boot MITSUBISHI ECLIPSE 1991 User Guide

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1991, Model line: ECLIPSE, Model: MITSUBISHI ECLIPSE 1991Pages: 1216, PDF Size: 67.42 MB

Page 68 of 1216

FRONT SUSPENSION - Drive Shaft

IllA0127

llE560

Grease

llE563

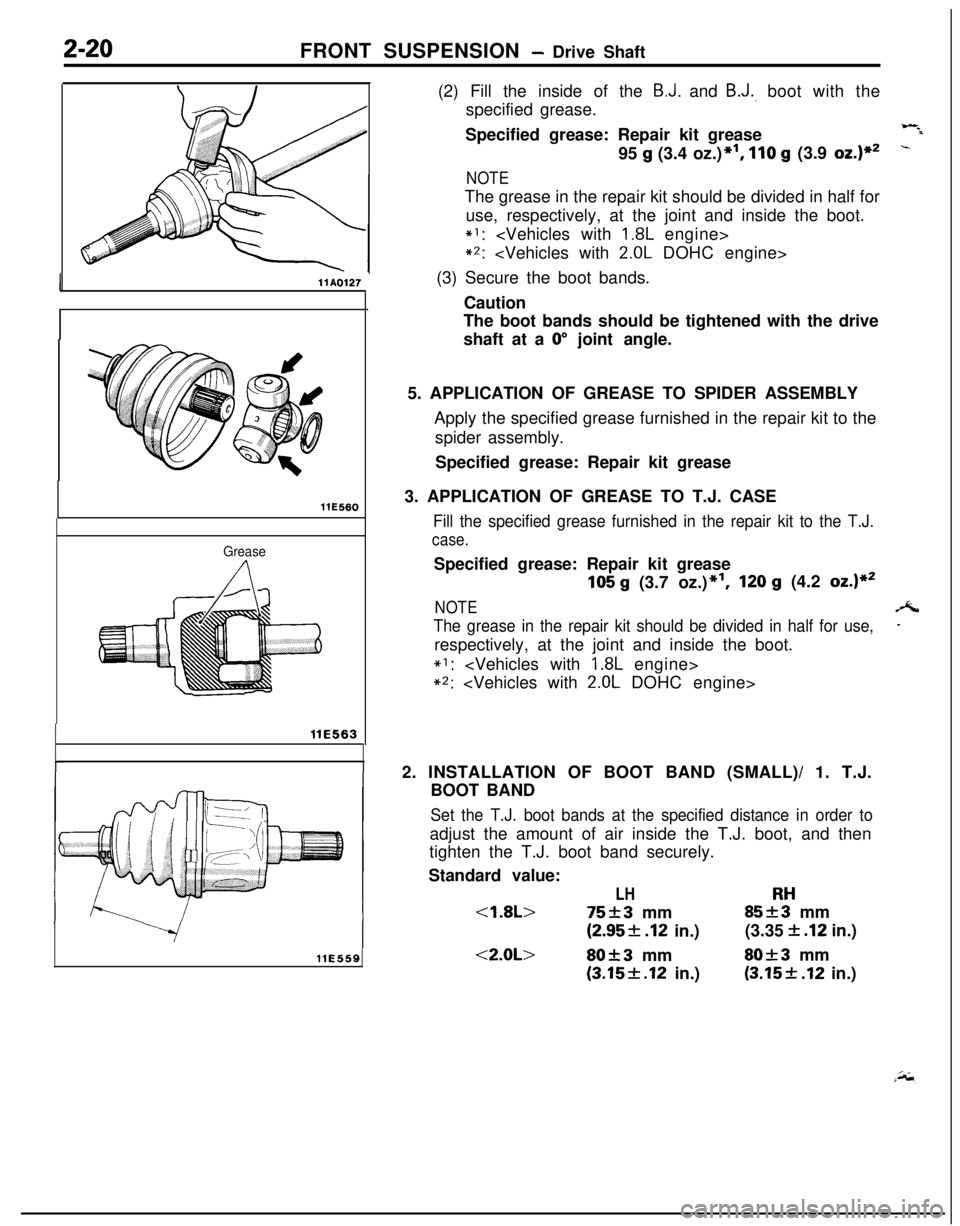

llE559(2) Fill the inside of the

B.J. and B.J., boot with the

specified grease.

Specified grease: Repair kit grease

Wil95

g (3.4 oz.)*I, 110 g (3.9 oz.)**-

NOTEThe grease in the repair kit should be divided in half for

use, respectively, at the joint and inside the boot.

*I:

*2:

(3) Secure the boot bands.

Caution

The boot bands should be tightened with the drive

shaft at a

0” joint angle.

5. APPLICATION OF GREASE TO SPIDER ASSEMBLY

Apply the specified grease furnished in the repair kit to the

spider assembly.

Specified grease: Repair kit grease

3. APPLICATION OF GREASE TO T.J. CASE

Fill the specified grease furnished in the repair kit to the T.J.

case.Specified grease: Repair kit grease

105 g (3.7 oz.)*‘I,120 g (4.2 oz.)**

NOTEA

The grease in the repair kit should be divided in half for use,-respectively, at the joint and inside the boot.

*I:

*2:

2. INSTALLATION OF BOOT BAND (SMALL)/ 1. T.J.

BOOT BAND

Set the T.J. boot bands at the specified distance in order toadjust the amount of air inside the T.J. boot, and then

tighten the T.J. boot band securely.

Standard value:

LHRH

(2.95f .I2 in.)(3.35 f .I2 in.)

<2.0L>80f3 mmSO+3 mm

(3.15f.12 in.)(3.15+ .I2 in.)

Page 69 of 1216

FRONT SUSPENSION - Drive Shaft

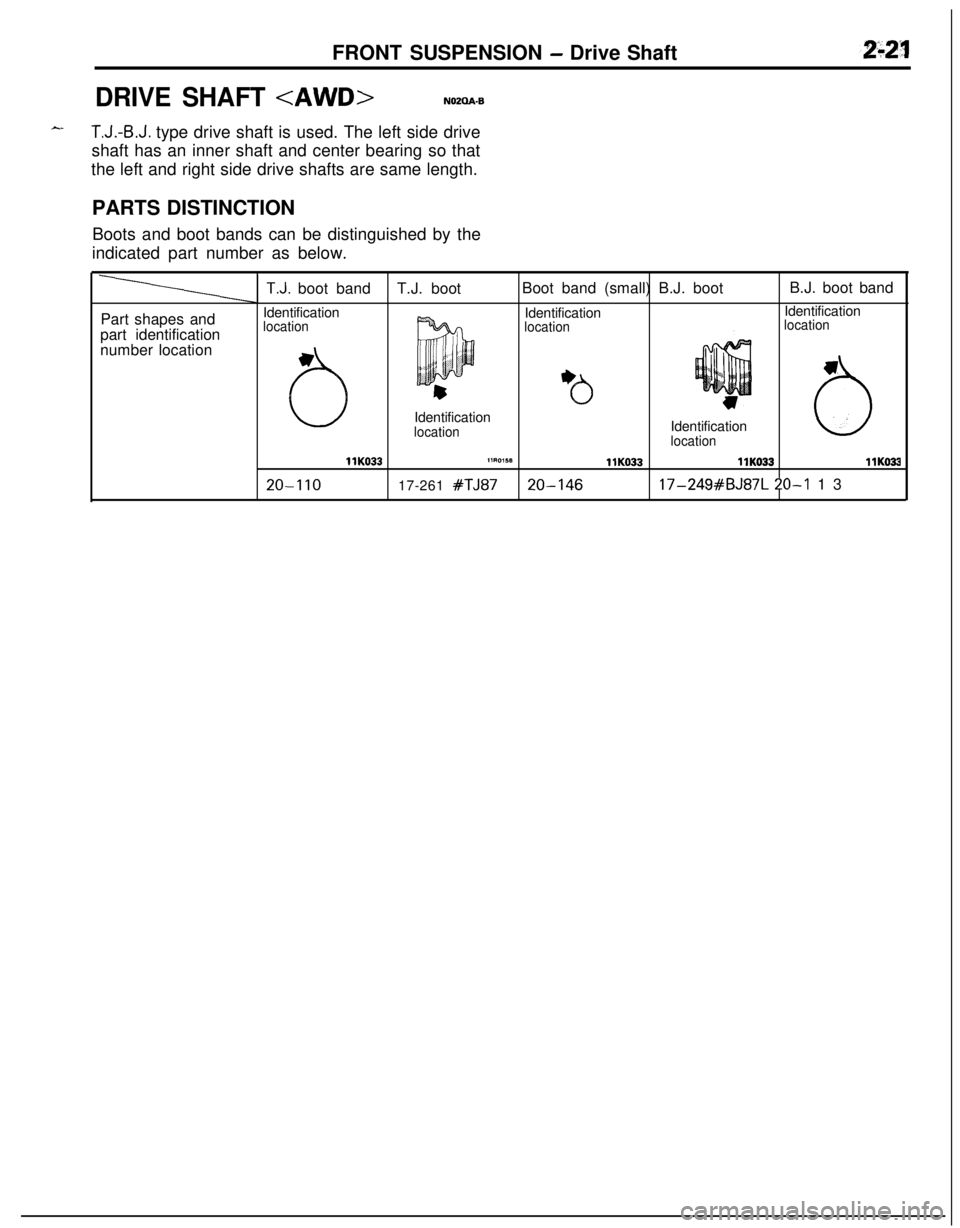

DRIVE SHAFT

T.J.-B.J. type drive shaft is used. The left side drive

shaft has an inner shaft and center bearing so that

the left and right side drive shafts are same length.

PARTS DISTINCTION

Boots and boot bands can be distinguished by the

indicated part number as below.

Part shapes and

part identification

number location

T.J. boot bandT.J. bootBoot band (small) B.J. bootB.J. boot band

Identification

IdentificationIdentification

location

locationlocation

uIdentification

locationIdentificationlocation6

llK033llRO,SBllK033llK033llKO33

20-I 1017-261 #TJ8720-14617-249#BJ87L 20-I 13

Page 71 of 1216

FRONT SUSPENSION - Drive Shaft2-23

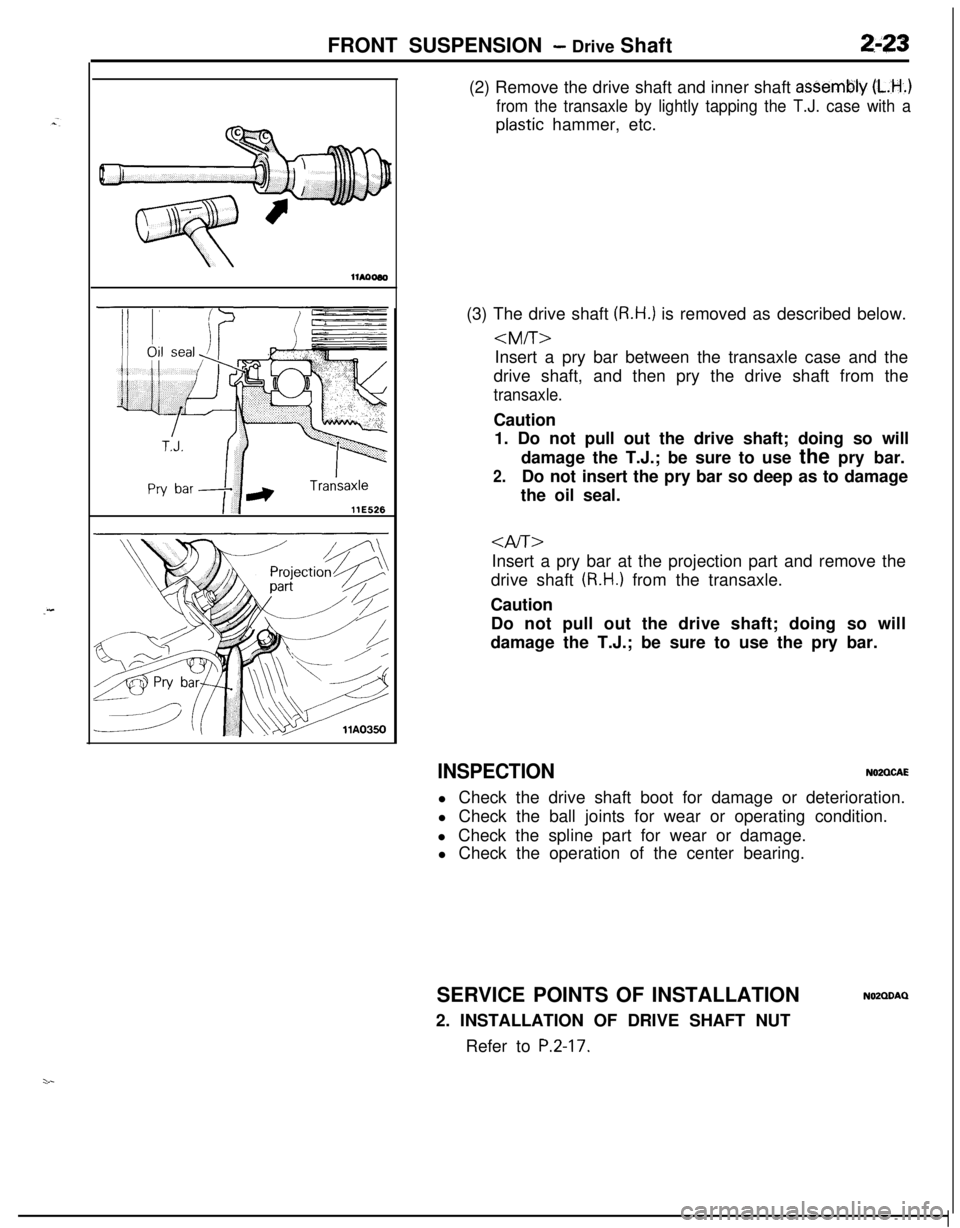

llE526(2) Remove the drive shaft and inner shaft

asSembly (L.H..)

from the transaxle by lightly tapping the T.J. case with a

plastic hammer, etc.

(3) The drive shaft

(R.H.) is removed as described below.

drive shaft, and then pry the drive shaft from the

transaxle.Caution

1. Do not pull out the drive shaft; doing so will

damage the T.J.; be sure to use the pry bar.

2.Do not insert the pry bar so deep as to damage

the oil seal.

Insert a pry bar at the projection part and remove the

drive shaft

(R.H.) from the transaxle.

Caution

Do not pull out the drive shaft; doing so will

damage the T.J.; be sure to use the pry bar.

INSPECTIONN02QCAEl Check the drive shaft boot for damage or deterioration.

l Check the ball joints for wear or operating condition.

l Check the spline part for wear or damage.

l Check the operation of the center bearing.

SERVICE POINTS OF INSTALLATION

2. INSTALLATION OF DRIVE SHAFT NUT

Refer to

P.2-17.

NOZQDAQ

Page 72 of 1216

2-24FRONT SUSPENSION - Drive Shaft

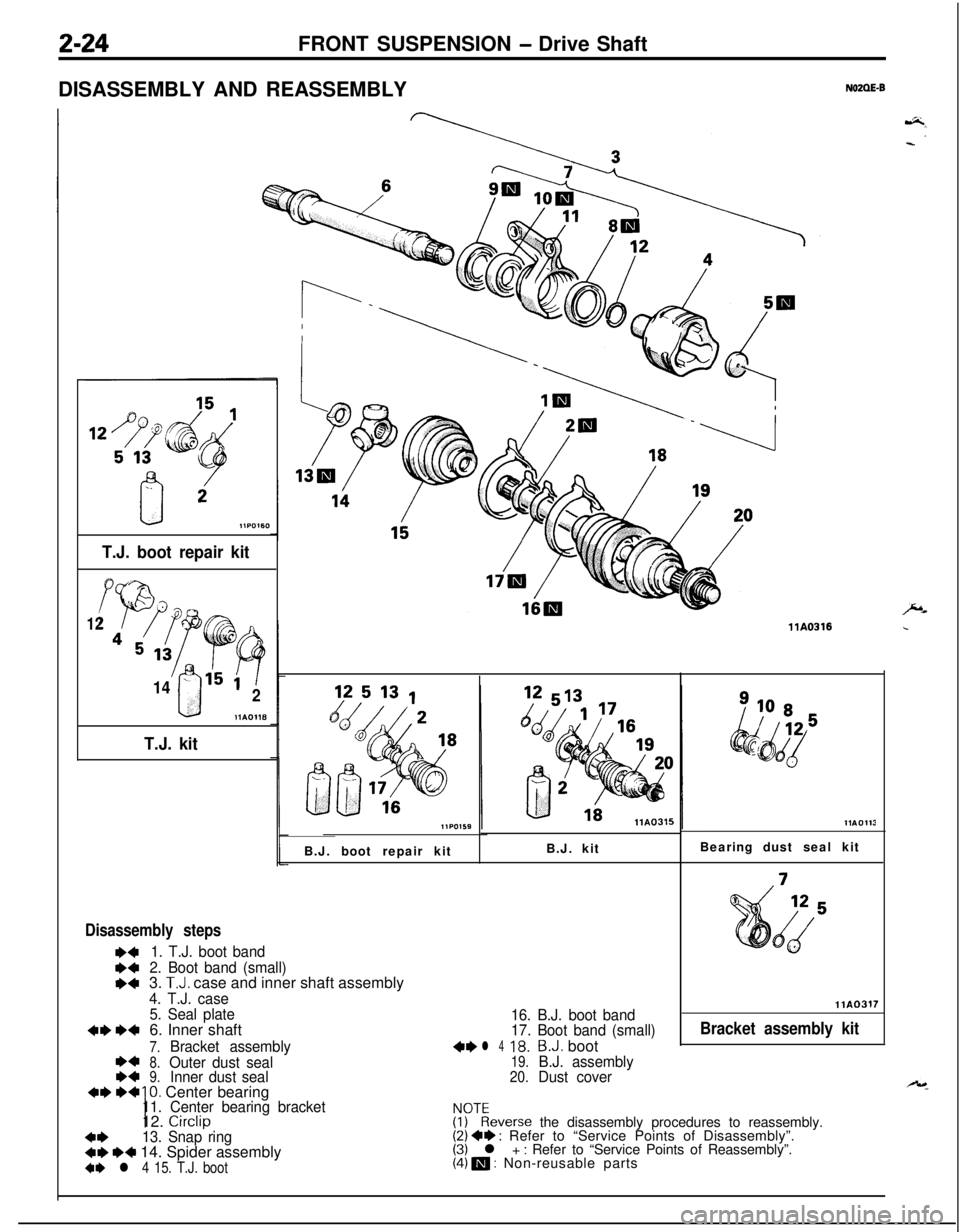

DISASSEMBLY AND REASSEMBLY

NOZQE-B

T.J. boot repair kit

d-

‘Pr12

45,3 ;c

!'F?

14- 151

0

92

11AOH8

T.J. kit

llA0316B.J. boot repair kitB.J. kit

Disassembly steps

1. T.J. boot band

2. Boot band (small)3.

T.J. case and inner shaft assembly

4. T.J. case

5. Seal plate6. Inner shaft

16. B.J. boot band

17. Boot band (small)

7.Bracket assembly+I)l 418.B.J. boot

8.Outer dust seal19.B.J. assembly9.Inner dust seal20.Dust coverBearing dust seal kit

llA0317

Bracket assembly kit

10. Center bearing11. Center bearing bracket12. Circlip

4*13. Snap ring+e e+ 14. Spider assembly4I) l 4 15. T.J. boot

FJ)TEeverse the disassembly procedures to reassembly.(2) +e : Refer to “Service Points of Disassembly”.(3) l + : Refer to “Service Points of Reassembly”.(4) m : Non-reusable parts

Page 73 of 1216

FRONT SUSPENSION - Drive Shaft2-25

T.J. caseI

\ \It/P-

IllA0092

-/ MB990938

11E561llYO97SERVICE POINTS OF DISASSEMBLY

NOZOFED6. REMOVAL OF INNER

SHAFT(1) Using the special tool, remove the inner shaft assem-

bly, together with the seal plate, from the T.J. case.

from

(2) Use the suitable puller to remove the inner shaft

the center bearing bracket.

10. REMOVAL OF CENTER BEARING

Use the special tools to remove the center bearing from thecenter bearing bracket.

ix13. REMOVAL OF SNAP

RING/l4. SPIDER ASSEMBLY

(1) Remove the snap ring from the drive shaft with the

snap ring pliers.

(2) Take out the spider assembly from the drive shaft.

(3) Clean the spider assembly.

Caution

1. Do not disassemble the spider assembly.

2.If the T.J. of the drive shaft assembly is bent, thejoint may be damaged. Use care in handling the

drive shaft.

3. The drive shaft joint use special grease. Do not

add another type of grease.

15. REMOVAL OF T.J.

BOOT/l8. B.J. BOOT

(1) Wrap vinyl tape around the spline part on the T.J. side

of the drive shaft so that the T.J. and B.J. boots are notdamaged when they are removed.

(2) Withdraw the T.J. and

B.J. boots from the drive shaft.

Caution

Do not disassemble the B.J.

Distinguish between B.J. boot and T.J. boot parts.

Page 74 of 1216

2-26FRONT SUSPENSION - Drive Shaft

llE560

INSPECTIONN02QGEB

0

0

0

0Check the dust cover for damage or deterioration.Check the drive shaft for damage, bending or corrosion.

Check the inner shaft for damage, bending or corrosion.

-Check the drive shaft spline part for wear or damage.

=-Check the inner shaft spline for wear or damage.

Check for entry of water and/or foreign material into

B-J..Check the spider assembly for roller rotation, wear or

corrosion.Check the groove inside T.J. case for wear of corrosion.

Check the boots for deterioration, damage or cracking.

Check the center bearing for seizure, discoloration or

roughness of rolling surface.

SERVICE POINTS OF REASSEMBLY

NOZQHEEa

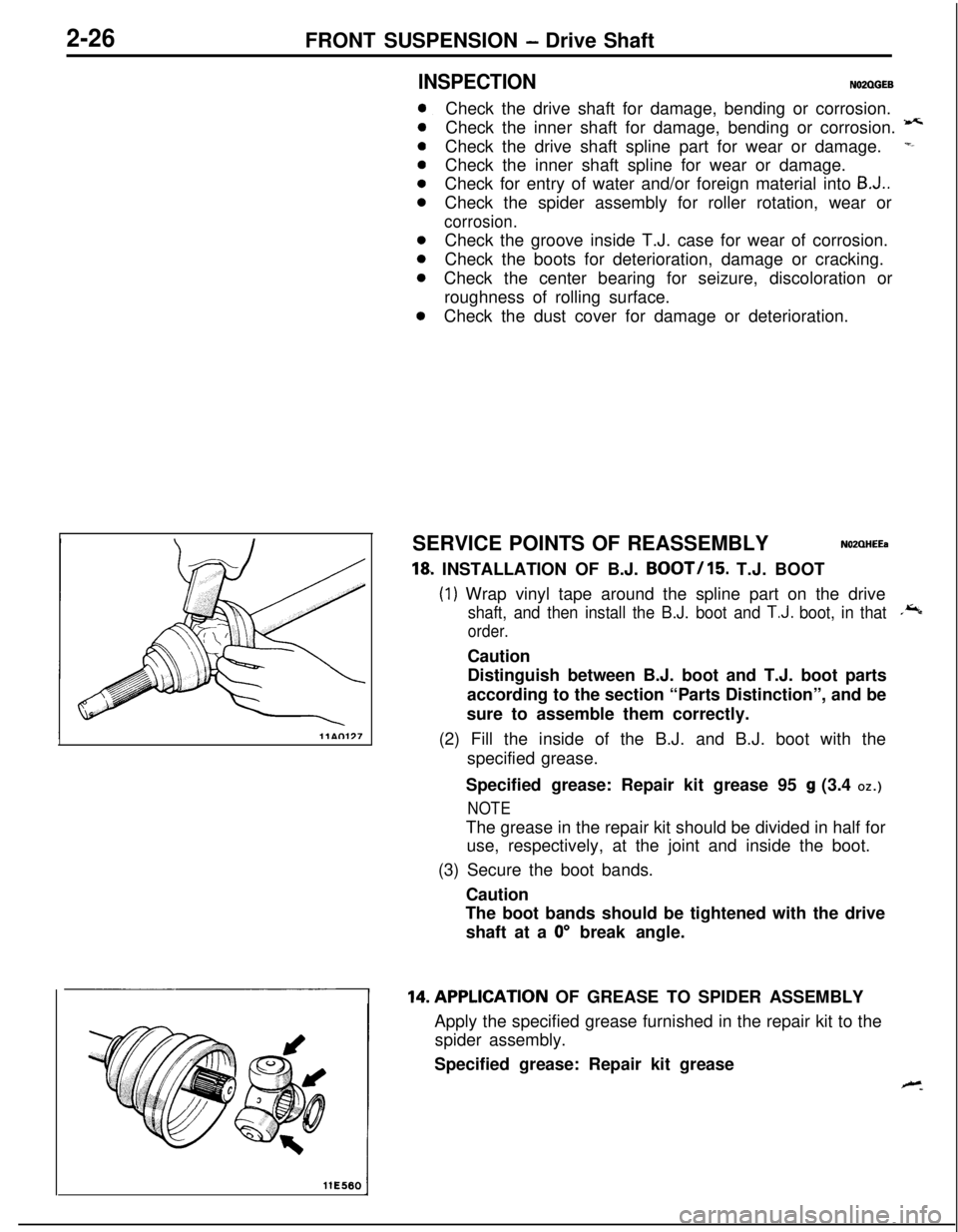

18, INSTALLATION OF B.J. BOOT/15. T.J. BOOT

(1) Wrap vinyl tape around the spline part on the drive

shaft, and then install the B.J. boot and T.J. boot, in that.*

order.Caution

Distinguish between B.J. boot and T.J. boot parts

according to the section “Parts Distinction”, and be

sure to assemble them correctly.

(2) Fill the inside of the B.J. and B.J. boot with the

specified grease.

Specified grease: Repair kit grease 95

g (3.4 OZ.)

NOTEThe grease in the repair kit should be divided in half for

use, respectively, at the joint and inside the boot.

(3) Secure the boot bands.

Caution

The boot bands should be tightened with the drive

shaft at a

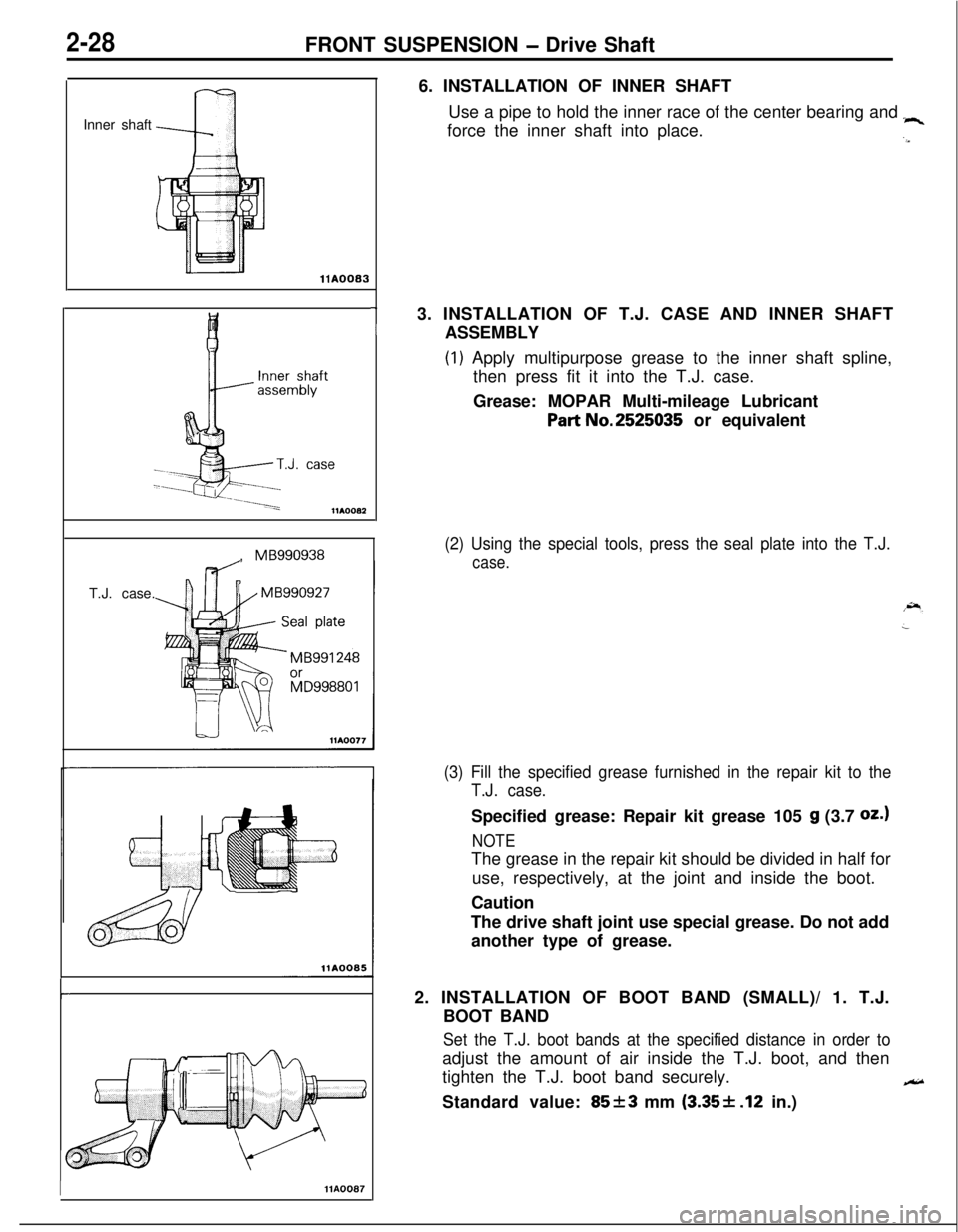

0” break angle.14.APPLlCATlON OF GREASE TO SPIDER ASSEMBLY

Apply the specified grease furnished in the repair kit to the

spider assembly.

Specified grease: Repair kit grease

Page 76 of 1216

2-28FRONT SUSPENSION - Drive Shaft

Inner shaft

llA0083

1T.J. case.,

MB9909383%QilD998801

r

IHA00876. INSTALLATION OF INNER SHAFT

Use a pipe to hold the inner race of the center bearing and

“4force the inner shaft into place.

.a3. INSTALLATION OF T.J. CASE AND INNER SHAFT

ASSEMBLY

(1) Apply multipurpose grease to the inner shaft spline,

then press fit it into the T.J. case.

Grease: MOPAR Multi-mileage Lubricant

Part No.2525035 or equivalent

(2) Using the special tools, press the seal plate into the T.J.

case.

(3) Fill the specified grease furnished in the repair kit to the

T.J. case.Specified grease: Repair kit grease 105

g (3.7 oz.1

NOTEThe grease in the repair kit should be divided in half for

use, respectively, at the joint and inside the boot.

Caution

The drive shaft joint use special grease. Do not add

another type of grease.

2. INSTALLATION OF BOOT BAND (SMALL)/ 1. T.J.

BOOT BAND

Set the T.J. boot bands at the specified distance in order toadjust the amount of air inside the T.J. boot, and then

tighten the T.J. boot band securely.

eStandard value:

85f3 mm (3.35+ .12 in.)

Page 104 of 1216

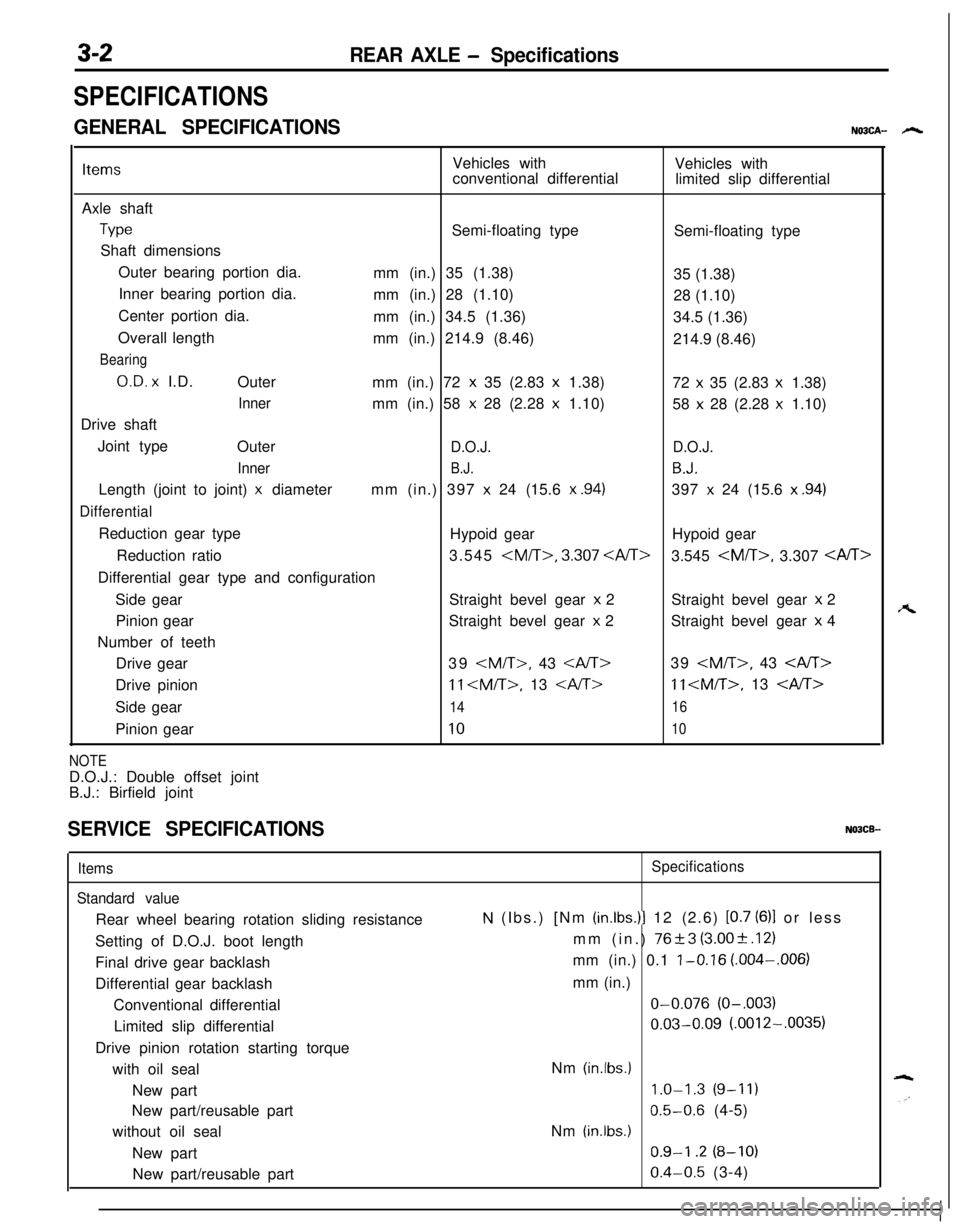

3-2REAR AXLE - Specifications

SPECIFICATIONS

GENERAL SPECIFICATIONSNO3CA- h

ItemsVehicles with

Vehicles with

conventional differential

limited slip differential

Axle shaft

TypeSemi-floating type

Semi-floating type

Shaft dimensions

Outer bearing portion dia.

mm (in.) 35 (1.38)

35 (1.38)

Inner bearing portion dia.

mm (in.) 28 (1.10)

28 (1.10)

Center portion dia.

mm (in.) 34.5 (1.36)

34.5 (1.36)

Overall length

mm (in.) 214.9 (8.46)

214.9 (8.46)

Bearing

O.D. x I.D.

Outer

mm (in.) 72 x 35 (2.83 x 1.38)

72 x 35 (2.83 x 1.38)

Innermm (in.) 58 x 28 (2.28 x 1.10)

58 x 28 (2.28 x 1.10)

Drive shaft

Joint type

Outer

D.O.J.D.O.J.

Inner

B.J.B.J.Length (joint to joint)

x diametermm (in.) 397 x 24 (15.6 x .94)397 x 24 (15.6 x .94)

DifferentialReduction gear type

Hypoid gearHypoid gear

Reduction ratio3.545

3.545

Side gearStraight bevel gear

x 2Straight bevel gear x 2

Pinion gearStraight bevel gear

x 2Straight bevel gear x 4

Number of teeth

Drive gear39

11

Side gear

1416Pinion gear

1010

NOTED.O.J.: Double offset joint

B.J.: Birfield joint

SERVICE SPECIFICATIONSNOBCB-

Items

Standard valueRear wheel bearing rotation sliding resistance

Setting of D.O.J. boot length

Final drive gear backlash

Differential gear backlash

Conventional differential

Limited slip differential

Drive pinion rotation starting torque

with oil seal

New part

New part/reusable part

without oil seal

New part

New part/reusable partSpecifications

N (Ibs.) [Nm (in.lbs.)l 12 (2.6) [0.7 (6)l or less

mm (in.)

76+3 (3.00+.12)

mm (in.) 0.1

l-0.16 (.004-,006)

mm (in.)O-0.076

(O-.003)

0.03-0.09 (.0012-.0035)

Nm

(in.lbs.)

1.0-1.3 (9-11)

0.5-0.6 (4-5)

Nm

(in.lbs.)

0.9-I .2 (8-10)

0.4-0.5 (3-4)

A

Page 105 of 1216

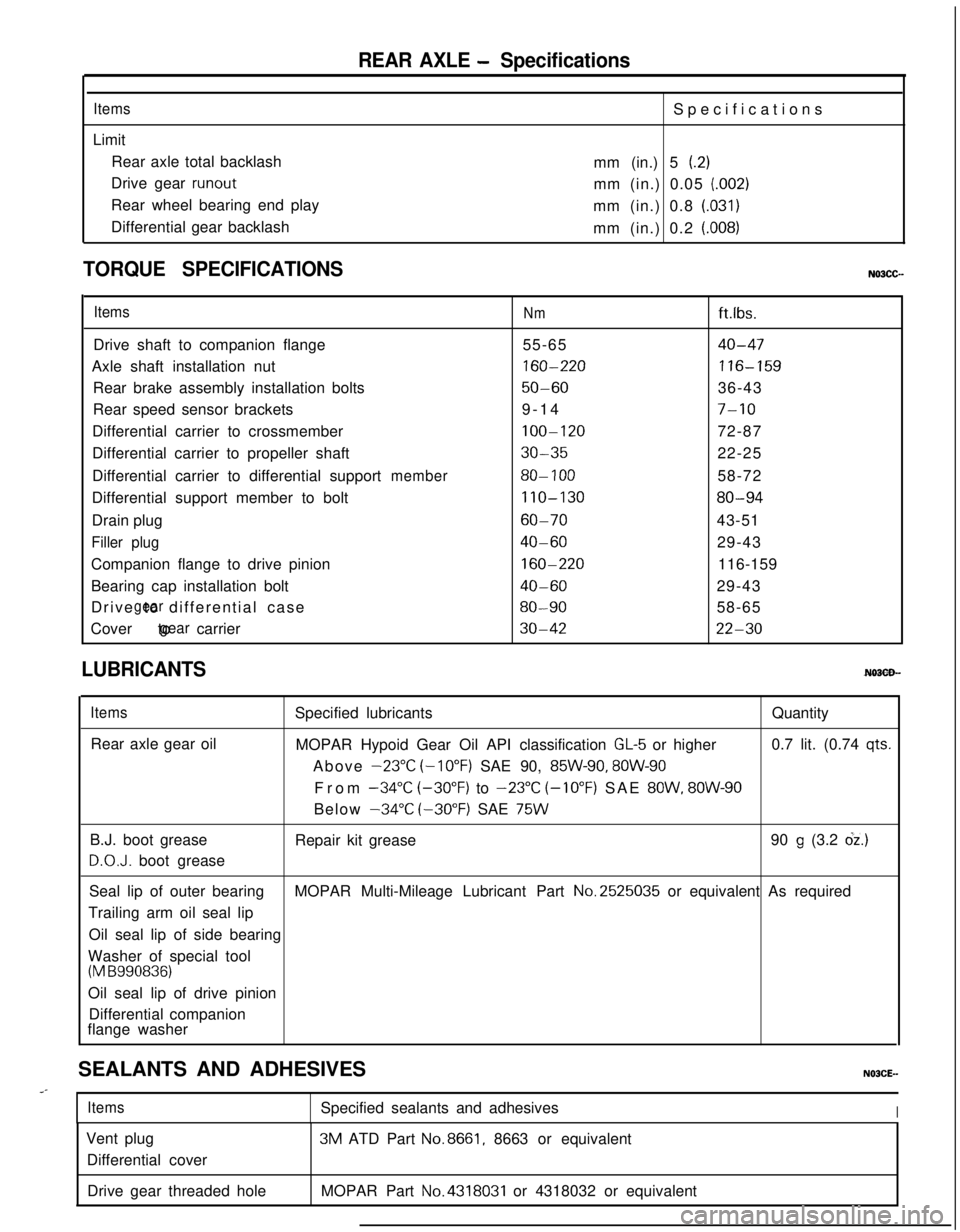

REAR AXLE - Specifications

ItemsLimit

Rear axle total backlash

Drive gear

runoutRear wheel bearing end play

Differential gear backlashSpecifications

mm (in.) 5

(.2)mm (in.) 0.05

(.002)mm (in.) 0.8

(.031)mm (in.) 0.2

(.008)

TORQUE SPECIFICATIONS

ItemsNmft.lbs.

Drive shaft to companion flange55-65

40-47Axle shaft installation nut

160-220116-159Rear brake assembly installation bolts

50-6036-43

Rear speed sensor brackets9-14

7-10Differential carrier to crossmember

100-12072-87

Differential carrier to propeller shaft

30-3522-25

Differential carrier to differential support

member80- 10058-72

Differential support member to bolt

110-13080-94Drain plug

60-7043-51

Filler plug40-6029-43

Companion flange to drive pinion

160-220116-159

Bearing cap installation bolt

40-6029-43

Drive to differential case

gear80-9058-65

Cover to carrier

gear30-4222-30

LUBRICANTS

ItemsRear axle gear oilSpecified lubricantsQuantity

MOPAR Hypoid Gear Oil API classification

GL-5 or higher0.7 lit. (0.74 qts.Above

-23°C (-10°F) SAE 90, 85W-90, 8OW-90From

-34°C (-30°F) to -23°C (-10°F) SAE 8OW, 8OW-90Below

-34°C (-30°F) SAE 75WB.J. boot grease

D.O.J. boot greaseRepair kit grease90

g (3.2 dz.)Seal lip of outer bearingMOPAR Multi-Mileage Lubricant Part No.2525035 or equivalent As required

Trailing arm oil seal lip

Oil seal lip of side bearing

Washer of special tool

(M B990836)Oil seal lip of drive pinion

Differential companion

flange washer

SEALANTS AND ADHESIVES

..-

ItemsSpecified sealants and adhesivesIVent plug

Differential cover3M ATD Part

No.8661, 8663 or equivalent

Drive gear threaded holeMOPAR Part

No.4318031 or 4318032 or equivalent

Page 115 of 1216

REAR AXLE - Axle Shaft/Drive Shaft3-13

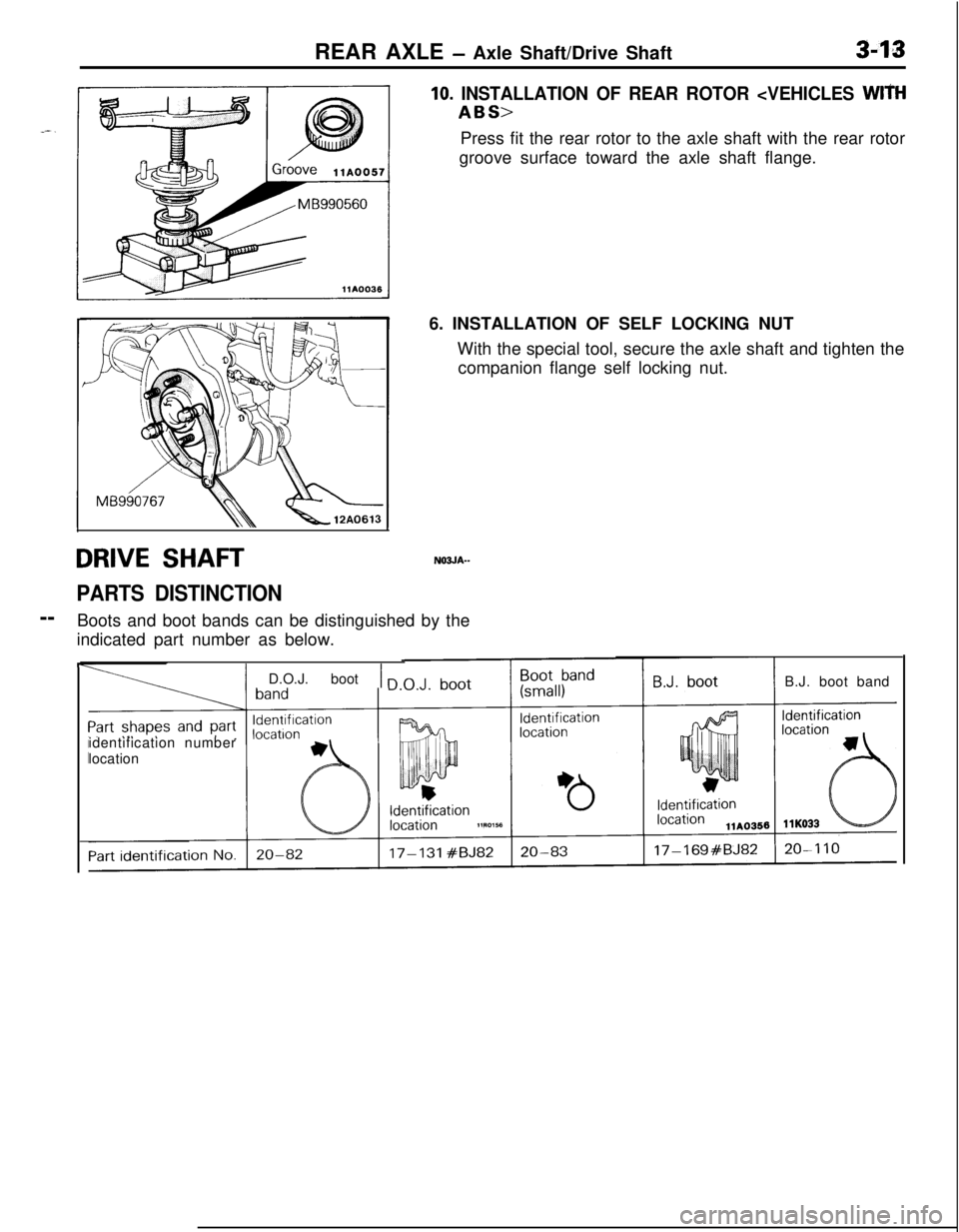

DRIVE SHAFTN03JA--

PARTS DISTINCTION--

Boots and boot bands can be distinguished by the

indicated part number as below.

10. INSTALLATION OF REAR ROTOR

groove surface toward the axle shaft flange.

6. INSTALLATION OF SELF LOCKING NUT

With the special tool, secure the axle shaft and tighten the

companion flange self locking nut.

F

I

IIidentification number

location

1 D.O.J. boot 1 nB.J. boot band