NISSAN PICK-UP 1998 Repair Manual

Manufacturer: NISSAN, Model Year: 1998, Model line: PICK-UP, Model: NISSAN PICK-UP 1998Pages: 1659, PDF Size: 53.39 MB

Page 1001 of 1659

5. Wipe clean fuel filter mounting surface on fuel filter bracket

and smear a little fuel on rubber seal of fuel filter.

6. Screw fuel filter on until a slight resistance is felt, then tighten

an additional more than 2/3 of a turn.

7. Install fuel filter sensor to new fuel filter. (Type A)

8. Bleed air from fuel line.

Refer to Bleeding Fuel System in EC section.

9. Start engine and check for leaks.

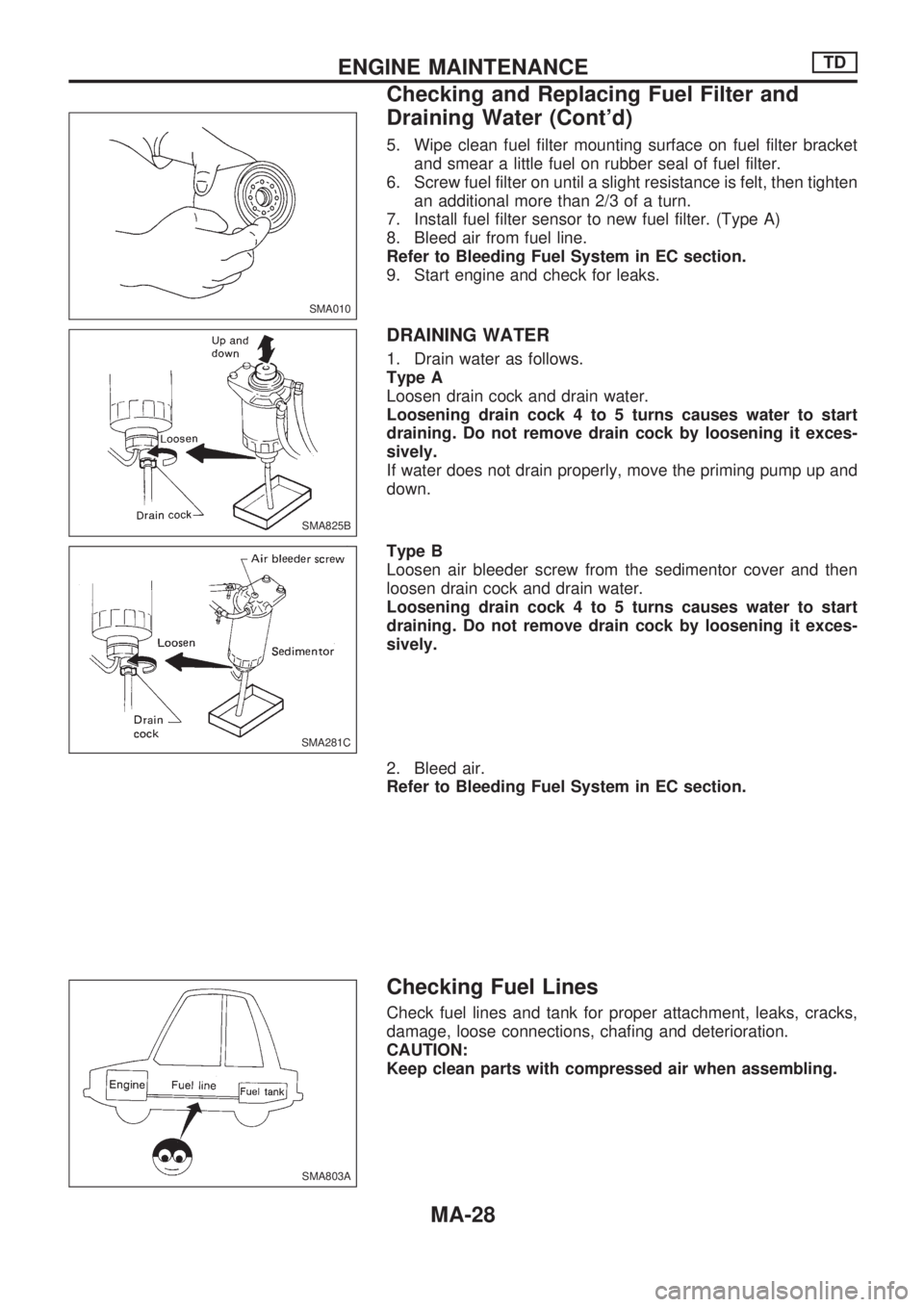

DRAINING WATER

1. Drain water as follows.

Type A

Loosen drain cock and drain water.

Loosening drain cock 4 to 5 turns causes water to start

draining. Do not remove drain cock by loosening it exces-

sively.

If water does not drain properly, move the priming pump up and

down.

Type B

Loosen air bleeder screw from the sedimentor cover and then

loosen drain cock and drain water.

Loosening drain cock 4 to 5 turns causes water to start

draining. Do not remove drain cock by loosening it exces-

sively.

2. Bleed air.

Refer to Bleeding Fuel System in EC section.

Checking Fuel Lines

Check fuel lines and tank for proper attachment, leaks, cracks,

damage, loose connections, chafing and deterioration.

CAUTION:

Keep clean parts with compressed air when assembling.

SMA010

SMA825B

SMA281C

SMA803A

ENGINE MAINTENANCETD

Checking and Replacing Fuel Filter and

Draining Water (Cont'd)

MA-28

Page 1002 of 1659

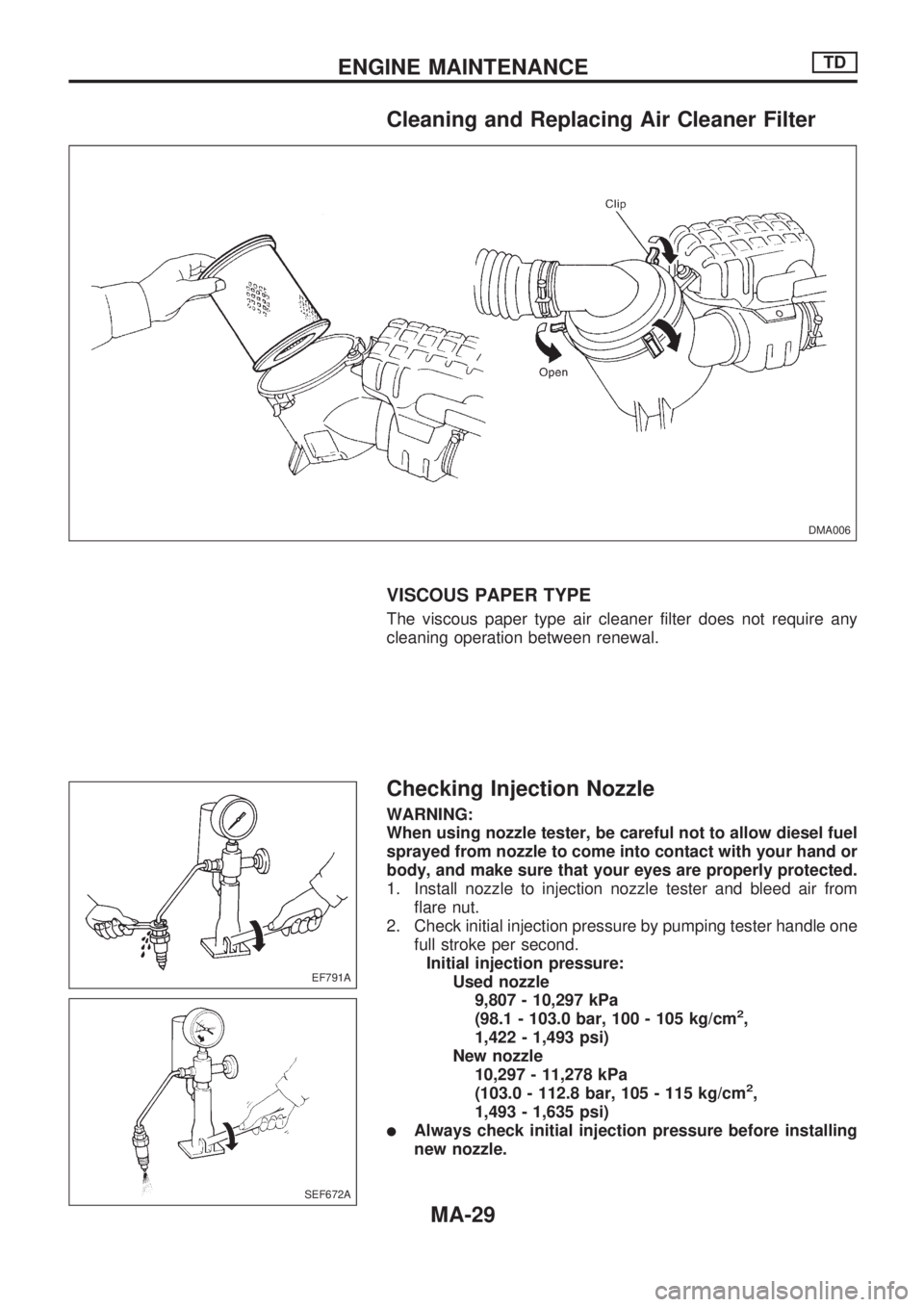

Cleaning and Replacing Air Cleaner Filter

VISCOUS PAPER TYPE

The viscous paper type air cleaner filter does not require any

cleaning operation between renewal.

Checking Injection Nozzle

WARNING:

When using nozzle tester, be careful not to allow diesel fuel

sprayed from nozzle to come into contact with your hand or

body, and make sure that your eyes are properly protected.

1. Install nozzle to injection nozzle tester and bleed air from

flare nut.

2. Check initial injection pressure by pumping tester handle one

full stroke per second.

Initial injection pressure:

Used nozzle

9,807 - 10,297 kPa

(98.1 - 103.0 bar, 100 - 105 kg/cm

2,

1,422 - 1,493 psi)

New nozzle

10,297 - 11,278 kPa

(103.0 - 112.8 bar, 105 - 115 kg/cm

2,

1,493 - 1,635 psi)

lAlways check initial injection pressure before installing

new nozzle.

DMA006

EF791A

SEF672A

ENGINE MAINTENANCETD

MA-29

Page 1003 of 1659

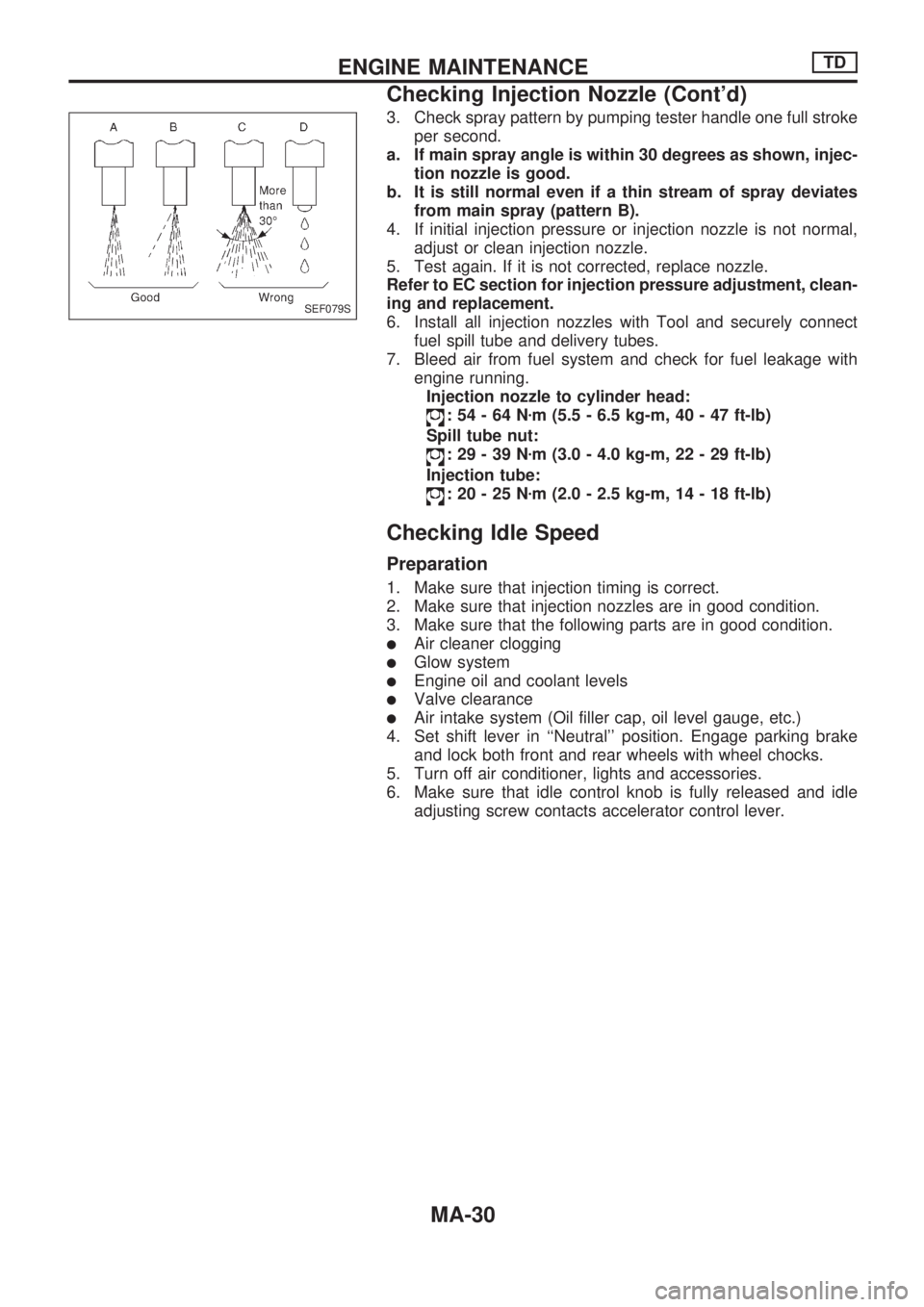

3. Check spray pattern by pumping tester handle one full stroke

per second.

a. If main spray angle is within 30 degrees as shown, injec-

tion nozzle is good.

b. It is still normal even if a thin stream of spray deviates

from main spray (pattern B).

4. If initial injection pressure or injection nozzle is not normal,

adjust or clean injection nozzle.

5. Test again. If it is not corrected, replace nozzle.

Refer to EC section for injection pressure adjustment, clean-

ing and replacement.

6. Install all injection nozzles with Tool and securely connect

fuel spill tube and delivery tubes.

7. Bleed air from fuel system and check for fuel leakage with

engine running.

Injection nozzle to cylinder head:

:54-64Nzm (5.5 - 6.5 kg-m, 40 - 47 ft-lb)

Spill tube nut:

:29-39Nzm (3.0 - 4.0 kg-m, 22 - 29 ft-lb)

Injection tube:

:20-25Nzm (2.0 - 2.5 kg-m, 14 - 18 ft-lb)

Checking Idle Speed

Preparation

1. Make sure that injection timing is correct.

2. Make sure that injection nozzles are in good condition.

3. Make sure that the following parts are in good condition.

lAir cleaner clogging

lGlow system

lEngine oil and coolant levels

lValve clearance

lAir intake system (Oil filler cap, oil level gauge, etc.)

4. Set shift lever in ``Neutral'' position. Engage parking brake

and lock both front and rear wheels with wheel chocks.

5. Turn off air conditioner, lights and accessories.

6. Make sure that idle control knob is fully released and idle

adjusting screw contacts accelerator control lever.

SEF079S

ENGINE MAINTENANCETD

Checking Injection Nozzle (Cont'd)

MA-30

Page 1004 of 1659

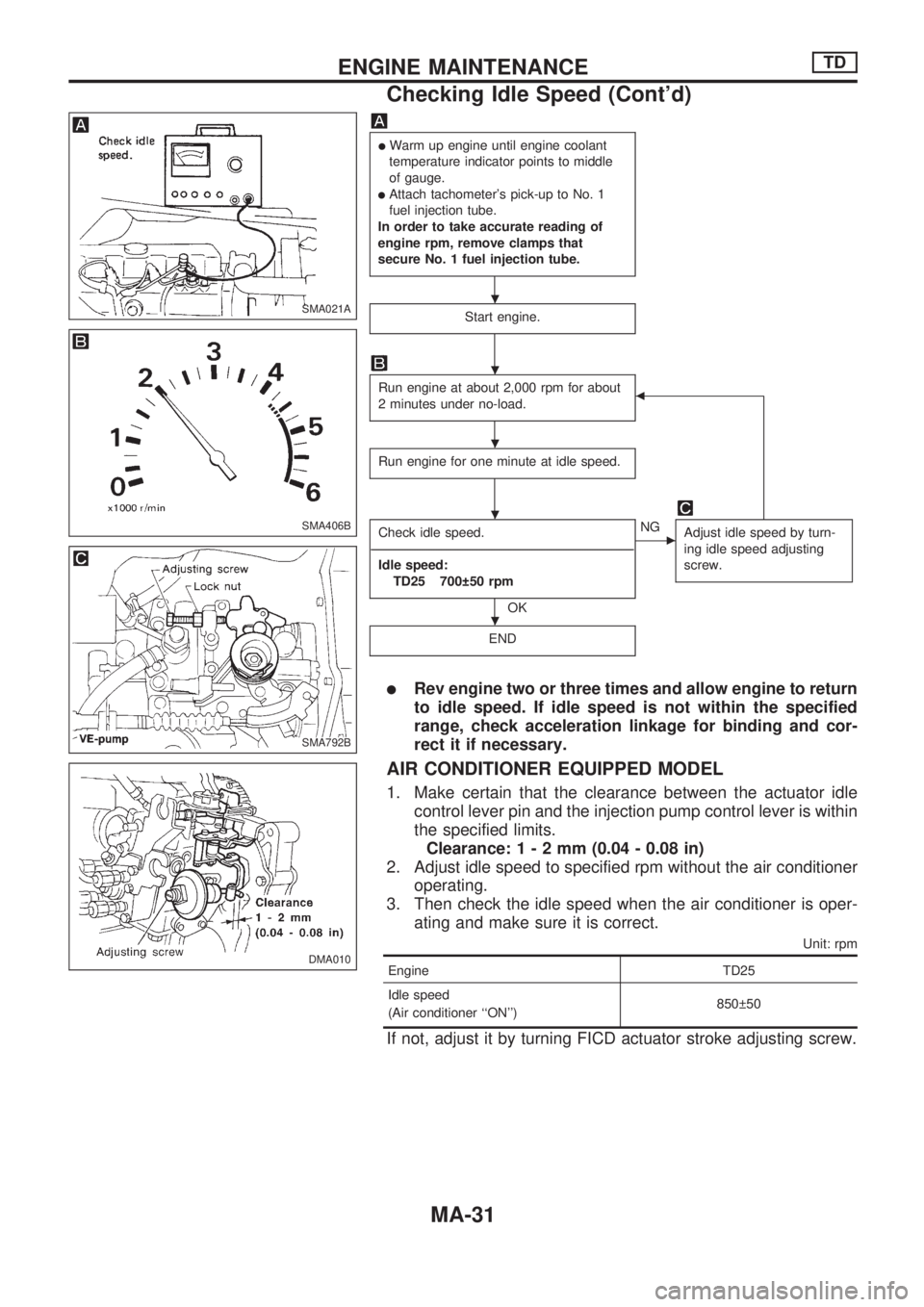

lWarm up engine until engine coolant

temperature indicator points to middle

of gauge.

lAttach tachometer's pick-up to No. 1

fuel injection tube.

In order to take accurate reading of

engine rpm, remove clamps that

secure No. 1 fuel injection tube.

Start engine.

Run engine at about 2,000 rpm for about

2 minutes under no-load.b

Run engine for one minute at idle speed.

Check idle speed.

--------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

Idle speed:

TD25 700 50 rpm

OK

cNG

Adjust idle speed by turn-

ing idle speed adjusting

screw.

END

lRev engine two or three times and allow engine to return

to idle speed. If idle speed is not within the specified

range, check acceleration linkage for binding and cor-

rect it if necessary.

AIR CONDITIONER EQUIPPED MODEL

1. Make certain that the clearance between the actuator idle

control lever pin and the injection pump control lever is within

the specified limits.

Clearance:1-2mm(0.04 - 0.08 in)

2. Adjust idle speed to specified rpm without the air conditioner

operating.

3. Then check the idle speed when the air conditioner is oper-

ating and make sure it is correct.

Unit: rpm

Engine TD25

Idle speed

(Air conditioner ``ON'')850 50

If not, adjust it by turning FICD actuator stroke adjusting screw.

SMA021A

SMA406B

SMA792B

DMA010

.

.

.

.

.

ENGINE MAINTENANCETD

Checking Idle Speed (Cont'd)

MA-31

Page 1005 of 1659

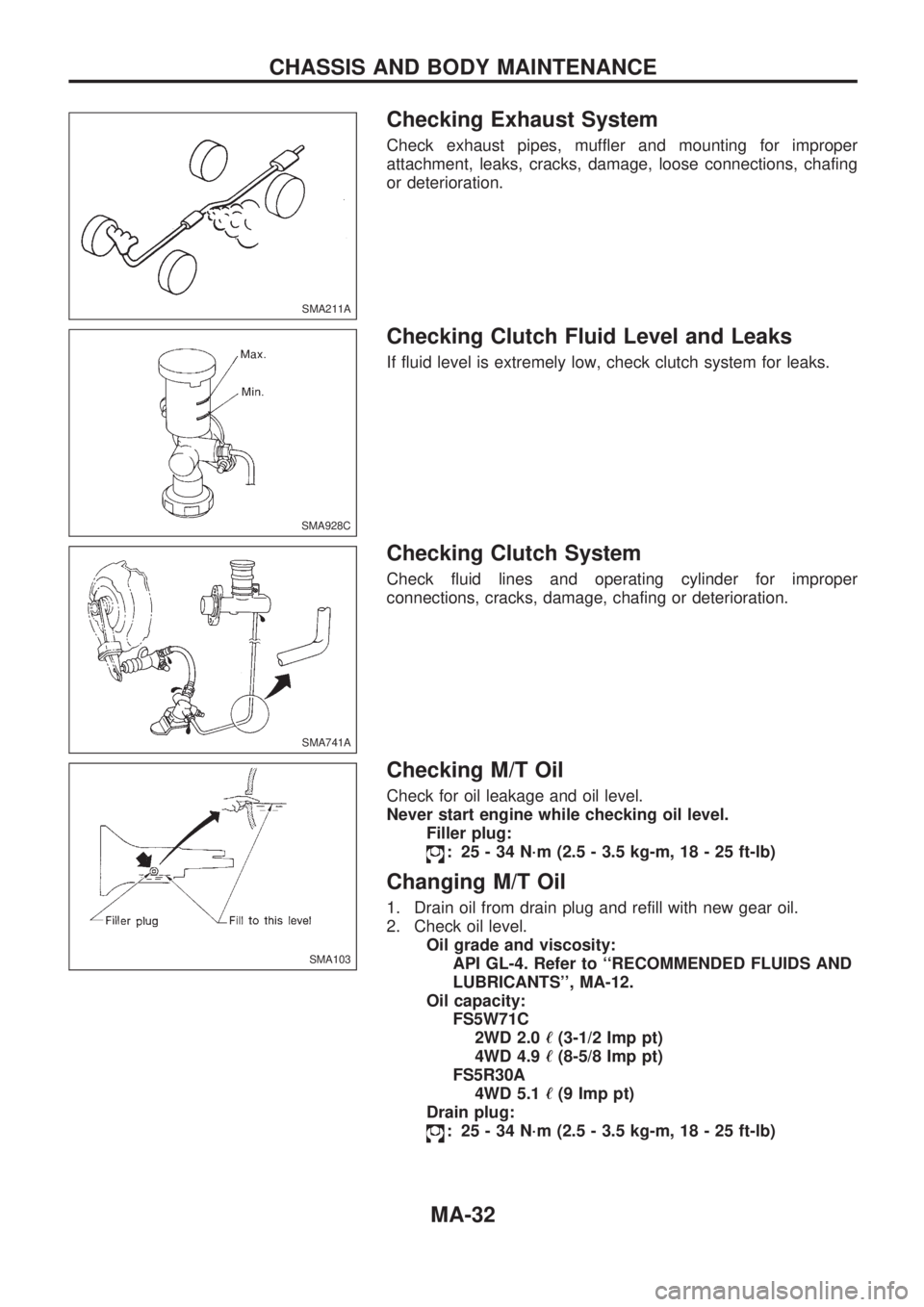

Checking Exhaust System

Check exhaust pipes, muffler and mounting for improper

attachment, leaks, cracks, damage, loose connections, chafing

or deterioration.

Checking Clutch Fluid Level and Leaks

If fluid level is extremely low, check clutch system for leaks.

Checking Clutch System

Check fluid lines and operating cylinder for improper

connections, cracks, damage, chafing or deterioration.

Checking M/T Oil

Check for oil leakage and oil level.

Never start engine while checking oil level.

Filler plug:

: 25 - 34 N´m (2.5 - 3.5 kg-m, 18 - 25 ft-lb)

Changing M/T Oil

1. Drain oil from drain plug and refill with new gear oil.

2. Check oil level.

Oil grade and viscosity:

API GL-4. Refer to ``RECOMMENDED FLUIDS AND

LUBRICANTS'', MA-12.

Oil capacity:

FS5W71C

2WD 2.0ø(3-1/2 Imp pt)

4WD 4.9ø(8-5/8 Imp pt)

FS5R30A

4WD 5.1ø(9 Imp pt)

Drain plug:

: 25 - 34 N´m (2.5 - 3.5 kg-m, 18 - 25 ft-lb)

SMA211A

SMA928C

SMA741A

SMA103

CHASSIS AND BODY MAINTENANCE

MA-32

Page 1006 of 1659

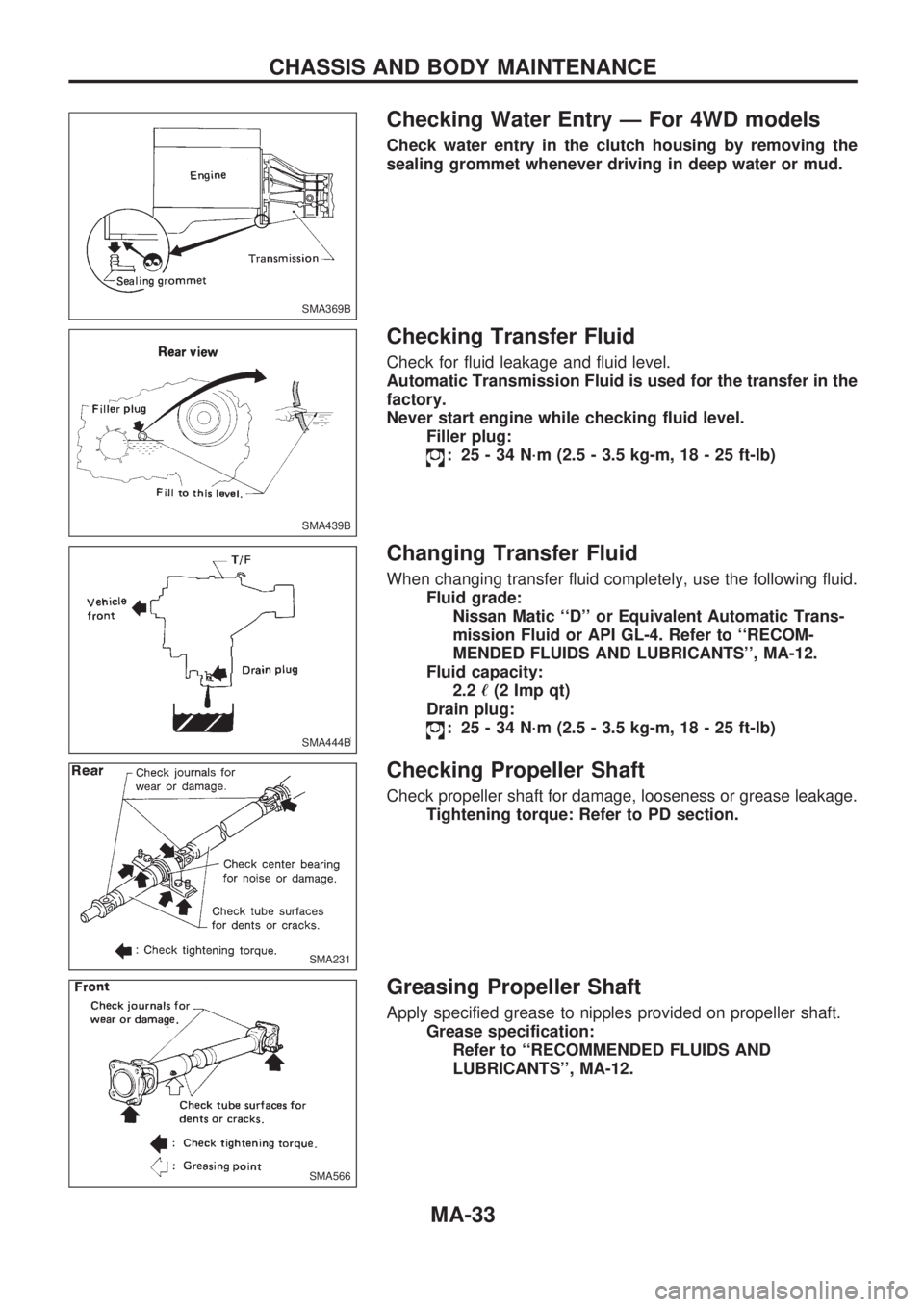

Checking Water Entry Ð For 4WD models

Check water entry in the clutch housing by removing the

sealing grommet whenever driving in deep water or mud.

Checking Transfer Fluid

Check for fluid leakage and fluid level.

Automatic Transmission Fluid is used for the transfer in the

factory.

Never start engine while checking fluid level.

Filler plug:

: 25 - 34 N´m (2.5 - 3.5 kg-m, 18 - 25 ft-lb)

Changing Transfer Fluid

When changing transfer fluid completely, use the following fluid.

Fluid grade:

Nissan Matic ``D'' or Equivalent Automatic Trans-

mission Fluid or API GL-4. Refer to ``RECOM-

MENDED FLUIDS AND LUBRICANTS'', MA-12.

Fluid capacity:

2.2ø(2 Imp qt)

Drain plug:

: 25 - 34 N´m (2.5 - 3.5 kg-m, 18 - 25 ft-lb)

Checking Propeller Shaft

Check propeller shaft for damage, looseness or grease leakage.

Tightening torque: Refer to PD section.

Greasing Propeller Shaft

Apply specified grease to nipples provided on propeller shaft.

Grease specification:

Refer to ``RECOMMENDED FLUIDS AND

LUBRICANTS'', MA-12.

SMA369B

SMA439B

SMA444B

SMA231

SMA566

CHASSIS AND BODY MAINTENANCE

MA-33

Page 1007 of 1659

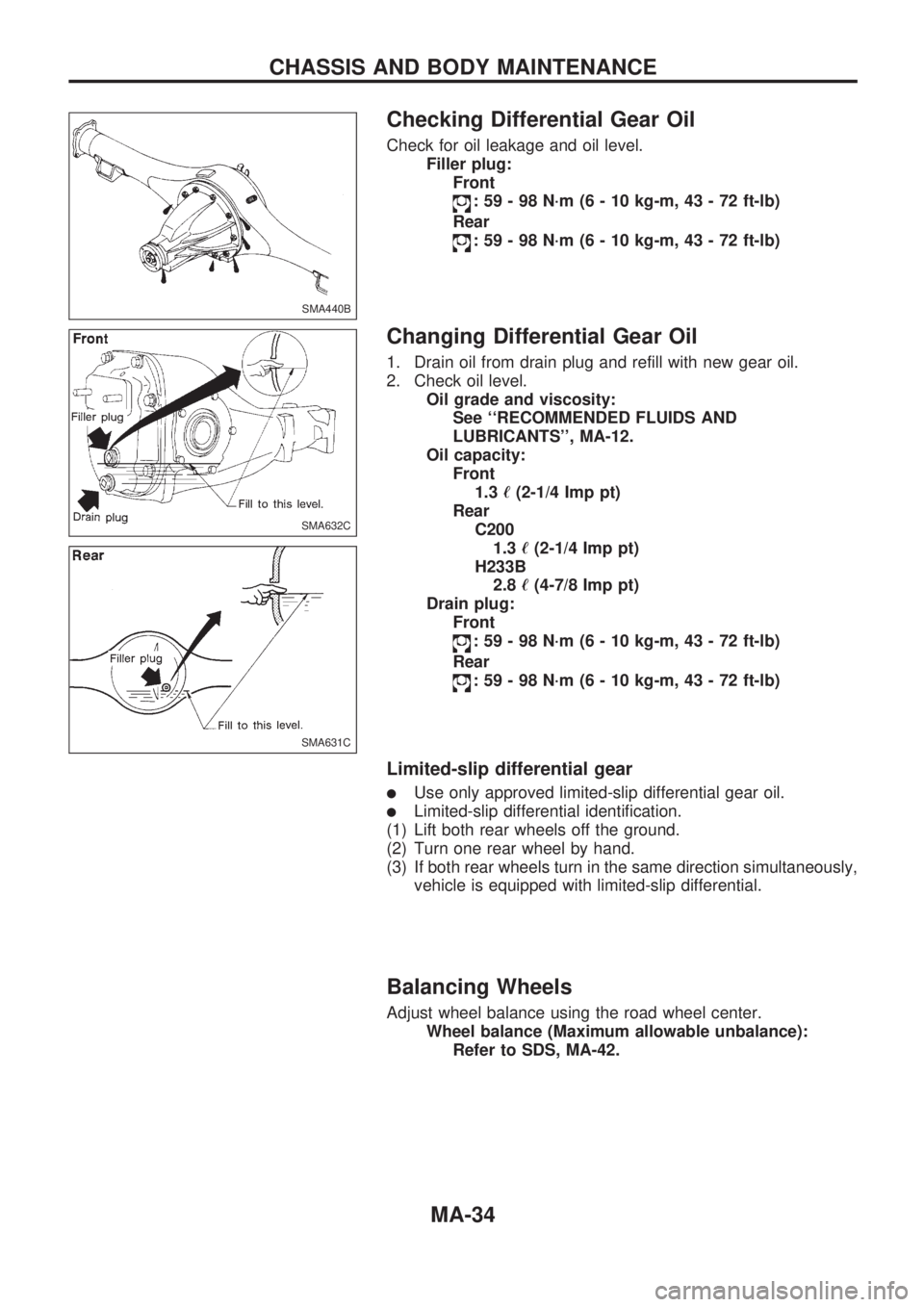

Checking Differential Gear Oil

Check for oil leakage and oil level.

Filler plug:

Front

: 59 - 98 N´m (6 - 10 kg-m, 43 - 72 ft-lb)

Rear

: 59 - 98 N´m (6 - 10 kg-m, 43 - 72 ft-lb)

Changing Differential Gear Oil

1. Drain oil from drain plug and refill with new gear oil.

2. Check oil level.

Oil grade and viscosity:

See ``RECOMMENDED FLUIDS AND

LUBRICANTS'', MA-12.

Oil capacity:

Front

1.3ø(2-1/4 Imp pt)

Rear

C200

1.3ø(2-1/4 Imp pt)

H233B

2.8ø(4-7/8 Imp pt)

Drain plug:

Front

: 59 - 98 N´m (6 - 10 kg-m, 43 - 72 ft-lb)

Rear

: 59 - 98 N´m (6 - 10 kg-m, 43 - 72 ft-lb)

Limited-slip differential gear

lUse only approved limited-slip differential gear oil.

lLimited-slip differential identification.

(1) Lift both rear wheels off the ground.

(2) Turn one rear wheel by hand.

(3) If both rear wheels turn in the same direction simultaneously,

vehicle is equipped with limited-slip differential.

Balancing Wheels

Adjust wheel balance using the road wheel center.

Wheel balance (Maximum allowable unbalance):

Refer to SDS, MA-42.

SMA440B

SMA632C

SMA631C

CHASSIS AND BODY MAINTENANCE

MA-34

Page 1008 of 1659

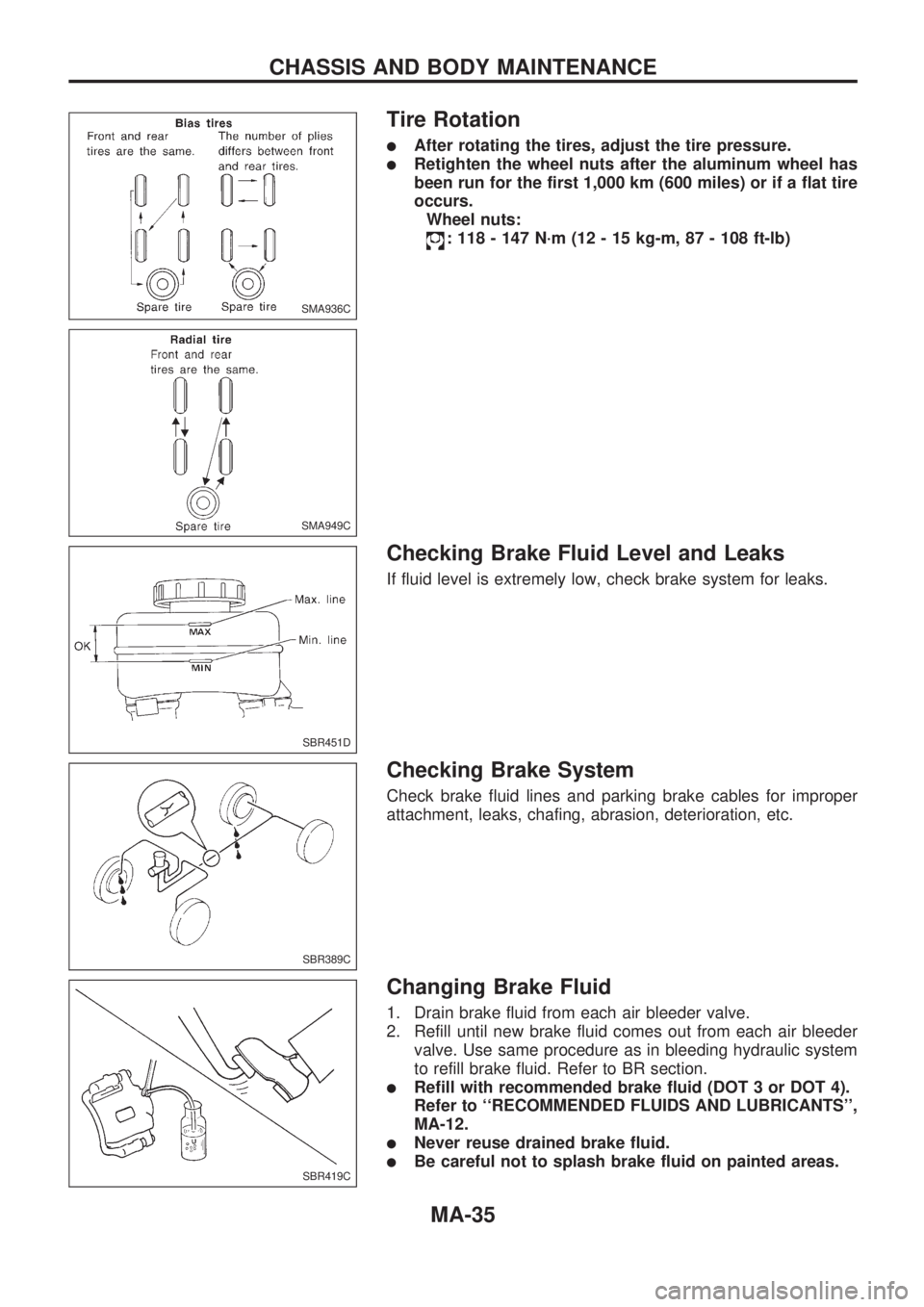

Tire Rotation

lAfter rotating the tires, adjust the tire pressure.

lRetighten the wheel nuts after the aluminum wheel has

been run for the first 1,000 km (600 miles) or if a flat tire

occurs.

Wheel nuts:

: 118 - 147 N´m (12 - 15 kg-m, 87 - 108 ft-lb)

Checking Brake Fluid Level and Leaks

If fluid level is extremely low, check brake system for leaks.

Checking Brake System

Check brake fluid lines and parking brake cables for improper

attachment, leaks, chafing, abrasion, deterioration, etc.

Changing Brake Fluid

1. Drain brake fluid from each air bleeder valve.

2. Refill until new brake fluid comes out from each air bleeder

valve. Use same procedure as in bleeding hydraulic system

to refill brake fluid. Refer to BR section.

lRefill with recommended brake fluid (DOT 3 or DOT 4).

Refer to ``RECOMMENDED FLUIDS AND LUBRICANTS'',

MA-12.

lNever reuse drained brake fluid.

lBe careful not to splash brake fluid on painted areas.

SMA936C

SMA949C

SBR451D

SBR389C

SBR419C

CHASSIS AND BODY MAINTENANCE

MA-35

Page 1009 of 1659

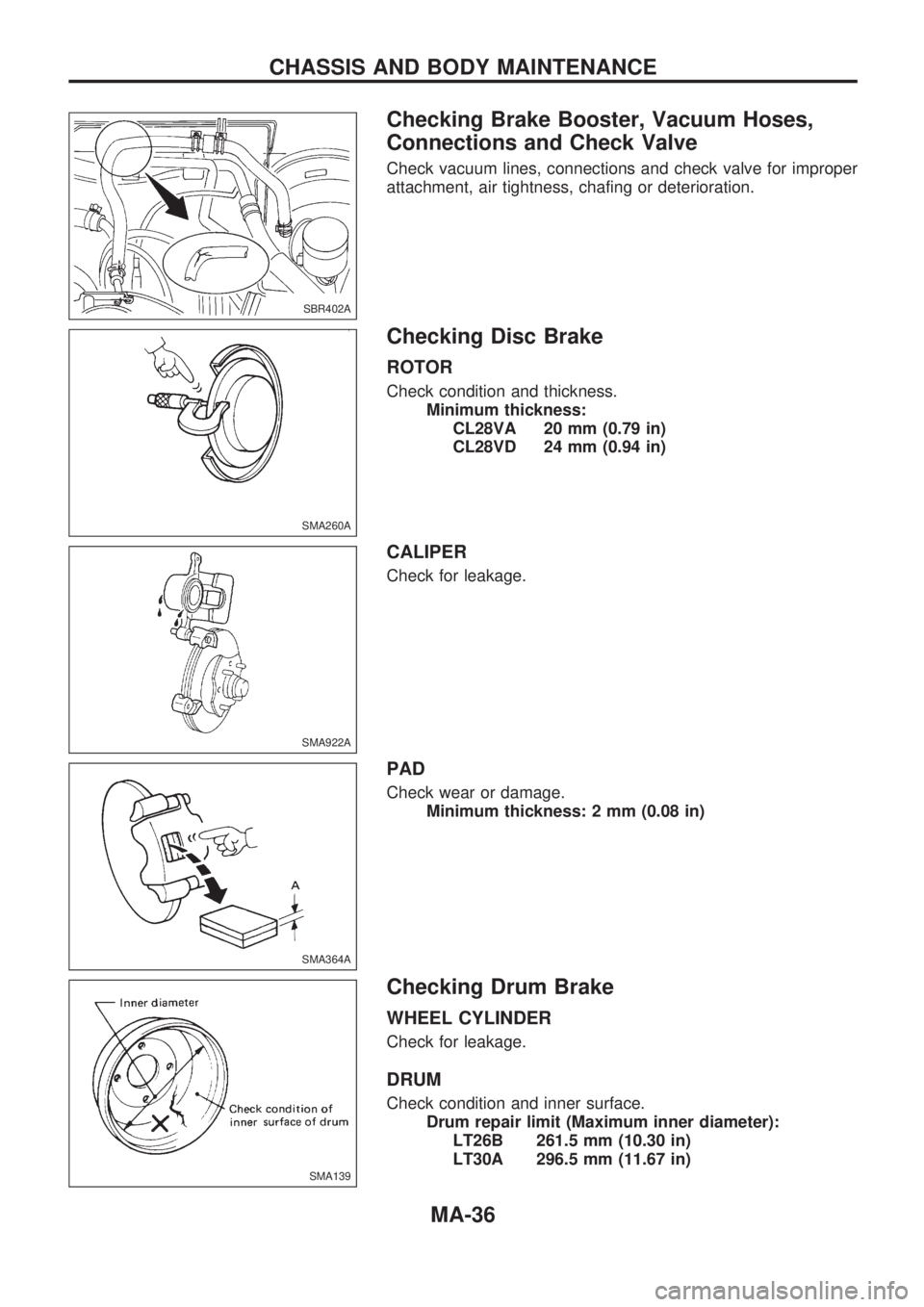

Checking Brake Booster, Vacuum Hoses,

Connections and Check Valve

Check vacuum lines, connections and check valve for improper

attachment, air tightness, chafing or deterioration.

Checking Disc Brake

ROTOR

Check condition and thickness.

Minimum thickness:

CL28VA 20 mm (0.79 in)

CL28VD 24 mm (0.94 in)

CALIPER

Check for leakage.

PAD

Check wear or damage.

Minimum thickness: 2 mm (0.08 in)

Checking Drum Brake

WHEEL CYLINDER

Check for leakage.

DRUM

Check condition and inner surface.

Drum repair limit (Maximum inner diameter):

LT26B 261.5 mm (10.30 in)

LT30A 296.5 mm (11.67 in)

SBR402A

SMA260A

SMA922A

SMA364A

SMA139

CHASSIS AND BODY MAINTENANCE

MA-36

Page 1010 of 1659

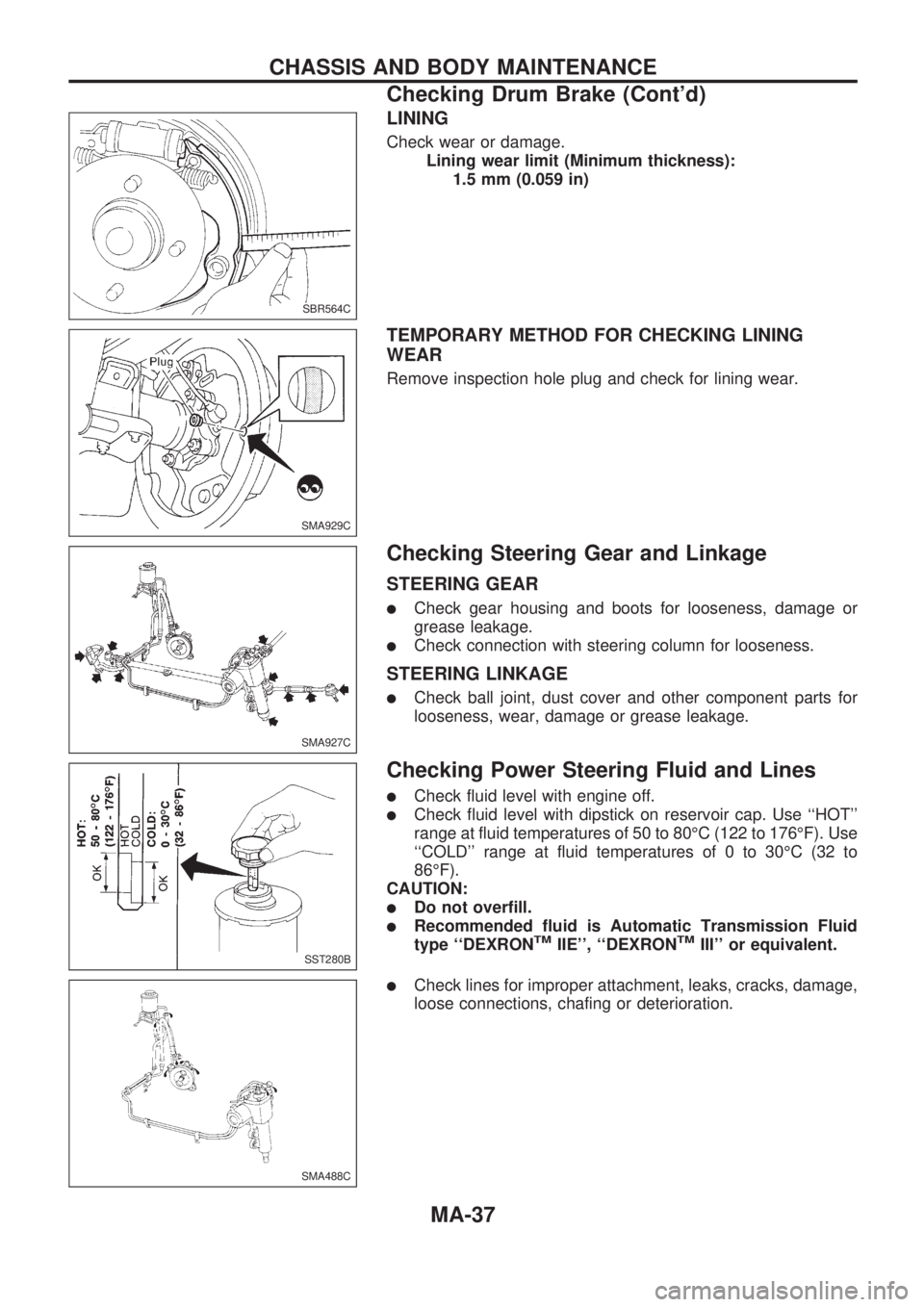

LINING

Check wear or damage.

Lining wear limit (Minimum thickness):

1.5 mm (0.059 in)

TEMPORARY METHOD FOR CHECKING LINING

WEAR

Remove inspection hole plug and check for lining wear.

Checking Steering Gear and Linkage

STEERING GEAR

lCheck gear housing and boots for looseness, damage or

grease leakage.

lCheck connection with steering column for looseness.

STEERING LINKAGE

lCheck ball joint, dust cover and other component parts for

looseness, wear, damage or grease leakage.

Checking Power Steering Fluid and Lines

lCheck fluid level with engine off.

lCheck fluid level with dipstick on reservoir cap. Use ``HOT''

range at fluid temperatures of 50 to 80ÉC (122 to 176ÉF). Use

``COLD'' range at fluid temperatures of 0 to 30ÉC (32 to

86ÉF).

CAUTION:

lDo not overfill.

lRecommended fluid is Automatic Transmission Fluid

type ``DEXRONTMIIE'', ``DEXRONTMIII'' or equivalent.

lCheck lines for improper attachment, leaks, cracks, damage,

loose connections, chafing or deterioration.

SBR564C

SMA929C

SMA927C

SST280B

SMA488C

CHASSIS AND BODY MAINTENANCE

Checking Drum Brake (Cont'd)

MA-37