MITSUBISHI SPYDER 1990 Service Repair Manual

Manufacturer: MITSUBISHI, Model Year: 1990, Model line: SPYDER, Model: MITSUBISHI SPYDER 1990Pages: 2103, PDF Size: 68.98 MB

Page 361 of 2103

ENGINE OVERHAUL Piston and

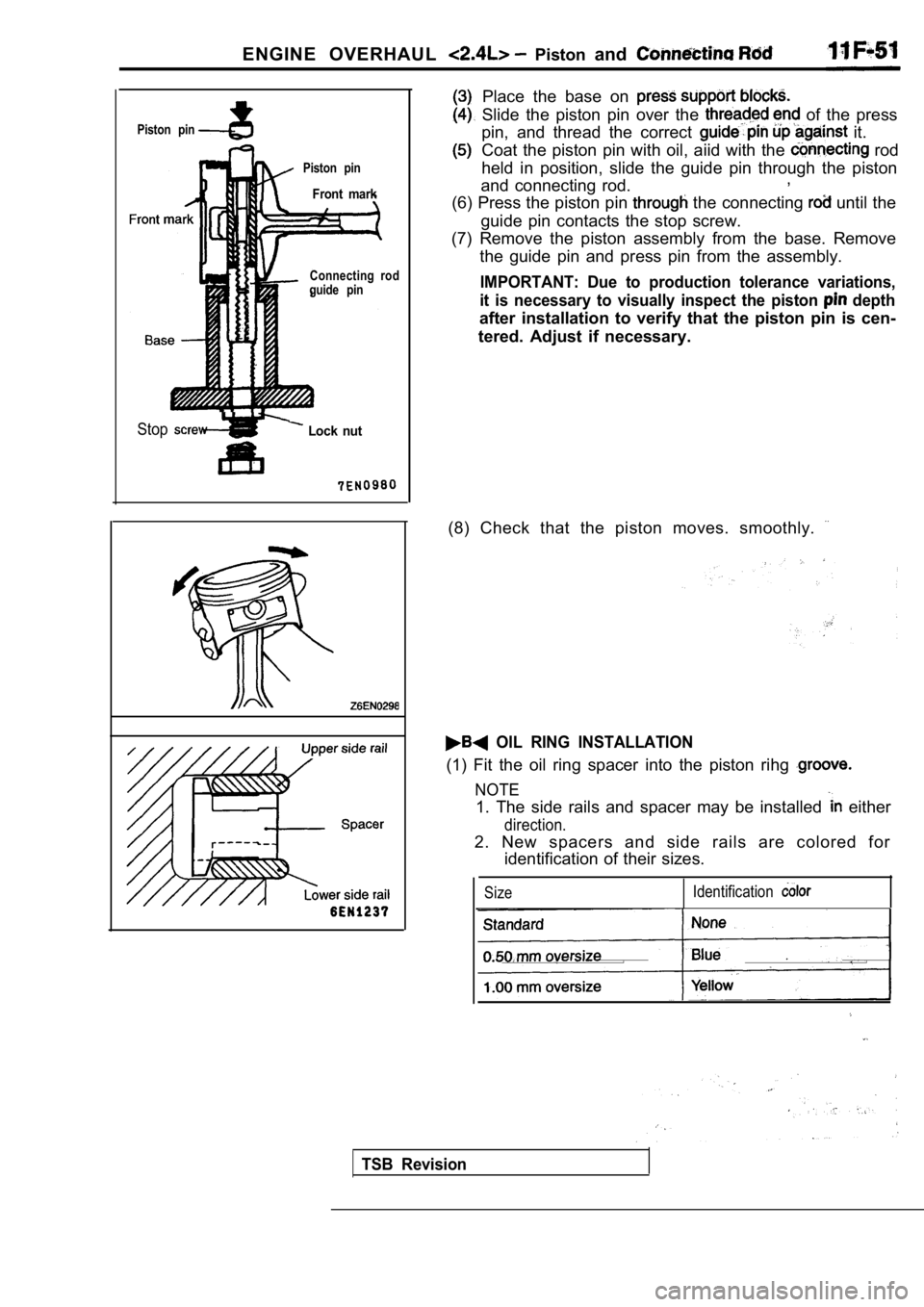

Piston pin

Piston pin

Front mark

Stop Lock nut

Connecting rod

guide pin

Place the base on

Slide the piston pin over the of the press

pin, and thread the correct

it.

Coat the piston pin with oil, aiid with the

rod

held in position, slide the guide pin through the p iston

and connecting rod. ,

(6) Press the piston pin

the connecting until the

guide pin contacts the stop screw.

(7) Remove the piston assembly from the base. Remov e

the guide pin and press pin from the assembly.

IMPORTANT: Due to production tolerance variations,

it is necessary to visually inspect the piston

depth

after installation to verify that the piston pin is cen-

tered. Adjust if necessary.

(8) Check that the piston moves. smoothly.

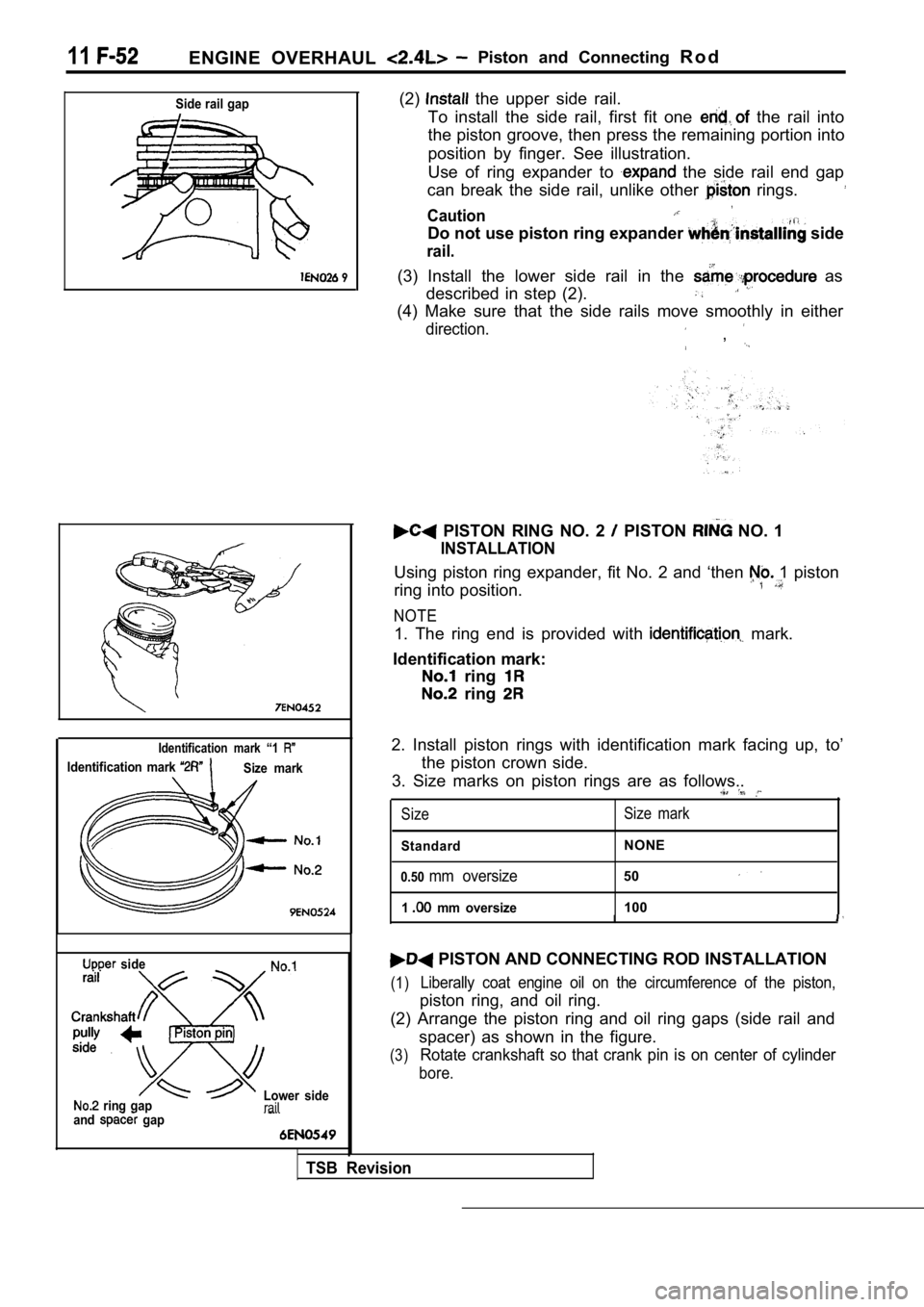

OIL RING INSTALLATION

(1) Fit the oil ring spacer into the piston rihg

NOTE

1. The side rails and spacer may be installed either

direction.

2. New spacers and side rails are colored for identification of their sizes.

Size Identification

TSB Revision

Page 362 of 2103

11ENGINE OVERHAUL Piston and Connecting R o d

Side rail gap

9

Identification mark “1

Identification mark Size mark

side

ring gap

and gap Lower siderail

TSB Revision

(2) the upper side rail.

To install the side rail, first fit one

the rail into

the piston groove, then press the remaining portion into

position by finger. See illustration.

Use of ring expander to

the side rail end gap

can break the side rail, unlike other

rings.

Caution

Do not use piston ring expander side

rail.

(3) Install the lower side rail in the as

described in step (2).

(4) Make sure that the side rails move smoothly in either

direction.,

PISTON RING NO. 2 PISTON NO. 1

INSTALLATION

Using piston ring expander, fit No. 2 and ‘then 1 piston

ring into position.

NOTE

1. The ring end is provided with mark.

Identification mark:

ring

ring

2. Install piston rings with identification mark fa cing up, to’

the piston crown side.

3. Size marks on piston rings are as follows..

Size Size mark

StandardNONE

0.50mm oversize50

1 mm oversize100

II

PISTON AND CONNECTING ROD INSTALLATION

(1)Liberally coat engine oil on the circumference of t he piston,

piston ring, and oil ring.

(2) Arrange the piston ring and oil ring gaps (side rail and

spacer) as shown in the figure.

(3)Rotate crankshaft so that crank pin is on center of cylinder

bore.

Page 363 of 2103

ENGINE OVERHAUL Piston Rod

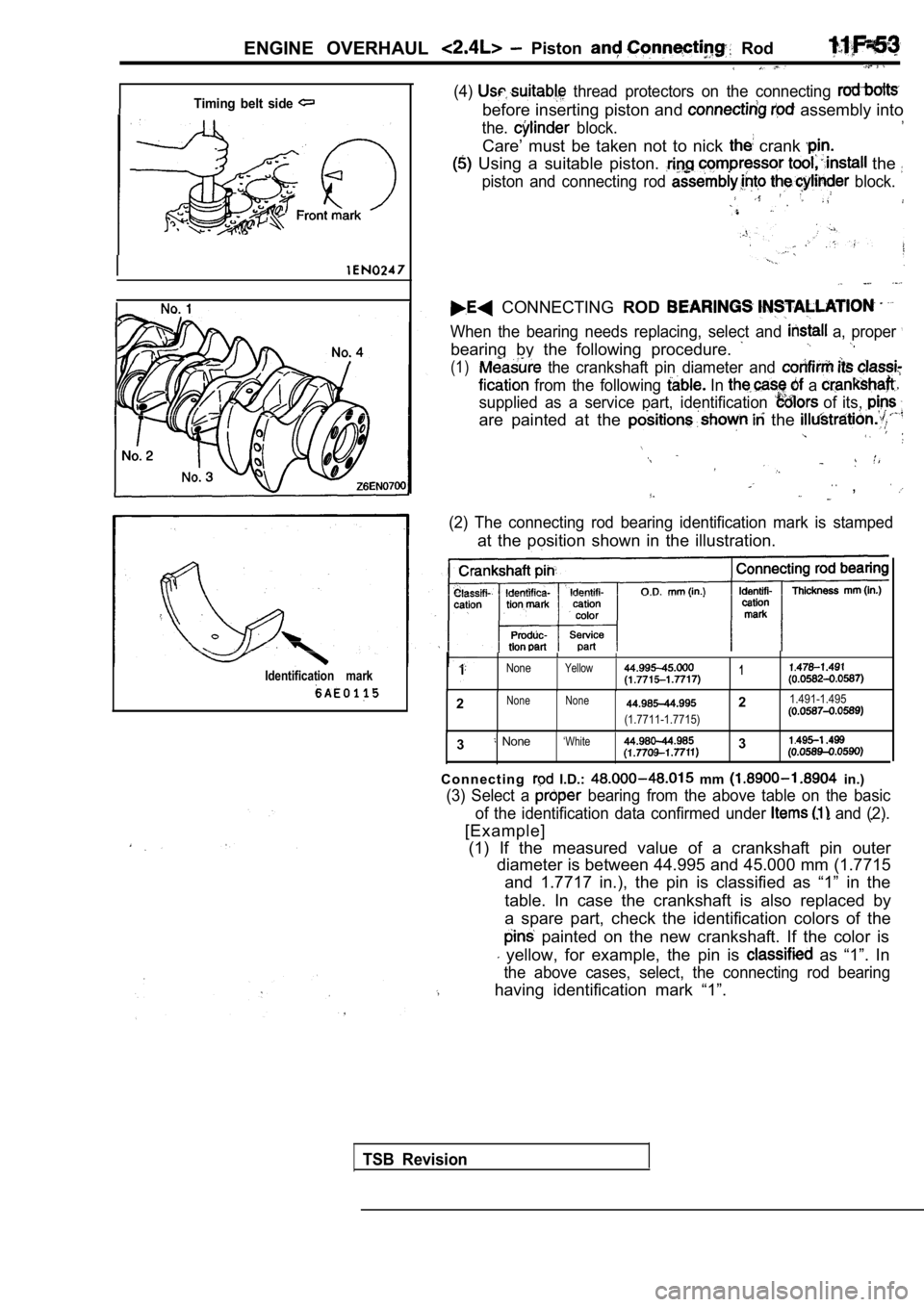

Timing belt side

Identification mark

(4) thread protectors on the connecting

before inserting piston and assembly into

the. block.

Care’ must be taken not to nick crank

Using a suitable piston. the

piston and connecting rod block.

CONNECTING ROD

When the bearing needs replacing, select and a, proper

bearing by the following procedure.

(1) the crankshaft pin diameter and

from the following In a

supplied as a service part, identification of its,

are painted at the the

. .,

(2) The connecting rod bearing identification mark is stamped

at the position shown in the illustration.

NoneYellow1

2None None21.491-1.495

(1.7711-1.7715)

3 None‘White3

C o n n e c t i n g I.D.: mm in.)

(3) Select a bearing from the above table on the basic

of the identification data confirmed under

and (2).

[Example]

(1) If the measured value of a crankshaft pin outer diameter is between 44.995 and 45.000 mm (1.7715

and 1.7717 in.), the pin is classified as “1” in th e

table. In case the crankshaft is also replaced by

a spare part, check the identification colors of th e

painted on the new crankshaft. If the color is

yellow, for example, the pin is as “1”. In

the above cases, select, the connecting rod bearing

having identification mark “1”.

TSB Revision

Page 364 of 2103

11ENGINE OVERHAUL P i s t o n

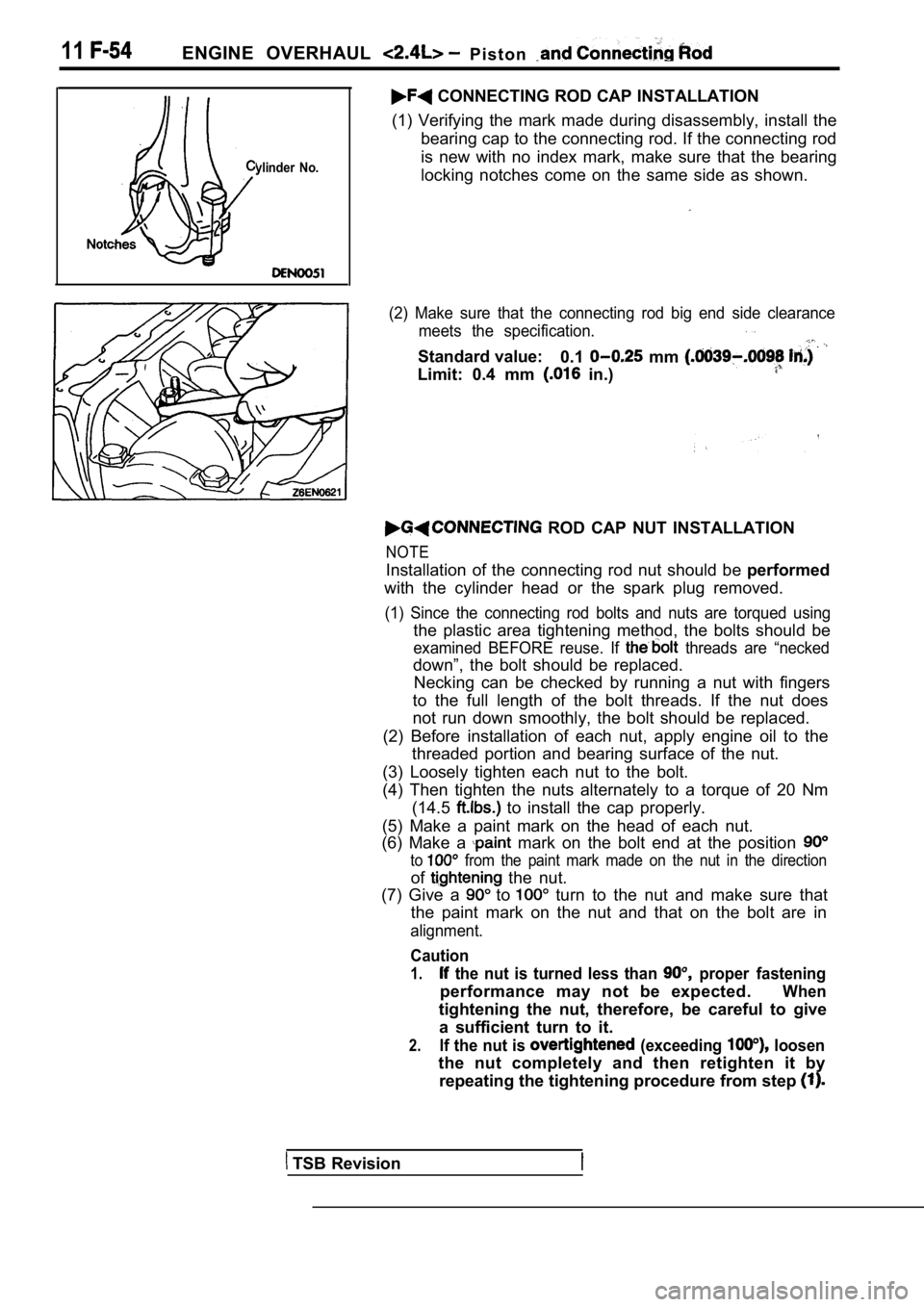

ylinder No.

CONNECTING ROD CAP INSTALLATION

(1) Verifying the mark made during disassembly, ins tall the

bearing cap to the connecting rod. If the connectin g rod

is new with no index mark, make sure that the beari ng

locking notches come on the same side as shown.

(2) Make sure that the connecting rod big end side clearance

meets the specification.

Standard value: 0.1 mm

Limit: 0.4 mm in.)

ROD CAP NUT INSTALLATION

NOTE

Installation of the connecting rod nut should be performed

with the cylinder head or the spark plug removed.

(1) Since the connecting rod bolts and nuts are tor qued using

the plastic area tightening method, the bolts should be

examined BEFORE reuse. If threads are “necked

down”, the bolt should be replaced.

Necking can be checked by running a nut with finger s

to the full length of the bolt threads. If the nut does

not run down smoothly, the bolt should be replaced.

(2) Before installation of each nut, apply engine o il to the

threaded portion and bearing surface of the nut.

(3) Loosely tighten each nut to the bolt.

(4) Then tighten the nuts alternately to a torque o f 20 Nm

(14.5

to install the cap properly.

(5) Make a paint mark on the head of each nut.

(6) Make a

mark on the bolt end at the position

to from the paint mark made on the nut in the directi on

of the nut.

(7) Give a

to turn to the nut and make sure that

the paint mark on the nut and that on the bolt are in

alignment.

Caution

1. the nut is turned less than proper fastening

performance may not be expected.When

tightening the nut, therefore, be careful to give

a sufficient turn to it.

2.If the nut is (exceeding loosen

the nut completely and then retighten it by repeating the tightening procedure from step

TSB Revision

Page 365 of 2103

ENGINE OVERHAUL Piston and Rod

INSPECTION

PISTON RING (1) Check the piston ring for

excessive and

breakage and replace if defects. If the’ piston

has been replaced with ,a new one, the piston rings must

also be replaced with, new. ones.

(2) Check for the clearance between the piston ring and

ring groove. If the limit is exceeded, replace the ring

or piston, or both.

Standard value:

mm

Limit: 0.1 mm in.)

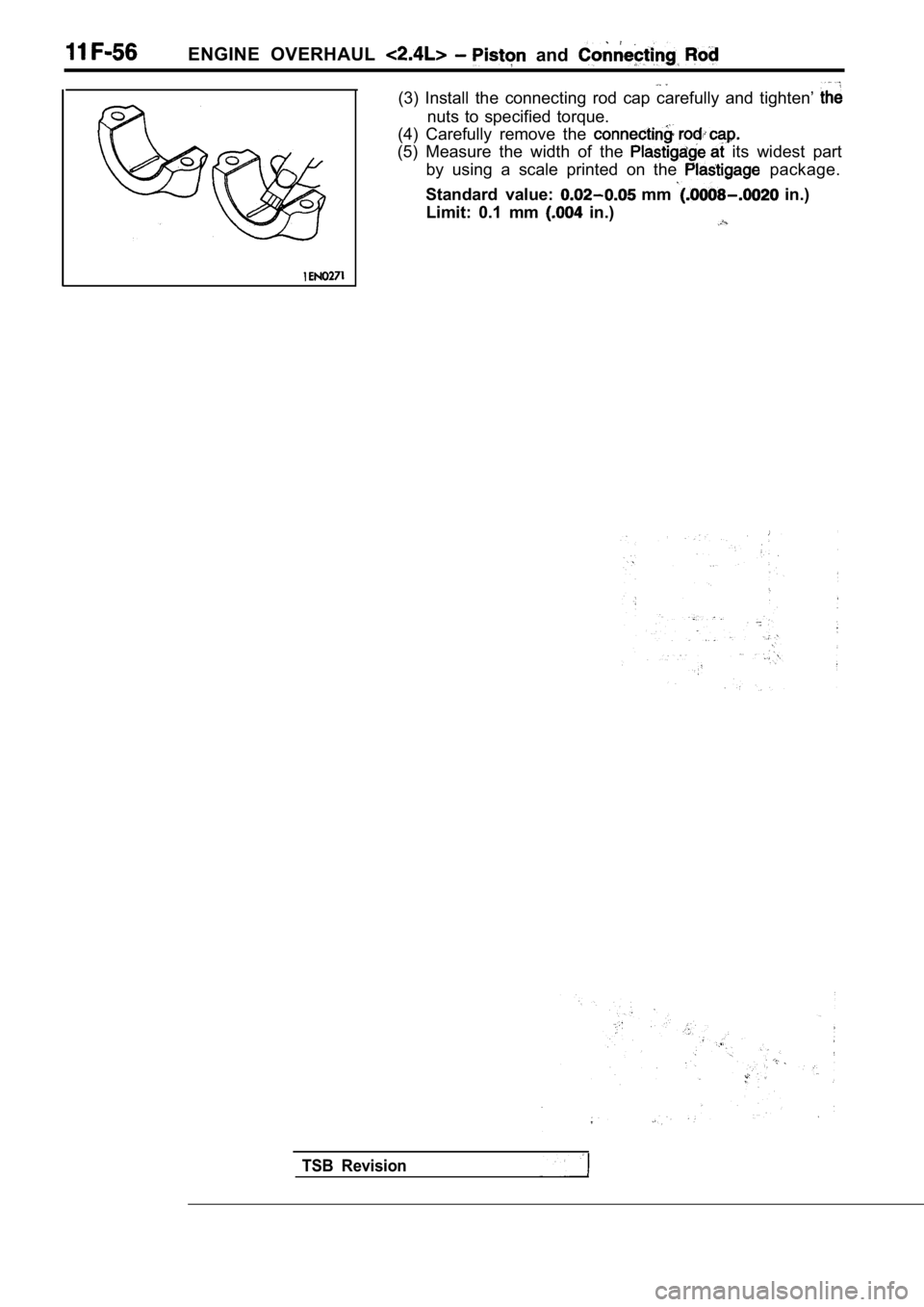

(3) Install the piston ring into the cylinder bore. Force it

down with a piston, its crown being in contact with the

ring, to correctly position it at right angles to the cylinder

wall. Then, measure the end gap with a feeler gauge .

If the ring gap is excessive, replace the piston ri ng.

Standard value:

ring mm

ring mm in.)

Oil ring

mm

Limit:

No. 1, No. 2 ring 0.8 mm in.)

Oil ring 1.0 mm

in.)

Revision

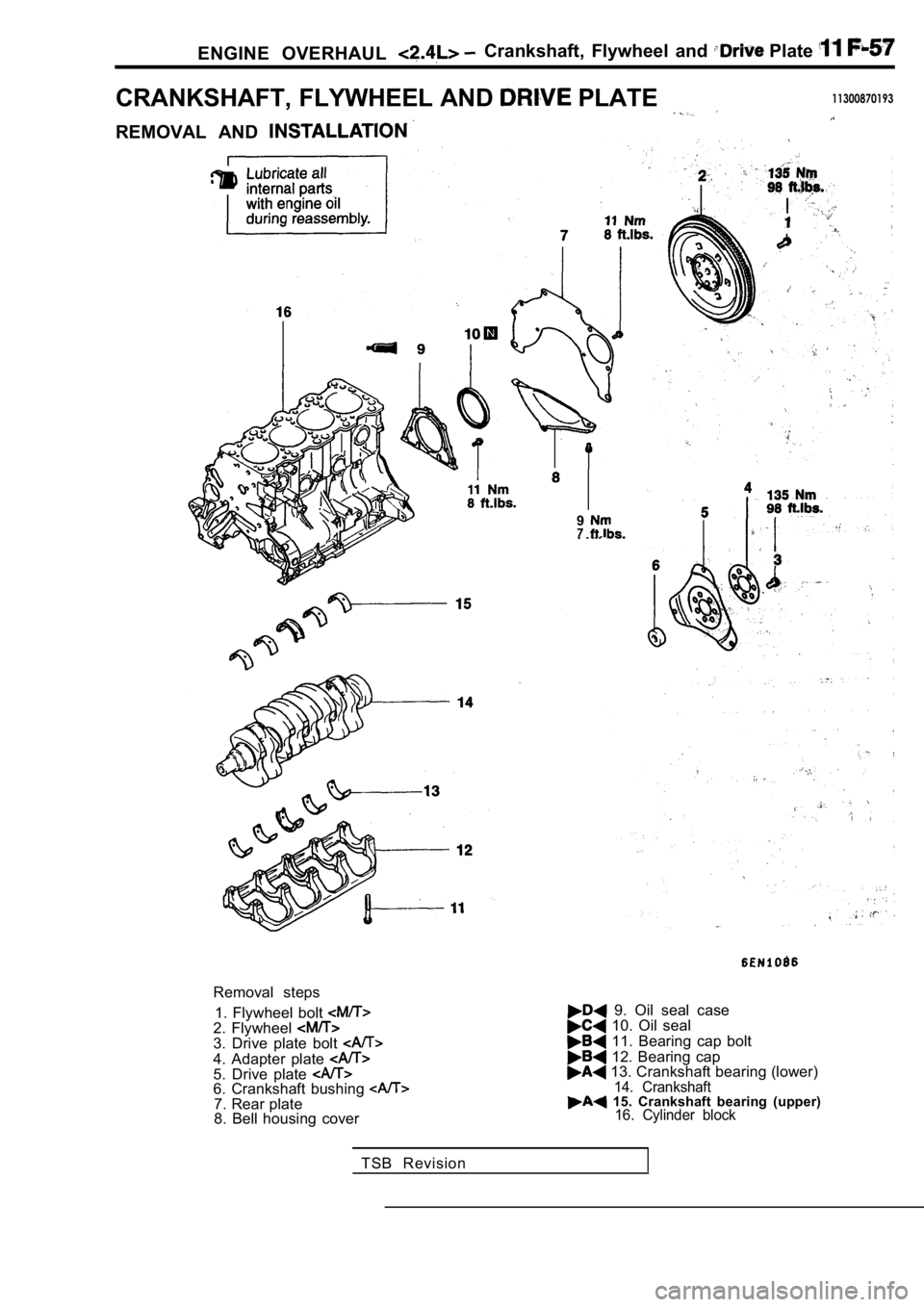

CRANKSHAFT PIN OIL CLEARANCE

(PLASTIGAGE METHOD)

(1) Remove oil from crankshaft pin and connecting r od

bearing.

(2) Cut the Plastigage to the same length as the width of

bearing and place it on crankshaft pin in parallel with

its axis.

Page 366 of 2103

ENGINE OVERHAUL and

(3) Install the connecting rod cap carefully and tighten’

nuts to specified torque.

(4) Carefully remove the

(5) Measure the width of the its widest part

by using a scale printed on the

package.

Standard value:

mm in.)

Limit: 0.1 mm

in.)

TSB Revision

Page 367 of 2103

ENGINE OVERHAUL Crankshaft, Flywheel and Plate

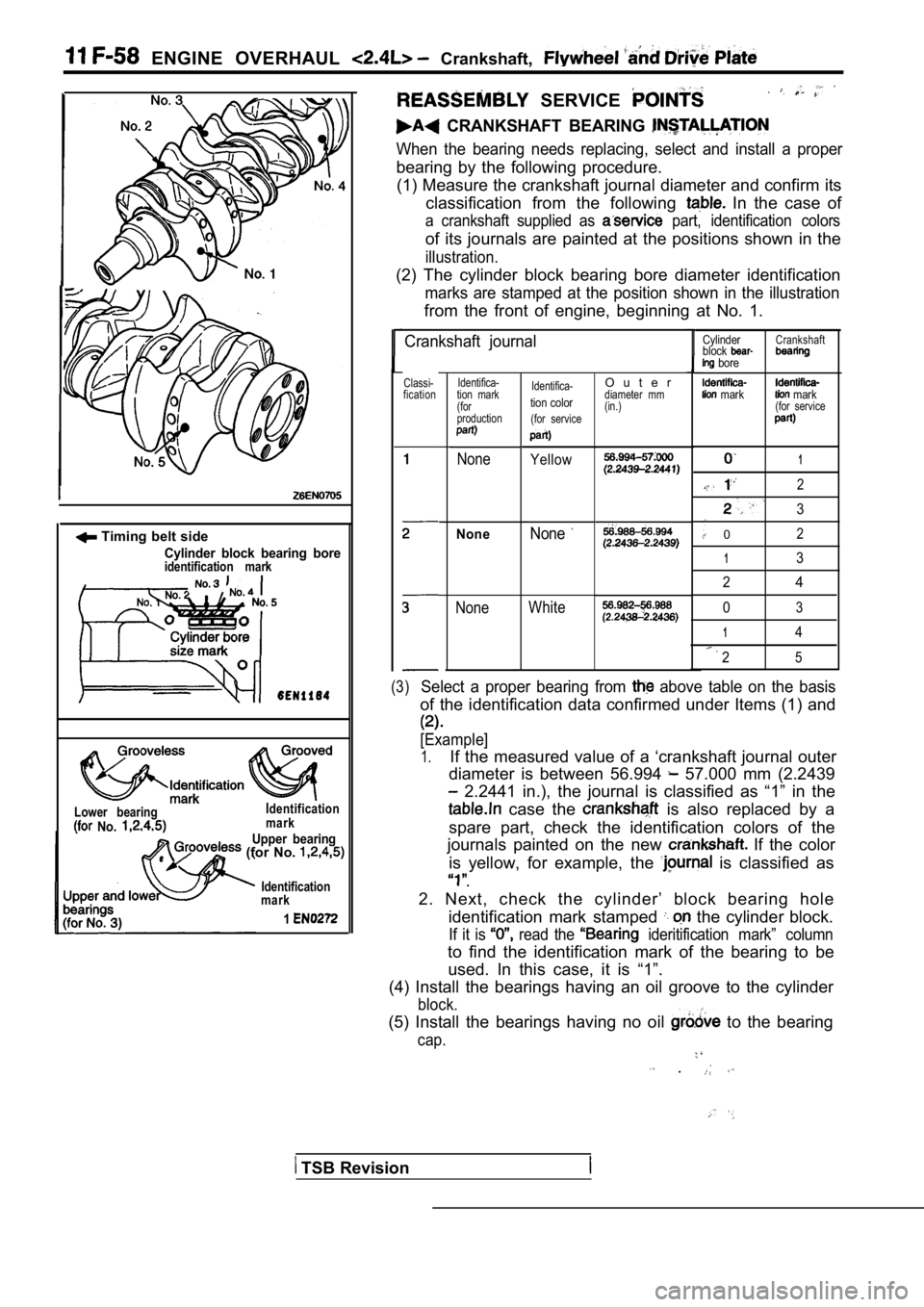

CRANKSHAFT, FLYWHEEL AND PLATE11300870193

REMOVAL AND

97

Removal steps1. Flywheel bolt

2. Flywheel 3. Drive plate bolt

4. Adapter plate 5. Drive plate 6. Crankshaft bushing 7. Rear plate

8. Bell housing cover

9. Oil seal case 10. Oil seal

11. Bearing cap bolt

12. Bearing cap 13. Crankshaft bearing (lower)14. Crankshaft 15. Crankshaft bearing (upper)16. Cylinder block

TSB Revision

Page 368 of 2103

ENGINE OVERHAUL Crankshaft,

Timing belt side

Cylinder block bearing boreidentification mark

Lower bearing No.

Identification

mark

Upper bearing (for No.

Identification

mark

1

SERVICE

CRANKSHAFT BEARING

When the bearing needs replacing, select and instal l a proper

bearing by the following procedure.

(1) Measure the crankshaft journal diameter and con firm its

classification from the following

In the case of

a crankshaft supplied as part, identification colors

of its journals are painted at the positions shown in the

illustration.

(2) The cylinder block bearing bore diameter identi fication

marks are stamped at the position shown in the illustration

from the front of engine, beginning at No. 1.

Crankshaft journal

Classi-

fication Identifica-

tion mark

(for

production

None

NoneNone

Identifica-

tion color

(for service

Yellow

WhiteNone

1

2

3

02

13

2

4

03

14

25

(3)Select a proper bearing from above table on the basis

of the identification data confirmed under Items (1 ) and

[Example]

1.If the measured value of a ‘crankshaft journal oute r

diameter is between 56.994

57.000 mm (2.2439

2.2441 in.), the journal is classified as “1” in t he

case the is also replaced by a

spare part, check the identification colors of the

journals painted on the new

If the color

is yellow, for example, the

is classified as

.

2. Next, check the cylinder’ block bearing hole identification mark stamped

the cylinder block.

If it is read the ideritification mark” column

to find the identification mark of the bearing to b e

used. In this case, it is “1”.

(4) Install the bearings having an oil groove to th e cylinder

block.

(5) Install the bearings having no oil to the bearing

cap.

.

O u t e rdiameter mm

(in.)

Cylinder

block

bore

mark

Crankshaft

mark(for service

TSB Revision

Page 369 of 2103

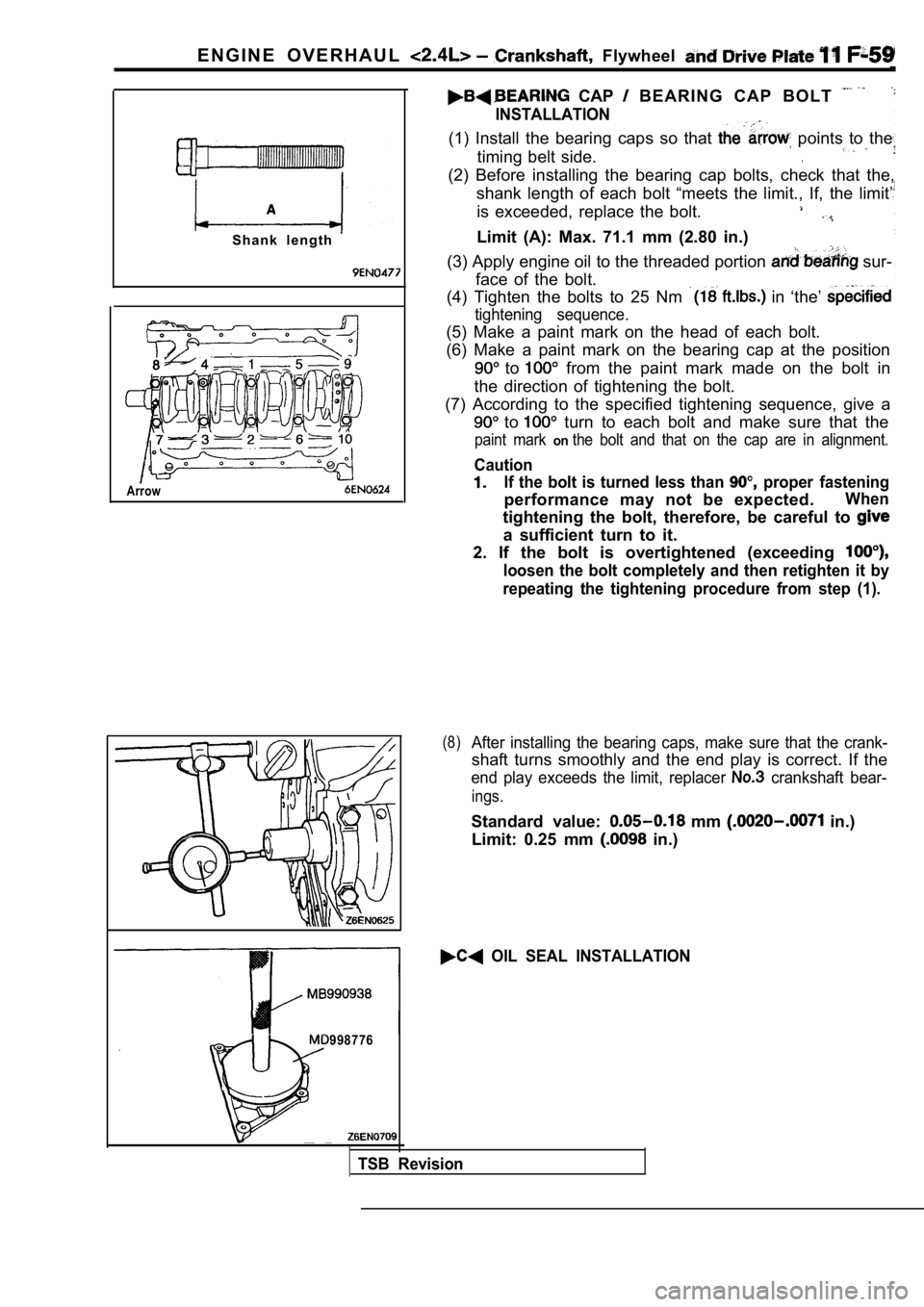

E N G I N E O V E R H A U L Flywheel

S h a n k l e n g t h

Arrow

CAP B E A R I N G C A P B O L T

INSTALLATION

(1) Install the bearing caps so that points to the

timing belt side.

(2) Before installing the bearing cap bolts, check that the,

shank length of each bolt “meets the limit., If, th e limit’

is exceeded, replace the bolt.

Limit (A): Max. 71.1 mm (2.80 in.)

(3) Apply engine oil to the threaded portion

sur-

face of the bolt.

(4) Tighten the bolts to 25 Nm

in ‘the’

tightening sequence.

(5) Make a paint mark on the head of each bolt.

(6) Make a paint mark on the bearing cap at the pos ition

to from the paint mark made on the bolt in

the direction of tightening the bolt.

(7) According to the specified tightening sequence, give a

to turn to each bolt and make sure that the

paint mark onthe bolt and that on the cap are in alignment.

Caution

If the bolt is turned less than proper fastening

performance may not be expected.When

tightening the bolt, therefore, be careful to

a sufficient turn to it.

2. If the bolt is overtightened (exceeding

loosen the bolt completely and then retighten it by

repeating the tightening procedure from step (1).

(8)After installing the bearing caps, make sure that t he crank-

shaft turns smoothly and the end play is correct. I f the

end play exceeds the limit, replacer crankshaft bear-

ings.

Standard value: mm in.)

Limit: 0.25 mm

in.)

OIL SEAL INSTALLATION

998776

TSB Revision

Page 370 of 2103

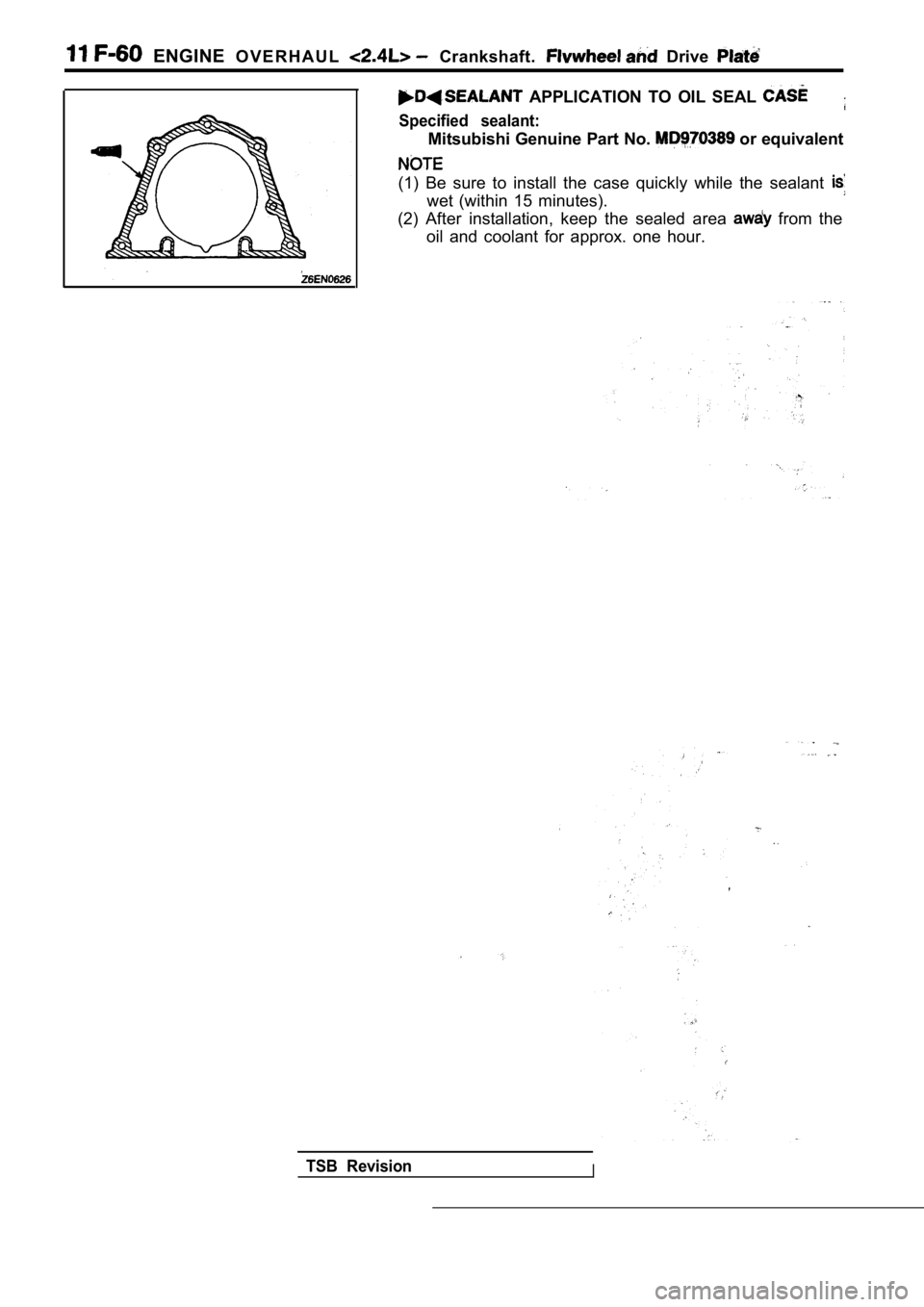

ENGINE O V E R H A U L Crankshaft. Drive

APPLICATION TO OIL SEAL

Specified sealant:

Mitsubishi Genuine Part No. or equivalent

(1) Be sure to install the case quickly while the s ealant

wet (within 15 minutes).

(2) After installation, keep the sealed area

from the

oil and coolant for approx. one hour.

TSB RevisionI