engine MITSUBISHI ECLIPSE 1991 Service Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1991, Model line: ECLIPSE, Model: MITSUBISHI ECLIPSE 1991Pages: 1216, PDF Size: 67.42 MB

Page 612 of 1216

17-2REAR SUSPENSION

GENERAL SPECIFICATIONS

LN17CAA

ItemsVehicles with 1.8L EngineVehicles with 2.0L DOHC

Engine

jSuspension system

3-link, torsion axle with coil spring type

Coil spring

Wire dia.

x O.D. x free length

mm (in.) 10.1 x 105.1 x 336.510.2 x 105.2 x 316.5

(40 x 4.14 x 13.25)(40 x 4.14 x 12.46)

[Coil spring identification color]

[Light Blue

x 11[Orange x 11Spring constant

N/mm

(Ibs./in.) 20 (112.0)23 (128.8)

Shock absorber

TypeHydraulic, cylindrical, double-acting type

Max. length

mm (in.) 495 (19.5)485 (19.1)

Min. length

mm (in.) 315 (12.4)315 (12.4)

Strokemm (in.) 180 (7.1)170 (6.7)Damping force [at 0.3 m/set. (0.9

ft./set.)]

ExpansionN (Ibs.)800 (176)

ContractionN (Ibs.)300 (66)

Wheel bearing

TypeUnit ball bearing

SERVICE SPECIFICATIONS

Items

Standard valueToe-in (Left-right difference)

Camber

LimitWheel bearing end play

Rear hub rotary-sliding resistance

Rear hub rotary-sliding torque

NOTEToe-in and camber cannot be adjusted.mm (in.)

mm (in.)

N (Ibs.)

Nm

(ftlbs.)

TORQUE SPECIFICATIONS

Specifications

0+3 (Of.1 18)

-45’

f 30’

0.01 (004) or less

31

(7) or less

1.8

(1.30) or lessNI’ICB-A

ItemsNmft.lbs.

Wheel bearing nut

Shock absorber upper mounting nut

Shock absorber lower mounting nut

Lateral rod mounting nut (body side)

Lateral rod mounting bolt (axle beam side)

Trailing arm mounting bolt

Piston rod tightening nut

Brake hose and tube bracket mounting bolt

Caliper assembly mounting nut

Rear speed sensor mounting bolt

200-260

40-50

80- 100

80-100

100-120

100-120

20-2517-26

50-609-14144-188

29-36

58-72

58-72

72-87

72-87

14-18

12-19

36-43

I7-10

Nl7CGA

Page 650 of 1216

19-2STEERING - Specifications

SPECIFICATIONS

GENERAL SPECIFICATIONS

ItemsSteering wheel

Steering wheel O.D.mm (in.)

Gear boxSteering gear type

Power steering oil pump

Oil pump type

Displacementcm3/rev. (cu.in./rev.)

Relief set pressureMPa (psi)

SERVICE SPECIFICATIONS

MANUAL STEERING

Items

Standard value

Steering angleInner wheel

Outer wheel

Tie rod end ball joint starting torqueNm

(in.lbs.)Assembly dimension of lower column tubemm (in.)

Total pinion torqueNm

(in.lbs.)From

O-90”From

90”-650”Tie-rod joint swing resistance

N (Ibs.)Tie-rod joint swing torque

Nm

(in.lbs.)

LimitSteering wheel free play

mm (in.)

Variation of tie rod end ball joint shaft directionmm (in.)

POWER STEERING

Items

Standard valueSteering wheel free play (with engine stopped)

mm (in.

Steering angle

Turbo

Inner wheel

Outer wheel

Other models

Inner wheel

Outer wheel

Tie rod end ball joint starting torque

Nm

(in.lbs.)Stationary steering effort

N (Ibs.)Assembly dimension of lower column tube

mm (in.)

V-belt deflection

mm (in.)

NlSCA--

Specifications372 (14.6)

Rack and pinion

Vane type

9.6 t.59)

8 (1,138)NlSCB-

Specifications37000’

* 20

3OOOO’

0.5-2.5 (4-22)

24.8-25.2

(.98-,991

0.6-l .3 (5-l 1 I

0.2-l .o (2-9)

8-20 (I .8-4.4)2-5

(17-43)30 (1.2)

1.5 l.059)

Specifications

11

(.43)

31"30'+2"

27"OO'

35"00'f2"

29"20'

0.5-2.5 (4-22)

37 (8) or less

24.8-25.2

(.98-.99)6-9 (.24-.35)

Page 652 of 1216

19-4STEERING - Specifications

ItemsNmIft.lbs.Power steering gear box

Joint assembly

Pressure hose to gear box

Return tube to gear box

Tie rod end to knuckle

Stay to crossmember

Stabilizer bar bracket

Front roll stopper insulator nut

Centermember to body

Front exhaust pipe to rubber hanger

Front exhaust pipe mounting bolt

Front exhaust pipe mounting nut

Tie rod end lock nut

Tie rod to rack

Feed tubes

End plugPinion and valve assembly to self-locking nut

Rack support cover locking nut

Valve housing installation bolts

Power steering oil pump

Pressure hose to oil pump

Oil pump to oil pump bracket

Heat protector installation nut

Oil pump bracket to engine

1.8L Engine

Front side

Left side2.0L DOHC Engine

Oil reservoir installation bolt

Oil reservoir bracket installation bolt

Pump cover to pump body

Suction connector to pump body

Connector to pump body

Terminal assembly to pump body

ower steering hoses

Cooler tube to body

Cooler tube to hood lock stay

Cooler tube clamp

Return tube to body

Pressure tube to gear box

Return tube to gear box

Pressure hose to body

Pressure hose to oil pump

Pressure hose to pressure tube

Pressure hose bracket11-14

9-13

9-13

17-25

51-58

22-3036-47

58-72

7-11

22-29

22-29

43-58

36-4058-72

9-13

36-51

14-22

36-51

12-19

15-2012-18

12-18

24-34

70-80

30-42

50-65

80-100

10-15

30-40

30-40

60-80

50-55

80-10012-18

50-70

20-30

50-7017-26

14-21

10-1535-45

25-33

9-14

7-1027-41

20-3025-33

18-24

25-33

18-24

9-14

7-109-14

7-1018-22

13-16

6-104-7

50-7036-51

25-3018-22

9-14

7-104-6

29-43

3.0-4.5'2-3

9-14

7-1012-18

9-13

12-18

9-13

9-14

7-1014-21

IO-15

30-4022-29

9-14

7-10

Page 658 of 1216

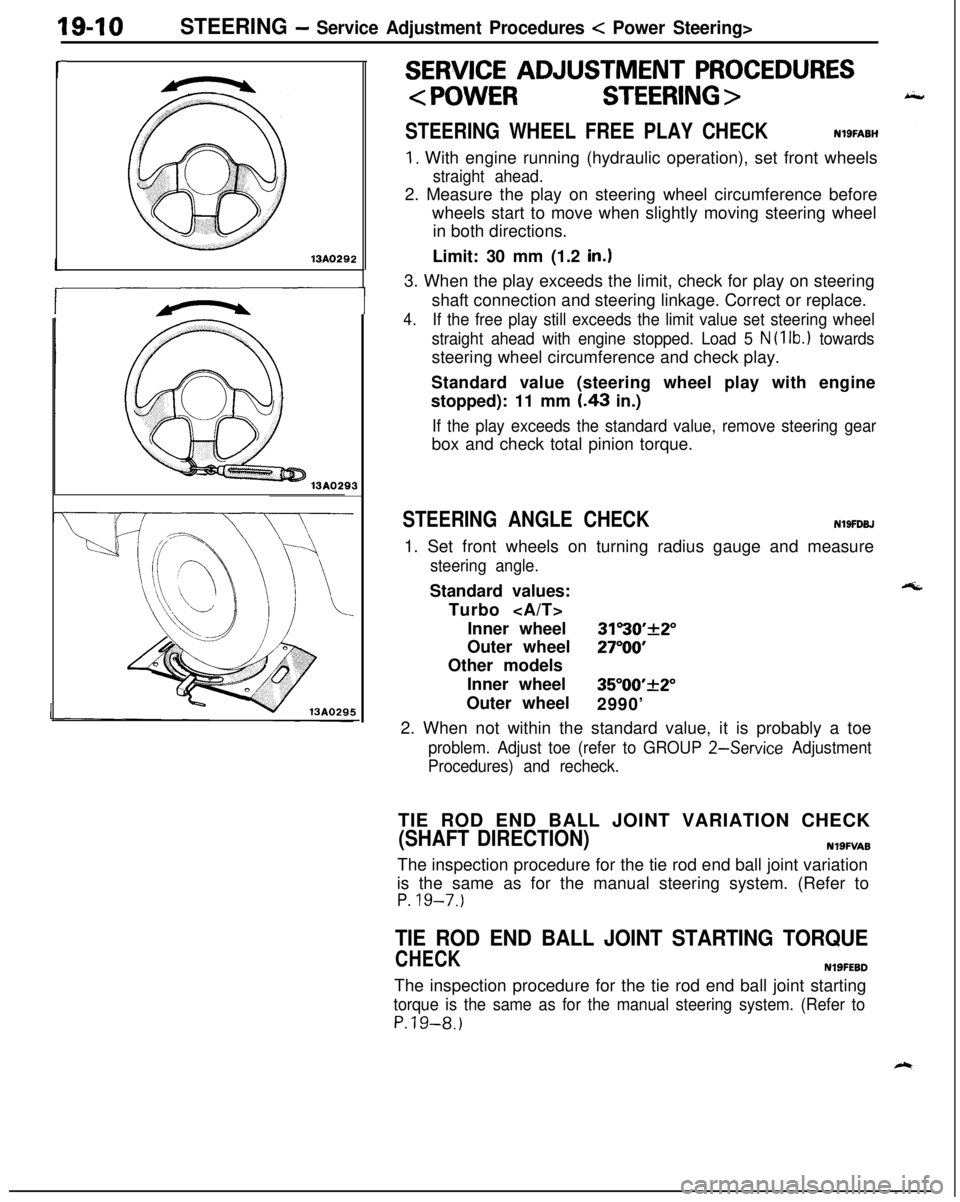

19-10STEERING - Service Adjustment Procedures c Power Steering>

r13A029213A0293

r

1

i

SERVICE ADJUSTMENT PROCEDURES

STEERING WHEEL FREE PLAY CHECKNlSFABH

1. With engine running (hydraulic operation), set front wheels

straight ahead.2. Measure the play on steering wheel circumference before

wheels start to move when slightly moving steering wheel

in both directions.

Limit: 30 mm (1.2

in.13. When the play exceeds the limit, check for play on steering

shaft connection and steering linkage. Correct or replace.

4.If the free play still exceeds the limit value set steering wheel

straight ahead with engine stopped. Load 5

N (1 lb.1 towardssteering wheel circumference and check play.

Standard value (steering wheel play with engine

stopped): 11 mm

I.43 in.)

If the play exceeds the standard value, remove steering gearbox and check total pinion torque.

STEERING ANGLE CHECKN19FDBJ1. Set front wheels on turning radius gauge and measure

steering angle.Standard values:

Turbo

Inner wheel

31”30’+2”Outer wheel

27”OOOther models

Inner wheel

35”00’_+2”Outer wheel

2990’

2. When not within the standard value, it is probably a toe

problem. Adjust toe (refer to GROUP 2-Service Adjustment

Procedures) and recheck.TIE ROD END BALL JOINT VARIATION CHECK

(SHAFT DIRECTION)N19FVA8The inspection procedure for the tie rod end ball joint variation

is the same as for the manual steering system. (Refer to

P. 19-7.)

TIE ROD END BALL JOINT STARTING TORQUE

CHECKNlSFEBDThe inspection procedure for the tie rod end ball joint starting

torque is the same as for the manual steering system. (Refer to

P.19-8.)

Page 659 of 1216

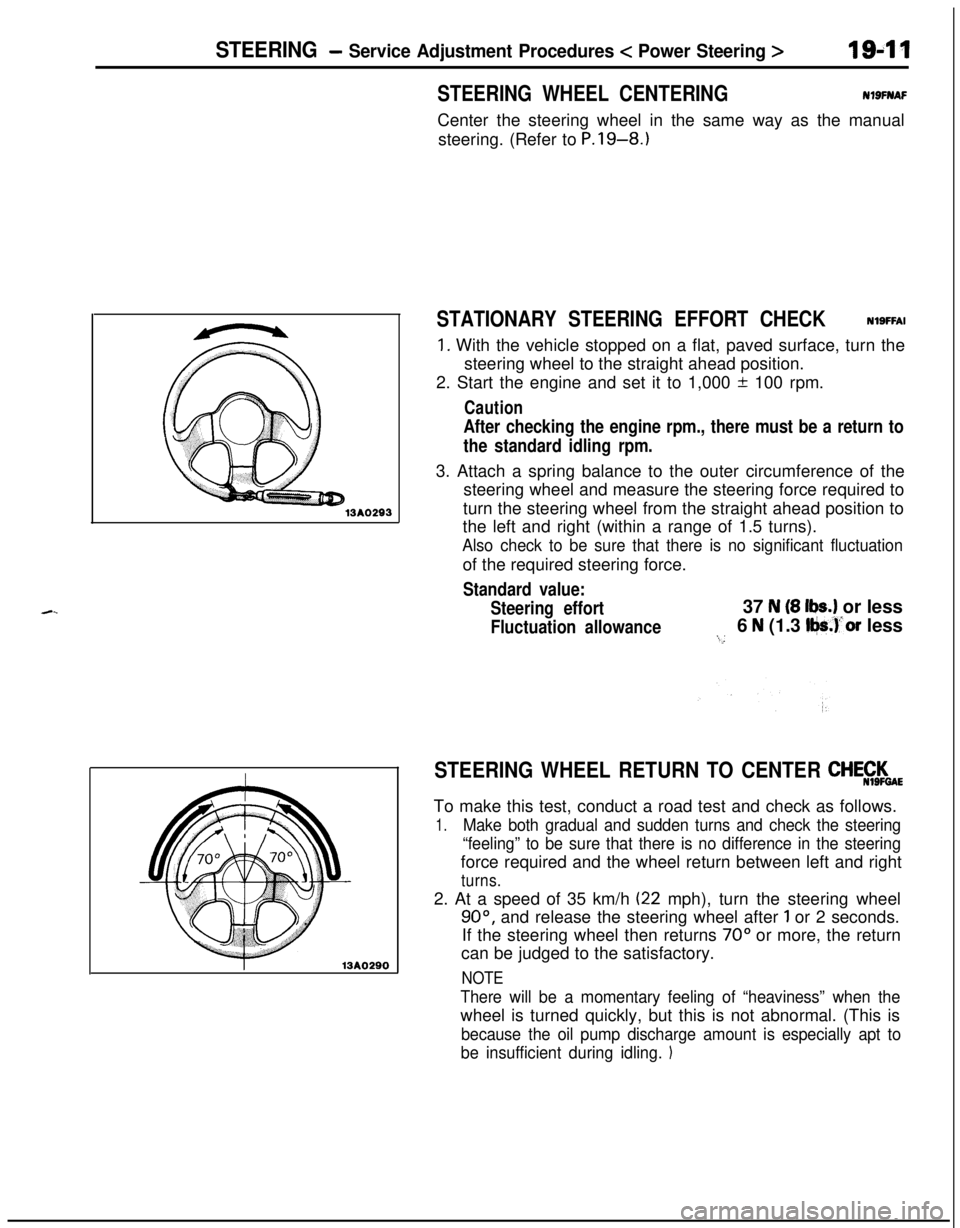

STEERING - Service Adjustment Procedures < Power Steering >194113AO29313AO290

STEERING WHEEL CENTERINGNlSFIYAFCenter the steering wheel in the same way as the manual

steering. (Refer to P.19-8.1

STATIONARY STEERING EFFORT CHECKNlSFFAI

1. With the vehicle stopped on a flat, paved surface, turn the

steering wheel to the straight ahead position.

2. Start the engine and set it to 1,000 + 100 rpm.

Caution

After checking the engine rpm., there must be a return to

the standard idling rpm.3. Attach a spring balance to the outer circumference of the

steering wheel and measure the steering force required to

turn the steering wheel from the straight ahead position to

the left and right (within a range of 1.5 turns).

Also check to be sure that there is no significant fluctuationof the required steering force.

Standard value:

Steering effort37

N (8 lbs.) or less

Fluctuation allowance6 N (1.3 Iljs.)‘or less:...

STEERING WHEEL RETURN TO CENTER CHE$$$aETo make this test, conduct a road test and check as follows.

1.Make both gradual and sudden turns and check the steering

“feeling” to be sure that there is no difference in the steeringforce required and the wheel return between left and right

turns.2. At a speed of 35 km/h

(22 mph), turn the steering wheel

90°, and release the steering wheel after 1 or 2 seconds.

If the steering wheel then returns

70” or more, the return

can be judged to the satisfactory.

NOTE

There will be a momentary feeling of “heaviness” when thewheel is turned quickly, but this is not abnormal. (This is

because the oil pump discharge amount is especially apt to

be insufficient during idling.

1

Page 660 of 1216

19-12STEERING - Service Adjustment Procedures

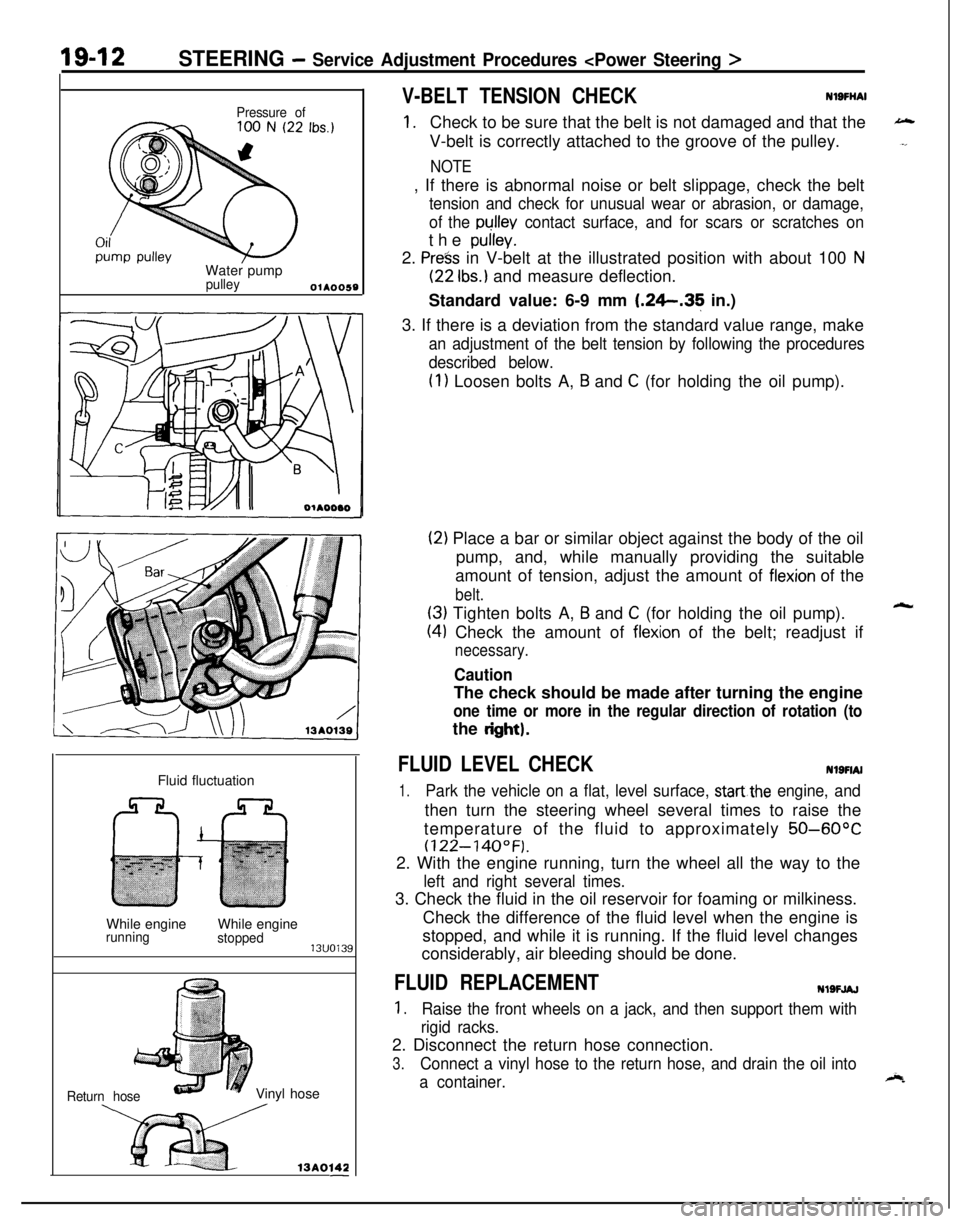

Pressure ofWater pump

pulleyOlA0059Fluid fluctuation

While engine

runningWhile enginestopped13uo139

Return hoseVinyl hose

x ,3Ao,42-

V-BELT TENSION CHECKNlSFliAl

1.Check to be sure that the belt is not damaged and that the

V-belt is correctly attached to the groove of the pulley.

NOTE, If there is abnormal noise or belt slippage, check the belt

tension and check for unusual wear or abrasion, or damage,

of the

pullev contact surface, and for scars or scratches onthe

pulley.2.

Press in V-belt at the illustrated position with about 100 N

(22 Ibs.) and measure deflection.

Standard value: 6-9 mm

1.26.35 in.)

3. If there is a deviation from the standard value range, make

an adjustment of the belt tension by following the procedures

described below.

(1) Loosen bolts A, B and C (for holding the oil pump).

(2) Place a bar or similar object against the body of the oil

pump, and, while manually providing the suitable

amount of tension, adjust the amount of

flexion of the

belt.

(3) Tighten bolts A, B and C (for holding the oil pump).

(4) Check the amount of flexion of the belt; readjust if

necessary.

CautionThe check should be made after turning the engine

one time or more in the regular direction of rotation (tothe

dght).

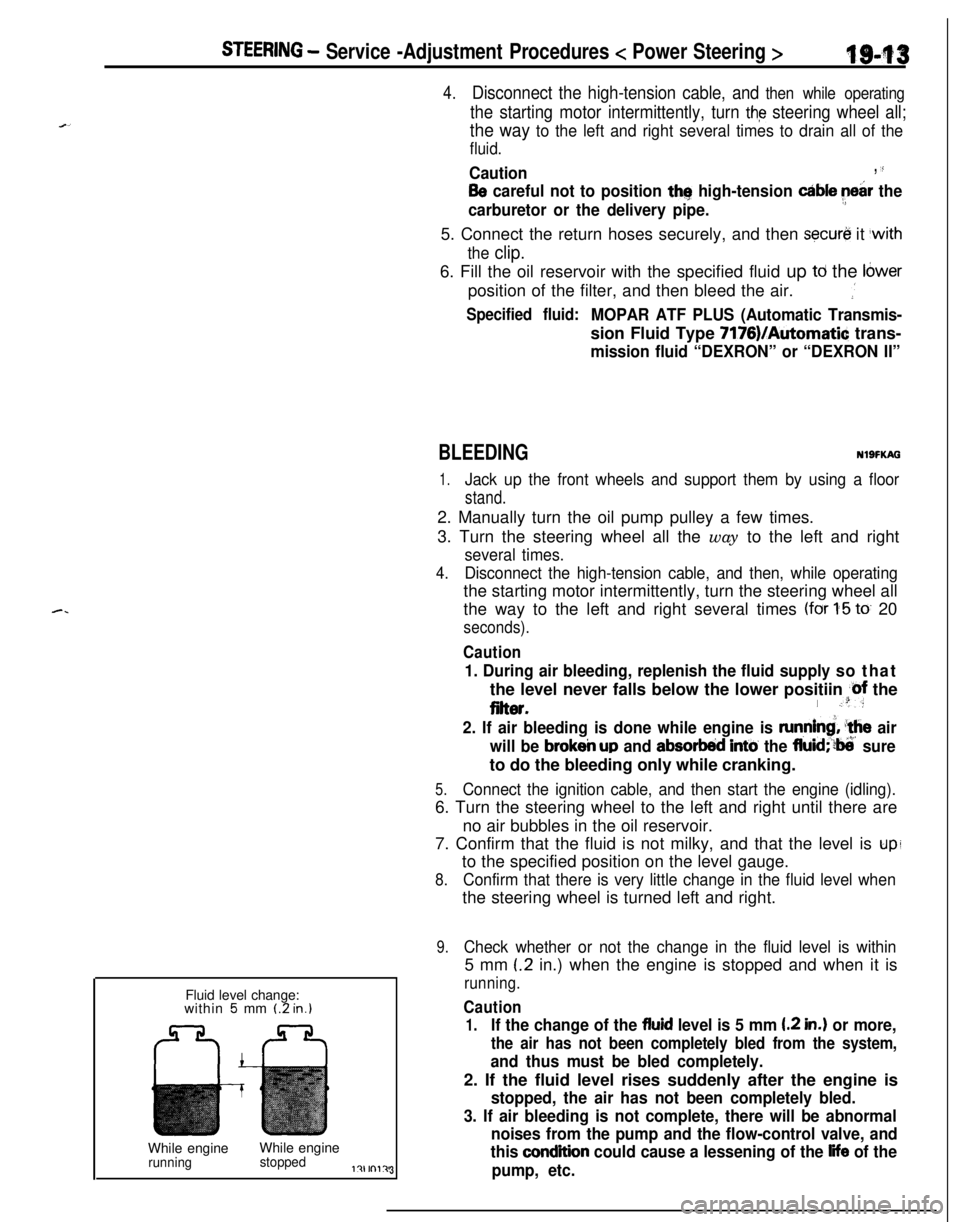

FLUID LEVEL CHECKNlSFIAI

1.Park the vehicle on a flat, level surface, startthe engine, andthen turn the steering wheel several times to raise the

temperature of the fluid to approximately

50-60°C

(122-140°F).2. With the engine running, turn the wheel all the way to the

left and right several times.3. Check the fluid in the oil reservoir for foaming or milkiness.

Check the difference of the fluid level when the engine is

stopped, and while it is running. If the fluid level changes

considerably, air bleeding should be done.

FLUID REPLACEMENTNlSFJAJ

1.Raise the front wheels on a jack, and then support them with

rigid racks.2. Disconnect the return hose connection.

3.Connect a vinyl hose to the return hose, and drain the oil into

a container.

Page 661 of 1216

STEERING - Service -Adjustment Procedures < Power Steering >IgJf~

4.Disconnect the high-tension cable, and then while operating

the starting motor intermittently, turn the steering wheel all;

the way to the left and right several times to drain all of the

fluid.

Caution, 35

Be careful not to position thq high-tension able ye&r the

carburetor or the delivery pipe.5. Connect the return hoses securely, and then

secur& it ,with

the clip.6. Fill the oil reservoir with the specified fluid up

td the Ibwerposition of the filter, and then bleed the air.

.’

Specified fluid:MOPAR ATF PLUS (Automatic Transmis-sion Fluid Type 7176)/Automatic trans-

mission fluid “DEXRON” or “DEXRON II”Fluid level change:

within

5 mm (2 in.)While engineWhile engine

runningstoppedl?lrnl?J3

BLEEDINGNlSFKAG

1.Jack up the front wheels and support them by using a floor

stand.2. Manually turn the oil pump pulley a few times.

3. Turn the steering wheel all the way to the left and right

several times.

4.Disconnect the high-tension cable, and then, while operatingthe starting motor intermittently, turn the steering wheel all

the way to the left and right several times

(for 1-5 to 20

seconds).

Caution

1. During air bleeding, replenish the fluid supply so thatthe level never falls below the lower positiin

@f the

eiter.I .“:

2. If air bleeding is done while engine is runnind, ‘the air

will be

brokeir up and absorbed intti the fluid;‘?ti’ sureto do the bleeding only while cranking.

5.Connect the ignition cable, and then start the engine (idling).6. Turn the steering wheel to the left and right until there are

no air bubbles in the oil reservoir.

7. Confirm that the fluid is not milky, and that the level is

upito the specified position on the level gauge.

8.Confirm that there is very little change in the fluid level whenthe steering wheel is turned left and right.

9.Check whether or not the change in the fluid level is within5 mm

(.2 in.) when the engine is stopped and when it is

running.

Caution

1.If the change of the fluid level is 5 mm I.2 in.) or more,

the air has not been completely bled from the system,

and thus must be bled completely.2. If the fluid level rises suddenly after the engine is

stopped, the air has not been completely bled.

3. If air bleeding is not complete, there will be abnormal

noises from the pump and the flow-control valve, and

this

condition could cause a lessening of the life of the

pump, etc.

Page 662 of 1216

19-14STEERING - Service Adjustment Procedures < Power Steering >Shut-off valv

Pressure gauge

(FW close)

(C-3309-E)I

Temperature

gauge

\e’\

Pressure hoses

Re(Mti990994)

\Oil pump

713AO145Shut-off valve

Pressure gauge(FullY ?penl

Pressure hoses

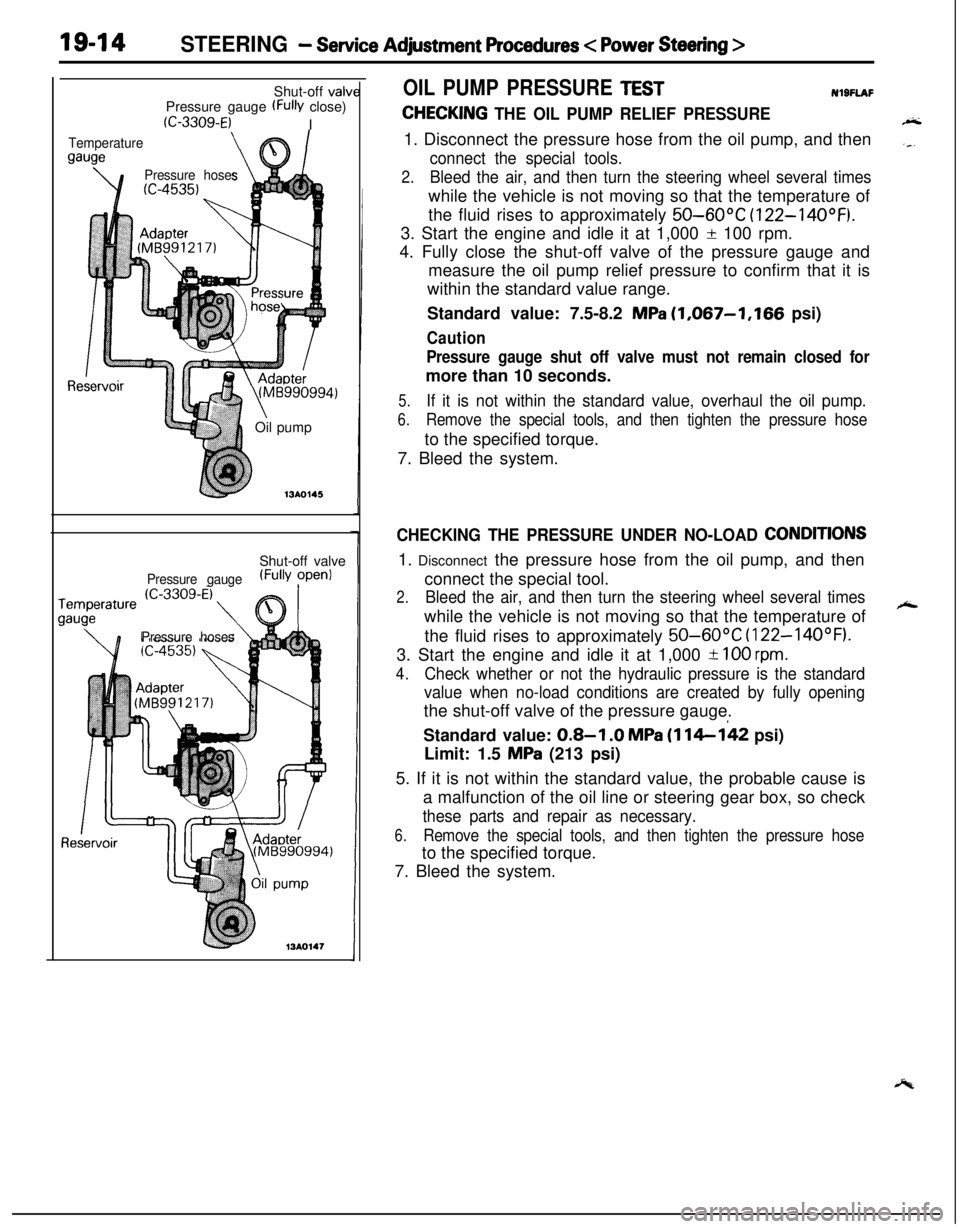

OIL PUMP PRESSURE TESTNl9FlAF

CHECKING THE OIL PUMP RELIEF PRESSURE1. Disconnect the pressure hose from the oil pump, and then

connect the special tools.

2.Bleed the air, and then turn the steering wheel several timeswhile the vehicle is not moving so that the temperature of

the fluid rises to approximately

50-60°C (122-14OOF).3. Start the engine and idle it at 1,000

f 100 rpm.

4. Fully close the shut-off valve of the pressure gauge and

measure the oil pump relief pressure to confirm that it is

within the standard value range.

Standard value: 7.5-8.2

MPa (1,067-1,166 psi)

Caution

Pressure gauge shut off valve must not remain closed formore than 10 seconds.

5.If it is not within the standard value, overhaul the oil pump.

6.Remove the special tools, and then tighten the pressure hoseto the specified torque.

7. Bleed the system.

CHECKING THE PRESSURE UNDER NO-LOAD CONDITIONS1. Disconnect the pressure hose from the oil pump, and then

connect the special tool.

2.Bleed the air, and then turn the steering wheel several timeswhile the vehicle is not moving so that the temperature of

the fluid rises to approximately

50-60°C (122-14OOF).3. Start the engine and idle it at 1,000

-t 100 rpm.

4.

Check whether or not the hydraulic pressure is the standard

value when no-load conditions are created by fully openingthe shut-off valve of the pressure gauge.

Standard value:

0.8-I .O MPa (114-142 psi)

Limit: 1.5

MPa (213 psi)

5. If it is not within the standard value, the probable cause is

a malfunction of the oil line or steering gear box, so check

these parts and repair as necessary.

6.Remove the special tools, and then tighten the pressure hoseto the specified torque.

7. Bleed the system.

Page 663 of 1216

-

c. .

STEERING - Service Adiustment Procedures

Shut-off valve

Pressure gauge

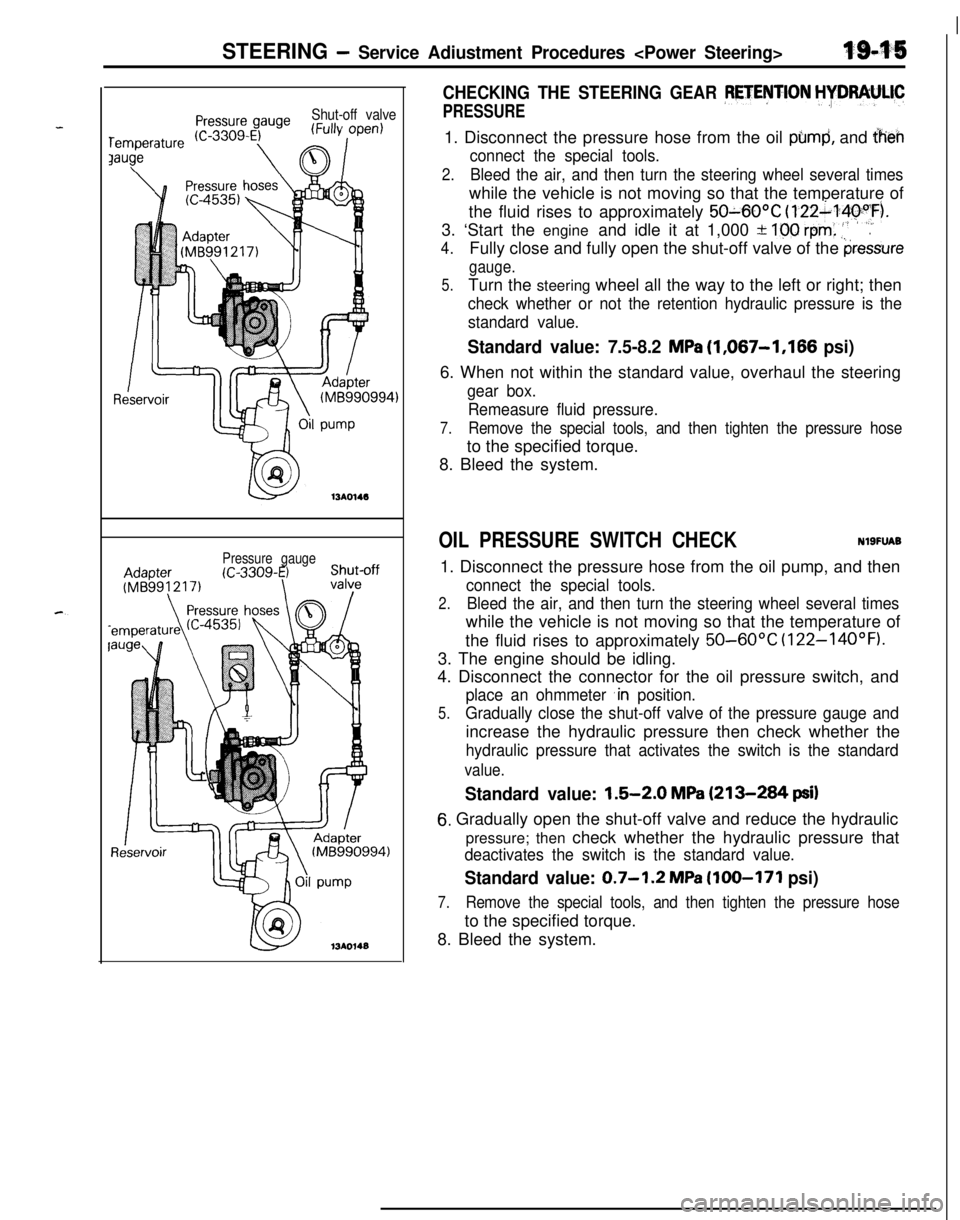

CHECKING THE STEERING GEAR PETENTION HYDRAULIC

PRESSURE1. Disconnect the pressure hose from the oil

pbmd, and iheh

connect the special tools.

2.Bleed the air, and then turn the steering wheel several timeswhile the vehicle is not moving so that the temperature of

the fluid rises to approximately

50~60OC (122~14pyF).

3. ‘Start the engine and idle it at 1,000 +

100 rem: .‘,’.

4.Fully close and fully open the shut-off valve of the pressure

gauge.

5.Turn the steering wheel all the way to the left or right; then

check whether or not the retention hydraulic pressure is the

standard value.

Standard value: 7.5-8.2 MPa (1,067-1,166 psi)6. When not within the standard value, overhaul the steering

gear box.

Remeasure fluid pressure.

7.Remove the special tools, and then tighten the pressure hoseto the specified torque.

8. Bleed the system.

OIL PRESSURE SWITCH CHECKNlSFUAB1. Disconnect the pressure hose from the oil pump, and then

connect the special tools.

2.Bleed the air, and then turn the steering wheel several timeswhile the vehicle is not moving so that the temperature of

the fluid rises to approximately

50-60°C (122-14OOF).3. The engine should be idling.

4. Disconnect the connector for the oil pressure switch, and

place an ohmmeter ,in position.

5.Gradually close the shut-off valve of the pressure gauge andincrease the hydraulic pressure then check whether the

hydraulic pressure that activates the switch is the standard

value.

Standard value: 1.5-2.0 MPa (213-284 psi)

6. Gradually open the shut-off valve and reduce the hydraulic

pressure; then check whether the hydraulic pressure that

deactivates the switch is the standard value.

Standard value: 0.7-1.2 MPa (100-171 psi)

7.Remove the special tools, and then tighten the pressure hoseto the specified torque.

8. Bleed the system.

Page 687 of 1216

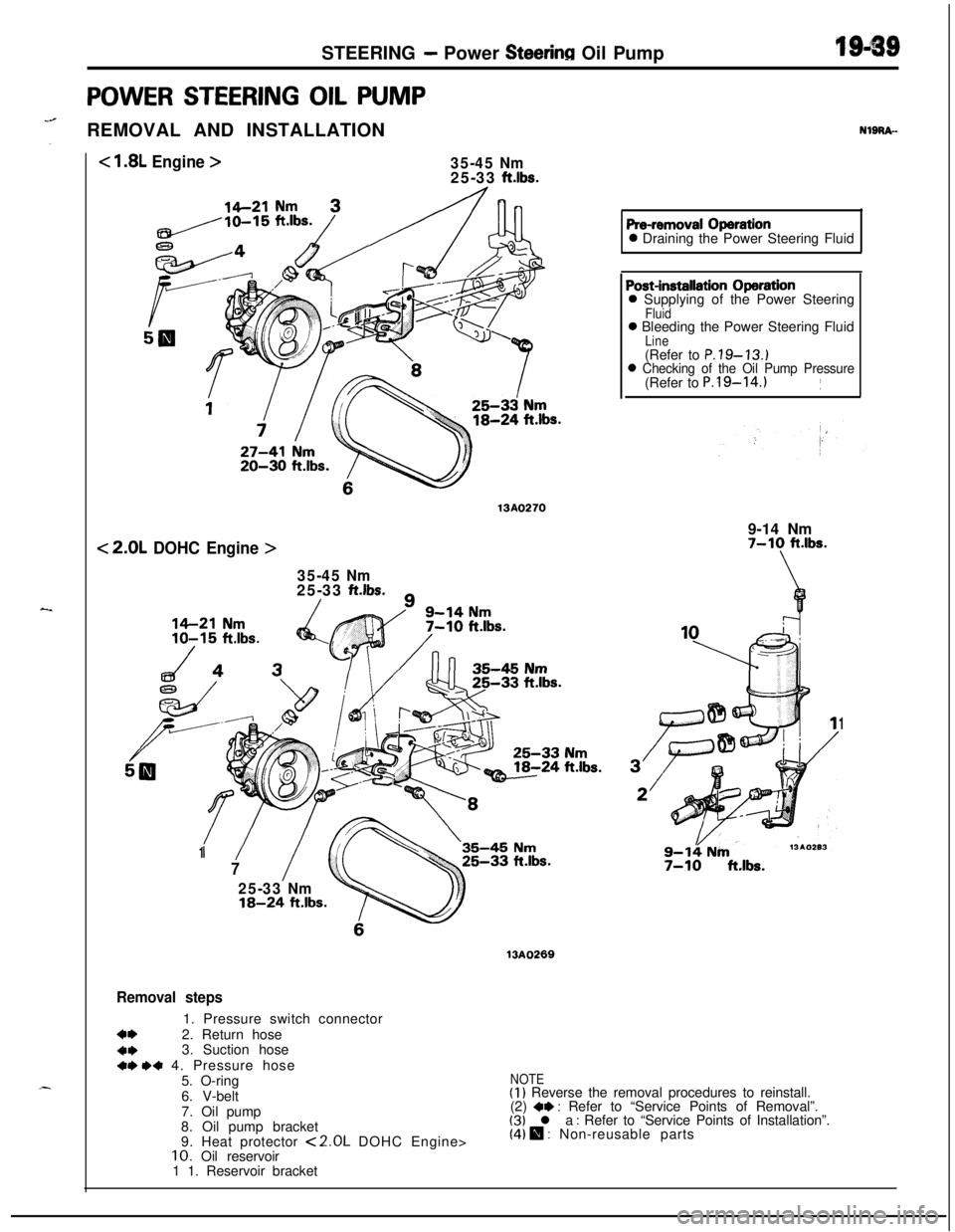

STEERING - Power Steering Oil Pump1849

POWER STEERING OIL PUMP

“@REMOVAL AND INSTALLATION

< 1.8L Engine >35-45 Nm25-33 ft.lbs.

20-30 ft.lbs.

13A0270

< 2.0L DOHC Engine >

35-45 Nm25-33 ft.lbs./

NlgRA-

Pre-removal Operation0 Draining the Power Steering Fluid

‘/1

7

25-33 Nm18-24 ft.lbs.

35-45 Nm

Post-installation Operation0 Supplying of the Power Steering

Fluid0 Bleeding the Power Steering Fluid

Line(Refer to P.79-13.)0 Checking of the Oil Pump Pressure(Refer to P.l9-14.)~

9-14 Nm

7-10 ft.lbs.

\

1

9-14 Nm7-10 ft.lbs.

13AO269

Removal steps1. Pressure switch connector

a*2. Return hose

4*3. Suction hose+r) .+ 4. Pressure hose

5. O-ring

6. V-belt

7. Oil pump

8. Oil pump bracket

9. Heat protector

<2.0L DOHC Engine>10. Oil reservoir

1 1. Reservoir bracket

NOTE(I) Reverse the removal procedures to reinstall.

(2) *I) : Refer to “Service Points of Removal”.(3) l a : Refer to “Service Points of Installation”.(4) 0 : Non-reusable parts