MITSUBISHI MONTERO 1987 1.G Workshop Manual

Manufacturer: MITSUBISHI, Model Year: 1987, Model line: MONTERO, Model: MITSUBISHI MONTERO 1987 1.GPages: 284, PDF Size: 14.74 MB

Page 231 of 284

AUTOMATIC FREE-WHEELING HUB INDICATOR SYSTEM - Generallnformation 8-211

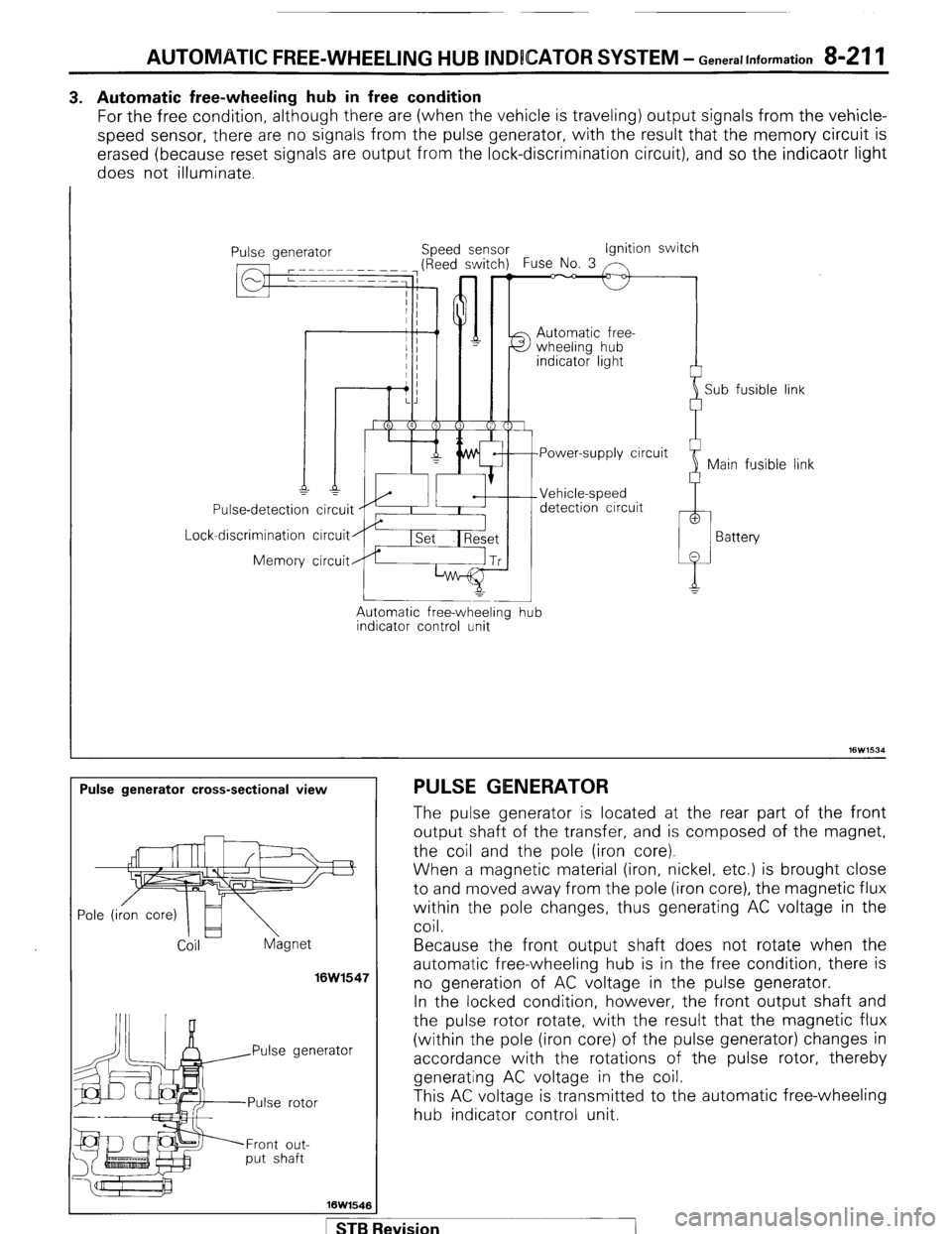

3. Automatic free-wheeling hub in free condition

For the free condition, although there are (when the vehicle is traveling) output signals from the vehicle-

speed sensor, there are no signals from the pulse generator, with the result that the memory circuit is

erased (because reset signals are output from the lock-discrimination circuit), and so the indicaotr light

does not illuminate.

I

Lock Use-detection

-discrimination

Memory ipeed sensor Ignition switch

Automatic free-

detection circuit

circuit

circuit

Automatic free-wheeling

indicator control unit -

hub i

Sub fusible link

link

Pulse generator cross-sectional view PULSE GENERATOR

Coil hgnet

16W1547

rator

Front out-

put shaft

16W1546 The pulse generator is located at the rear part of the front

output shaft of the transfer, and is composed of the magnet,

the coil and the pole (iron core).

When a magnetic material (iron, nickel, etc.) is brought close

to and moved away from the pole (iron core), the magnetic flux

within the pole changes, thus generating AC voltage in the

coil.

Because the front output shaft does not rotate when the

automatic free-wheeling hub is in the free condition, there is

no generation of AC voltage in the pulse generator.

In the locked condition, however, the front output shaft and

the pulse rotor rotate, with the result that the magnetic flux

(within the p o e I (’ Iron core) of the pulse generator) changes in

accordance with the rotations of the pulse rotor, thereby

generating AC voltage in the coil.

This AC voltage is transmitted to the automatic free-wheeling

hub indicator control unit.

STB Revision

Page 232 of 284

8-212 AUTOMATIC FREE-WHEELING HUB lNCDlCATOR SYSTEM - $%%60n’~at’on’

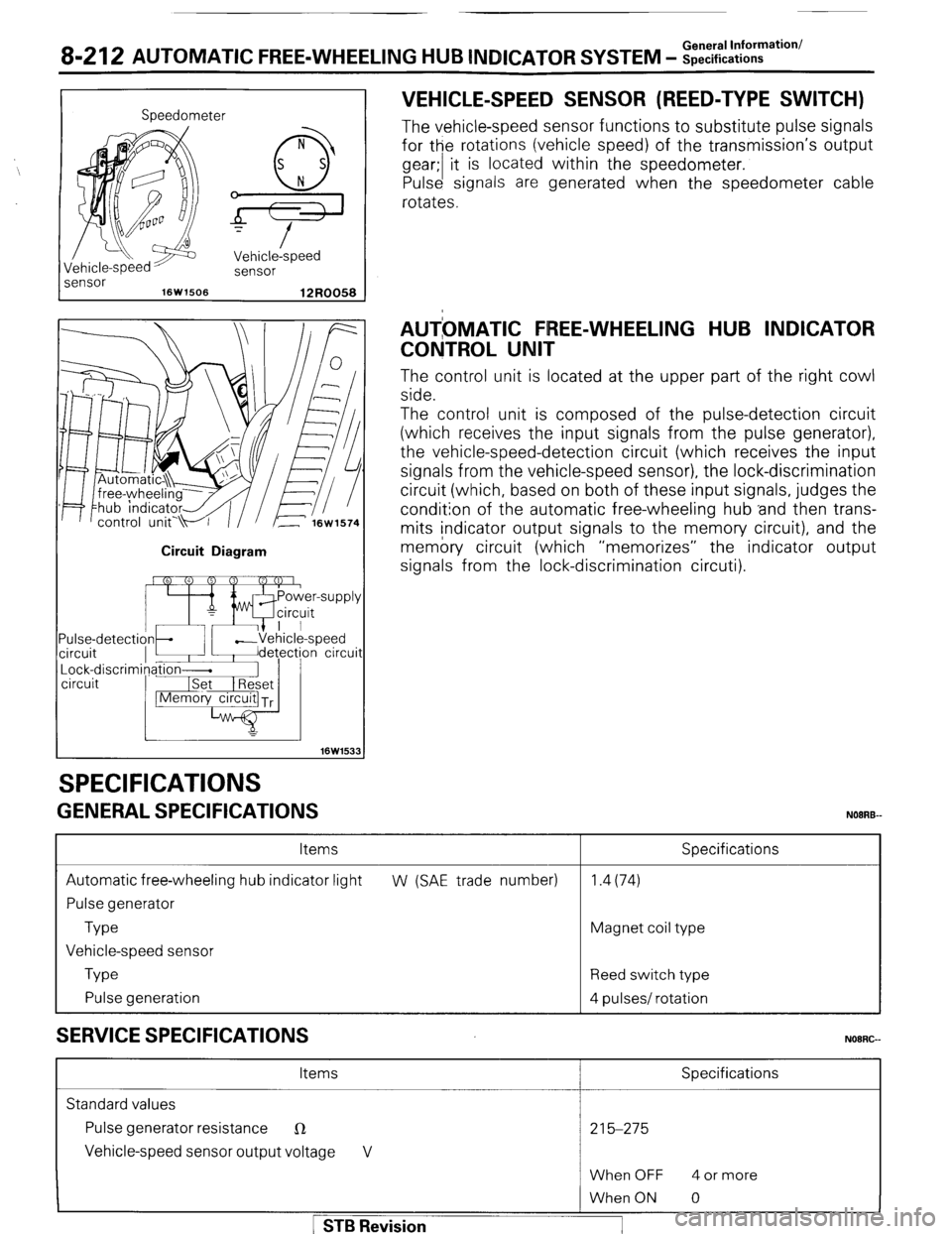

Speedometer

I

iensor Vehicle-speed

sensor

16W1506

12R0058

Circuit Diagram

16W153

SPECIFICATIONS

GENERAL SPECIFICATIONS VEHICLE-SPEED SENSOR (REED-TYPE SWITCH)

The vehicle-speed sensor functions to substitute pulse signals

for the rotations (vehicle speed) of the transmission’s output

gear;/ t i is located within the speedometer.

Pulse signals are generated when the speedometer cable

rotates.

AUTbMATlC FREE-WHEELING HUB INDICATOR

CONTROL UNIT

The control unit is located at the upper part of the right cowl

side.

The control unit is composed of the pulse-detection circuit

(which receives the input signals from the pulse generator),

the vehicle-speed-detection circuit (which receives the input

signals from the vehicle-speed sensor), the lock-discrimination

circuit (which, based on both of these input signals, judges the

condition of the automatic free-wheeling hub ‘and then trans-

mits indicator output signals to the memory circuit), and the

memory circuit (which “memorizes” the indicator output

signals from the lock-discrimination circuti).

Items

Automatic free-wheeling hub indicator light

Pulse generator

Type

Vehicle-speed sensor

Type

Pulse generation

SERVICE SPECIFICATIONS

Specifications

W (SAE trade number) 1.4(74)

Magnet coil type

Reed switch type

4 pulses/ rotation

NOORG-

Items Specifications

Standard values

Pulse generator resistance

R 215-275

Vehicle-speed sensor output voltage V

When OFF 4 or more 1 STB Revision

When ON 0

Page 233 of 284

AUTOMATIC FREE-WHEELING HUB INDICATOR SYSTEM -Troubleshooting 8-213

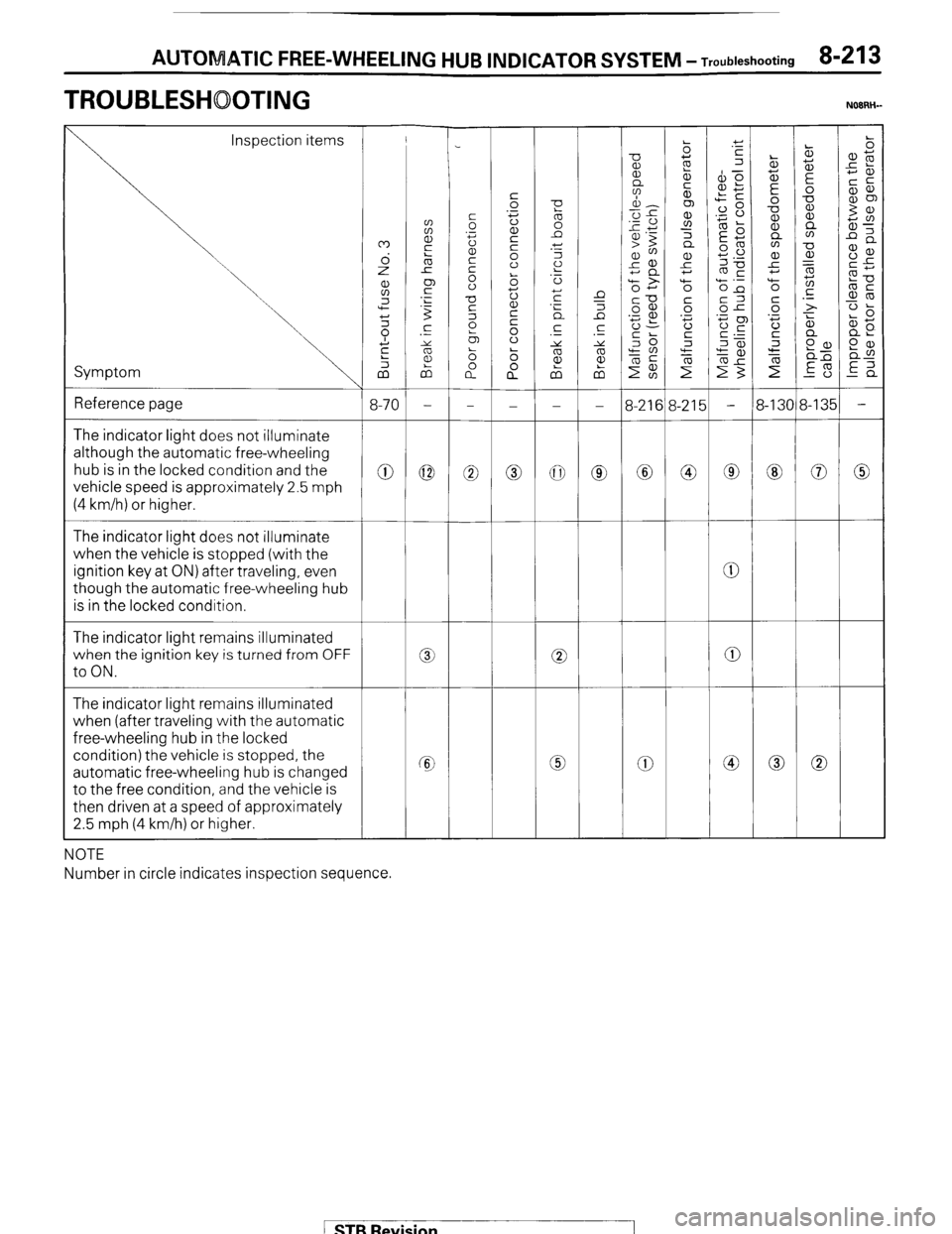

TROUBLESHOOTING NOIRH-

Inspection items

Symptom

Reference page

3-21E

0 The indicator light does not illuminate

although the automatic free-wheeling

hub is in the locked condition and the

vehicle speed is approximately 2.5 mph

(4 km/h) or higher.

0 0 0

0

The indicator light does not illuminate

when the vehicle is stopped (with the

ignition key at ON) after traveling, even

though the automatic free-wheeling hub

is in the locked condition.

The indicator light remains illuminated

when the ignition key is turned from OFF

to ON.

0

0 0 0

a 0

The indicator light remains illuminated

when (after traveling with the automatic

free-wheeling hub in the locked

condition) the vehicle is stopped, the

automatic free-wheeling hub is changed

to the free condition, and the vehicle is

then driven at a speed of approximately

2.5 mph (4 km/h) or higher.

0 Cc 0

NOTE

Number in circle indicates inspection sequence.

/ STB Revision

Page 234 of 284

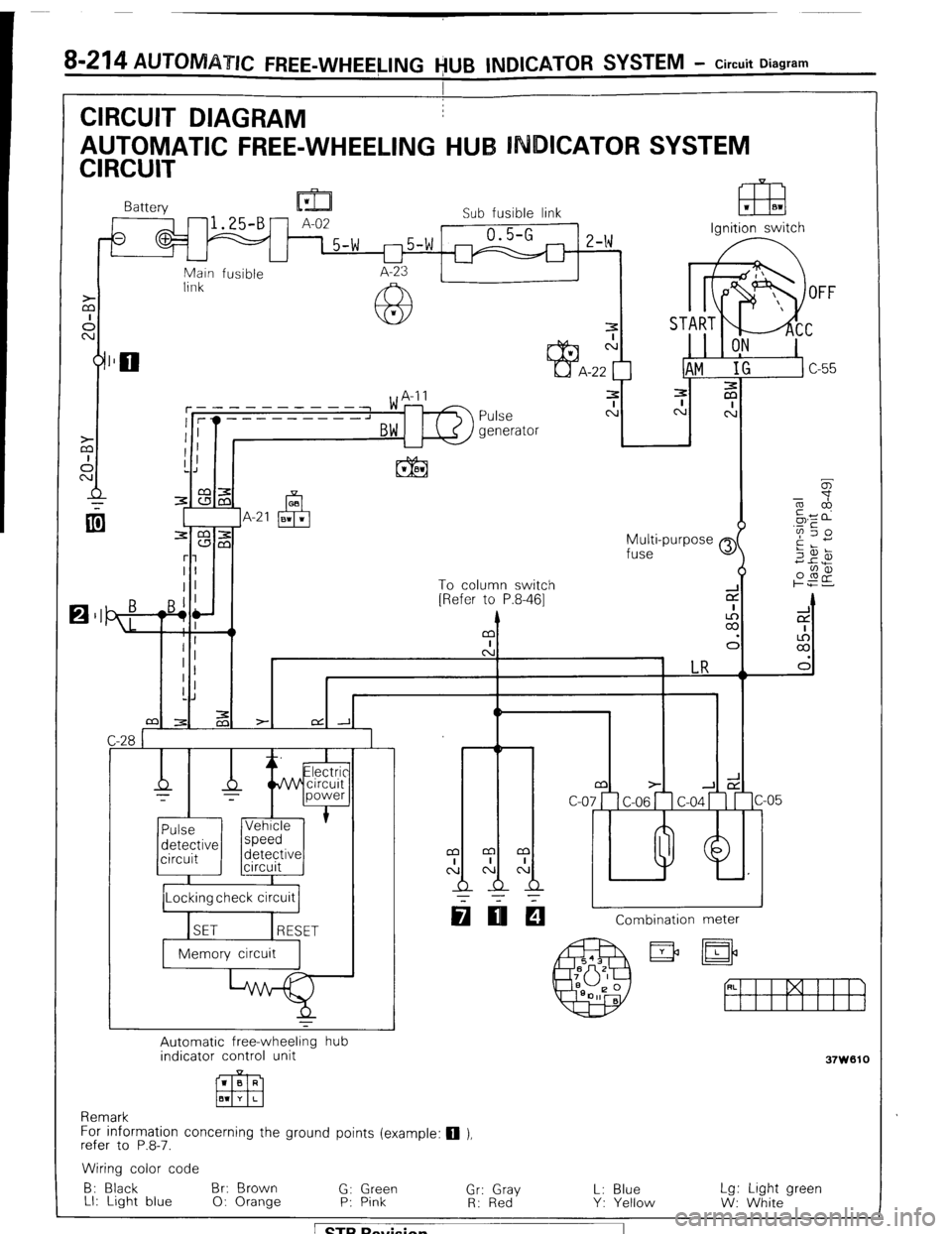

8-214 AUTOM TIC FREE-WHEELING VU6 INDICATOR SYSTEM - Circuit Diagram

I

m I IA-21 m

v?~

r:

BI I To column switch

2

[Refer to P.8-461 CT

= 9’i A I

I

m z

I ’

c: d

I ’

LR

!J

I I 1

CIRCUIT DIAGRAM

AUTOMATIC FREE-WHEELING HUB INDICATOR SYSTEM

CIRCUIT

F==e=%

Battery lu-!

A-02 Sub fusible link

- 15-w r-)5-w 0.5-G

2-w

I I I I

Main fusible

link

7

N

-22

3

Pulse c:

generator

h Ignition switch

I /Locking check circuit 1

q IIEI Combination meter

Automatic free-wheeling hub

indicator control unit

1 B R

Em El1 Y L

Remark

For information concerning the ground points (example: q ),

refer to P.8-7.

37W610

Wiring color code

B: Black Br: Brown

G: Green L: Blue

LI: Light blue Lg: Light green

0: Orange P: Pink “,r: RG,‘d”Y

Y: Yellow

W: White

1 STB Revision

Page 235 of 284

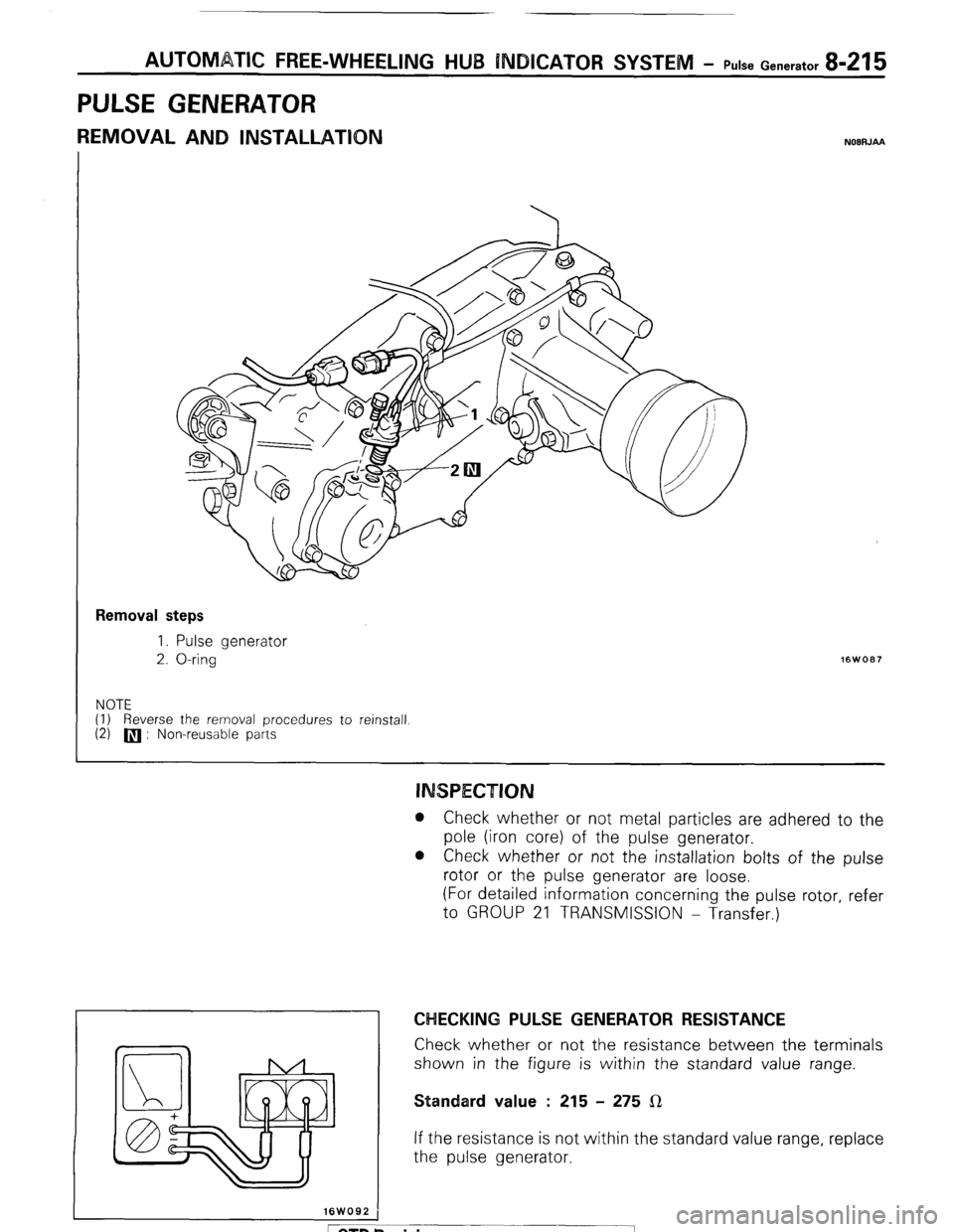

AUTOMATIC FREE-WHEELING HUB INDICATOR SYSTEM - Pulse Generator 8-215

PULSE GENERATOR

REMOVAL AND INSTALLATION NOBRJM

Removal steps

I. Pulse generator

2. O-ring

NOTE

(1) Reverse the removal procedures to reinstall

(2)

q : Non-reusable parts

I 16WO92 i

l Check whether or not metal particles are adhered to the

pole (iron core) of the pulse generator.

l Check whether or not the installation bolts of the pulse

rotor or the pulse generator are loose.

(For detailed information concerning the pulse rotor, refer

to GROUP 21 TRANSMISSION - Transfer.)

CHECKING PULSE GENERATOR RESISTANCE

Check whether or not the resistance between the terminals

shown in the figure is within the standard value range.

Standard value : 215 - 275 LR

If the resistance is not within the standard value range, replace

the pulse generator.

1 STB Revision

Page 236 of 284

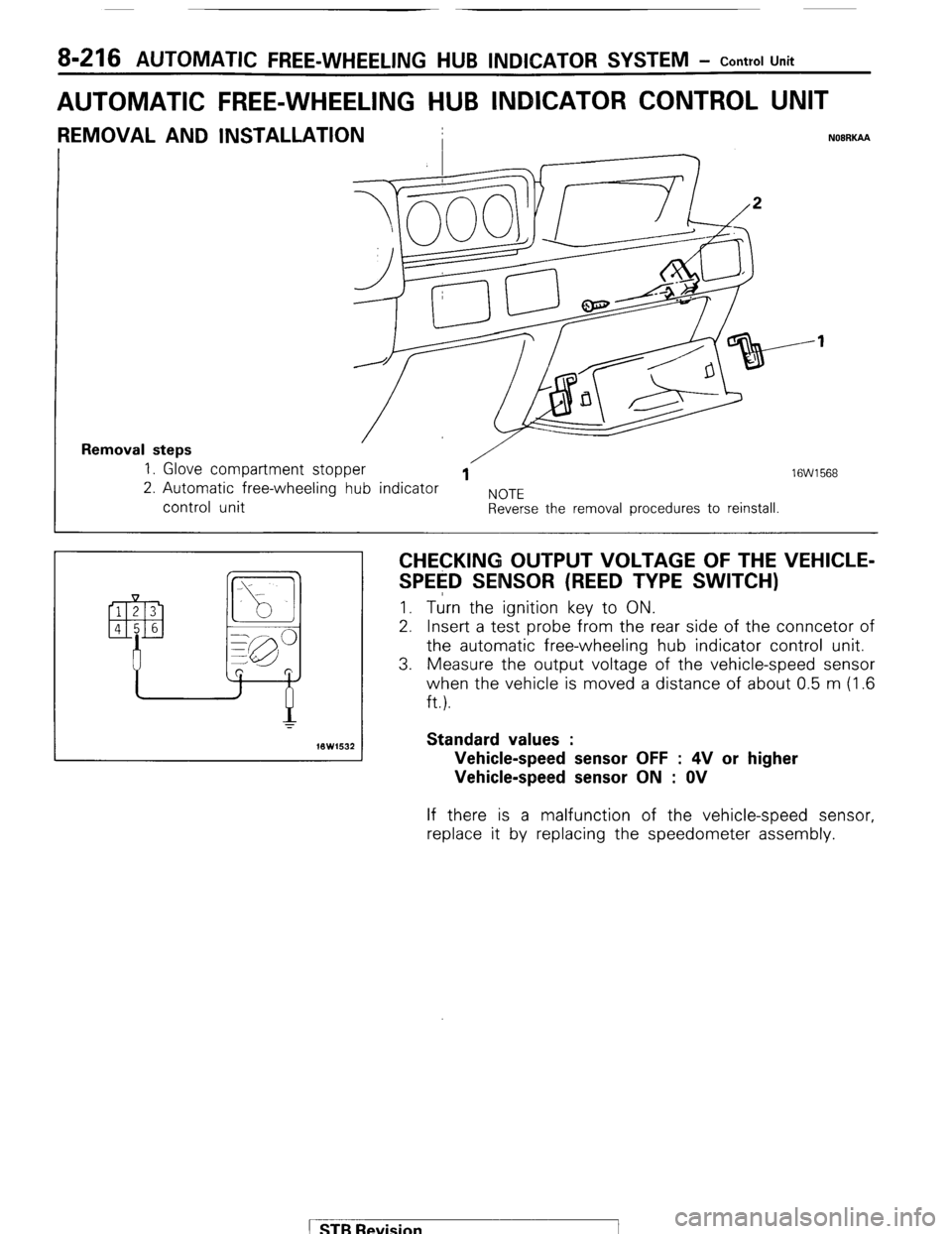

8-216 AUTOMATIC FREE-WHEELING HUB INDICATOR SYSTEM - Control Unit

AUTOMATIC FREE-WHEELING HUB INDICATOR CONTROL UNIT

REMOVAL AND INSTALLATION

I NOBRKAA

Removal steps 1. Glove compartment stopper /

1 16W1568 2. Automatic free-wheeling hub indicator

NOTE control unit Reverse the removal procedures to reinstall.

CHECKING OUTPUT VOLTAGE OF THE VEHICLE-

SPE$D SENSOR (REED TYPE SWITCH) I. Turn the ignition key to ON.

2. Insert a test probe from the rear side of the conncetor of

the automatic free-wheeling hub indicator control unit.

3. Measure the output voltage of the vehicle-speed sensor

when the vehicle is moved a distance of about 0.5 m (1.6

ft.).

Standard values :

Vehicle-speed sensor OFF : 4V or higher

Vehicle-speed sensor ON : OV If there is a malfunction of the vehicle-speed sensor,

replace it by replacing the speedometer assembly.

( STB Revision

Page 237 of 284

24-1

AIR-CO IONING

CONTENTS

AIR-CONDITIONING

AIR CONDITIONER SWITCH ......................... 42

CIRCUIT DIAGRAM ...................................... . . 26

COMPRESSOR ............................................... 46

EVAPORATOR ............................................ . ... 43

GENERAL INFORMATION .............. . ....... . . . .... 19

RECEIVER DRIER, CONDENSER,

COMPRESSOR CLUTCH ASSEMBLY .......... 45

SAFETY PRECAUTIONS ................................ 28

SERVICE ADJUSTMENT PROCEDURES ...... 29

Compressor Drive Belt Adjustment ...........

40

Compressor Noise ..................................... 41

Handling Tubing and Fittings ..................... 39

Manifold Gauge Set Installation ................ 29

Performance Test ...................................... 34

Refrigerant Leak Repair Procedure ........... 34

Test Procedures ......................................... 29

Testing System for Leaks .......................... 33

SPECIAL TOOLS ............................................ 22

SPECIFICATIONS ...... . .

.. . ................................ 21

General Specifications ...............................

21

Service Specifications ................................

21

Torque Specifications ................................

21

TROUBLESHOOTING .................................... 22 Air is Emitted but Is Not Cool

Cool Air Flow Is Intermittent

Insufficient Air Flow

Insufficient Cooling

HEATERS

BLOWER ASSEMBLY . . . . . . . . . . . . . . . . . . ..a............... 14

CIRCUIT DIAGRAM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

GENERAL INFORMATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

HEATER CONTROL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

HEATER UNIT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

SERVICE ADJUSTMENT PROCEDURES . . . . . . 5

Temperature Control System

Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Water Valve Replacement . . . . . . . . . . . . . . . . . . . . . . . 8

TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Blower Motor Inoperative

Blower Motor Operates on High

Speed Only

Improper Heat

No Ventilation Even When Mode

Selection Lever Is Operated

VENTILATORS . . . . . . . . . . . . . . . . . . . . . . . . . . . ..a..... . . . . . . . . . . . .

16

Page 238 of 284

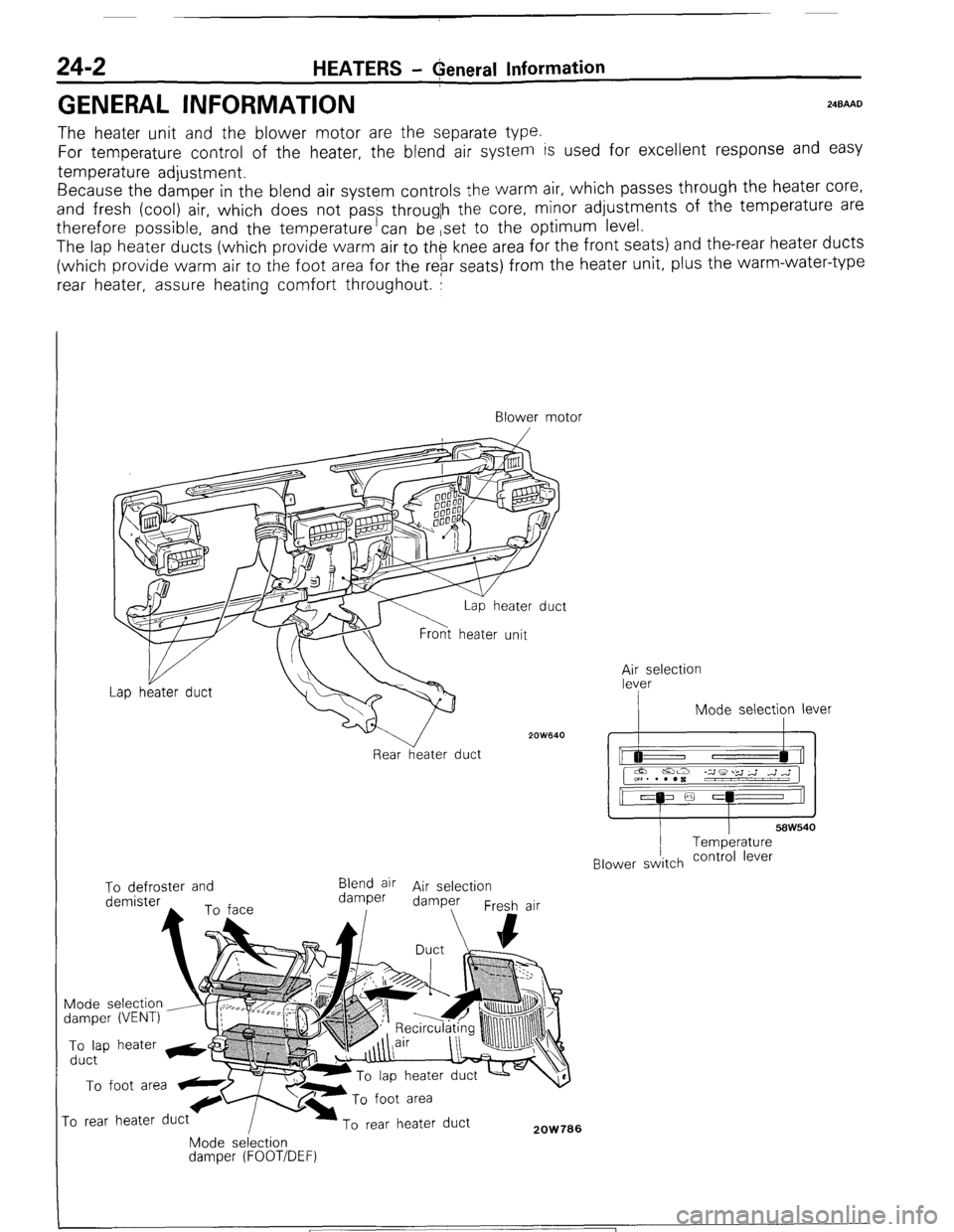

24-2 HEATERS - General Information

GENERAL INFORMATION 24BAAD

The heater unit and the blower motor are the separate type.

For temperature control of the heater, the blend air system is used for excellent response and easy

temperature adjustment.

Because the damper in the blend air system controls the warm air, which passes through the heater core,

and fresh (cool) air, which does not pass througlh the core, minor adjustments of the temperature are

therefore possible, and the temperature’can be ,set to the optimum level.

The lap heater ducts (which provide warm air to th$ knee area for the front seats) and the-rear heater ducts

(which provide warm air to the foot area for the rebr seats) from the heater unit, plus the warm-water-type

rear heater, assure heating comfort throughout. :

Blower motor

/

2OW640

Rear heater duct ;;eselection

I Mode selection lever

I I

58W540 Temperature

Blower switch contra’ lever To defroster and

Blend air Air selection

demister damper damper

Fresh air

Mode selection

damper (VENT) To lap heater &@

duct To foot area

ro rear heater duct To rear heater duct 2OW706 Mode selection damper (FOOT/DEF)

1 ST6 Revision

Page 239 of 284

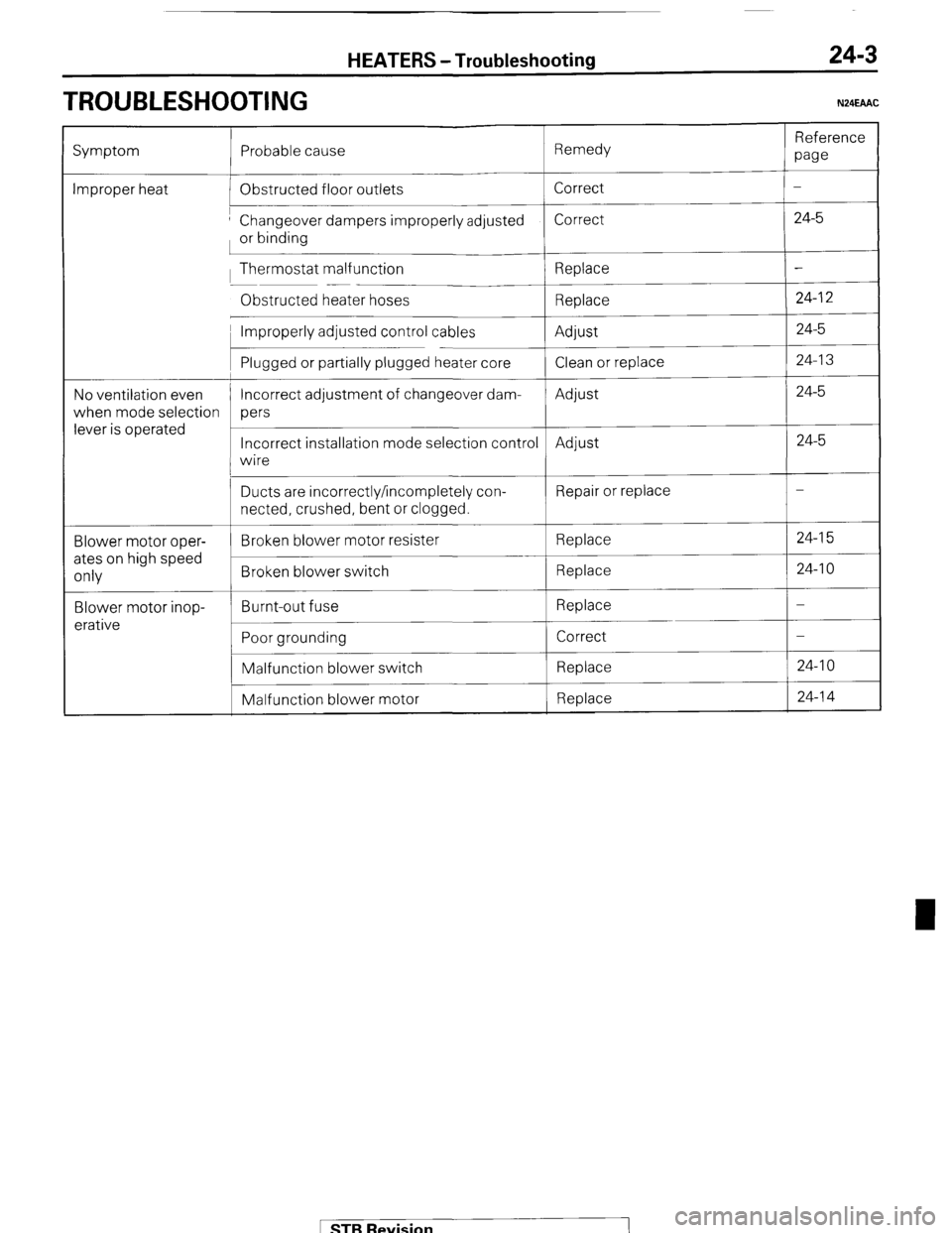

TROUBLESHOOTING

HEATERS -Troubleshooting 24-3

N24EAAC

Reference

Symptom Probable cause Remedy

paw

Improper heat Obstructed floor outlets Correct -

’ Changeover dampers improperly adjusted Correct 24-5

or binding

, Thermostat malfunction

Replace -

Obstructed heater hoses

Replace 24-l 2

’ Improperly adjusted control cables

Adjust 24-5

Plugged or partially plugged heater core

Clean or replace 24-l 3

No ventilation even Incorrect adjustment of changeover dam-

Adjust 24-5

when mode selection pers

lever is operated

Incorrect installation mode selection control

Adjust 24-5

wire

Blower motor oper-

ates on high speed

only

Blower motor inop-

erative Ducts are incorrectly/incompletely con-

netted, crushed, bent or clogged.

Broken blower motor resister

Broken blower switch

Burnt-out fuse

Poor grounding

Malfunction blower switch

Malfunction blower motor Repair or replace

Replace

Replace

Replace

Correct

Replace

Replace -

24-l 5

24-l 0

-

-

24-l 0

24-l 4 1 STB Revision

Page 240 of 284

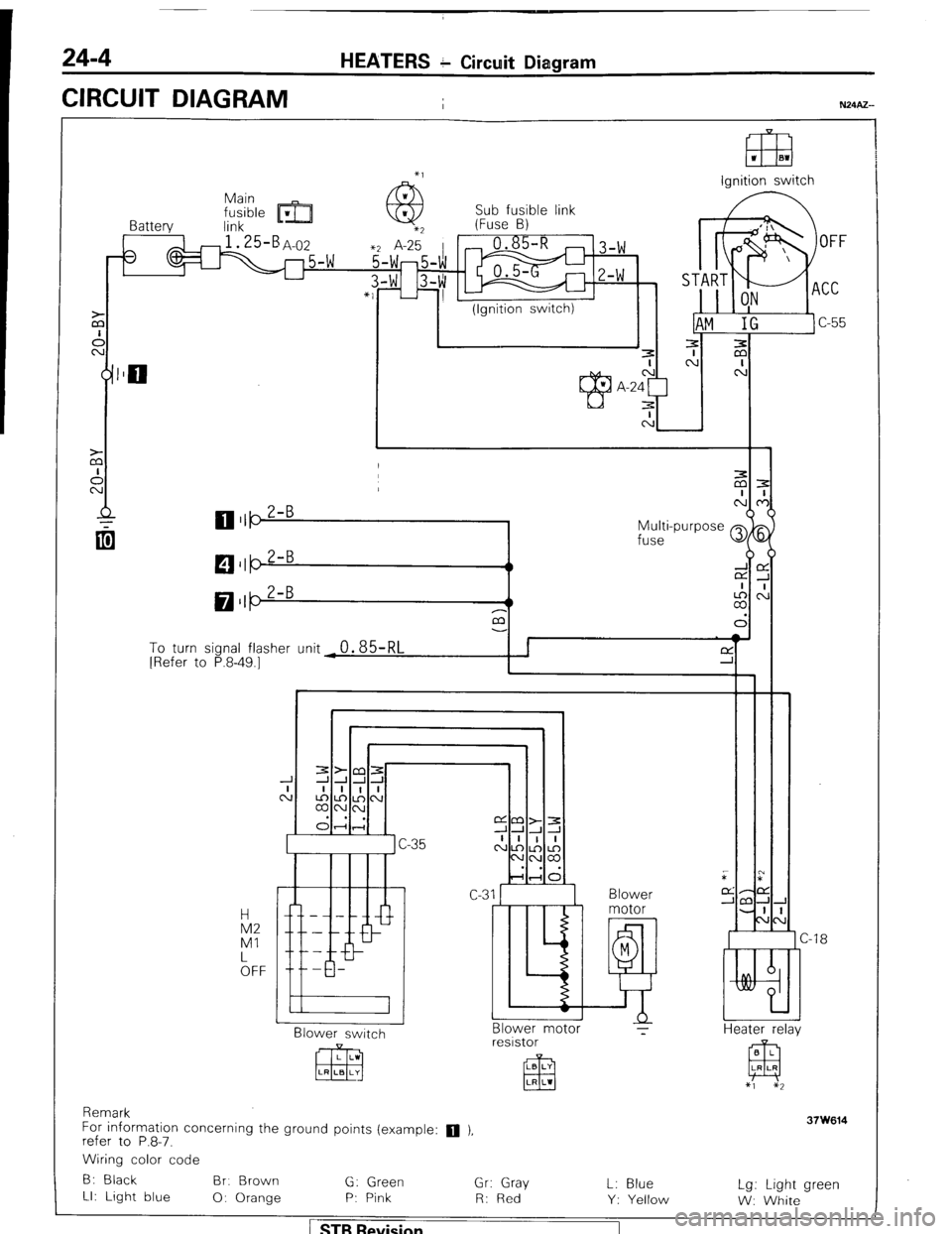

24-4 HEATERS c Circuit Diagram

CIRCUIT DIAGRAM

I

El3 1 El1

lanition switch

Sub fusible link

Battery link m- (Fuse B)

3

1 I (Ignition switch)

Multi-purpose Q

fuse

M $5

LA,:

a3

To turn sional flasher (Init

0.85RI I I f-Y ’ I [Refer to P.8-49.7- - - ‘d -r i

I Blower

Blower switch

CJ -18

Heater r&v Blower motor ?

resistor

Remark

For information concerning the ground points (example:

q ),

refer to P.8-7.

Wiring color code

B: Black Br. Brown

G: Green

Gr: Gray

LI: Light blue

0: Orange P: Pink

R: Red L: Blue

Y: Yellow Lg: Light green

W: White

1 STB Revision