NISSAN PRIMERA 1999 Electronic Repair Manual

Manufacturer: NISSAN, Model Year: 1999, Model line: PRIMERA, Model: NISSAN PRIMERA 1999Pages: 2267, PDF Size: 35.74 MB

Page 1641 of 2267

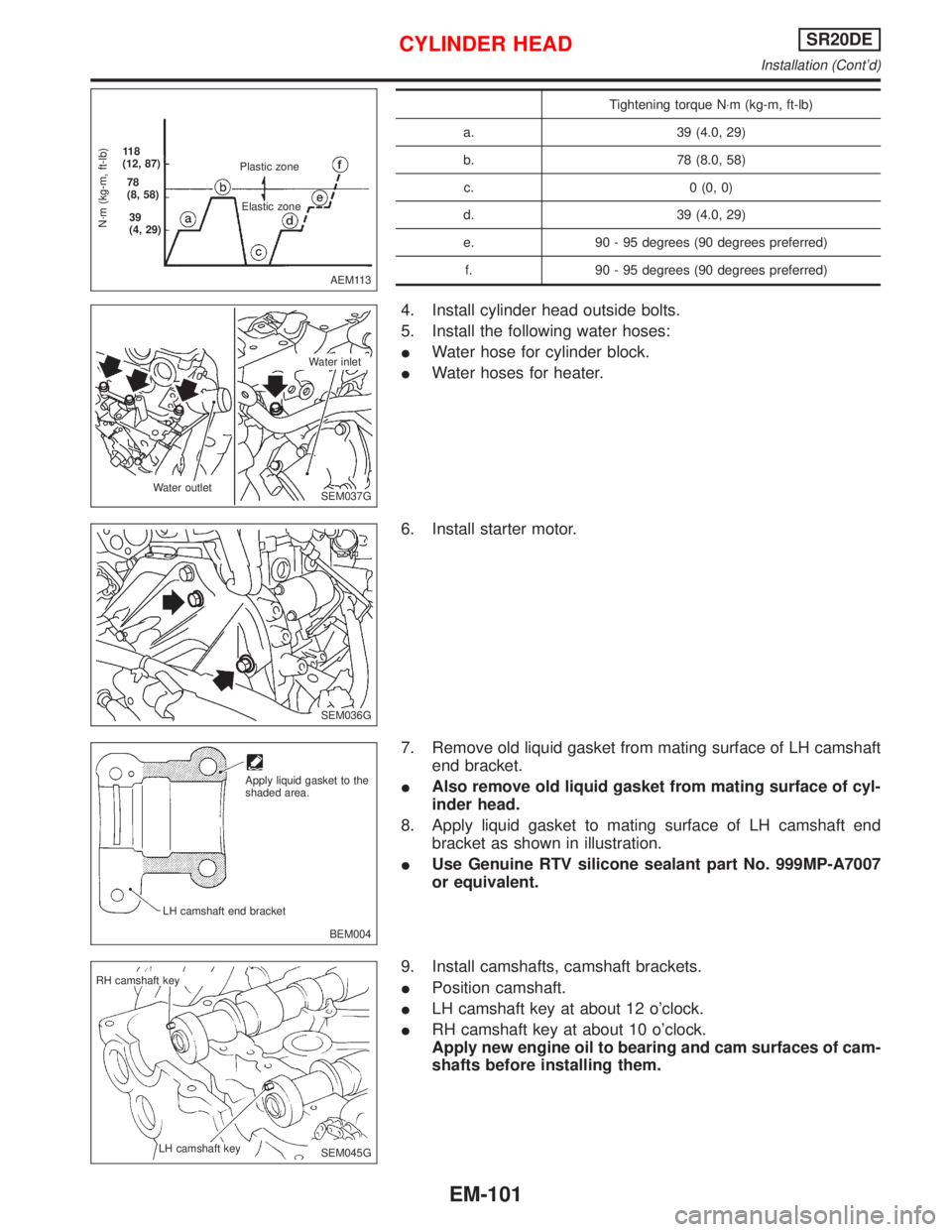

Tightening torque N×m (kg-m, ft-lb)

a. 39 (4.0, 29)

b. 78 (8.0, 58)

c. 0 (0, 0)

d. 39 (4.0, 29)

e. 90 - 95 degrees (90 degrees preferred)

f. 90 - 95 degrees (90 degrees preferred)

4. Install cylinder head outside bolts.

5. Install the following water hoses:

IWater hose for cylinder block.

IWater hoses for heater.

6. Install starter motor.

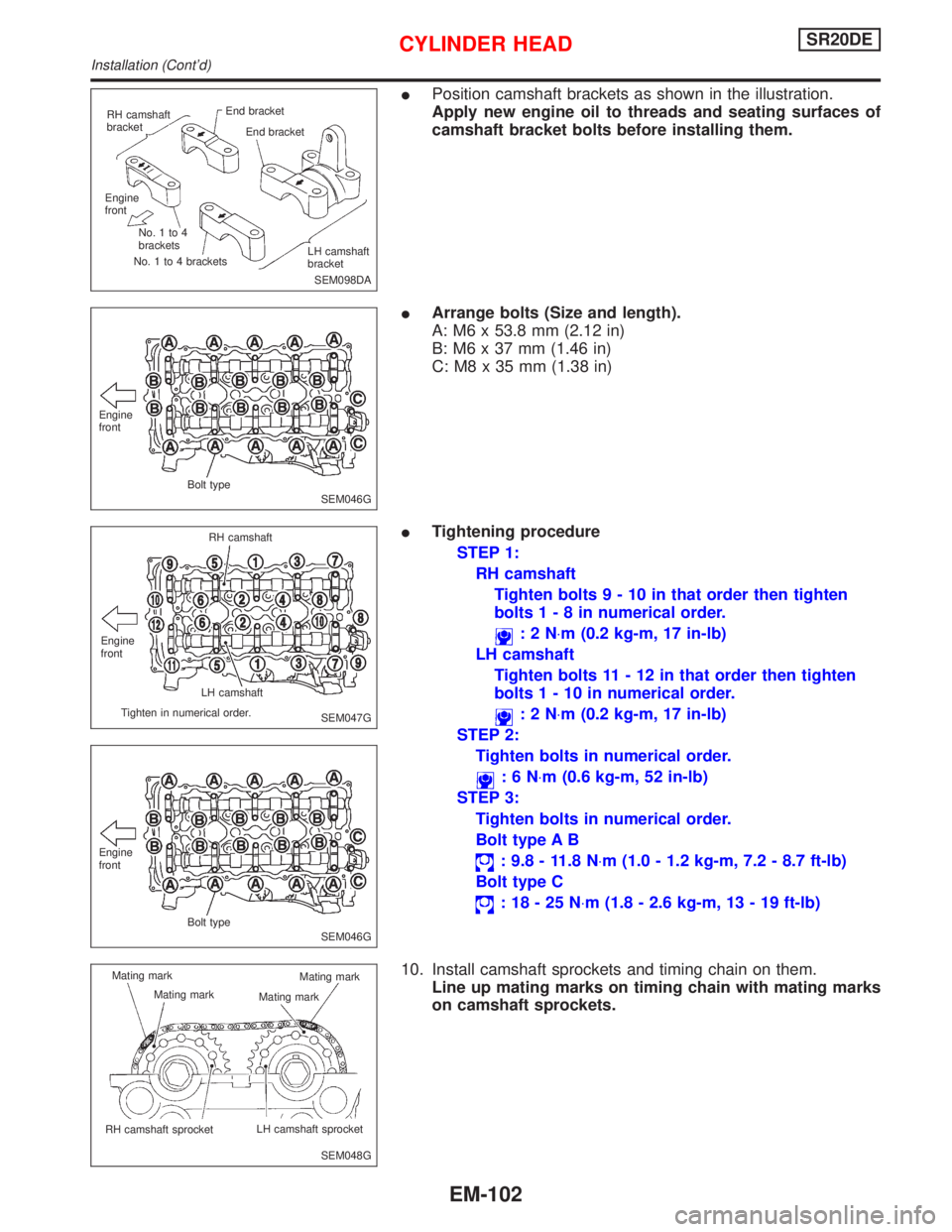

7. Remove old liquid gasket from mating surface of LH camshaft

end bracket.

IAlso remove old liquid gasket from mating surface of cyl-

inder head.

8. Apply liquid gasket to mating surface of LH camshaft end

bracket as shown in illustration.

IUse Genuine RTV silicone sealant part No. 999MP-A7007

or equivalent.

9. Install camshafts, camshaft brackets.

IPosition camshaft.

ILH camshaft key at about 12 o'clock.

IRH camshaft key at about 10 o'clock.

Apply new engine oil to bearing and cam surfaces of cam-

shafts before installing them.

AEM113

N´m (kg-m, ft-lb)

11 8

(12, 87)

78

(8, 58)

39

(4, 29)Plastic zone

Elastic zone

SEM037G Water outletWater inlet

SEM036G

BEM004 Apply liquid gasket to the

shaded area.

LH camshaft end bracket

SEM045G RH camshaft key

LH camshaft key

CYLINDER HEADSR20DE

Installation (Cont'd)

EM-101

Page 1642 of 2267

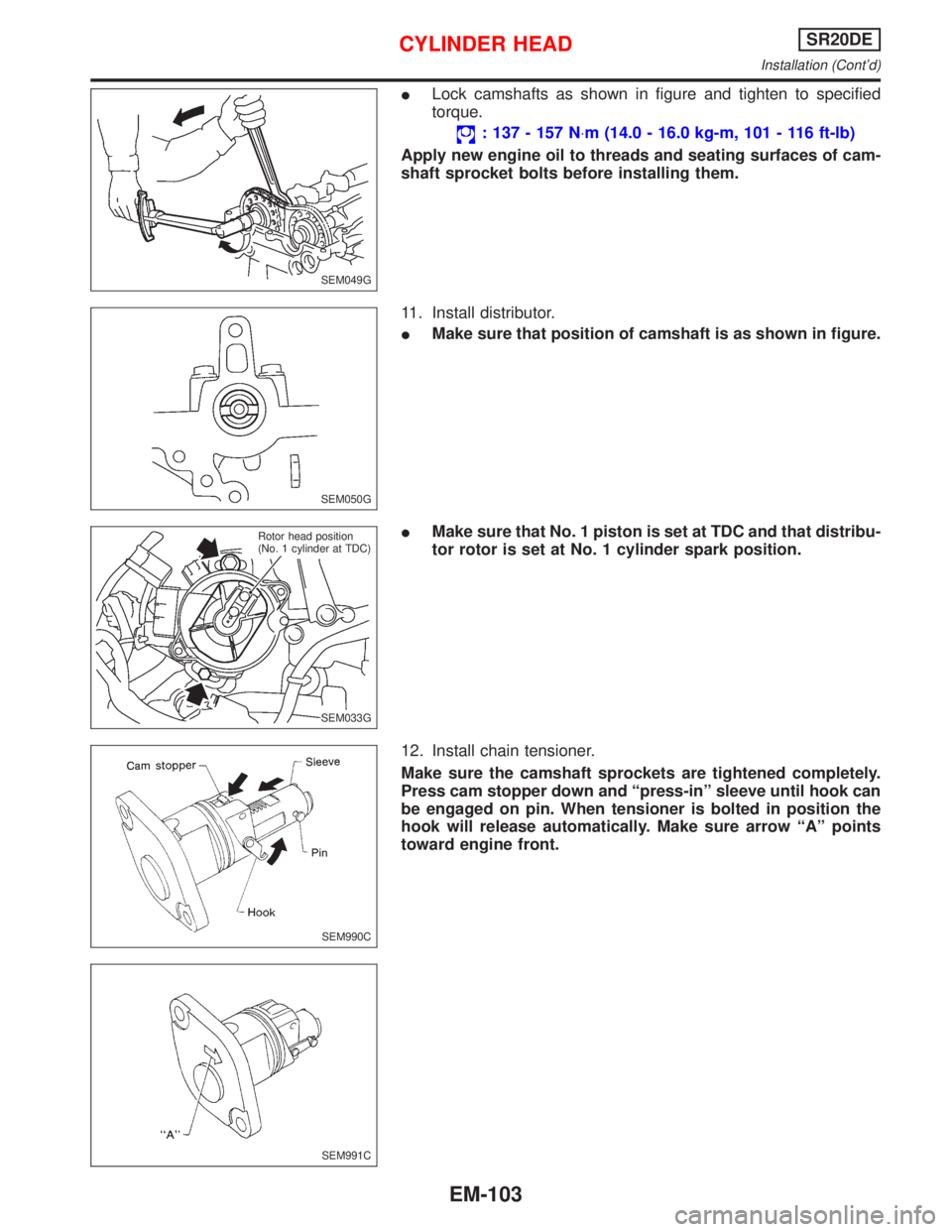

IPosition camshaft brackets as shown in the illustration.

Apply new engine oil to threads and seating surfaces of

camshaft bracket bolts before installing them.

IArrange bolts (Size and length).

A: M6 x 53.8 mm (2.12 in)

B: M6 x 37 mm (1.46 in)

C: M8 x 35 mm (1.38 in)

ITightening procedure

STEP 1:

RH camshaft

Tighten bolts9-10inthat order then tighten

bolts1-8innumerical order.

:2N×m (0.2 kg-m, 17 in-lb)

LH camshaft

Tighten bolts 11 - 12 in that order then tighten

bolts1-10innumerical order.

:2N×m (0.2 kg-m, 17 in-lb)

STEP 2:

Tighten bolts in numerical order.

:6N×m (0.6 kg-m, 52 in-lb)

STEP 3:

Tighten bolts in numerical order.

Bolt type A B

: 9.8 - 11.8 N×m (1.0 - 1.2 kg-m, 7.2 - 8.7 ft-lb)

Bolt type C

:18-25N×m (1.8 - 2.6 kg-m, 13 - 19 ft-lb)

10. Install camshaft sprockets and timing chain on them.

Line up mating marks on timing chain with mating marks

on camshaft sprockets.

SEM098DA RH camshaft

bracketEnd bracket

End bracket

Engine

front

No.1to4

brackets

No. 1 to 4 bracketsLH camshaft

bracket

SEM046G Engine

front

Bolt type

SEM047G Engine

frontRH camshaft

LH camshaft

Tighten in numerical order.

SEM046G Engine

front

Bolt type

SEM048G Mating mark

Mating mark

.RH camshaft sprocket.LH camshaft sprocket Mating mark

Mating mark

CYLINDER HEADSR20DE

Installation (Cont'd)

EM-102

Page 1643 of 2267

ILock camshafts as shown in figure and tighten to specified

torque.

: 137 - 157 N×m (14.0 - 16.0 kg-m, 101 - 116 ft-lb)

Apply new engine oil to threads and seating surfaces of cam-

shaft sprocket bolts before installing them.

11. Install distributor.

IMake sure that position of camshaft is as shown in figure.

IMake sure that No. 1 piston is set at TDC and that distribu-

tor rotor is set at No. 1 cylinder spark position.

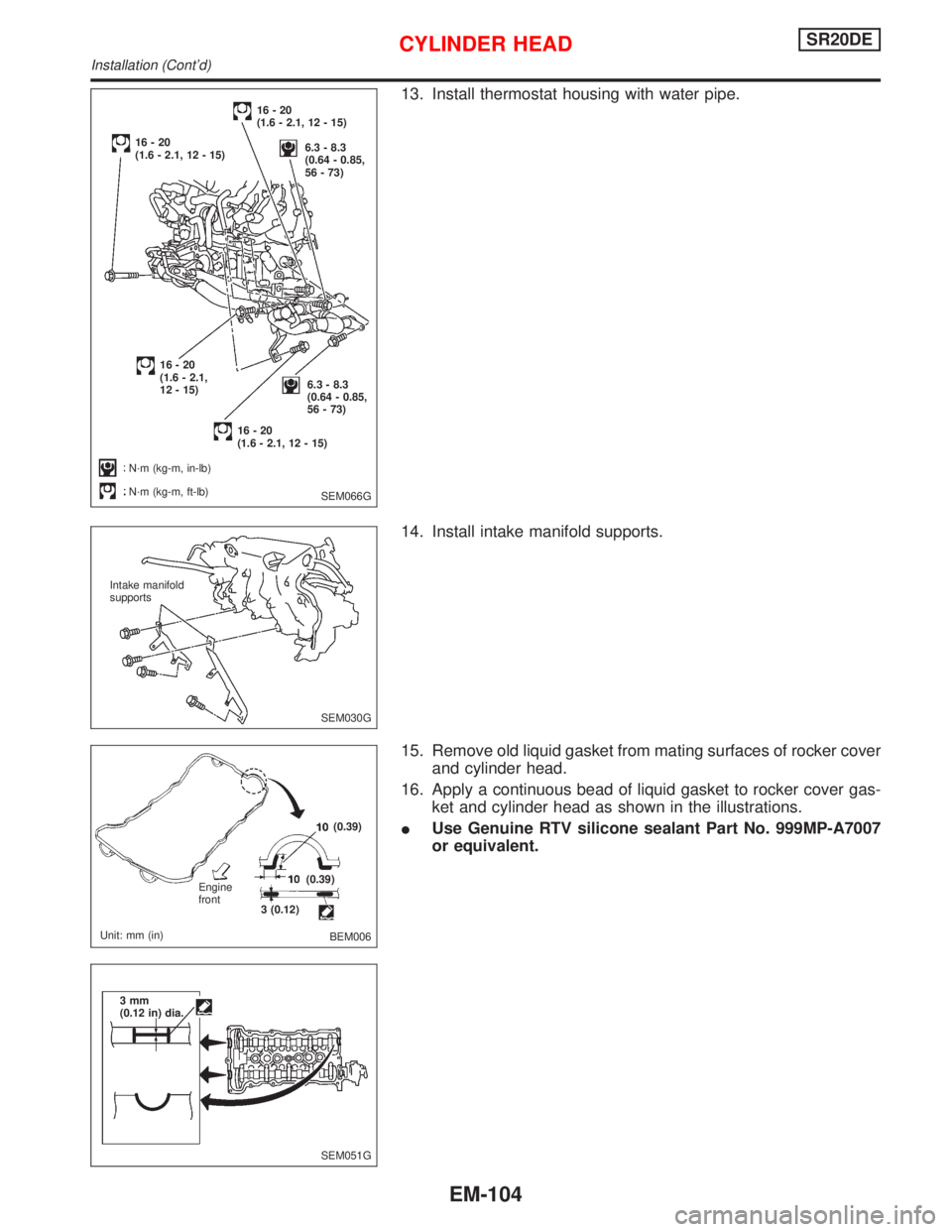

12. Install chain tensioner.

Make sure the camshaft sprockets are tightened completely.

Press cam stopper down and ªpress-inº sleeve until hook can

be engaged on pin. When tensioner is bolted in position the

hook will release automatically. Make sure arrow ªAº points

toward engine front.

SEM049G

SEM050G

SEM033G Rotor head position

(No. 1 cylinder at TDC)

SEM990C

SEM991C

CYLINDER HEADSR20DE

Installation (Cont'd)

EM-103

Page 1644 of 2267

13. Install thermostat housing with water pipe.

14. Install intake manifold supports.

15. Remove old liquid gasket from mating surfaces of rocker cover

and cylinder head.

16. Apply a continuous bead of liquid gasket to rocker cover gas-

ket and cylinder head as shown in the illustrations.

IUse Genuine RTV silicone sealant Part No. 999MP-A7007

or equivalent.

SEM066G

16-20

(1.6 - 2.1, 12 - 15)

6.3 - 8.3

(0.64 - 0.85,

56 - 73)16-20

(1.6 - 2.1, 12 - 15)

16-20

(1.6 - 2.1,

12 - 15)

16-20

(1.6 - 2.1, 12 - 15)

6.3 - 8.3

(0.64 - 0.85,

56 - 73)

N´m (kg-m, in-lb)

N´m (kg-m, ft-lb)

SEM030G Intake manifold

supports

BEM006 Engine

front

Unit: mm (in)3 (0.12)(0.39)

(0.39)

SEM051G 3mm

(0.12 in) dia.

CYLINDER HEADSR20DE

Installation (Cont'd)

EM-104

Page 1645 of 2267

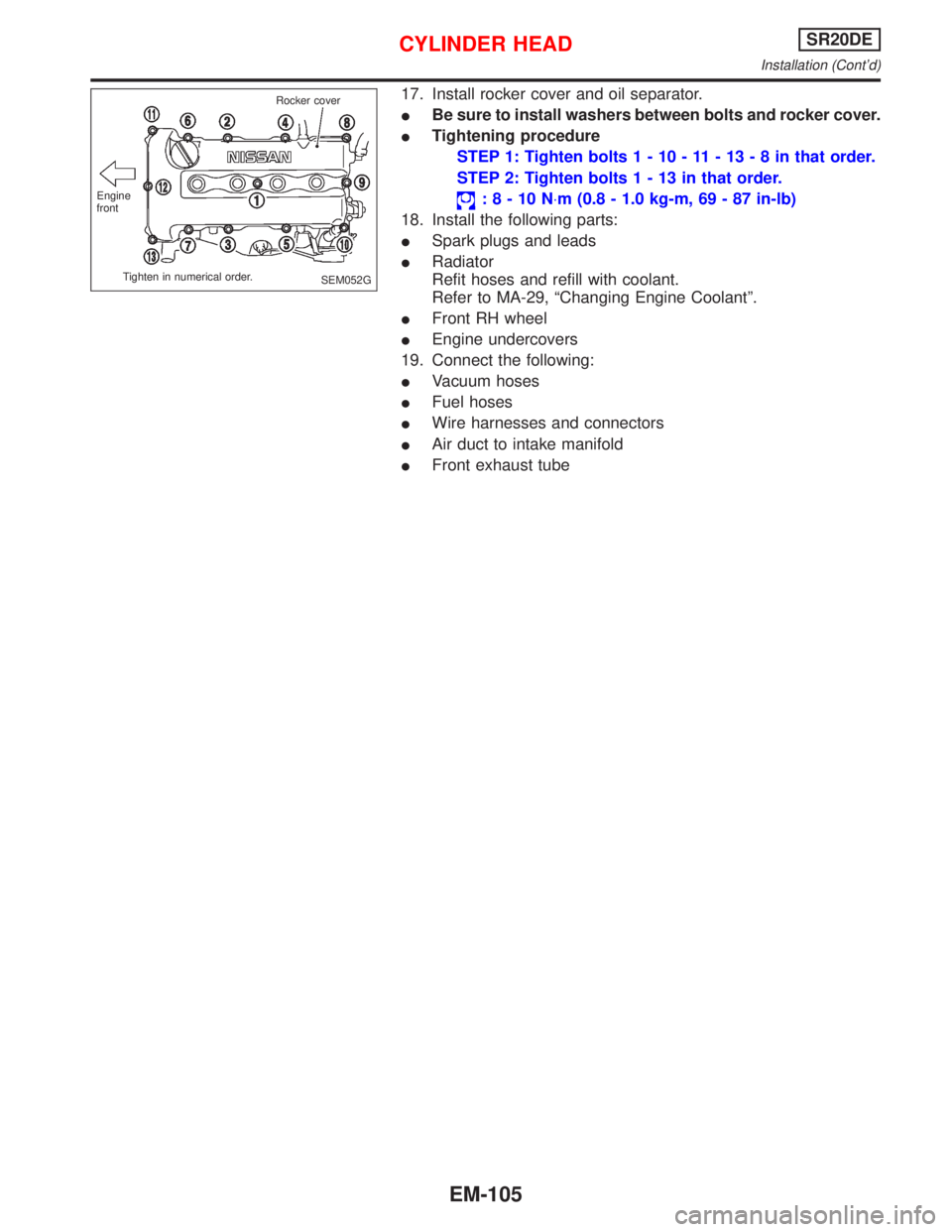

17. Install rocker cover and oil separator.

IBe sure to install washers between bolts and rocker cover.

ITightening procedure

STEP 1: Tighten bolts1-10-11-13-8inthat order.

STEP 2: Tighten bolts1-13inthat order.

:8-10N×m (0.8 - 1.0 kg-m, 69 - 87 in-lb)

18. Install the following parts:

ISpark plugs and leads

IRadiator

Refit hoses and refill with coolant.

Refer to MA-29, ªChanging Engine Coolantº.

IFront RH wheel

IEngine undercovers

19. Connect the following:

IVacuum hoses

IFuel hoses

IWire harnesses and connectors

IAir duct to intake manifold

IFront exhaust tube

SEM052G Engine

front

Tighten in numerical order.Rocker cover

CYLINDER HEADSR20DE

Installation (Cont'd)

EM-105

Page 1646 of 2267

Components

NEM340 Front engine slinger

Rear insulator

49-59

(5.0 - 6.0, 36 - 44)Rear engine mounting

43-55

(4.4 - 5.6,

32 - 41)

43-55

(4.4 - 5.6,

32 - 41)Rear engine slinger

20.6 - 26.5

(2.1 - 2.7, 15 - 20)

20.6 - 26.5

(2.1 - 2.7,

15 - 20)

43-55

(4.4 - 5.6,

32 - 41)

55-65

(5.6 - 6.6, 41 - 48)

49 - 59 (5.0 - 6.0, 36 - 44) Front mounting

bracket

Insulator

Center member

77-98

(7.9 - 100, 57 - 72)

: N´m (kg-m, ft-lb)

.43-55

(4.4 - 5.6, 32 - 41)

.49-59

(5.0 - 6.0,

36 - 44)

43-55

(4.4 - 5.6, 32 - 41)

43-55

(4.9 - 5.6, 32 - 41)49-59

(5.0 - 6.0,

36 - 44)

Front engine

mounting

Mounting

bracket

74 - 83 (7.5 - 8.5, 54 - 61)

43-55

(4.4 - 5.6, 32 - 41)

64-74

(6.5 - 7.5, 47 - 54)

64-74

(6.5 - 7.5, 47 - 54)

62-78

(6.3 - 8.0, 46 - 58)

64-74

(6.5 - 7.5, 47 - 54)

SEC. 112

.43-55

(4.4 - 5.6, 32 - 41)

CVT models

ENGINE REMOVALSR20DE

Components

EM-106

Page 1647 of 2267

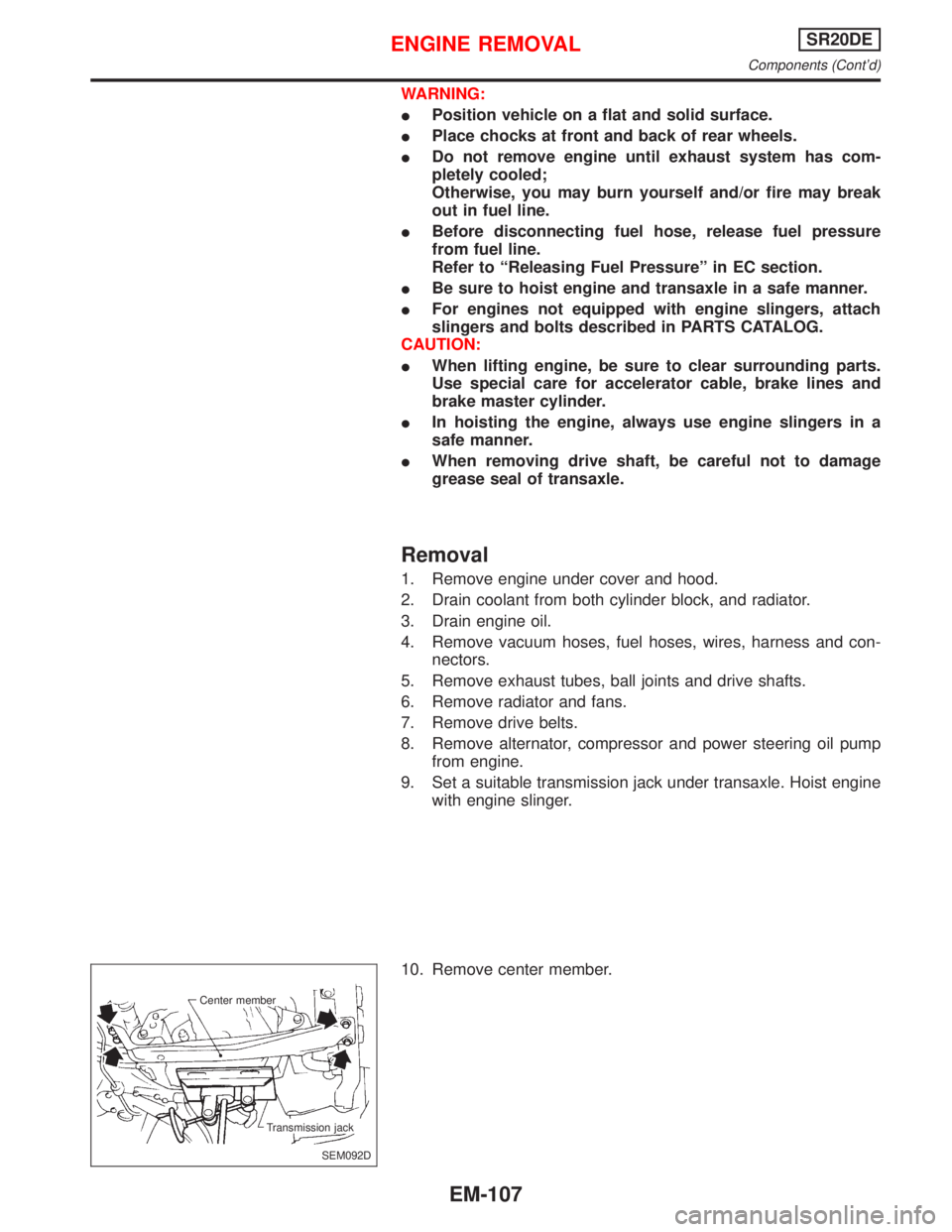

WARNING:

IPosition vehicle on a flat and solid surface.

IPlace chocks at front and back of rear wheels.

IDo not remove engine until exhaust system has com-

pletely cooled;

Otherwise, you may burn yourself and/or fire may break

out in fuel line.

IBefore disconnecting fuel hose, release fuel pressure

from fuel line.

Refer to ªReleasing Fuel Pressureº in EC section.

IBe sure to hoist engine and transaxle in a safe manner.

IFor engines not equipped with engine slingers, attach

slingers and bolts described in PARTS CATALOG.

CAUTION:

IWhen lifting engine, be sure to clear surrounding parts.

Use special care for accelerator cable, brake lines and

brake master cylinder.

IIn hoisting the engine, always use engine slingers in a

safe manner.

IWhen removing drive shaft, be careful not to damage

grease seal of transaxle.

Removal

1. Remove engine under cover and hood.

2. Drain coolant from both cylinder block, and radiator.

3. Drain engine oil.

4. Remove vacuum hoses, fuel hoses, wires, harness and con-

nectors.

5. Remove exhaust tubes, ball joints and drive shafts.

6. Remove radiator and fans.

7. Remove drive belts.

8. Remove alternator, compressor and power steering oil pump

from engine.

9. Set a suitable transmission jack under transaxle. Hoist engine

with engine slinger.

10. Remove center member.

SEM092D Center member

Transmission jack

ENGINE REMOVALSR20DE

Components (Cont'd)

EM-107

Page 1648 of 2267

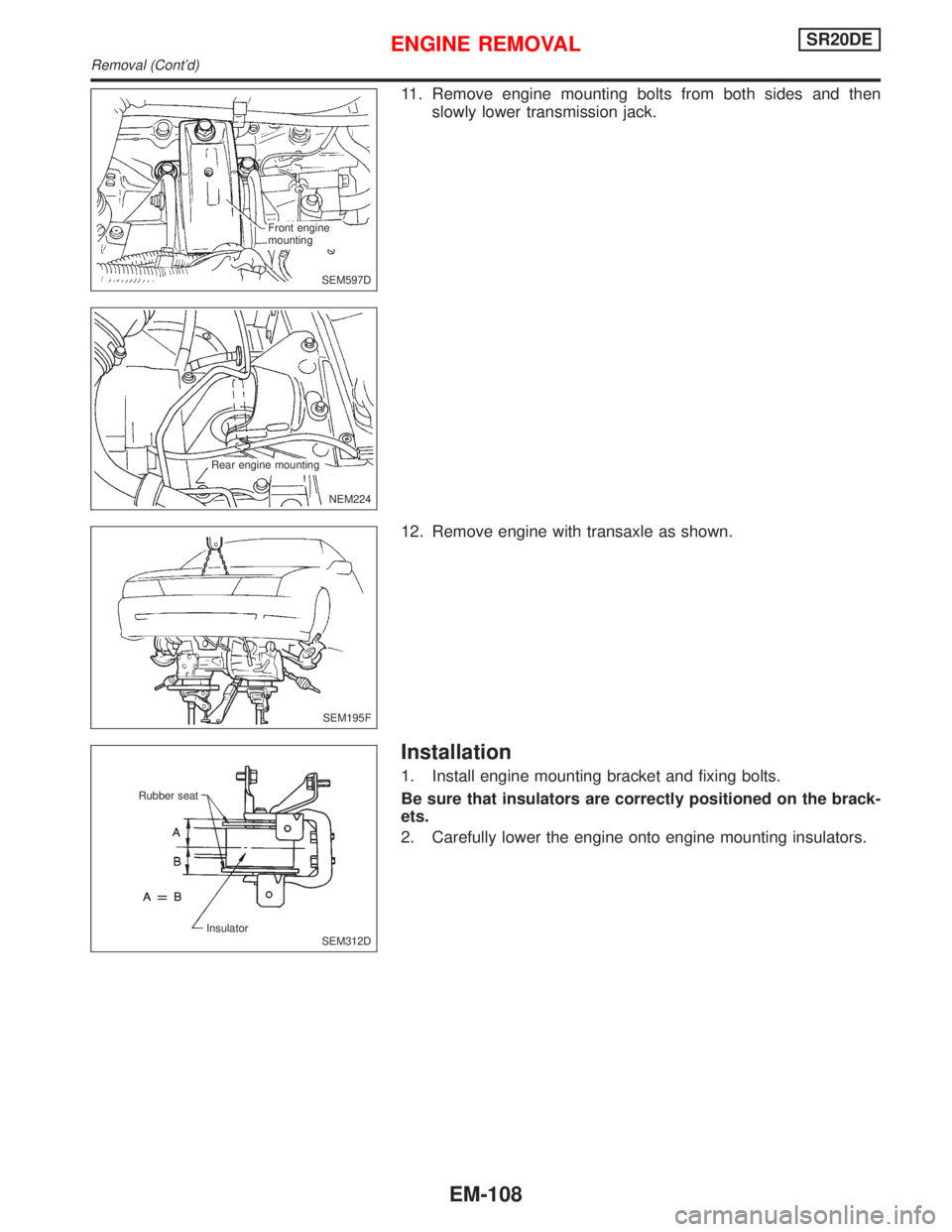

11. Remove engine mounting bolts from both sides and then

slowly lower transmission jack.

12. Remove engine with transaxle as shown.

Installation

1. Install engine mounting bracket and fixing bolts.

Be sure that insulators are correctly positioned on the brack-

ets.

2. Carefully lower the engine onto engine mounting insulators.

SEM597D Front engine

mounting

NEM224

.Rear engine mounting

SEM195F

SEM312D Insulator Rubber seat

ENGINE REMOVALSR20DE

Removal (Cont'd)

EM-108

Page 1649 of 2267

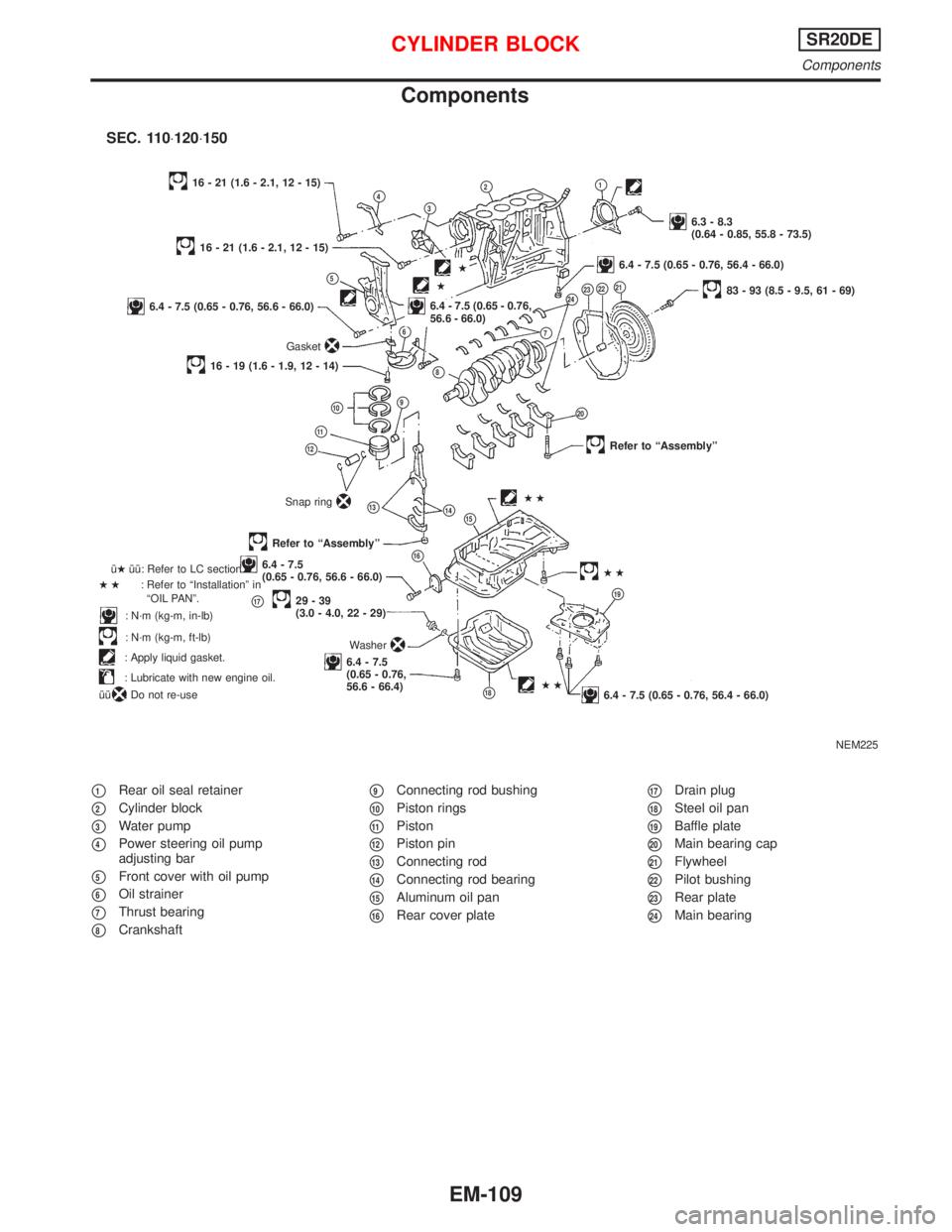

Components

p1Rear oil seal retainer

p2Cylinder block

p3Water pump

p4Power steering oil pump

adjusting bar

p5Front cover with oil pump

p6Oil strainer

p7Thrust bearing

p8Crankshaft

p9Connecting rod bushing

p10Piston rings

p11Piston

p12Piston pin

p13Connecting rod

p14Connecting rod bearing

p15Aluminum oil pan

p16Rear cover plate

p17Drain plug

p18Steel oil pan

p19Baffle plate

p20Main bearing cap

p21Flywheel

p22Pilot bushing

p23Rear plate

p24Main bearing

NEM225

p4p3

p2p1

6.3 - 8.3

(0.64 - 0.85, 55.8 - 73.5)

16 - 21 (1.6 - 2.1, 12 - 15)

p5

16 - 21 (1.6 - 2.1, 12 - 15)

6.4 - 7.5 (0.65 - 0.76, 56.6 - 66.0)

Gasket

p6

.6.4 - 7.5 (0.65 - 0.76,

56.6 - 66.0)

16 - 19 (1.6 - 1.9, 12 - 14)

p2383 - 93 (8.5 - 9.5, 61 - 69)

p10p9

p8

p22

p11

p12

Snap ringp14

Refer to ªAssemblyº

Refer to ªAssemblyº

p166.4 - 7.5

(0.65 - 0.76, 56.6 - 66.0)

p1729-39

(3.0 - 4.0, 22 - 29)

6.4 - 7.5

(0.65 - 0.76,

56.6 - 66.4) îHîî: Refer to LC section.

HH: Refer to ªInstallationº in

ªOIL PANº.

: N´m (kg-m, in-lb)

: N´m (kg-m, ft-lb)

: Apply liquid gasket.

: Lubricate with new engine oil.

îî

: Do not re-useHH

p24

Washer

p21

p20

HH

p19

6.4 - 7.5 (0.65 - 0.76, 56.4 - 66.0)

p13HH

p7

6.4 - 7.5 (0.65 - 0.76, 56.4 - 66.0).H

H

SEC. 110×120×150

p15

p18

CYLINDER BLOCKSR20DE

Components

EM-109

Page 1650 of 2267

CAUTION:

IWhen installing sliding parts (bearings, pistons, etc.),

apply new engine oil to the sliding surfaces.

IPlace removed parts such as bearings and bearing caps

in their correct order and direction.

IWhen installing connecting rod nuts and main bearing cap

bolts, apply new engine oil to threads and seating sur-

faces.

IDo not allow any magnetic materials to contact the ring

gear teeth of flywheel/drive plate.

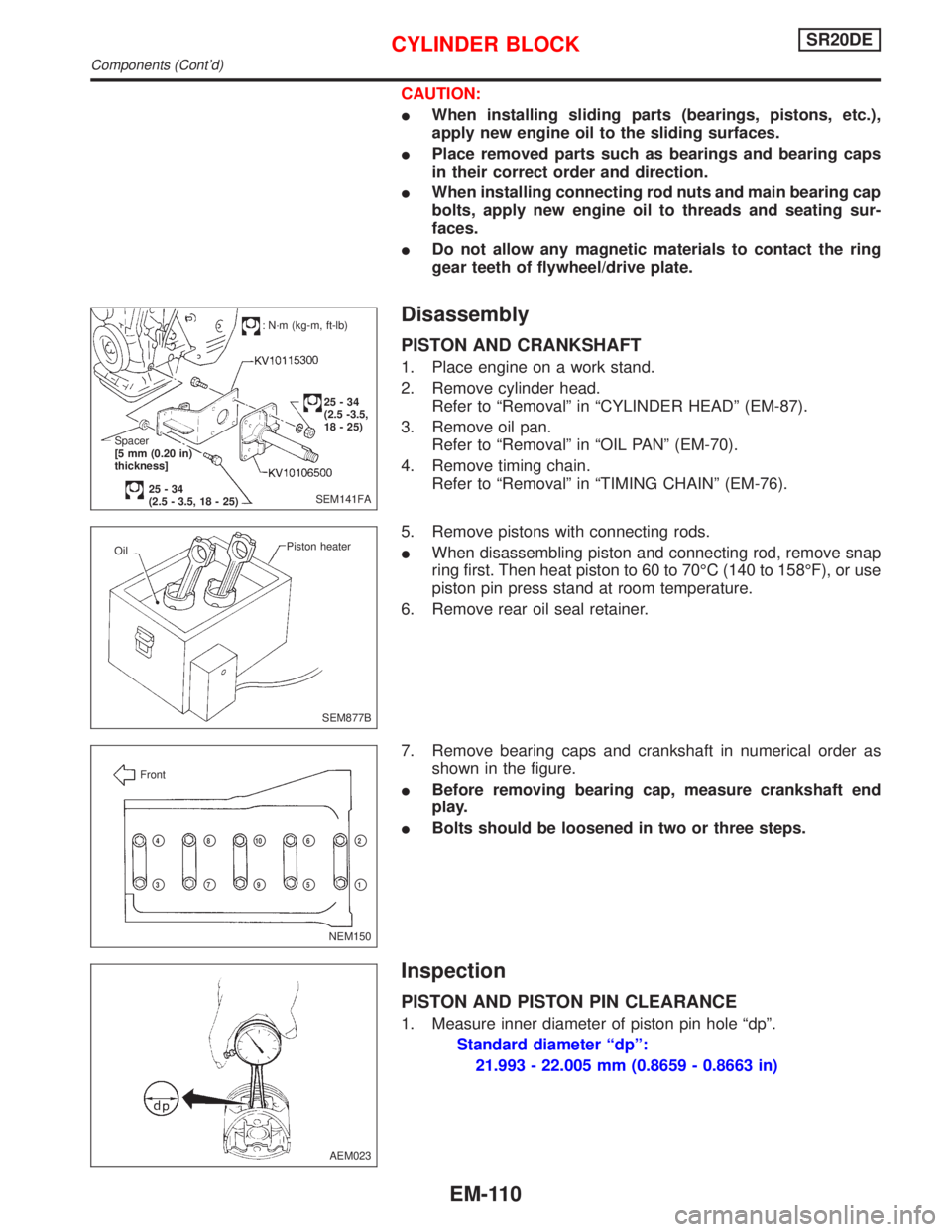

Disassembly

PISTON AND CRANKSHAFT

1. Place engine on a work stand.

2. Remove cylinder head.

Refer to ªRemovalº in ªCYLINDER HEADº (EM-87).

3. Remove oil pan.

Refer to ªRemovalº in ªOIL PANº (EM-70).

4. Remove timing chain.

Refer to ªRemovalº in ªTIMING CHAINº (EM-76).

5. Remove pistons with connecting rods.

IWhen disassembling piston and connecting rod, remove snap

ring first. Then heat piston to 60 to 70ÉC (140 to 158ÉF), or use

piston pin press stand at room temperature.

6. Remove rear oil seal retainer.

7. Remove bearing caps and crankshaft in numerical order as

shown in the figure.

IBefore removing bearing cap, measure crankshaft end

play.

IBolts should be loosened in two or three steps.

Inspection

PISTON AND PISTON PIN CLEARANCE

1. Measure inner diameter of piston pin hole ªdpº.

Standard diameter ªdpº:

21.993 - 22.005 mm (0.8659 - 0.8663 in)

SEM141FA

: N´m (kg-m, ft-lb)

25-34

(2.5 -3.5,

18 - 25)

Spacer

[5 mm (0.20 in)

thickness]

25-34

(2.5 - 3.5, 18 - 25)

SEM877B Piston heater

Oil

NEM150 Front

p2

p1

p4

p3

p8

p7

p10

p9

p6

p5

AEM023

CYLINDER BLOCKSR20DE

Components (Cont'd)

EM-110