NISSAN PICK-UP 1998 Repair Manual

Manufacturer: NISSAN, Model Year: 1998, Model line: PICK-UP, Model: NISSAN PICK-UP 1998Pages: 1659, PDF Size: 53.39 MB

Page 281 of 1659

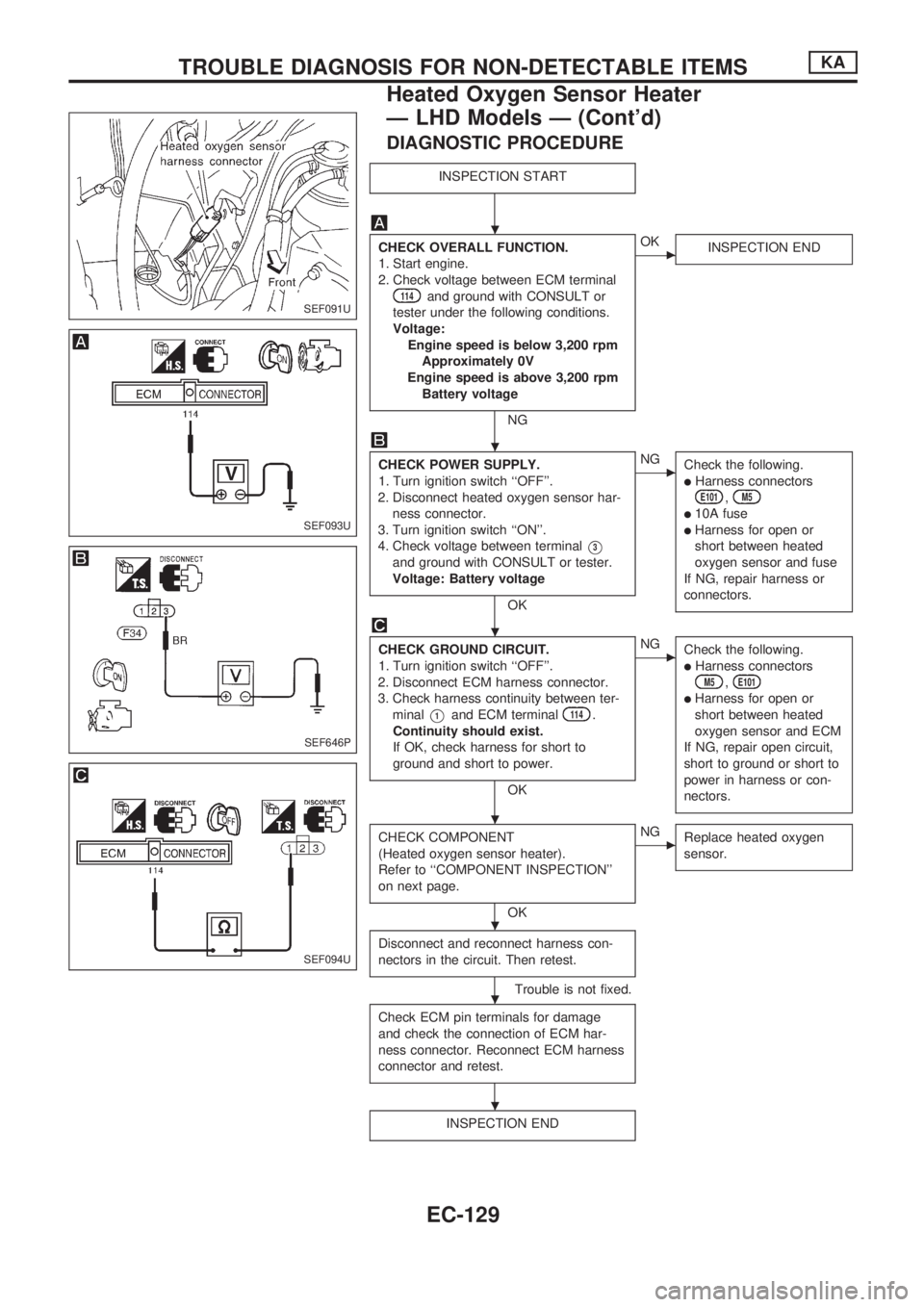

DIAGNOSTIC PROCEDURE

INSPECTION START

CHECK OVERALL FUNCTION.

1. Start engine.

2. Check voltage between ECM terminal

114and ground with CONSULT or

tester under the following conditions.

Voltage:

Engine speed is below 3,200 rpm

Approximately 0V

Engine speed is above 3,200 rpm

Battery voltage

NG

cOK

INSPECTION END

CHECK POWER SUPPLY.

1. Turn ignition switch ``OFF''.

2. Disconnect heated oxygen sensor har-

ness connector.

3. Turn ignition switch ``ON''.

4. Check voltage between terminal

V3

and ground with CONSULT or tester.

Voltage: Battery voltage

OK

cNG

Check the following.

lHarness connectorsE101,M5

l10A fuse

lHarness for open or

short between heated

oxygen sensor and fuse

If NG, repair harness or

connectors.

CHECK GROUND CIRCUIT.

1. Turn ignition switch ``OFF''.

2. Disconnect ECM harness connector.

3. Check harness continuity between ter-

minal

V1and ECM terminal114.

Continuity should exist.

If OK, check harness for short to

ground and short to power.

OK

cNG

Check the following.

lHarness connectorsM5,E101

lHarness for open or

short between heated

oxygen sensor and ECM

If NG, repair open circuit,

short to ground or short to

power in harness or con-

nectors.

CHECK COMPONENT

(Heated oxygen sensor heater).

Refer to ``COMPONENT INSPECTION''

on next page.

OK

cNG

Replace heated oxygen

sensor.

Disconnect and reconnect harness con-

nectors in the circuit. Then retest.

Trouble is not fixed.

Check ECM pin terminals for damage

and check the connection of ECM har-

ness connector. Reconnect ECM harness

connector and retest.

INSPECTION END

SEF091U

SEF093U

SEF646P

SEF094U

.

.

.

.

.

.

.

TROUBLE DIAGNOSIS FOR NON-DETECTABLE ITEMSKA

Heated Oxygen Sensor Heater

Ð LHD Models Ð (Cont'd)

EC-129

Page 282 of 1659

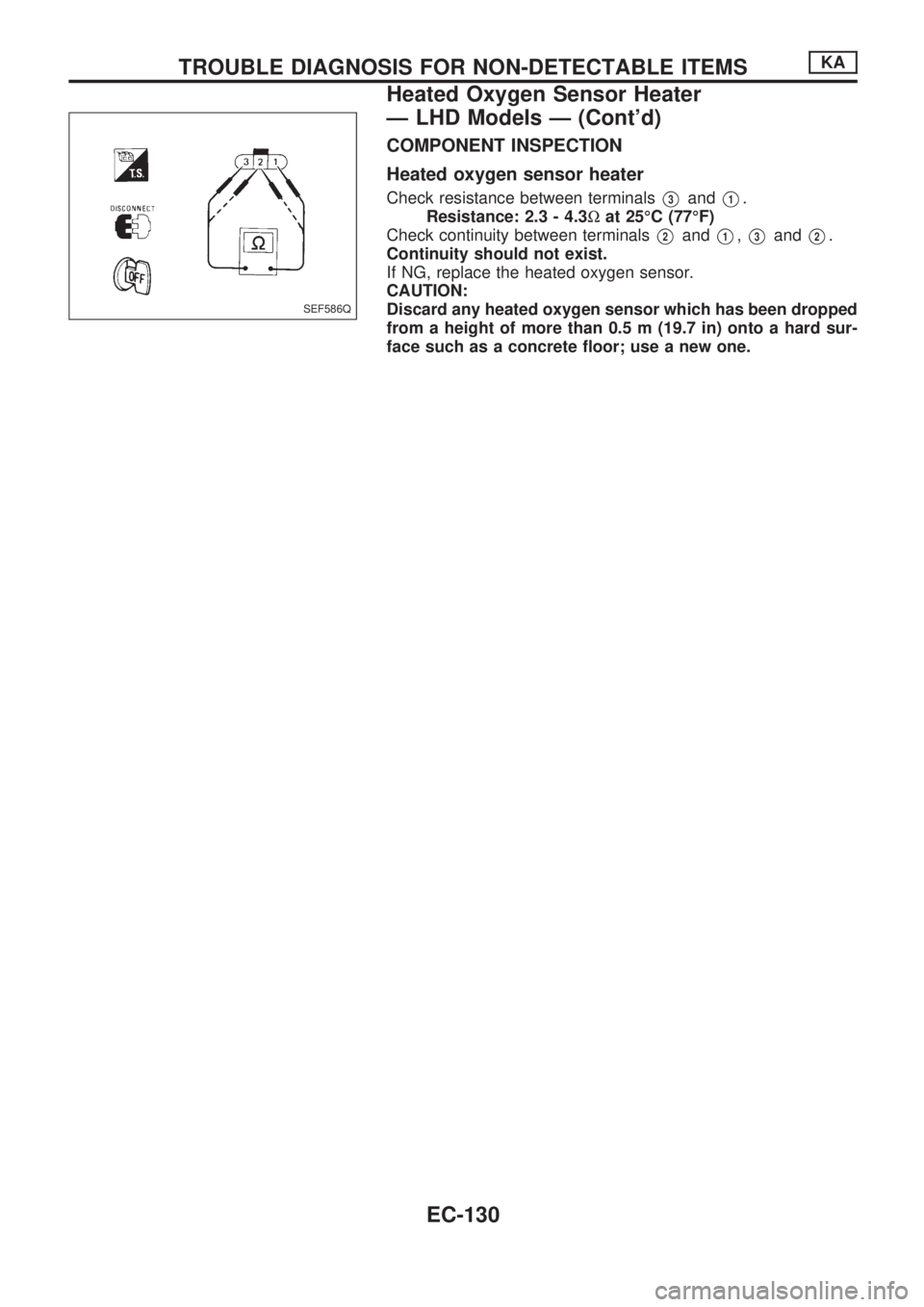

COMPONENT INSPECTION

Heated oxygen sensor heater

Check resistance between terminalsV3andV1.

Resistance: 2.3 - 4.3Wat 25ÉC (77ÉF)

Check continuity between terminals

V2andV1,V3andV2.

Continuity should not exist.

If NG, replace the heated oxygen sensor.

CAUTION:

Discard any heated oxygen sensor which has been dropped

from a height of more than 0.5 m (19.7 in) onto a hard sur-

face such as a concrete floor; use a new one.

SEF586Q

TROUBLE DIAGNOSIS FOR NON-DETECTABLE ITEMSKA

Heated Oxygen Sensor Heater

Ð LHD Models Ð (Cont'd)

EC-130

Page 283 of 1659

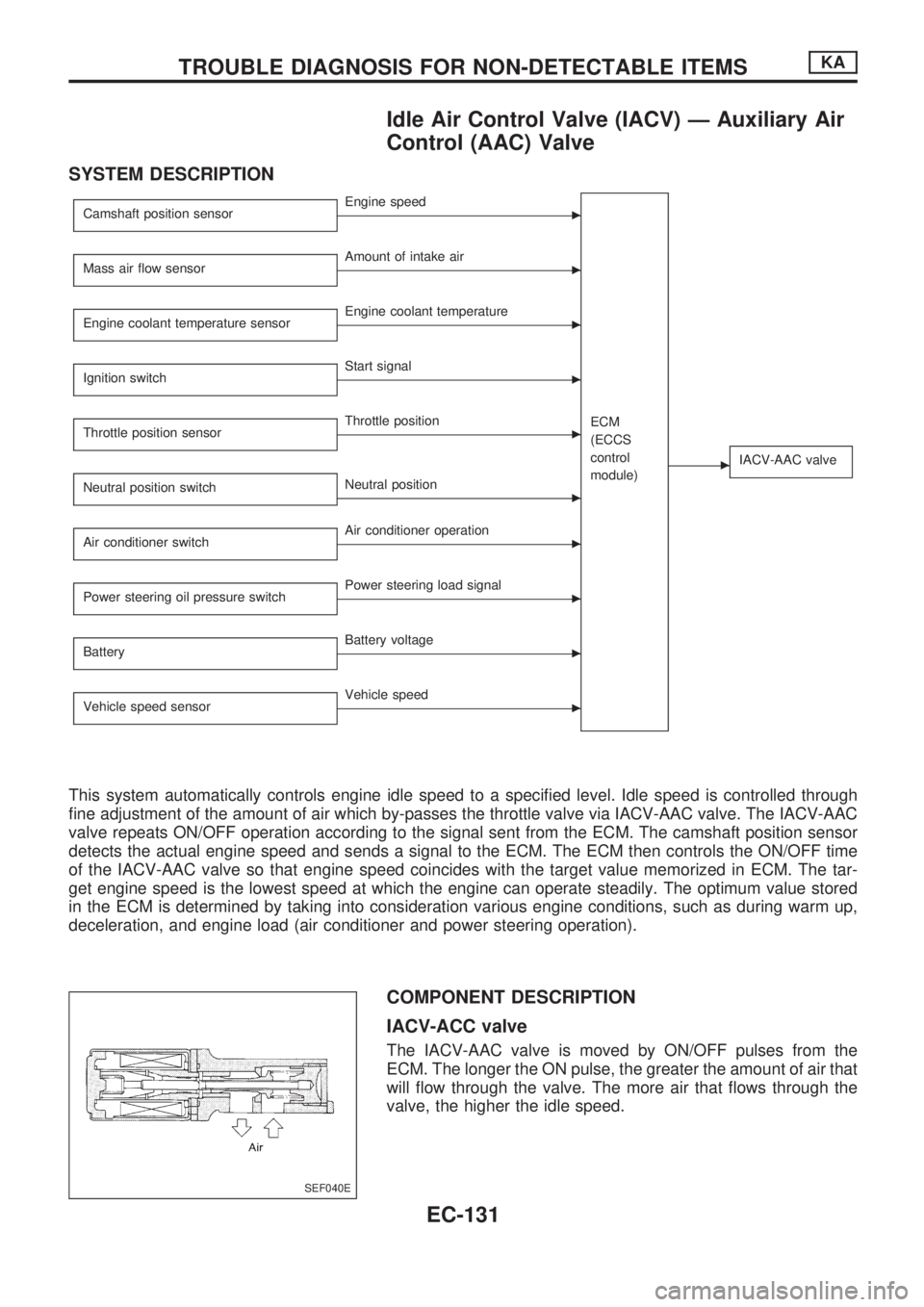

Idle Air Control Valve (IACV) Ð Auxiliary Air

Control (AAC) Valve

SYSTEM DESCRIPTION

Camshaft position sensorcEngine speed

ECM

(ECCS

control

module)

cIACV-AAC valve

Mass air flow sensorcAmount of intake air

Engine coolant temperature sensor

cEngine coolant temperature

Ignition switch

cStart signal

Throttle position sensor

cThrottle position

Neutral position switch

cNeutral position

Air conditioner switch

cAir conditioner operation

Power steering oil pressure switch

cPower steering load signal

Battery

cBattery voltage

Vehicle speed sensor

cVehicle speed

This system automatically controls engine idle speed to a specified level. Idle speed is controlled through

fine adjustment of the amount of air which by-passes the throttle valve via IACV-AAC valve. The IACV-AAC

valve repeats ON/OFF operation according to the signal sent from the ECM. The camshaft position sensor

detects the actual engine speed and sends a signal to the ECM. The ECM then controls the ON/OFF time

of the IACV-AAC valve so that engine speed coincides with the target value memorized in ECM. The tar-

get engine speed is the lowest speed at which the engine can operate steadily. The optimum value stored

in the ECM is determined by taking into consideration various engine conditions, such as during warm up,

deceleration, and engine load (air conditioner and power steering operation).

COMPONENT DESCRIPTION

IACV-ACC valve

The IACV-AAC valve is moved by ON/OFF pulses from the

ECM. The longer the ON pulse, the greater the amount of air that

will flow through the valve. The more air that flows through the

valve, the higher the idle speed.

SEF040E

TROUBLE DIAGNOSIS FOR NON-DETECTABLE ITEMSKA

EC-131

Page 284 of 1659

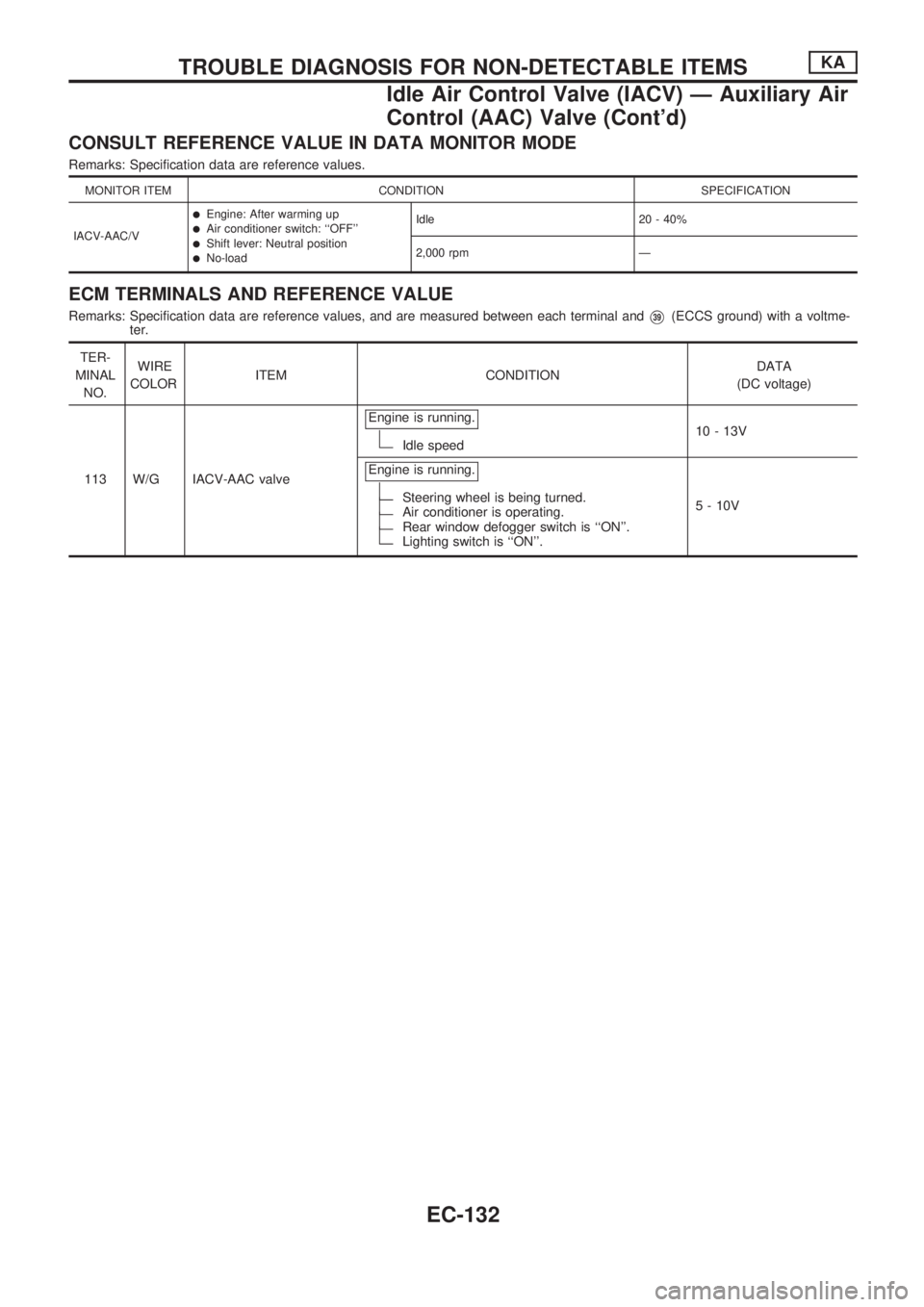

CONSULT REFERENCE VALUE IN DATA MONITOR MODE

Remarks: Specification data are reference values.

MONITOR ITEM CONDITION SPECIFICATION

IACV-AAC/V

lEngine: After warming uplAir conditioner switch: ``OFF''lShift lever: Neutral positionlNo-loadIdle 20 - 40%

2,000 rpm Ð

ECM TERMINALS AND REFERENCE VALUE

Remarks: Specification data are reference values, and are measured between each terminal andV39(ECCS ground) with a voltme-

ter.

TER-

MINAL

NO.WIRE

COLORITEM CONDITIONDATA

(DC voltage)

113 W/G IACV-AAC valveEngine is running.

Idle speed10 - 13V

Engine is running.

Steering wheel is being turned.Air conditioner is operating.Rear window defogger switch is ``ON''.Lighting switch is ``ON''.5 - 10V

TROUBLE DIAGNOSIS FOR NON-DETECTABLE ITEMSKA

Idle Air Control Valve (IACV) Ð Auxiliary Air

Control (AAC) Valve (Cont'd)

EC-132

Page 285 of 1659

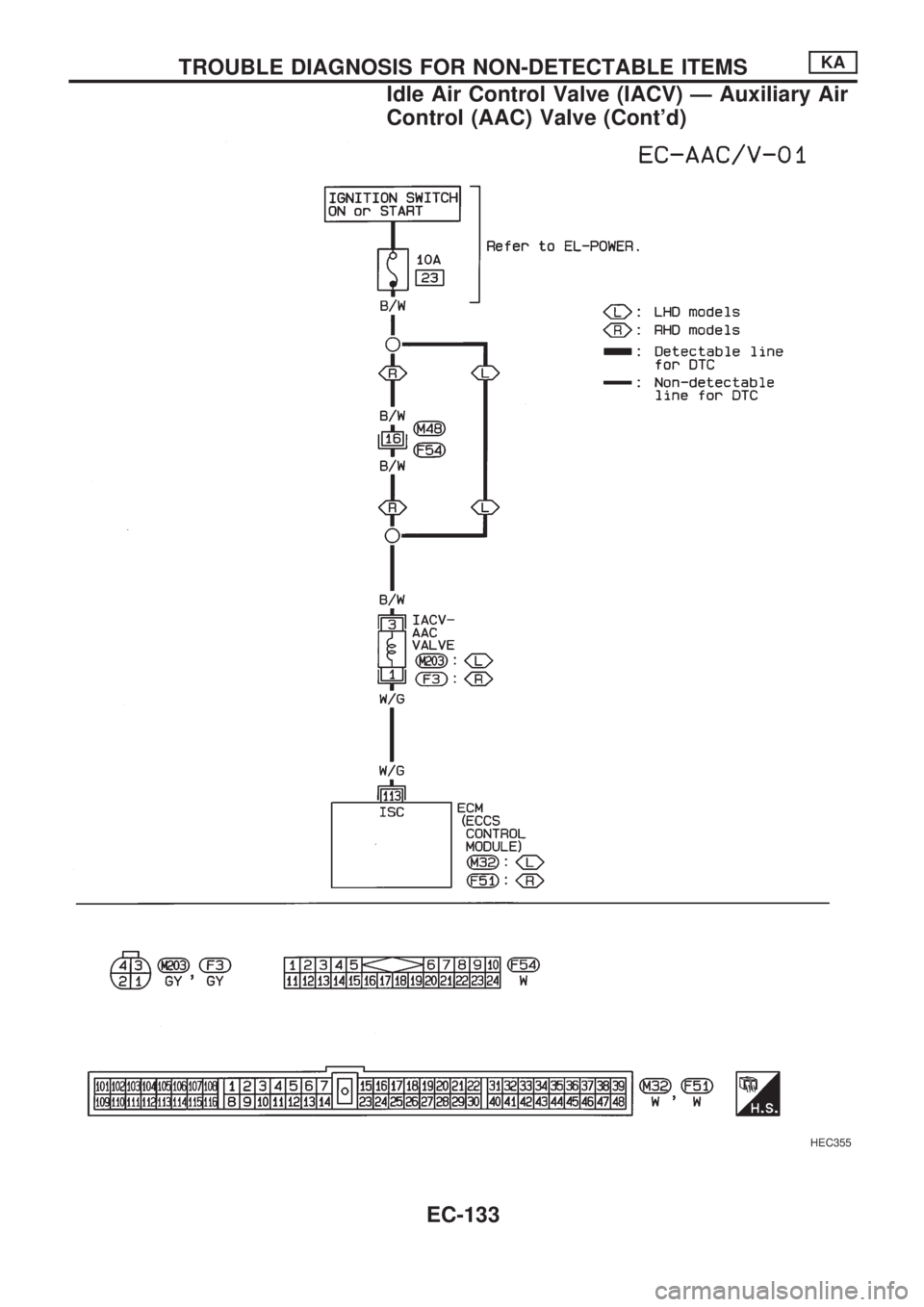

HEC355

TROUBLE DIAGNOSIS FOR NON-DETECTABLE ITEMSKA

Idle Air Control Valve (IACV) Ð Auxiliary Air

Control (AAC) Valve (Cont'd)

EC-133

Page 286 of 1659

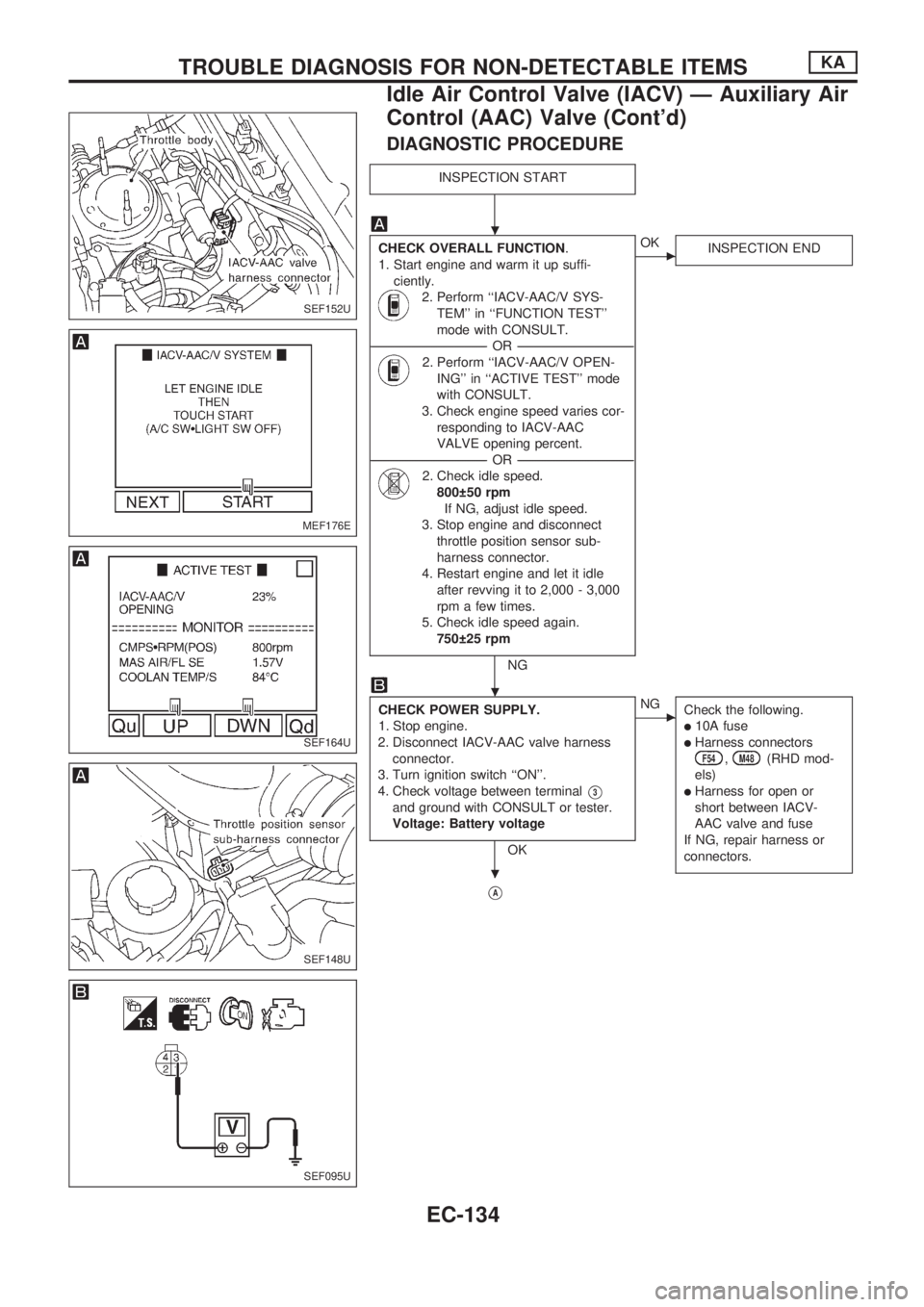

DIAGNOSTIC PROCEDURE

INSPECTION START

CHECK OVERALL FUNCTION.

1. Start engine and warm it up suffi-

ciently.

2. Perform ``IACV-AAC/V SYS-

TEM'' in ``FUNCTION TEST''

mode with CONSULT.

----------------------------------------------------------------------------------------------------------------------------------OR----------------------------------------------------------------------------------------------------------------------------------

2. Perform ``IACV-AAC/V OPEN-

ING'' in ``ACTIVE TEST'' mode

with CONSULT.

3. Check engine speed varies cor-

responding to IACV-AAC

VALVE opening percent.

----------------------------------------------------------------------------------------------------------------------------------OR----------------------------------------------------------------------------------------------------------------------------------

2. Check idle speed.

800 50 rpm

If NG, adjust idle speed.

3. Stop engine and disconnect

throttle position sensor sub-

harness connector.

4. Restart engine and let it idle

after revving it to 2,000 - 3,000

rpm a few times.

5. Check idle speed again.

750 25 rpm

NG

cOK

INSPECTION END

CHECK POWER SUPPLY.

1. Stop engine.

2. Disconnect IACV-AAC valve harness

connector.

3. Turn ignition switch ``ON''.

4. Check voltage between terminal

V3

and ground with CONSULT or tester.

Voltage: Battery voltage

OK

cNG

Check the following.

l10A fuse

lHarness connectorsF54,M48(RHD mod-

els)

lHarness for open or

short between IACV-

AAC valve and fuse

If NG, repair harness or

connectors.

VA

SEF152U

MEF176E

SEF164U

SEF148U

SEF095U

.

.

.

TROUBLE DIAGNOSIS FOR NON-DETECTABLE ITEMSKA

Idle Air Control Valve (IACV) Ð Auxiliary Air

Control (AAC) Valve (Cont'd)

EC-134

Page 287 of 1659

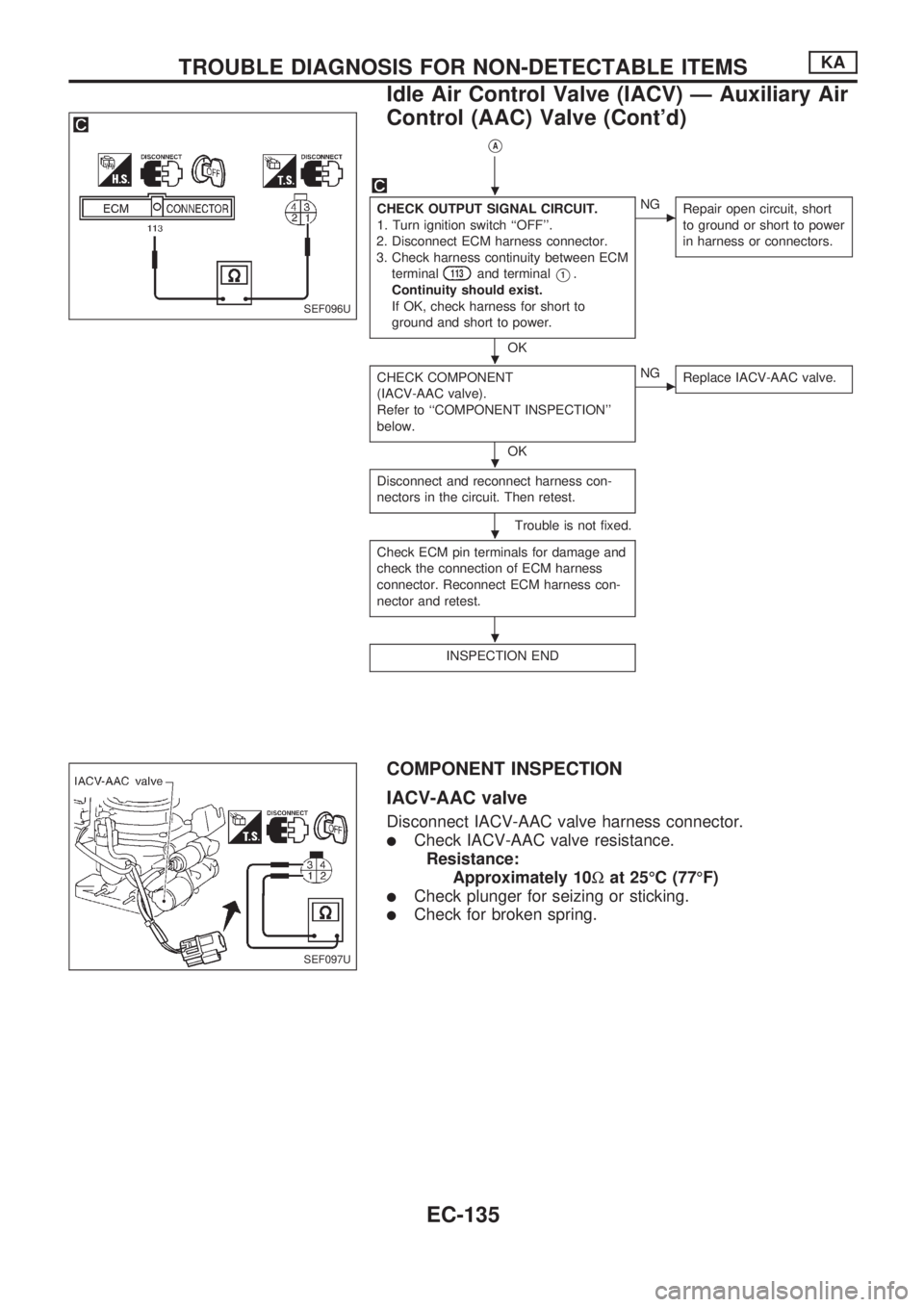

VA

CHECK OUTPUT SIGNAL CIRCUIT.

1. Turn ignition switch ``OFF''.

2. Disconnect ECM harness connector.

3. Check harness continuity between ECM

terminal

113and terminalV1.

Continuity should exist.

If OK, check harness for short to

ground and short to power.

OK

cNG

Repair open circuit, short

to ground or short to power

in harness or connectors.

CHECK COMPONENT

(IACV-AAC valve).

Refer to ``COMPONENT INSPECTION''

below.

OK

cNG

Replace IACV-AAC valve.

Disconnect and reconnect harness con-

nectors in the circuit. Then retest.

Trouble is not fixed.

Check ECM pin terminals for damage and

check the connection of ECM harness

connector. Reconnect ECM harness con-

nector and retest.

INSPECTION END

COMPONENT INSPECTION

IACV-AAC valve

Disconnect IACV-AAC valve harness connector.

lCheck IACV-AAC valve resistance.

Resistance:

Approximately 10Wat 25ÉC (77ÉF)

lCheck plunger for seizing or sticking.

lCheck for broken spring.

SEF096U

SEF097U

.

.

.

.

.

TROUBLE DIAGNOSIS FOR NON-DETECTABLE ITEMSKA

Idle Air Control Valve (IACV) Ð Auxiliary Air

Control (AAC) Valve (Cont'd)

EC-135

Page 288 of 1659

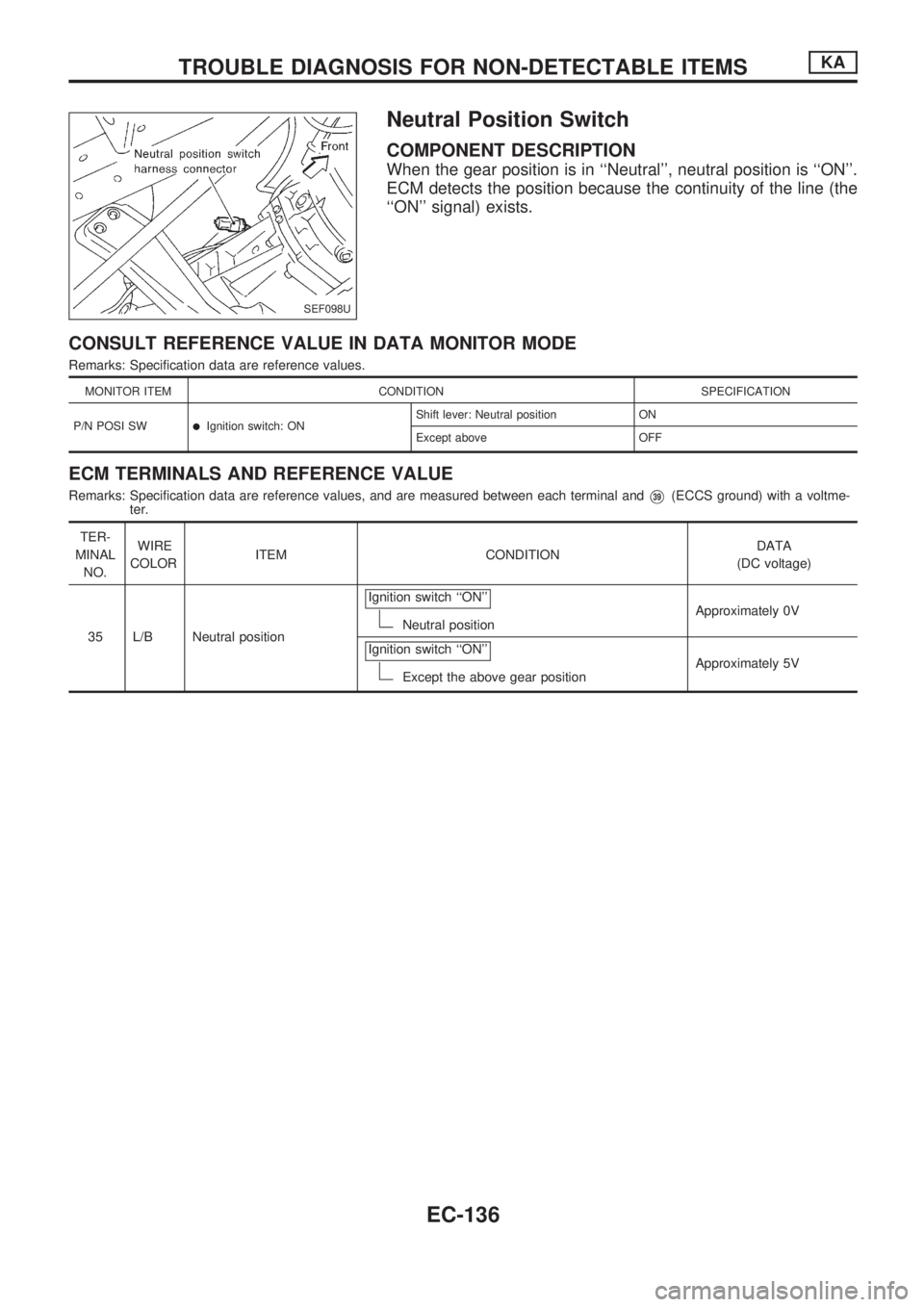

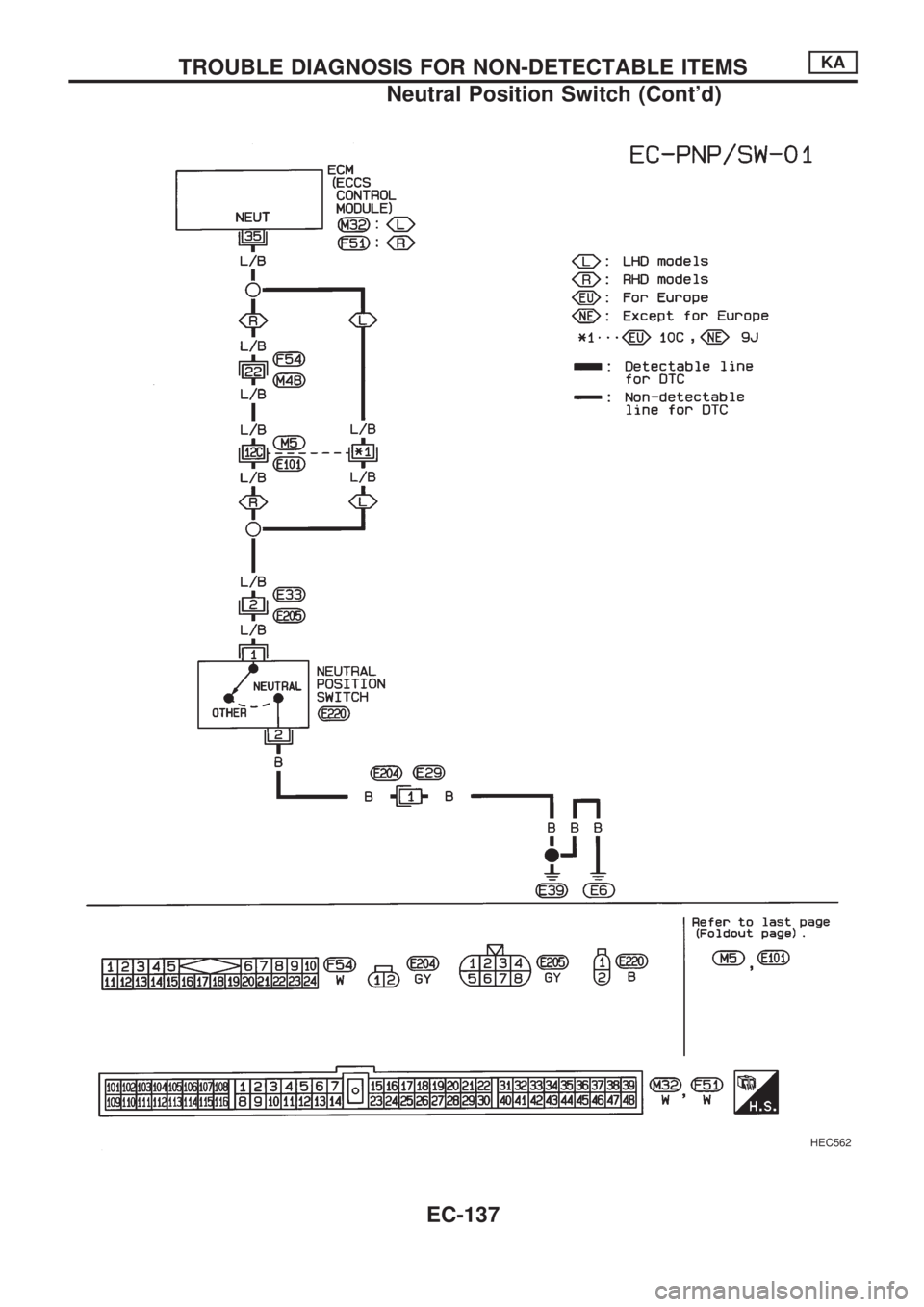

Neutral Position Switch

COMPONENT DESCRIPTION

When the gear position is in ``Neutral'', neutral position is ``ON''.

ECM detects the position because the continuity of the line (the

``ON'' signal) exists.

CONSULT REFERENCE VALUE IN DATA MONITOR MODE

Remarks: Specification data are reference values.

MONITOR ITEM CONDITION SPECIFICATION

P/N POSI SW

lIgnition switch: ONShift lever: Neutral position ON

Except above OFF

ECM TERMINALS AND REFERENCE VALUE

Remarks: Specification data are reference values, and are measured between each terminal andV39(ECCS ground) with a voltme-

ter.

TER-

MINAL

NO.WIRE

COLORITEM CONDITIONDATA

(DC voltage)

35 L/B Neutral positionIgnition switch ``ON''

Neutral positionApproximately 0V

Ignition switch ``ON''

Except the above gear positionApproximately 5V

SEF098U

TROUBLE DIAGNOSIS FOR NON-DETECTABLE ITEMSKA

EC-136

Page 289 of 1659

HEC562

TROUBLE DIAGNOSIS FOR NON-DETECTABLE ITEMSKA

Neutral Position Switch (Cont'd)

EC-137

Page 290 of 1659

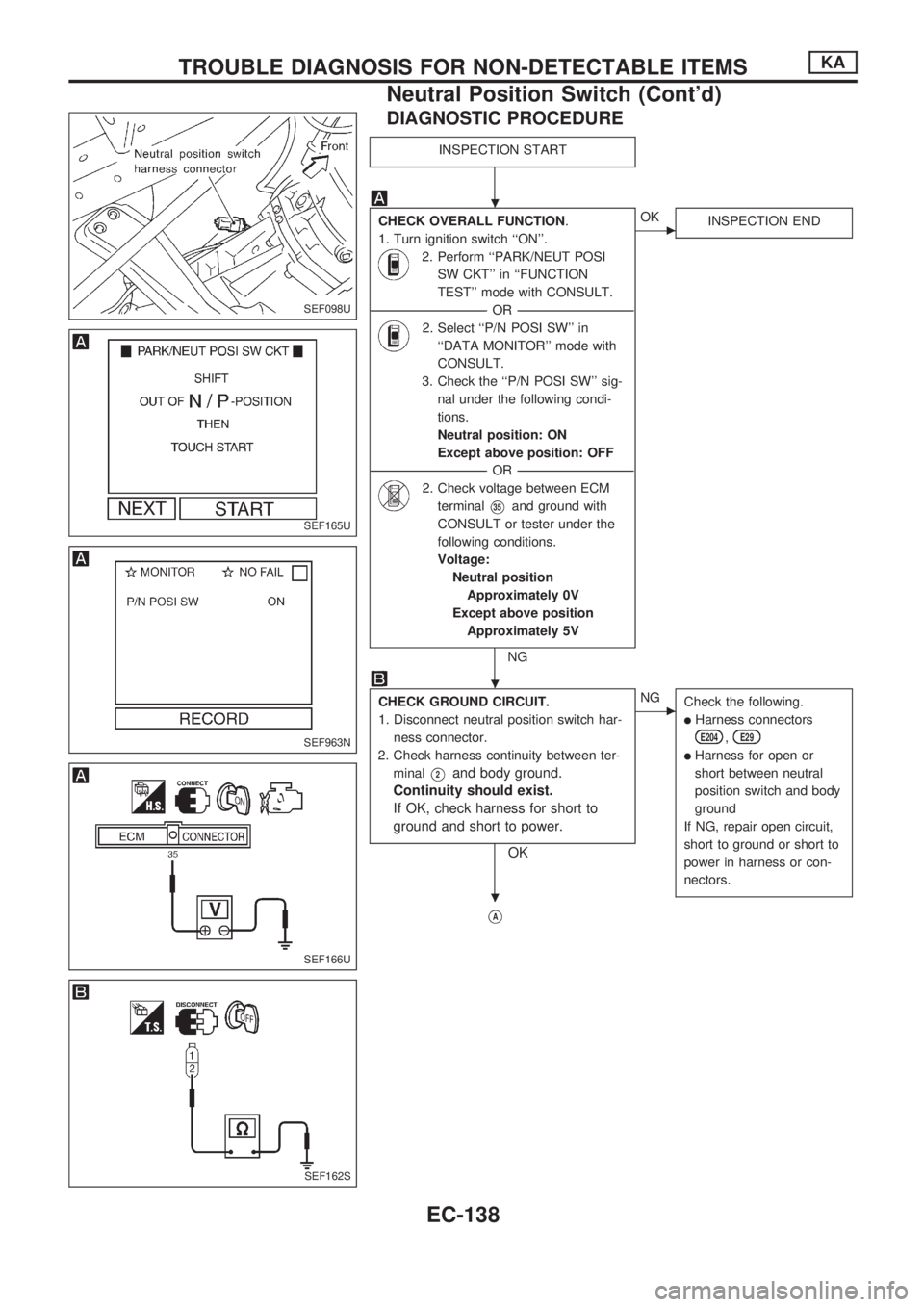

DIAGNOSTIC PROCEDURE

INSPECTION START

CHECK OVERALL FUNCTION.

1. Turn ignition switch ``ON''.

2. Perform ``PARK/NEUT POSI

SW CKT'' in ``FUNCTION

TEST'' mode with CONSULT.

----------------------------------------------------------------------------------------------------------------------------------OR----------------------------------------------------------------------------------------------------------------------------------

2. Select ``P/N POSI SW'' in

``DATA MONITOR'' mode with

CONSULT.

3. Check the ``P/N POSI SW'' sig-

nal under the following condi-

tions.

Neutral position: ON

Except above position: OFF

----------------------------------------------------------------------------------------------------------------------------------OR----------------------------------------------------------------------------------------------------------------------------------

2. Check voltage between ECM

terminal

V35and ground with

CONSULT or tester under the

following conditions.

Voltage:

Neutral position

Approximately 0V

Except above position

Approximately 5V

NG

cOK

INSPECTION END

CHECK GROUND CIRCUIT.

1. Disconnect neutral position switch har-

ness connector.

2. Check harness continuity between ter-

minal

V2and body ground.

Continuity should exist.

If OK, check harness for short to

ground and short to power.

OK

cNG

Check the following.

lHarness connectors

E204,E29

lHarness for open or

short between neutral

position switch and body

ground

If NG, repair open circuit,

short to ground or short to

power in harness or con-

nectors.

VA

SEF098U

SEF165U

SEF963N

SEF166U

SEF162S

.

.

.

TROUBLE DIAGNOSIS FOR NON-DETECTABLE ITEMSKA

Neutral Position Switch (Cont'd)

EC-138