NISSAN PICK-UP 1998 Repair Manual

Manufacturer: NISSAN, Model Year: 1998, Model line: PICK-UP, Model: NISSAN PICK-UP 1998Pages: 1659, PDF Size: 53.39 MB

Page 311 of 1659

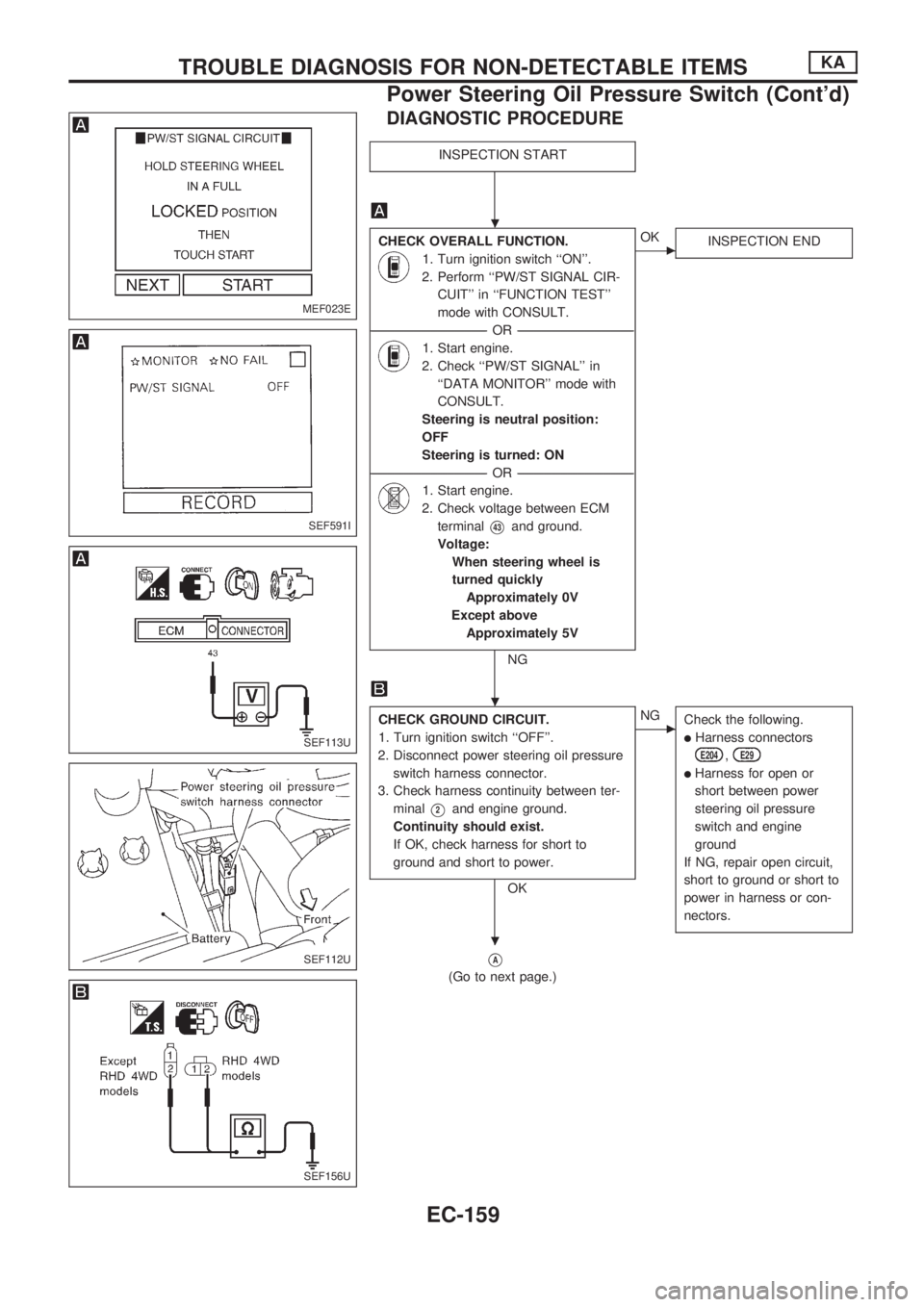

DIAGNOSTIC PROCEDURE

INSPECTION START

CHECK OVERALL FUNCTION.

1. Turn ignition switch ``ON''.

2. Perform ``PW/ST SIGNAL CIR-

CUIT'' in ``FUNCTION TEST''

mode with CONSULT.

----------------------------------------------------------------------------------------------------------------------------------OR----------------------------------------------------------------------------------------------------------------------------------

1. Start engine.

2. Check ``PW/ST SIGNAL'' in

``DATA MONITOR'' mode with

CONSULT.

Steering is neutral position:

OFF

Steering is turned: ON

----------------------------------------------------------------------------------------------------------------------------------OR----------------------------------------------------------------------------------------------------------------------------------

1. Start engine.

2. Check voltage between ECM

terminal

V43and ground.

Voltage:

When steering wheel is

turned quickly

Approximately 0V

Except above

Approximately 5V

NG

cOK

INSPECTION END

CHECK GROUND CIRCUIT.

1. Turn ignition switch ``OFF''.

2. Disconnect power steering oil pressure

switch harness connector.

3. Check harness continuity between ter-

minal

V2and engine ground.

Continuity should exist.

If OK, check harness for short to

ground and short to power.

OK

cNG

Check the following.

lHarness connectors

E204,E29

lHarness for open or

short between power

steering oil pressure

switch and engine

ground

If NG, repair open circuit,

short to ground or short to

power in harness or con-

nectors.

VA

(Go to next page.)

MEF023E

SEF591I

SEF113U

SEF112U

SEF156U

.

.

.

TROUBLE DIAGNOSIS FOR NON-DETECTABLE ITEMSKA

Power Steering Oil Pressure Switch (Cont'd)

EC-159

Page 312 of 1659

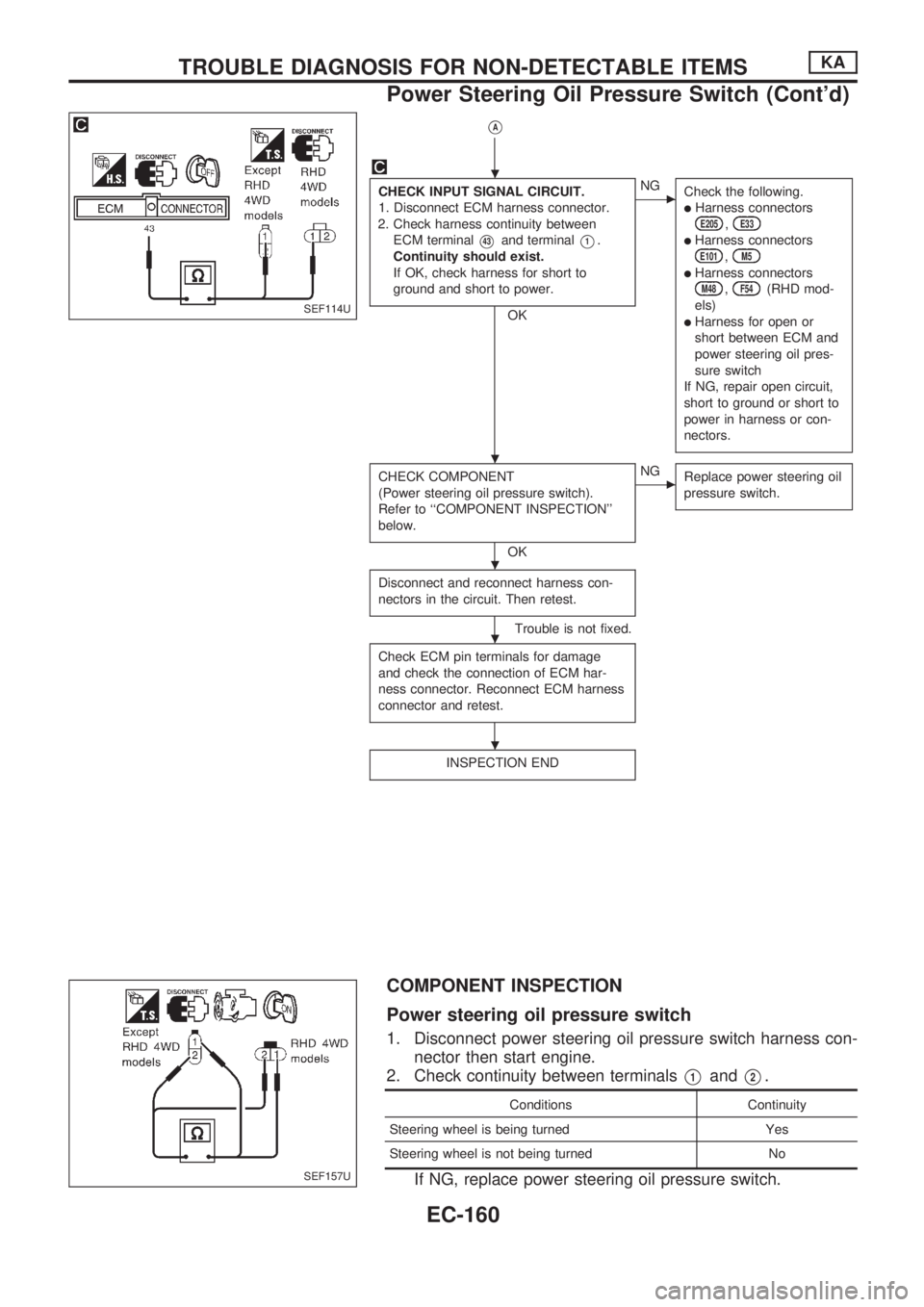

VA

CHECK INPUT SIGNAL CIRCUIT.

1. Disconnect ECM harness connector.

2. Check harness continuity between

ECM terminal

V43and terminalV1.

Continuity should exist.

If OK, check harness for short to

ground and short to power.

OK

cNG

Check the following.

lHarness connectorsE205,E33

lHarness connectorsE101,M5

lHarness connectorsM48,F54(RHD mod-

els)

lHarness for open or

short between ECM and

power steering oil pres-

sure switch

If NG, repair open circuit,

short to ground or short to

power in harness or con-

nectors.

CHECK COMPONENT

(Power steering oil pressure switch).

Refer to ``COMPONENT INSPECTION''

below.

OK

cNG

Replace power steering oil

pressure switch.

Disconnect and reconnect harness con-

nectors in the circuit. Then retest.

Trouble is not fixed.

Check ECM pin terminals for damage

and check the connection of ECM har-

ness connector. Reconnect ECM harness

connector and retest.

INSPECTION END

COMPONENT INSPECTION

Power steering oil pressure switch

1. Disconnect power steering oil pressure switch harness con-

nector then start engine.

2. Check continuity between terminals

V1andV2.

Conditions Continuity

Steering wheel is being turned Yes

Steering wheel is not being turned No

If NG, replace power steering oil pressure switch.

SEF114U

SEF157U

.

.

.

.

.

TROUBLE DIAGNOSIS FOR NON-DETECTABLE ITEMSKA

Power Steering Oil Pressure Switch (Cont'd)

EC-160

Page 313 of 1659

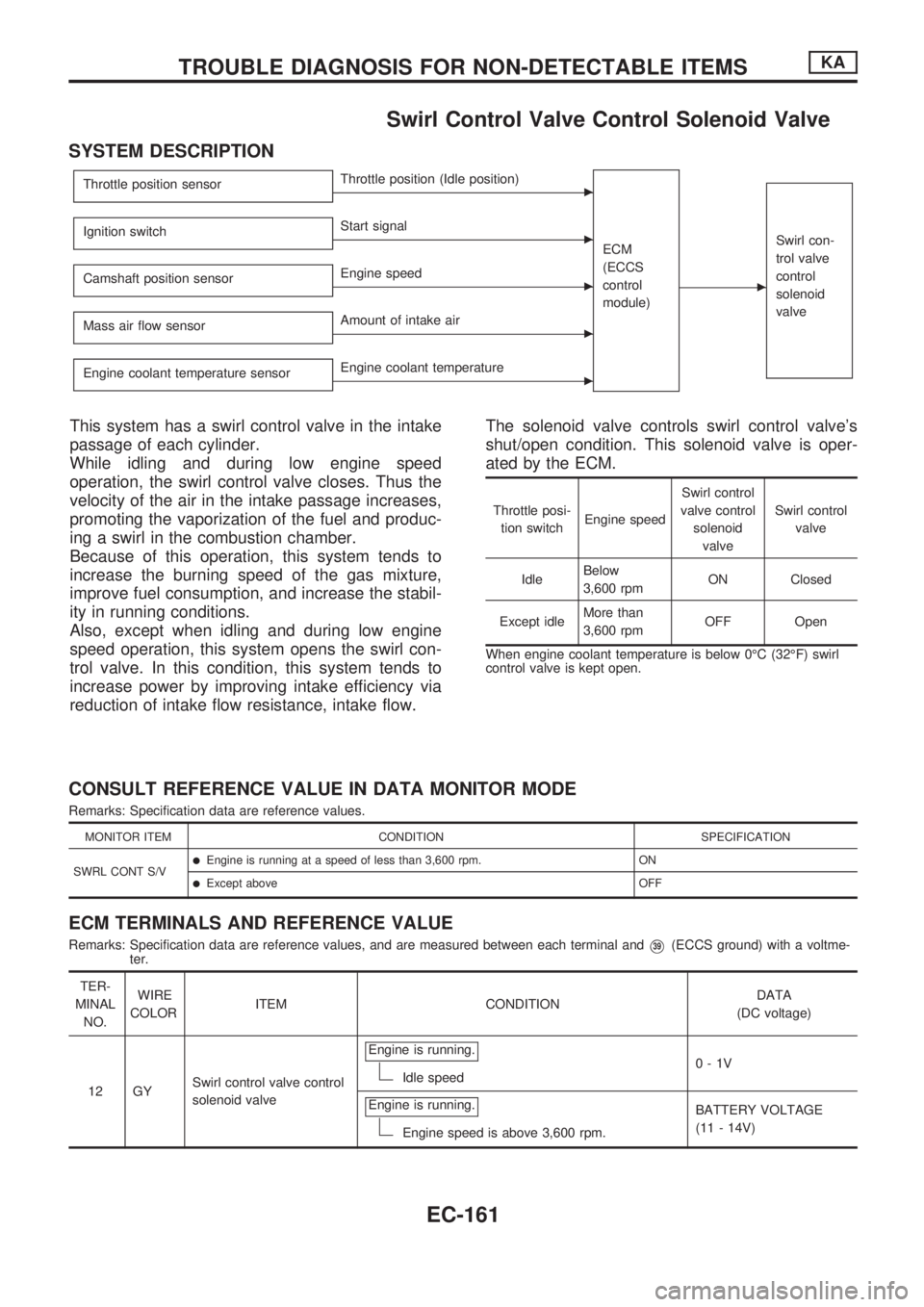

Swirl Control Valve Control Solenoid Valve

SYSTEM DESCRIPTION

Throttle position sensorcThrottle position (Idle position)

ECM

(ECCS

control

module)

c

Swirl con-

trol valve

control

solenoid

valveIgnition switchcStart signal

Camshaft position sensor

cEngine speed

Mass air flow sensor

cAmount of intake air

Engine coolant temperature sensor

cEngine coolant temperature

This system has a swirl control valve in the intake

passage of each cylinder.

While idling and during low engine speed

operation, the swirl control valve closes. Thus the

velocity of the air in the intake passage increases,

promoting the vaporization of the fuel and produc-

ing a swirl in the combustion chamber.

Because of this operation, this system tends to

increase the burning speed of the gas mixture,

improve fuel consumption, and increase the stabil-

ity in running conditions.

Also, except when idling and during low engine

speed operation, this system opens the swirl con-

trol valve. In this condition, this system tends to

increase power by improving intake efficiency via

reduction of intake flow resistance, intake flow.The solenoid valve controls swirl control valve's

shut/open condition. This solenoid valve is oper-

ated by the ECM.

Throttle posi-

tion switchEngine speedSwirl control

valve control

solenoid

valveSwirl control

valve

IdleBelow

3,600 rpmON Closed

Except idleMore than

3,600 rpmOFF Open

When engine coolant temperature is below 0ÉC (32ÉF) swirl

control valve is kept open.

CONSULT REFERENCE VALUE IN DATA MONITOR MODE

Remarks: Specification data are reference values.

MONITOR ITEM CONDITION SPECIFICATION

SWRL CONT S/V

lEngine is running at a speed of less than 3,600 rpm. ON

lExcept above OFF

ECM TERMINALS AND REFERENCE VALUE

Remarks: Specification data are reference values, and are measured between each terminal andV39(ECCS ground) with a voltme-

ter.

TER-

MINAL

NO.WIRE

COLORITEM CONDITIONDATA

(DC voltage)

12 GYSwirl control valve control

solenoid valveEngine is running.

Idle speed0-1V

Engine is running.

Engine speed is above 3,600 rpm.BATTERY VOLTAGE

(11 - 14V)

TROUBLE DIAGNOSIS FOR NON-DETECTABLE ITEMSKA

EC-161

Page 314 of 1659

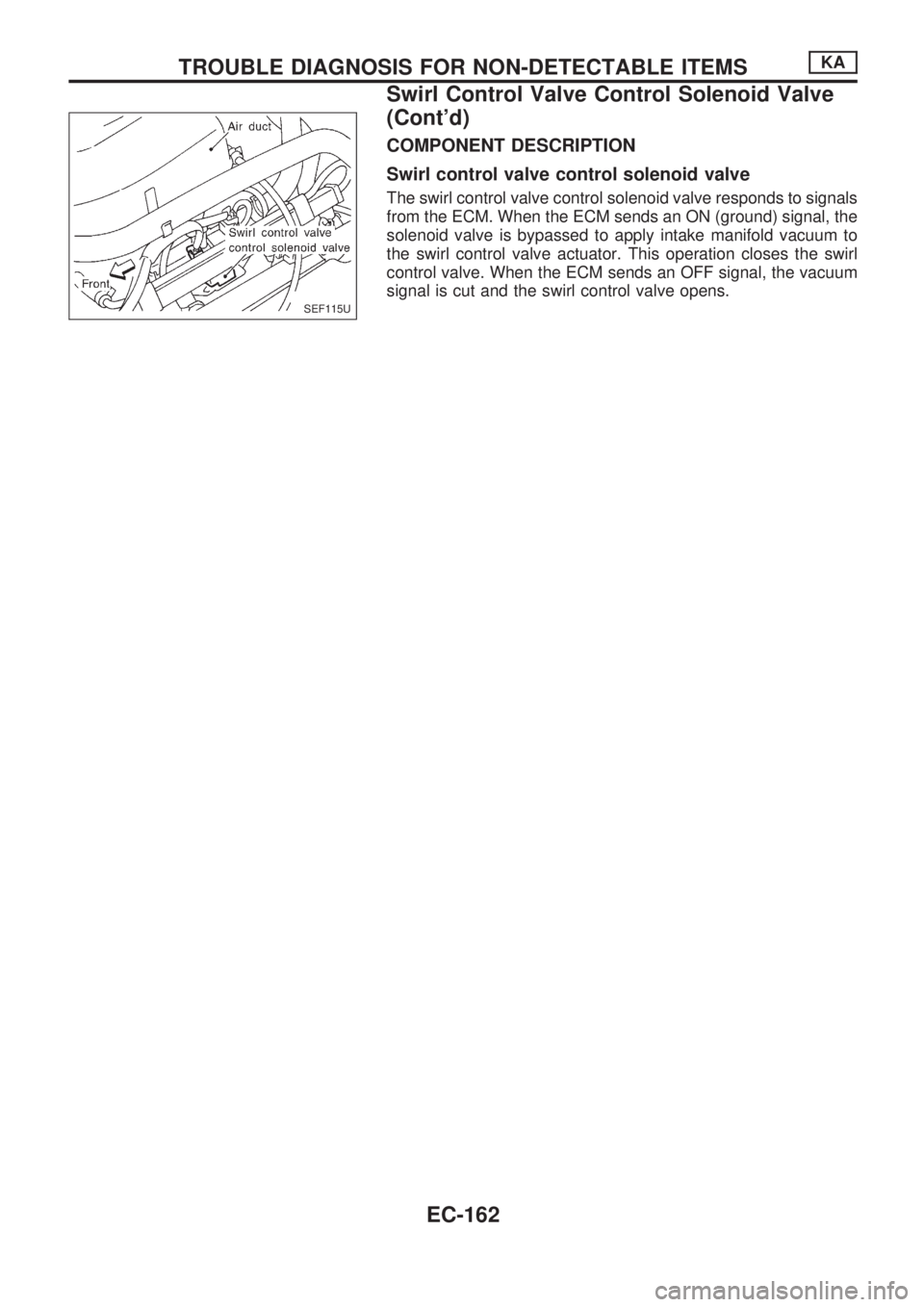

COMPONENT DESCRIPTION

Swirl control valve control solenoid valve

The swirl control valve control solenoid valve responds to signals

from the ECM. When the ECM sends an ON (ground) signal, the

solenoid valve is bypassed to apply intake manifold vacuum to

the swirl control valve actuator. This operation closes the swirl

control valve. When the ECM sends an OFF signal, the vacuum

signal is cut and the swirl control valve opens.

SEF115U

TROUBLE DIAGNOSIS FOR NON-DETECTABLE ITEMSKA

Swirl Control Valve Control Solenoid Valve

(Cont'd)

EC-162

Page 315 of 1659

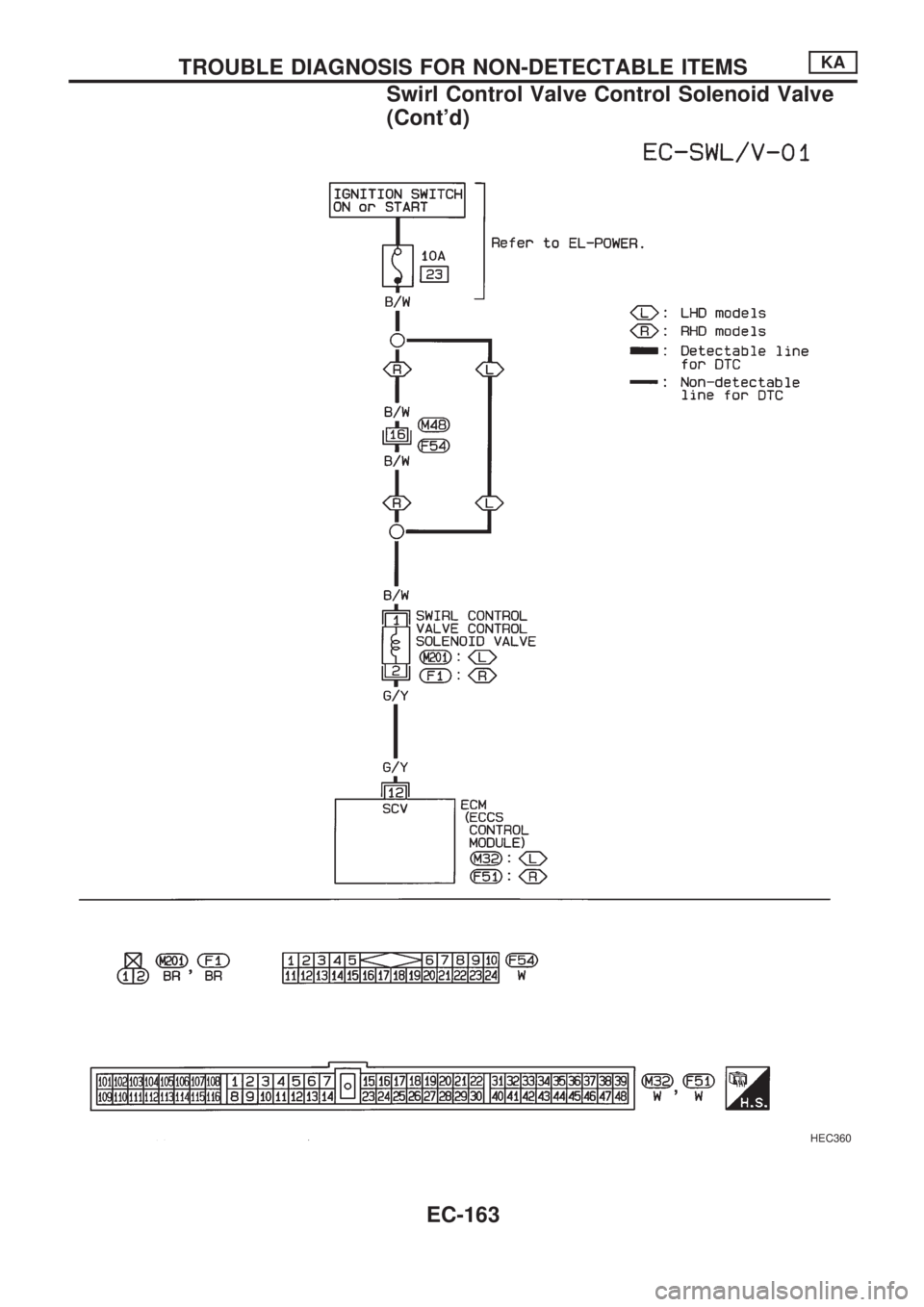

HEC360

TROUBLE DIAGNOSIS FOR NON-DETECTABLE ITEMSKA

Swirl Control Valve Control Solenoid Valve

(Cont'd)

EC-163

Page 316 of 1659

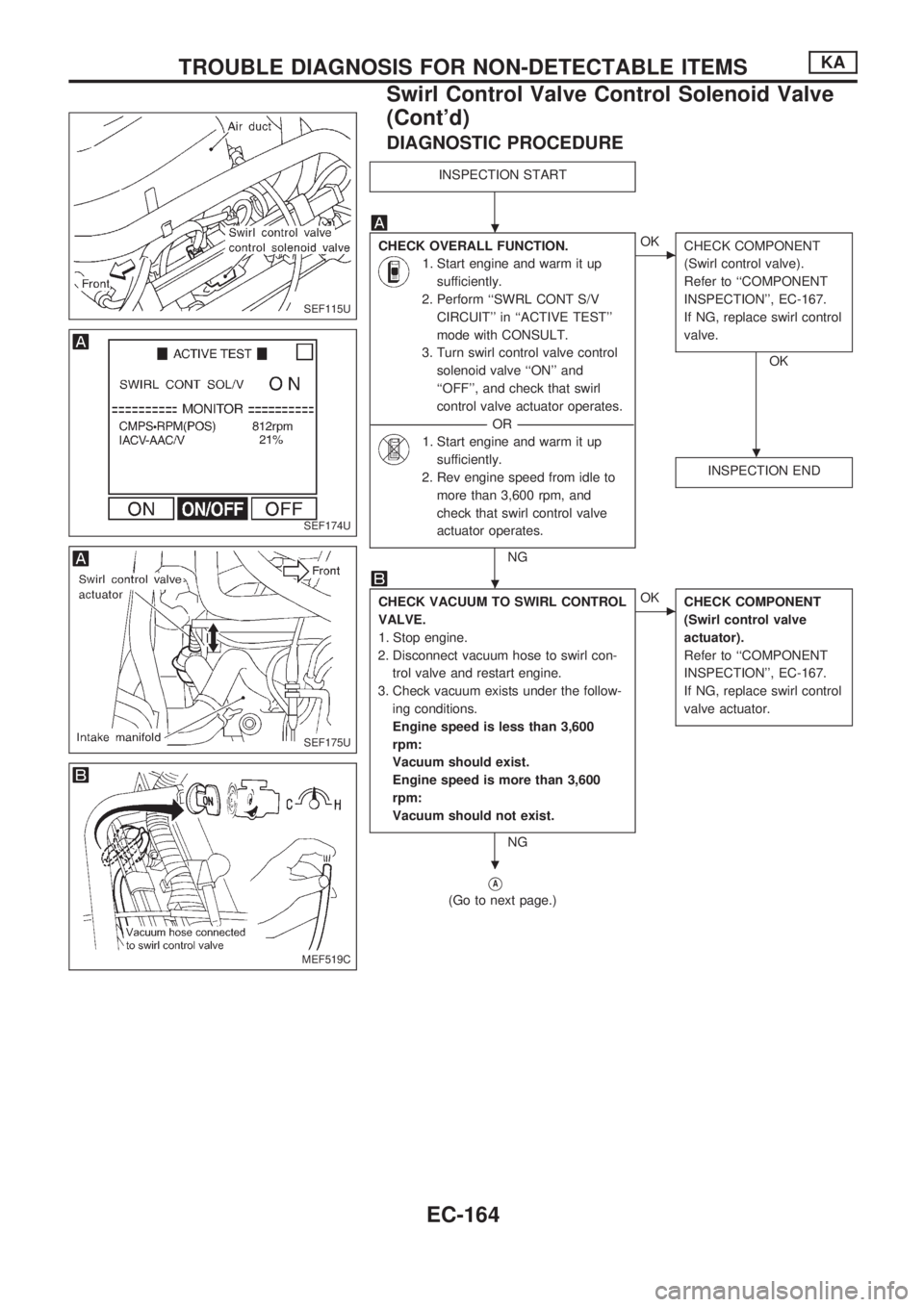

DIAGNOSTIC PROCEDURE

INSPECTION START

CHECK OVERALL FUNCTION.

1. Start engine and warm it up

sufficiently.

2. Perform ``SWRL CONT S/V

CIRCUIT'' in ``ACTIVE TEST''

mode with CONSULT.

3. Turn swirl control valve control

solenoid valve ``ON'' and

``OFF'', and check that swirl

control valve actuator operates.

----------------------------------------------------------------------------------------------------------------------------------OR----------------------------------------------------------------------------------------------------------------------------------

1. Start engine and warm it up

sufficiently.

2. Rev engine speed from idle to

more than 3,600 rpm, and

check that swirl control valve

actuator operates.

NG

cOK

CHECK COMPONENT

(Swirl control valve).

Refer to ``COMPONENT

INSPECTION'', EC-167.

If NG, replace swirl control

valve.

OK

INSPECTION END

CHECK VACUUM TO SWIRL CONTROL

VALVE.

1. Stop engine.

2. Disconnect vacuum hose to swirl con-

trol valve and restart engine.

3. Check vacuum exists under the follow-

ing conditions.

Engine speed is less than 3,600

rpm:

Vacuum should exist.

Engine speed is more than 3,600

rpm:

Vacuum should not exist.

NG

cOK

CHECK COMPONENT

(Swirl control valve

actuator).

Refer to ``COMPONENT

INSPECTION'', EC-167.

If NG, replace swirl control

valve actuator.

VA

(Go to next page.)

SEF115U

SEF174U

SEF175U

MEF519C

.

.

.

.

TROUBLE DIAGNOSIS FOR NON-DETECTABLE ITEMSKA

Swirl Control Valve Control Solenoid Valve

(Cont'd)

EC-164

Page 317 of 1659

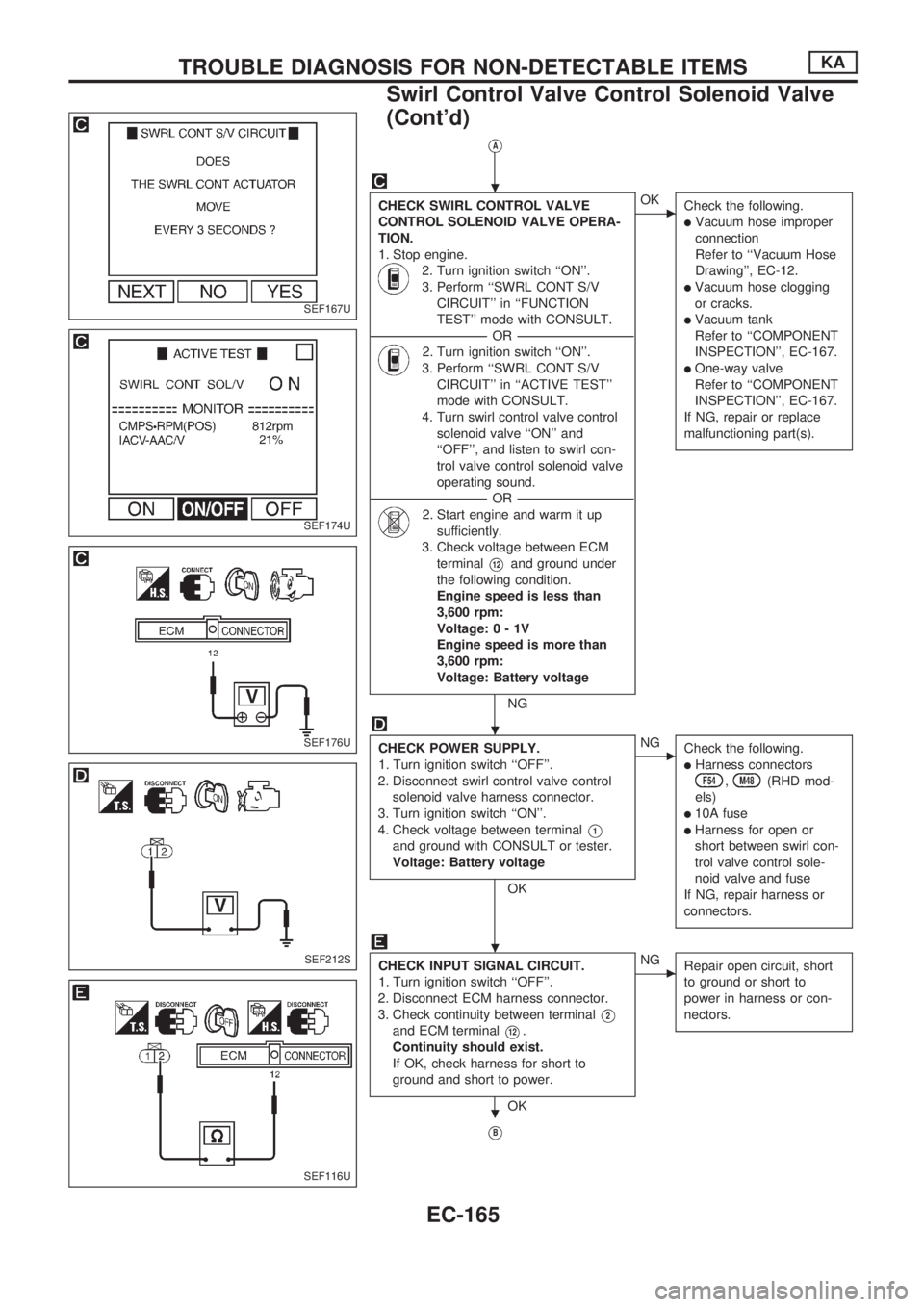

VA

CHECK SWIRL CONTROL VALVE

CONTROL SOLENOID VALVE OPERA-

TION.

1. Stop engine.

2. Turn ignition switch ``ON''.

3. Perform ``SWRL CONT S/V

CIRCUIT'' in ``FUNCTION

TEST'' mode with CONSULT.

----------------------------------------------------------------------------------------------------------------------------------OR----------------------------------------------------------------------------------------------------------------------------------

2. Turn ignition switch ``ON''.

3. Perform ``SWRL CONT S/V

CIRCUIT'' in ``ACTIVE TEST''

mode with CONSULT.

4. Turn swirl control valve control

solenoid valve ``ON'' and

``OFF'', and listen to swirl con-

trol valve control solenoid valve

operating sound.

----------------------------------------------------------------------------------------------------------------------------------OR----------------------------------------------------------------------------------------------------------------------------------

2. Start engine and warm it up

sufficiently.

3. Check voltage between ECM

terminal

V12and ground under

the following condition.

Engine speed is less than

3,600 rpm:

Voltage:0-1V

Engine speed is more than

3,600 rpm:

Voltage: Battery voltage

NG

cOK

Check the following.

lVacuum hose improper

connection

Refer to ``Vacuum Hose

Drawing'', EC-12.

lVacuum hose clogging

or cracks.

lVacuum tank

Refer to ``COMPONENT

INSPECTION'', EC-167.

lOne-way valve

Refer to ``COMPONENT

INSPECTION'', EC-167.

If NG, repair or replace

malfunctioning part(s).

CHECK POWER SUPPLY.

1. Turn ignition switch ``OFF''.

2. Disconnect swirl control valve control

solenoid valve harness connector.

3. Turn ignition switch ``ON''.

4. Check voltage between terminal

V1

and ground with CONSULT or tester.

Voltage: Battery voltage

OK

cNG

Check the following.

lHarness connectorsF54,M48(RHD mod-

els)

l10A fuse

lHarness for open or

short between swirl con-

trol valve control sole-

noid valve and fuse

If NG, repair harness or

connectors.

CHECK INPUT SIGNAL CIRCUIT.

1. Turn ignition switch ``OFF''.

2. Disconnect ECM harness connector.

3. Check continuity between terminal

V2

and ECM terminalV12.

Continuity should exist.

If OK, check harness for short to

ground and short to power.

OK

cNG

Repair open circuit, short

to ground or short to

power in harness or con-

nectors.

VB

SEF167U

SEF174U

SEF176U

SEF212S

SEF116U

.

.

.

.

TROUBLE DIAGNOSIS FOR NON-DETECTABLE ITEMSKA

Swirl Control Valve Control Solenoid Valve

(Cont'd)

EC-165

Page 318 of 1659

VB

Disconnect and reconnect harness con-

nectors in the circuit. Then retest.

Trouble is not fixed.

Check ECM pin terminals for damage

and check the connection for ECM har-

ness connector. Reconnect ECM harness

connector and retest.

INSPECTION END

.

.

.

TROUBLE DIAGNOSIS FOR NON-DETECTABLE ITEMSKA

Swirl Control Valve Control Solenoid Valve

(Cont'd)

EC-166

Page 319 of 1659

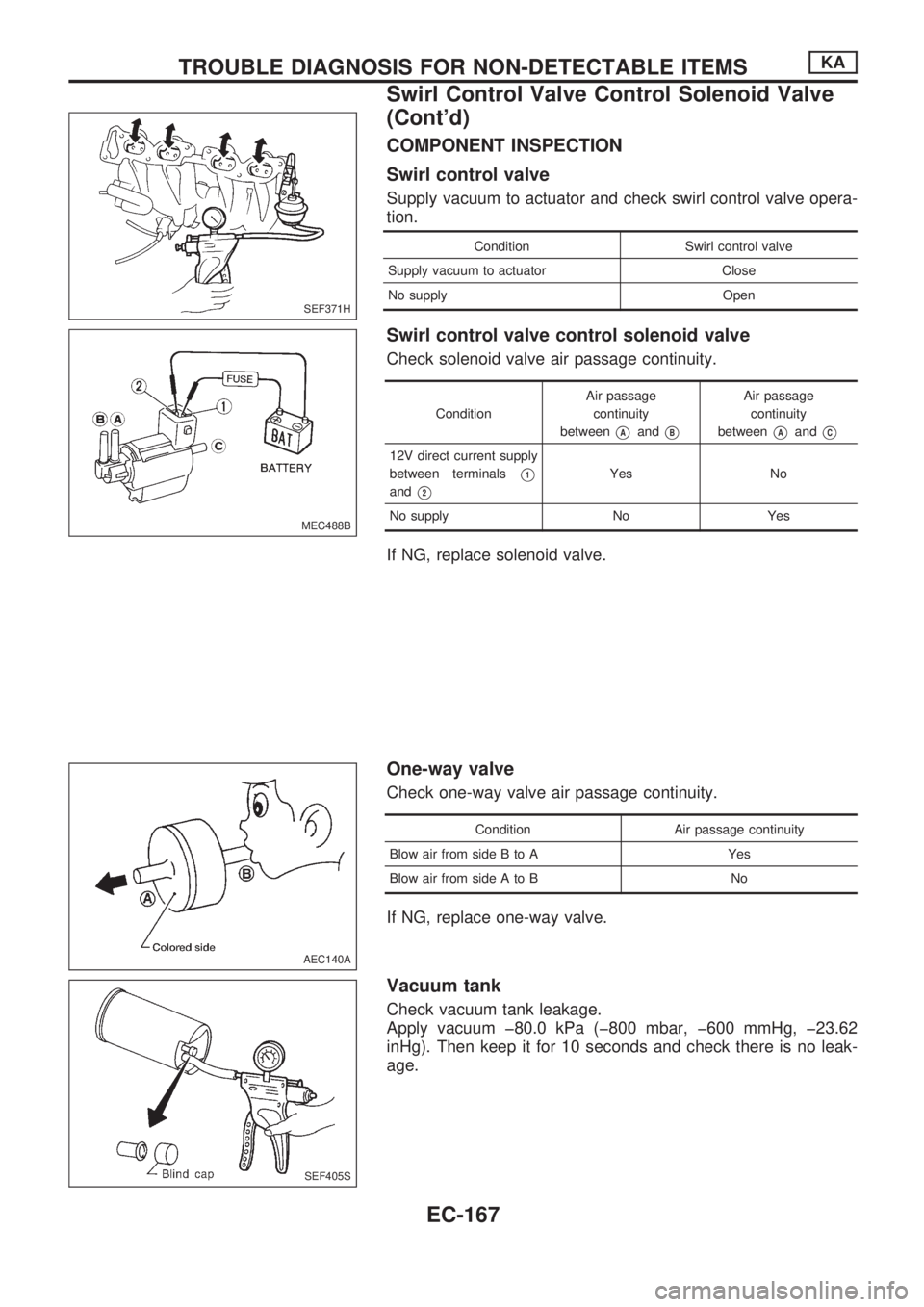

COMPONENT INSPECTION

Swirl control valve

Supply vacuum to actuator and check swirl control valve opera-

tion.

Condition Swirl control valve

Supply vacuum to actuator Close

No supply Open

Swirl control valve control solenoid valve

Check solenoid valve air passage continuity.

ConditionAir passage

continuity

between

VAandVB

Air passage

continuity

between

VAandVC

12V direct current supply

between terminals

V1

andV2

Yes No

No supply No Yes

If NG, replace solenoid valve.

One-way valve

Check one-way valve air passage continuity.

Condition Air passage continuity

Blow air from side B to A Yes

Blow air from side A to B No

If NG, replace one-way valve.

Vacuum tank

Check vacuum tank leakage.

Apply vacuum þ80.0 kPa (þ800 mbar, þ600 mmHg, þ23.62

inHg). Then keep it for 10 seconds and check there is no leak-

age.

SEF371H

MEC488B

AEC140A

SEF405S

TROUBLE DIAGNOSIS FOR NON-DETECTABLE ITEMSKA

Swirl Control Valve Control Solenoid Valve

(Cont'd)

EC-167

Page 320 of 1659

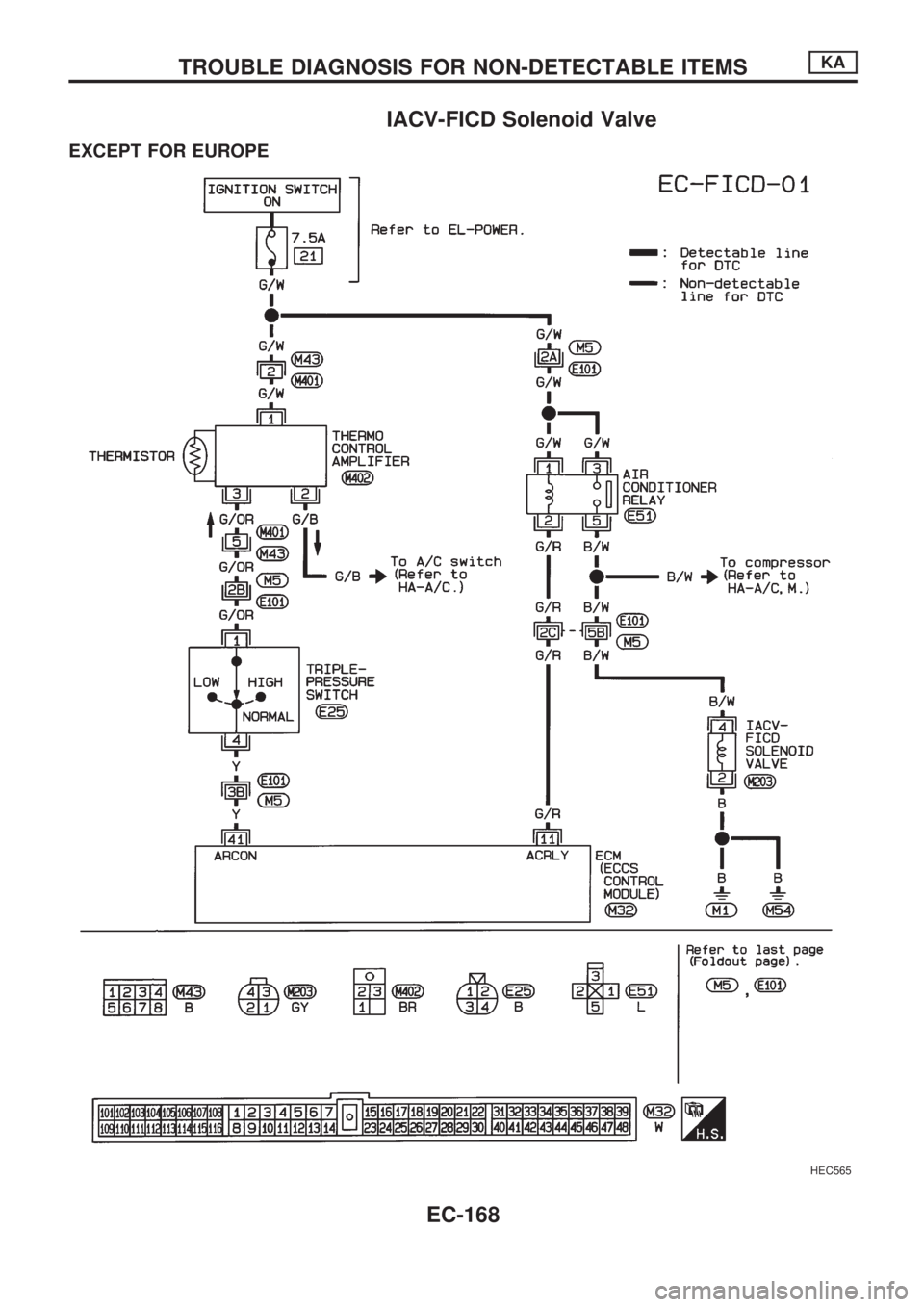

IACV-FICD Solenoid Valve

EXCEPT FOR EUROPE

HEC565

TROUBLE DIAGNOSIS FOR NON-DETECTABLE ITEMSKA

EC-168