engine NISSAN PATROL 1998 Y61 / 5.G Engine Control Manual Online

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1998, Model line: PATROL, Model: NISSAN PATROL 1998 Y61 / 5.GPages: 192, PDF Size: 4.28 MB

Page 119 of 192

DIAGNOSTIC PROCEDURE

INSPECTION START

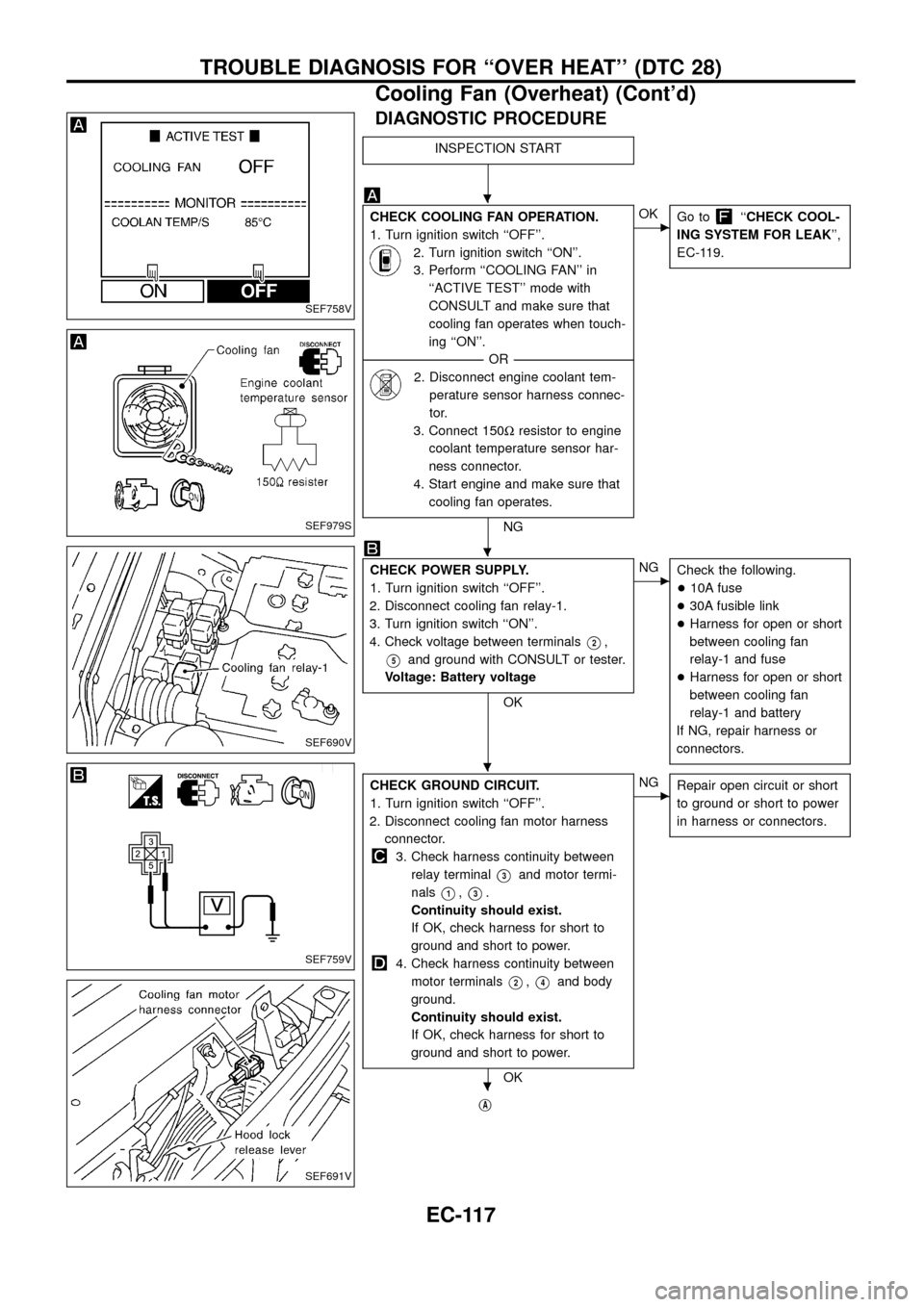

CHECK COOLING FAN OPERATION.

1. Turn ignition switch ``OFF''.

2. Turn ignition switch ``ON''.

3. Perform ``COOLING FAN'' in

``ACTIVE TEST'' mode with

CONSULT and make sure that

cooling fan operates when touch-

ing ``ON''.

--------------------------------------------------------------------------------------------------------------------------------------OR--------------------------------------------------------------------------------------------------------------------------------------

2. Disconnect engine coolant tem-

perature sensor harness connec-

tor.

3. Connect 150Wresistor to engine

coolant temperature sensor har-

ness connector.

4. Start engine and make sure that

cooling fan operates.

NG

cOK

Go to``CHECK COOL-

ING SYSTEM FOR LEAK'',

EC-119.

CHECK POWER SUPPLY.

1. Turn ignition switch ``OFF''.

2. Disconnect cooling fan relay-1.

3. Turn ignition switch ``ON''.

4. Check voltage between terminals

V2,

V5and ground with CONSULT or tester.

Voltage: Battery voltage

OK

cNG

Check the following.

+10A fuse

+30A fusible link

+Harness for open or short

between cooling fan

relay-1 and fuse

+Harness for open or short

between cooling fan

relay-1 and battery

If NG, repair harness or

connectors.

CHECK GROUND CIRCUIT.

1. Turn ignition switch ``OFF''.

2. Disconnect cooling fan motor harness

connector.

3. Check harness continuity between

relay terminal

V3and motor termi-

nals

V1,V3.

Continuity should exist.

If OK, check harness for short to

ground and short to power.

4. Check harness continuity between

motor terminals

V2,V4and body

ground.

Continuity should exist.

If OK, check harness for short to

ground and short to power.

OK

cNG

Repair open circuit or short

to ground or short to power

in harness or connectors.

jA

SEF758V

SEF979S

SEF690V

SEF759V

SEF691V

.

.

.

.

TROUBLE DIAGNOSIS FOR ``OVER HEAT'' (DTC 28)

Cooling Fan (Overheat) (Cont'd)

EC-117

Page 121 of 192

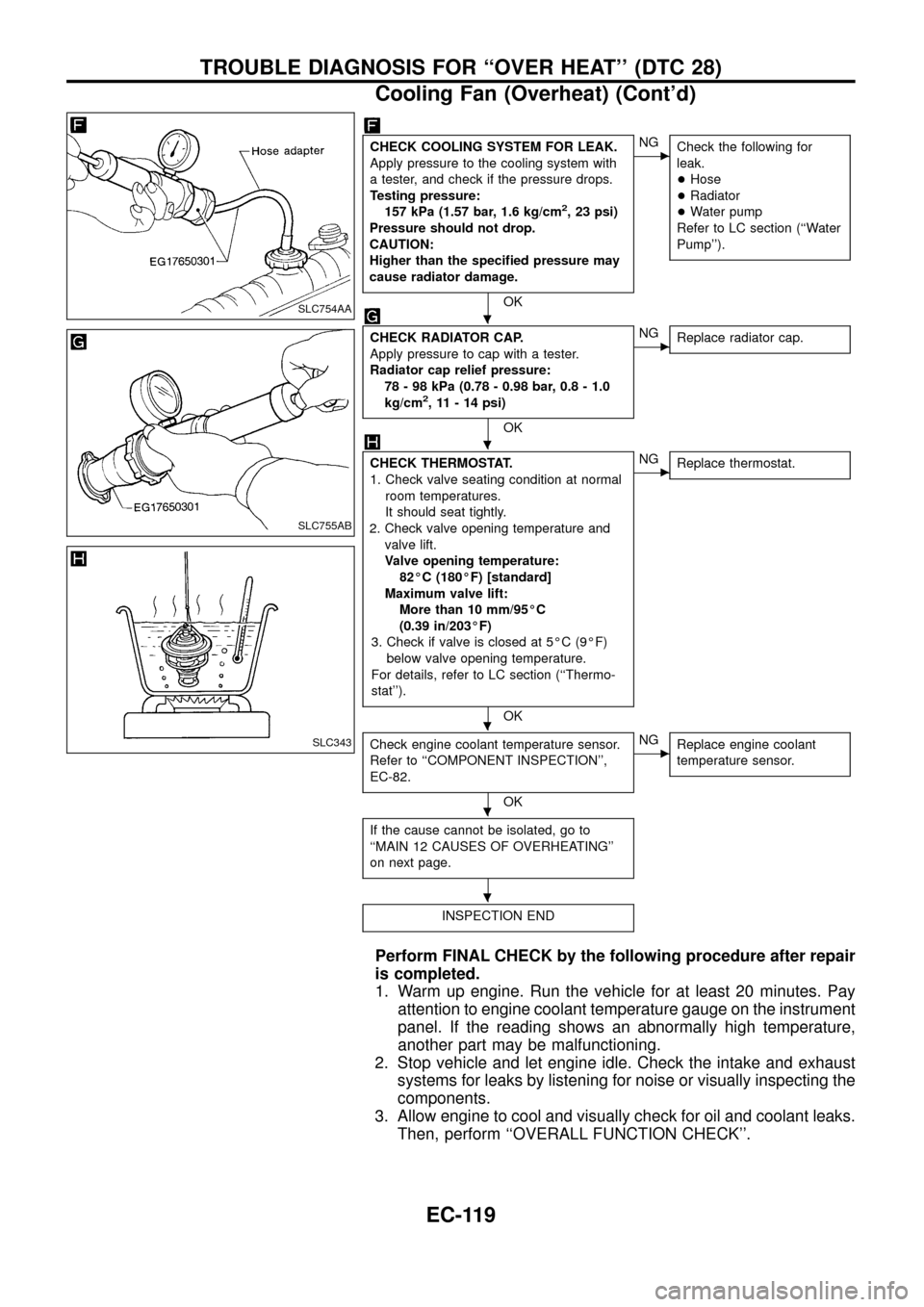

CHECK COOLING SYSTEM FOR LEAK.

Apply pressure to the cooling system with

a tester, and check if the pressure drops.

Testing pressure:

157 kPa (1.57 bar, 1.6 kg/cm

2, 23 psi)

Pressure should not drop.

CAUTION:

Higher than the speci®ed pressure may

cause radiator damage.

OK

cNG

Check the following for

leak.

+Hose

+Radiator

+Water pump

Refer to LC section (``Water

Pump'').

CHECK RADIATOR CAP.

Apply pressure to cap with a tester.

Radiator cap relief pressure:

78 - 98 kPa (0.78 - 0.98 bar, 0.8 - 1.0

kg/cm

2, 11 - 14 psi)

OK

cNG

Replace radiator cap.

CHECK THERMOSTAT.

1. Check valve seating condition at normal

room temperatures.

It should seat tightly.

2. Check valve opening temperature and

valve lift.

Valve opening temperature:

82ÉC (180ÉF) [standard]

Maximum valve lift:

More than 10 mm/95ÉC

(0.39 in/203ÉF)

3. Check if valve is closed at 5ÉC (9ÉF)

below valve opening temperature.

For details, refer to LC section (``Thermo-

stat'').

OK

cNG

Replace thermostat.

Check engine coolant temperature sensor.

Refer to ``COMPONENT INSPECTION'',

EC-82.

OK

cNG

Replace engine coolant

temperature sensor.

If the cause cannot be isolated, go to

``MAIN 12 CAUSES OF OVERHEATING''

on next page.

INSPECTION END

Perform FINAL CHECK by the following procedure after repair

is completed.

1. Warm up engine. Run the vehicle for at least 20 minutes. Pay

attention to engine coolant temperature gauge on the instrument

panel. If the reading shows an abnormally high temperature,

another part may be malfunctioning.

2. Stop vehicle and let engine idle. Check the intake and exhaust

systems for leaks by listening for noise or visually inspecting the

components.

3. Allow engine to cool and visually check for oil and coolant leaks.

Then, perform ``OVERALL FUNCTION CHECK''.

SLC754AA

SLC755AB

SLC343

.

.

.

.

.

TROUBLE DIAGNOSIS FOR ``OVER HEAT'' (DTC 28)

Cooling Fan (Overheat) (Cont'd)

EC-119

Page 122 of 192

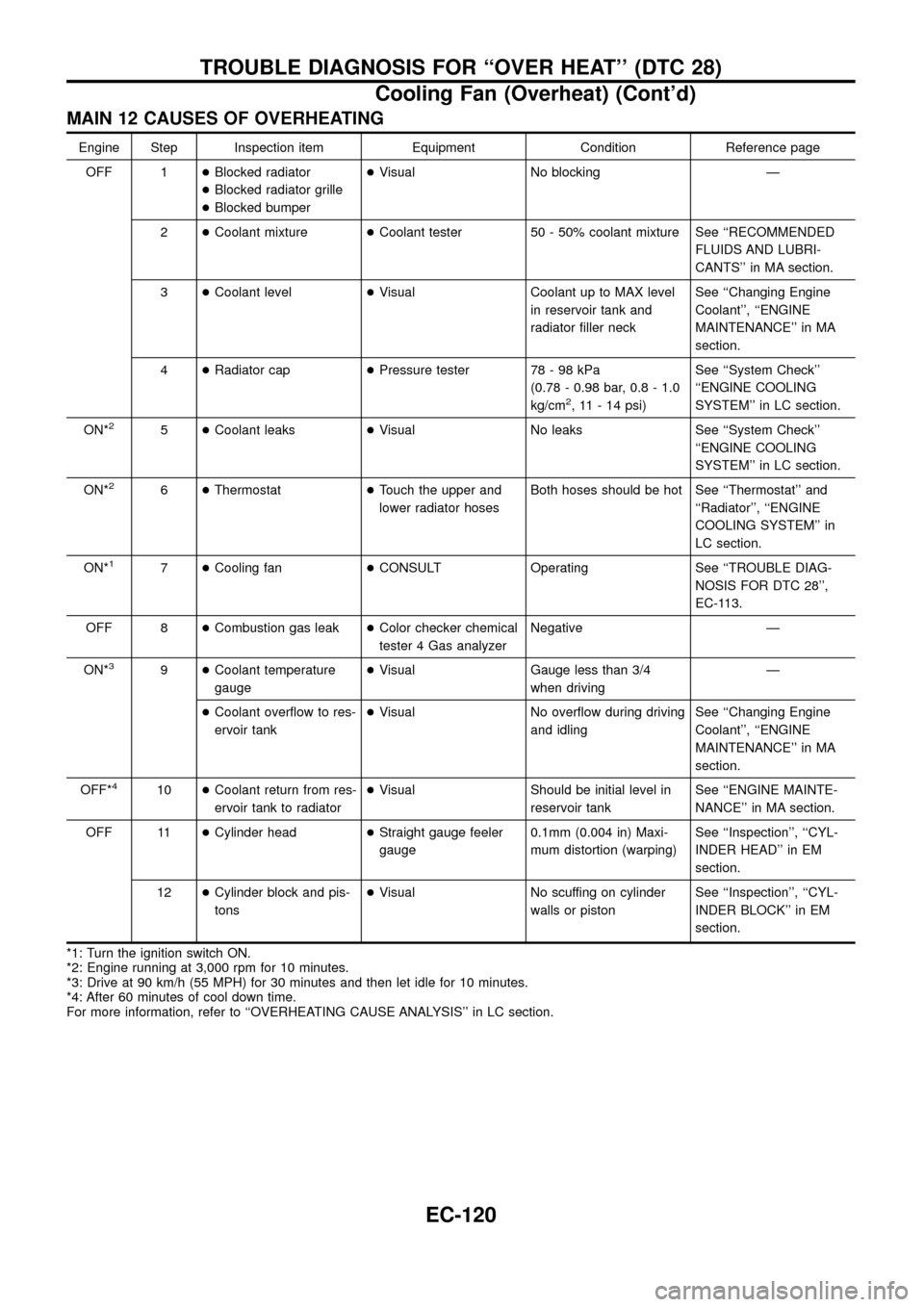

MAIN 12 CAUSES OF OVERHEATING

Engine Step Inspection item Equipment Condition Reference page

OFF 1+Blocked radiator

+Blocked radiator grille

+Blocked bumper+Visual No blocking Ð

2+Coolant mixture+Coolant tester 50 - 50% coolant mixture See ``RECOMMENDED

FLUIDS AND LUBRI-

CANTS'' in MA section.

3+Coolant level+Visual Coolant up to MAX level

in reservoir tank and

radiator ®ller neckSee ``Changing Engine

Coolant'', ``ENGINE

MAINTENANCE'' in MA

section.

4+Radiator cap+Pressure tester 78 - 98 kPa

(0.78 - 0.98 bar, 0.8 - 1.0

kg/cm

2, 11 - 14 psi)See ``System Check''

``ENGINE COOLING

SYSTEM'' in LC section.

ON*

25+Coolant leaks+Visual No leaks See ``System Check''

``ENGINE COOLING

SYSTEM'' in LC section.

ON*

26+Thermostat+Touch the upper and

lower radiator hosesBoth hoses should be hot See ``Thermostat'' and

``Radiator'', ``ENGINE

COOLING SYSTEM'' in

LC section.

ON*

17+Cooling fan+CONSULT Operating See ``TROUBLE DIAG-

NOSIS FOR DTC 28'',

EC-113.

OFF 8+Combustion gas leak+Color checker chemical

tester 4 Gas analyzerNegative Ð

ON*

39+Coolant temperature

gauge+Visual Gauge less than 3/4

when drivingÐ

+Coolant over¯ow to res-

ervoir tank+Visual No over¯ow during driving

and idlingSee ``Changing Engine

Coolant'', ``ENGINE

MAINTENANCE'' in MA

section.

OFF*

410+Coolant return from res-

ervoir tank to radiator+Visual Should be initial level in

reservoir tankSee ``ENGINE MAINTE-

NANCE'' in MA section.

OFF 11+Cylinder head+Straight gauge feeler

gauge0.1mm (0.004 in) Maxi-

mum distortion (warping)See ``Inspection'', ``CYL-

INDER HEAD'' in EM

section.

12+Cylinder block and pis-

tons+Visual No scuffing on cylinder

walls or pistonSee ``Inspection'', ``CYL-

INDER BLOCK'' in EM

section.

*1: Turn the ignition switch ON.

*2: Engine running at 3,000 rpm for 10 minutes.

*3: Drive at 90 km/h (55 MPH) for 30 minutes and then let idle for 10 minutes.

*4: After 60 minutes of cool down time.

For more information, refer to ``OVERHEATING CAUSE ANALYSIS'' in LC section.

TROUBLE DIAGNOSIS FOR ``OVER HEAT'' (DTC 28)

Cooling Fan (Overheat) (Cont'd)

EC-120

Page 124 of 192

Charge Air Temperature Sensor

The charge air temperature sensor is used to detect the charge air

temperature. The sensor modi®es a voltage signal from the ECM.

The modi®ed signal returns to the ECM as the charge air tempera-

ture input. The sensor uses a thermistor which is sensitive to the

change in temperature. The electrical resistance of the thermistor

decreases as temperature increases.

The ECM uses this signal for the charge air cooler control.

Charge air temperatureÉC (ÉF) Voltage

(V) Resistance

(kW)

þ10 (14) 4.4 7.0 - 11.4 20 (68) 3.5 2.1 - 2.9

50 (122) 2.3 0.68 - 1.00

90 (194) 1.0 0.236 - 0.260

110 (230) 0.64 0.143 - 0.153

150 (302) 0.30 0.050 - 0.065

ECM TERMINALS AND REFERENCE VALUE

Remarks: Speci®cation data are reference values and are measured between each terminal andV43(ECCS

ground) with a voltmeter.

TER-

MINAL NO. WIRE

COLOR ITEM CONDITION DATA

(DC Voltage and Pulse Signal)

36 LG Charge air temperature

sensor Engine is running.

Approximatel

y 0 - 4.8V

Output voltage varies with

charge air temperature.

50 B Sensors' ground Engine is running.

(Warm-up condition)

Idle speed Approximately 0V

ON BOARD DIAGNOSIS LOGIC

Diagnostic

Trouble Code No. Malfunction is detected when ...

Check Items

(Possible Cause)

33 *1 +An excessively high or low voltage from the sensor is

entered to ECM. +

Harness or connectors

(The sensor circuit is open or shorted.)

+ Charge air temperature sensor

*1: When nothing is displayed or the meaningless symbol is displayed in the ``Self-diag result'' mode with CONSULT, perform ``Diagnostic Test Mode II

(Self-diagnostic results)'' with ECM. Refer to EC-32.

DIAGNOSTIC TROUBLE CODE CONFIRMATION

PROCEDURE

1) Turn ignition switch ``ON'' and wait at least 5 seconds.

2) Turn ignition switch ``OFF'', wait at least 5 seconds and then turn ``ON''.

3) Perform ``Diagnostic Test Mode II (Self-diagnostic results)'' with ECM.

SEF594K

SEF012P

TROUBLE DIAGNOSIS FOR ``I/C INT/A TEMP SEN'' (DTC 33)

EC-122

Page 126 of 192

DIAGNOSTIC PROCEDURE

INSPECTION START

CHECK POWER SUPPLY.

1. Turn ignition switch ``OFF''.

2. Disconnect charge air temperature sen-

sor harness connector.

3. Turn ignition switch ``ON''.

4. Check voltage between terminal

V2

and ground with CONSULT or tester.

Voltage:

Approximately 5V

OK

cNG

Repair harness or connec-

tors.

CHECK GROUND CIRCUIT.

1. Turn ignition switch ``OFF''.

2. Check harness continuity between ter-

minal

V1and engine ground.

Continuity should exist.

If OK, check harness for short to

ground and short to power.

OK

cNG

Check the following.

+Harness connectors

F6,M51

+Harness connectors

M88,E106

+Harness for open or

short between ECM and

charge air temperature

sensor

+Harness for open or

short between TCM and

charge air temperature

sensor

If NG, repair open circuit or

short to ground or short to

power in harness or con-

nectors.

CHECK COMPONENT

(Charge air temperature sensor).

Refer to ``COMPONENT INSPECTION''

on next page.

OK

cNG

Replace charge air tem-

perature sensor.

Disconnect and reconnect harness con-

nectors in the circuit. Then retest.

Trouble is not ®xed.

Check ECM pin terminals for damage and

check the connection of ECM harness

connector. Reconnect ECM harness con-

nector and retest.

INSPECTION END

SEF710V

SEF764V

SEF765V

.

.

.

.

.

.

TROUBLE DIAGNOSIS FOR ``I/C INT/A TEMP SEN'' (DTC 33)

Charge Air Temperature Sensor (Cont'd)

EC-124

Page 128 of 192

Needle Lift Sensor (NLS)

The needle lift sensor is built into the No. 1 injection nozzle. Its

piezoelectric element senses changes in fuel injection timing

caused by fuel temperature, etc. This change of fuel injection tim-

ing is sent as a pulse signal to the ECM.

ECM TERMINALS AND REFERENCE VALUE

Remarks: Speci®cation data are reference values and are measured between each terminal andV43(ECCS

ground) with a voltmeter.

TER-

MINAL

NO.WIRE

COLORITEM CONDITIONDATA

(DC Voltage and Pulse

Signal)

34 W Needle lift sensorEngine is running.

(Warm-up condition)

Idle speedApproximately 0V

SEF718V

Engine is running.(Warm-up condition)

Engine speed is 2,000 rpm.Approximately 0V

SEF719V

ON BOARD DIAGNOSIS LOGIC

Diagnostic

Trouble Code

No.Malfunction is detected when ....Check Items

(Possible Cause)

34+An improper signal from the sensor is sent to ECM.+Harness or connectors

(The sensor circuit is open or shorted.)

+Needle lift sensor

+Air in fuel line

+Clogging No. 1 injection nozzle

SEF604S

Terminal

Piezoelectric element

TROUBLE DIAGNOSIS FOR ``NEEDLE LIFT SEN'' (DTC 34)

EC-126

Page 129 of 192

DIAGNOSTIC TROUBLE CODE CONFIRMATION

PROCEDURE

1) Turn ignition switch ``ON'' and select ``DATA MONITOR''

mode with CONSULT.

2) Start engine and run it for at least 10 seconds at idle

speed.

-------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------OR-------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

1) Start engine and run it for at least 10 seconds at idle

speed.

2) Turn ignition switch ``OFF'', wait at least 5 seconds and

then turn ``ON''.

3) Perform ``Diagnostic Test Mode II (Self-diagnostic

results)'' with ECM.

SEF714V

TROUBLE DIAGNOSIS FOR ``NEEDLE LIFT SEN'' (DTC 34)

Needle Lift Sensor (NLS) (Cont'd)

EC-127

Page 131 of 192

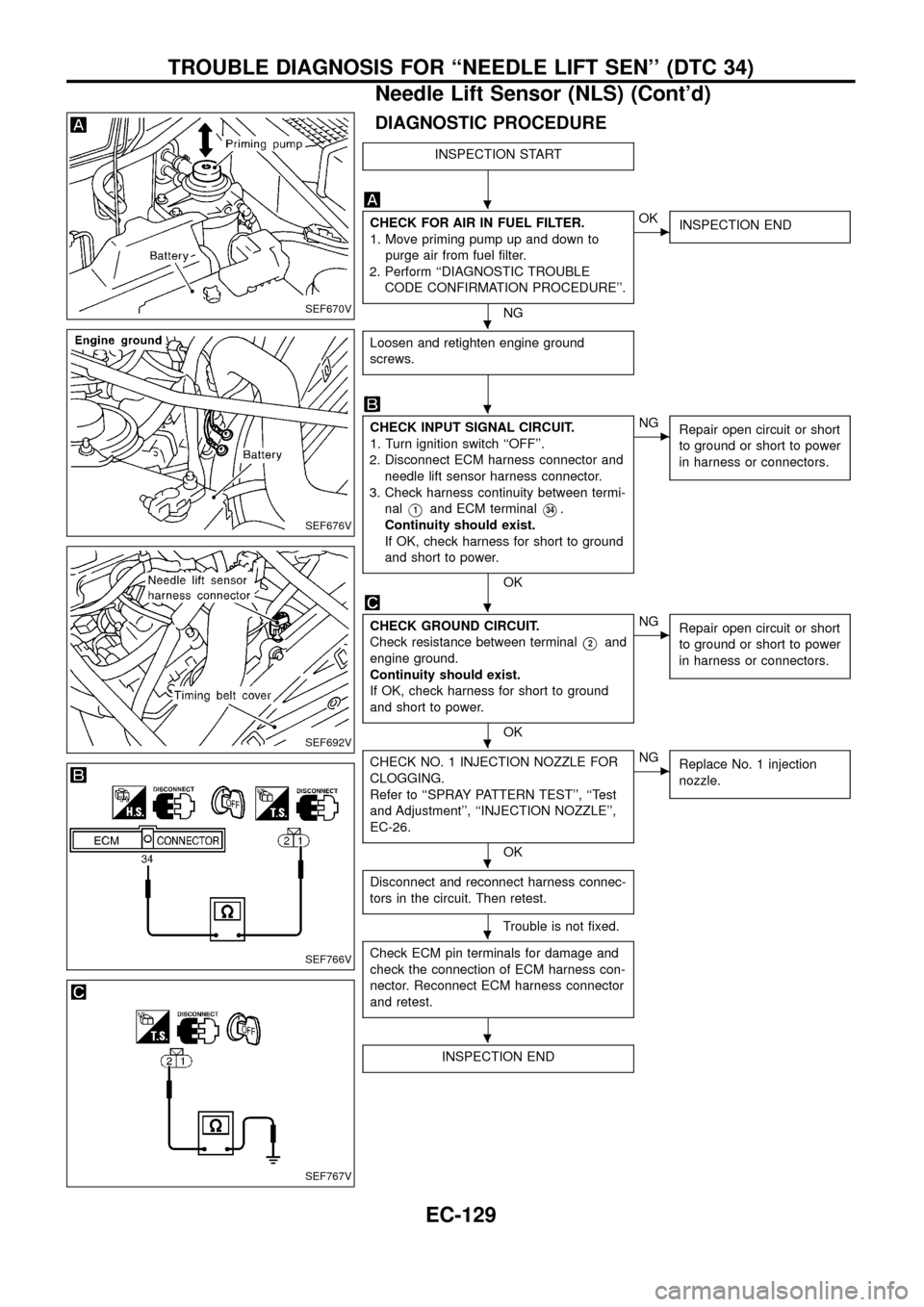

DIAGNOSTIC PROCEDURE

INSPECTION START

CHECK FOR AIR IN FUEL FILTER.

1. Move priming pump up and down to

purge air from fuel ®lter.

2. Perform ``DIAGNOSTIC TROUBLE

CODE CONFIRMATION PROCEDURE''.

NG

cOK

INSPECTION END

Loosen and retighten engine ground

screws.

CHECK INPUT SIGNAL CIRCUIT.

1. Turn ignition switch ``OFF''.

2. Disconnect ECM harness connector and

needle lift sensor harness connector.

3. Check harness continuity between termi-

nal

V1and ECM terminalV34.

Continuity should exist.

If OK, check harness for short to ground

and short to power.

OK

cNG

Repair open circuit or short

to ground or short to power

in harness or connectors.

CHECK GROUND CIRCUIT.

Check resistance between terminal

V2and

engine ground.

Continuity should exist.

If OK, check harness for short to ground

and short to power.

OK

cNG

Repair open circuit or short

to ground or short to power

in harness or connectors.

CHECK NO. 1 INJECTION NOZZLE FOR

CLOGGING.

Refer to ``SPRAY PATTERN TEST'', ``Test

and Adjustment'', ``INJECTION NOZZLE'',

EC-26.

OK

cNG

Replace No. 1 injection

nozzle.

Disconnect and reconnect harness connec-

tors in the circuit. Then retest.

Trouble is not ®xed.

Check ECM pin terminals for damage and

check the connection of ECM harness con-

nector. Reconnect ECM harness connector

and retest.

INSPECTION END

SEF670V

SEF676V

SEF692V

SEF766V

SEF767V

.

.

.

.

.

.

.

.

TROUBLE DIAGNOSIS FOR ``NEEDLE LIFT SEN'' (DTC 34)

Needle Lift Sensor (NLS) (Cont'd)

EC-129

Page 132 of 192

Fuel Cut Solenoid Valve

When the ignition switch is OFF, the ECM turns the fuel cut sole-

noid valve OFF (under this condition, no current ¯ows through the

fuel cut solenoid valve), shutting off fuel supply.

When the engine is not operating due to trouble, the fuel cut sole-

noid valve may or may not be OFF even when the ignition switch

is ON.

CONSULT REFERENCE VALUE IN DATA MONITOR MODE

Remarks: Speci®cation data are reference values.

MONITOR ITEM CONDITION SPECIFICATION

DECELER F/CUT+Engine: After warming upIdle OFF

When accelerator pedal is released

quickly with engine speed at 3,000

rpm or more.ON

FUEL CUT S/V+Ignition switch: ON®OFF ON®OFF

ECM TERMINALS AND REFERENCE VALUE

Remarks: Speci®cation data are reference values and are measured between each terminal andV43(ECCS

ground) with a voltmeter.

TER-

MINAL

NO.WIRE

COLORITEM CONDITIONDATA

(DC Voltage and Pulse

Signal)

4 B/Y ECCS relay (Self-shutoff)Ignition switch ``ON''

Ignition switch ``OFF''

For a few seconds after turning ignition switch

``OFF''0 - 1.5V

Ignition switch ``OFF''

A few seconds passed after turning ignition

switch ``OFF''BATTERY VOLTAGE

(11 - 14V)

56

61W Power supply for ECM Ignition switch ``ON''

BATTERY VOLTAGE

(11 - 14V)

11 3

11 5R/W Fuel cut solenoid valveIgnition switch ``OFF''

Approximately 0V

Ignition switch ``ON''

BATTERY VOLTAGE

(11 - 14V)

11 6

11 7W Power supply for ECM Ignition switch ``ON''

BATTERY VOLTAGE

(11 - 14V)

SEF667S

TROUBLE DIAGNOSIS FOR ``FUEL CUT S/V 1'' (DTC 36),

``FCV SHORT'' (DTC 37), ``FUEL CUT S/V 2'' (DTC 38)

EC-130

Page 133 of 192

ON BOARD DIAGNOSIS LOGIC

Diagnostic

Trouble

Code No.Malfunction is detected when ...Check Items

(Possible Cause)

36, 37, 38+Fuel cut solenoid valve circuit is malfunctioning.+Main power supply circuit (ECM terminals

11 6,11 7)

and fuse

+Harness or connectors

(The solenoid valve circuit is open or shorted.)

+Fuel cut solenoid valve

+ECM

DIAGNOSTIC TROUBLE CODE CONFIRMATION

PROCEDURE

1) Turn ignition switch ``ON''.

2) Select ``DATA MONITOR'' mode with CONSULT.

3) Start engine.

4) Turn ignition switch ``OFF'', wait at least 5 seconds and

then turn ``ON''.

-------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------OR-------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

1) Start engine.

2) Turn ignition switch ``OFF'', wait at least 5 seconds and

then turn ``ON''.

3) Perform ``Diagnostic Test Mode II (Self-diagnostic

results)'' with ECM.

SEF748V

TROUBLE DIAGNOSIS FOR ``FUEL CUT S/V 1'' (DTC 36),

``FCV SHORT'' (DTC 37), ``FUEL CUT S/V 2'' (DTC 38)

Fuel Cut Solenoid Valve (Cont'd)

EC-131