to remove the

side air dam.

(21 Scale off the both-side adhesive tape with the plastic trim

tool.5.

REMOVAL OF REAR AIR SPOILER ASSEMBLY (CENTER)/9. REAR AIR SPOILER ASSEMBLY

(SIDE)

After the rear air spoiler mounting bolts or screws have been

removed, move the rear air spoiler to the rear of the vehicle,

remove the rear air spoiler from the tapping screws, and pulloff the rear air spoiler.

SERVICE POINTS OF INSTALLATION

11. INSTALLATION OF DOOR AIR SPOILER(I

1 After removal of oils and greases from the body side and

the door air spoiler side, warm the adhesive surface. (Refer

to the section concerning installation of the side air dam.)

(2) Remove backing paper from adhesive tape, and apply

adhesive tape as shown in the illustration.

Specified adhesive tape:

3M ATD Part No.6383 or equivalent

(3) Use hand roller or similar tool to apply even pressure to

entire surface of door air spoiler.

NOTE

Press door air spoiler ends firmly against the body surface.9. INSTALLATION OF REAR AIR SPOILER ASSEMBLY

(SIDE)/5. REAR AIR SPOILER ASSEMBLY (CENTER)

Install the rear air spoiler in position so that its clips are heldby the tapping screws.

NOTE

When the clip remains on the body side, securely attach theclip to the rear air spoiler, and mount them.

3.INSTALLATION OF SIDE AIR DAM (SIDE SILL)/1 . SIDE AIRDAM (DOOR)

(I 1 Wipe off application surface of body with clean cloth

dampened with degreaser

IMOPAR SUPER KLEEN or

equivalent).

NOTE

After wiping surface, leave surface as it is to volatilize

degreaser .

Page 1120 of 1216

23-76BODY - Aero Parts

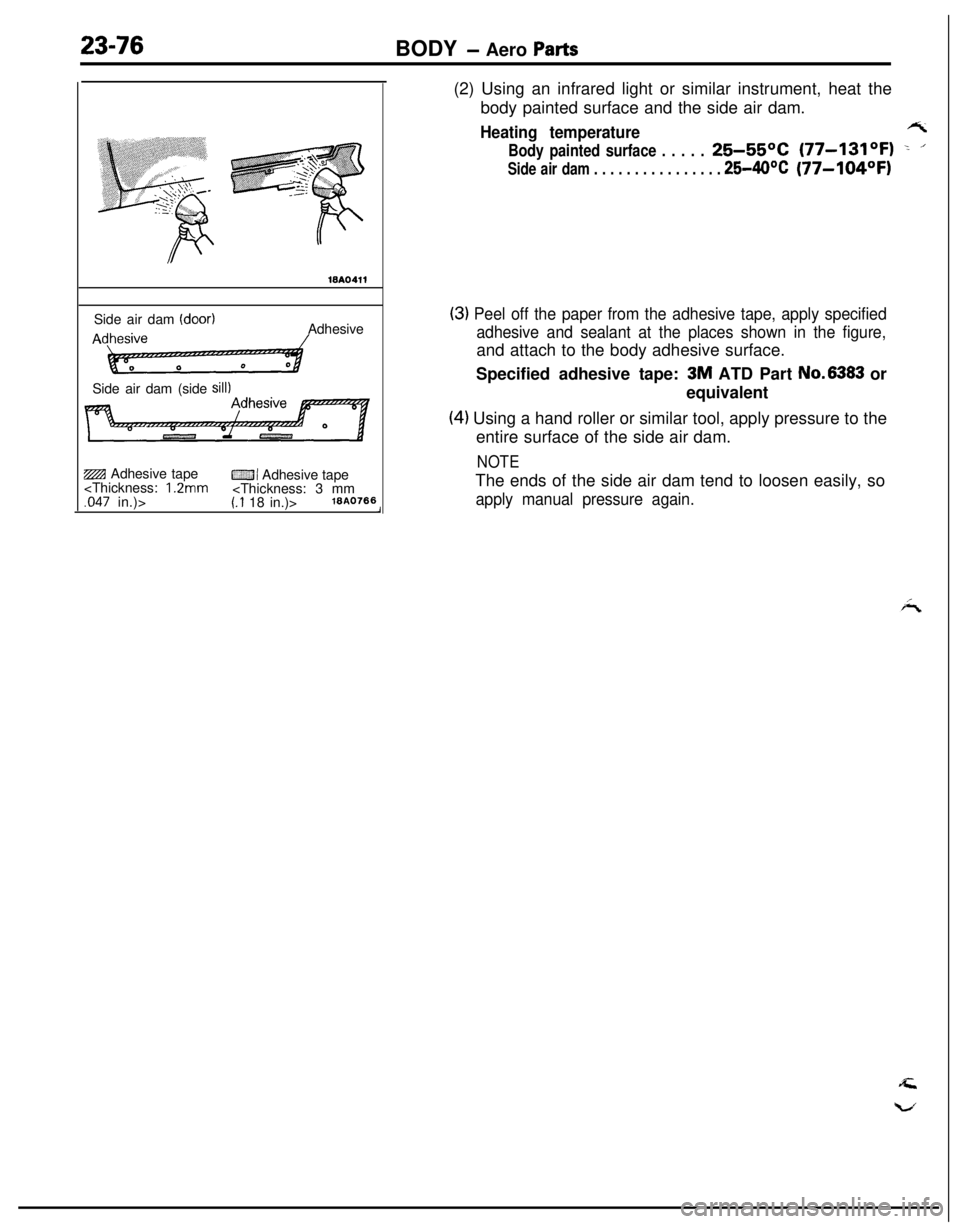

WA0411Side air dam

(door)AAdhesive

Side air dam (side

sill)ZBI Adhesive tape

CZJI Adhesive tape

body painted surface and the side air dam.

Heating temperaturert

Body painted surface . . . . .25-55OC (77-131OF) -. ’

Side air dam . . . . . . . . . . . . . . . . 25-40°C(77-104OFI

(3) Peel off the paper from the adhesive tape, apply specified

adhesive and sealant at the places shown in the figure,and attach to the body adhesive surface.

Specified adhesive tape:

3M ATD Part No.6383 or

equivalent

(4) Using a hand roller or similar tool, apply pressure to the

entire surface of the side air dam.

NOTEThe ends of the side air dam tend to loosen easily, so

apply manual pressure again.