NISSAN PICK-UP 1998 Repair Manual

Manufacturer: NISSAN, Model Year: 1998, Model line: PICK-UP, Model: NISSAN PICK-UP 1998Pages: 1659, PDF Size: 53.39 MB

Page 1011 of 1659

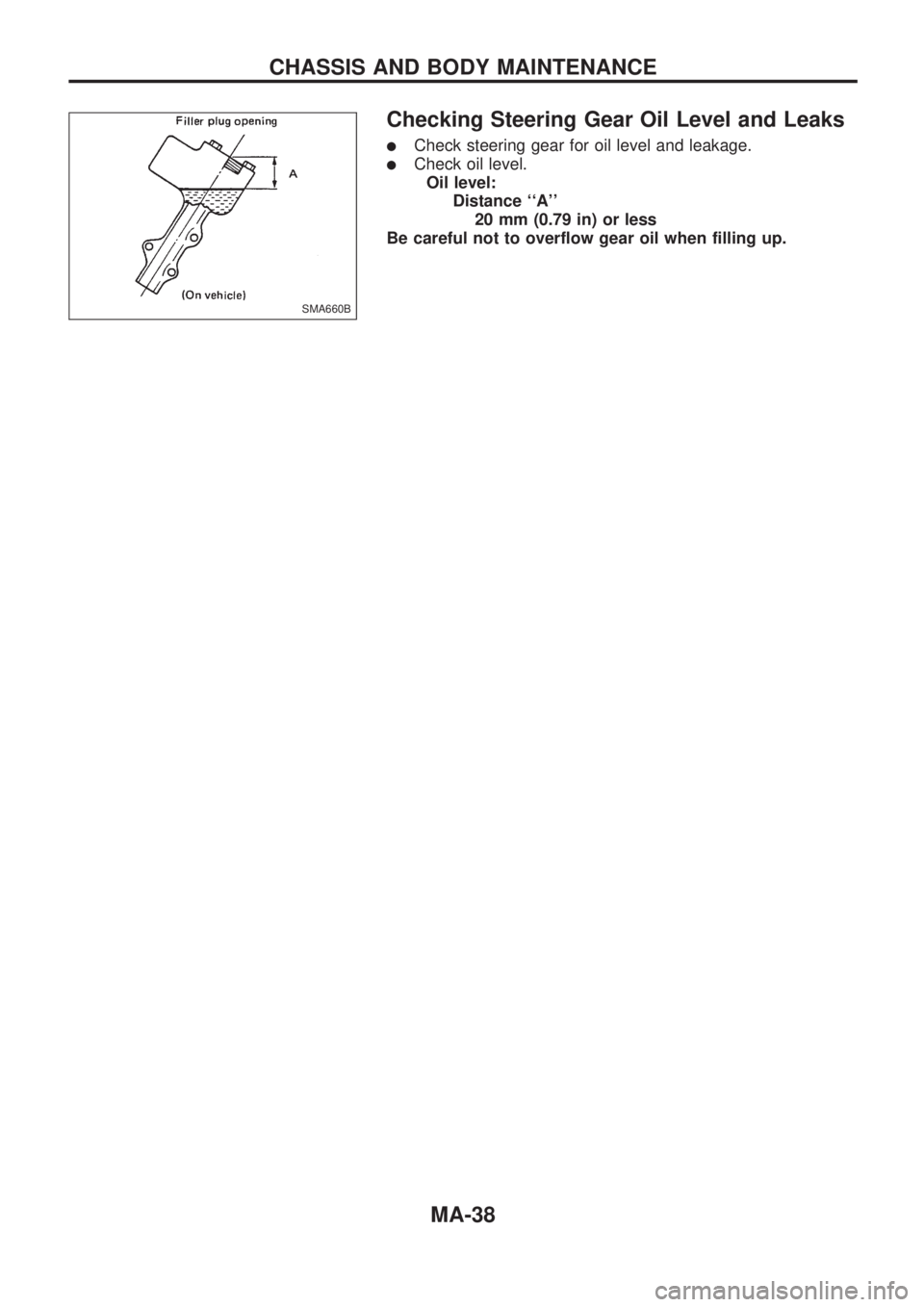

Checking Steering Gear Oil Level and Leaks

lCheck steering gear for oil level and leakage.

lCheck oil level.

Oil level:

Distance ``A''

20 mm (0.79 in) or less

Be careful not to overflow gear oil when filling up.

SMA660B

CHASSIS AND BODY MAINTENANCE

MA-38

Page 1012 of 1659

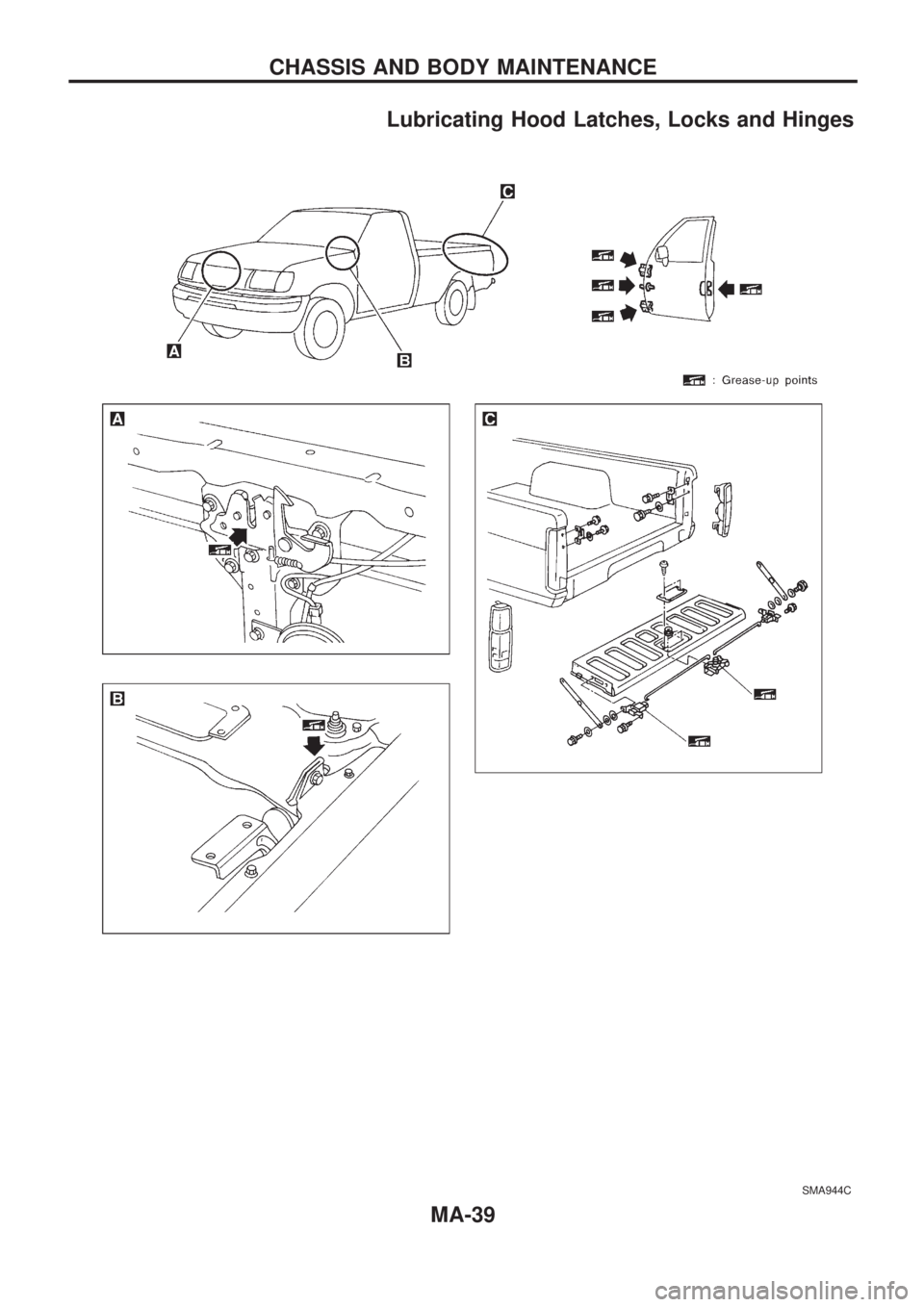

Lubricating Hood Latches, Locks and Hinges

SMA944C

CHASSIS AND BODY MAINTENANCE

MA-39

Page 1013 of 1659

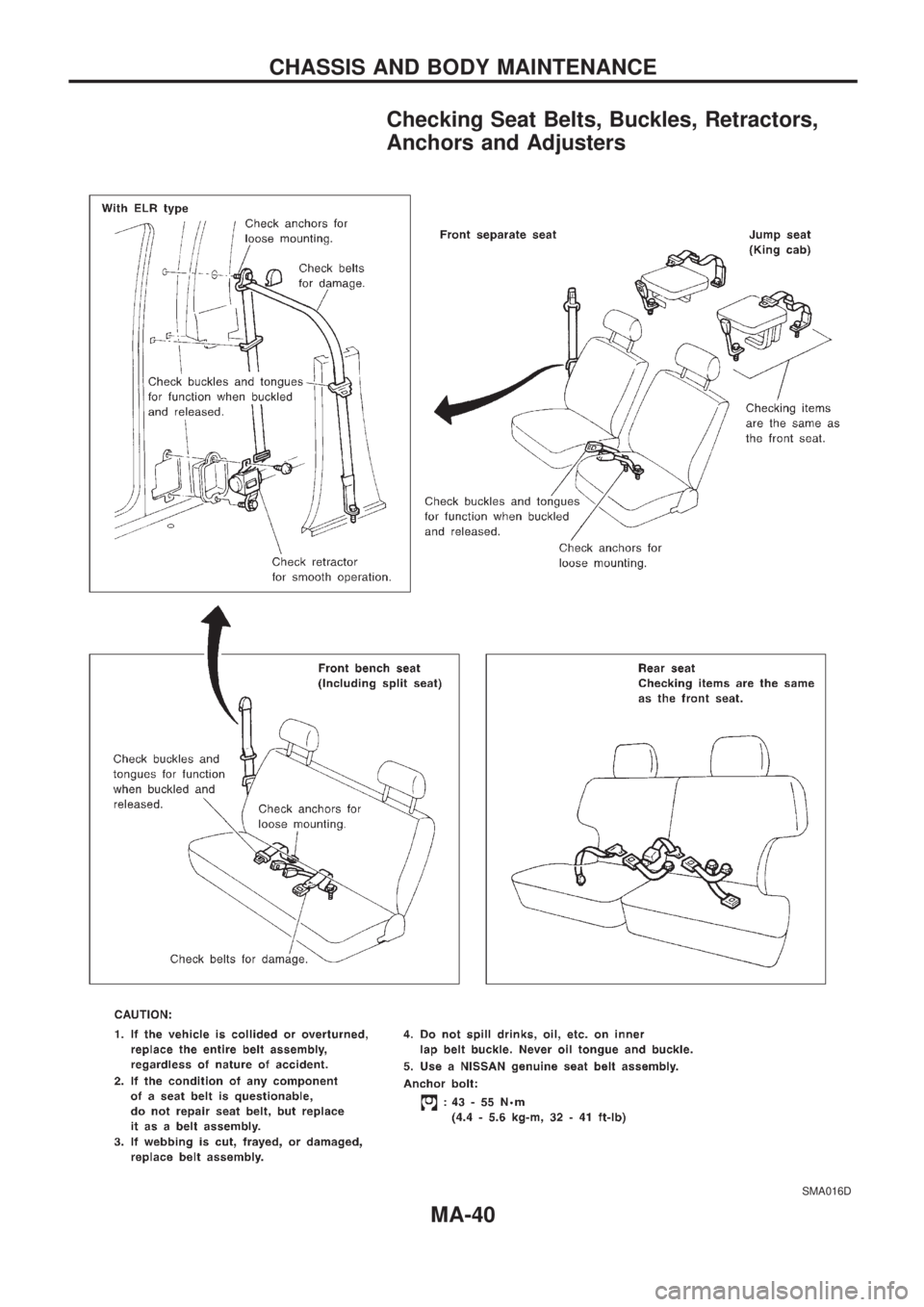

Checking Seat Belts, Buckles, Retractors,

Anchors and Adjusters

SMA016D

CHASSIS AND BODY MAINTENANCE

MA-40

Page 1014 of 1659

Checking Body Corrosion

Visually check the body sheet metal panel for corrosion, paint damage (scratches, chipping, rubbing, etc.)

or damage to the anti-corrosion materials. In particular, check the following locations.

Hemmed portion

Hood front end, door lower end, trunk lid rear end, etc.

Panel joint

Side sill of rear fender and center pillar, rear wheel housing of rear fender, around strut tower in engine

compartment, etc.

Panel edge

Trunk lid opening, sunroof opening, fender wheelarch flange, fuel filler lid flange, around holes in panel, etc.

Parts contact

Waist molding, windshield molding, bumper, etc.

Protectors

Damage or condition of mudguard, fender protector, chipping protector, etc.

Anti-corrosion materials

Damage or separation of anti-corrosion materials under the body.

Drain holes

Condition of drain holes at door and side sill.

When repairing corroded areas, refer to the Corrosion Repair Manual.

CHASSIS AND BODY MAINTENANCE

MA-41

Page 1015 of 1659

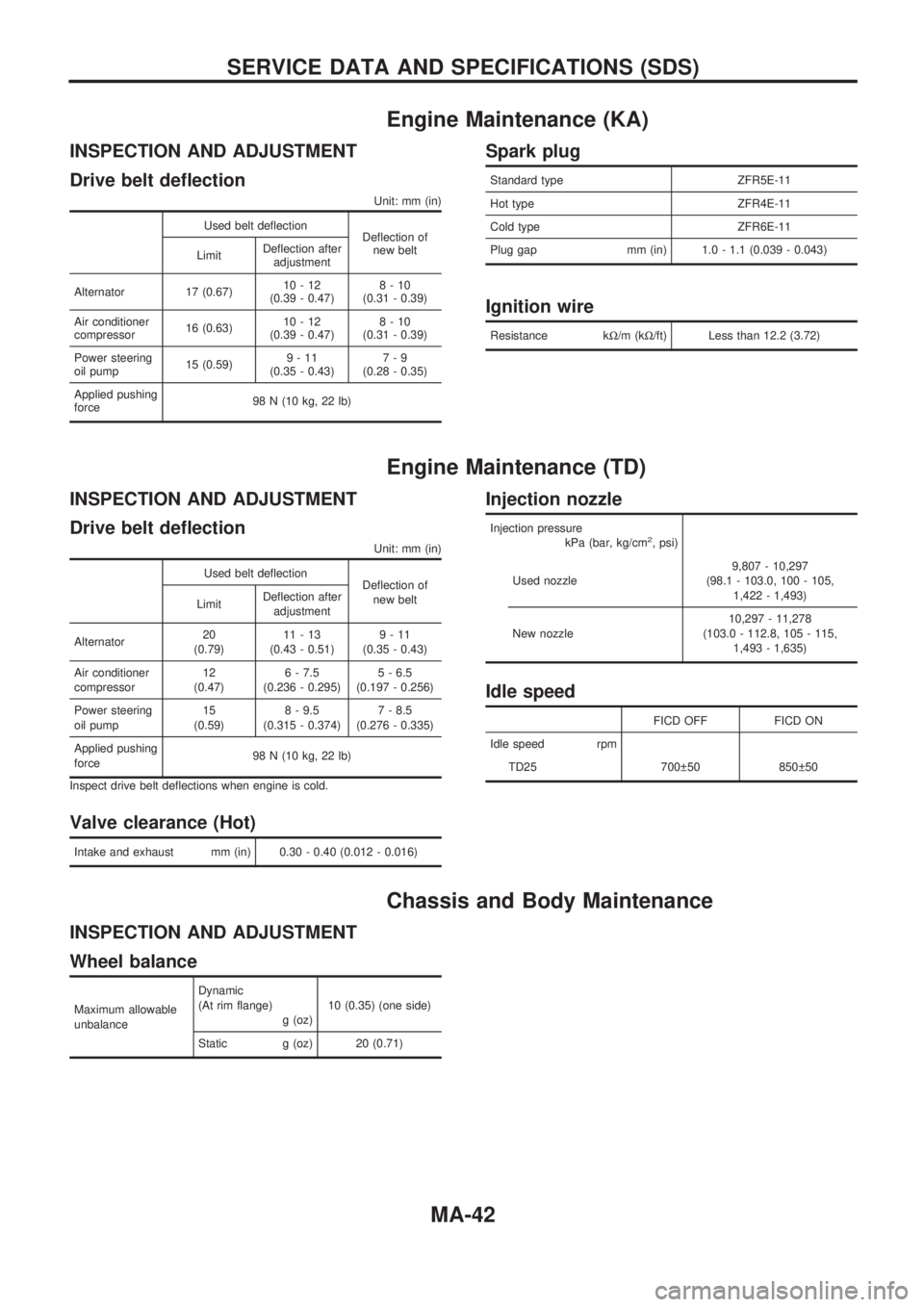

Engine Maintenance (KA)

INSPECTION AND ADJUSTMENT

Drive belt deflection

Unit: mm (in)

Used belt deflection

Deflection of

new belt

LimitDeflection after

adjustment

Alternator 17 (0.67)10-12

(0.39 - 0.47)8-10

(0.31 - 0.39)

Air conditioner

compressor16 (0.63)10-12

(0.39 - 0.47)8-10

(0.31 - 0.39)

Power steering

oil pump15 (0.59)9-11

(0.35 - 0.43)7-9

(0.28 - 0.35)

Applied pushing

force98 N (10 kg, 22 lb)

Spark plug

Standard type ZFR5E-11

Hot type ZFR4E-11

Cold type ZFR6E-11

Plug gap mm (in) 1.0 - 1.1 (0.039 - 0.043)

Ignition wire

Resistance kW/m (kW/ft) Less than 12.2 (3.72)

Engine Maintenance (TD)

INSPECTION AND ADJUSTMENT

Drive belt deflection

Unit: mm (in)

Used belt deflection

Deflection of

new belt

LimitDeflection after

adjustment

Alternator20

(0.79)11-13

(0.43 - 0.51)9-11

(0.35 - 0.43)

Air conditioner

compressor12

(0.47)6 - 7.5

(0.236 - 0.295)5 - 6.5

(0.197 - 0.256)

Power steering

oil pump15

(0.59)8 - 9.5

(0.315 - 0.374)7 - 8.5

(0.276 - 0.335)

Applied pushing

force98 N (10 kg, 22 lb)

Inspect drive belt deflections when engine is cold.

Valve clearance (Hot)

Intake and exhaust mm (in) 0.30 - 0.40 (0.012 - 0.016)

Injection nozzle

Injection pressure

kPa (bar, kg/cm2, psi)

Used nozzle9,807 - 10,297

(98.1 - 103.0, 100 - 105,

1,422 - 1,493)

New nozzle10,297 - 11,278

(103.0 - 112.8, 105 - 115,

1,493 - 1,635)

Idle speed

FICD OFF FICD ON

Idle speed rpm

TD25 700 50 850 50

Chassis and Body Maintenance

INSPECTION AND ADJUSTMENT

Wheel balance

Maximum allowable

unbalanceDynamic

(At rim flange)

g (oz)10 (0.35) (one side)

Static g (oz) 20 (0.71)

SERVICE DATA AND SPECIFICATIONS (SDS)

MA-42

Page 1016 of 1659

MANUALTRANSAXLESECTION

MT

CONTENTS

FS5W71C

PREPARATION ......................................................... 1

Special Service Tools ............................................ 1

Commercial Service Tools ..................................... 3

FS5R30A

PREPARATION......................................................... 4

Special Service Tools ............................................ 4

Commercial Service Tool....................................... 5

FS5W71C

DESCRIPTION........................................................... 6

Cross-sectional View - 2WD Model ....................... 6

Cross-sectional View - 4WD Model ....................... 7

FS5R30A

DESCRIPTION........................................................... 8

Cross-sectional View - 4WD Model ....................... 8

FS5W71C

ON-VEHICLE SERVICE ............................................ 9

Replacing Rear Oil Seal - 2WD Model.................. 9

Position Switch Check ........................................... 9

FS5R30A

ON-VEHICLE SERVICE .......................................... 10

Position Switch Check - 4WD Model................... 10

FS5W71C & FS5R30A

REMOVAL AND INSTALLATION ........................... 11

Removal ............................................................... 11 Installation ............................................................ 12

FS5W71C

MAJOR OVERHAUL ............................................... 14

Case Components ............................................... 14

Gear Components - 2WD Model ......................... 15

Gear Components - 4WD Model ......................... 16

Shift Control Components - 2WD Model ............. 17

Shift Control Components - 4WD Model ............. 18

DISASSEMBLY ........................................................ 19

Case Components ............................................... 19

Shift Control Components.................................... 20

Gear Components................................................ 20

INSPECTION ............................................................ 23

Shift Control Components.................................... 23

Gear Components................................................ 23

ASSEMBLY .............................................................. 25

Gear Components................................................ 25

Shift Control Components.................................... 31

Case Components ............................................... 32

FS5R30A

MAJOR OVERHAUL ............................................... 35

Case Components ............................................... 35

Gear Components................................................ 36

Shift Control Components.................................... 38

DISASSEMBLY ........................................................ 39

Case Components ............................................... 39

Shift Control Components.................................... 40

Gear Components................................................ 41

INSPECTION ............................................................ 45

Shift Control Components.................................... 45

Gear Components................................................ 45

MT

Page 1017 of 1659

ASSEMBLY.............................................................. 47

Gear Components................................................ 47

Shift Control Components.................................... 55

Case Components ............................................... 55

FS5W71C & FS5R30A

SERVICE DATA AND SPECIFICATIONS (SDS)... 58

General Specifications ......................................... 58FS5W71C

SERVICE DATA AND SPECIFICATIONS (SDS)... 59

Inspection and Adjustment .................................. 59

FS5R30A

SERVICE DATA AND SPECIFICATIONS (SDS)... 61

Inspection and Adjustment .................................. 61

Page 1018 of 1659

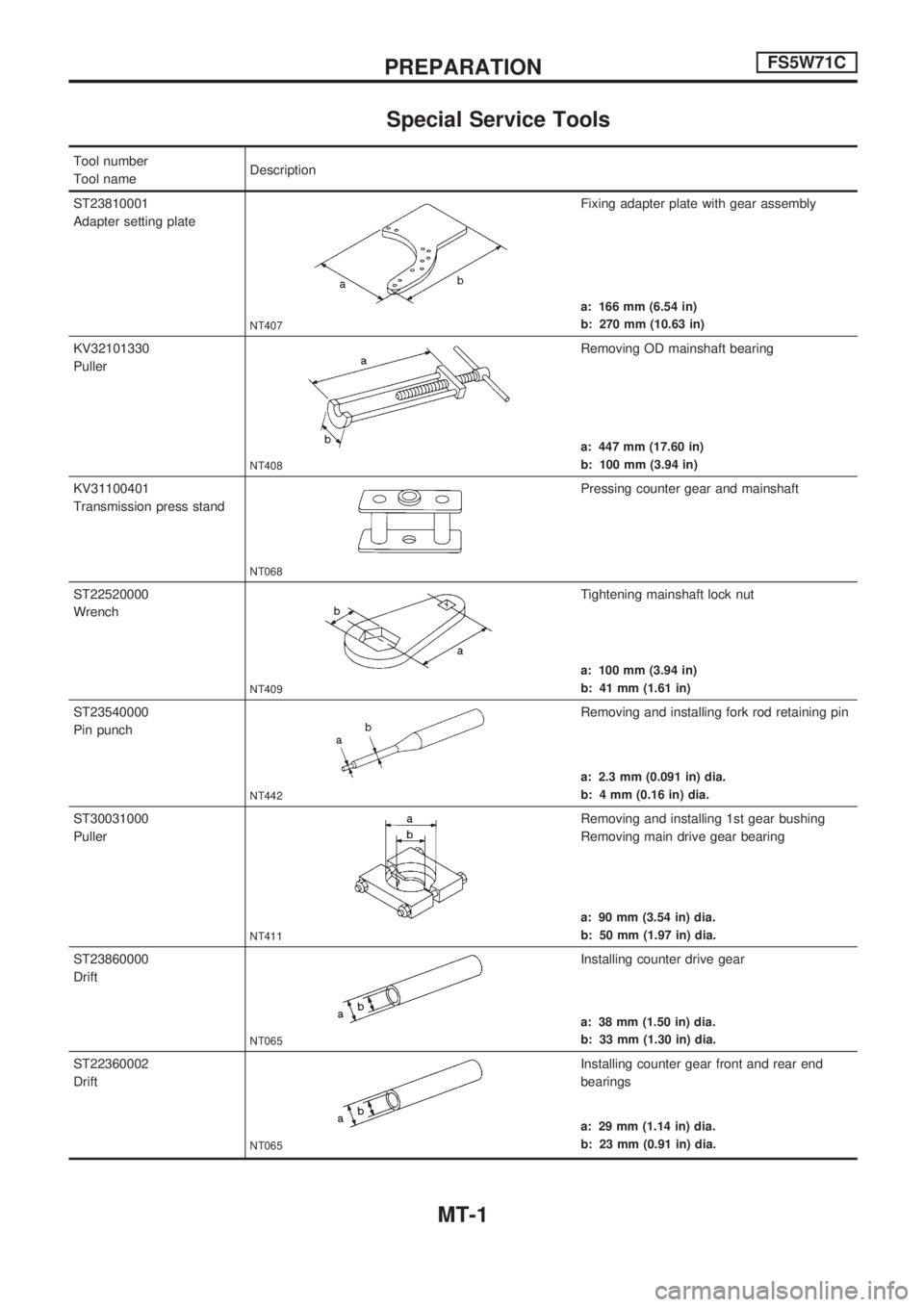

Special Service Tools

Tool number

Tool nameDescription

ST23810001

Adapter setting plate

NT407

Fixing adapter plate with gear assembly

a: 166 mm (6.54 in)

b: 270 mm (10.63 in)

KV32101330

Puller

NT408

Removing OD mainshaft bearing

a: 447 mm (17.60 in)

b: 100 mm (3.94 in)

KV31100401

Transmission press stand

NT068

Pressing counter gear and mainshaft

ST22520000

Wrench

NT409

Tightening mainshaft lock nut

a: 100 mm (3.94 in)

b: 41 mm (1.61 in)

ST23540000

Pin punch

NT442

Removing and installing fork rod retaining pin

a: 2.3 mm (0.091 in) dia.

b: 4 mm (0.16 in) dia.

ST30031000

Puller

NT411

Removing and installing 1st gear bushing

Removing main drive gear bearing

a: 90 mm (3.54 in) dia.

b: 50 mm (1.97 in) dia.

ST23860000

Drift

NT065

Installing counter drive gear

a: 38 mm (1.50 in) dia.

b: 33 mm (1.30 in) dia.

ST22360002

Drift

NT065

Installing counter gear front and rear end

bearings

a: 29 mm (1.14 in) dia.

b: 23 mm (0.91 in) dia.

PREPARATIONFS5W71C

MT-1

Page 1019 of 1659

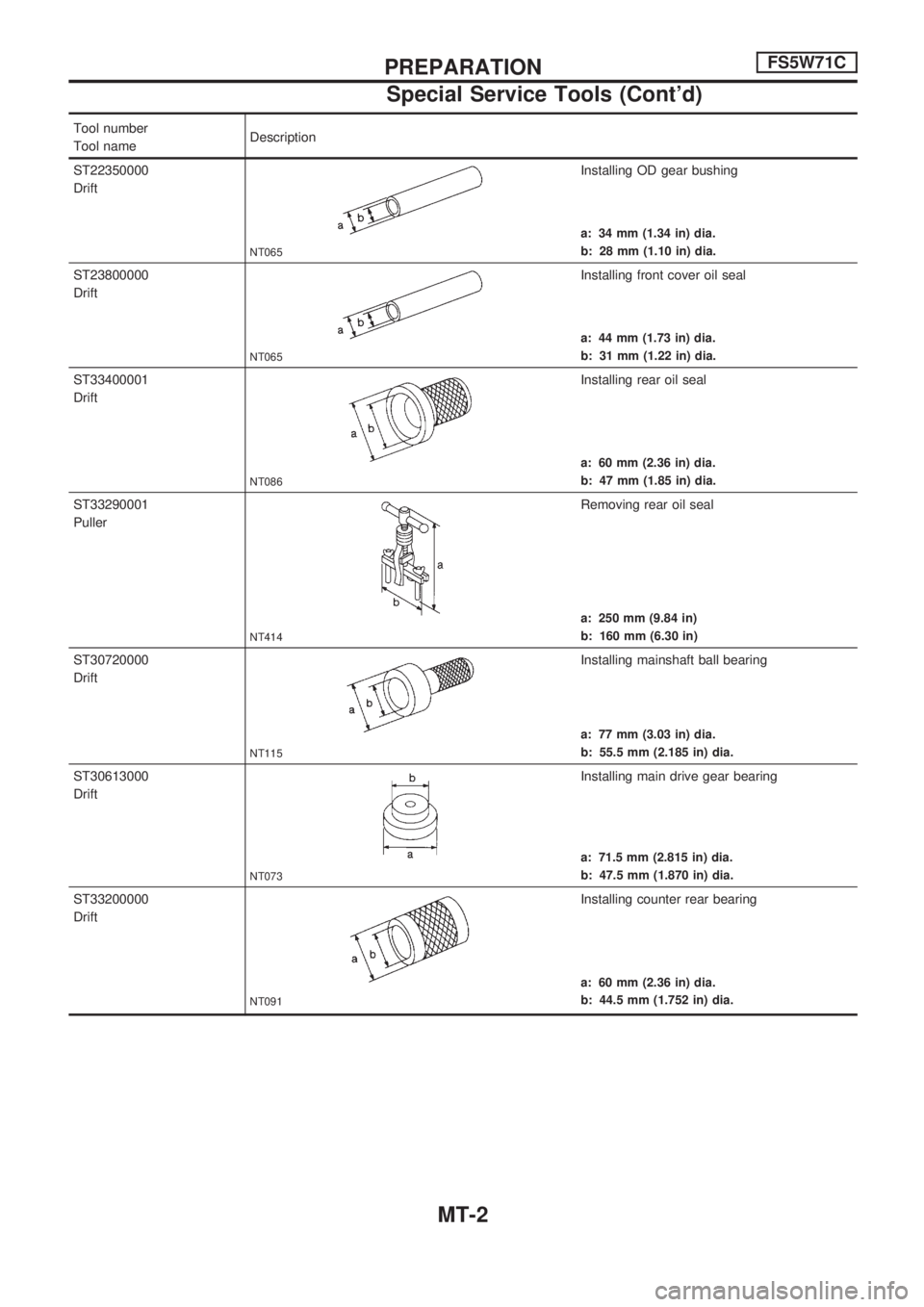

Tool number

Tool nameDescription

ST22350000

Drift

NT065

Installing OD gear bushing

a: 34 mm (1.34 in) dia.

b: 28 mm (1.10 in) dia.

ST23800000

Drift

NT065

Installing front cover oil seal

a: 44 mm (1.73 in) dia.

b: 31 mm (1.22 in) dia.

ST33400001

Drift

NT086

Installing rear oil seal

a: 60 mm (2.36 in) dia.

b: 47 mm (1.85 in) dia.

ST33290001

Puller

NT414

Removing rear oil seal

a: 250 mm (9.84 in)

b: 160 mm (6.30 in)

ST30720000

Drift

NT115

Installing mainshaft ball bearing

a: 77 mm (3.03 in) dia.

b: 55.5 mm (2.185 in) dia.

ST30613000

Drift

NT073

Installing main drive gear bearing

a: 71.5 mm (2.815 in) dia.

b: 47.5 mm (1.870 in) dia.

ST33200000

Drift

NT091

Installing counter rear bearing

a: 60 mm (2.36 in) dia.

b: 44.5 mm (1.752 in) dia.

PREPARATIONFS5W71C

Special Service Tools (Cont'd)

MT-2

Page 1020 of 1659

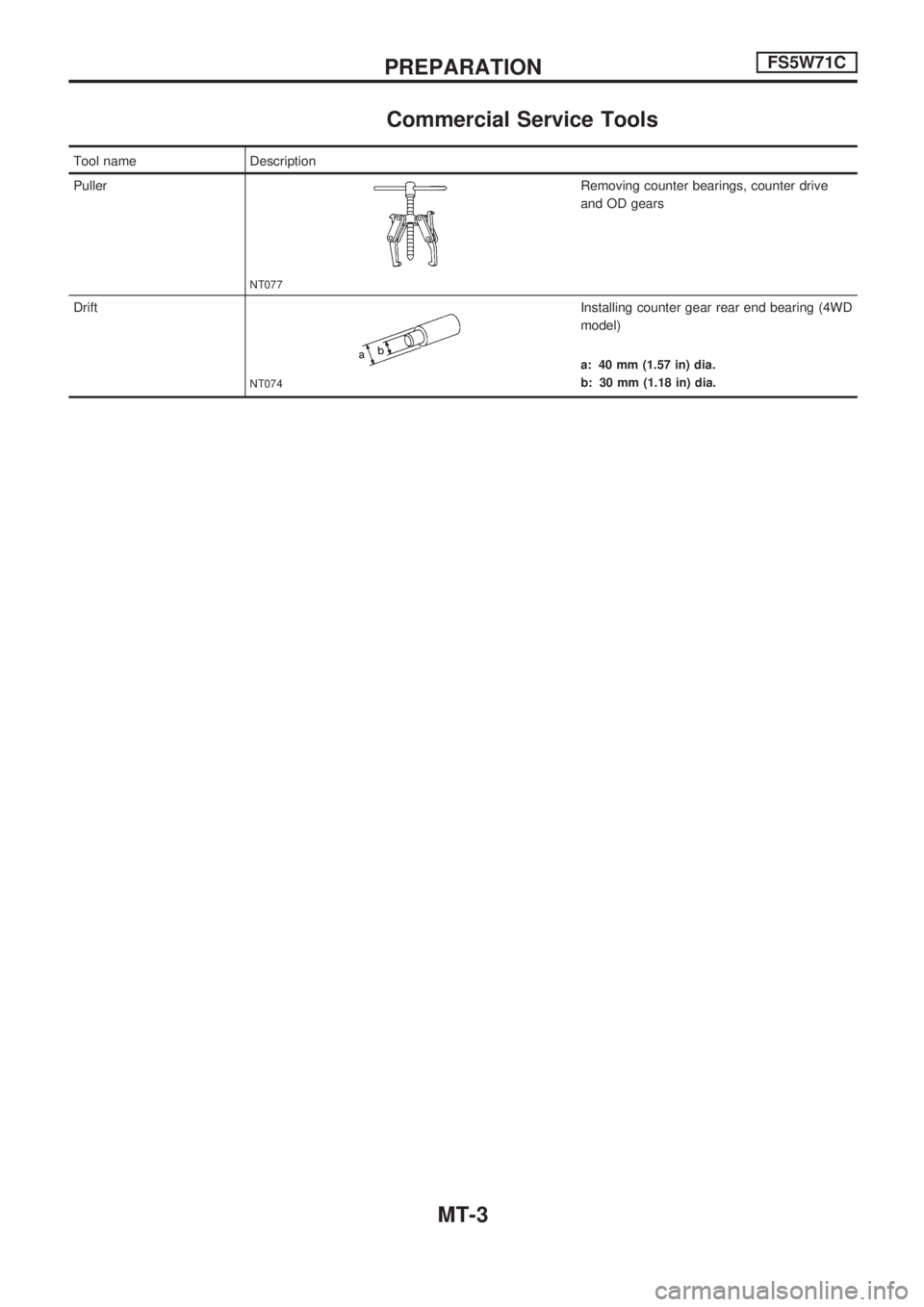

Commercial Service Tools

Tool name Description

Puller

NT077

Removing counter bearings, counter drive

and OD gears

Drift

NT074

Installing counter gear rear end bearing (4WD

model)

a: 40 mm (1.57 in) dia.

b: 30 mm (1.18 in) dia.

PREPARATIONFS5W71C

MT-3