MITSUBISHI ECLIPSE 1991 Service Manual

Manufacturer: MITSUBISHI, Model Year: 1991, Model line: ECLIPSE, Model: MITSUBISHI ECLIPSE 1991Pages: 1216, PDF Size: 67.42 MB

Page 431 of 1216

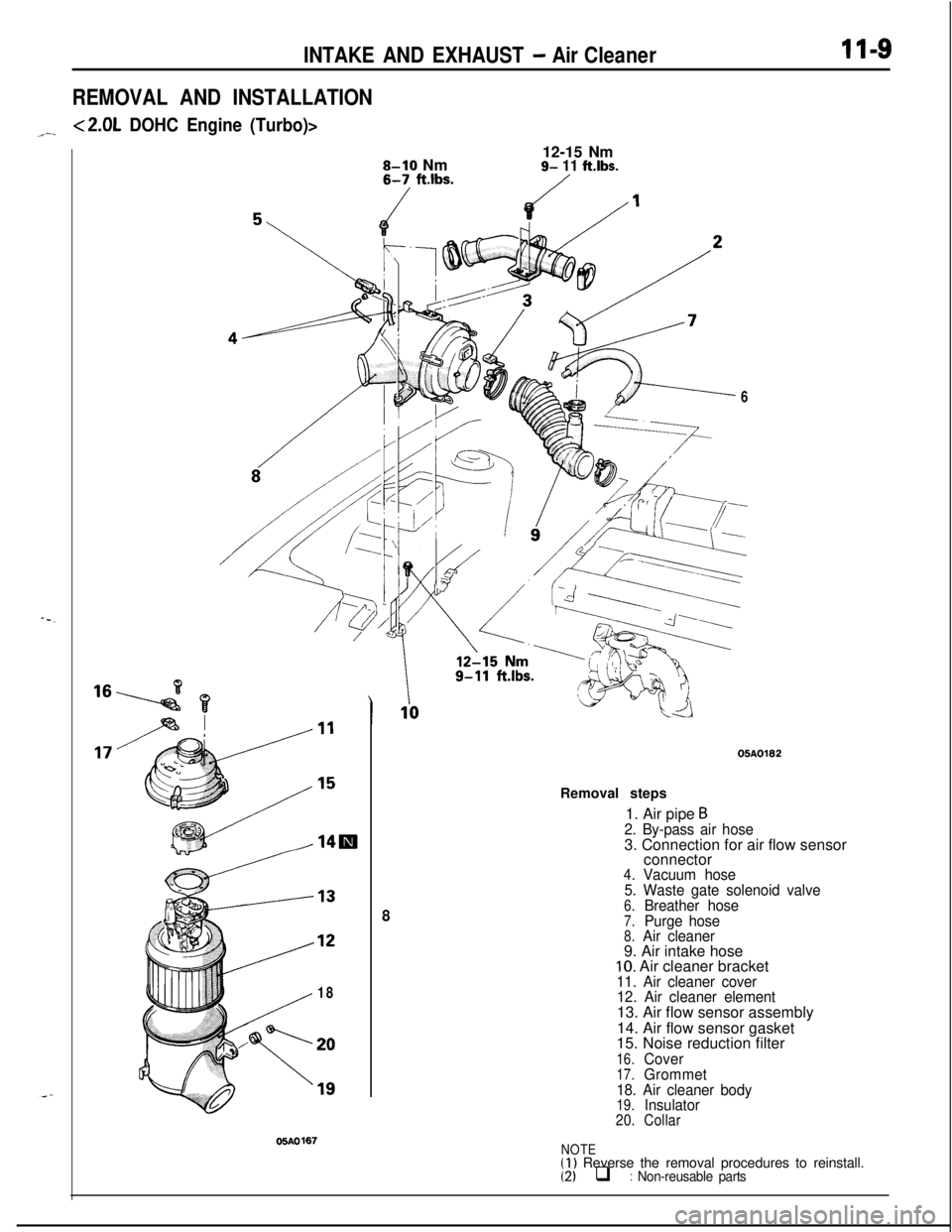

INTAKE AND EXHAUST - Air Cleaner

REMOVAL AND INSTALLATION

<2.0L DOHC Engine (Turbo)>

II-S

8-10 Nm6-7, ft.lbs.12-15 Nm9- 11 ftlbs.

/

8

18

05AO167

605A0182

Removal steps

1. Air pipe

B2. By-pass air hose3. Connection for air flow sensor

connector

4.Vacuum hose

5. Waste gate solenoid valve

6.Breather hose7.Purge hose8.Air cleaner9. Air intake hose

10. Air cleaner bracket11. Air cleaner cover

12. Air cleaner element13. Air flow sensor assembly

14. Air flow sensor gasket

15. Noise reduction filter

16.Cover17.Grommet

18. Air cleaner body

19.Insulator20.Collar

NOTE(1) Reverse the removal procedures to reinstall.(2) q : Non-reusable parts

Page 432 of 1216

INTAKE AND EXHAUST - Air Cleaner

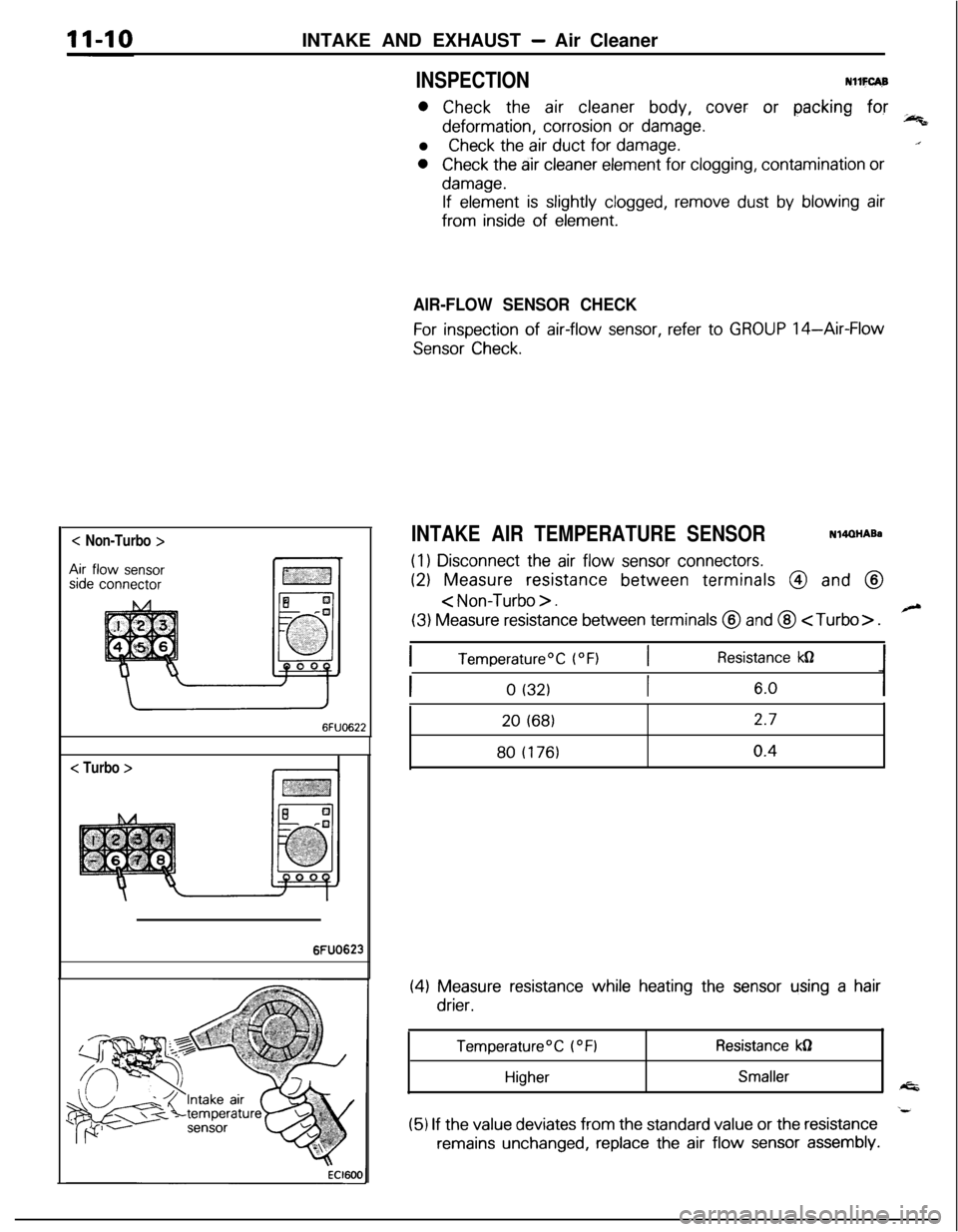

< Non-Turbo >

Air flow sensorside connector

6FUO622

c Turbo >

6FUO623

INSPECTIONNllFCAB0

Check the air cleaner body, cover or packing for ~

deformation, corrosion or damage.%al

Check the air duct for damage.d0

Check the air cleaner element for clogging, contamination or

damage.

If element is slightly clogged, remove dust by blowing air

from inside of element.

AIR-FLOW SENSOR CHECK

For inspection of air-flow sensor, refer to GROUP 14-Air-Flow

Sensor Check.

INTAKE AIR TEMPERATURE SENSORN14QHABa

(1) Disconnect the air flow sensor connectors.

(2) Measure resistance between terminals @ and @

< Non-Turbo > .

(3) Measure resistance between terminals @ and @

ITemperature”C (“F)IResistance kn

0 (32)6.020

(68)2.780

(176)0.4

(4) Measure resistance while heating the sensor using a hair

drier.

Temperature’C (OFIResistance kdl

HigherSmaller

(5) If the value deviates from the standard value or the resistance

remains unchanged, replace the air flow sensor assembly.

Page 433 of 1216

INTAKE AND EXHAUST - Intercooler11-11

INTERCOOLER

A-- REMOVAL AND INSTALLATIONNllTA-.

615-22

Nm11-16 ft.lbs.

Removal steps

1. Air hose C

2. Air pipe B3. Air by-pass hose4.Vacuumhose

5.Vacuumhose

l *6. Air cleaner7. Air intake hose8. Air hose B

9. Splash shield extensionl + 10. Intercooler11. Air hose A12. Air by-pass valve13.Gasket

i

05AOl85

05A0140

NOTE(1) Reverse the removal procedures to reinstall.(2) l * : Refer to “Service Points of Removal”.(3) *+ : Refer to “Service Points of Installation”(4) q : Non-reusable parts

Page 434 of 1216

11-12INTAKE AND EXHAUST - Intercooler

05AO184

SERVICE POINTS OF REMOVAL6. REMOVAL OF AIR CLEANER

Refer to P.l l-9.

INSPECTIONNllTCAA

l

Check the intercooler fins for bending, damage, or foreign

matter.0

Check the intercooler hoses for cracking, damage, or wear.

SERVICE POINTS OF INSTALLATIONNllTDAB

10. INSTALLATION OF

INTERCObLER

Connect the air hoses and air pipes by aligning the paint

marks on the hoses with the projections and indentations on?

the pipes.

Caution

Be careful not to allow any foreign matter to get into thehoses, pipes, or the

intercooler itself.

NOTE

@ : Projection or indentation (pipe)

+ : Paint mark (hose)

Page 435 of 1216

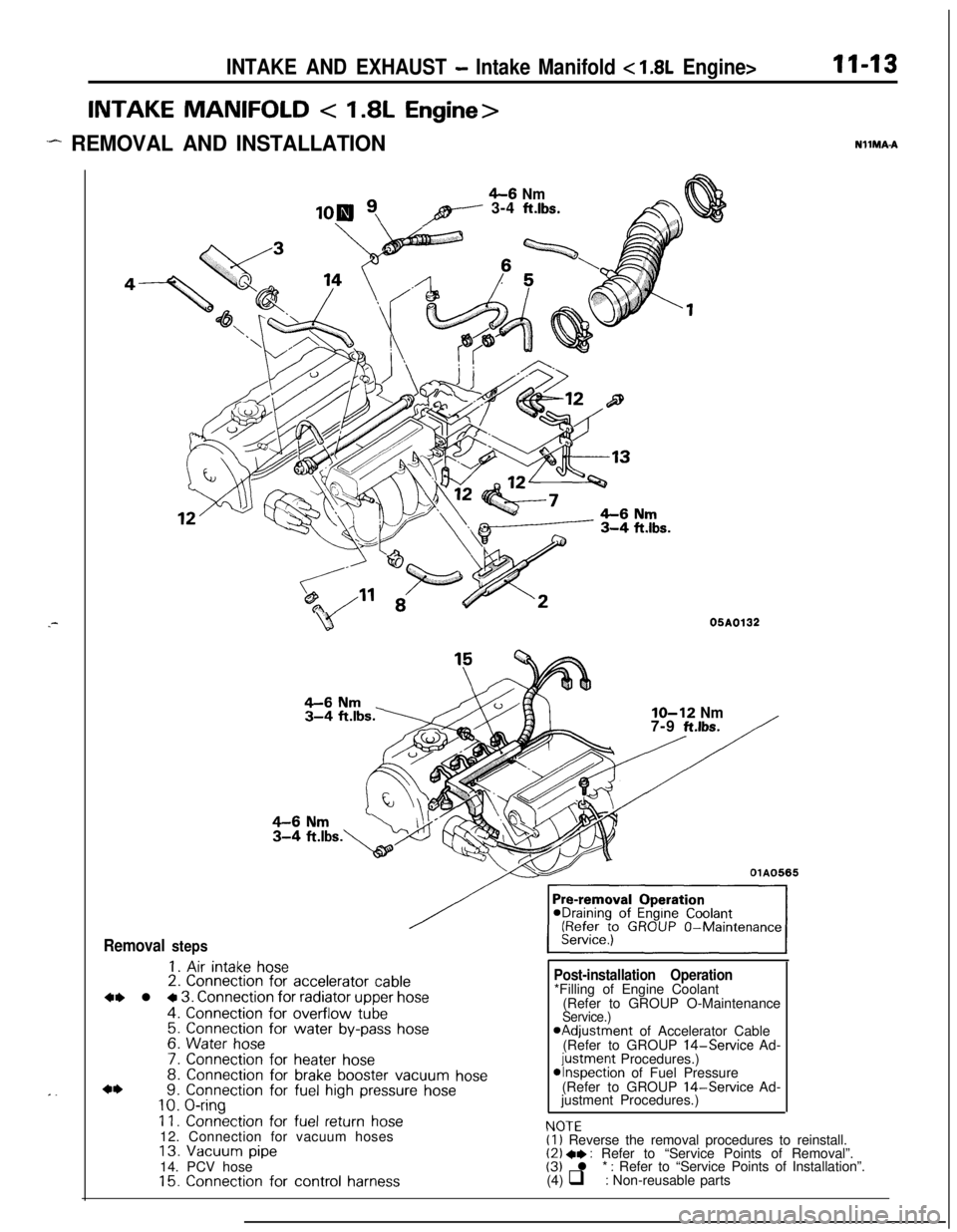

INTAKE AND EXHAUST - Intake Manifold < 1.8L Engine>

INTAKE MANIFOLD < 1.8L Engine>

.- REMOVAL AND INSTALLATION

11-13NllMA-A.-

. .

4-6 Nmpy---- 3-4 ft.lbs.

B05A0132

Removal steps

1. Air intake hose2. Connection for accelerator cable

4, l + 3. Connection for radiator upper hose

4. Connection for overflow tube5. Connection for water by-pass hose6. Water hose

7. Connection for heater hose8. Connection for brake booster vacuum hose9. Connection for fuel high pressure hose10. O-ring

11. Connection for fuel return hose12. Connection for vacuum hoses

13. Vacuum pipe14. PCV hose

15. Connection for control harness

IO-12 Nm7-9 ft.lbs.

OlA0565

Post-installation Operation

NfJTF*Filling of Engine Coolant

(Refer to GROUP O-Maintenance

Service.)aAdjustment of Accelerator Cable

(Refer to GROUP 14-Service Ad-

justment Procedures.)*Inspection of Fuel Pressure

(Refer to GROUP 14-Service Ad-

justment Procedures.)

I.” IL(1) Reverse the removal procedures to reinstall.(2) +* : Refer to “Service Points of Removal”.(3) l * : Refer to “Service Points of Installation”.

(4) q : Non-reusable parts

Page 436 of 1216

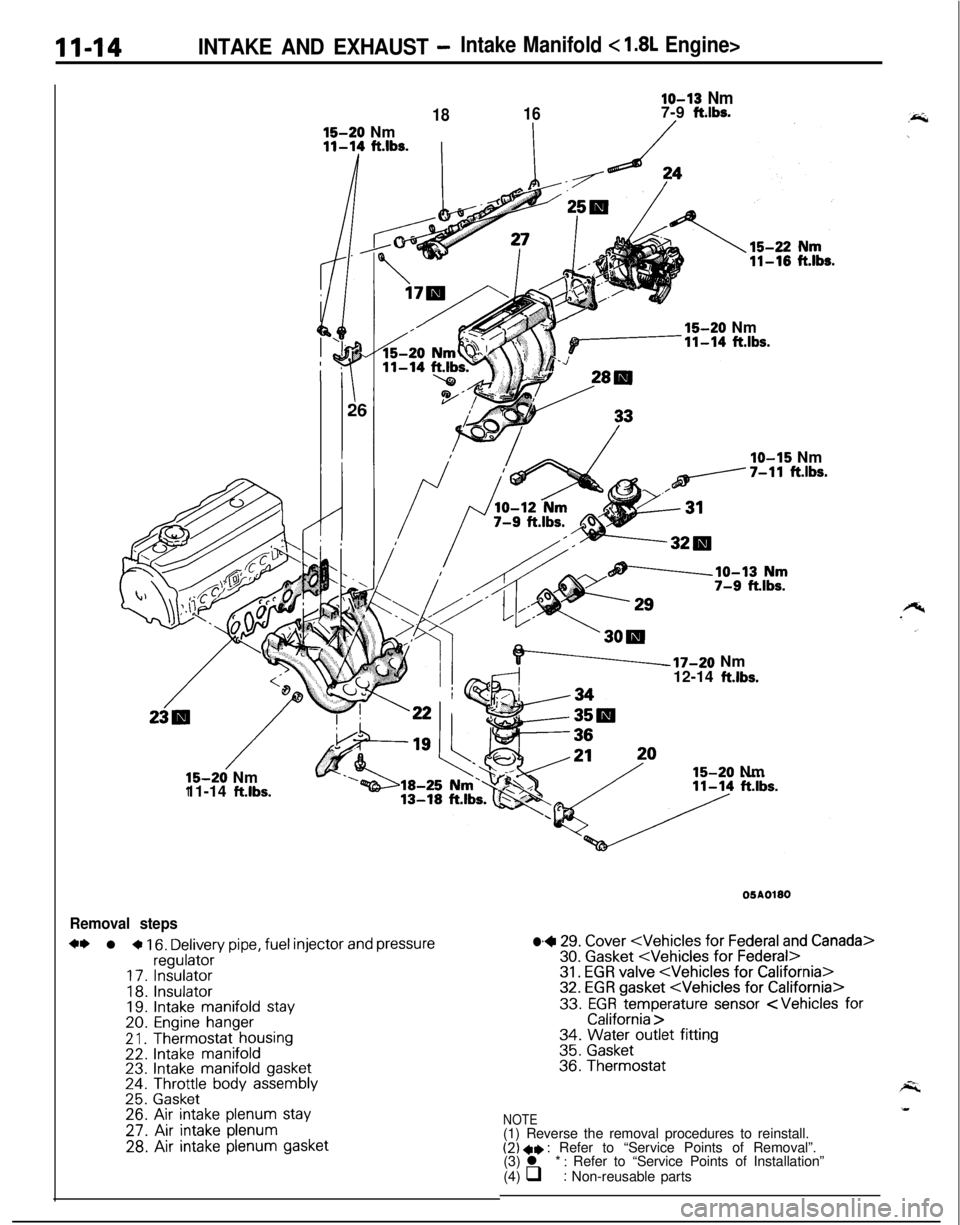

II-14INTAKE AND EXHAUST -Intake Manifold < 1.8L Engine>

/15-20 Nm

11-14

ft.lbs.

lo-13 Nm

18167-9 ft.lbs.15-20 Nm11-14

ft.lbs.I/15-20 Nm

I26IO-15 Nm7-11

ftm’bs.

-17-20 Nm

12-14 ft.lbs.15-20 Nm

Removal steps05AO180

+* l a 16. Delivery pipe, fuel injector and pressureregulator17.Insulator

18.Insulator19. Intake manifold stay20.Engine hanger

2 1.Thermostat housing22.Intake manifold23. Intake manifold gasket24. Throttle body assembly25.Gasket26. Air intake plenum stay

27. Air intake plenum

28. Air intake plenum gasket

lb+ 29. Cover

33. EGR temperature sensor

NOTE(1) Reverse the removal procedures to reinstall.

(2) a* : Refer to “Service Points of Removal”.

(3) l * : Refer to “Service Points of Installation”

(4) q : Non-reusable parts

Page 437 of 1216

INTAKE AND EXHAUST - Intake Manifold < 1.8L Engine>1145

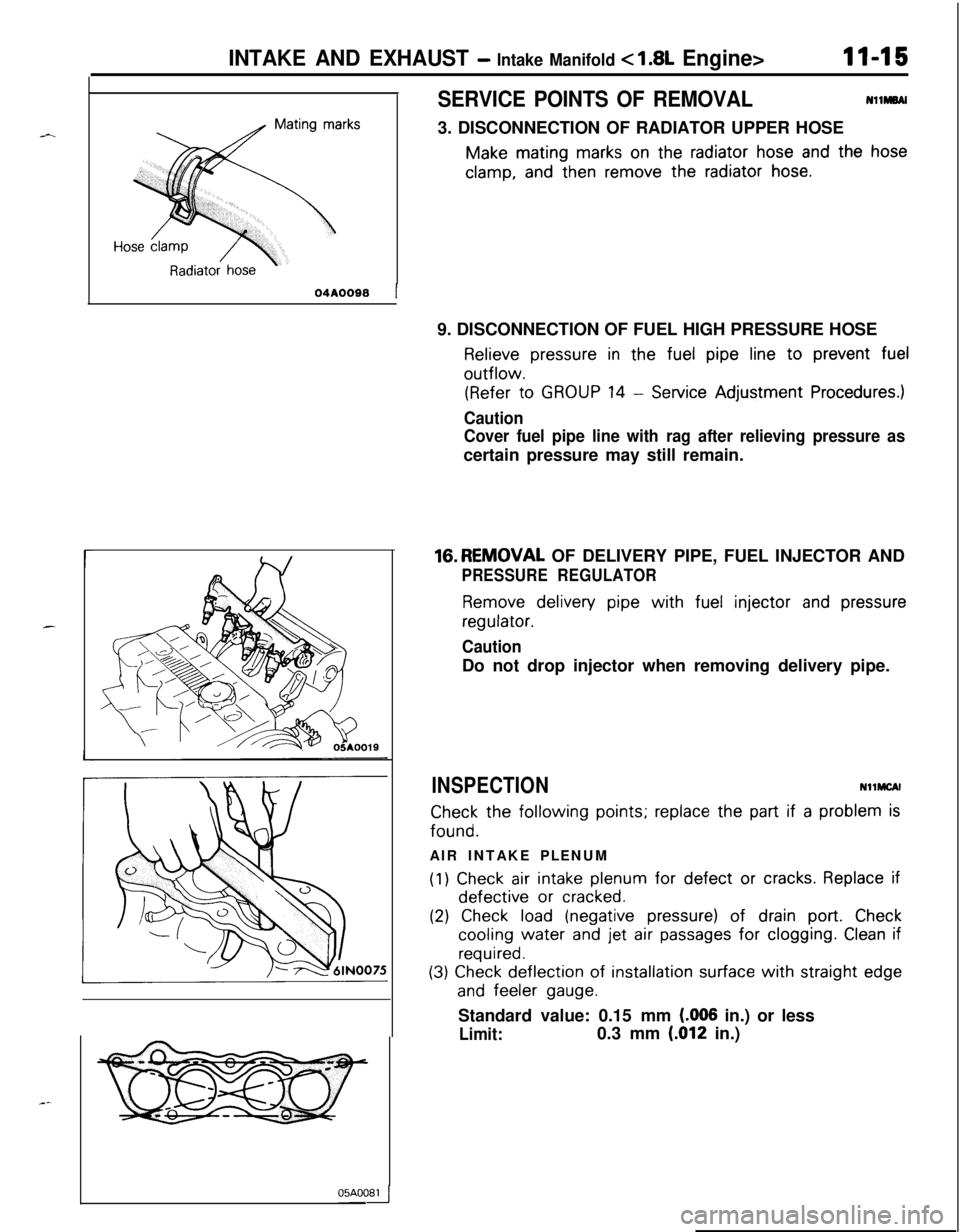

SERVICE POINTS OF REMOVALNllMBAI

3. DISCONNECTION OF RADIATOR UPPER HOSE

Make mating marks on the radiator hose and the hose

clamp, and then remove the radiator hose.

r

04A0088 19. DISCONNECTION OF FUEL HIGH PRESSURE HOSE

Relieve pressure in the fuel pipe line to prevent fueloutflow.

(Refer to GROUP 14 - Service Adjustment Procedures.)

Caution

Cover fuel pipe line with rag after relieving pressure ascertain pressure may still remain.16.REMOVAL OF DELIVERY PIPE, FUEL INJECTOR AND

PRESSURE REGULATOR

Remove delivery pipe with fuel injector and pressure

regulator.

CautionDo not drop injector when removing delivery pipe.

INSPECTIONNllMCAl

Check the following points; replace the part if a problem isfound.

AIR INTAKE PLENUM

(1) Check air intake plenum for defect or cracks. Replace ifdefective

or cracked.

(2) Check load (negative pressure) of drain port. Check

cooling water and jet air passages for clogging. Clean if

required.

(3) Check deflection of installation surface with straight edge

and feeler gauge.Standard value: 0.15 mm

(.006 in.) or less

Limit:0.3 mm (.012 in.)05AOOB4

Page 438 of 1216

II-16INTAKE AND EXHAUST - Intake Manifold c 1.8L Engine>

05A0033

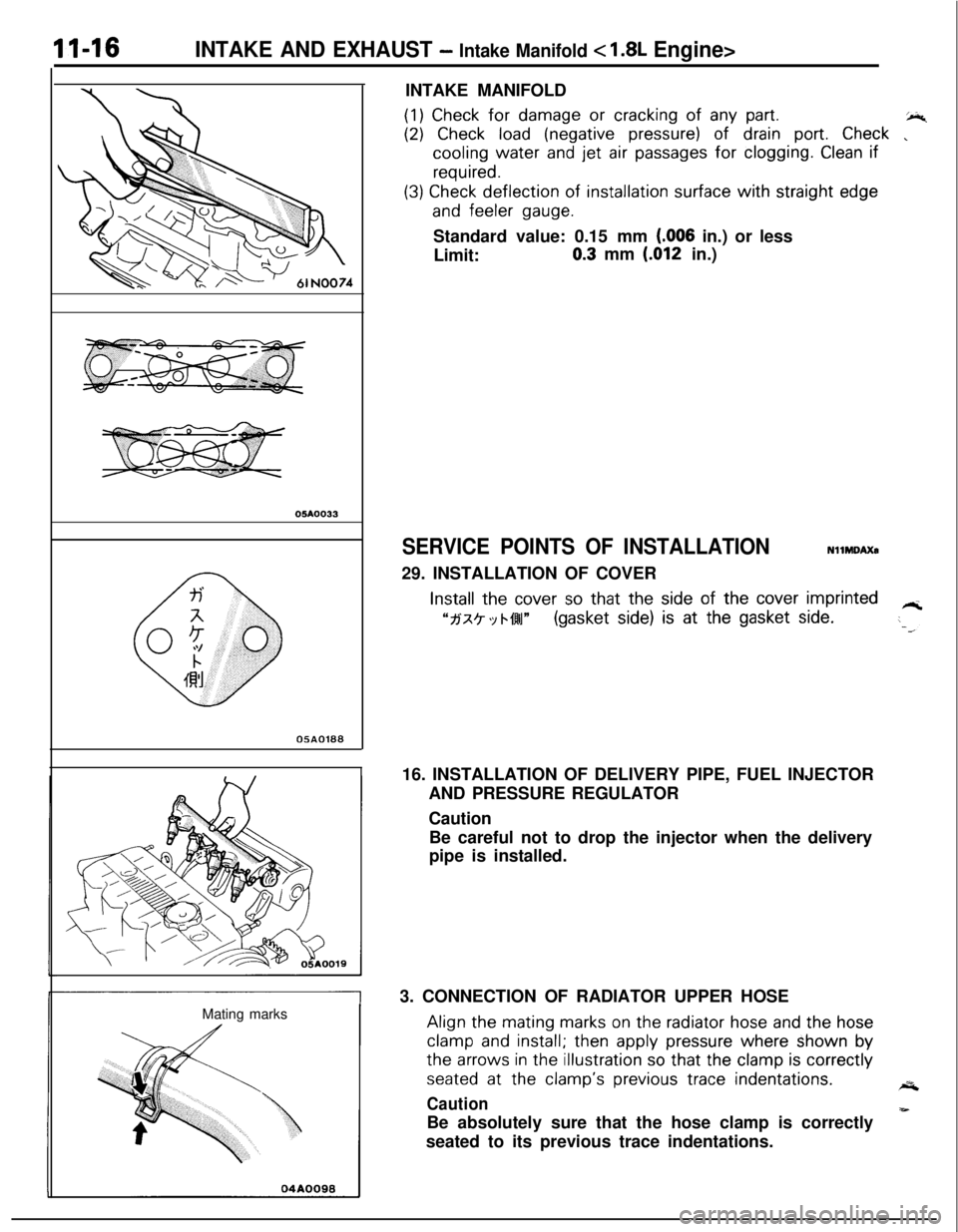

0580188Mating marksINTAKE MANIFOLD

(1) Check for damage or cracking of any part.+4

(2) Check load (negative pressure) of drain port. Check ,cooling water

and jet air passages for clogging. Clean if

required.

(3) Check deflection of installation surface with straight edge

and feeler gauge.Standard value: 0.15 mm

(006 in.) or less

Limit:

0.3 mm (.012 in.)

SERVICE POINTS OF INSTALLATIONNllMDAXa

29. INSTALLATION OF COVER

Install the cover so that the side of the cover imprinted

“fj‘x? ‘Y bf4l~(gasket side) is at the gasket side.-T16. INSTALLATION OF DELIVERY PIPE, FUEL INJECTOR

AND PRESSURE REGULATOR

Caution

Be careful not to drop the injector when the delivery

pipe is installed.

3. CONNECTION OF RADIATOR UPPER HOSEAlign the

mating marks on the radiator hose and the hose

clamp and install; then apply pressure where shown bythe

arrows in the illustration so that the clamp is correctly

seated at the clamp’s previous trace indentations.A

Caution

-Be absolutely sure that the hose clamp is correctly

seated to its previous trace indentations.

Page 439 of 1216

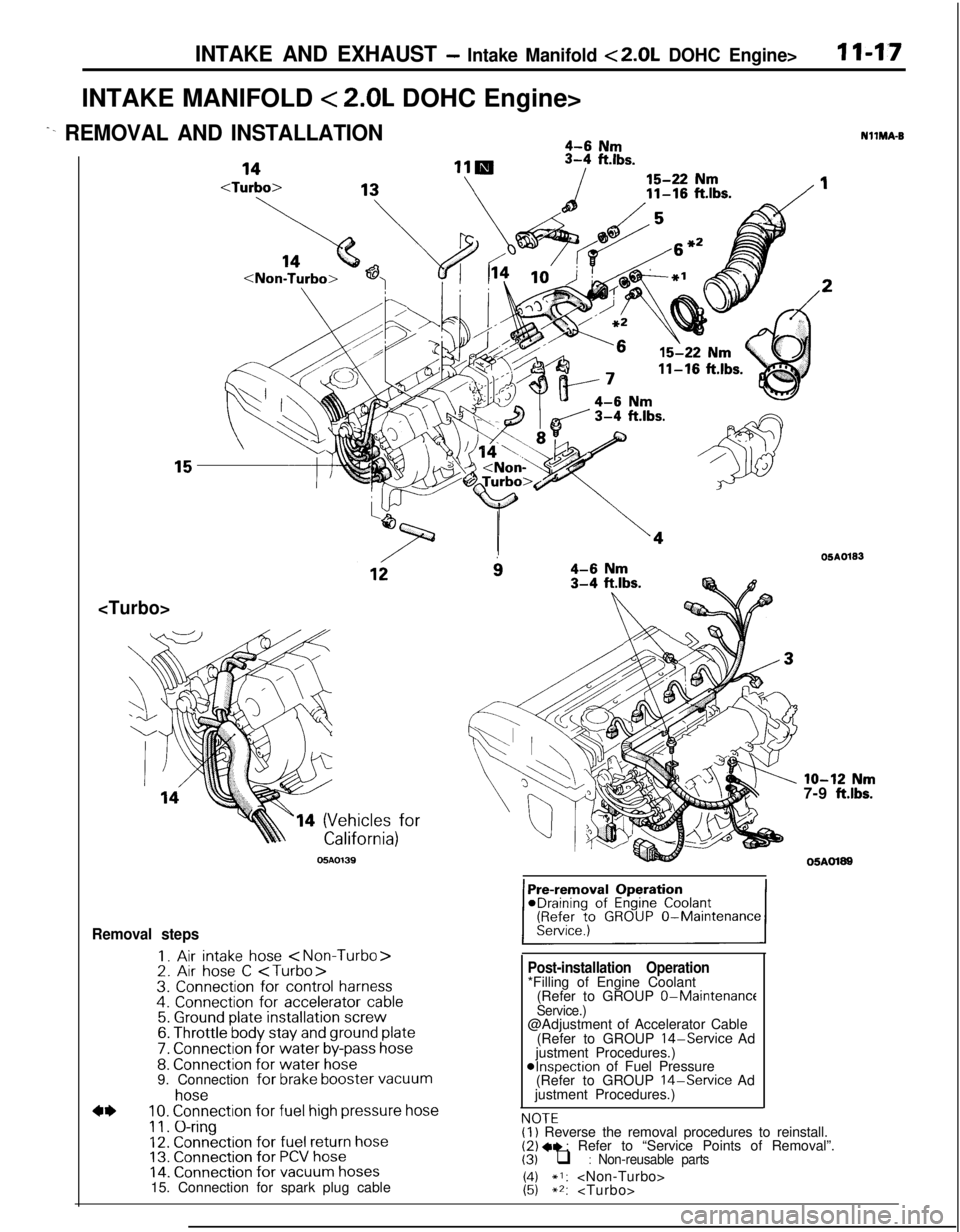

INTAKE AND EXHAUST - Intake Manifold <2.0L DOHC Engine>I I-1.7INTAKE MANIFOLD

< 2.0L DOHC Engine>

^- REMOVAL AND INSTALLATION4-6 Nm

ft.lbs.

14 (Vehicles for

05AO139

i34-6 Nm3-4 ftlbs.

Removal steps

I. Air intake hose

7. Connection for water by-pass hose8. Connection for water hose9. Connection for brake booster vacuum

4*

hose10. Connection for fuel high pressure hose

11. O-ring12. Connection for fuel return hose13. Connection for PCV hose14. Connection for vacuum hoses15. Connection for spark plug cable

Post-installation Operation*Filling of Engine Coolant

(Refer to GROUP 0-Maintenance

Service.)@Adjustment of Accelerator Cable

(Refer to GROUP

14-Service Ad

justment Procedures.)

@Inspection of Fuel Pressure

(Refer to GROUP 14-Service Ad

justment Procedures.)

NOTFNllMA-B

OSAO133

lo-12 Nm7-9 ft.lbs.

05AOl89

,.-.-(I) Reverse the removal procedures to reinstall.(2) +e : Refer to “Service Points of Removal”.(3) q : Non-reusable parts

1:;*I:

Page 440 of 1216

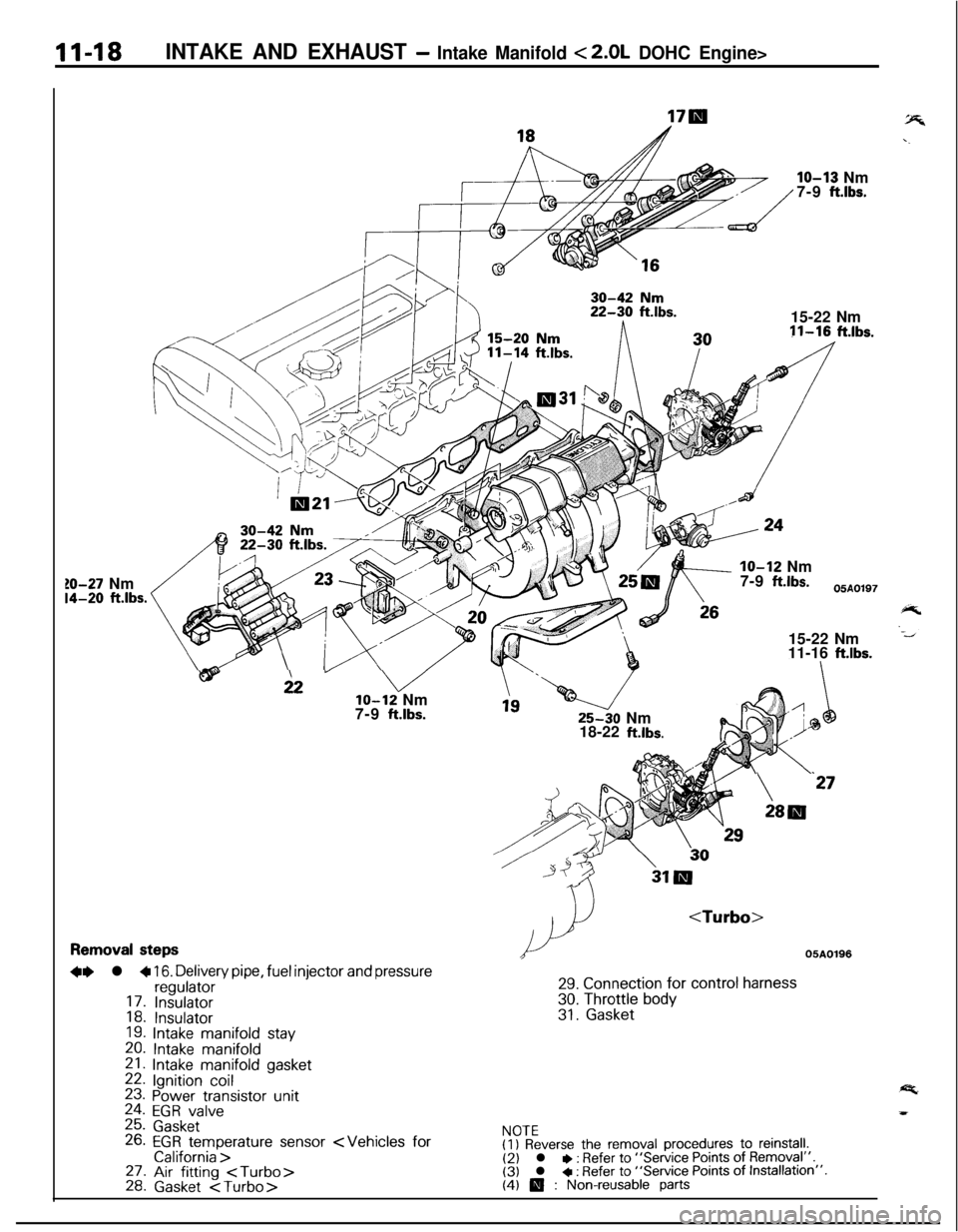

11-18INTAKE AND EXHAUST - Intake Manifold < 2.0L DOHC Engine>

10-27 Nm14-20 ft.lbs.

18hIO-13 Nm

7-9

ft.lbs.15-22 Nm11-16

ft.lbs.IO-12 Nm

7-9

ftlbs.05A0197

15-22 Nm

11-16

ftlbs.

wi2” vlo-12 Nm

7-9 ftlbs.25-30 Nm

18-22

ft.lbs.

24

\‘27

28lll

Removal steps

+e l + 16. Delivery pipe, fuel injector and pressureregulator17. Insulator18. Insulator19. Intake manifold stay

20. Intake manifold21. Intake manifold gasket22. Ignition coil23. Power transistor unit24. EGR valve25. Gasket26. EGR temperature sensor

29. Connection for control harness

30. Throttle body31. Gasket

NOTE(I) Reverse the removal procedures to reinstall.(2) l * : Refer to “Service Points of Removal”.(3) l + : Refer to “Service Points of Installation”.(4) 0 : Non-reusable parts