NISSAN PICK-UP 1998 Repair Manual

Manufacturer: NISSAN, Model Year: 1998, Model line: PICK-UP, Model: NISSAN PICK-UP 1998Pages: 1659, PDF Size: 53.39 MB

Page 641 of 1659

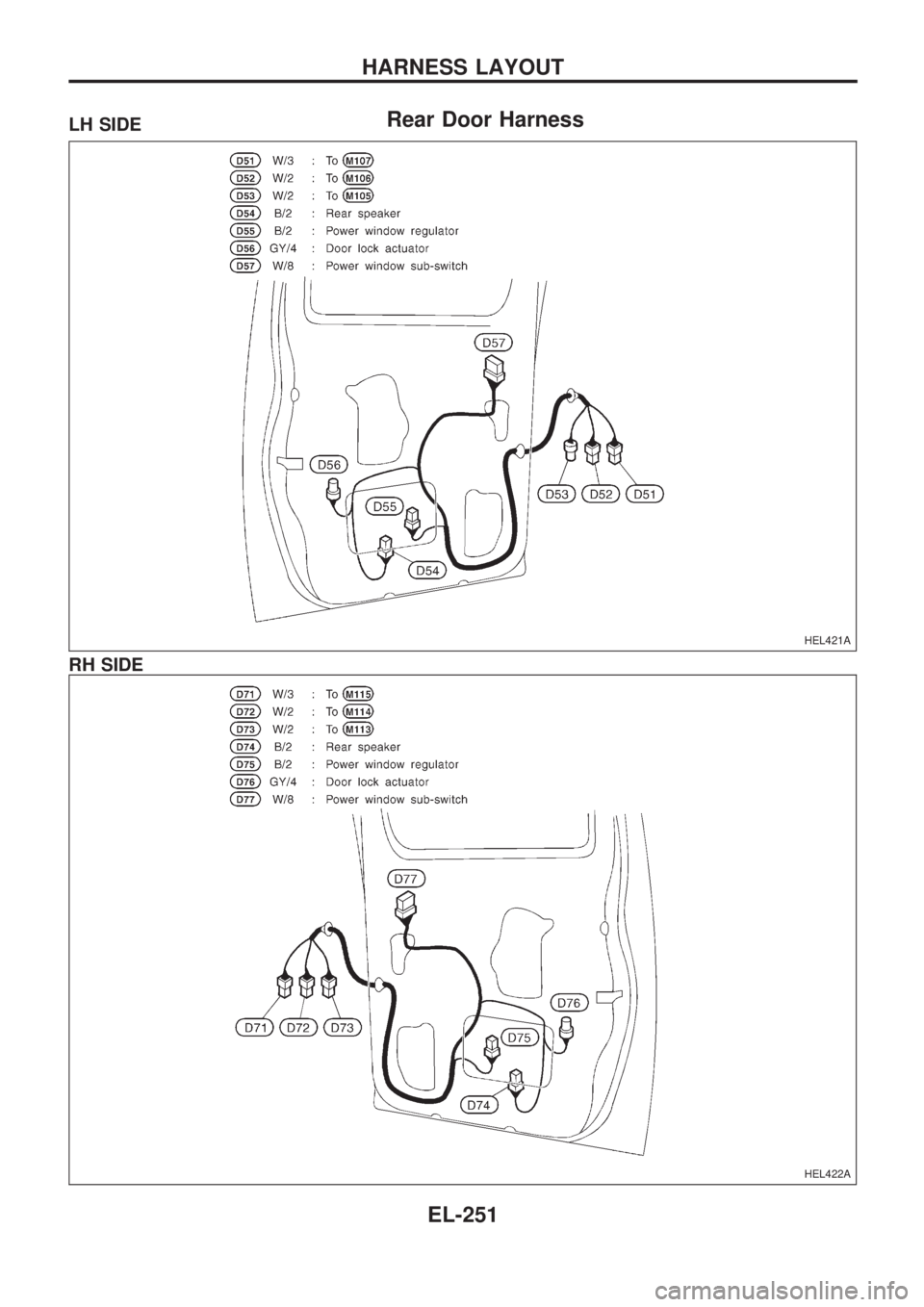

Rear Door HarnessLH SIDE

RH SIDE

HEL421A

HEL422A

HARNESS LAYOUT

EL-251

Page 642 of 1659

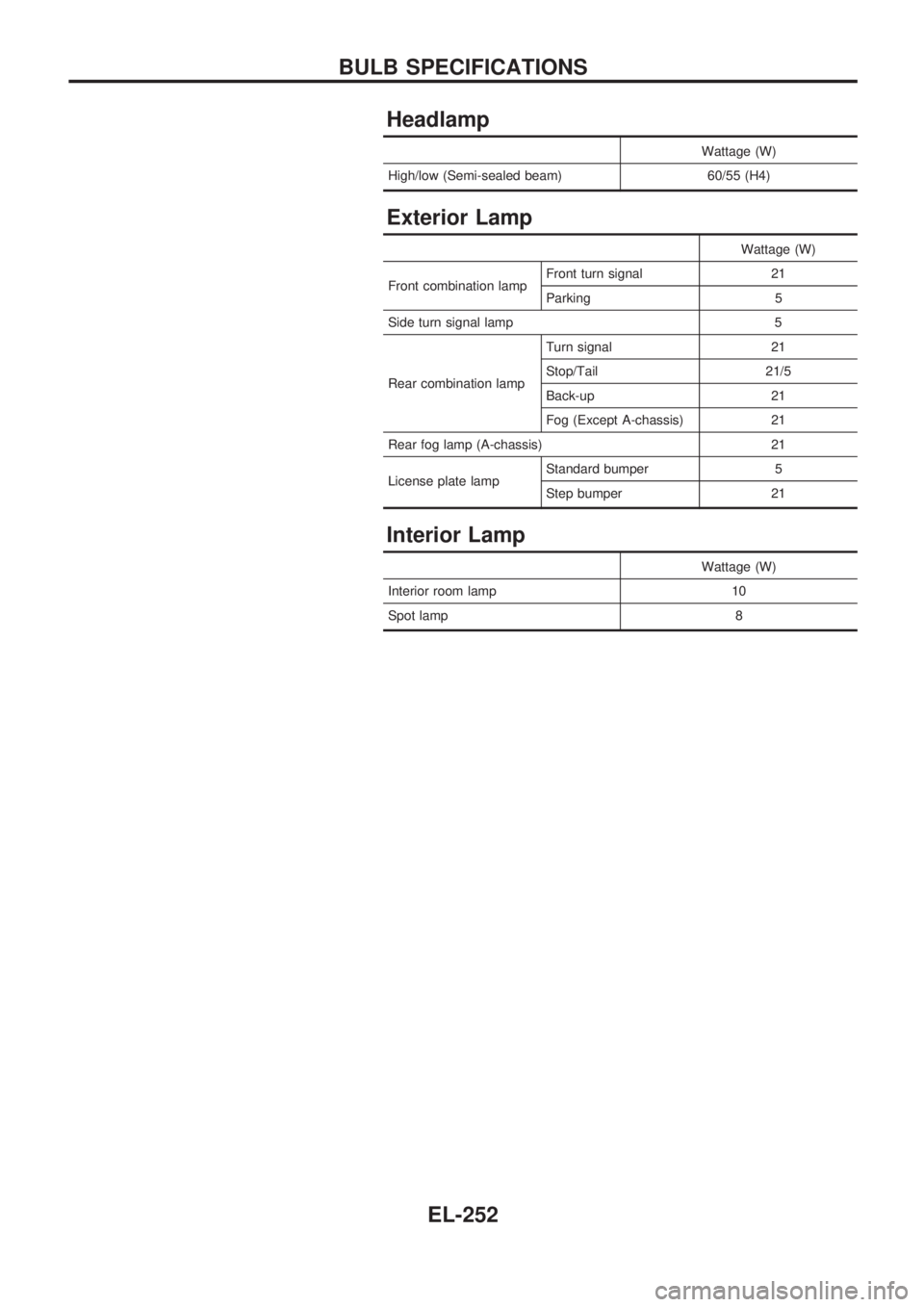

Headlamp

Wattage (W)

High/low (Semi-sealed beam) 60/55 (H4)

Exterior Lamp

Wattage (W)

Front combination lampFront turn signal 21

Parking 5

Side turn signal lamp 5

Rear combination lampTurn signal 21

Stop/Tail 21/5

Back-up 21

Fog (Except A-chassis) 21

Rear fog lamp (A-chassis) 21

License plate lampStandard bumper 5

Step bumper 21

Interior Lamp

Wattage (W)

Interior room lamp 10

Spot lamp 8

BULB SPECIFICATIONS

EL-252

Page 643 of 1659

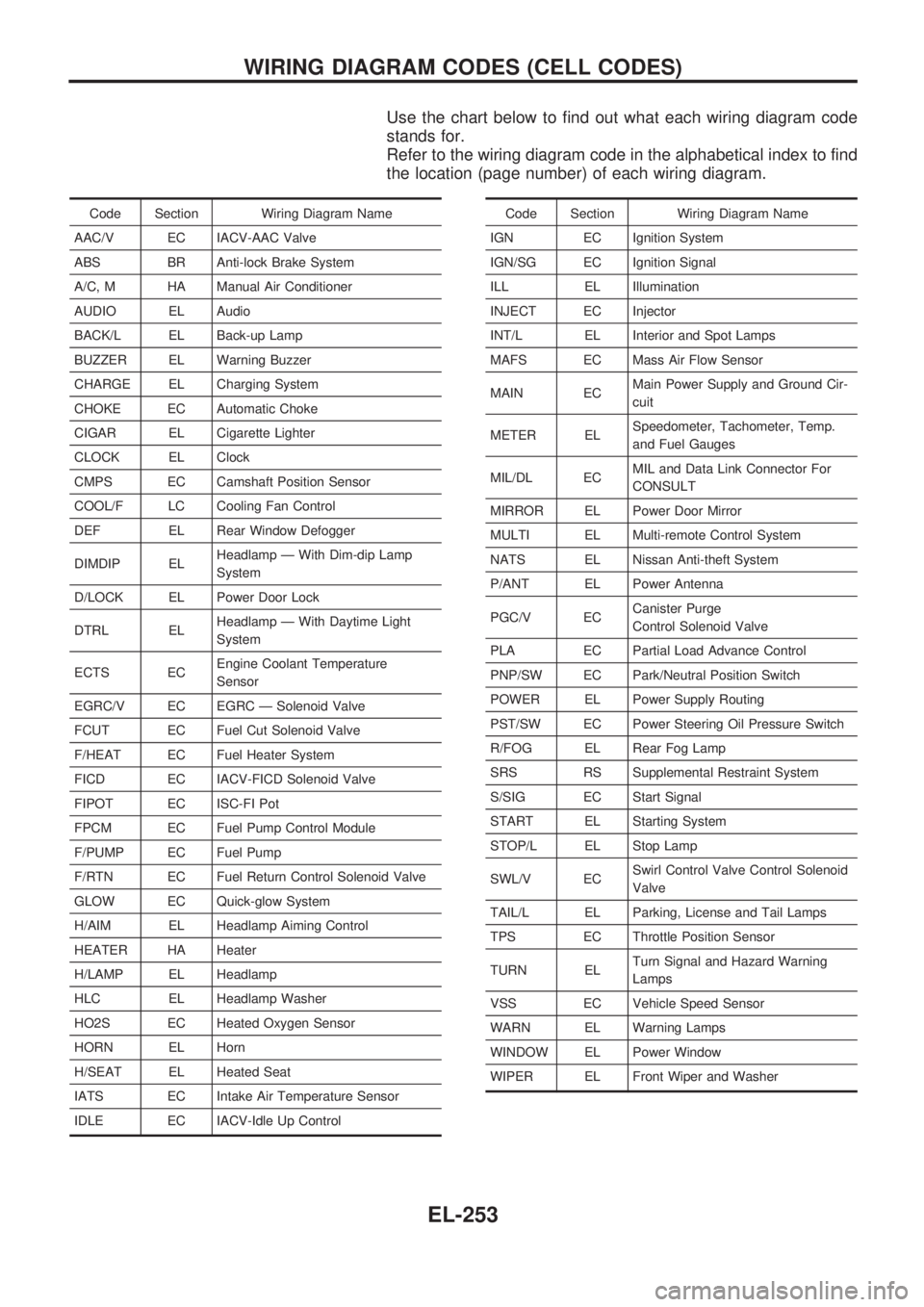

Use the chart below to find out what each wiring diagram code

stands for.

Refer to the wiring diagram code in the alphabetical index to find

the location (page number) of each wiring diagram.

Code Section Wiring Diagram Name

AAC/V EC IACV-AAC Valve

ABS BR Anti-lock Brake System

A/C, M HA Manual Air Conditioner

AUDIO EL Audio

BACK/L EL Back-up Lamp

BUZZER EL Warning Buzzer

CHARGE EL Charging System

CHOKE EC Automatic Choke

CIGAR EL Cigarette Lighter

CLOCK EL Clock

CMPS EC Camshaft Position Sensor

COOL/F LC Cooling Fan Control

DEF EL Rear Window Defogger

DIMDIP ELHeadlamp Ð With Dim-dip Lamp

System

D/LOCK EL Power Door Lock

DTRL ELHeadlamp Ð With Daytime Light

System

ECTS ECEngine Coolant Temperature

Sensor

EGRC/V EC EGRC Ð Solenoid Valve

FCUT EC Fuel Cut Solenoid Valve

F/HEAT EC Fuel Heater System

FICD EC IACV-FICD Solenoid Valve

FIPOT EC ISC-FI Pot

FPCM EC Fuel Pump Control Module

F/PUMP EC Fuel Pump

F/RTN EC Fuel Return Control Solenoid Valve

GLOW EC Quick-glow System

H/AIM EL Headlamp Aiming Control

HEATER HA Heater

H/LAMP EL Headlamp

HLC EL Headlamp Washer

HO2S EC Heated Oxygen Sensor

HORN EL Horn

H/SEAT EL Heated Seat

IATS EC Intake Air Temperature Sensor

IDLE EC IACV-Idle Up ControlCode Section Wiring Diagram Name

IGN EC Ignition System

IGN/SG EC Ignition Signal

ILL EL Illumination

INJECT EC Injector

INT/L EL Interior and Spot Lamps

MAFS EC Mass Air Flow Sensor

MAIN ECMain Power Supply and Ground Cir-

cuit

METER ELSpeedometer, Tachometer, Temp.

and Fuel Gauges

MIL/DL ECMIL and Data Link Connector For

CONSULT

MIRROR EL Power Door Mirror

MULTI EL Multi-remote Control System

NATS EL Nissan Anti-theft System

P/ANT EL Power Antenna

PGC/V ECCanister Purge

Control Solenoid Valve

PLA EC Partial Load Advance Control

PNP/SW EC Park/Neutral Position Switch

POWER EL Power Supply Routing

PST/SW EC Power Steering Oil Pressure Switch

R/FOG EL Rear Fog Lamp

SRS RS Supplemental Restraint System

S/SIG EC Start Signal

START EL Starting System

STOP/L EL Stop Lamp

SWL/V ECSwirl Control Valve Control Solenoid

Valve

TAIL/L EL Parking, License and Tail Lamps

TPS EC Throttle Position Sensor

TURN ELTurn Signal and Hazard Warning

Lamps

VSS EC Vehicle Speed Sensor

WARN EL Warning Lamps

WINDOW EL Power Window

WIPER EL Front Wiper and Washer

WIRING DIAGRAM CODES (CELL CODES)

EL-253

Page 644 of 1659

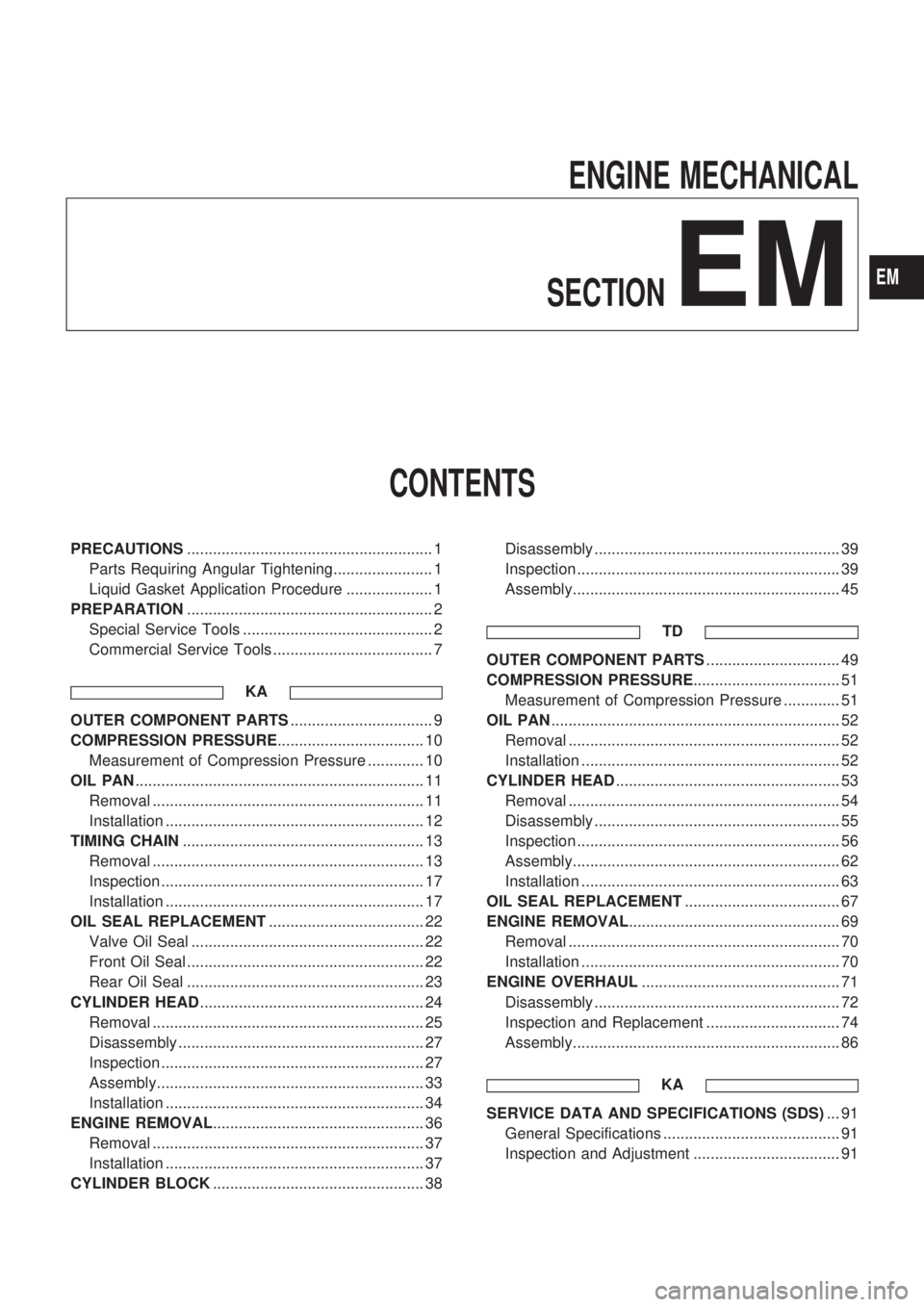

ENGINE MECHANICAL

SECTION

EM

CONTENTS

PRECAUTIONS......................................................... 1

Parts Requiring Angular Tightening....................... 1

Liquid Gasket Application Procedure .................... 1

PREPARATION......................................................... 2

Special Service Tools ............................................ 2

Commercial Service Tools ..................................... 7

KA

OUTER COMPONENT PARTS................................. 9

COMPRESSION PRESSURE.................................. 10

Measurement of Compression Pressure ............. 10

OIL PAN................................................................... 11

Removal ............................................................... 11

Installation ............................................................ 12

TIMING CHAIN........................................................ 13

Removal ............................................................... 13

Inspection ............................................................. 17

Installation ............................................................ 17

OIL SEAL REPLACEMENT.................................... 22

Valve Oil Seal ...................................................... 22

Front Oil Seal ....................................................... 22

Rear Oil Seal ....................................................... 23

CYLINDER HEAD.................................................... 24

Removal ............................................................... 25

Disassembly ......................................................... 27

Inspection ............................................................. 27

Assembly.............................................................. 33

Installation ............................................................ 34

ENGINE REMOVAL................................................. 36

Removal ............................................................... 37

Installation ............................................................ 37

CYLINDER BLOCK................................................. 38Disassembly ......................................................... 39

Inspection ............................................................. 39

Assembly.............................................................. 45

TD

OUTER COMPONENT PARTS............................... 49

COMPRESSION PRESSURE.................................. 51

Measurement of Compression Pressure ............. 51

OIL PAN................................................................... 52

Removal ............................................................... 52

Installation ............................................................ 52

CYLINDER HEAD.................................................... 53

Removal ............................................................... 54

Disassembly ......................................................... 55

Inspection ............................................................. 56

Assembly.............................................................. 62

Installation ............................................................ 63

OIL SEAL REPLACEMENT.................................... 67

ENGINE REMOVAL................................................. 69

Removal ............................................................... 70

Installation ............................................................ 70

ENGINE OVERHAUL.............................................. 71

Disassembly ......................................................... 72

Inspection and Replacement ............................... 74

Assembly.............................................................. 86

KA

SERVICE DATA AND SPECIFICATIONS (SDS)... 91

General Specifications ......................................... 91

Inspection and Adjustment .................................. 91

EM

Page 645 of 1659

TD

SERVICE DATA AND SPECIFICATIONS (SDS)... 98

General Specifications ......................................... 98

Inspection and Adjustment .................................. 98

Page 646 of 1659

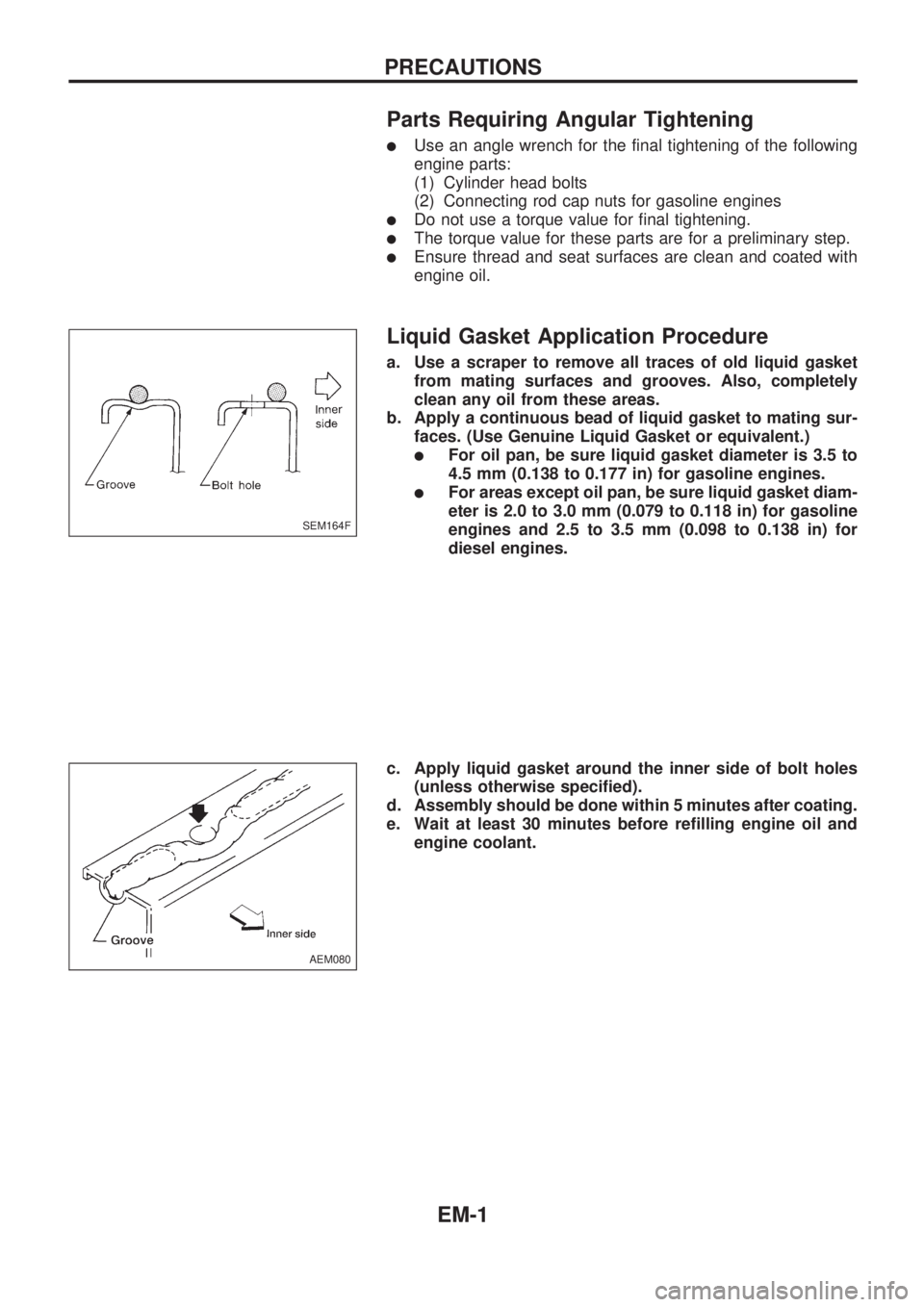

Parts Requiring Angular Tightening

lUse an angle wrench for the final tightening of the following

engine parts:

(1) Cylinder head bolts

(2) Connecting rod cap nuts for gasoline engines

lDo not use a torque value for final tightening.

lThe torque value for these parts are for a preliminary step.

lEnsure thread and seat surfaces are clean and coated with

engine oil.

Liquid Gasket Application Procedure

a. Use a scraper to remove all traces of old liquid gasket

from mating surfaces and grooves. Also, completely

clean any oil from these areas.

b. Apply a continuous bead of liquid gasket to mating sur-

faces. (Use Genuine Liquid Gasket or equivalent.)

lFor oil pan, be sure liquid gasket diameter is 3.5 to

4.5 mm (0.138 to 0.177 in) for gasoline engines.

lFor areas except oil pan, be sure liquid gasket diam-

eter is 2.0 to 3.0 mm (0.079 to 0.118 in) for gasoline

engines and 2.5 to 3.5 mm (0.098 to 0.138 in) for

diesel engines.

c. Apply liquid gasket around the inner side of bolt holes

(unless otherwise specified).

d. Assembly should be done within 5 minutes after coating.

e. Wait at least 30 minutes before refilling engine oil and

engine coolant.

SEM164F

AEM080

PRECAUTIONS

EM-1

Page 647 of 1659

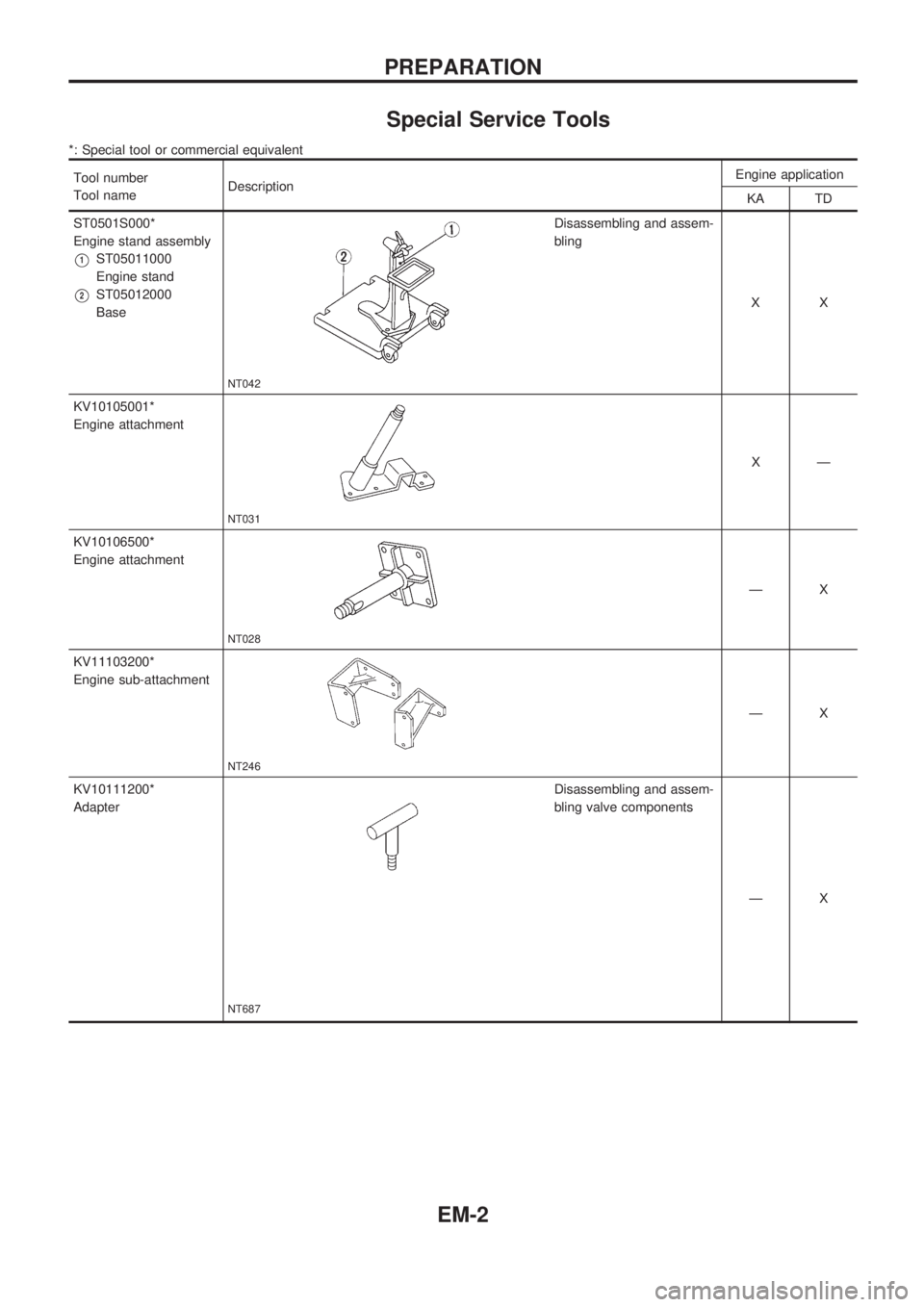

Special Service Tools

*: Special tool or commercial equivalent

Tool number

Tool nameDescriptionEngine application

KA TD

ST0501S000*

Engine stand assembly

V1ST05011000

Engine stand

V2ST05012000

Base

NT042

Disassembling and assem-

bling

XX

KV10105001*

Engine attachment

NT031

XÐ

KV10106500*

Engine attachment

NT028

ÐX

KV11103200*

Engine sub-attachment

NT246

ÐX

KV10111200*

Adapter

NT687

Disassembling and assem-

bling valve components

ÐX

PREPARATION

EM-2

Page 648 of 1659

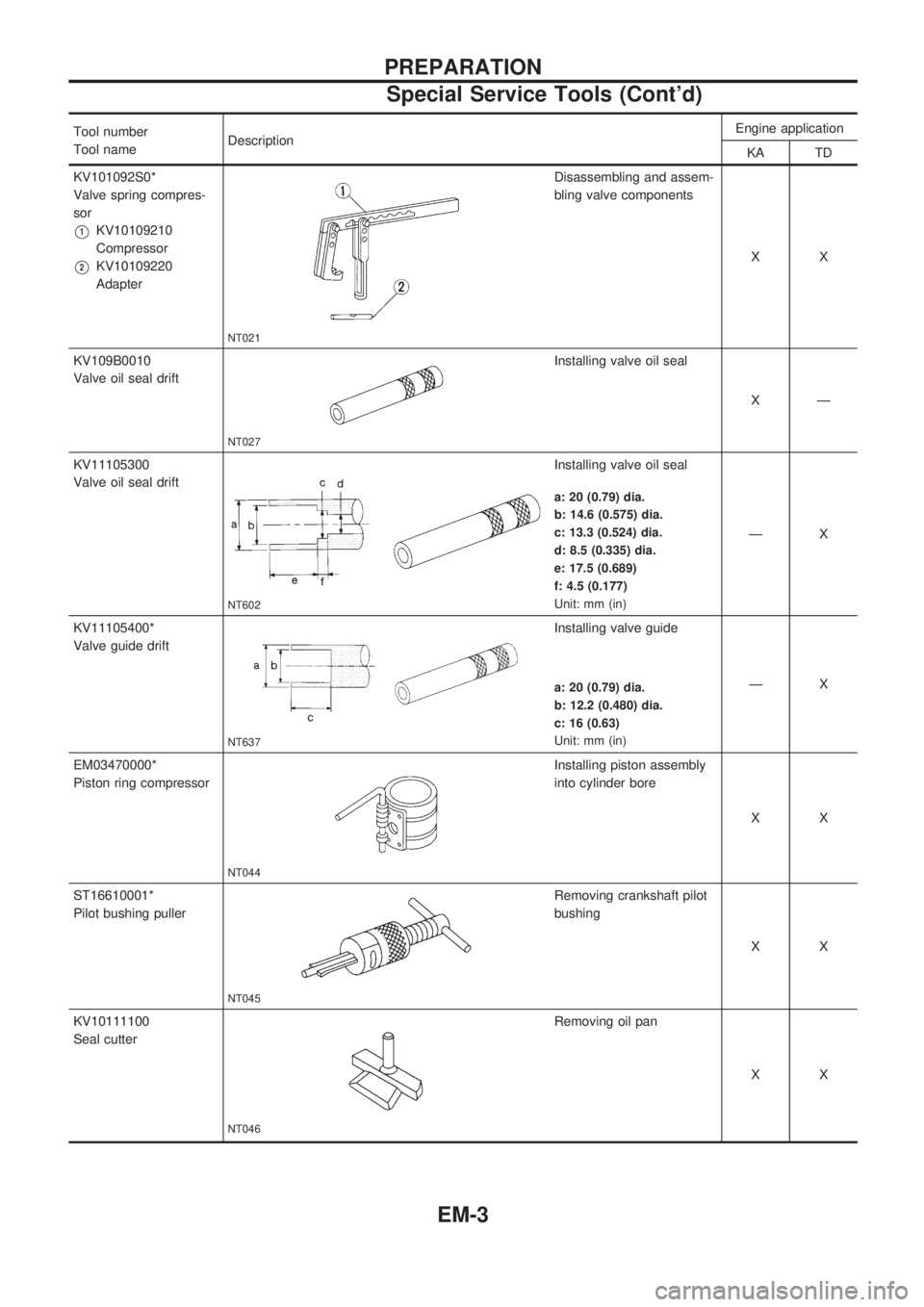

Tool number

Tool nameDescriptionEngine application

KA TD

KV101092S0*

Valve spring compres-

sor

V1KV10109210

Compressor

V2KV10109220

Adapter

NT021

Disassembling and assem-

bling valve components

XX

KV109B0010

Valve oil seal drift

NT027

Installing valve oil seal

XÐ

KV11105300

Valve oil seal drift

NT602

Installing valve oil seal

ÐX

a: 20 (0.79) dia.

b: 14.6 (0.575) dia.

c: 13.3 (0.524) dia.

d: 8.5 (0.335) dia.

e: 17.5 (0.689)

f: 4.5 (0.177)

Unit: mm (in)

KV11105400*

Valve guide drift

NT637

Installing valve guide

ÐX

a: 20 (0.79) dia.

b: 12.2 (0.480) dia.

c: 16 (0.63)

Unit: mm (in)

EM03470000*

Piston ring compressor

NT044

Installing piston assembly

into cylinder bore

XX

ST16610001*

Pilot bushing puller

NT045

Removing crankshaft pilot

bushing

XX

KV10111100

Seal cutter

NT046

Removing oil pan

XX

PREPARATION

Special Service Tools (Cont'd)

EM-3

Page 649 of 1659

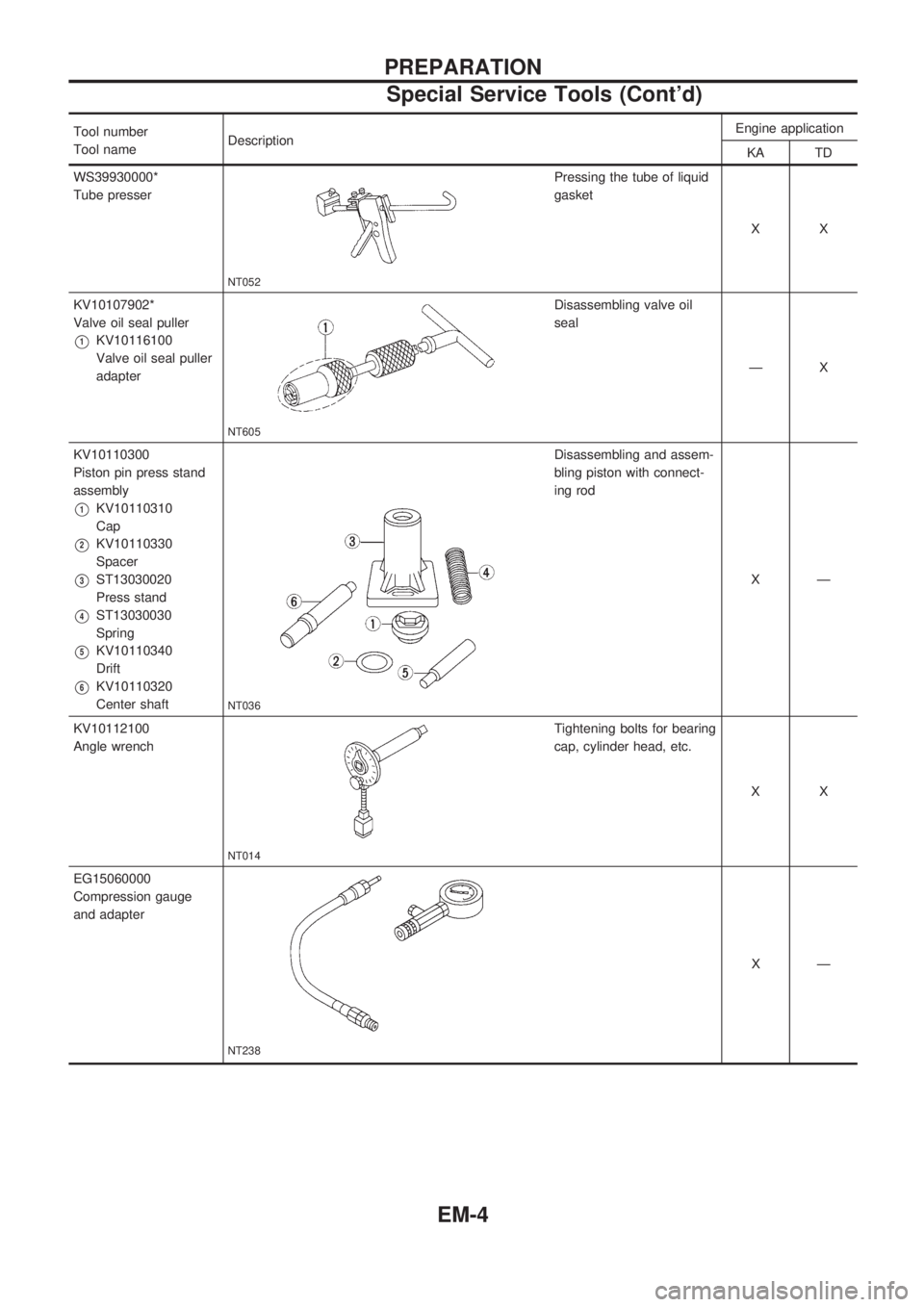

Tool number

Tool nameDescriptionEngine application

KA TD

WS39930000*

Tube presser

NT052

Pressing the tube of liquid

gasket

XX

KV10107902*

Valve oil seal puller

V1KV10116100

Valve oil seal puller

adapter

NT605

Disassembling valve oil

seal

ÐX

KV10110300

Piston pin press stand

assembly

V1KV10110310

Cap

V2KV10110330

Spacer

V3ST13030020

Press stand

V4ST13030030

Spring

V5KV10110340

Drift

V6KV10110320

Center shaft

NT036

Disassembling and assem-

bling piston with connect-

ing rod

XÐ

KV10112100

Angle wrench

NT014

Tightening bolts for bearing

cap, cylinder head, etc.

XX

EG15060000

Compression gauge

and adapter

NT238

XÐ

PREPARATION

Special Service Tools (Cont'd)

EM-4

Page 650 of 1659

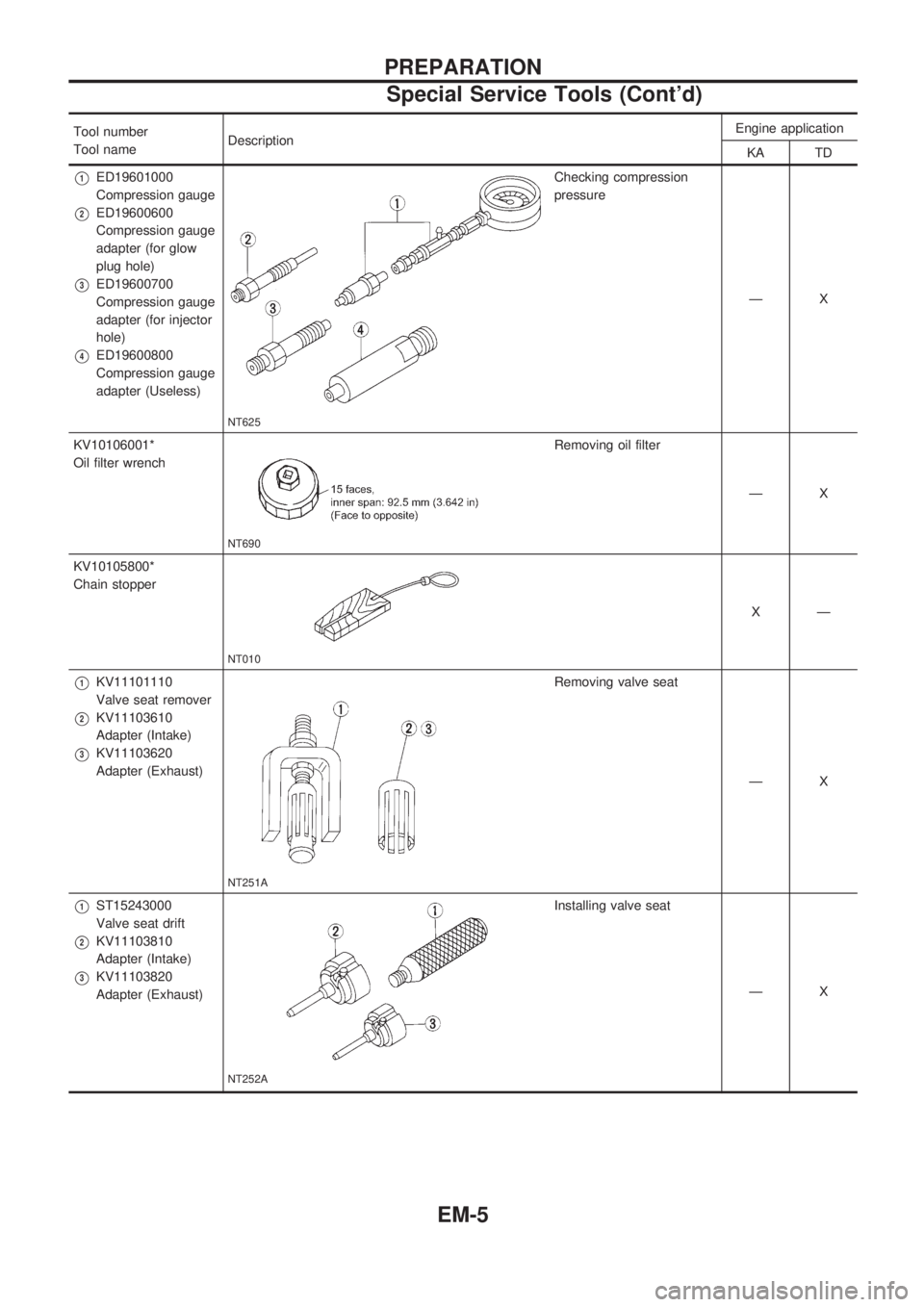

Tool number

Tool nameDescriptionEngine application

KA TD

V1ED19601000

Compression gauge

V2ED19600600

Compression gauge

adapter (for glow

plug hole)

V3ED19600700

Compression gauge

adapter (for injector

hole)

V4ED19600800

Compression gauge

adapter (Useless)

NT625

Checking compression

pressure

ÐX

KV10106001*

Oil filter wrench

NT690

Removing oil filter

ÐX

KV10105800*

Chain stopper

NT010

XÐ

V1KV11101110

Valve seat remover

V2KV11103610

Adapter (Intake)

V3KV11103620

Adapter (Exhaust)

NT251A

Removing valve seat

ÐX

V1ST15243000

Valve seat drift

V2KV11103810

Adapter (Intake)

V3KV11103820

Adapter (Exhaust)

NT252A

Installing valve seat

ÐX

PREPARATION

Special Service Tools (Cont'd)

EM-5