NISSAN PICK-UP 1998 Repair Manual

Manufacturer: NISSAN, Model Year: 1998, Model line: PICK-UP, Model: NISSAN PICK-UP 1998Pages: 1659, PDF Size: 53.39 MB

Page 291 of 1659

VA

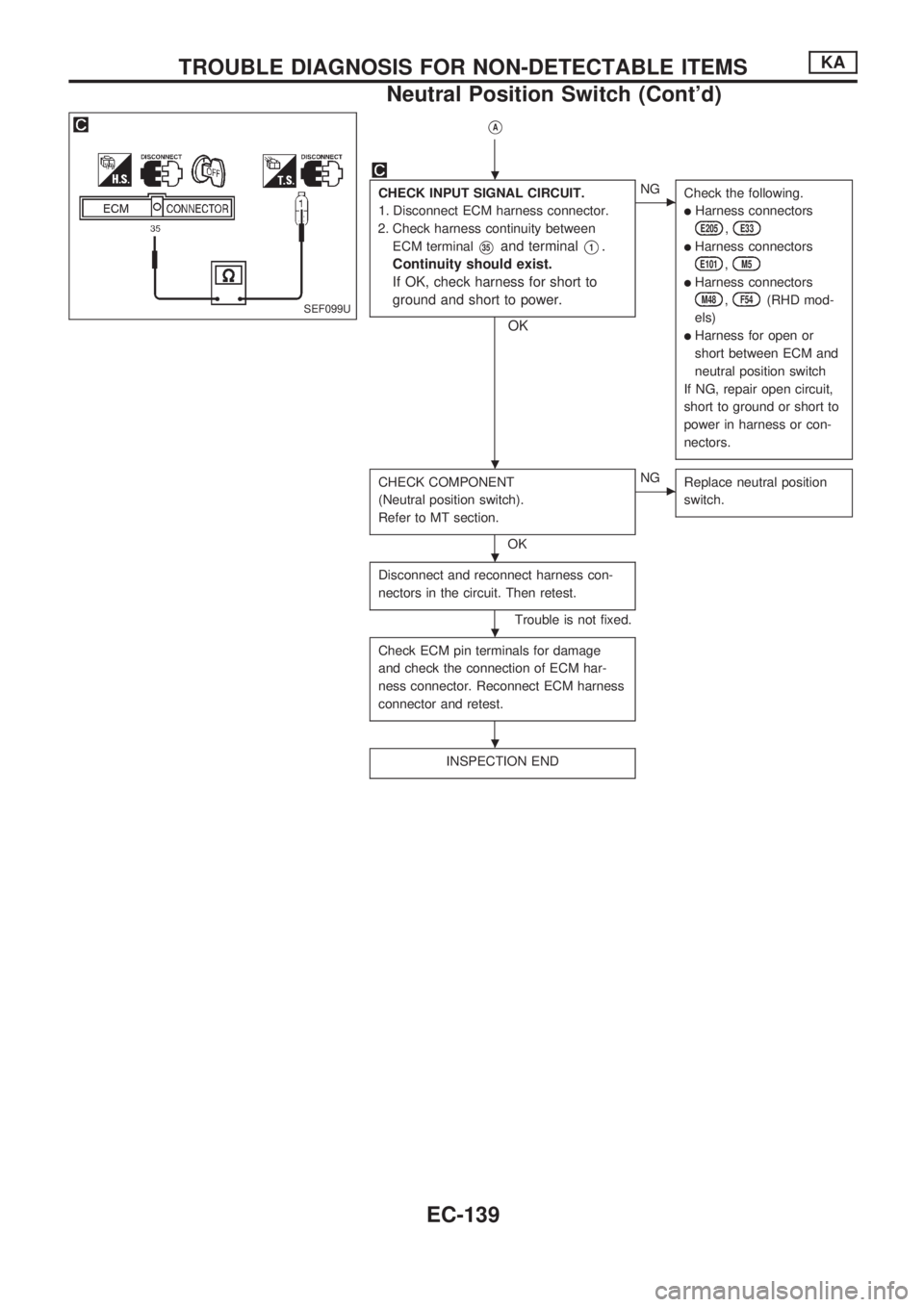

CHECK INPUT SIGNAL CIRCUIT.

1. Disconnect ECM harness connector.

2. Check harness continuity between

ECM terminal

V35and terminalV1.

Continuity should exist.

If OK, check harness for short to

ground and short to power.

OK

cNG

Check the following.

lHarness connectors

E205,E33

lHarness connectors

E101,M5

lHarness connectors

M48,F54(RHD mod-

els)

lHarness for open or

short between ECM and

neutral position switch

If NG, repair open circuit,

short to ground or short to

power in harness or con-

nectors.

CHECK COMPONENT

(Neutral position switch).

Refer to MT section.

OK

cNG

Replace neutral position

switch.

Disconnect and reconnect harness con-

nectors in the circuit. Then retest.

Trouble is not fixed.

Check ECM pin terminals for damage

and check the connection of ECM har-

ness connector. Reconnect ECM harness

connector and retest.

INSPECTION END

SEF099U

.

.

.

.

.

TROUBLE DIAGNOSIS FOR NON-DETECTABLE ITEMSKA

Neutral Position Switch (Cont'd)

EC-139

Page 292 of 1659

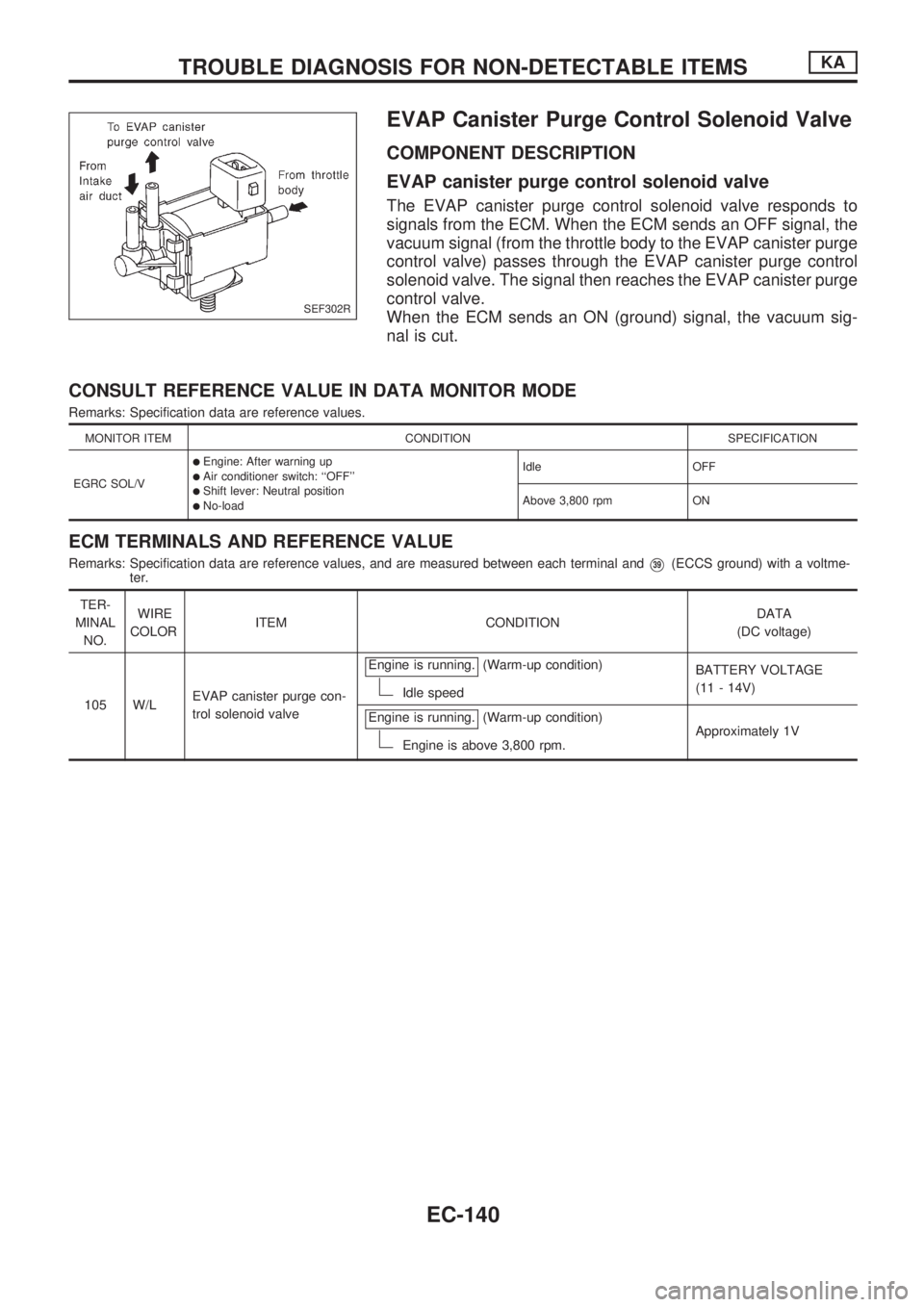

EVAP Canister Purge Control Solenoid Valve

COMPONENT DESCRIPTION

EVAP canister purge control solenoid valve

The EVAP canister purge control solenoid valve responds to

signals from the ECM. When the ECM sends an OFF signal, the

vacuum signal (from the throttle body to the EVAP canister purge

control valve) passes through the EVAP canister purge control

solenoid valve. The signal then reaches the EVAP canister purge

control valve.

When the ECM sends an ON (ground) signal, the vacuum sig-

nal is cut.

CONSULT REFERENCE VALUE IN DATA MONITOR MODE

Remarks: Specification data are reference values.

MONITOR ITEM CONDITION SPECIFICATION

EGRC SOL/V

lEngine: After warning uplAir conditioner switch: ``OFF''lShift lever: Neutral positionlNo-loadIdle OFF

Above 3,800 rpm ON

ECM TERMINALS AND REFERENCE VALUE

Remarks: Specification data are reference values, and are measured between each terminal andV39(ECCS ground) with a voltme-

ter.

TER-

MINAL

NO.WIRE

COLORITEM CONDITIONDATA

(DC voltage)

105 W/LEVAP canister purge con-

trol solenoid valveEngine is running.

(Warm-up condition)

Idle speedBATTERY VOLTAGE

(11 - 14V)

Engine is running.

(Warm-up condition)

Engine is above 3,800 rpm.Approximately 1V

SEF302R

TROUBLE DIAGNOSIS FOR NON-DETECTABLE ITEMSKA

EC-140

Page 293 of 1659

HEC358

TROUBLE DIAGNOSIS FOR NON-DETECTABLE ITEMSKA

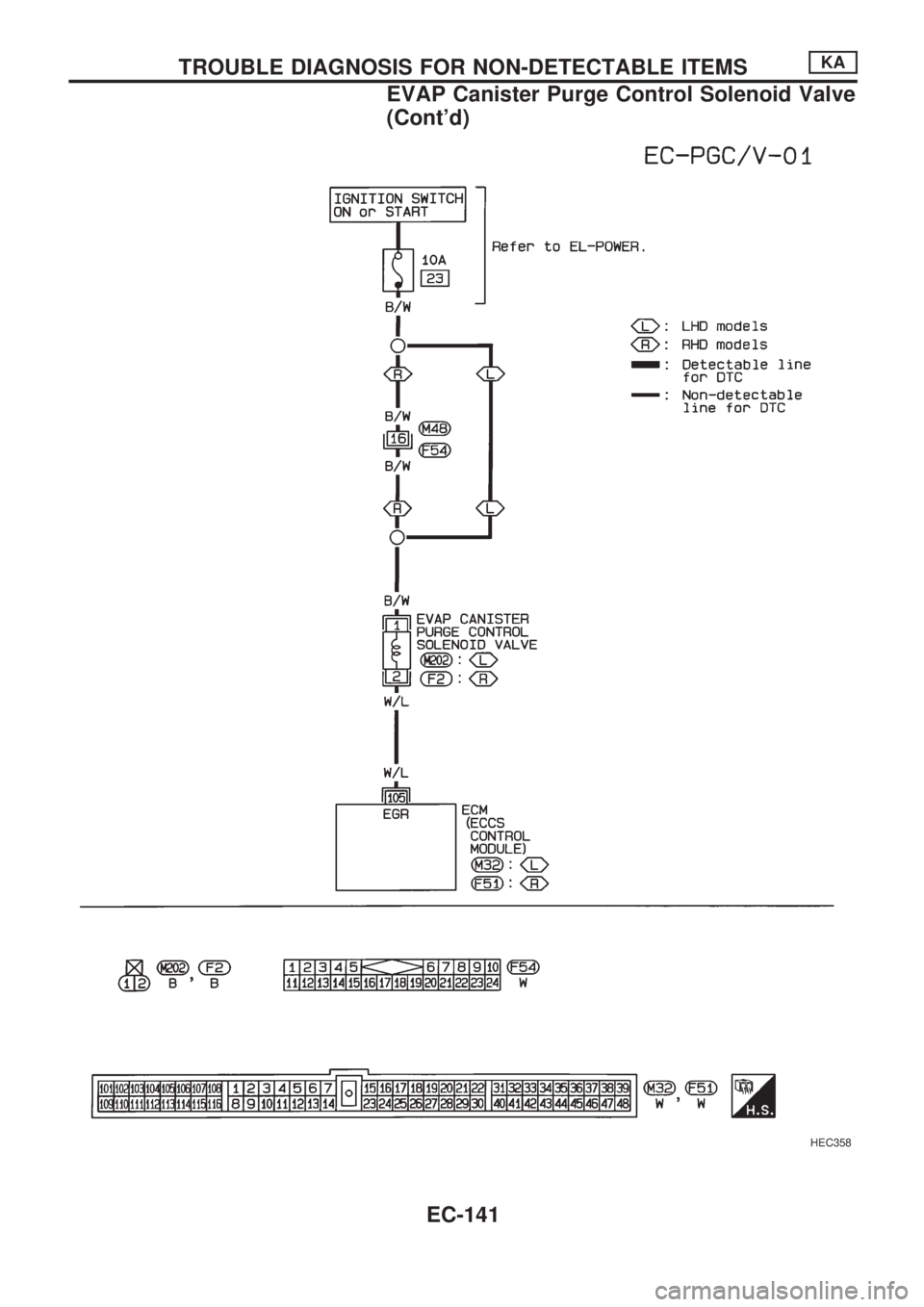

EVAP Canister Purge Control Solenoid Valve

(Cont'd)

EC-141

Page 294 of 1659

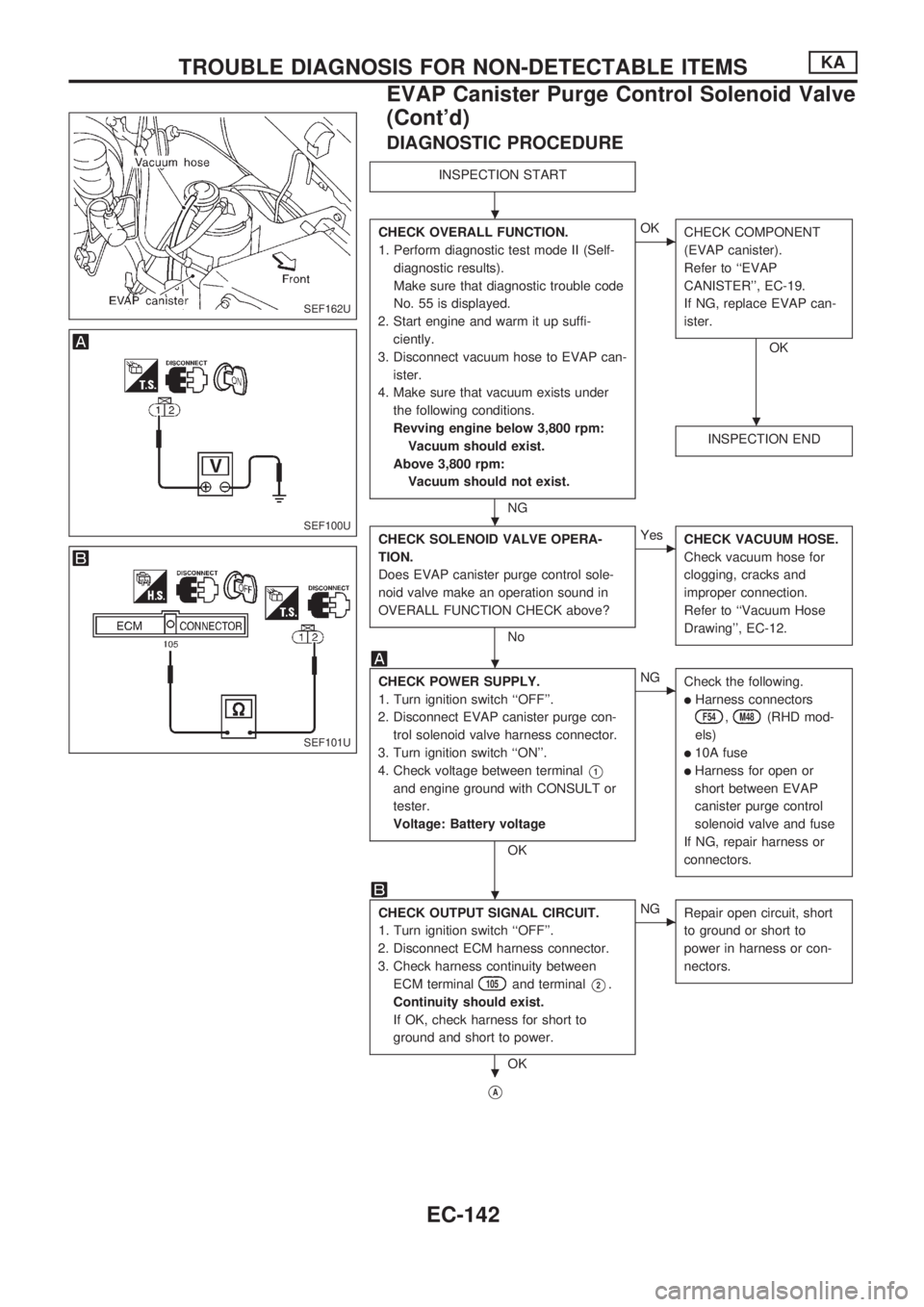

DIAGNOSTIC PROCEDURE

INSPECTION START

CHECK OVERALL FUNCTION.

1. Perform diagnostic test mode II (Self-

diagnostic results).

Make sure that diagnostic trouble code

No. 55 is displayed.

2. Start engine and warm it up suffi-

ciently.

3. Disconnect vacuum hose to EVAP can-

ister.

4. Make sure that vacuum exists under

the following conditions.

Revving engine below 3,800 rpm:

Vacuum should exist.

Above 3,800 rpm:

Vacuum should not exist.

NG

cOK

CHECK COMPONENT

(EVAP canister).

Refer to ``EVAP

CANISTER'', EC-19.

If NG, replace EVAP can-

ister.

OK

INSPECTION END

CHECK SOLENOID VALVE OPERA-

TION.

Does EVAP canister purge control sole-

noid valve make an operation sound in

OVERALL FUNCTION CHECK above?

No

cYes

CHECK VACUUM HOSE.

Check vacuum hose for

clogging, cracks and

improper connection.

Refer to ``Vacuum Hose

Drawing'', EC-12.

CHECK POWER SUPPLY.

1. Turn ignition switch ``OFF''.

2. Disconnect EVAP canister purge con-

trol solenoid valve harness connector.

3. Turn ignition switch ``ON''.

4. Check voltage between terminal

V1

and engine ground with CONSULT or

tester.

Voltage: Battery voltage

OK

cNG

Check the following.

lHarness connectors

F54,M48(RHD mod-

els)

l10A fuse

lHarness for open or

short between EVAP

canister purge control

solenoid valve and fuse

If NG, repair harness or

connectors.

CHECK OUTPUT SIGNAL CIRCUIT.

1. Turn ignition switch ``OFF''.

2. Disconnect ECM harness connector.

3. Check harness continuity between

ECM terminal

105and terminalV2.

Continuity should exist.

If OK, check harness for short to

ground and short to power.

OK

cNG

Repair open circuit, short

to ground or short to

power in harness or con-

nectors.

VA

SEF162U

SEF100U

SEF101U

.

.

.

.

.

.

TROUBLE DIAGNOSIS FOR NON-DETECTABLE ITEMSKA

EVAP Canister Purge Control Solenoid Valve

(Cont'd)

EC-142

Page 295 of 1659

VA

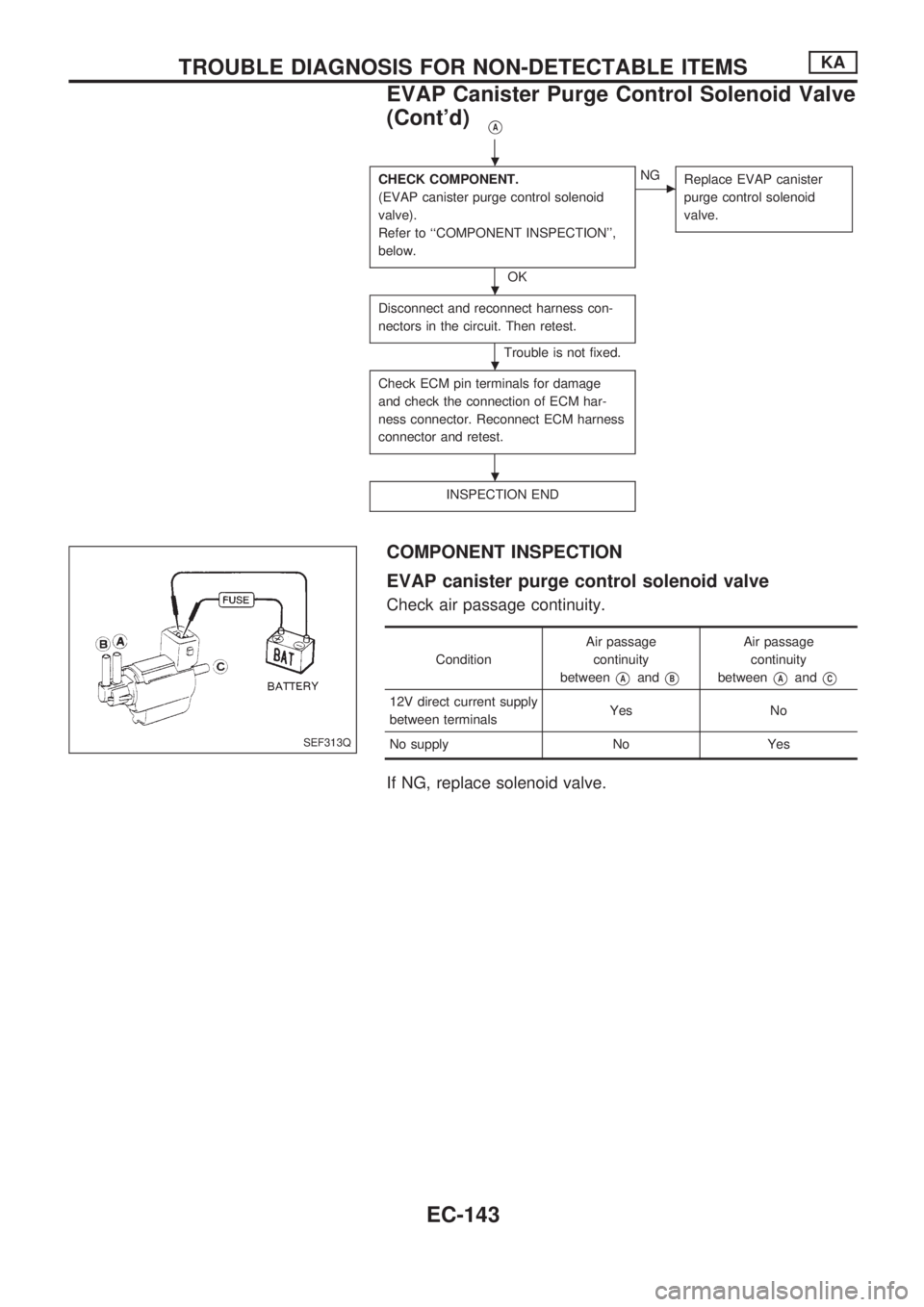

CHECK COMPONENT.

(EVAP canister purge control solenoid

valve).

Refer to ``COMPONENT INSPECTION'',

below.

OK

cNG

Replace EVAP canister

purge control solenoid

valve.

Disconnect and reconnect harness con-

nectors in the circuit. Then retest.

Trouble is not fixed.

Check ECM pin terminals for damage

and check the connection of ECM har-

ness connector. Reconnect ECM harness

connector and retest.

INSPECTION END

COMPONENT INSPECTION

EVAP canister purge control solenoid valve

Check air passage continuity.

ConditionAir passage

continuity

between

VAandVB

Air passage

continuity

between

VAandVC

12V direct current supply

between terminalsYes No

No supply No Yes

If NG, replace solenoid valve.

SEF313Q

.

.

.

.

TROUBLE DIAGNOSIS FOR NON-DETECTABLE ITEMSKA

EVAP Canister Purge Control Solenoid Valve

(Cont'd)

EC-143

Page 296 of 1659

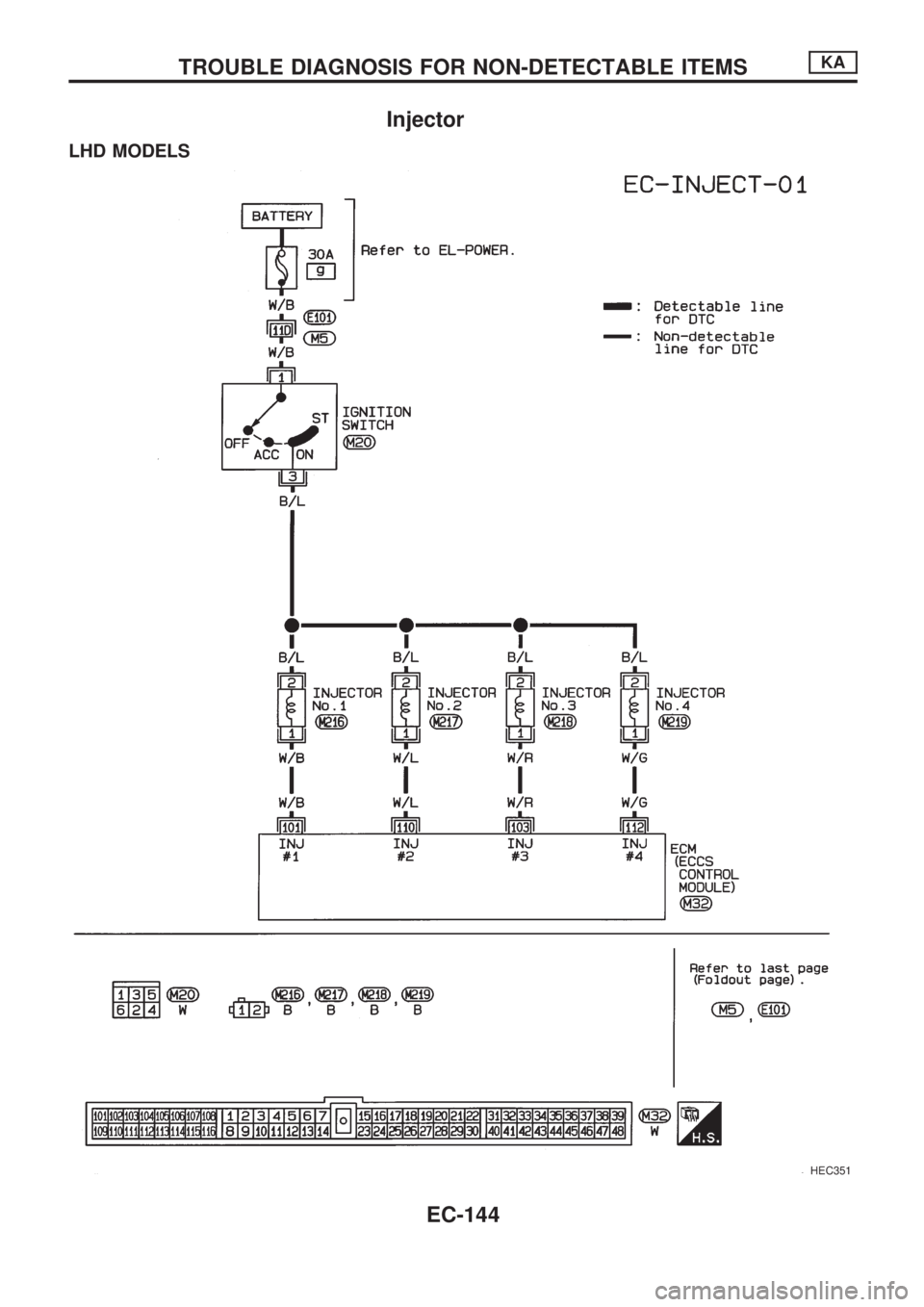

Injector

LHD MODELS

HEC351

TROUBLE DIAGNOSIS FOR NON-DETECTABLE ITEMSKA

EC-144

Page 297 of 1659

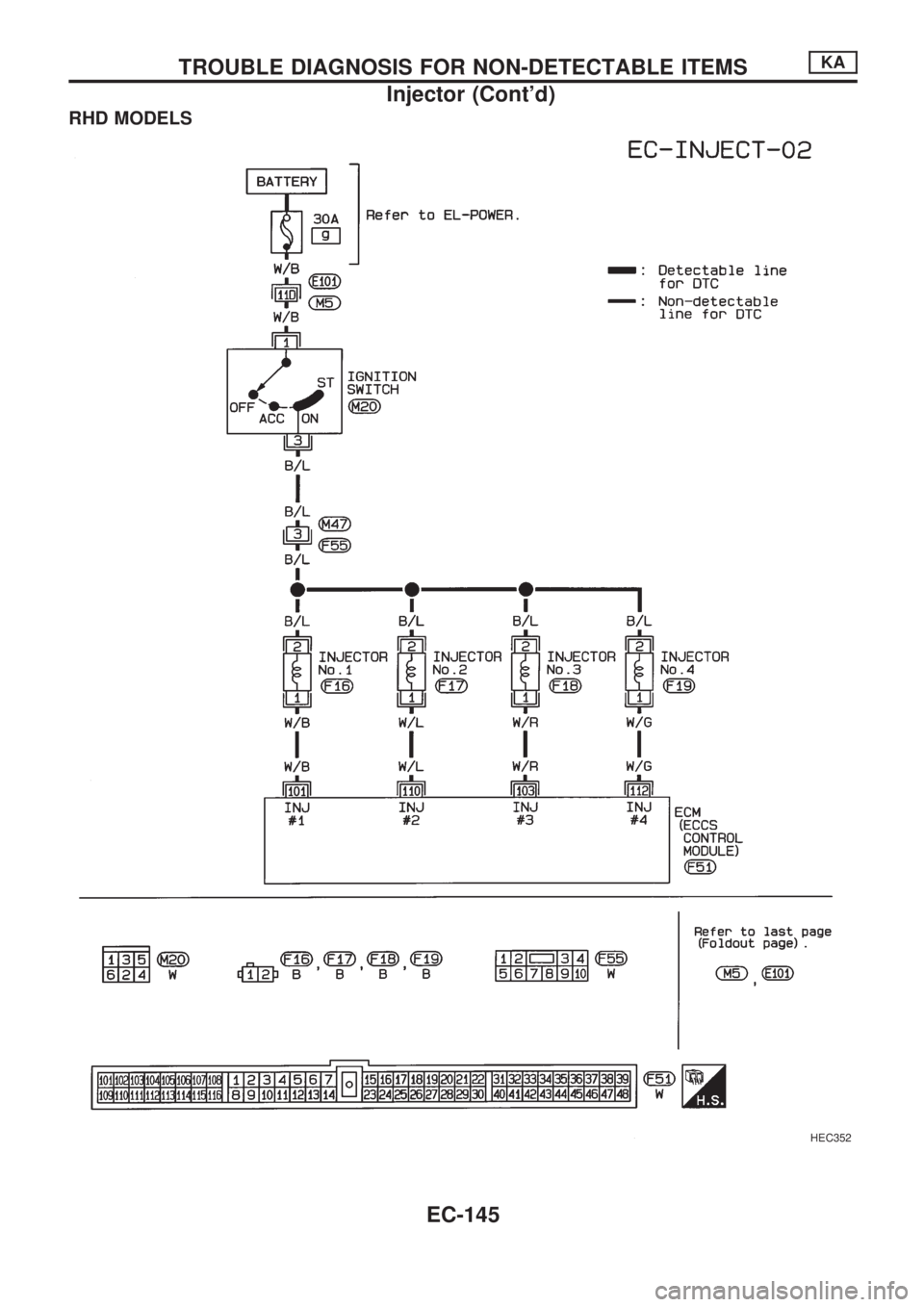

RHD MODELS

HEC352

TROUBLE DIAGNOSIS FOR NON-DETECTABLE ITEMSKA

Injector (Cont'd)

EC-145

Page 298 of 1659

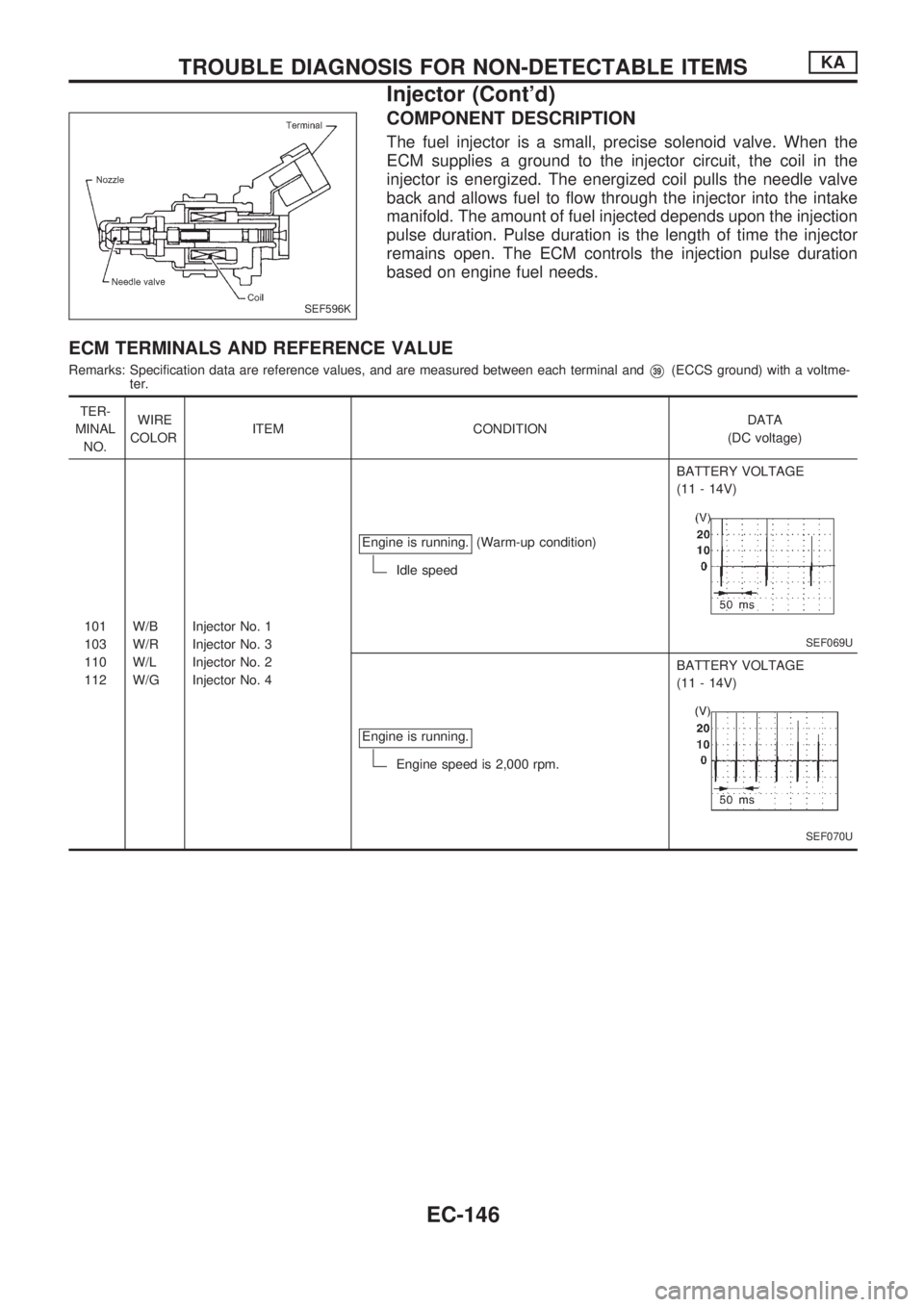

COMPONENT DESCRIPTION

The fuel injector is a small, precise solenoid valve. When the

ECM supplies a ground to the injector circuit, the coil in the

injector is energized. The energized coil pulls the needle valve

back and allows fuel to flow through the injector into the intake

manifold. The amount of fuel injected depends upon the injection

pulse duration. Pulse duration is the length of time the injector

remains open. The ECM controls the injection pulse duration

based on engine fuel needs.

ECM TERMINALS AND REFERENCE VALUE

Remarks: Specification data are reference values, and are measured between each terminal andV39(ECCS ground) with a voltme-

ter.

TER-

MINAL

NO.WIRE

COLORITEM CONDITIONDATA

(DC voltage)

101

103

110

112W/B

W/R

W/L

W/GInjector No. 1

Injector No. 3

Injector No. 2

Injector No. 4Engine is running.

(Warm-up condition)

Idle speedBATTERY VOLTAGE

(11 - 14V)

SEF069U

Engine is running.

Engine speed is 2,000 rpm.BATTERY VOLTAGE

(11 - 14V)

SEF070U

SEF596K

TROUBLE DIAGNOSIS FOR NON-DETECTABLE ITEMSKA

Injector (Cont'd)

EC-146

Page 299 of 1659

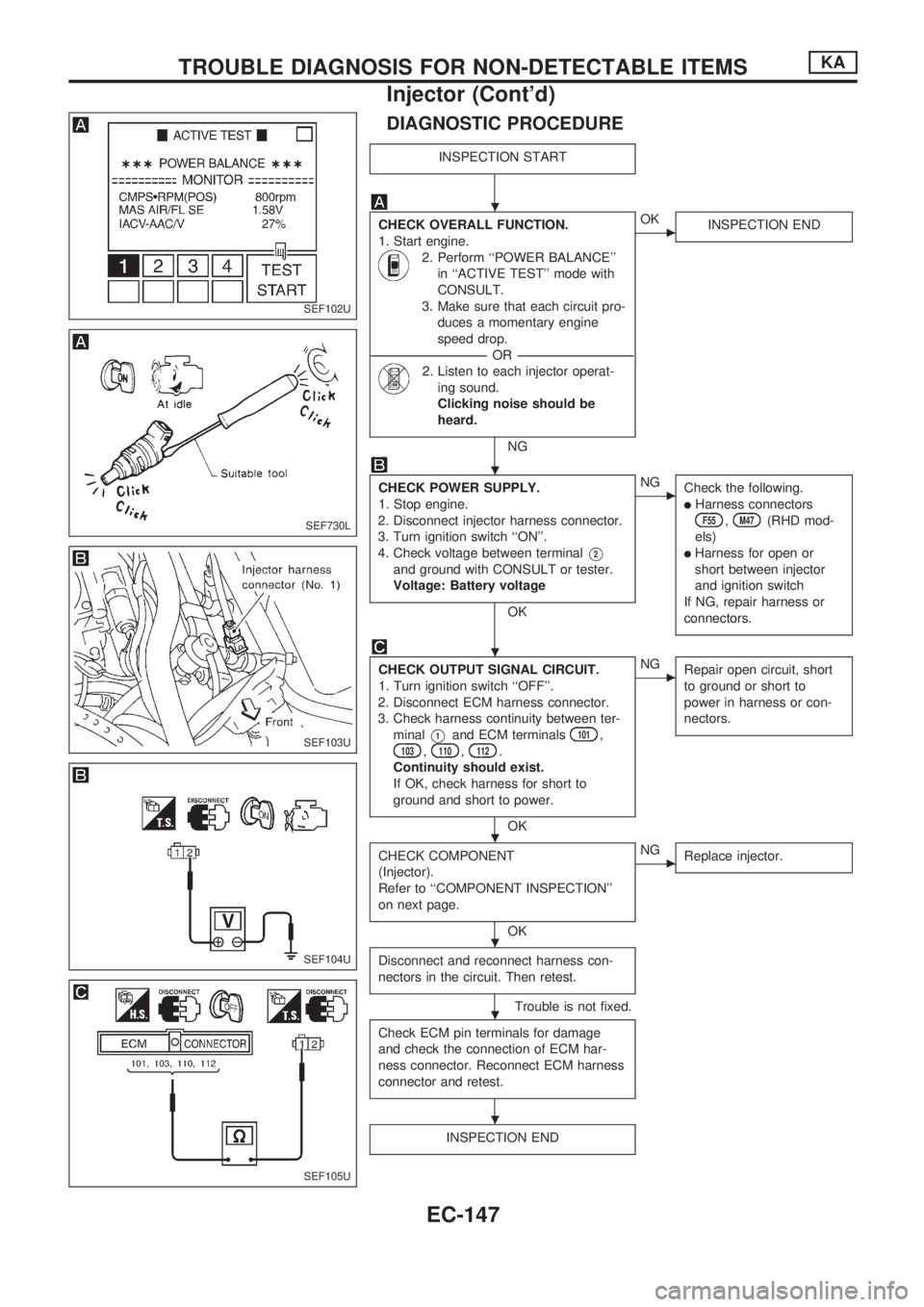

DIAGNOSTIC PROCEDURE

INSPECTION START

CHECK OVERALL FUNCTION.

1. Start engine.

2. Perform ``POWER BALANCE''

in ``ACTIVE TEST'' mode with

CONSULT.

3. Make sure that each circuit pro-

duces a momentary engine

speed drop.

----------------------------------------------------------------------------------------------------------------------------------OR----------------------------------------------------------------------------------------------------------------------------------

2. Listen to each injector operat-

ing sound.

Clicking noise should be

heard.

NG

cOK

INSPECTION END

CHECK POWER SUPPLY.

1. Stop engine.

2. Disconnect injector harness connector.

3. Turn ignition switch ``ON''.

4. Check voltage between terminal

V2

and ground with CONSULT or tester.

Voltage: Battery voltage

OK

cNG

Check the following.

lHarness connectorsF55,M47(RHD mod-

els)

lHarness for open or

short between injector

and ignition switch

If NG, repair harness or

connectors.

CHECK OUTPUT SIGNAL CIRCUIT.

1. Turn ignition switch ``OFF''.

2. Disconnect ECM harness connector.

3. Check harness continuity between ter-

minal

V1and ECM terminals101,103,110,112.

Continuity should exist.

If OK, check harness for short to

ground and short to power.

OK

cNG

Repair open circuit, short

to ground or short to

power in harness or con-

nectors.

CHECK COMPONENT

(Injector).

Refer to ``COMPONENT INSPECTION''

on next page.

OK

cNG

Replace injector.

Disconnect and reconnect harness con-

nectors in the circuit. Then retest.

Trouble is not fixed.

Check ECM pin terminals for damage

and check the connection of ECM har-

ness connector. Reconnect ECM harness

connector and retest.

INSPECTION END

SEF102U

SEF730L

SEF103U

SEF104U

SEF105U

.

.

.

.

.

.

.

TROUBLE DIAGNOSIS FOR NON-DETECTABLE ITEMSKA

Injector (Cont'd)

EC-147

Page 300 of 1659

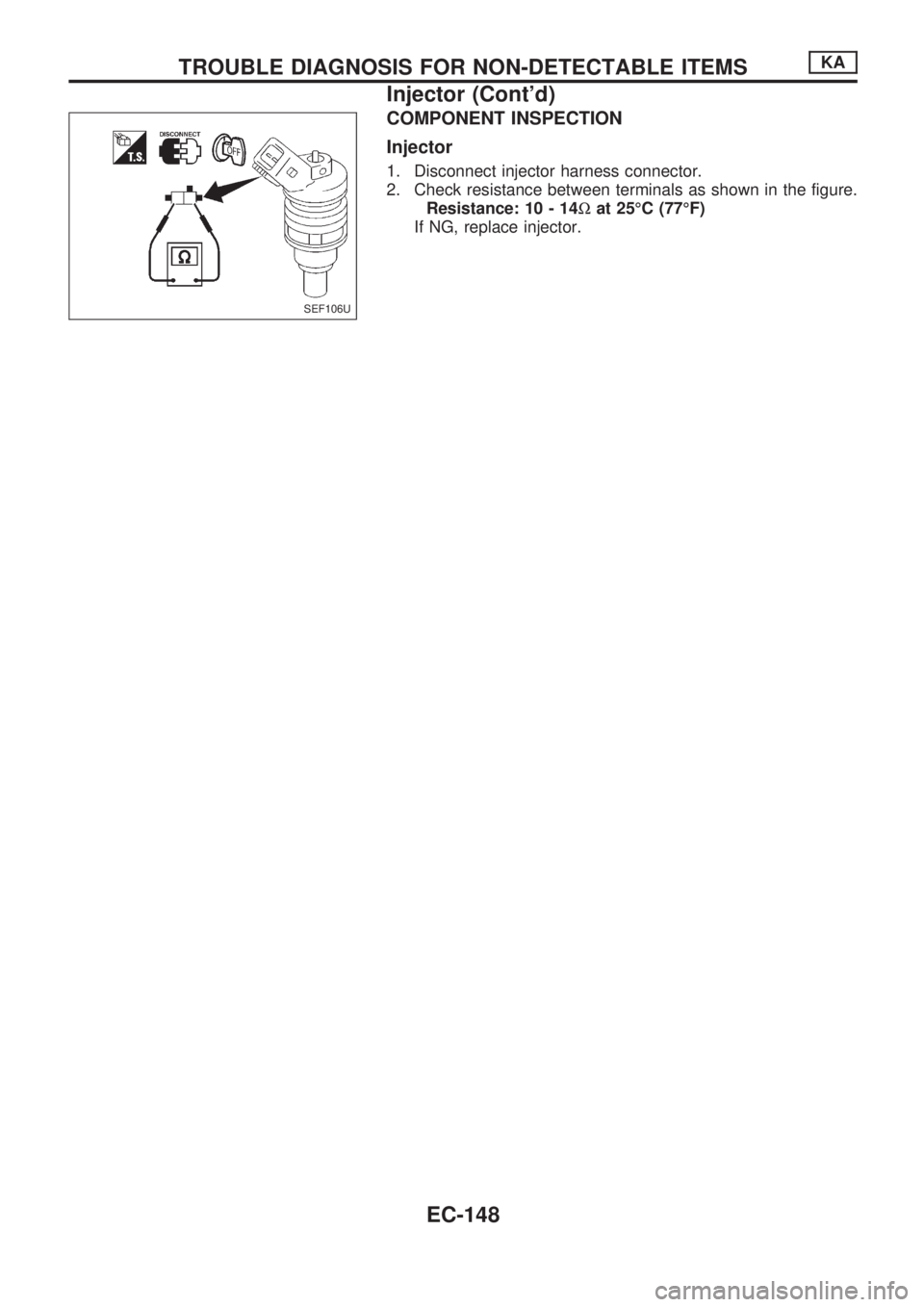

COMPONENT INSPECTION

Injector

1. Disconnect injector harness connector.

2. Check resistance between terminals as shown in the figure.

Resistance: 10 - 14Wat 25ÉC (77ÉF)

If NG, replace injector.

SEF106U

TROUBLE DIAGNOSIS FOR NON-DETECTABLE ITEMSKA

Injector (Cont'd)

EC-148