MITSUBISHI ECLIPSE 1991 Service Manual

Manufacturer: MITSUBISHI, Model Year: 1991, Model line: ECLIPSE, Model: MITSUBISHI ECLIPSE 1991Pages: 1216, PDF Size: 67.42 MB

Page 531 of 1216

FUEL SYSTEM - MPI Svstem InsDection <2.0L DOHC Engine>14-77INSTALLATION

(1) Apply specified sealant to threaded portion and tighten to

specified torque.

Specified sealant: MOPAR Part No.4318034 or

equivalent

Specified torque: 20

- 40 Nm (15 - 29 ft.lbs.1(2) Fasten harness connectors securely.

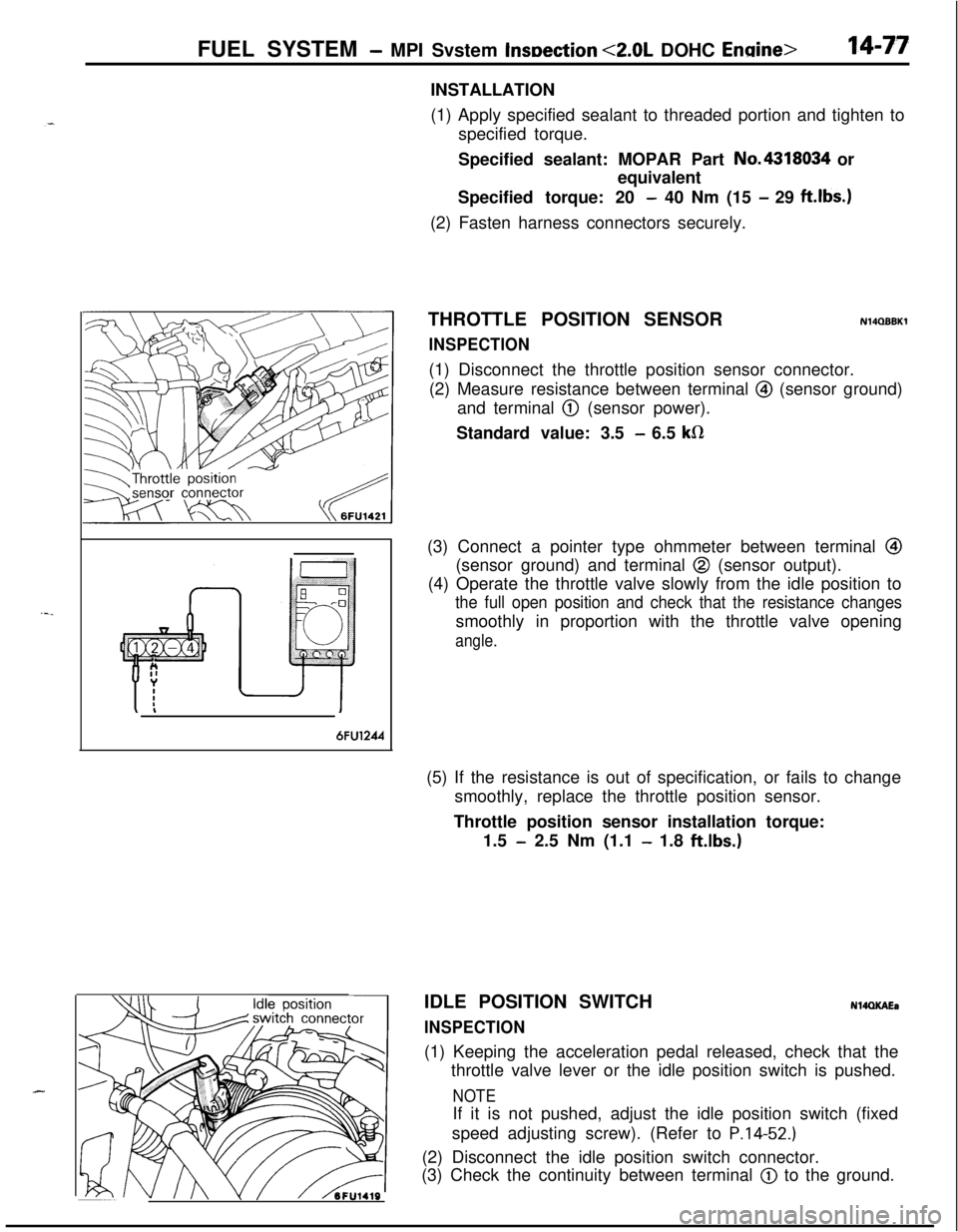

THROTTLE POSITION SENSOR

INSPECTION

N14QBBKl(1) Disconnect the throttle position sensor connector.

(2) Measure resistance between terminal

@I (sensor ground)

and terminal

@ (sensor power).

Standard value: 3.5

- 6.5 kR(3) Connect a pointer type ohmmeter between terminal

@I(sensor ground) and terminal

@ (sensor output).

(4) Operate the throttle valve slowly from the idle position to

the full open position and check that the resistance changessmoothly in proportion with the throttle valve opening

angle.

6FU1244(5) If the resistance is out of specification, or fails to change

smoothly, replace the throttle position sensor.

Throttle position sensor installation torque:

1.5

- 2.5 Nm (1.1 - 1.8 ft.lbs.)

J II\/ hFU1419IDLE POSITION SWITCH

INSPECTION

N14QKAEa(1) Keeping the acceleration pedal released, check that the

throttle valve lever or the idle position switch is pushed.

NOTEIf it is not pushed, adjust the idle position switch (fixed

speed adjusting screw). (Refer to

P.14-52.)(2) Disconnect the idle position switch connector.

(3) Check the continuity between terminal

@) to the ground.

Page 532 of 1216

FUEL SYSTEM - MPI System Inspection <2.0L DOHC Engine>

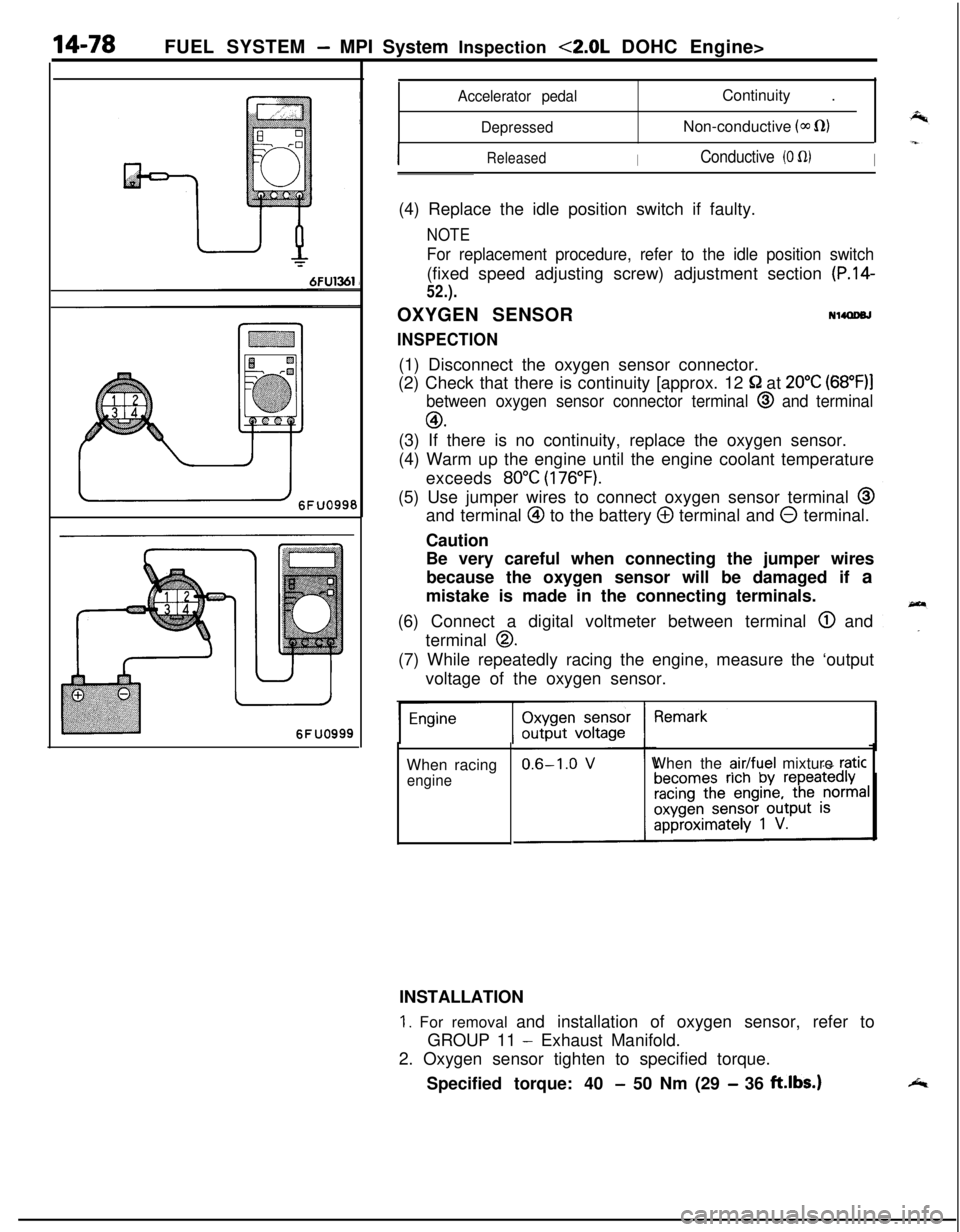

6FUO999

Accelerator pedal

DepressedContinuity .

Non-conductive

(03 fl)

ReleasedIConductive (0 fl)I(4) Replace the idle position switch if faulty.

NOTE

For replacement procedure, refer to the idle position switch(fixed speed adjusting screw) adjustment section

(P.14-

52.).OXYGEN SENSOR

NllQDeJ

INSPECTION(1) Disconnect the oxygen sensor connector.

(2) Check that there is continuity [approx. 12

52 at 20°C (68”F)l

between oxygen sensor connector terminal @ and terminal

GO.(3) If there is no continuity, replace the oxygen sensor.

(4) Warm up the engine until the engine coolant temperature

exceeds

80°C (176°F).(5) Use jumper wires to connect oxygen sensor terminal

@and terminal

@ to the battery @ terminal and 0 terminal.

Caution

Be very careful when connecting the jumper wires

because the oxygen sensor will be damaged if a

mistake is made in the connecting terminals.

(6) Connect a digital voltmeter between terminal

@ and

terminal

0.(7) While repeatedly racing the engine, measure the ‘output

voltage of the oxygen sensor.

When racing

engineWhen the

air/fuel mixture raticINSTALLATION

1. For removal and installation of oxygen sensor, refer to

GROUP 11

- Exhaust Manifold.

2. Oxygen sensor tighten to specified torque.

Specified torque: 40

- 50 Nm (29 - 36 ft.lbs.)

Page 533 of 1216

FUEL SYSTEM - MPI System Inspection <2.0L QOHC Engine>14-79EGR TEMPERATURE SENSOR

N14RCHAaRefer to GROUP 25

- Exhaust Gas Recirculation System.

VEHICLE SPEED SENSOR

Refer to GROUP 8

- Meters and Gauges.

N140EBBaAIR CONDITIONER SWITCH

Nl4QQAEaRefer to GROUP 8

- Column Switch.

POWER STEERING OIL PRESSURE SWITCH

N14RCJBRefer to GROUP 19 for power steering system inspection.

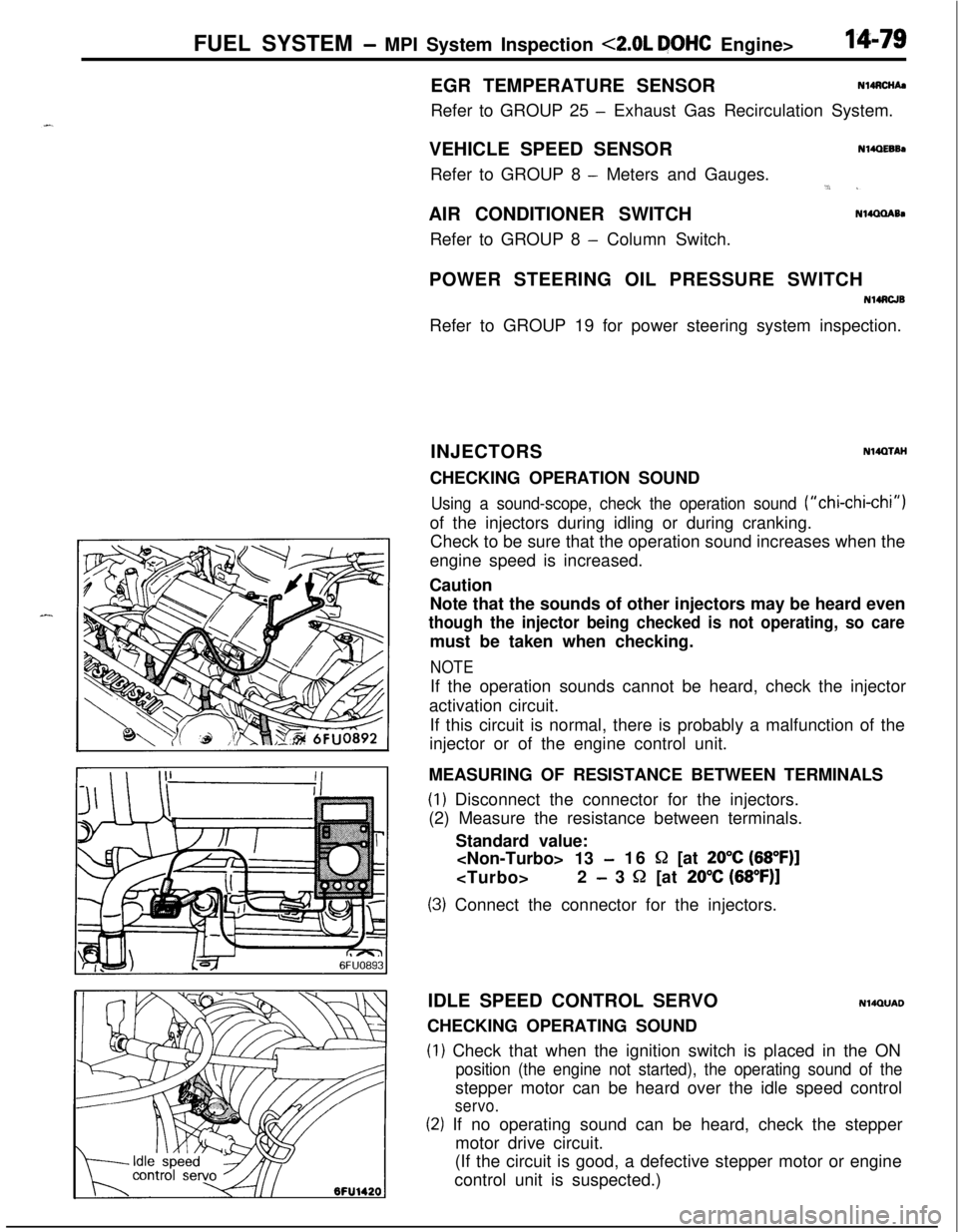

INJECTORS

NWXAHCHECKING OPERATION SOUND

Using a sound-scope, check the operation sound (“chi-chi-chi”)of the injectors during idling or during cranking.

Check to be sure that the operation sound increases when the

engine speed is increased.

Caution

Note that the sounds of other injectors may be heard even

though the injector being checked is not operating, so caremust be taken when checking.

NOTEIf the operation sounds cannot be heard, check the injector

activation circuit.

If this circuit is normal, there is probably a malfunction of the

injector or of the engine control unit.

MEASURING OF RESISTANCE BETWEEN TERMINALS

(1) Disconnect the connector for the injectors.

(2) Measure the resistance between terminals.

Standard value:

-16 S2 [at 20°C (68”F)]

- 3 52 [at 20% (68”F)]

(3) Connect the connector for the injectors.

IDLE SPEED CONTROL SERVO

N14QUADCHECKING OPERATING SOUND

(1) Check that when the ignition switch is placed in the ON

position (the engine not started), the operating sound of thestepper motor can be heard over the idle speed control

servo.

(2) If no operating sound can be heard, check the stepper

motor drive circuit.

(If the circuit is good, a defective stepper motor or engine

control unit is suspected.)

Page 534 of 1216

14-80FUEL SYSTEM - MPI System Inspection <2.0L DOHC Enginh

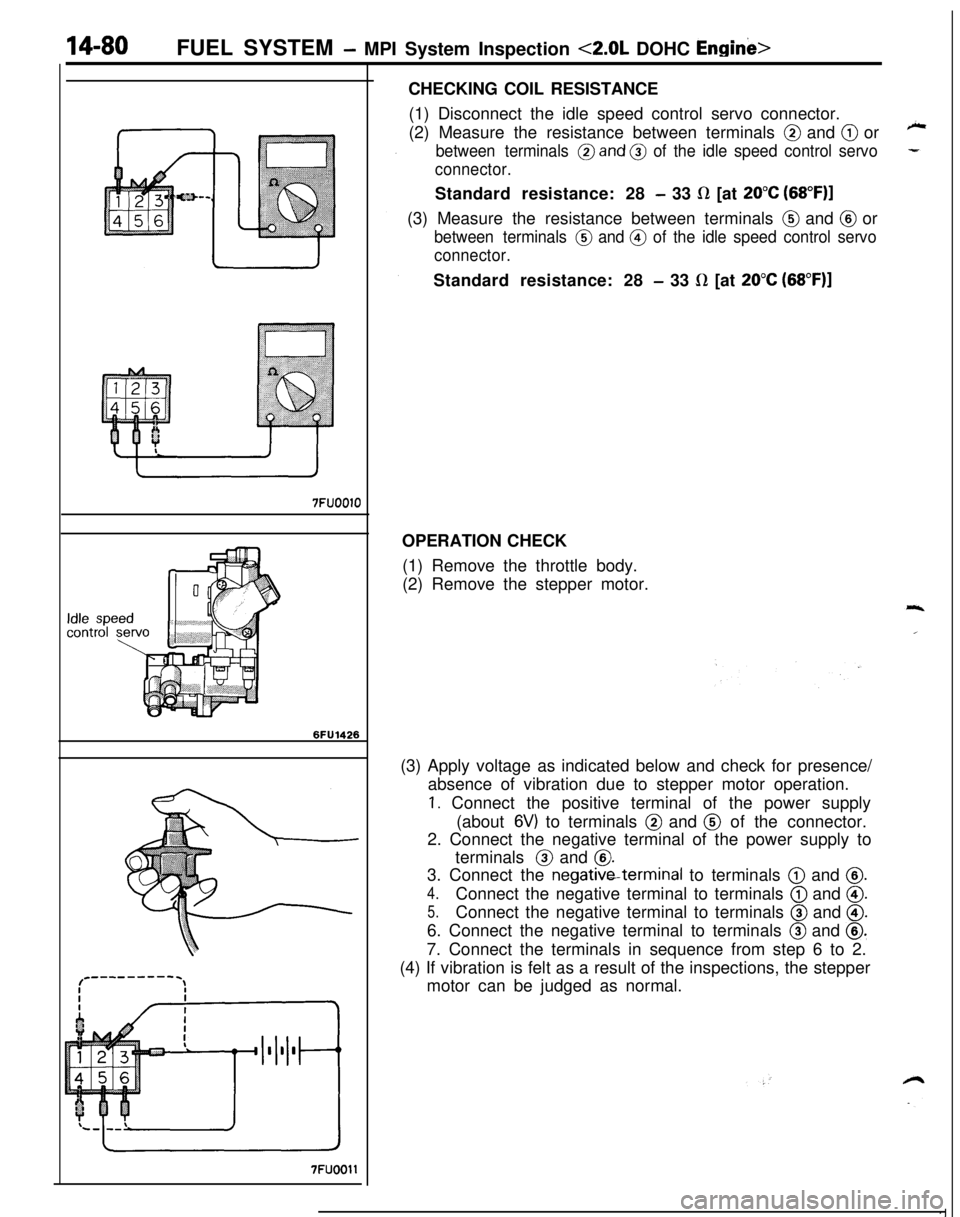

7FUOOlO6FU1426

7FUOOllCHECKING COIL RESISTANCE

(1) Disconnect the idle speed control servo connector.

(2) Measure the resistance between terminals

@ and @ or

between terminals @and @ of the idle speed control servo

connector.Standard resistance: 28

- 33 fl [at 20°C (68”F)l(3) Measure the resistance between terminals

@ and @ or

between terminals @ and @ of the idle speed control servo

connector.Standard resistance: 28

- 33 LR [at 20°C (68”F)]OPERATION CHECK

(1) Remove the throttle body.

(2) Remove the stepper motor.

(3) Apply voltage as indicated below and check for presence/

absence of vibration due to stepper motor operation.

1. Connect the positive terminal of the power supply

(about

6V) to terminals @ and @ of the connector.

2. Connect the negative terminal of the power supply to

terminals @ and

@.3. Connect the negativeterminal to terminals

@ and @.

4.Connect the negative terminal to terminals @ and @.

5.Connect the negative terminal to terminals @ and @.6. Connect the negative terminal to terminals

@ and @.7. Connect the terminals in sequence from step 6 to 2.

(4) If vibration is felt as a result of the inspections, the stepper

motor can be judged as normal.

Page 535 of 1216

_-

FUEL SYSTEM - MPI System Inspection <2.0L DOHC Engine>'I4181

OlLO22Z

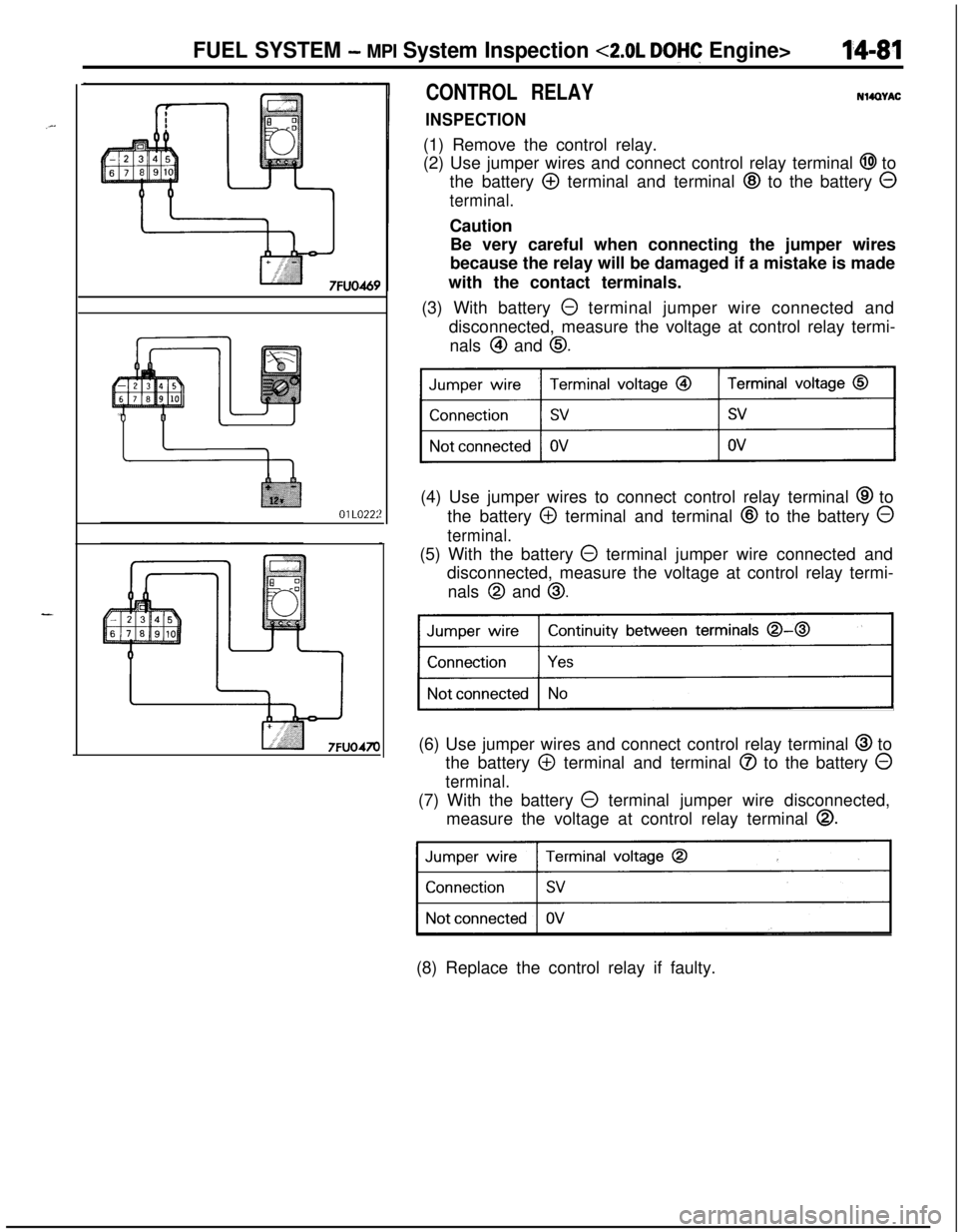

CONTROL RELAY

INSPECTIONNWWAC

(1) Remove the control relay.

(2) Use jumper wires and connect control relay terminal

@I to

the battery

@ terminal and terminal @ to the battery 0

terminal.Caution

Be very careful when connecting the jumper wires

because the relay will be damaged if a mistake is made

with the contact terminals.

(3) With battery

0 terminal jumper wire connected and

disconnected, measure the voltage at control relay termi-

nals

@I and 0.(4) Use jumper wires to connect control relay terminal

@ to

the battery

@ terminal and terminal @ to the battery 0

terminal.(5) With the battery

@ terminal jumper wire connected and

disconnected, measure the voltage at control relay termi-

nals

@I and 0.

Continuity between terminals 0-0

)(6) Use jumper wires and connect control relay terminal

@ to

the battery

@ terminal and terminal @ to the battery 0

terminal.(7) With the battery

0 terminal jumper wire disconnected,

measure the voltage at control relay terminal

0.

31(8) Replace the control relay if faulty.

Page 536 of 1216

14-82FUEL SYSTEM - MPI System Inspection <2.0L DOHC Engine>

\ \\I \3FUO352

,\ \

\I \3FUO353

,\ ‘\R/

\ \\I \3FUo354

POWER TRANSISTORRefer to GROUP 8

- Ignition System

NlIAcQAl

a-4

AIR CONDITIONER POWER RELAYN14NCl.a -Refer to GROUP 24

- Air Conditioner.

PURGE CONTROL SOLENOID VALVEN14RCKARefer to GROUP 25

- Evaporative Emission Control System.

EGR CONTROL SOLENOID VALVE

N14NCURefer to GROUP 25

- Exhaust Gas Recirculation System.

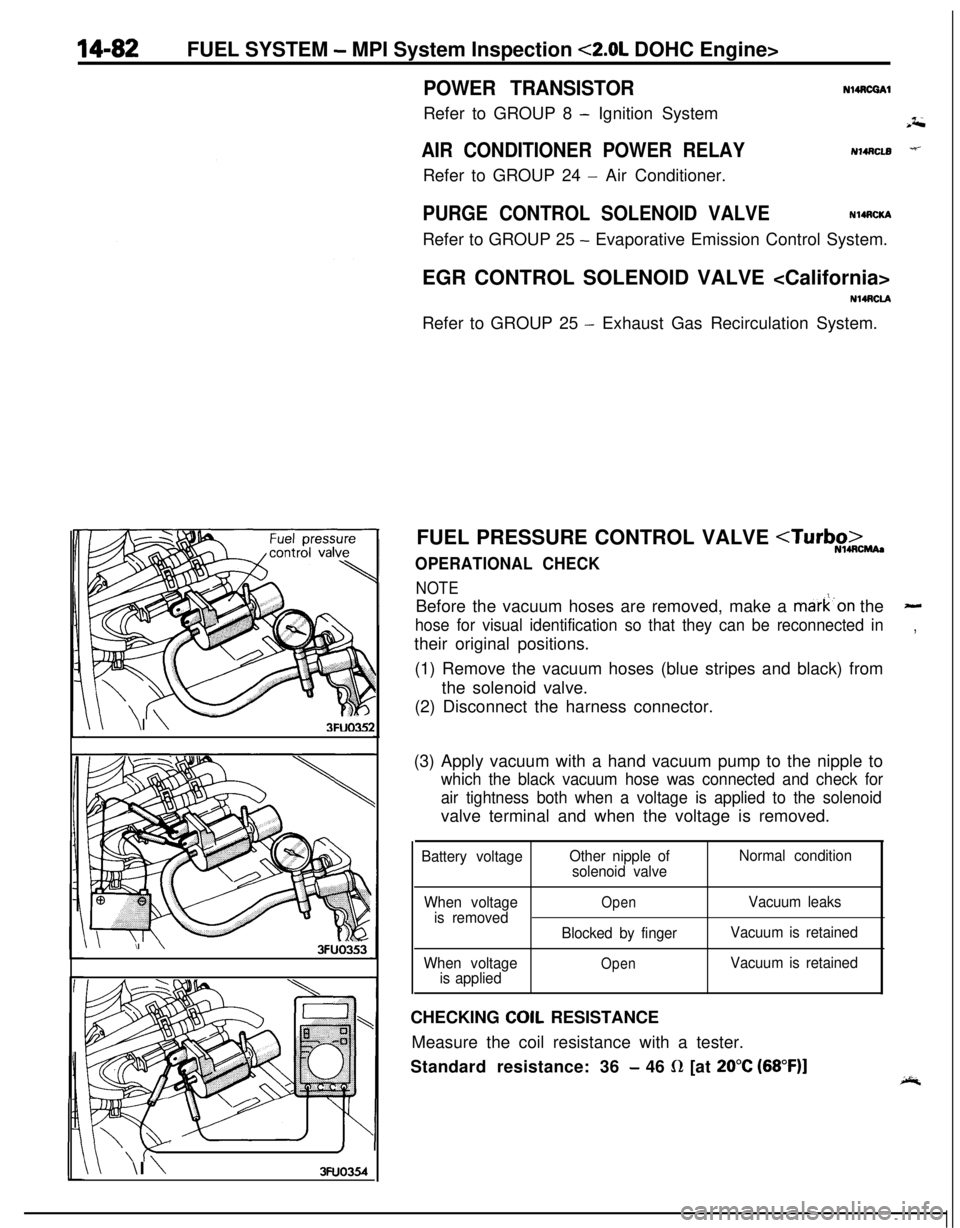

FUEL PRESSURE CONTROL VALVE

NOTEBefore the vacuum hoses are removed, make a mark’on the

-

hose for visual identification so that they can be reconnected in,their original positions.

(1) Remove the vacuum hoses (blue stripes and black) from

the solenoid valve.

(2) Disconnect the harness connector.

(3) Apply vacuum with a hand vacuum pump to the nipple to

which the black vacuum hose was connected and check for

air tightness both when a voltage is applied to the solenoidvalve terminal and when the voltage is removed.

Battery voltageOther nipple of

solenoid valveNormal condition

When voltage

is removed

When voltage

is applied

OpenVacuum leaks

Blocked by fingerVacuum is retained

OpenVacuum is retainedCHECKING

COIL RESISTANCE

Measure the coil resistance with a tester.

Standard resistance: 36

- 46 R [at 20°C (68”F)]

Page 537 of 1216

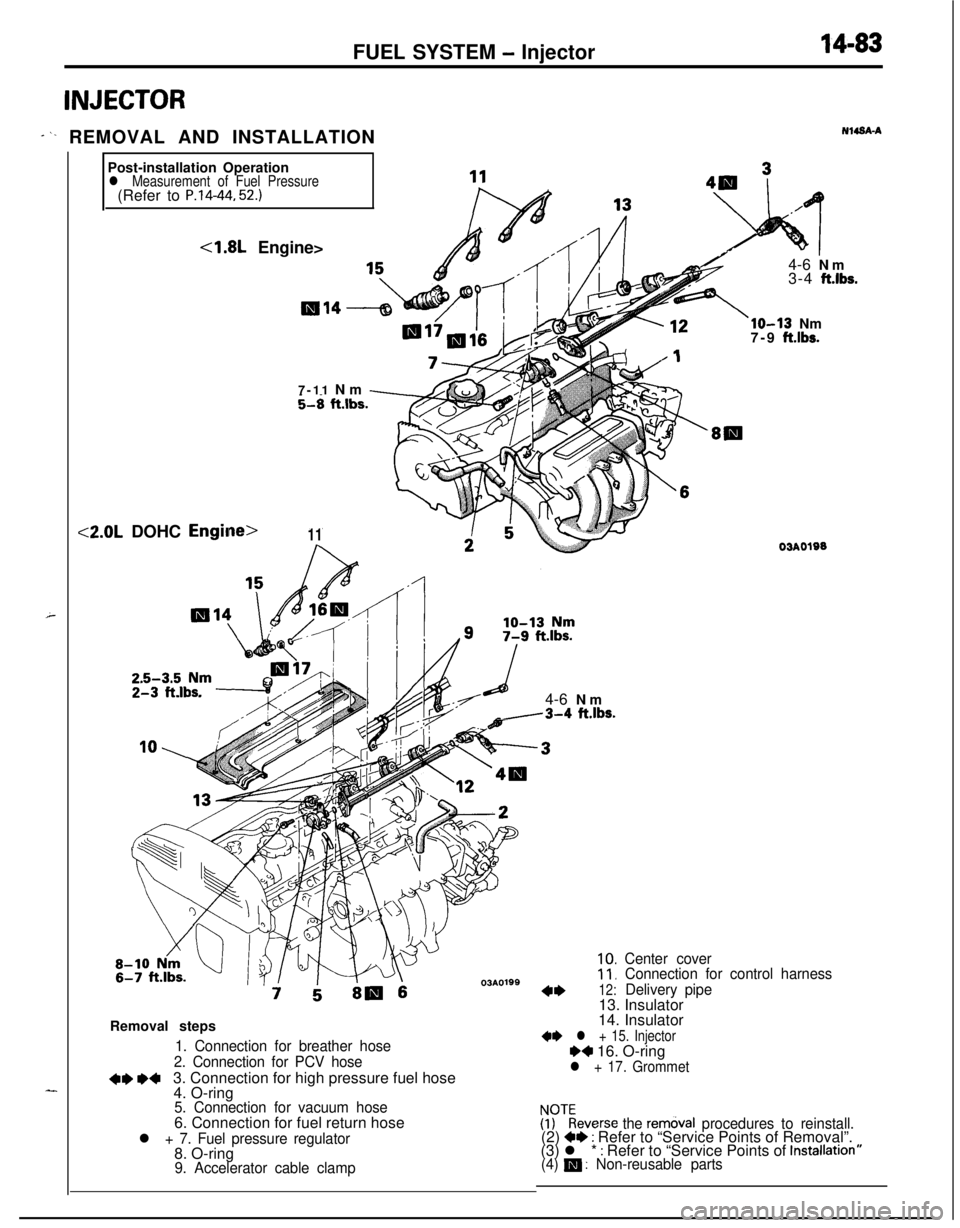

INJECTORFUEL SYSTEM

- Injector14-83

* ‘- REMOVAL AND INSTALLATIONNWSA-A

Post-installation Operation

l Measurement of Fuel Pressure(Refer to P.14-44. 52.)

4.8L Engine><2.0L DOHC

Engilme>11R7-11 Nm

-hl ft.lbs.-zF!

;533i5,b;m-. .-Y-71s4-6 Nma-3-4 ft.lbs.

03AOlSS::,

4*12:

Center cover

Connection for control harness

Delivery pipe

d-- -13. Insulator4-6 Nm

3-4

ft.lbs.

lo-13 Nm

7-9 ft.lbs.Removal steps

1. Connection for breather hose

2. Connection for PCV hose

+e *+3. Connection for high pressure fuel hose

4. O-ring

5. Connection for vacuum hose6. Connection for fuel return hose

l + 7. Fuel pressure regulator8. O-ring

9. Accelerator cable clamp

03AO19014. Insulator

** l + 15. InjectorH 16. O-ringl + 17. Grommet

!PTkeverse the rem&al procedures to reinstall.(2) +* : Refer to “Service Points of Removal”.

(3) l * : Refer to “Service Points of Installatron”(4) m : Non-reusable parts

Page 538 of 1216

14-84FUEL SYSTEM - Injector

03*0095

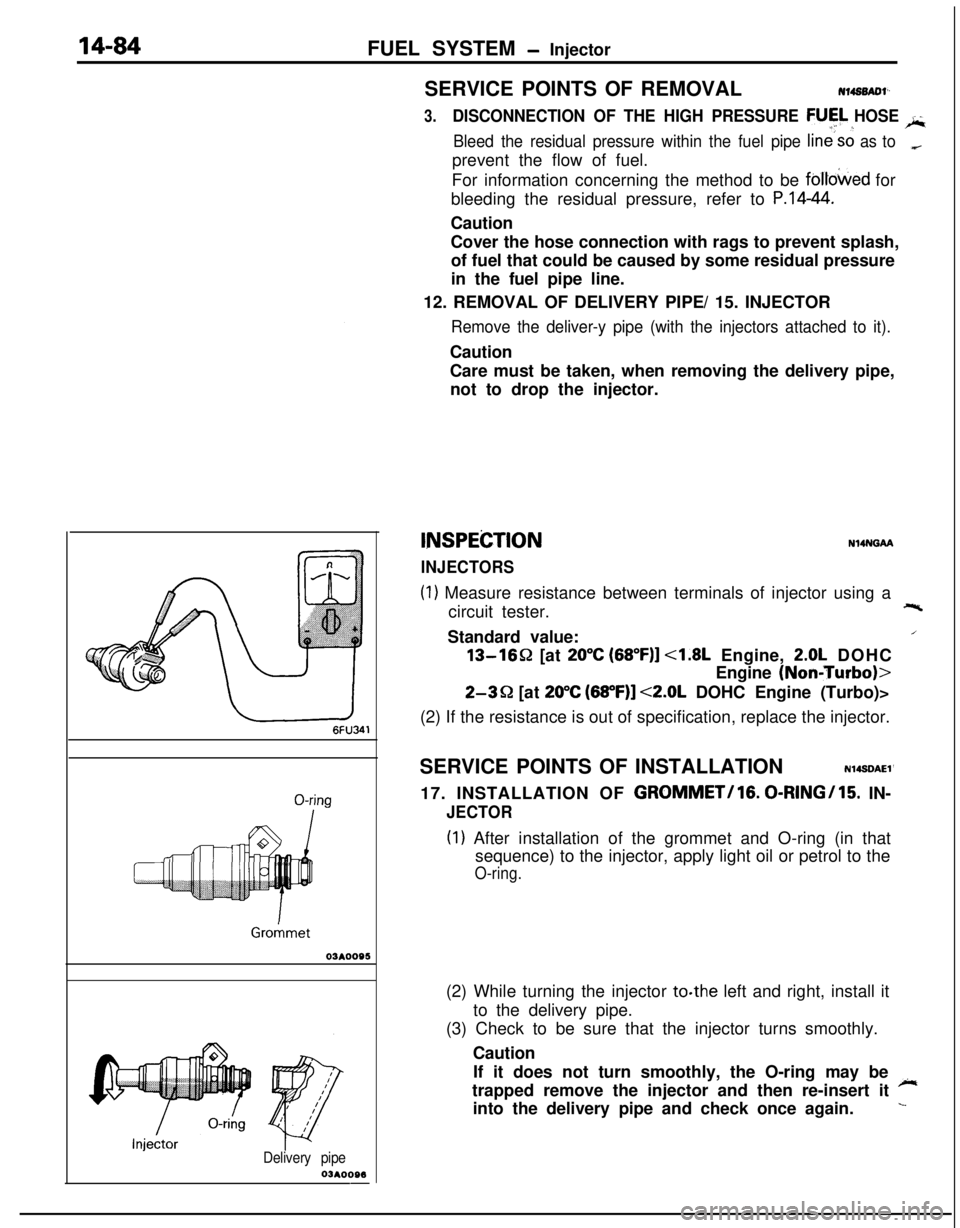

Delivery pipe03A0095-SERVICE POINTS OF REMOVAL

H4s0m1‘~

3.DISCONNECTION OF THE HIGH PRESSURE FlJFL HOSE /;;

Bleed the residual pressure within the fuel pipe line’& as to~prevent the flow of fuel.

For information concerning the method to be folfowed for

bleeding the residual pressure, refer to

P.14-44.Caution

Cover the hose connection with rags to prevent splash,

of fuel that could be caused by some residual pressure

in the fuel pipe line.

12. REMOVAL OF DELIVERY PIPE/ 15. INJECTOR

Remove the deliver-y pipe (with the injectors attached to it).Caution

Care must be taken, when removing the delivery pipe,

not to drop the injector.

INSPEiZTION

INJECTORS

N14NGAA

(1) Measure resistance between terminals of injector using a

circuit tester.+-%Standard value:

/13-1652 [at

20°C (68”F)] <1.8L Engine, 2.0L DOHC

Engine

(NoniTurbo)>

2-3Q [at 20°C (68”F)] <2.0L DOHC Engine (Turbo)>

(2) If the resistance is out of specification, replace the injector.

SERVICE POINTS OF INSTALLATION

N14SDAEl’17. INSTALLATION OF

GROMMET/lG. 0-RINGI15. IN-

JECTOR

(I) After installation of the grommet and O-ring (in that

sequence) to the injector, apply light oil or petrol to the

O-ring.(2) While turning the injector to.the left and right, install it

to the delivery pipe.

(3) Check to be sure that the injector turns smoothly.

Caution

If it does not turn smoothly, the O-ring may be

~trapped remove the injector and then re-insert it

into the delivery pipe and check once again.

L

Page 539 of 1216

FUEL SYSTEM - Injector/Throttle Body <1.8L Engine>14-85

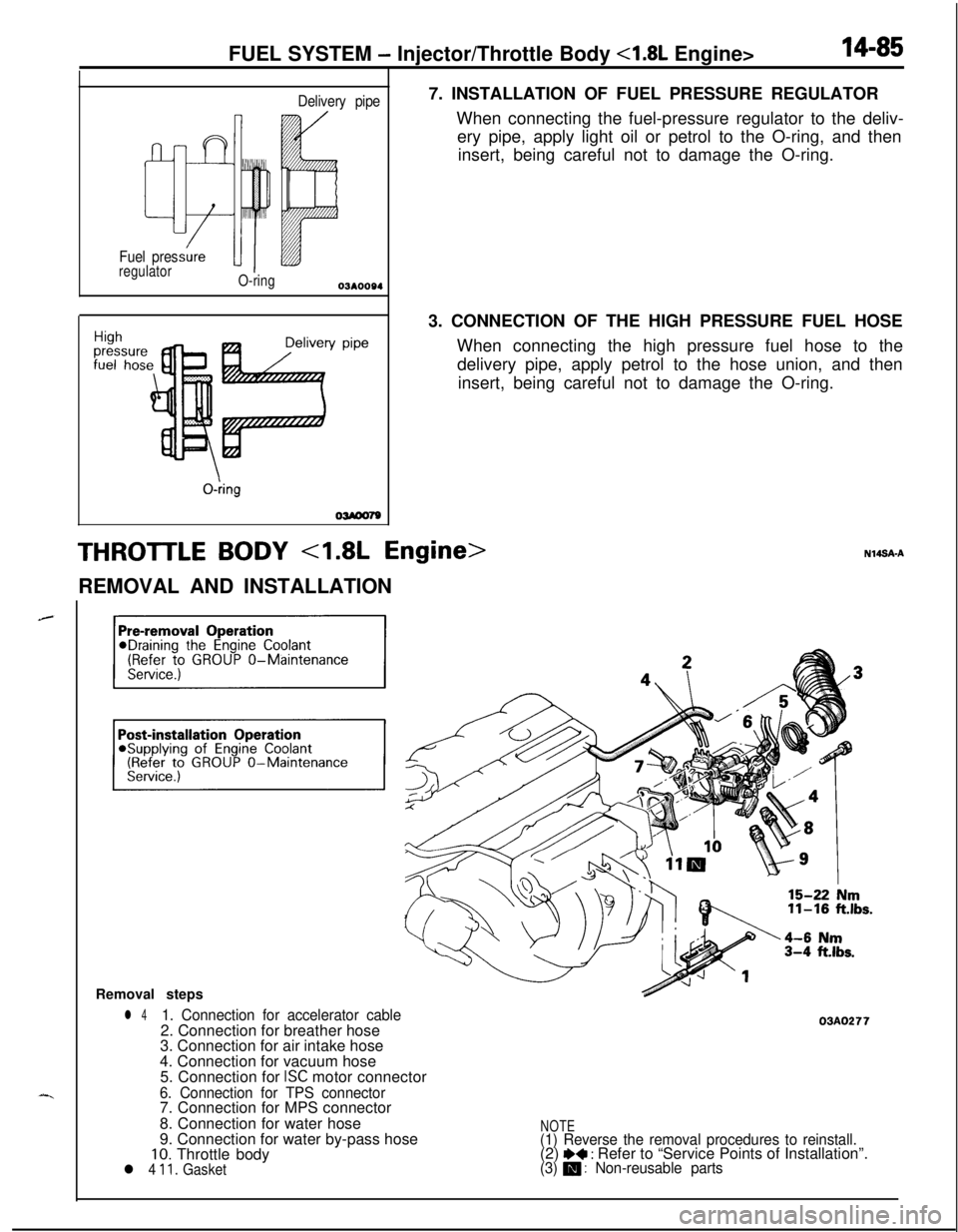

Delivery pipe

Fuel pres

regulator

O-ringY pipe

O-kg

OWOO797. INSTALLATION OF FUEL PRESSURE REGULATOR

When connecting the fuel-pressure regulator to the deliv-

ery pipe, apply light oil or petrol to the O-ring, and then

insert, being careful not to damage the O-ring.

3. CONNECTION OF THE HIGH PRESSURE FUEL HOSE

When connecting the high pressure fuel hose to the

delivery pipe, apply petrol to the hose union, and then

insert, being careful not to damage the O-ring.

THROTTLE BODY 4.8L Engine>REMOVAL AND INSTALLATION

Removal steps

l 41. Connection for accelerator cable2. Connection for breather hose

3. Connection for air intake hose

4. Connection for vacuum hose

5. Connection for

ISC motor connector

6. Connection for TPS connector7. Connection for MPS connector

8. Connection for water hose

9. Connection for water by-pass hose

10. Throttle bodyl 4 11. Gasket

03AO277

NOTE(1) Reverse the removal procedures to reinstall.(2) I)+ : Refer to “Service Points of Installation”.(3) m : Non-reusable parts

Page 540 of 1216

14-86FUEL SYSTEM - Throttle Bodv 4.8L Enaine>

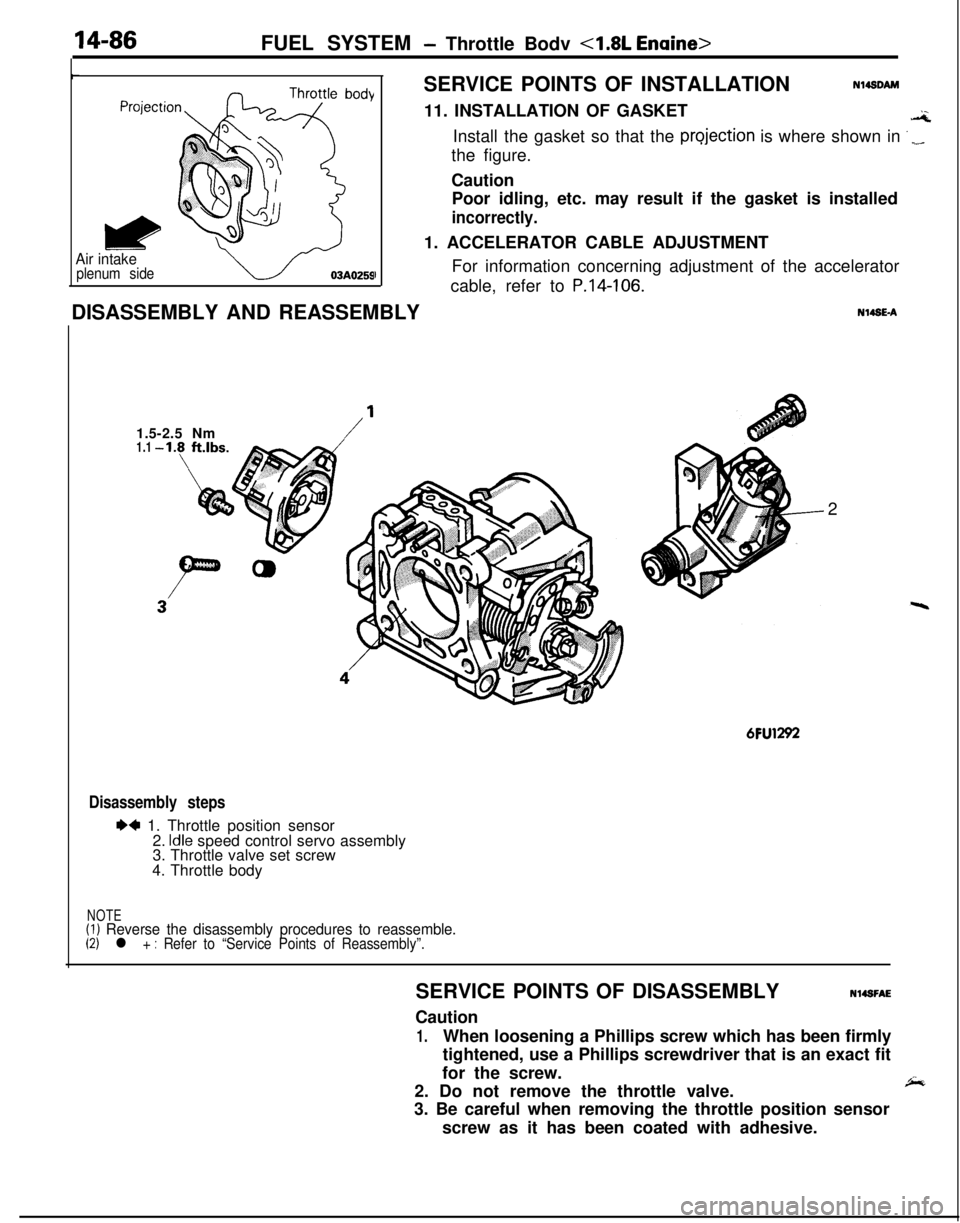

Air intakeplenum sideISERVICE POINTS OF INSTALLATION

Nl4sDAM11. INSTALLATION OF GASKET

.aInstall the gasket so that the

projection is where shown in ‘_the figure.

Caution

Poor idling, etc. may result if the gasket is installed

incorrectly.1. ACCELERATOR CABLE ADJUSTMENT

For information concerning adjustment of the accelerator

cable, refer to

P.14-106.DISASSEMBLY AND REASSEMBLYN14SE-A

1.5-2.5 Nm

/’1.12

6FU1292

Disassembly steps

I)4 1. Throttle position sensor

2. Idle speed control servo assembly

3. Throttle valve set screw

4. Throttle body

NOTE(1) Reverse the disassembly procedures to reassemble.(2) l + : Refer to “Service Points of Reassembly”.SERVICE POINTS OF DISASSEMBLYN14SFAE

Caution

1.When loosening a Phillips screw which has been firmly

tightened, use a Phillips screwdriver that is an exact fit

for the screw.

2. Do not remove the throttle valve.

,&3. Be careful when removing the throttle position sensor

screw as it has been coated with adhesive.