NISSAN NAVARA 2005 Repair Workshop Manual

Manufacturer: NISSAN, Model Year: 2005, Model line: NAVARA, Model: NISSAN NAVARA 2005Pages: 3171, PDF Size: 49.59 MB

Page 3061 of 3171

TF-94

TROUBLE DIAGNOSIS FOR SYMPTOMS

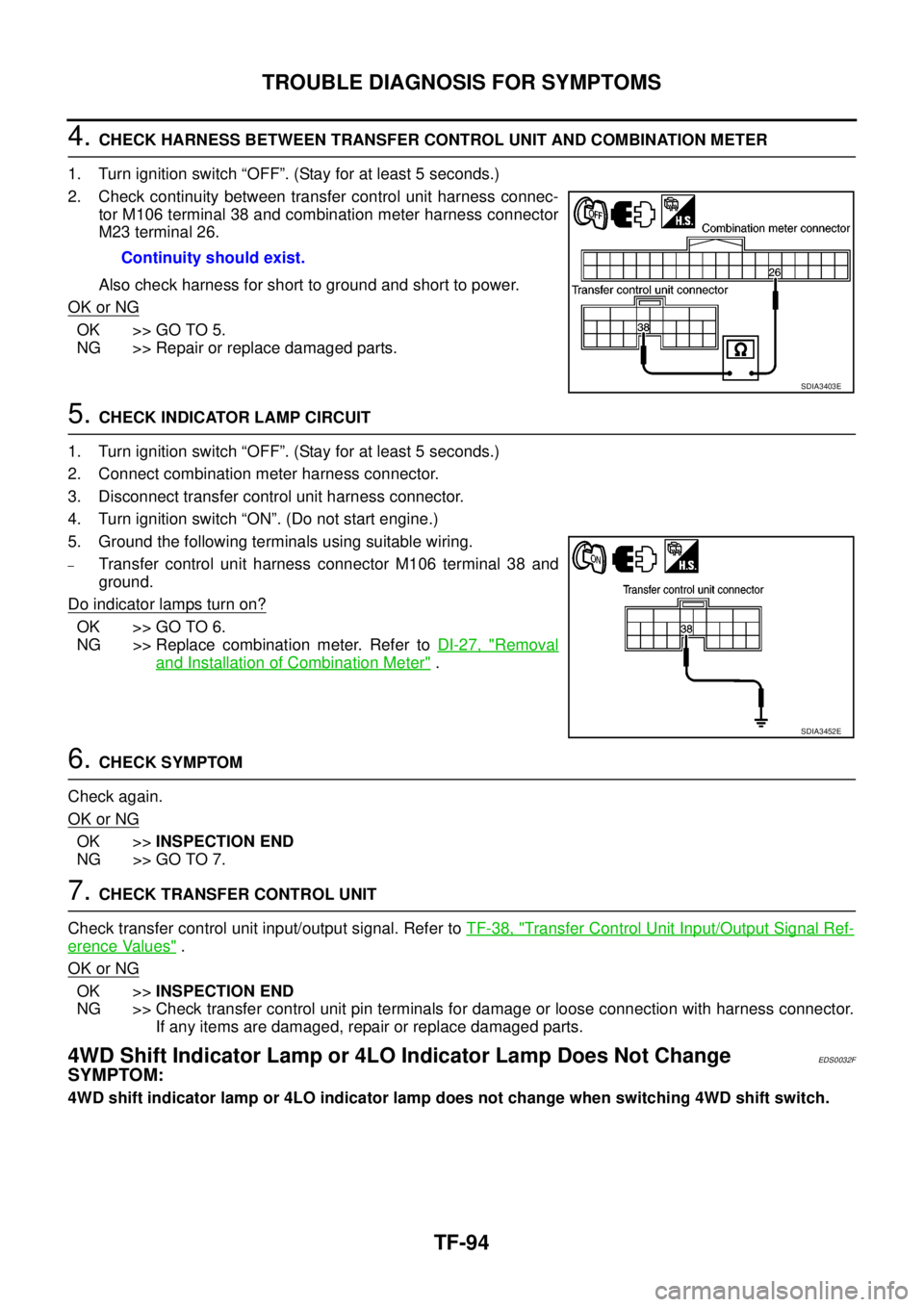

4.CHECK HARNESS BETWEEN TRANSFER CONTROL UNIT AND COMBINATION METER

1. Turn ignition switch “OFF”. (Stay for at least 5 seconds.)

2. Check continuity between transfer control unit harness connec-

tor M106 terminal 38 and combination meter harness connector

M23 terminal 26.

Also check harness for short to ground and short to power.

OK or NG

OK >> GO TO 5.

NG >> Repair or replace damaged parts.

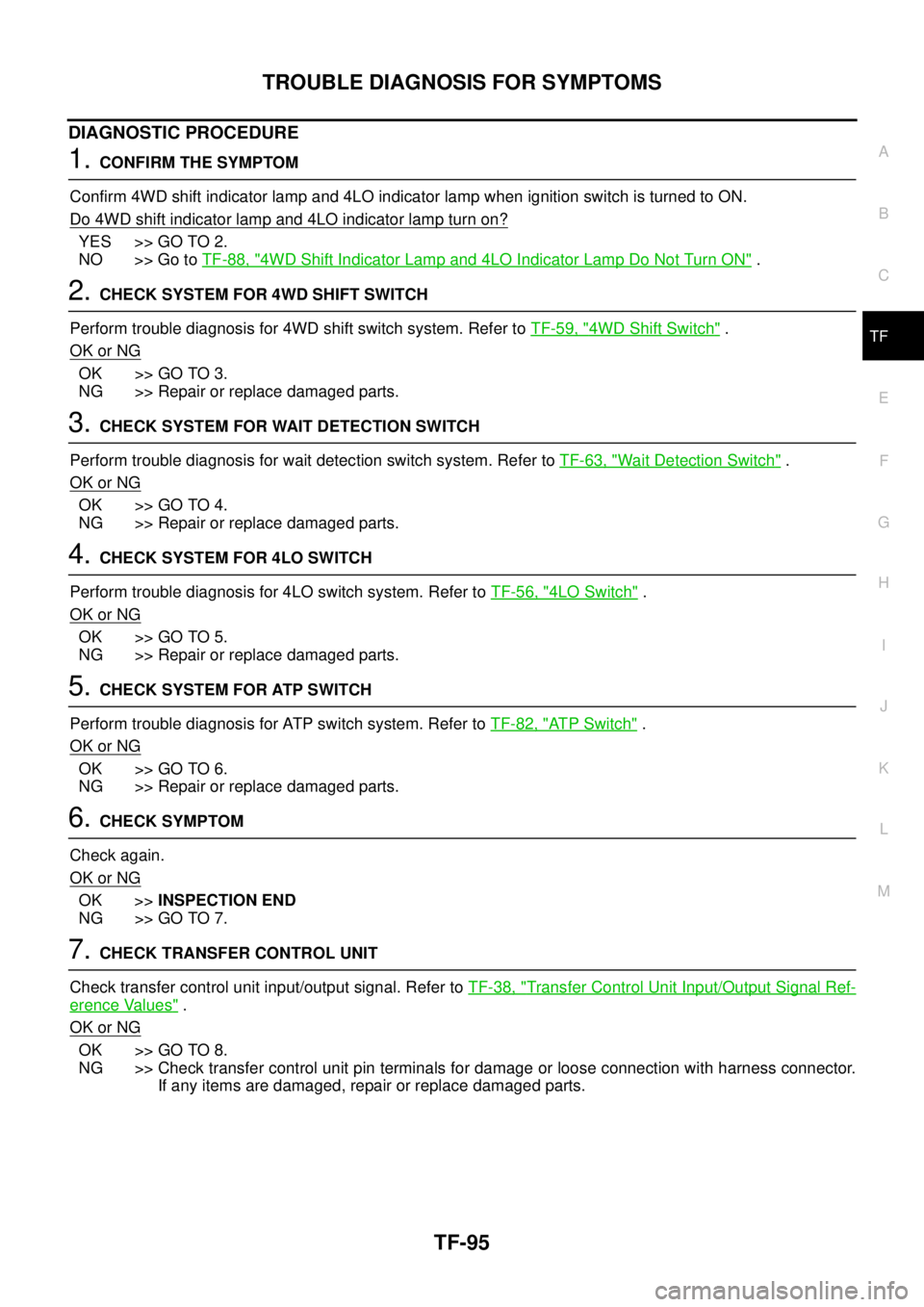

5.CHECK INDICATOR LAMP CIRCUIT

1. Turn ignition switch “OFF”. (Stay for at least 5 seconds.)

2. Connect combination meter harness connector.

3. Disconnect transfer control unit harness connector.

4. Turn ignition switch “ON”. (Do not start engine.)

5. Ground the following terminals using suitable wiring.

–Transfer control unit harness connector M106 terminal 38 and

ground.

Do indicator lamps turn on?

OK >> GO TO 6.

NG >> Replace combination meter. Refer toDI-27, "

Removal

and Installation of Combination Meter".

6.CHECK SYMPTOM

Check again.

OK or NG

OK >>INSPECTION END

NG >> GO TO 7.

7.CHECK TRANSFER CONTROL UNIT

Check transfer control unit input/output signal. Refer toTF-38, "

Transfer Control Unit Input/Output Signal Ref-

erence Values".

OK or NG

OK >>INSPECTION END

NG >> Check transfer control unit pin terminals for damage or loose connection with harness connector.

If any items are damaged, repair or replace damaged parts.

4WD Shift Indicator Lamp or 4LO Indicator Lamp Does Not ChangeEDS0032F

SYMPTOM:

4WD shift indicator lamp or 4LO indicator lamp does not change when switching 4WD shift switch.Continuity should exist.

SDIA3403E

SDIA3452E

Page 3062 of 3171

TROUBLE DIAGNOSIS FOR SYMPTOMS

TF-95

C

E

F

G

H

I

J

K

L

MA

B

TF

DIAGNOSTIC PROCEDURE

1.CONFIRM THE SYMPTOM

Confirm 4WD shift indicator lamp and 4LO indicator lamp when ignition switch is turned to ON.

Do 4WD shift indicator lamp and 4LO indicator lamp turn on?

YES >> GO TO 2.

NO >> Go toTF-88, "

4WD Shift Indicator Lamp and 4LO Indicator Lamp Do Not Turn ON".

2.CHECK SYSTEM FOR 4WD SHIFT SWITCH

Perform trouble diagnosis for 4WD shift switch system. Refer toTF-59, "

4WD Shift Switch".

OK or NG

OK >> GO TO 3.

NG >> Repair or replace damaged parts.

3.CHECK SYSTEM FOR WAIT DETECTION SWITCH

Perform trouble diagnosis for wait detection switch system. Refer toTF-63, "

Wait Detection Switch".

OK or NG

OK >> GO TO 4.

NG >> Repair or replace damaged parts.

4.CHECK SYSTEM FOR 4LO SWITCH

Perform trouble diagnosis for 4LO switch system. Refer toTF-56, "

4LO Switch".

OK or NG

OK >> GO TO 5.

NG >> Repair or replace damaged parts.

5.CHECK SYSTEM FOR ATP SWITCH

Perform trouble diagnosis for ATP switch system. Refer toTF-82, "

AT P S w i t c h".

OK or NG

OK >> GO TO 6.

NG >> Repair or replace damaged parts.

6.CHECK SYMPTOM

Check again.

OK or NG

OK >>INSPECTION END

NG >> GO TO 7.

7.CHECK TRANSFER CONTROL UNIT

Check transfer control unit input/output signal. Refer toTF-38, "

Transfer Control Unit Input/Output Signal Ref-

erence Values".

OK or NG

OK >> GO TO 8.

NG >> Check transfer control unit pin terminals for damage or loose connection with harness connector.

If any items are damaged, repair or replace damaged parts.

Page 3063 of 3171

TF-96

TROUBLE DIAGNOSIS FOR SYMPTOMS

8.CHECK TRANSFER INNER PARTS

1. Disassemble transfer assembly. Refer toTF-112, "

Disassembly and Assembly".

2. Check transfer inner parts.

OK or NG

OK >>INSPECTION END

NG >> Repair or replace damaged parts.

ATP Warning Lamp Does Not Turn ONEDS0032G

SYMPTOM:

ATP warning lamp does not turn ON when 4WD shift switch from “4H” to “4LO” or “4LO” to “4H” with

A/T selector lever in “N” position.

DIAGNOSTIC PROCEDURE

1.CHECK SYSTEM FOR CAN COMMUNICATION LINE

Perform self-diagnosis. Refer toTF-49, "

Self-Diagnostic Procedure".

Do the self-diagnostic results indicate CAN communication?

YES >> Perform trouble diagnosis for CAN communication line. Refer toTF-82, "CAN Communication

Line".

NO >> GO TO 2.

2.CHECK SYSTEM FOR 4WD SHIFT SWITCH

Perform trouble diagnosis for 4WD shift switch system. Refer toTF-59, "

4WD Shift Switch".

OK or NG

OK >> GO TO 3.

NG >> Repair or replace damaged parts.

3.CHECK SYSTEM FOR PNP SWITCH SIGNAL

Perform trouble diagnosis for PNP switch signal system. Refer toTF-66, "

PNP Switch Signal (TCM)".

OK or NG

OK >> GO TO 4.

NG >> Repair or replace damaged parts.

4.CHECK SYSTEM FOR ATP SWITCH

Perform trouble diagnosis for ATP switch system. Refer toTF-82, "

AT P S w i t c h".

OK or NG

OK >> GO TO 5.

NG >> Repair or replace damaged parts.

Page 3064 of 3171

TROUBLE DIAGNOSIS FOR SYMPTOMS

TF-97

C

E

F

G

H

I

J

K

L

MA

B

TF

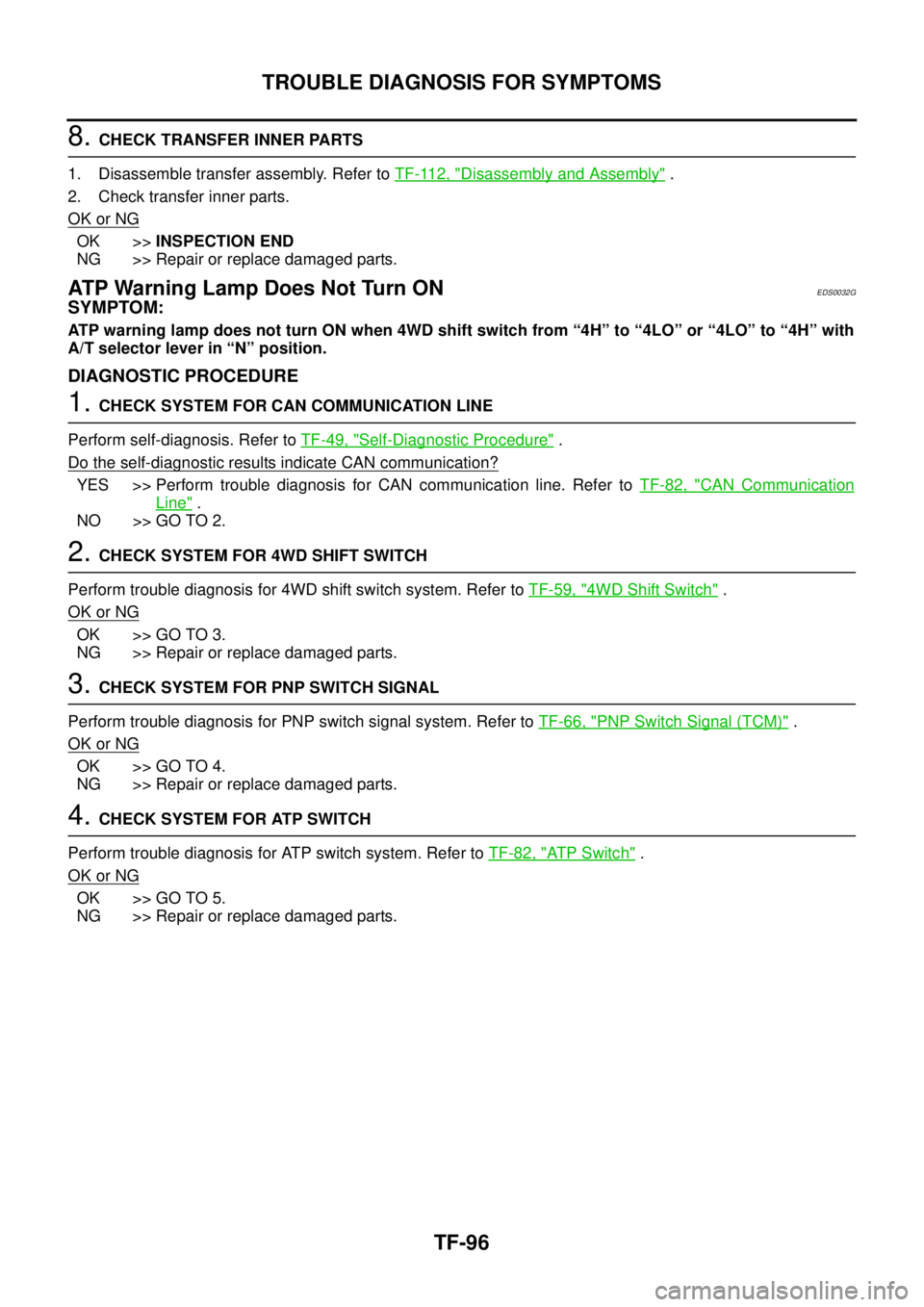

5.CHECK ATP WARNING LAMP CIRCUIT

1. Turn ignition switch “OFF”. (Stay for at least 5 seconds.)

2. Disconnect ATP switch harness connector.

3. Turn ignition switch “ON”. (Do not start engine.)

4. Ground the following terminal using suitable wiring.

–ATP switch harness connector F55 terminal 8 and ground.

Does ATP warning lamp turn on?

OK >> GO TO 8.

NG >> GO TO 6.

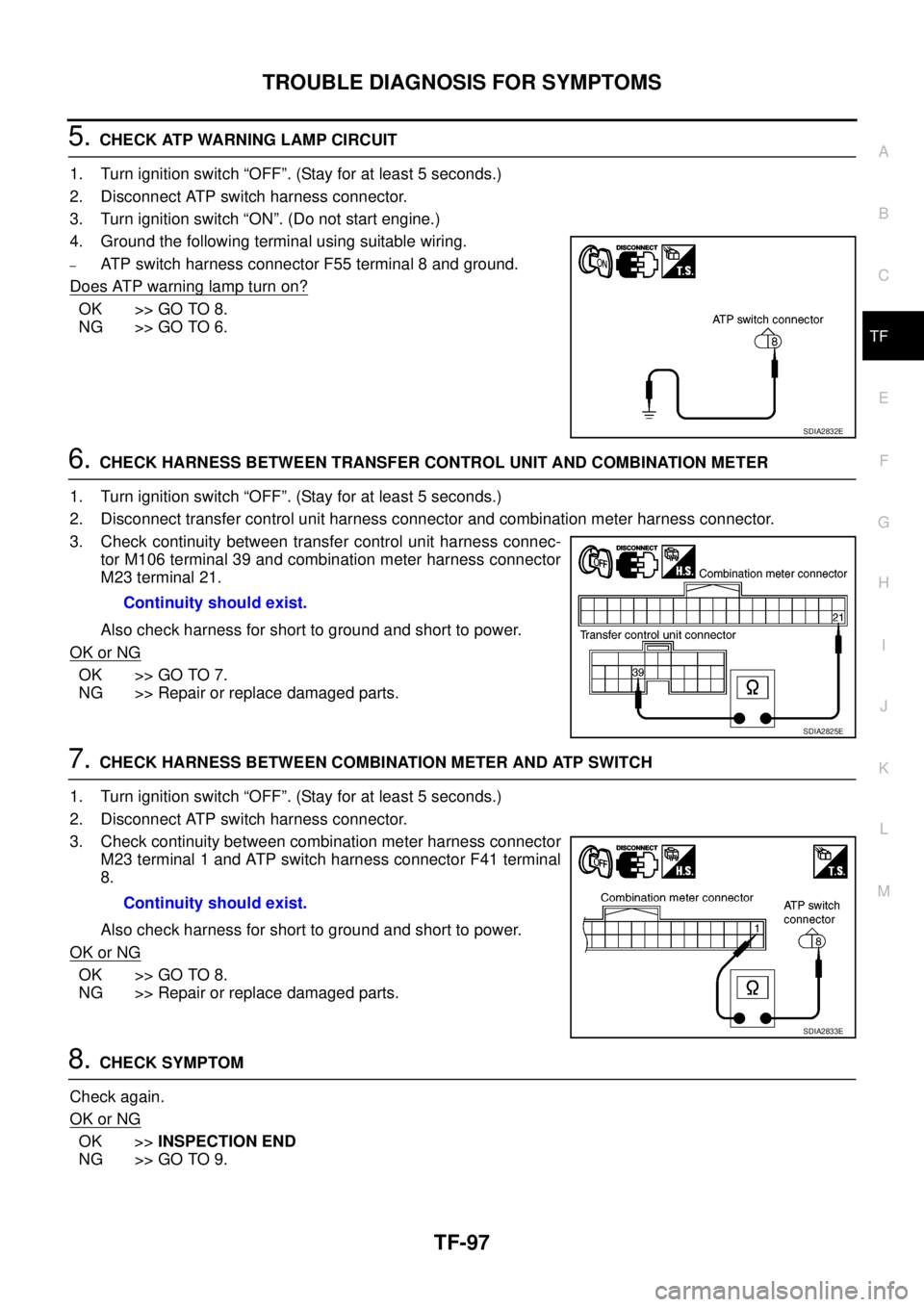

6.CHECK HARNESS BETWEEN TRANSFER CONTROL UNIT AND COMBINATION METER

1. Turn ignition switch “OFF”. (Stay for at least 5 seconds.)

2. Disconnect transfer control unit harness connector and combination meter harness connector.

3. Check continuity between transfer control unit harness connec-

tor M106 terminal 39 and combination meter harness connector

M23 terminal 21.

Also check harness for short to ground and short to power.

OK or NG

OK >> GO TO 7.

NG >> Repair or replace damaged parts.

7.CHECK HARNESS BETWEEN COMBINATION METER AND ATP SWITCH

1. Turn ignition switch “OFF”. (Stay for at least 5 seconds.)

2. Disconnect ATP switch harness connector.

3. Check continuity between combination meter harness connector

M23 terminal 1 and ATP switch harness connector F41 terminal

8.

Also check harness for short to ground and short to power.

OK or NG

OK >> GO TO 8.

NG >> Repair or replace damaged parts.

8.CHECK SYMPTOM

Check again.

OK or NG

OK >>INSPECTION END

NG >> GO TO 9.

SDIA2832E

Continuity should exist.

SDIA2825E

Continuity should exist.

SDIA2833E

Page 3065 of 3171

TF-98

TROUBLE DIAGNOSIS FOR SYMPTOMS

9.CHECK TRANSFER CONTROL UNIT

Check transfer control unit input/output signal. Refer toTF-38, "

Transfer Control Unit Input/Output Signal Ref-

erence Values".

OK or NG

OK >> GO TO 10.

NG >> Check transfer control unit pin terminals for damage or loose connection with harness connector.

If any items are damaged, repair or replace damaged parts.

10.CHECK TRANSFER INNER PARTS

1. Disassemble transfer assembly. Refer toTF-112, "

Disassembly and Assembly".

2. Check transfer inner parts.

OK or NG

OK >>INSPECTION END

NG >> Repair or replace damaged parts.

4WD Shift Indicator Lamp Repeats FlashingEDS0032H

SYMPTOM:

4WD shift indicator lamp keeps flashing.

DIAGNOSTIC PROCEDURE

1.CONFIRM THE SYMPTOM

1. Set4WDshiftswitchto“2WD”.

2. Move vehicle forward and backward, or drive straight increasing or decreasing under 20 km/h (12 MPH).

Dose 4WD shift indicator lamp keep flashing?

YES >> GO TO 2.

NO >>INSPECTION END

2.CHECK SYSTEM FOR WAIT DETECTION SWITCH

Perform trouble diagnosis for wait detection switch system. Refer toTF-63, "

Wait Detection Switch".

OK or NG

OK >> GO TO 3.

NG >> Repair or replace damaged parts.

3.CHECK SYSTEM FOR 4LO SWITCH

Perform trouble diagnosis for 4LO switch system. Refer toTF-56, "

4LO Switch".

OK or NG

OK >> GO TO 4.

NG >> Repair or replace damaged parts.

4.CHECK SYMPTOM

Check again.

OK or NG

OK >>INSPECTION END

NG >> GO TO 5.

Page 3066 of 3171

TROUBLE DIAGNOSIS FOR SYMPTOMS

TF-99

C

E

F

G

H

I

J

K

L

MA

B

TF

5.CHECK TRANSFER CONTROL UNIT

Check transfer control unit input/output signal. Refer toTF-38, "

Transfer Control Unit Input/Output Signal Ref-

erence Values".

OK or NG

OK >> GO TO 6.

NG >> Check transfer control unit pin terminals for damage or loose connection with harness connector.

If any items are damaged, repair or replace damaged parts.

6.CHECK TRANSFER INNER PARTS

1. Disassemble transfer assembly. Refer toTF-112, "

Disassembly and Assembly".

2. Check transfer inner parts.

OK or NG

OK >>INSPECTION END

NG >> Repair or replace damaged parts.

4WD Warning Lamp Flashes SlowlyEDS0032I

SYMPTOM:

While driving, 4WD warning lamp flashes slowly. (Continues to flash until turning ignition switch OFF.)

NOTE:

Slow flashing: 1 time/2 seconds

DIAGNOSTIC PROCEDURE

1.CHECK TIRES

Check the following.

lTire pressure

lWear condition

lLongitudinal tire size (There is no difference between longitudinal tires.)

OK or NG

OK >> GO TO 2.

NG >> Repair or replace damaged parts.

2.CHECK SYMPTOM

Check again.

OK or NG

OK >>INSPECTION END

NG >> GO TO 3.

3.CHECK TRANSFER CONTROL UNIT

Check transfer control unit input/output signal. Refer toTF-38, "

Transfer Control Unit Input/Output Signal Ref-

erence Values".

OK or NG

OK >>INSPECTION END

NG >> Check transfer control unit pin terminals for damage or loose connection with harness connector.

If any items are damaged, repair or replace damaged parts.

Page 3067 of 3171

TF-100

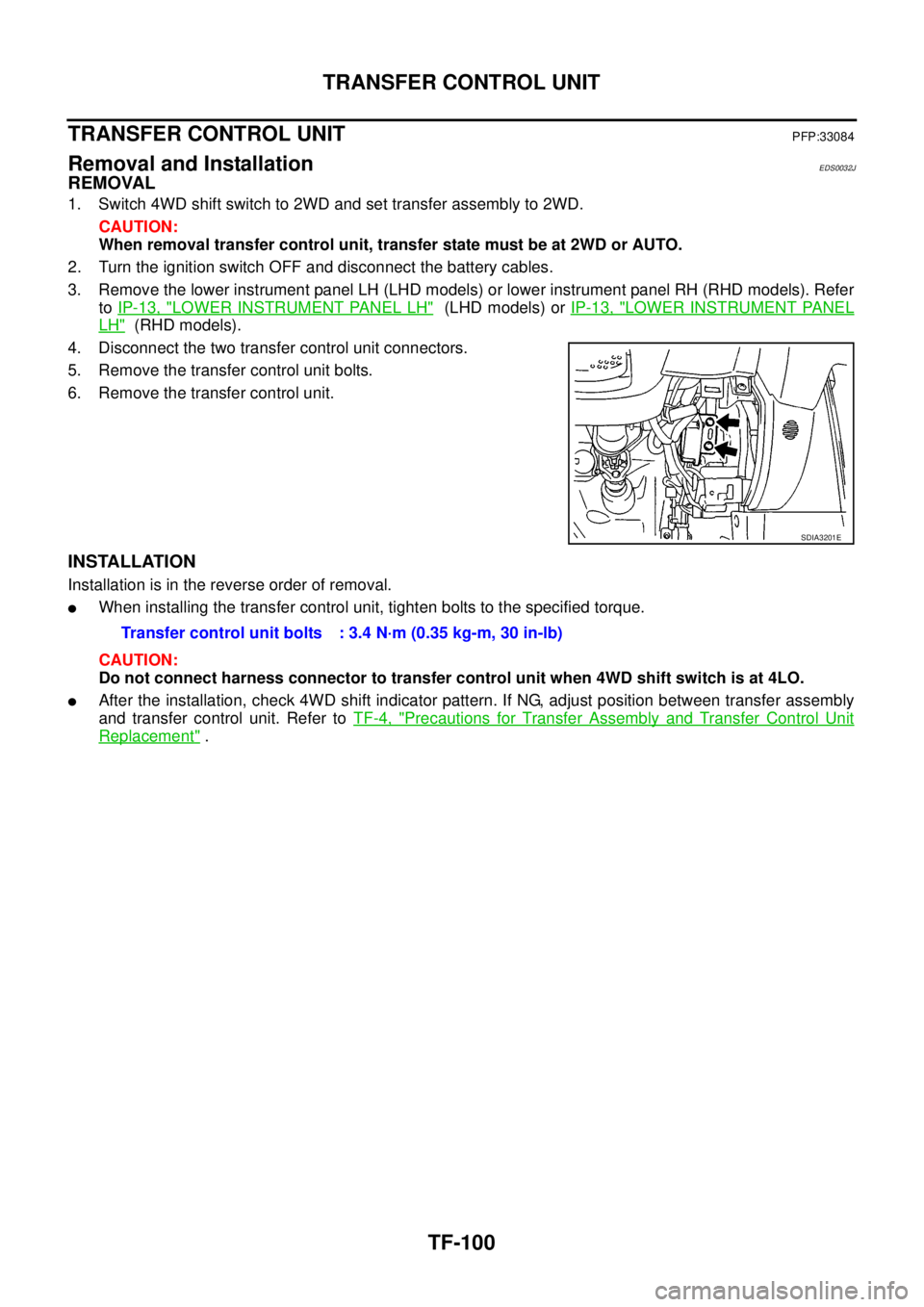

TRANSFER CONTROL UNIT

TRANSFER CONTROL UNIT

PFP:33084

Removal and InstallationEDS0032J

REMOVAL

1. Switch 4WD shift switch to 2WD and set transfer assembly to 2WD.

CAUTION:

When removal transfer control unit, transfer state must be at 2WD or AUTO.

2. Turn the ignition switch OFF and disconnect the battery cables.

3. Remove the lower instrument panel LH (LHD models) or lower instrument panel RH (RHD models). Refer

toIP-13, "

LOWER INSTRUMENT PANEL LH"(LHD models) orIP-13, "LOWER INSTRUMENT PANEL

LH"(RHD models).

4. Disconnect the two transfer control unit connectors.

5. Remove the transfer control unit bolts.

6. Remove the transfer control unit.

INSTALLATION

Installation is in the reverse order of removal.

lWhen installing the transfer control unit, tighten bolts to the specified torque.

CAUTION:

Do not connect harness connector to transfer control unit when 4WD shift switch is at 4LO.

lAfter the installation, check 4WD shift indicator pattern. If NG, adjust position between transfer assembly

and transfer control unit. Refer toTF-4, "

Precautions for Transfer Assembly and Transfer Control Unit

Replacement".

SDIA3201E

Transfer control unit bolts : 3.4 N·m (0.35 kg-m, 30 in-lb)

Page 3068 of 3171

FRONT OIL SEAL

TF-101

C

E

F

G

H

I

J

K

L

MA

B

TF

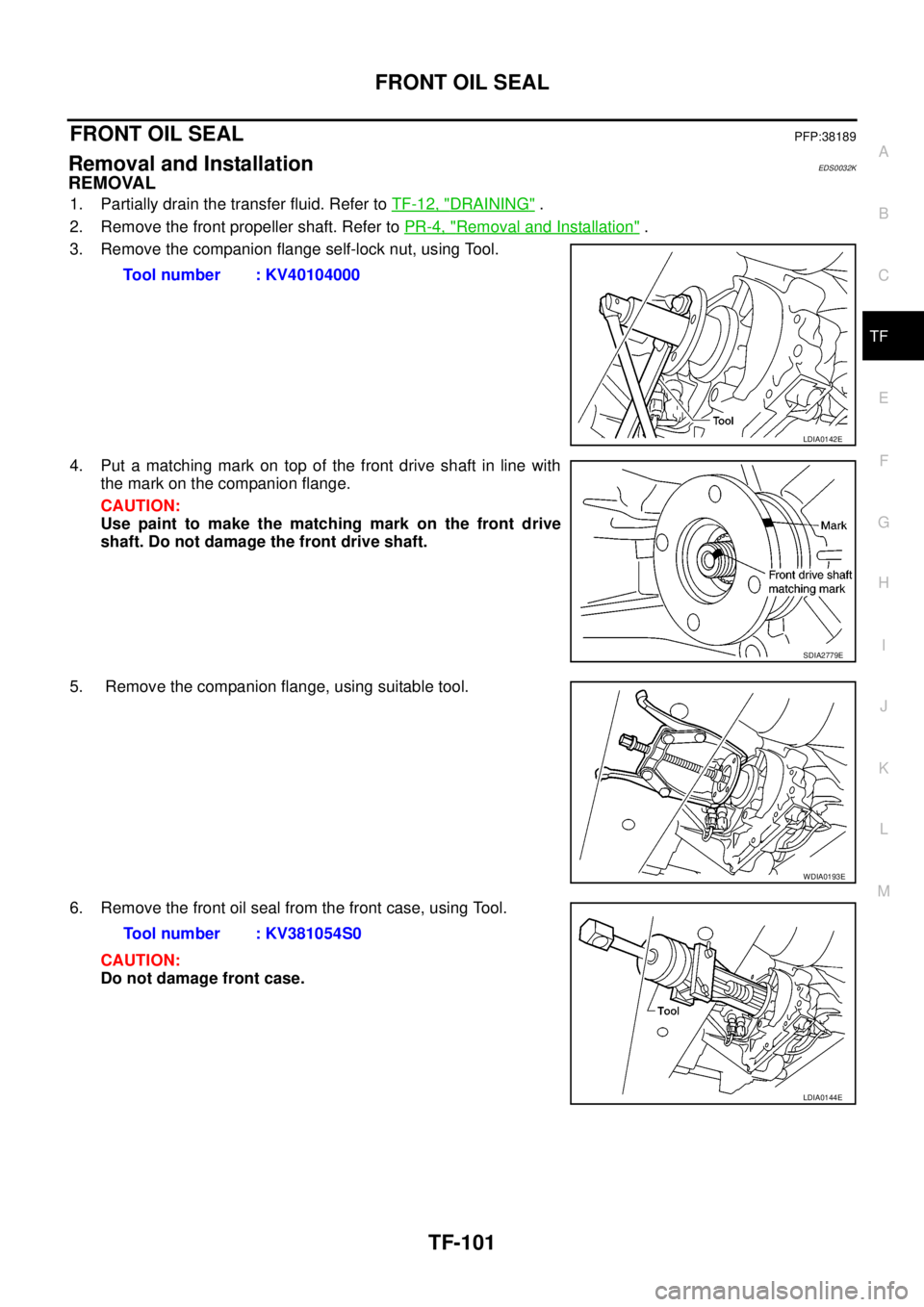

FRONT OIL SEALPFP:38189

Removal and InstallationEDS0032K

REMOVAL

1. Partially drain the transfer fluid. Refer toTF-12, "DRAINING".

2. Remove the front propeller shaft. Refer toPR-4, "

Removal and Installation".

3. Remove the companion flange self-lock nut, using Tool.

4. Put a matching mark on top of the front drive shaft in line with

the mark on the companion flange.

CAUTION:

Use paint to make the matching mark on the front drive

shaft. Do not damage the front drive shaft.

5. Remove the companion flange, using suitable tool.

6. Remove the front oil seal from the front case, using Tool.

CAUTION:

Do not damage front case.Tool number : KV40104000

LDIA0142E

SDIA2779E

WDIA0193E

Tool number : KV381054S0

LDIA0144E

Page 3069 of 3171

TF-102

FRONT OIL SEAL

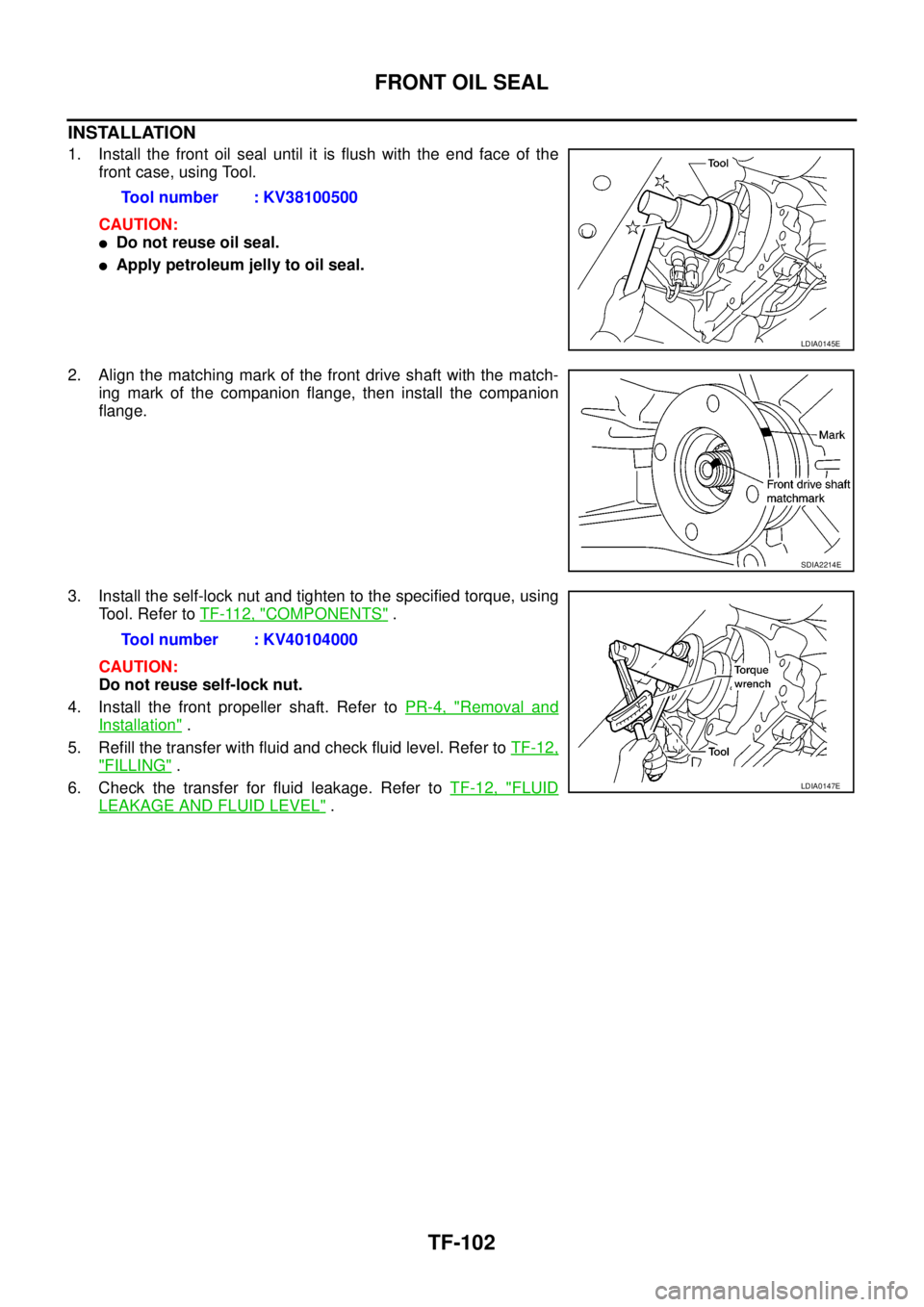

INSTALLATION

1. Install the front oil seal until it is flush with the end face of the

front case, using Tool.

CAUTION:

lDo not reuse oil seal.

lApply petroleum jelly to oil seal.

2. Align the matching mark of the front drive shaft with the match-

ing mark of the companion flange, then install the companion

flange.

3. Install the self-lock nut and tighten to the specified torque, using

Tool. Refer toTF-112, "

COMPONENTS".

CAUTION:

Do not reuse self-lock nut.

4. Install the front propeller shaft. Refer toPR-4, "

Removal and

Installation".

5. Refill the transfer with fluid and check fluid level. Refer toTF-12,

"FILLING".

6. Check the transfer for fluid leakage. Refer toTF-12, "

FLUID

LEAKAGE AND FLUID LEVEL". Tool number : KV38100500

LDIA0145E

SDIA2214E

Tool number : KV40104000

LDIA0147E

Page 3070 of 3171

REAR OIL SEAL

TF-103

C

E

F

G

H

I

J

K

L

MA

B

TF

REAR OIL SEALPFP:33140

Removal and InstallationEDS0032L

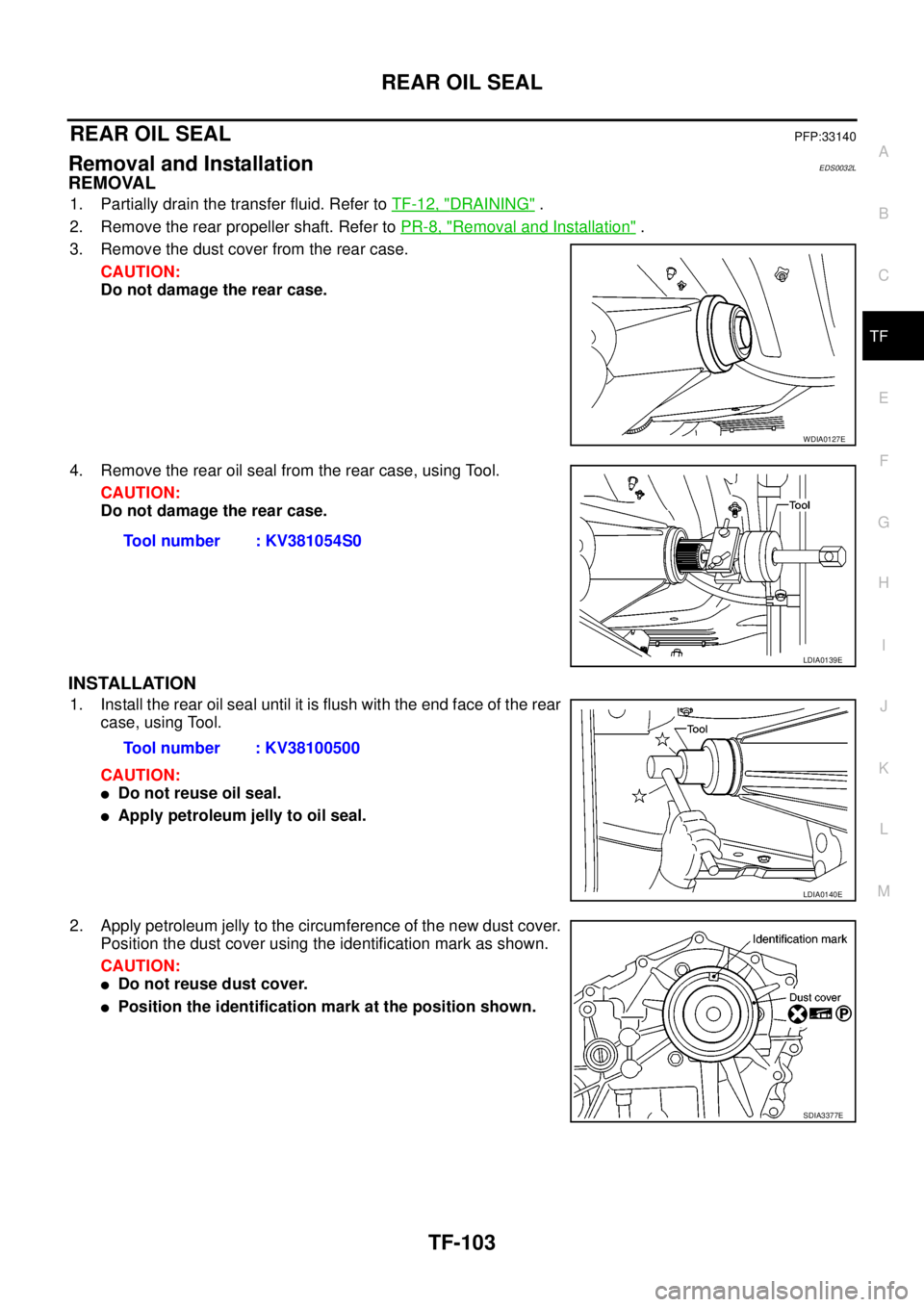

REMOVAL

1. Partially drain the transfer fluid. Refer toTF-12, "DRAINING".

2. Remove the rear propeller shaft. Refer toPR-8, "

Removal and Installation".

3. Remove the dust cover from the rear case.

CAUTION:

Do not damage the rear case.

4. Remove the rear oil seal from the rear case, using Tool.

CAUTION:

Do not damage the rear case.

INSTALLATION

1. Install the rear oil seal until it is flush with the end face of the rear

case, using Tool.

CAUTION:

lDo not reuse oil seal.

lApply petroleum jelly to oil seal.

2. Apply petroleum jelly to the circumference of the new dust cover.

Position the dust cover using the identification mark as shown.

CAUTION:

lDo not reuse dust cover.

lPosition the identification mark at the position shown.

WDIA0127E

Tool number : KV381054S0

LDIA0139E

Tool number : KV38100500

LDIA0140E

SDIA3377E