NISSAN PICK-UP 1998 Repair Manual

PICK-UP 1998

NISSAN

NISSAN

https://www.carmanualsonline.info/img/5/57374/w960_57374-0.png

NISSAN PICK-UP 1998 Repair Manual

Trending: brake sensor, el 133, cooling, sensor, fuse box diagram, low oil pressure, fuse chart

Page 1561 of 1659

Tool name DescriptionEngine application

KA TD

Rear oil seal drift

NT608

Installing rear oil seal

XÐ

a: 98 (3.86) dia.

b: 86 (3.39) dia.

c: 15.9 (0.626) dia.

d: 33 (1.30)

e: 14.5 (0.571)

f: 10.5 (0.413)

Unit: mm (in)

PREPARATION

Commercial Service Tools (Cont'd)

EM-8

Page 1562 of 1659

SEM811F

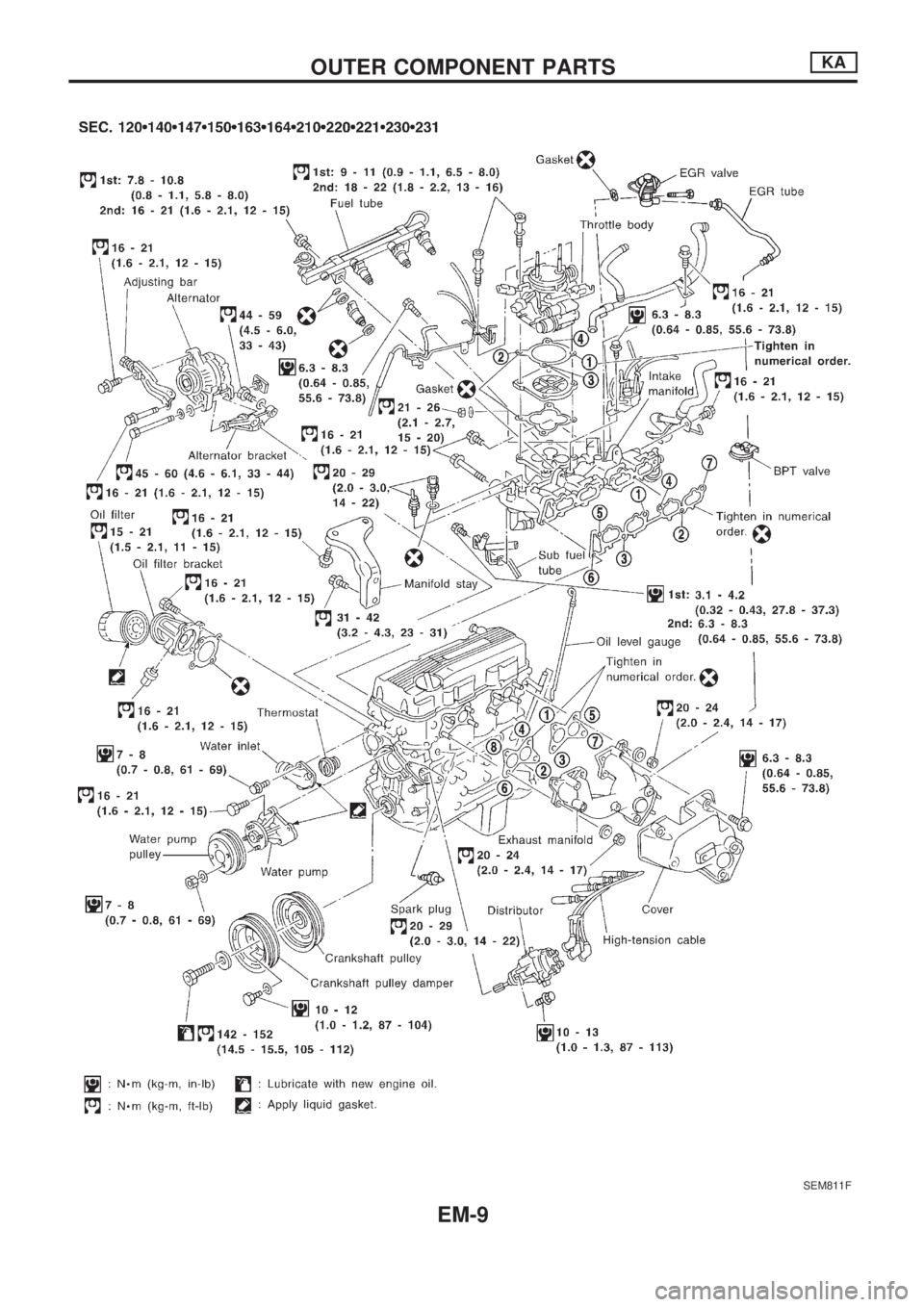

OUTER COMPONENT PARTSKA

EM-9

Page 1563 of 1659

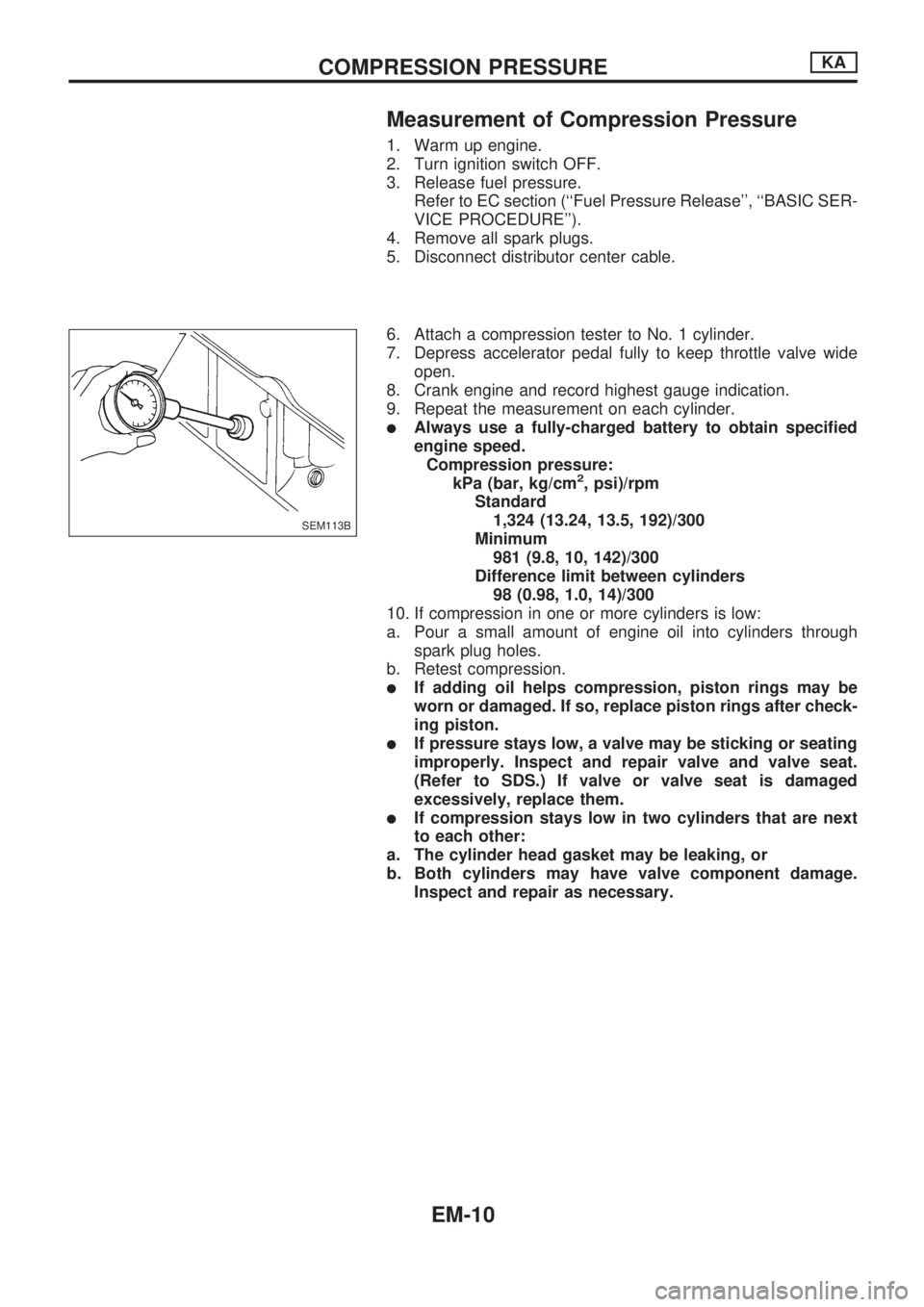

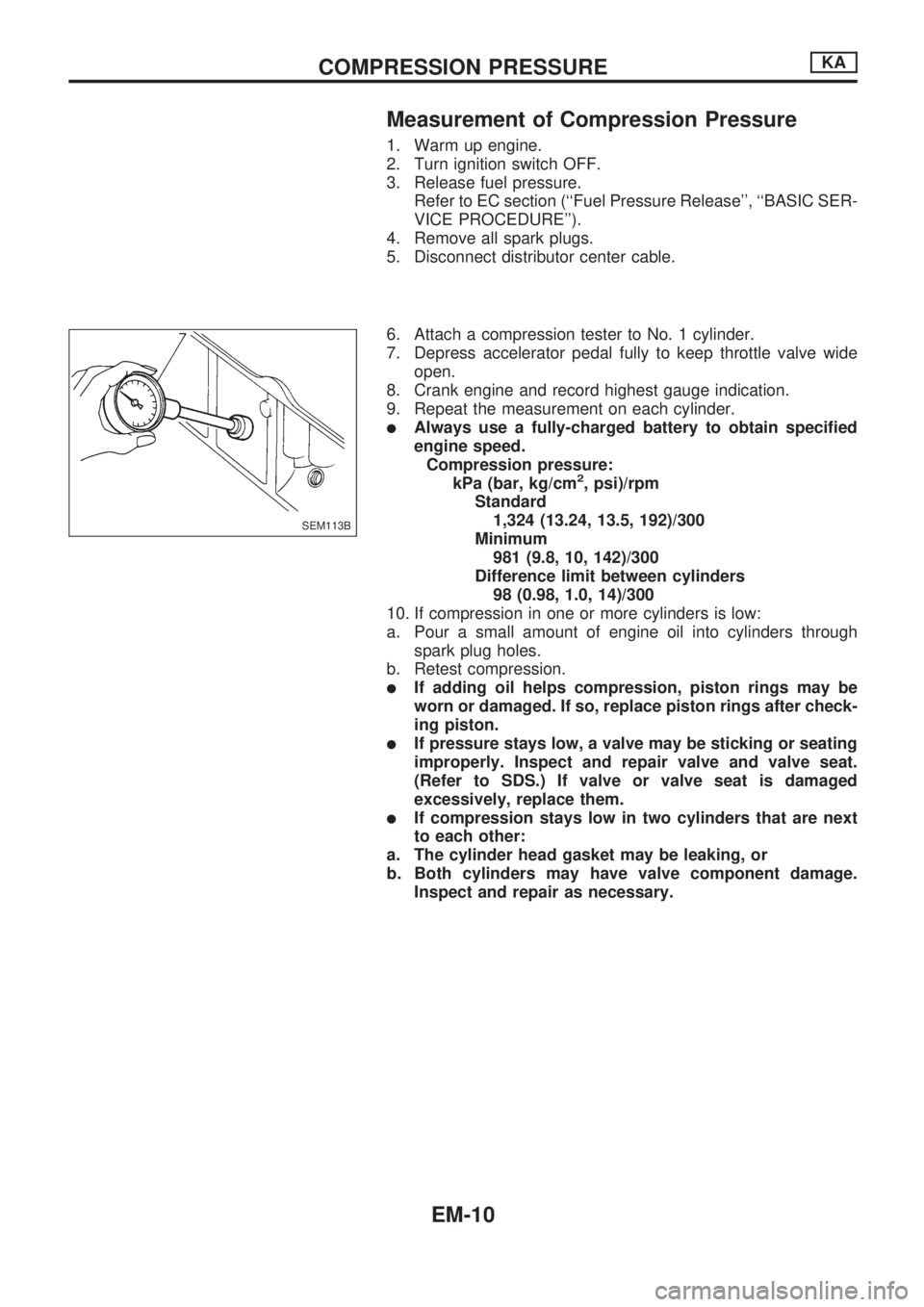

Measurement of Compression Pressure

1. Warm up engine.

2. Turn ignition switch OFF.

3. Release fuel pressure.

Refer to EC section (``Fuel Pressure Release'', ``BASIC SER-

VICE PROCEDURE'').

4. Remove all spark plugs.

5. Disconnect distributor center cable.

6. Attach a compression tester to No. 1 cylinder.

7. Depress accelerator pedal fully to keep throttle valve wide

open.

8. Crank engine and record highest gauge indication.

9. Repeat the measurement on each cylinder.

lAlways use a fully-charged battery to obtain specified

engine speed.

Compression pressure:

kPa (bar, kg/cm

2, psi)/rpm

Standard

1,324 (13.24, 13.5, 192)/300

Minimum

981 (9.8, 10, 142)/300

Difference limit between cylinders

98 (0.98, 1.0, 14)/300

10. If compression in one or more cylinders is low:

a. Pour a small amount of engine oil into cylinders through

spark plug holes.

b. Retest compression.

lIf adding oil helps compression, piston rings may be

worn or damaged. If so, replace piston rings after check-

ing piston.

lIf pressure stays low, a valve may be sticking or seating

improperly. Inspect and repair valve and valve seat.

(Refer to SDS.) If valve or valve seat is damaged

excessively, replace them.

lIf compression stays low in two cylinders that are next

to each other:

a. The cylinder head gasket may be leaking, or

b. Both cylinders may have valve component damage.

Inspect and repair as necessary.

SEM113B

COMPRESSION PRESSUREKA

EM-10

Page 1564 of 1659

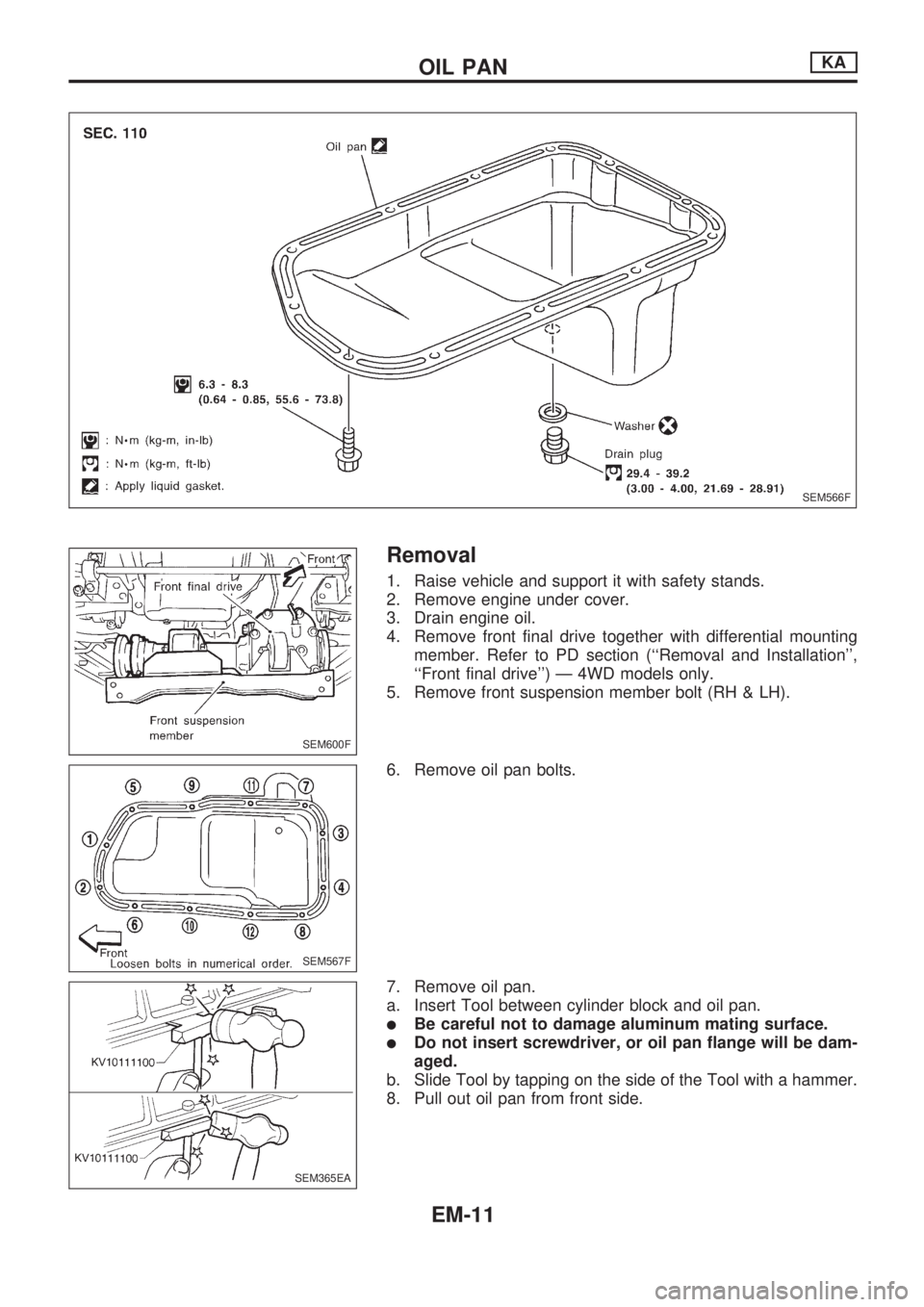

Removal

1. Raise vehicle and support it with safety stands.

2. Remove engine under cover.

3. Drain engine oil.

4. Remove front final drive together with differential mounting

member. Refer to PD section (``Removal and Installation'',

``Front final drive'') Ð 4WD models only.

5. Remove front suspension member bolt (RH & LH).

6. Remove oil pan bolts.

7. Remove oil pan.

a. Insert Tool between cylinder block and oil pan.

lBe careful not to damage aluminum mating surface.

lDo not insert screwdriver, or oil pan flange will be dam-

aged.

b. Slide Tool by tapping on the side of the Tool with a hammer.

8. Pull out oil pan from front side.

SEM566F

SEM600F

SEM567F

SEM365EA

OIL PANKA

EM-11

Page 1565 of 1659

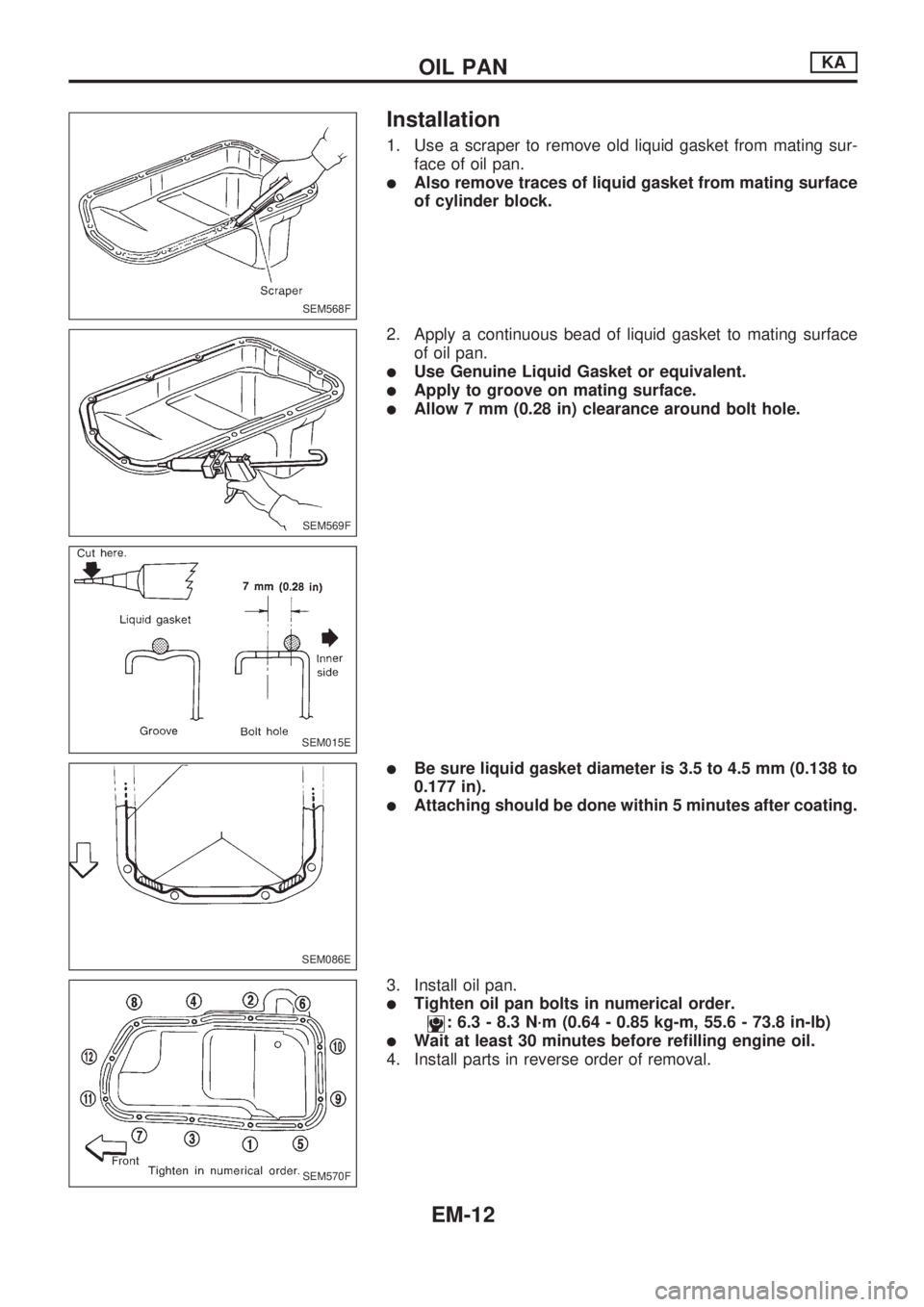

Installation

1. Use a scraper to remove old liquid gasket from mating sur-

face of oil pan.

lAlso remove traces of liquid gasket from mating surface

of cylinder block.

2. Apply a continuous bead of liquid gasket to mating surface

of oil pan.

lUse Genuine Liquid Gasket or equivalent.

lApply to groove on mating surface.

lAllow 7 mm (0.28 in) clearance around bolt hole.

lBe sure liquid gasket diameter is 3.5 to 4.5 mm (0.138 to

0.177 in).

lAttaching should be done within 5 minutes after coating.

3. Install oil pan.

lTighten oil pan bolts in numerical order.

: 6.3 - 8.3 N´m (0.64 - 0.85 kg-m, 55.6 - 73.8 in-lb)

lWait at least 30 minutes before refilling engine oil.

4. Install parts in reverse order of removal.

SEM568F

SEM569F

SEM015E

SEM086E

SEM570F

OIL PANKA

EM-12

Page 1566 of 1659

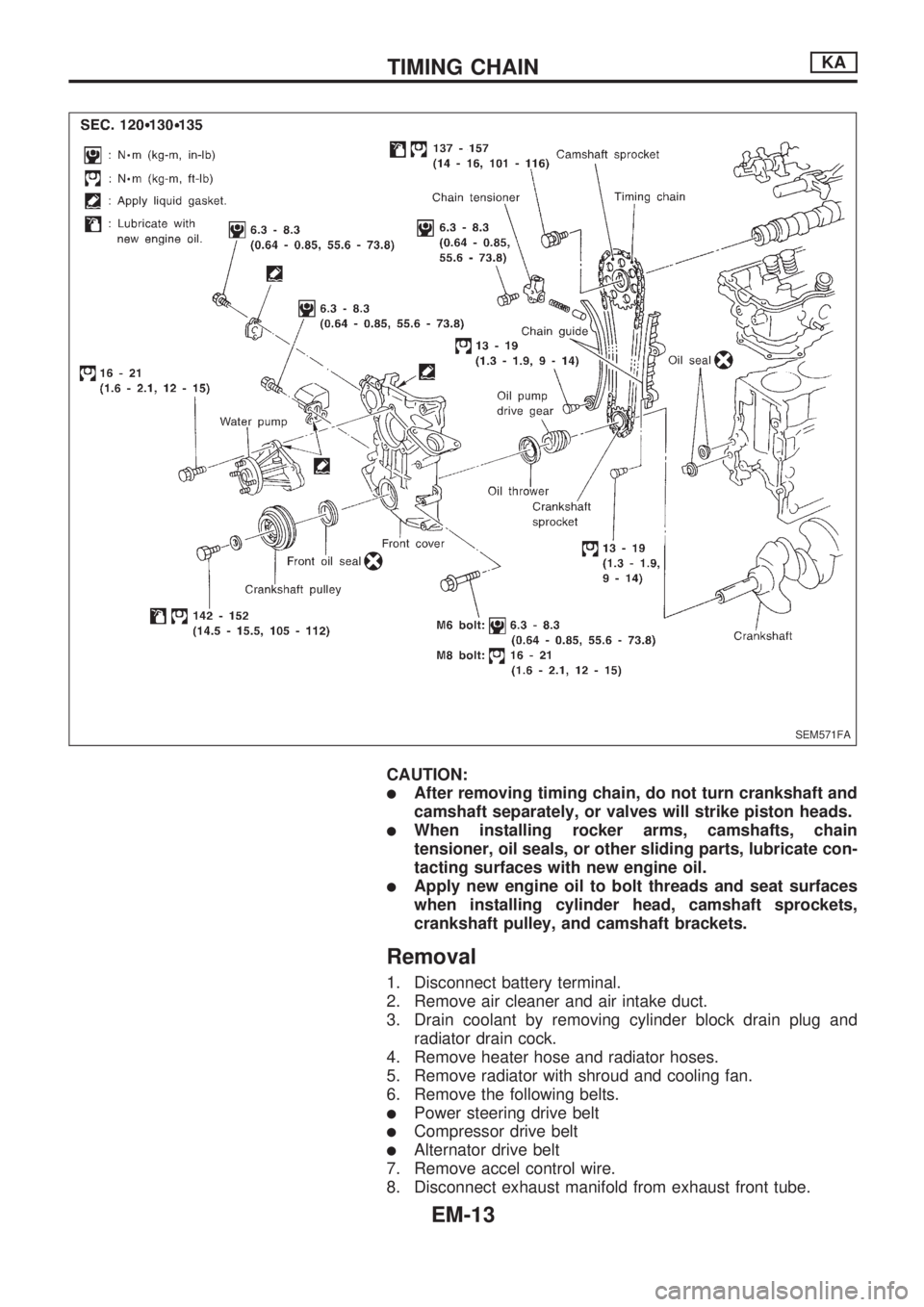

CAUTION:

lAfter removing timing chain, do not turn crankshaft and

camshaft separately, or valves will strike piston heads.

lWhen installing rocker arms, camshafts, chain

tensioner, oil seals, or other sliding parts, lubricate con-

tacting surfaces with new engine oil.

lApply new engine oil to bolt threads and seat surfaces

when installing cylinder head, camshaft sprockets,

crankshaft pulley, and camshaft brackets.

Removal

1. Disconnect battery terminal.

2. Remove air cleaner and air intake duct.

3. Drain coolant by removing cylinder block drain plug and

radiator drain cock.

4. Remove heater hose and radiator hoses.

5. Remove radiator with shroud and cooling fan.

6. Remove the following belts.

lPower steering drive belt

lCompressor drive belt

lAlternator drive belt

7. Remove accel control wire.

8. Disconnect exhaust manifold from exhaust front tube.

SEM571FA

TIMING CHAINKA

EM-13

Page 1567 of 1659

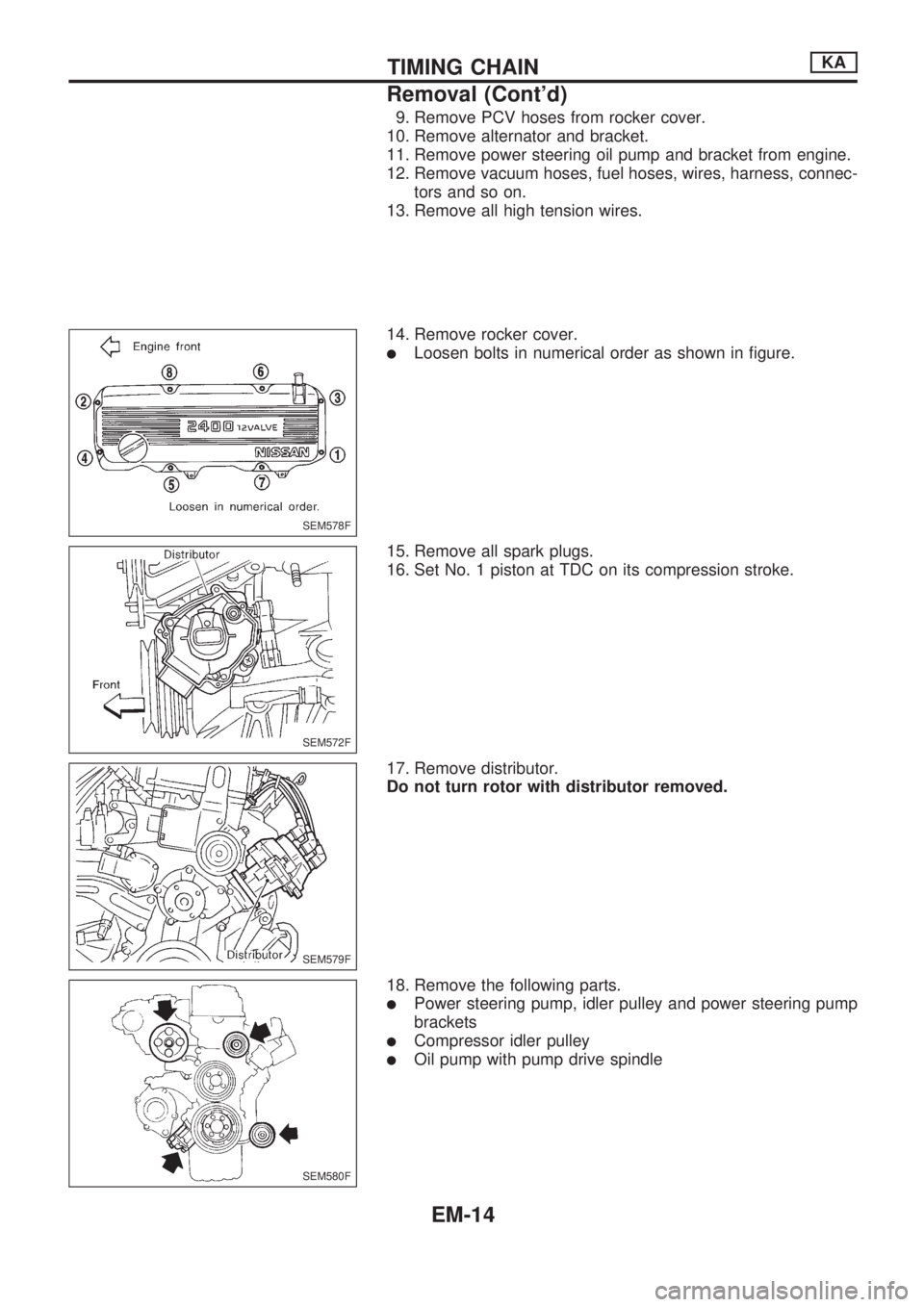

9. Remove PCV hoses from rocker cover.

10. Remove alternator and bracket.

11. Remove power steering oil pump and bracket from engine.

12. Remove vacuum hoses, fuel hoses, wires, harness, connec-

tors and so on.

13. Remove all high tension wires.

14. Remove rocker cover.

lLoosen bolts in numerical order as shown in figure.

15. Remove all spark plugs.

16. Set No. 1 piston at TDC on its compression stroke.

17. Remove distributor.

Do not turn rotor with distributor removed.

18. Remove the following parts.

lPower steering pump, idler pulley and power steering pump

brackets

lCompressor idler pulley

lOil pump with pump drive spindle

SEM578F

SEM572F

SEM579F

SEM580F

TIMING CHAINKA

Removal (Cont'd)

EM-14

Page 1568 of 1659

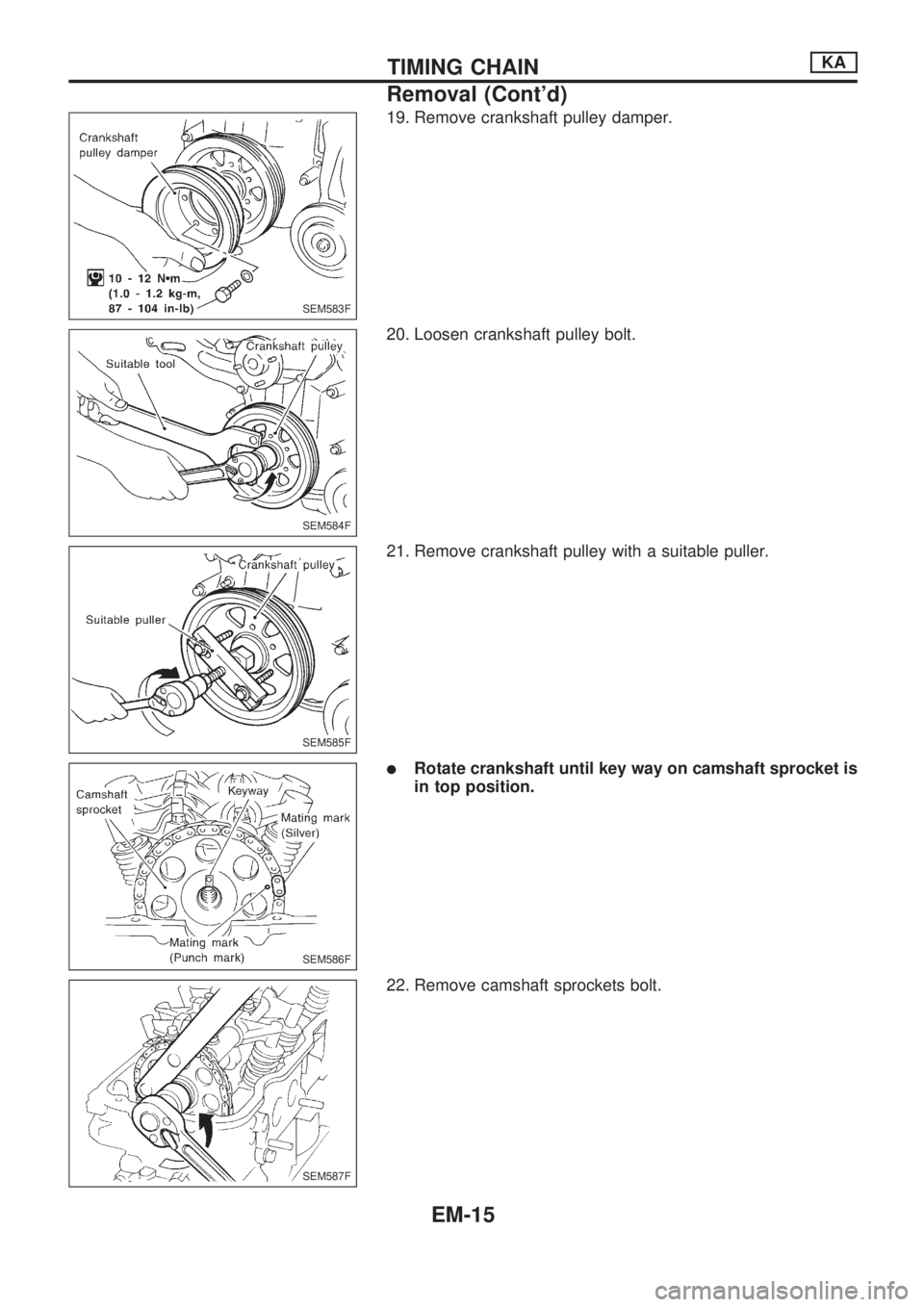

19. Remove crankshaft pulley damper.

20. Loosen crankshaft pulley bolt.

21. Remove crankshaft pulley with a suitable puller.

lRotate crankshaft until key way on camshaft sprocket is

in top position.

22. Remove camshaft sprockets bolt.

SEM583F

SEM584F

SEM585F

SEM586F

SEM587F

TIMING CHAINKA

Removal (Cont'd)

EM-15

Page 1569 of 1659

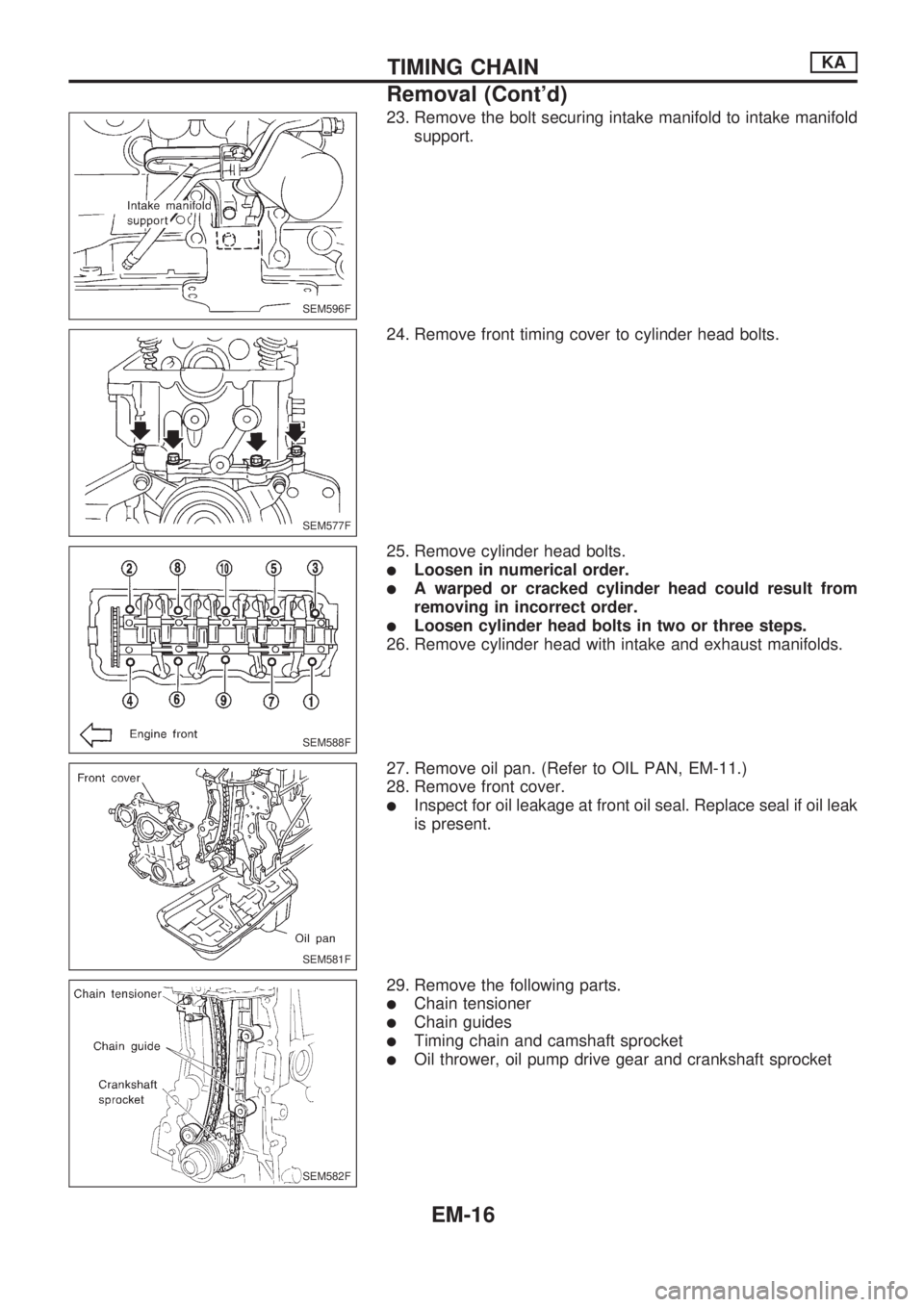

23. Remove the bolt securing intake manifold to intake manifold

support.

24. Remove front timing cover to cylinder head bolts.

25. Remove cylinder head bolts.

lLoosen in numerical order.

lA warped or cracked cylinder head could result from

removing in incorrect order.

lLoosen cylinder head bolts in two or three steps.

26. Remove cylinder head with intake and exhaust manifolds.

27. Remove oil pan. (Refer to OIL PAN, EM-11.)

28. Remove front cover.

lInspect for oil leakage at front oil seal. Replace seal if oil leak

is present.

29. Remove the following parts.

lChain tensioner

lChain guides

lTiming chain and camshaft sprocket

lOil thrower, oil pump drive gear and crankshaft sprocket

SEM596F

SEM577F

SEM588F

SEM581F

SEM582F

TIMING CHAINKA

Removal (Cont'd)

EM-16

Page 1570 of 1659

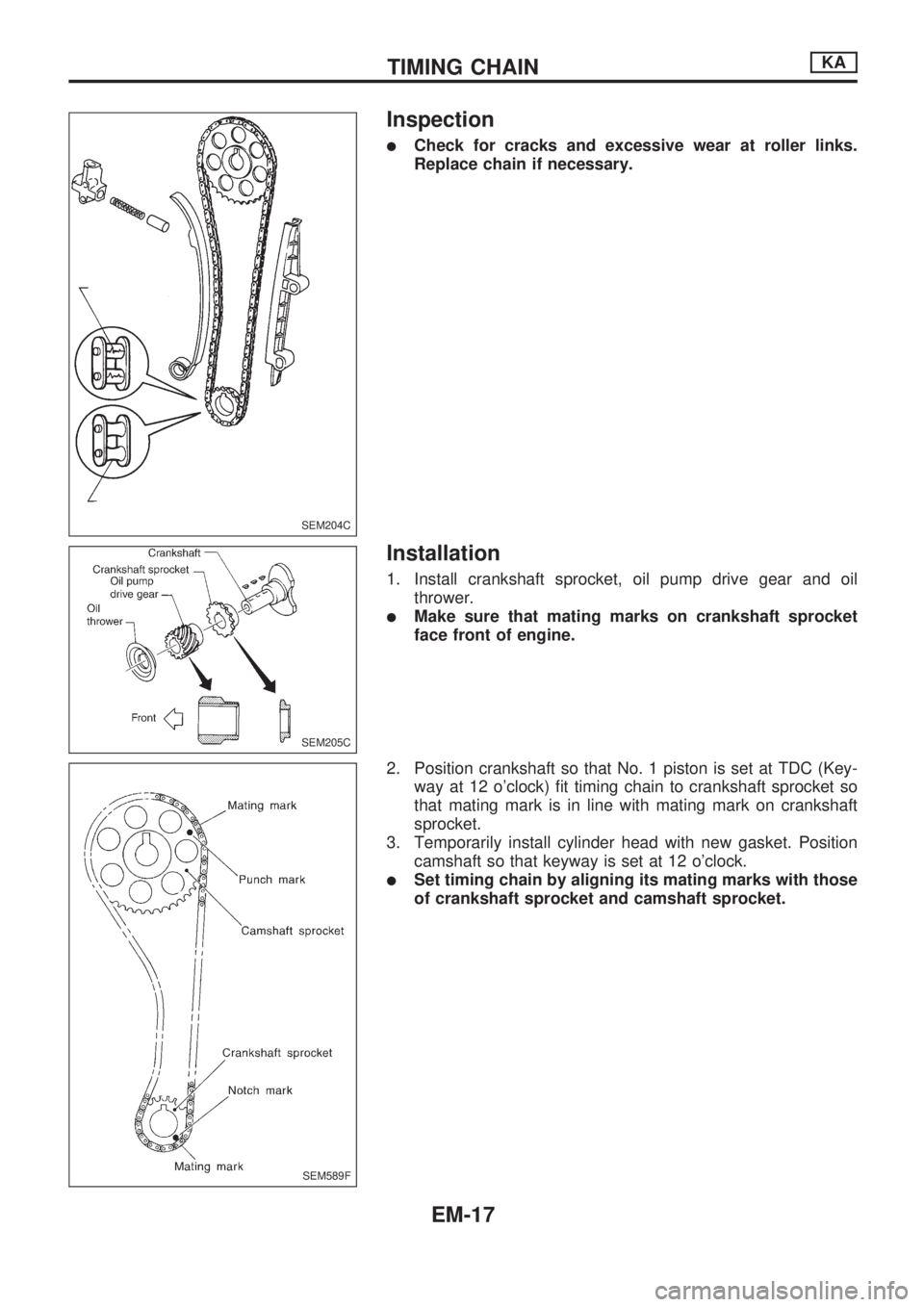

Inspection

lCheck for cracks and excessive wear at roller links.

Replace chain if necessary.

Installation

1. Install crankshaft sprocket, oil pump drive gear and oil

thrower.

lMake sure that mating marks on crankshaft sprocket

face front of engine.

2. Position crankshaft so that No. 1 piston is set at TDC (Key-

way at 12 o'clock) fit timing chain to crankshaft sprocket so

that mating mark is in line with mating mark on crankshaft

sprocket.

3. Temporarily install cylinder head with new gasket. Position

camshaft so that keyway is set at 12 o'clock.

lSet timing chain by aligning its mating marks with those

of crankshaft sprocket and camshaft sprocket.

SEM204C

SEM205C

SEM589F

TIMING CHAINKA

EM-17

Trending: rear view mirror, clock, fuse box diagram, 4WD, lug pattern, power steering, overheating