MITSUBISHI SPYDER 1990 Service Repair Manual

Manufacturer: MITSUBISHI, Model Year: 1990, Model line: SPYDER, Model: MITSUBISHI SPYDER 1990Pages: 2103, PDF Size: 68.98 MB

Page 371 of 2103

ENGINE OVERHAUL Crankshaft, Flywheel and, . .

INSPECTION11300880103

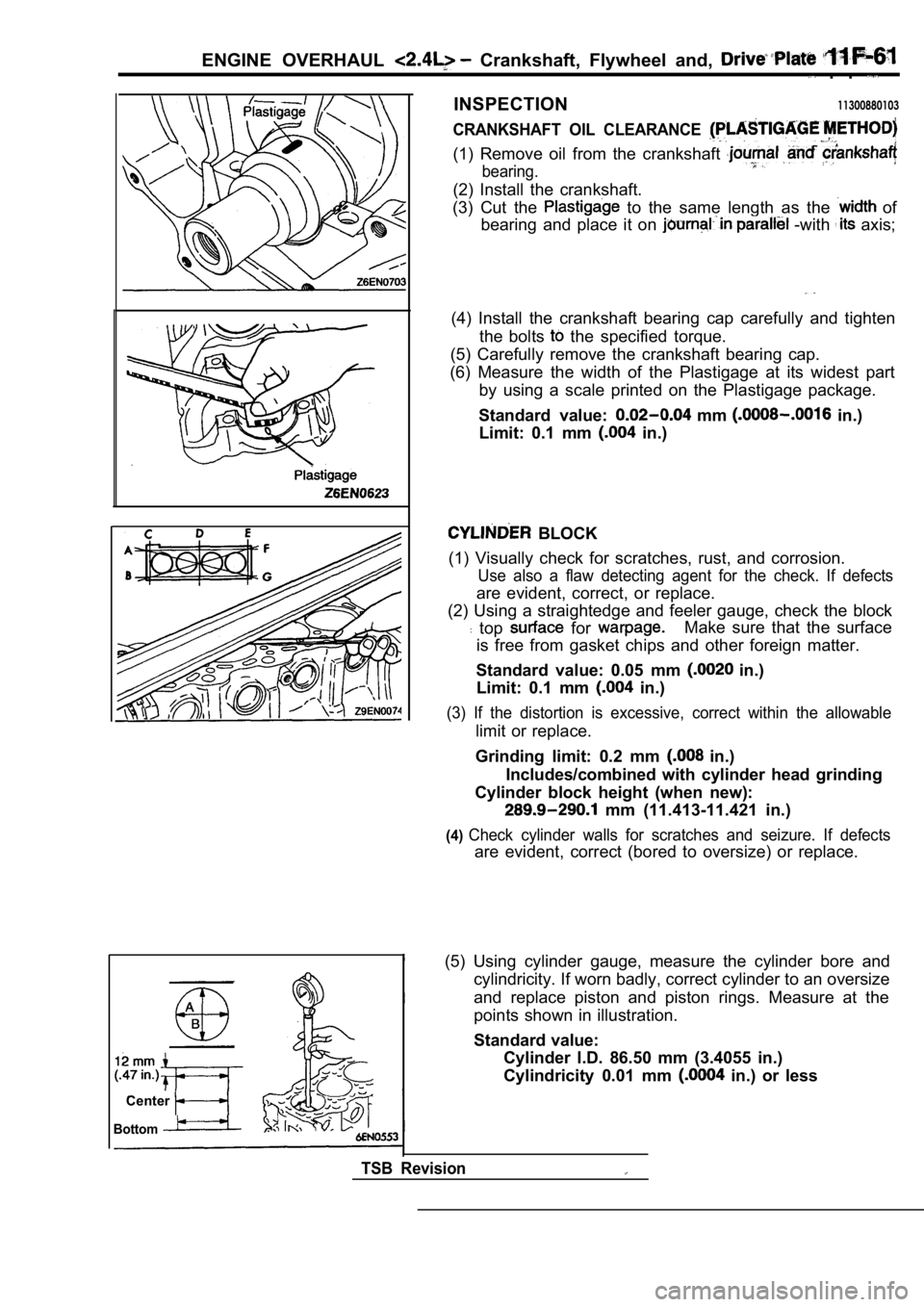

CRANKSHAFT OIL CLEARANCE

(1) Remove oil from the crankshaft

bearing.

(2) Install the crankshaft.

(3) Cut the

to the same length as the of

bearing and place it on

-with axis;

(4) Install the crankshaft bearing cap carefully an d tighten

the bolts

the specified torque.

(5) Carefully remove the crankshaft bearing cap.

(6) Measure the width of the Plastigage at its wide st part

by using a scale printed on the Plastigage package.

Standard value:

mm in.)

Limit: 0.1 mm

in.)

BLOCK

(1) Visually check for scratches, rust, and corrosi on.

Use also a flaw detecting agent for the check. If d efects

are evident, correct, or replace.

(2) Using a straightedge and feeler gauge, check th e block

top for Make sure that the surface

is free from gasket chips and other foreign matter.

Standard value: 0.05 mm

in.)

Limit: 0.1 mm

in.)

(3) If the distortion is excessive, correct within the allowable

limit or replace.

Grinding limit: 0.2 mm

in.)

Includes/combined with cylinder head grinding

Cylinder block height (when new):

mm (11.413-11.421 in.)

(4)Check cylinder walls for scratches and seizure. If defects

are evident, correct (bored to oversize) or replace.

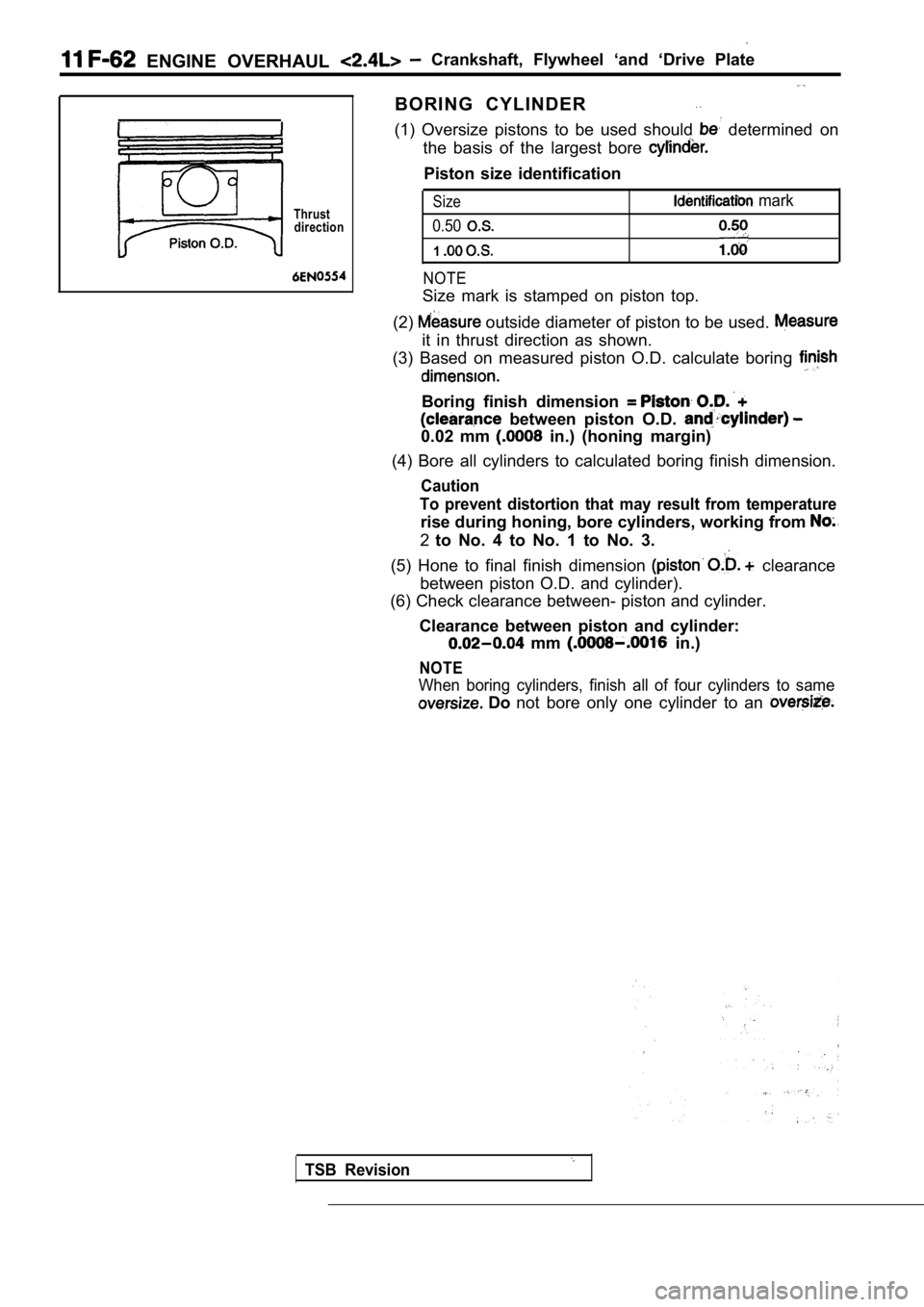

Center

Bottom

TSB Revision

(5) Using cylinder gauge, measure the cylinder bore and

cylindricity. If worn badly, correct cylinder to an oversize

and replace piston and piston rings. Measure at the

points shown in illustration.

Standard value: Cylinder I.D. 86.50 mm (3.4055 in.)

Cylindricity 0.01 mm

in.) or less

Page 372 of 2103

ENGINE OVERHAUL Crankshaft, Flywheel ‘and ‘Drive Plate

Thrustdirection

B O R I N G C Y L I N D E R

(1) Oversize pistons to be used should determined on

the basis of the largest bore

Piston size identification

Size mark

0.50

1

NOTE

Size mark is stamped on piston top.

(2)

outside diameter of piston to be used.

it in thrust direction as shown.

(3) Based on measured piston O.D. calculate boring

Boring finish dimension

between piston O.D.

0.02 mm in.) (honing margin)

(4) Bore all cylinders to calculated boring finish dimension.

Caution

To prevent distortion that may result from temperat ure

rise during honing, bore cylinders, working from

2to No. 4 to No. 1 to No. 3.

(5) Hone to final finish dimension

clearance

between piston O.D. and cylinder).

(6) Check clearance between- piston and cylinder.

Clearance between piston and cylinder:

mm in.)

NOTE

When boring cylinders, finish all of four cylinders to same

Do not bore only one cylinder to an

TSB Revision

Page 373 of 2103

ENGINE

.

CONTENTS

ENGINE OIL COOLER.. . . . . . . . . . . . . . . . . . . . . ON-VEHICLE SERVICE . . . . . . . . . . . . . . . . . . . 3

GENERAL INFORMATION. . . . . . . . . . . . . . . . . . 2Engine Oil . . . . . . . . . . . . . . . . . . . . . . . . .

Engine Oil Replacement . . . . . . . . . . . . . . . . . . . .3

LUBRICANTS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2Oil Filter Replacement . . . . . . . . . . . . . . . . . . . . .

4

Page 374 of 2103

ENGINE LUBRICATION General Information/Lubricants

G E N E R A L I N F O R M A T I O N

The lubrication method is a fully force-fed, full-f low

filtration type.

ENGINE OILS

Health Warning

Prolonged and repeated contact with mineral oil

will result in the removal of natural fats from the

skin, leading to dryness, irritation and dermatitis .

In addition, used engine oil

potentially

Recommended Precautions

The most effective precaution is to adapt working

practices which prevent, as far as practicable, the

risk of skin contact with mineral oils, for example

by using enclosed systems for handling used engine

oil and by degreasing components, where

practicable, before handling them.

Other precautions:

lAvoid prolonged and repeated contact with oils,

particularly used engine oils.

l Wear protective clothing, including impervious

gloves where practicable.

l Avoid contaminating clothes, particularly

underpants, with oil.

l Do not put oily rags in packets, the use of

overalls without pockets will avoid this.

l Do not wear heavily soiled clothing and

oil-impregnated foot-wear. Overalls must be

cleaned regularly and kept separate from

personal clothing.

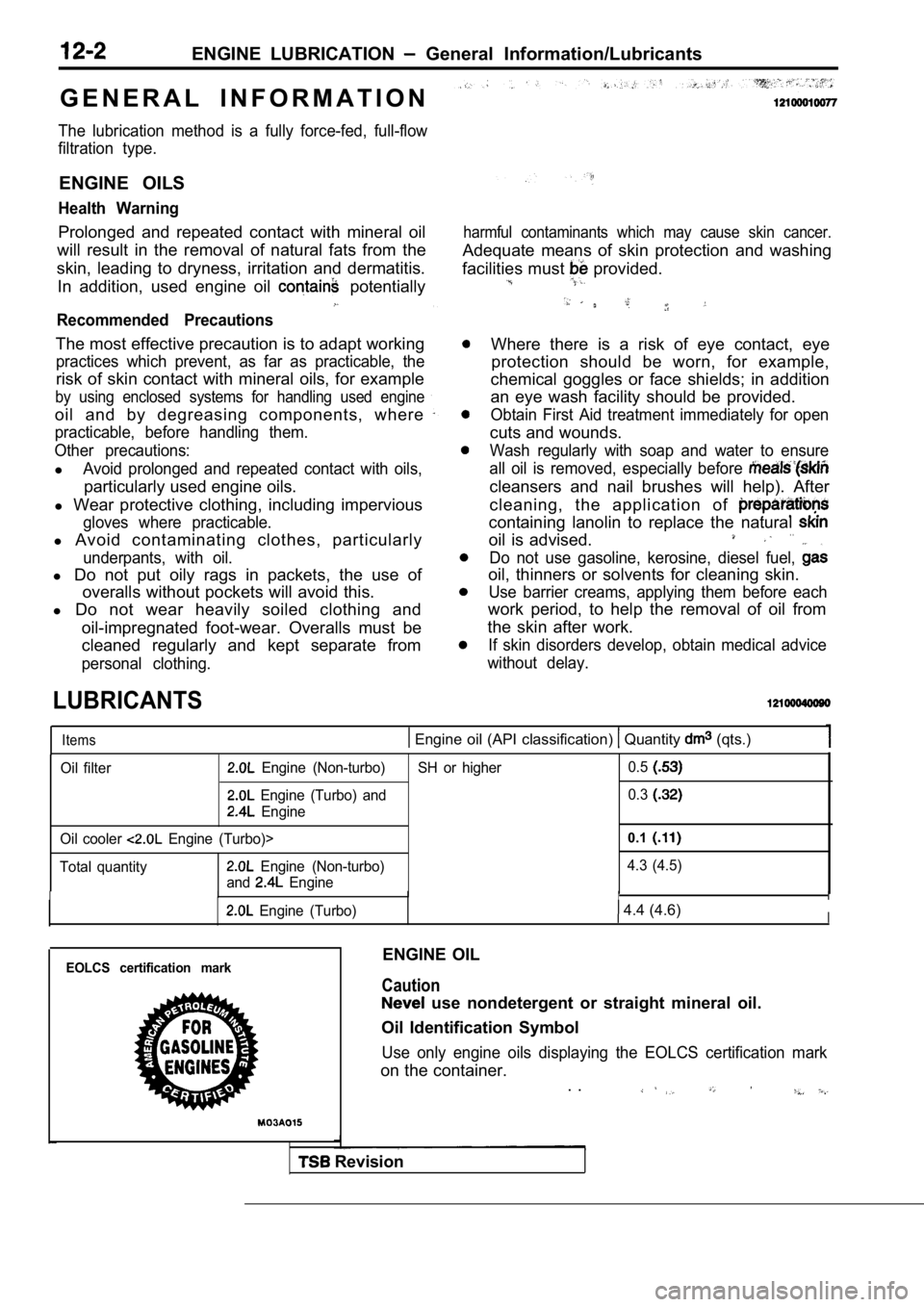

LUBRICANTS

harmful contaminants which may cause skin cancer.

Adequate means of skin protection and washing

facilities must

provided.

Where there is a risk of eye contact, eye protection should be worn, for example,

chemical goggles or face shields; in addition

an eye wash facility should be provided.

Obtain First Aid treatment immediately for open

cuts and wounds.

Wash regularly with soap and water to ensure

all oil is removed, especially before

cleansers and nail brushes will help). After

cleaning, the application of

containing lanolin to replace the natural

oil is advised.. .

Do not use gasoline, kerosine, diesel fuel,

oil, thinners or solvents for cleaning skin.

Use barrier creams, applying them before each

work period, to help the removal of oil from

the skin after work.

If skin disorders develop, obtain medical advice

without delay.

Items Engine oil (API classification) Quantity (qts.)

Oil filter Engine (Non-turbo)

Engine (Turbo) and

Engine

Oil cooler

Engine (Turbo)>

Total quantity

Engine (Non-turbo)

and

Engine SH or higher

0.5

0.3

0.1

4.3 (4.5)

IIIII

Engine (Turbo) 4.4 (4.6)I

EOLCS certification markENGINE OIL

Caution

use nondetergent or straight mineral oil.

Oil Identification Symbol

Use only engine oils displaying the EOLCS certifica tion mark

on the container.

. .

Revision

Page 375 of 2103

ENGINE LUBRICATION Service

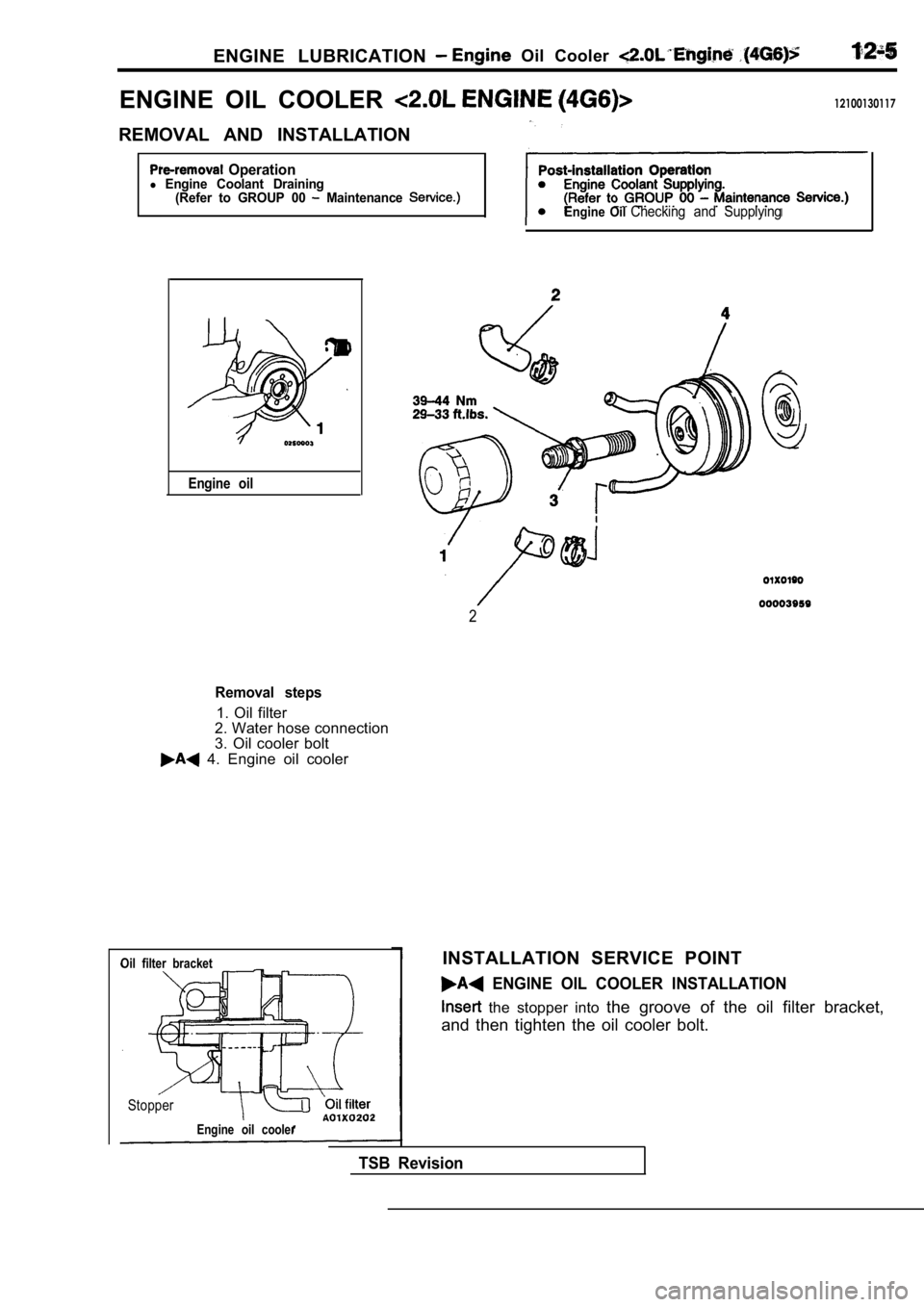

DraingasketOil pan side

Engine (Non-turbo)>

If these oils are not available, an API classificat

ion

or can be used.’ . .

ON-VEHICLE

ENGINE OIL

.

Pull out the oil dipstick slowly and check that the oil

is within the marks on the oil dipstick.

2.Check that the oil is dirty, that there is

no coolant or gasoline mixed in, ‘and that it has, sufficient

viscosity.

ENGINE OIL REPLACEMENT

After warming up the engine, remove the oil filler cap.

2.Remove the drain plug to allow the engine oil to drain.

3.Replace the drain plug gasket with a new one and ti ghten

the drain plug.

Page 376 of 2103

![MITSUBISHI SPYDER 1990 Service Repair Manual 12-4 L U B R I C A T I O N

EngineI

Turbo

4. Supply new engine oil through the oil filler.Engine oil total quantity:[including oil filter and oil cooler]

Engine (Non-turbo) arid MITSUBISHI SPYDER 1990 Service Repair Manual 12-4 L U B R I C A T I O N

EngineI

Turbo

4. Supply new engine oil through the oil filler.Engine oil total quantity:[including oil filter and oil cooler]

Engine (Non-turbo) arid](/img/19/57345/w960_57345-375.png)

12-4 L U B R I C A T I O N

EngineI

Turbo

4. Supply new engine oil through the oil filler.Engine oil total quantity:[including oil filter and oil cooler]

Engine (Non-turbo) arid

4 . 3 (4 q t s . )

Engine (Turbo)>

4.4

(4.6 qts.)

5. Start and run the engine a

minutes.

6.Stop the engine and check the engine oil level is w ithin

the level range indicated on the oil dipstick.

.

NOTE

may be used for operation in very cold weather

areas where the lowest ambient temperature is below

OIL REPLACEMENT

1. Remove the engine oil filler cap.

2.Remove the engine oil drain plug, and drain out the engine

o i l .

3.Remove the engine oil filter by using the oil filter wrench.

4.Clean the oil filter mounting, surface of the oil f ilter bracket.

5. Coat engine oil to the O-ring of’new filter: .

6.Screw on the oil filter by hand until it touchesthe surface

of the flange and then tighten it with. the filter wrench:

etc.

Engine (Turbo) Engine>

lFor One full turn or 14 Nm

lFor or 17 Nm (12

E n g i n e ( N o n - t u r b o ) >

lFor 090: turn or 21 Nm (15

7. Add new engine oil through the oil filter.

8. Start and run engine and check for engine oil le aks.

9. After stopping engine, check oil level and reple nish as

necessary.

TSB Revision

Page 377 of 2103

ENGINE LUBRICATION Oil Cooler

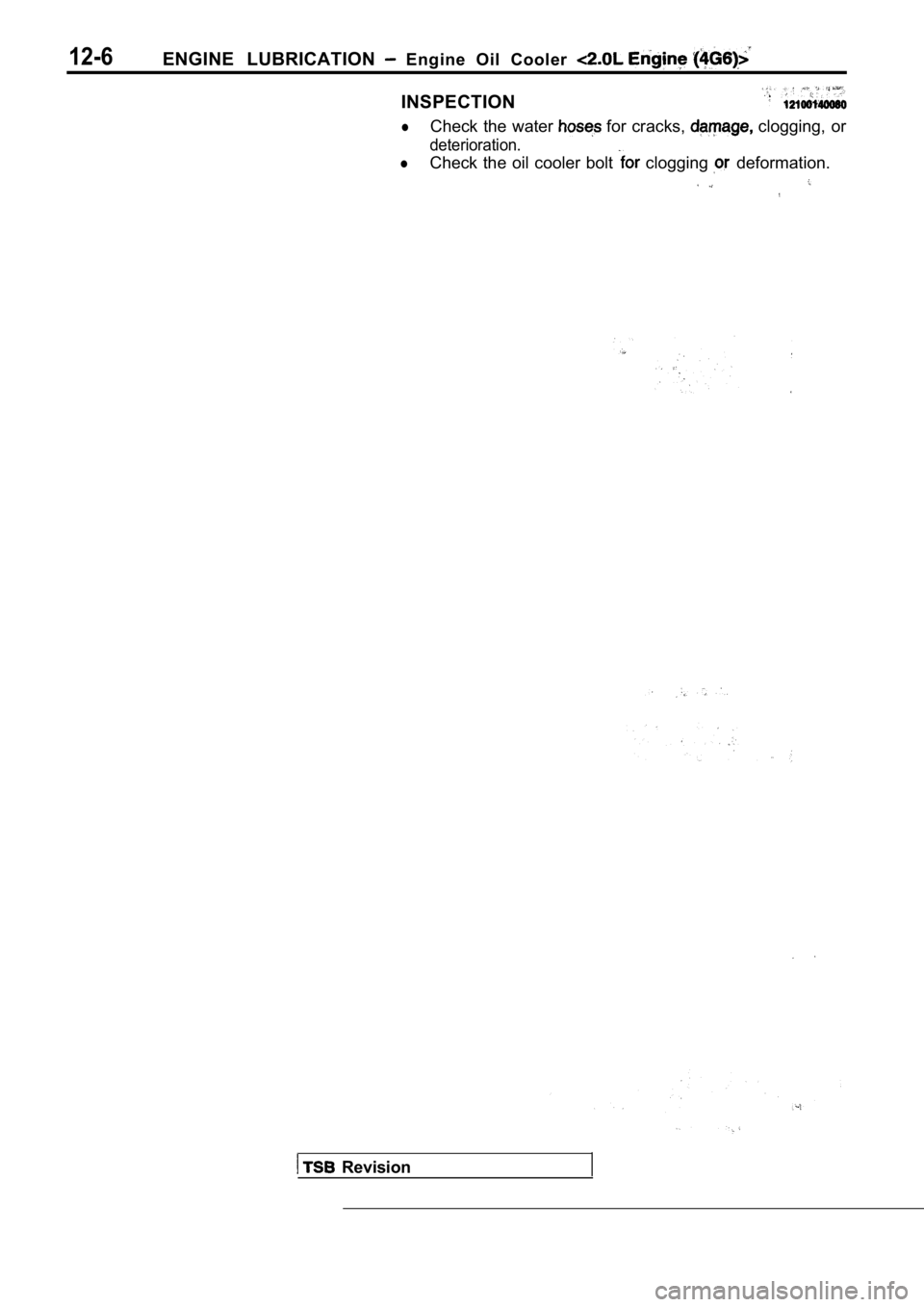

ENGINE OIL COOLER 12100130117

REMOVAL AND INSTALLATION

Operationl Engine Coolant Draining(Refer to GROUP 00 Maintenance

Engine oil

Engine Oil Checking and Supplying

2

Removal steps

1. Oil filter

2. Water hose connection

3. Oil cooler bolt

4. Engine oil cooler

Oil filter bracket

Stopper

Engine oil cooler

INSTALLATION SERVICE POINT

ENGINE OIL COOLER INSTALLATION

the stopper into the groove of the oil filter bracket,

and then tighten the oil cooler bolt.

TSB Revision

Page 378 of 2103

12-6ENGINE LUBRICATION Engine Oil Cooler

INSPECTION

lCheck the water for cracks, clogging, or

deterioration.

lCheck the oil cooler bolt clogging deformation.

Revision

Page 379 of 2103

FUEL

CONTENTS

FUEL INJECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

FUEL SUPPLY. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

AUTO-CRUISE CONTROL SYSTEM . . . . . . . . . . . . . . . . . Refer to GROUP 17

NOTE

Groups that have been shaded are not contained in this manual.

Page 380 of 2103

13-2