engine NISSAN PATROL 1998 Y61 / 5.G Engine Control Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1998, Model line: PATROL, Model: NISSAN PATROL 1998 Y61 / 5.GPages: 192, PDF Size: 4.28 MB

Page 84 of 192

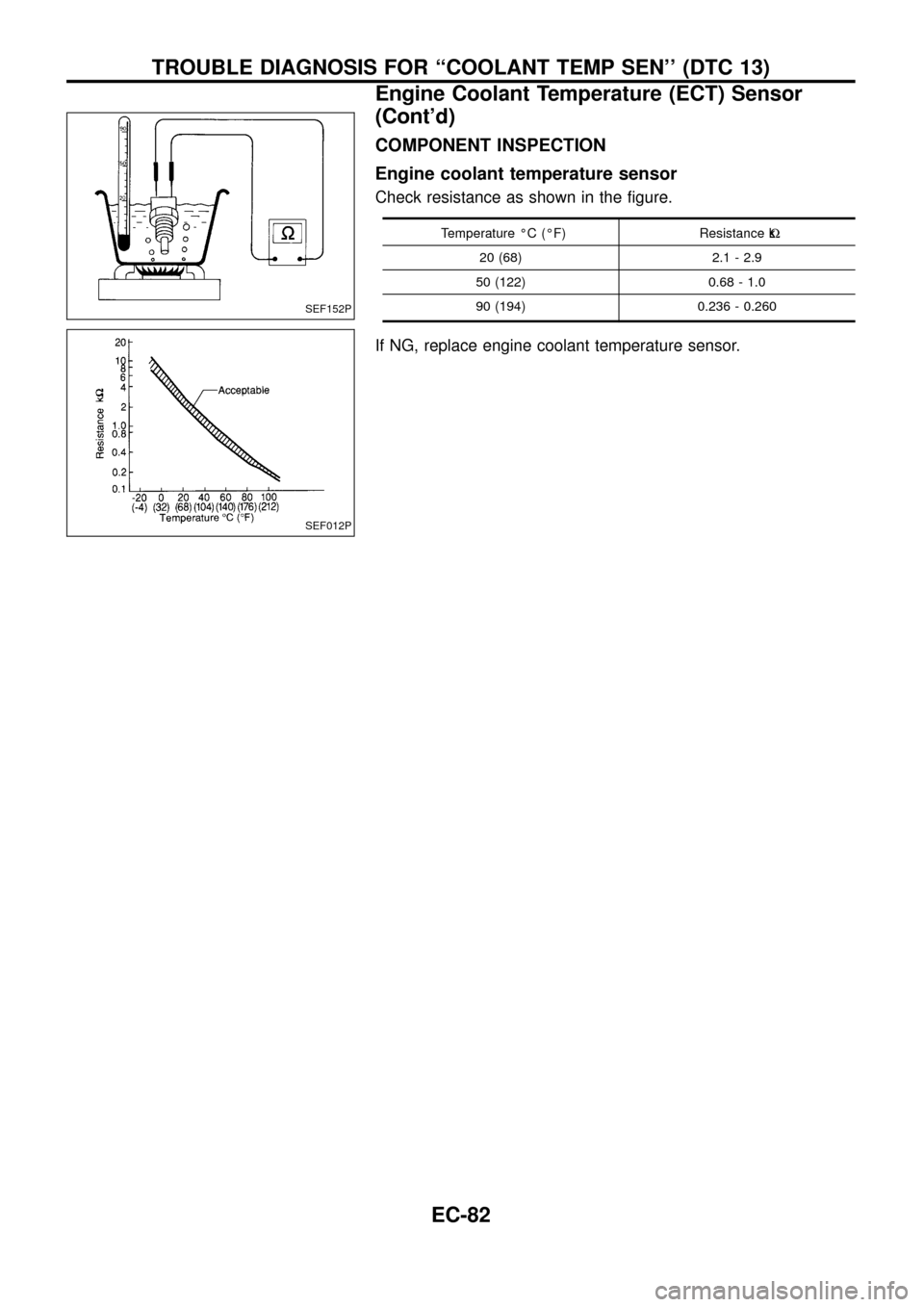

COMPONENT INSPECTION

Engine coolant temperature sensor

Check resistance as shown in the ®gure.

Temperature ÉC (ÉF) Resistance kW

20 (68) 2.1 - 2.9

50 (122) 0.68 - 1.0

90 (194) 0.236 - 0.260

If NG, replace engine coolant temperature sensor.

SEF152P

SEF012P

TROUBLE DIAGNOSIS FOR ``COOLANT TEMP SEN'' (DTC 13)

Engine Coolant Temperature (ECT) Sensor

(Cont'd)

EC-82

Page 85 of 192

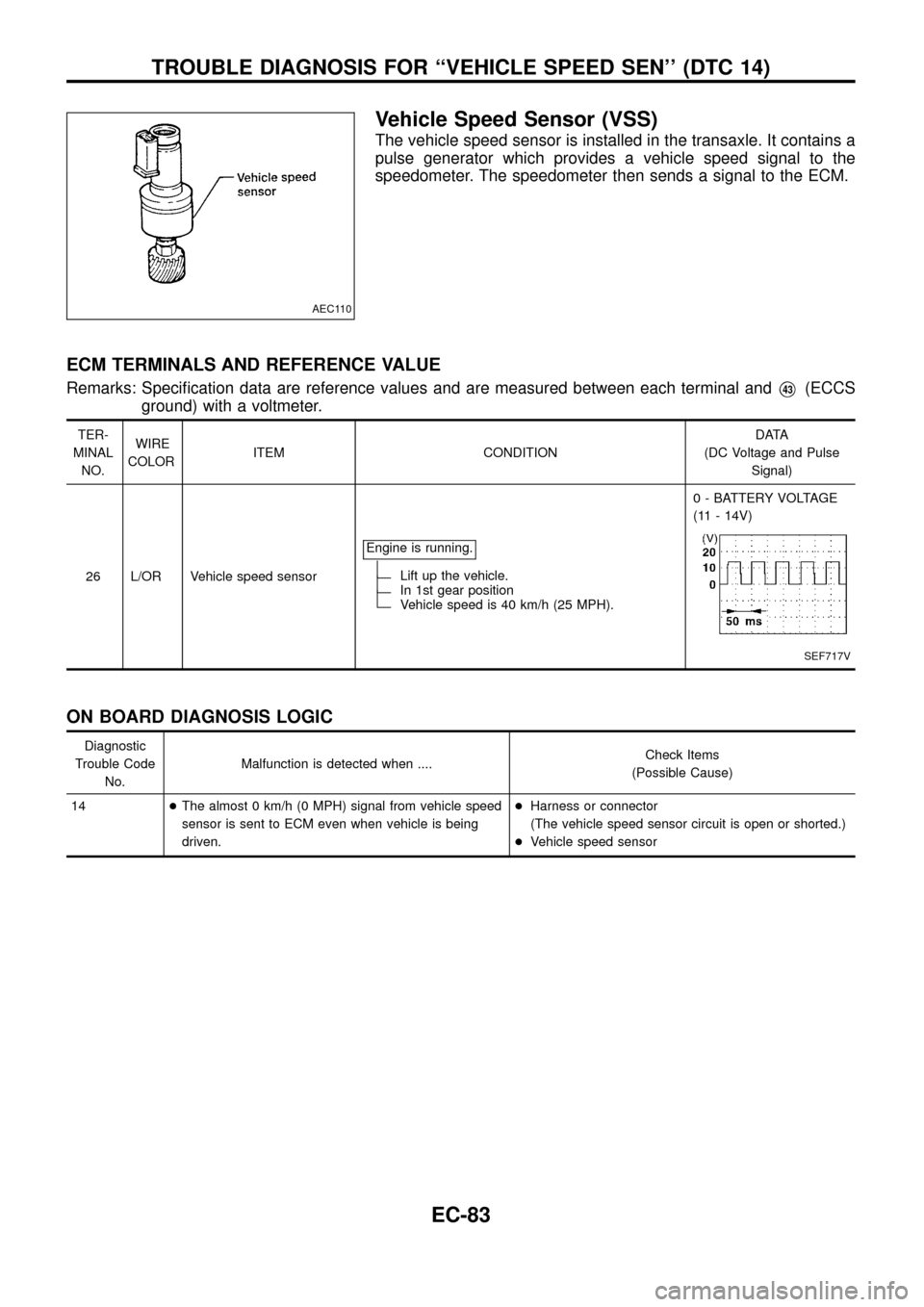

Vehicle Speed Sensor (VSS)

The vehicle speed sensor is installed in the transaxle. It contains a

pulse generator which provides a vehicle speed signal to the

speedometer. The speedometer then sends a signal to the ECM.

ECM TERMINALS AND REFERENCE VALUE

Remarks: Speci®cation data are reference values and are measured between each terminal andV43(ECCS

ground) with a voltmeter.

TER-

MINAL

NO.WIRE

COLORITEM CONDITIONDATA

(DC Voltage and Pulse

Signal)

26 L/OR Vehicle speed sensorEngine is running.

Lift up the vehicle.In 1st gear positionVehicle speed is 40 km/h (25 MPH).0 - BATTERY VOLTAGE

(11 - 14V)

SEF717V

ON BOARD DIAGNOSIS LOGIC

Diagnostic

Trouble Code

No.Malfunction is detected when ....Check Items

(Possible Cause)

14+The almost 0 km/h (0 MPH) signal from vehicle speed

sensor is sent to ECM even when vehicle is being

driven.+Harness or connector

(The vehicle speed sensor circuit is open or shorted.)

+Vehicle speed sensor

AEC110

TROUBLE DIAGNOSIS FOR ``VEHICLE SPEED SEN'' (DTC 14)

EC-83

Page 86 of 192

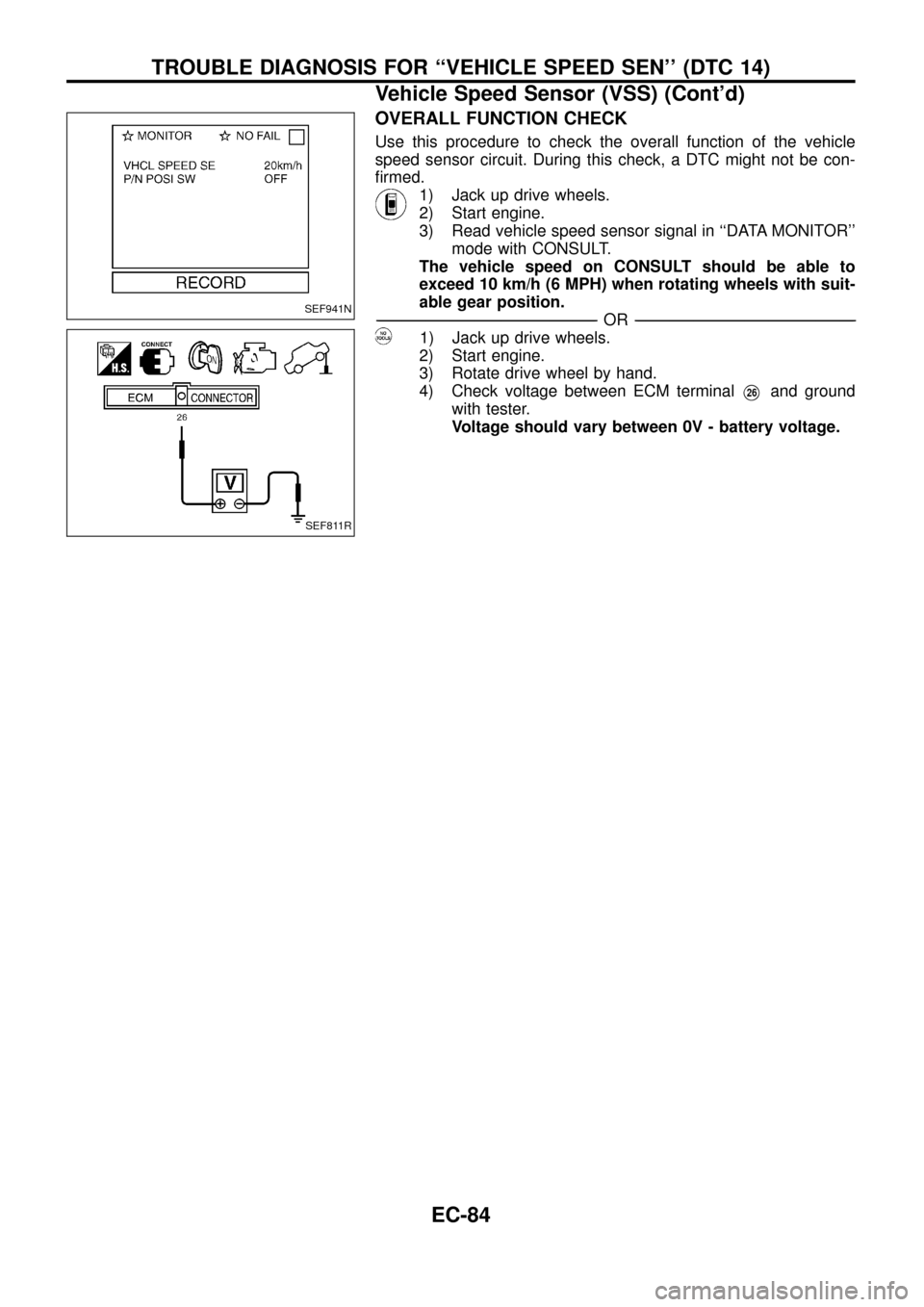

OVERALL FUNCTION CHECK

Use this procedure to check the overall function of the vehicle

speed sensor circuit. During this check, a DTC might not be con-

®rmed.

1) Jack up drive wheels.

2) Start engine.

3) Read vehicle speed sensor signal in ``DATA MONITOR''

mode with CONSULT.

The vehicle speed on CONSULT should be able to

exceed 10 km/h (6 MPH) when rotating wheels with suit-

able gear position.

-------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------OR-------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

1) Jack up drive wheels.

2) Start engine.

3) Rotate drive wheel by hand.

4) Check voltage between ECM terminal

V26and ground

with tester.

Voltage should vary between 0V - battery voltage.

SEF941N

SEF811R

TROUBLE DIAGNOSIS FOR ``VEHICLE SPEED SEN'' (DTC 14)

Vehicle Speed Sensor (VSS) (Cont'd)

EC-84

Page 89 of 192

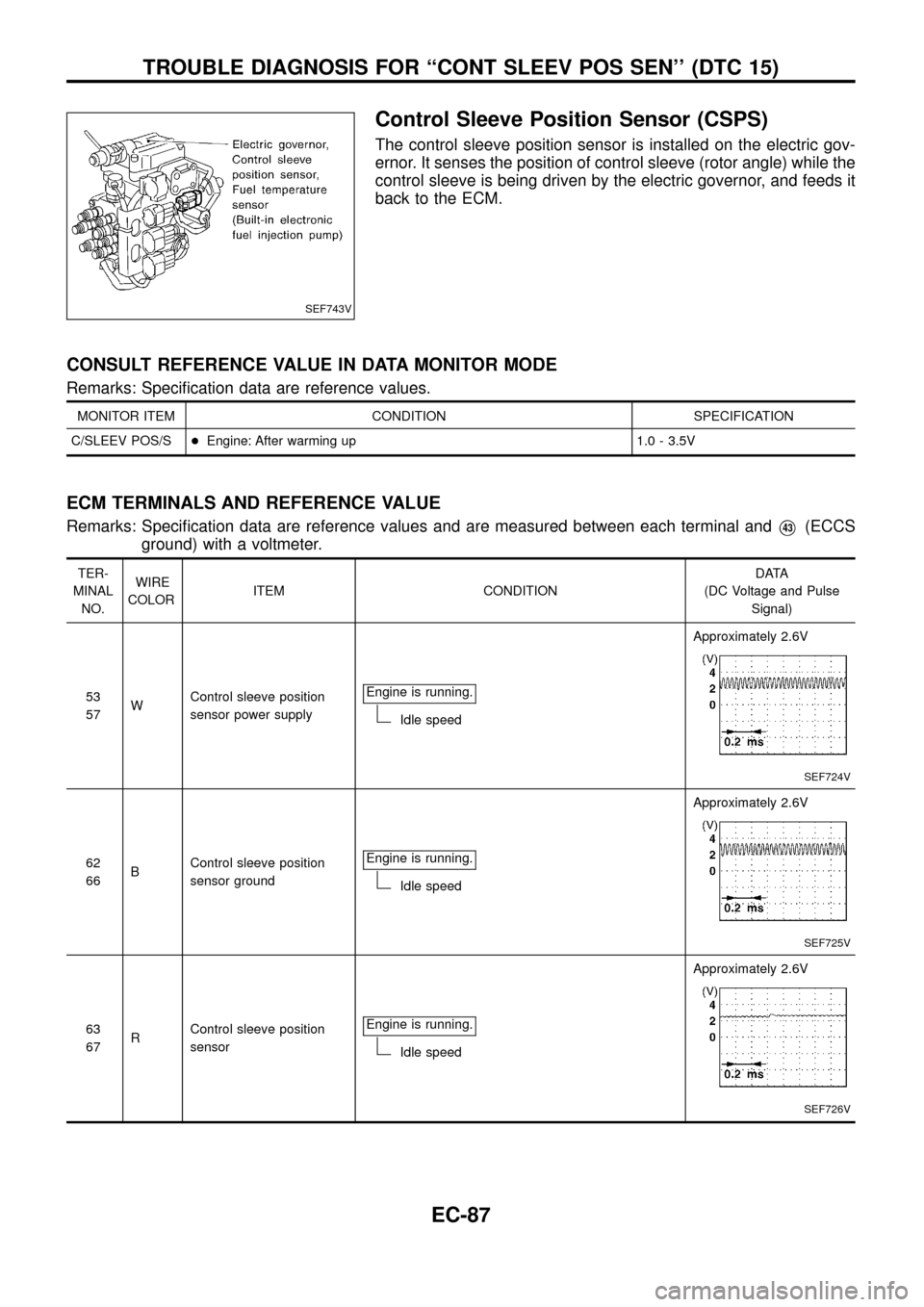

Control Sleeve Position Sensor (CSPS)

The control sleeve position sensor is installed on the electric gov-

ernor. It senses the position of control sleeve (rotor angle) while the

control sleeve is being driven by the electric governor, and feeds it

back to the ECM.

CONSULT REFERENCE VALUE IN DATA MONITOR MODE

Remarks: Speci®cation data are reference values.

MONITOR ITEM CONDITION SPECIFICATION

C/SLEEV POS/S+Engine: After warming up 1.0 - 3.5V

ECM TERMINALS AND REFERENCE VALUE

Remarks: Speci®cation data are reference values and are measured between each terminal andV43(ECCS

ground) with a voltmeter.

TER-

MINAL

NO.WIRE

COLORITEM CONDITIONDATA

(DC Voltage and Pulse

Signal)

53

57WControl sleeve position

sensor power supplyEngine is running.

Idle speedApproximately 2.6V

SEF724V

62

66BControl sleeve position

sensor groundEngine is running.

Idle speedApproximately 2.6V

SEF725V

63

67RControl sleeve position

sensorEngine is running.

Idle speedApproximately 2.6V

SEF726V

SEF743V

TROUBLE DIAGNOSIS FOR ``CONT SLEEV POS SEN'' (DTC 15)

EC-87

Page 90 of 192

ON BOARD DIAGNOSIS LOGIC

Diagnostic

Trouble Code

No.Malfunction is detected when ....Check Items

(Possible cause)

15+An excessively high or low voltage from the sensor is

detected by ECM.

...........................................................................................

+An improper voltage signal from the sensor is

detected by ECM during engine running.+Harness or connectors

(The control sleeve position sensor circuit is open or

shorted.)

+Control sleeve position sensor

DIAGNOSTIC TROUBLE CODE CONFIRMATION

PROCEDURE

1) Turn ignition switch ``ON'' and select ``DATA MONITOR''

mode with CONSULT.

2) Start engine and run it for at least 2 seconds at idle

speed.

-------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------OR-------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

1) Start engine and run it for at least 2 seconds at idle

speed.

2) Turn ignition switch ``OFF'', wait at least 5 seconds and

then ``ON''.

3) Perform ``Diagnostic Test Mode II (Self-diagnostic

results)'' with ECM.

SEF714V

TROUBLE DIAGNOSIS FOR ``CONT SLEEV POS SEN'' (DTC 15)

Control Sleeve Position Sensor (CSPS) (Cont'd)

EC-88

Page 92 of 192

DIAGNOSTIC PROCEDURE

INSPECTION START

CHECK POWER SUPPLY CIRCUIT.

1. Turn ignition switch ``OFF''.

2. Disconnect ECM harness connector

and electronic fuel injection pump har-

ness connector.

3. Check harness continuity between ter-

minal

V2and ECM terminalsV53,V57.

Continuity should exist.

If OK, check harness for short to

ground and short to power.

OK

cNG

Repair open circuit or short

to ground or short to power

in harness or connectors.

CHECK INPUT SIGNAL CIRCUIT.

Check harness continuity between sensor

terminal

V3and ECM terminalsV63,V67.

Continuity should exist.

If OK, check harness for short to ground

and short to power.

OK

cNG

Repair open circuit or short

to ground or short to power

in harness or connectors.

CHECK GROUND CIRCUIT-I.

Check harness continuity between sensor

terminal

V6and ECM terminalsV62,V66.

Continuity should exist.

If OK, check harness for short to ground

and short to power.

OK

cNG

Repair open circuit or short

to ground or short to power

in harness or connectors.

CHECK GROUND CIRCUIT-II.

1. Loosen and retighten engine ground

screws.

2. Check harness continuity between ter-

minal

V4and engine ground.

Continuity should exist.

If OK, check harness for short to

ground and short to power.

OK

cNG

Check the following.

+Joint connector

F19

+Harness for open or

short between control

sleeve position sensor

and engine ground

If NG, repair open circuit or

short to ground or short to

power in harness or con-

nectors.

jA

SEF679V

SEF744V

SEF745V

SEF746V

SEF676V

.

.

.

.

.

TROUBLE DIAGNOSIS FOR ``CONT SLEEV POS SEN'' (DTC 15)

Control Sleeve Position Sensor (CSPS) (Cont'd)

EC-90

Page 94 of 192

Adjustment Resistor

The adjustment resistor is used to achieve uniform pump charac-

teristics.

ECM TERMINALS AND REFERENCE VALUE

Remarks: Speci®cation data are reference values and are measured between each terminal andV43(ECCS

ground) with a voltmeter.

TER-

MINAL

NO.WIRE

COLORITEM CONDITIONDATA

(DC Voltage and Pulse

Signal)

46 Y Adjustment resistor Ignition switch ``ON''

Approximately 0 - 4.6V

(Voltage varies with part

number of adjustment

resistor.)

50 B Sensors' groundEngine is running.

(Warm-up condition)

Idle speedApproximately 0V

ON BOARD DIAGNOSIS LOGIC

Diagnostic

Trouble Code

No.Malfunction is detected when ...Check Items

(Possible Cause)

17+An excessively high or low voltage from the resistor is

detected by ECM.+Harness or connectors

(The adjustment resistor circuit is open or shorted.)

+Adjustment resistor

DIAGNOSTIC TROUBLE CODE CONFIRMATION

PROCEDURE

1) Turn ignition switch ``ON''.

2) Select ``DATA MONITOR'' mode with CONSULT.

3) Wait at least 5 seconds.

-------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------OR-------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

1) Turn ignition switch ``ON'' and wait at least 5 seconds.

2) Turn ignition switch ``OFF'', wait at least 5 seconds and

then turn ``ON''.

3) Perform ``Diagnostic Test Mode II (Self-diagnostic

results)'' with ECM.

SEF681V

SEF748V

TROUBLE DIAGNOSIS FOR ``ADJUST RESISTOR'' (DTC 17)

EC-92

Page 96 of 192

DIAGNOSTIC PROCEDURE

INSPECTION START

CHECK POWER SUPPLY.

1. Turn ignition switch ``OFF''.

2. Disconnect electronic fuel injection

pump harness connector.

3. Turn ignition switch ``ON''.

4. Check voltage between terminal

V2

and ground.

Voltage:

Approximately 5V

OK

cNG

Repair harness or connec-

tors.

CHECK GROUND CIRCUIT.

1. Turn ignition switch ``OFF''.

2. Check harness continuity between ter-

minal

V6and engine ground.

Continuity should exist.

If OK, check harness for short to

ground and short to power.

OK

cNG

Check the following.

+Harness connectors

F6,M51

+Harness connectors

M88,E106

+Harness for open or

short between ECM and

adjustment resistor

+Harness for open or

short between TCM and

adjustment resistor

If NG, repair open circuit or

short to ground or short to

power in harness or con-

nectors.

CHECK COMPONENT

(Adjustment resistor).

Refer to ``COMPONENT INSPECTION''

on next page.

OK

cNG

Replace adjustment resis-

tor.

Disconnect and reconnect harness con-

nectors in the circuit. Then retest.

Trouble is not ®xed.

Check ECM pin terminals for damage and

check the connection of ECM harness

connector.

Reconnect ECM harness connector and

retest.

INSPECTION END

SEF682V

SEF749V

SEF750V

.

.

.

.

.

.

TROUBLE DIAGNOSIS FOR ``ADJUST RESISTOR'' (DTC 17)

Adjustment Resistor (Cont'd)

EC-94

Page 98 of 192

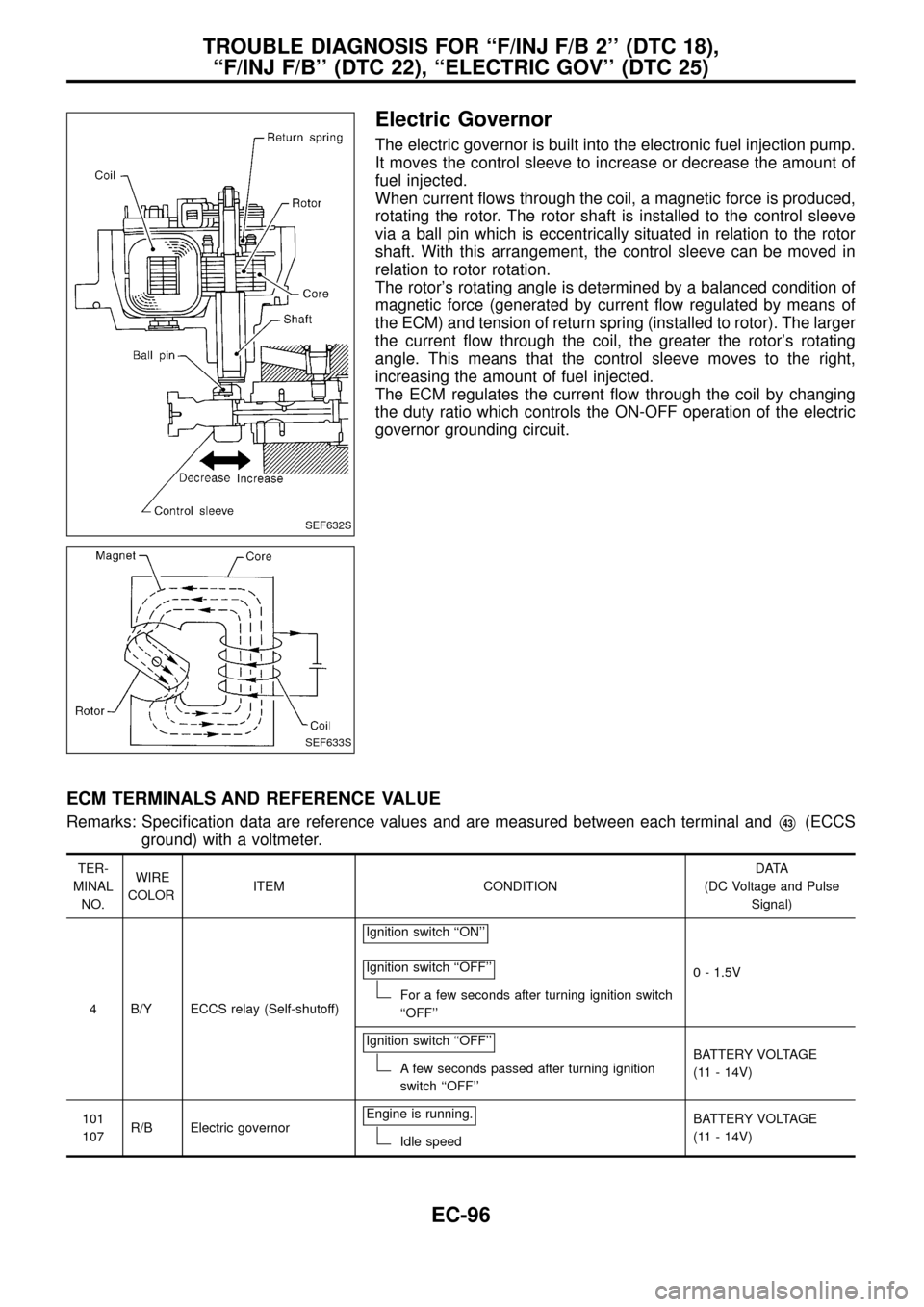

Electric Governor

The electric governor is built into the electronic fuel injection pump.

It moves the control sleeve to increase or decrease the amount of

fuel injected.

When current ¯ows through the coil, a magnetic force is produced,

rotating the rotor. The rotor shaft is installed to the control sleeve

via a ball pin which is eccentrically situated in relation to the rotor

shaft. With this arrangement, the control sleeve can be moved in

relation to rotor rotation.

The rotor's rotating angle is determined by a balanced condition of

magnetic force (generated by current ¯ow regulated by means of

the ECM) and tension of return spring (installed to rotor). The larger

the current ¯ow through the coil, the greater the rotor's rotating

angle. This means that the control sleeve moves to the right,

increasing the amount of fuel injected.

The ECM regulates the current ¯ow through the coil by changing

the duty ratio which controls the ON-OFF operation of the electric

governor grounding circuit.

ECM TERMINALS AND REFERENCE VALUE

Remarks: Speci®cation data are reference values and are measured between each terminal andV43(ECCS

ground) with a voltmeter.

TER-

MINAL

NO.WIRE

COLORITEM CONDITIONDATA

(DC Voltage and Pulse

Signal)

4 B/Y ECCS relay (Self-shutoff)Ignition switch ``ON''

Ignition switch ``OFF''

For a few seconds after turning ignition switch

``OFF''0 - 1.5V

Ignition switch ``OFF''

A few seconds passed after turning ignition

switch ``OFF''BATTERY VOLTAGE

(11 - 14V)

101

107R/B Electric governorEngine is running.

Idle speedBATTERY VOLTAGE

(11 - 14V)

SEF632S

SEF633S

TROUBLE DIAGNOSIS FOR ``F/INJ F/B 2'' (DTC 18),

``F/INJ F/B'' (DTC 22), ``ELECTRIC GOV'' (DTC 25)

EC-96

Page 99 of 192

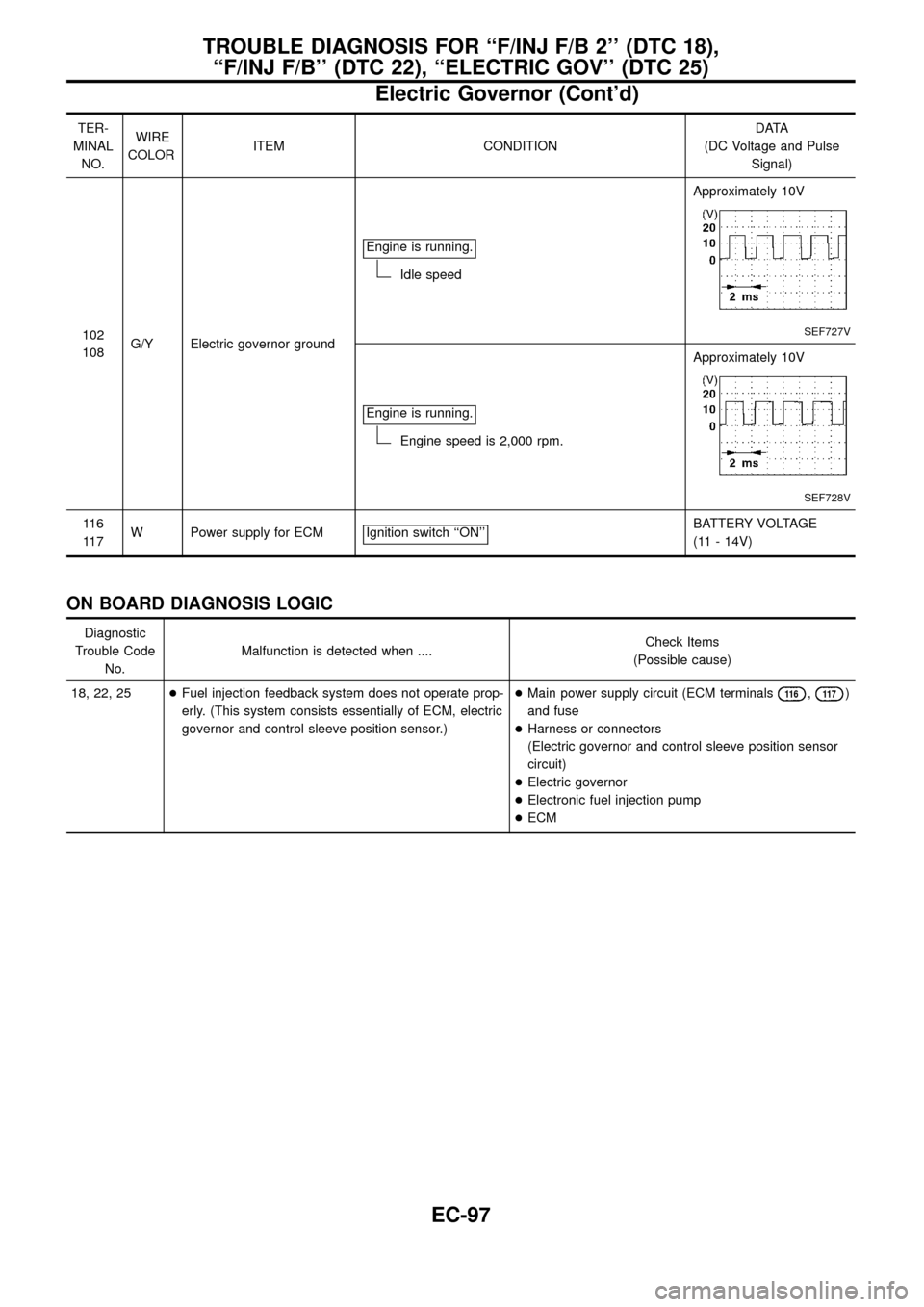

TER-

MINAL

NO.WIRE

COLORITEM CONDITIONDATA

(DC Voltage and Pulse

Signal)

102

108G/Y Electric governor groundEngine is running.

Idle speedApproximately 10V

SEF727V

Engine is running.

Engine speed is 2,000 rpm.Approximately 10V

SEF728V

11 6

11 7W Power supply for ECM Ignition switch ``ON''BATTERY VOLTAGE

(11 - 14V)

ON BOARD DIAGNOSIS LOGIC

Diagnostic

Trouble Code

No.Malfunction is detected when ....Check Items

(Possible cause)

18, 22, 25+Fuel injection feedback system does not operate prop-

erly. (This system consists essentially of ECM, electric

governor and control sleeve position sensor.)+Main power supply circuit (ECM terminals

11 6,11 7)

and fuse

+Harness or connectors

(Electric governor and control sleeve position sensor

circuit)

+Electric governor

+Electronic fuel injection pump

+ECM

TROUBLE DIAGNOSIS FOR ``F/INJ F/B 2'' (DTC 18),

``F/INJ F/B'' (DTC 22), ``ELECTRIC GOV'' (DTC 25)

Electric Governor (Cont'd)

EC-97