NISSAN PRIMERA 1999 Electronic Repair Manual

Manufacturer: NISSAN, Model Year: 1999, Model line: PRIMERA, Model: NISSAN PRIMERA 1999Pages: 2267, PDF Size: 35.74 MB

Page 1631 of 2267

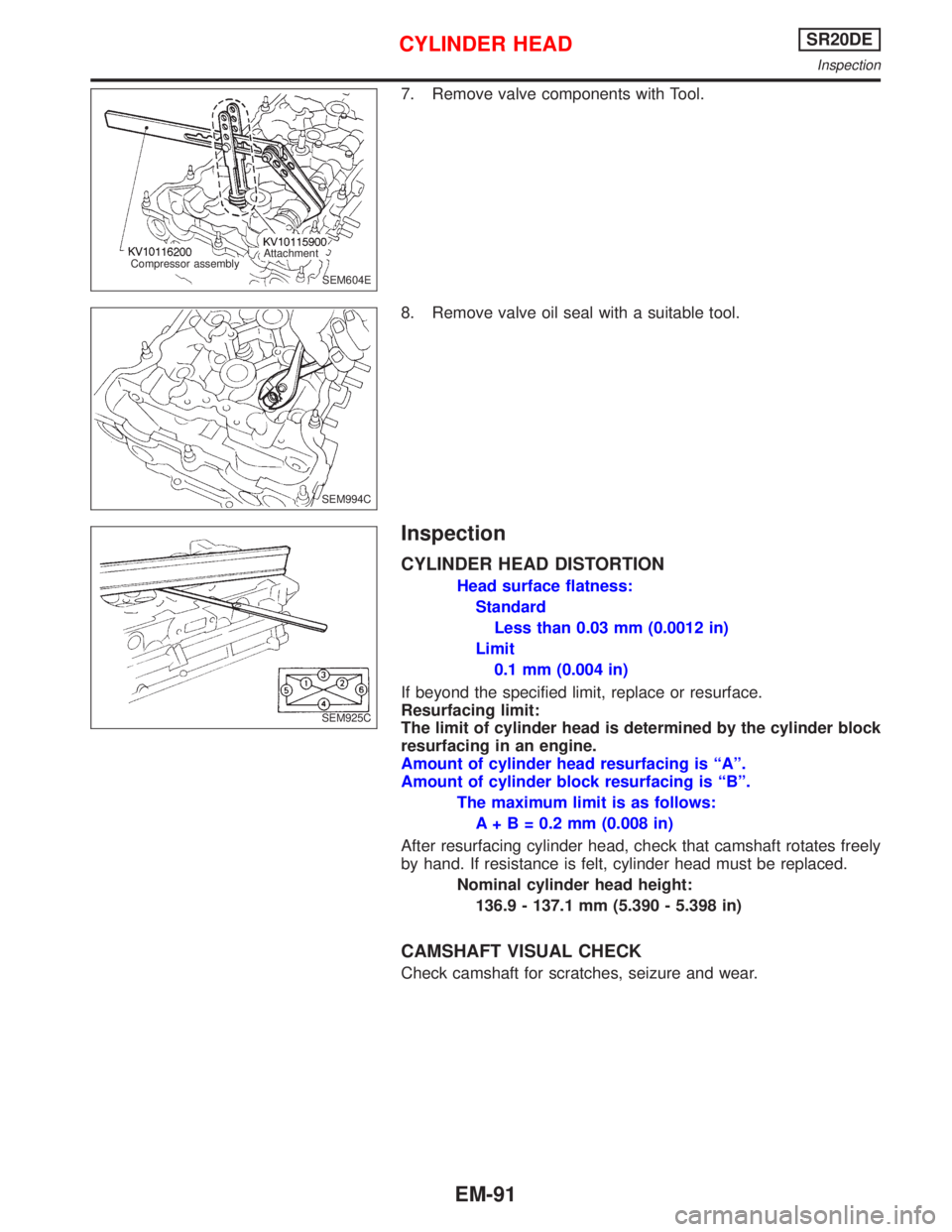

7. Remove valve components with Tool.

8. Remove valve oil seal with a suitable tool.

Inspection

CYLINDER HEAD DISTORTION

Head surface flatness:

Standard

Less than 0.03 mm (0.0012 in)

Limit

0.1 mm (0.004 in)

If beyond the specified limit, replace or resurface.

Resurfacing limit:

The limit of cylinder head is determined by the cylinder block

resurfacing in an engine.

Amount of cylinder head resurfacing is ªAº.

Amount of cylinder block resurfacing is ªBº.

The maximum limit is as follows:

A + B = 0.2 mm (0.008 in)

After resurfacing cylinder head, check that camshaft rotates freely

by hand. If resistance is felt, cylinder head must be replaced.

Nominal cylinder head height:

136.9 - 137.1 mm (5.390 - 5.398 in)

CAMSHAFT VISUAL CHECK

Check camshaft for scratches, seizure and wear.

SEM604E Compressor assemblyAttachment

SEM994C

SEM925C

CYLINDER HEADSR20DE

Inspection

EM-91

Page 1632 of 2267

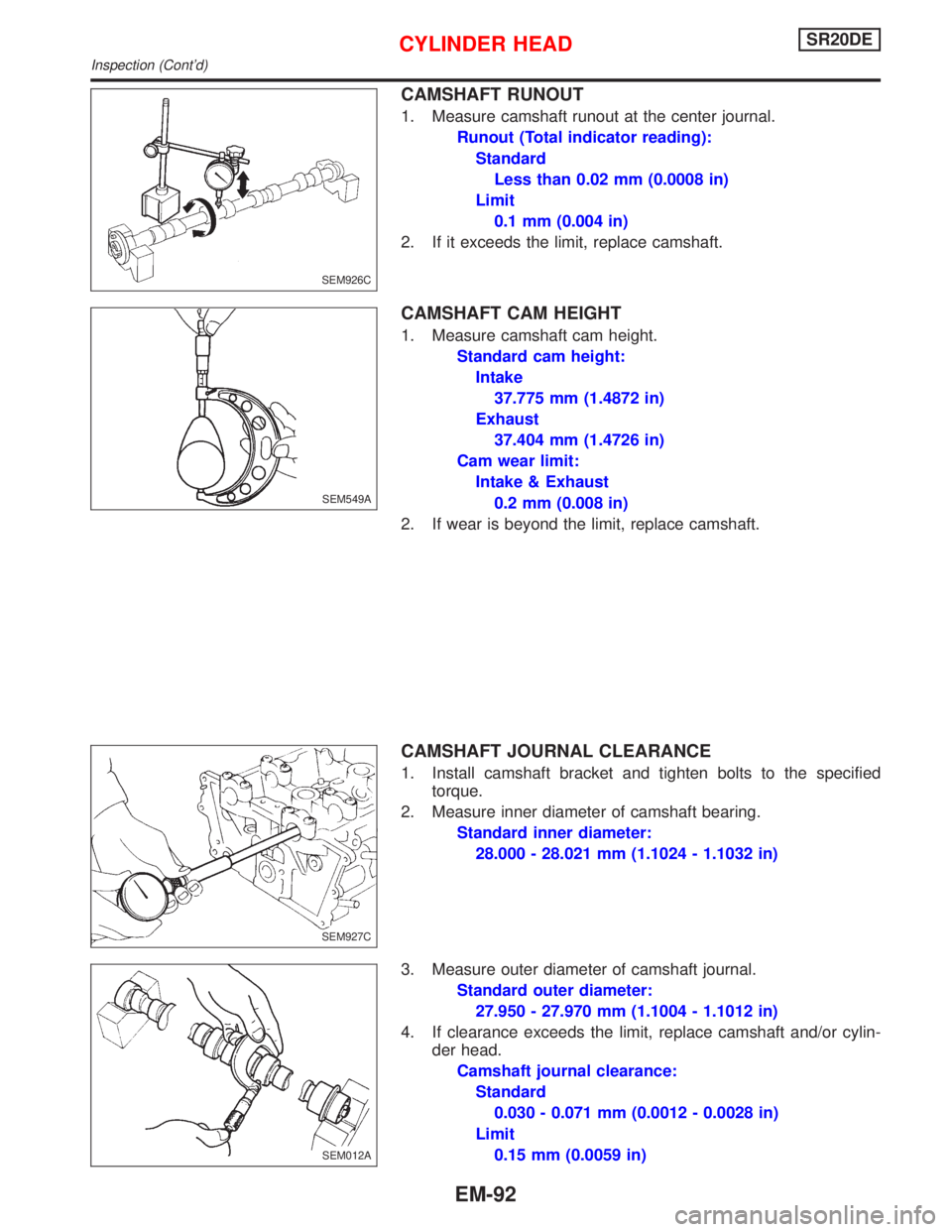

CAMSHAFT RUNOUT

1. Measure camshaft runout at the center journal.

Runout (Total indicator reading):

Standard

Less than 0.02 mm (0.0008 in)

Limit

0.1 mm (0.004 in)

2. If it exceeds the limit, replace camshaft.

CAMSHAFT CAM HEIGHT

1. Measure camshaft cam height.

Standard cam height:

Intake

37.775 mm (1.4872 in)

Exhaust

37.404 mm (1.4726 in)

Cam wear limit:

Intake & Exhaust

0.2 mm (0.008 in)

2. If wear is beyond the limit, replace camshaft.

CAMSHAFT JOURNAL CLEARANCE

1. Install camshaft bracket and tighten bolts to the specified

torque.

2. Measure inner diameter of camshaft bearing.

Standard inner diameter:

28.000 - 28.021 mm (1.1024 - 1.1032 in)

3. Measure outer diameter of camshaft journal.

Standard outer diameter:

27.950 - 27.970 mm (1.1004 - 1.1012 in)

4. If clearance exceeds the limit, replace camshaft and/or cylin-

der head.

Camshaft journal clearance:

Standard

0.030 - 0.071 mm (0.0012 - 0.0028 in)

Limit

0.15 mm (0.0059 in)

SEM926C

SEM549A

SEM927C

.SEM012A

CYLINDER HEADSR20DE

Inspection (Cont'd)

EM-92

Page 1633 of 2267

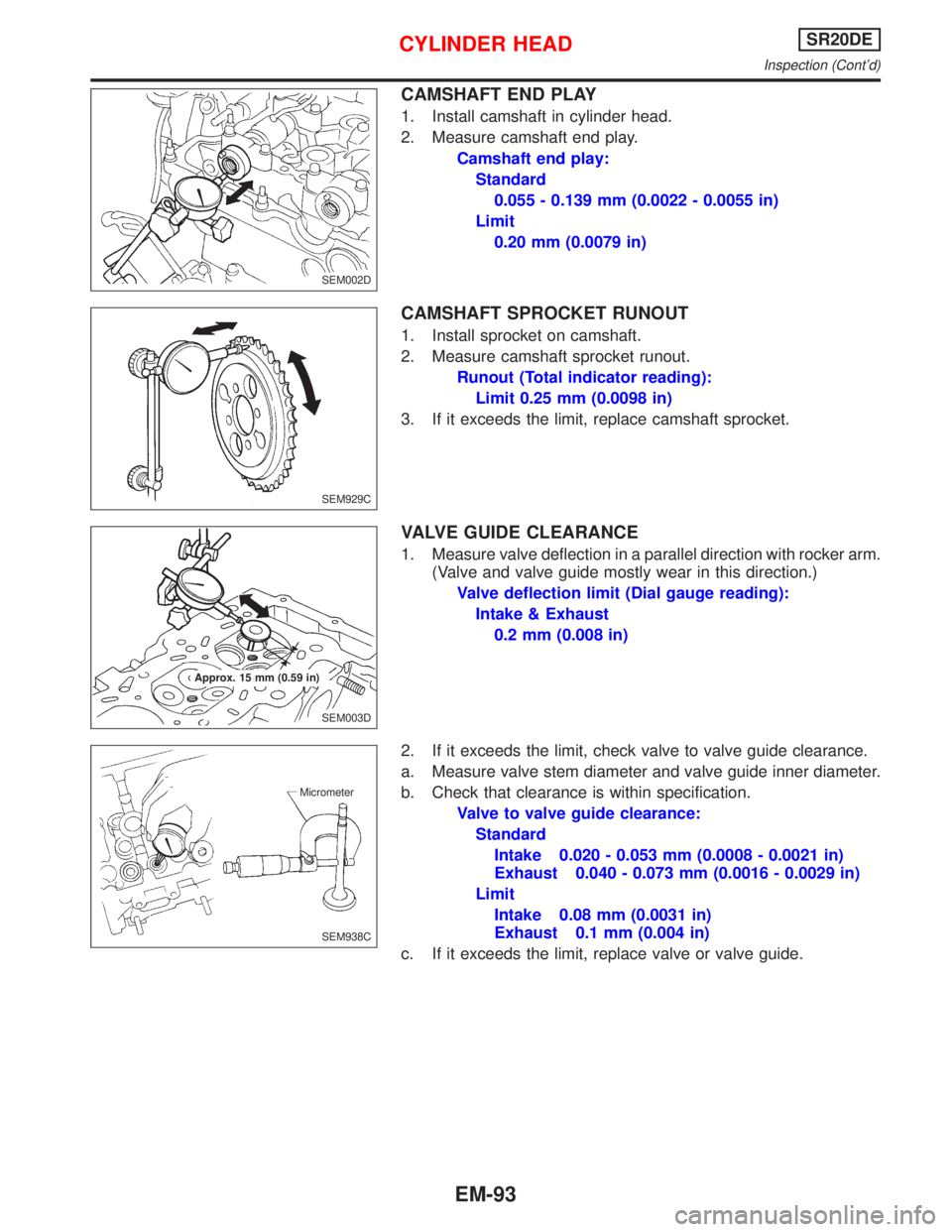

CAMSHAFT END PLAY

1. Install camshaft in cylinder head.

2. Measure camshaft end play.

Camshaft end play:

Standard

0.055 - 0.139 mm (0.0022 - 0.0055 in)

Limit

0.20 mm (0.0079 in)

CAMSHAFT SPROCKET RUNOUT

1. Install sprocket on camshaft.

2. Measure camshaft sprocket runout.

Runout (Total indicator reading):

Limit 0.25 mm (0.0098 in)

3. If it exceeds the limit, replace camshaft sprocket.

VALVE GUIDE CLEARANCE

1. Measure valve deflection in a parallel direction with rocker arm.

(Valve and valve guide mostly wear in this direction.)

Valve deflection limit (Dial gauge reading):

Intake & Exhaust

0.2 mm (0.008 in)

2. If it exceeds the limit, check valve to valve guide clearance.

a. Measure valve stem diameter and valve guide inner diameter.

b. Check that clearance is within specification.

Valve to valve guide clearance:

Standard

Intake 0.020 - 0.053 mm (0.0008 - 0.0021 in)

Exhaust 0.040 - 0.073 mm (0.0016 - 0.0029 in)

Limit

Intake 0.08 mm (0.0031 in)

Exhaust 0.1 mm (0.004 in)

c. If it exceeds the limit, replace valve or valve guide.

SEM002D

SEM929C

SEM003D Approx. 15 mm (0.59 in)

SEM938C Micrometer

CYLINDER HEADSR20DE

Inspection (Cont'd)

EM-93

Page 1634 of 2267

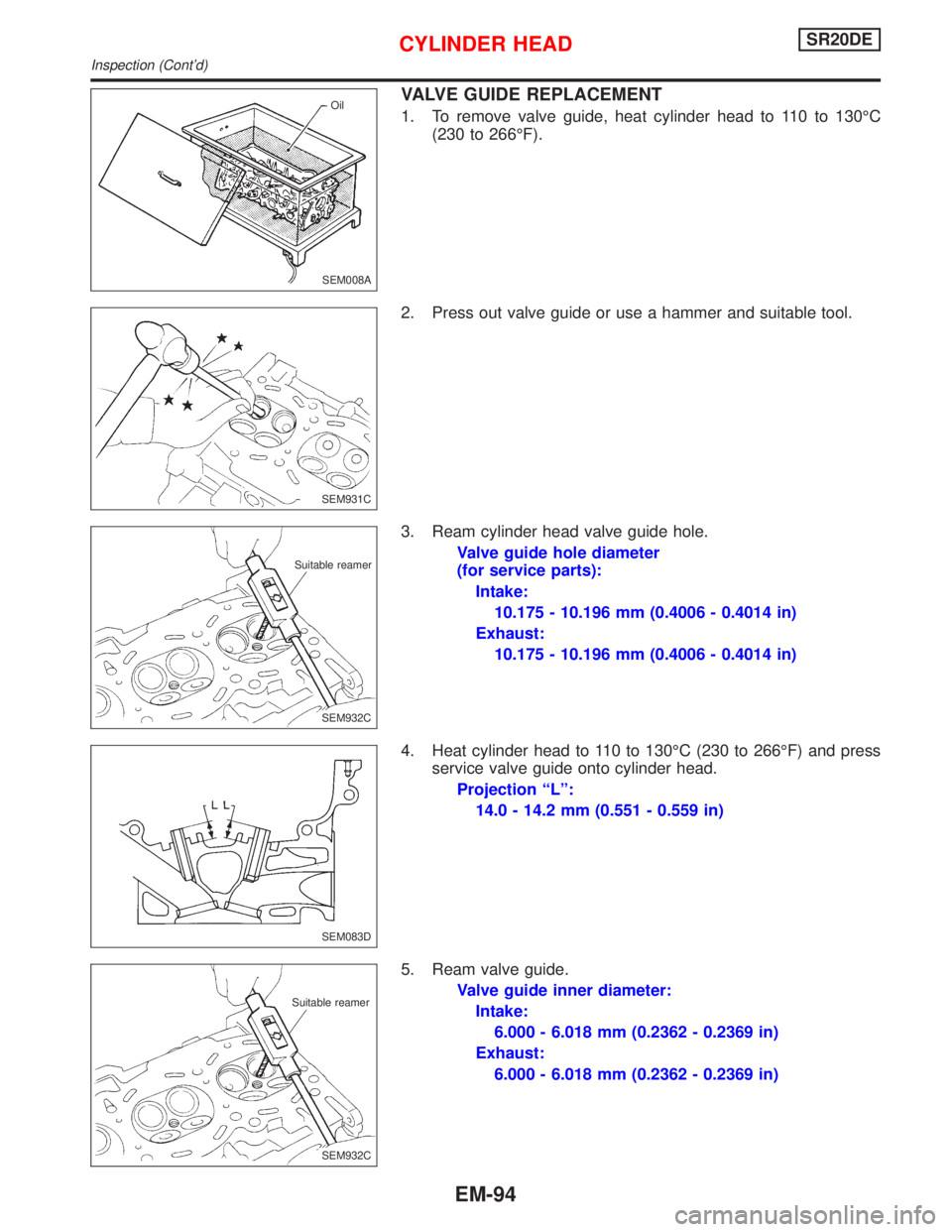

VALVE GUIDE REPLACEMENT

1. To remove valve guide, heat cylinder head to 110 to 130ÉC

(230 to 266ÉF).

2. Press out valve guide or use a hammer and suitable tool.

3. Ream cylinder head valve guide hole.

Valve guide hole diameter

(for service parts):

Intake:

10.175 - 10.196 mm (0.4006 - 0.4014 in)

Exhaust:

10.175 - 10.196 mm (0.4006 - 0.4014 in)

4. Heat cylinder head to 110 to 130ÉC (230 to 266ÉF) and press

service valve guide onto cylinder head.

Projection ªLº:

14.0 - 14.2 mm (0.551 - 0.559 in)

5. Ream valve guide.

Valve guide inner diameter:

Intake:

6.000 - 6.018 mm (0.2362 - 0.2369 in)

Exhaust:

6.000 - 6.018 mm (0.2362 - 0.2369 in)

SEM008AOil

SEM931C

.SEM932C Suitable reamer

SEM083D

.SEM932C Suitable reamer

CYLINDER HEADSR20DE

Inspection (Cont'd)

EM-94

Page 1635 of 2267

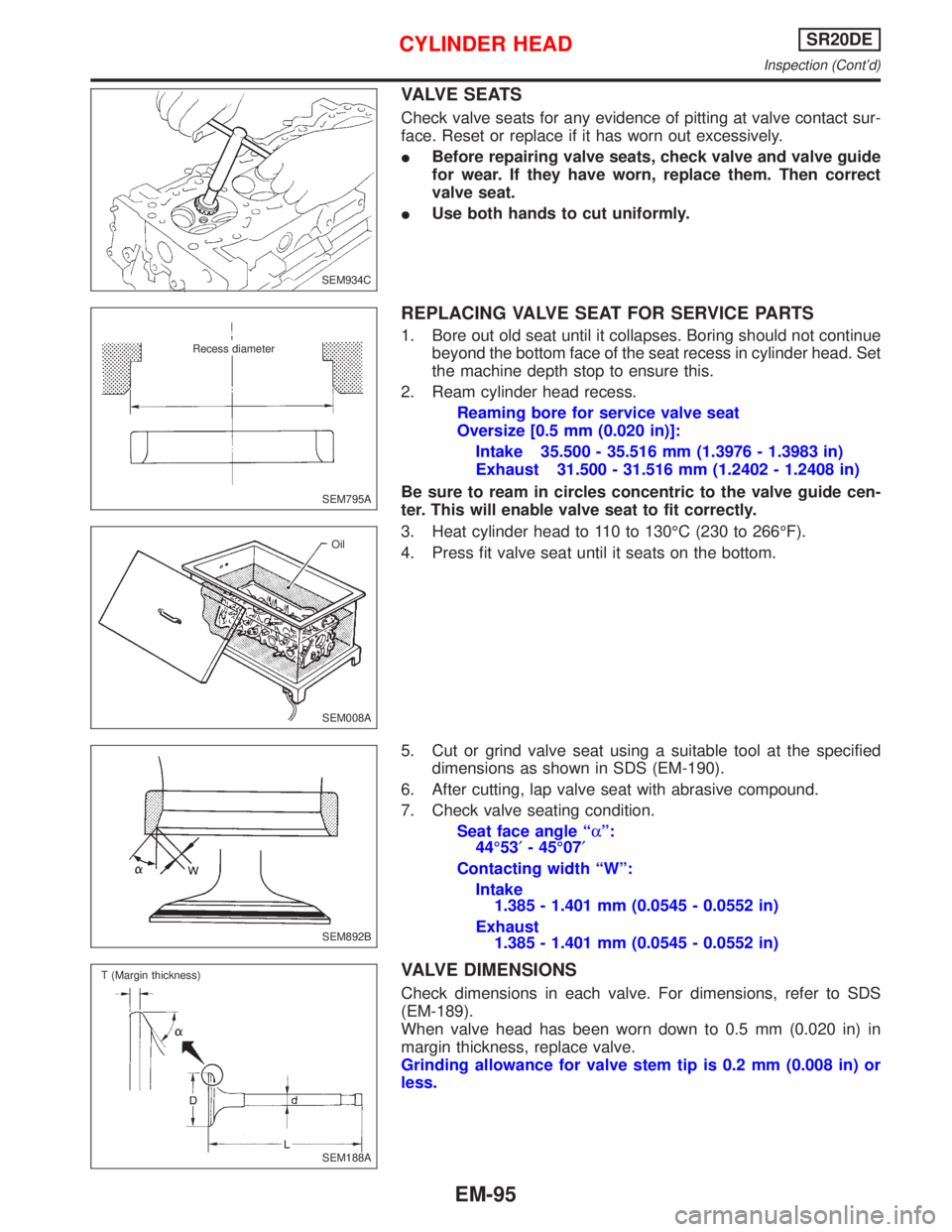

VALVE SEATS

Check valve seats for any evidence of pitting at valve contact sur-

face. Reset or replace if it has worn out excessively.

IBefore repairing valve seats, check valve and valve guide

for wear. If they have worn, replace them. Then correct

valve seat.

IUse both hands to cut uniformly.

REPLACING VALVE SEAT FOR SERVICE PARTS

1. Bore out old seat until it collapses. Boring should not continue

beyond the bottom face of the seat recess in cylinder head. Set

the machine depth stop to ensure this.

2. Ream cylinder head recess.

Reaming bore for service valve seat

Oversize [0.5 mm (0.020 in)]:

Intake 35.500 - 35.516 mm (1.3976 - 1.3983 in)

Exhaust 31.500 - 31.516 mm (1.2402 - 1.2408 in)

Be sure to ream in circles concentric to the valve guide cen-

ter. This will enable valve seat to fit correctly.

3. Heat cylinder head to 110 to 130ÉC (230 to 266ÉF).

4. Press fit valve seat until it seats on the bottom.

5. Cut or grind valve seat using a suitable tool at the specified

dimensions as shown in SDS (EM-190).

6. After cutting, lap valve seat with abrasive compound.

7. Check valve seating condition.

Seat face angle ªaº:

44É53¢- 45É07¢

Contacting width ªWº:

Intake

1.385 - 1.401 mm (0.0545 - 0.0552 in)

Exhaust

1.385 - 1.401 mm (0.0545 - 0.0552 in)

VALVE DIMENSIONS

Check dimensions in each valve. For dimensions, refer to SDS

(EM-189).

When valve head has been worn down to 0.5 mm (0.020 in) in

margin thickness, replace valve.

Grinding allowance for valve stem tip is 0.2 mm (0.008 in) or

less.

SEM934C

SEM795A

.Recess diameter

SEM008AOil

SEM892B

.SEM188A T (Margin thickness)

CYLINDER HEADSR20DE

Inspection (Cont'd)

EM-95

Page 1636 of 2267

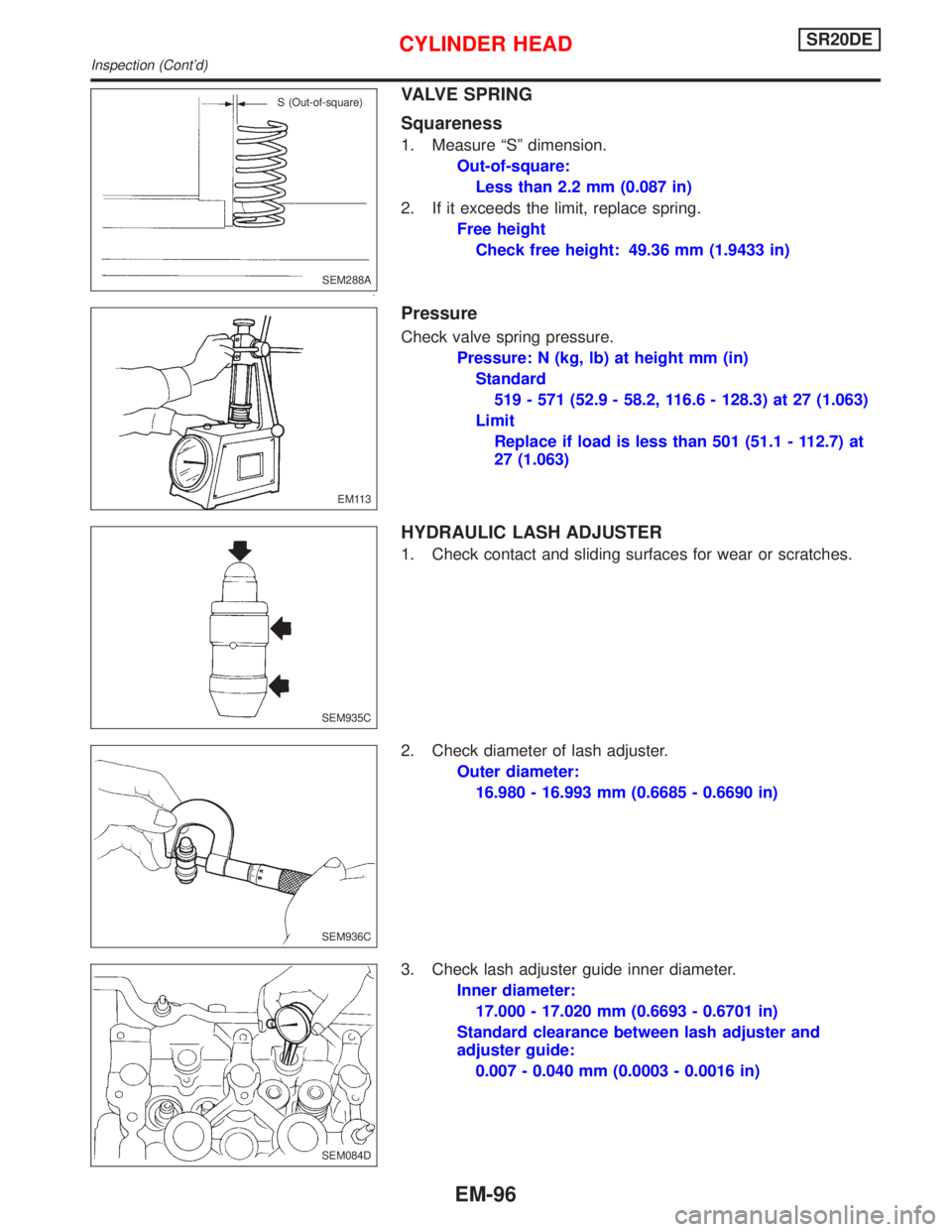

VALVE SPRING

Squareness

1. Measure ªSº dimension.

Out-of-square:

Less than 2.2 mm (0.087 in)

2. If it exceeds the limit, replace spring.

Free height

Check free height: 49.36 mm (1.9433 in)

Pressure

Check valve spring pressure.

Pressure: N (kg, lb) at height mm (in)

Standard

519 - 571 (52.9 - 58.2, 116.6 - 128.3) at 27 (1.063)

Limit

Replace if load is less than 501 (51.1 - 112.7) at

27 (1.063)

HYDRAULIC LASH ADJUSTER

1. Check contact and sliding surfaces for wear or scratches.

2. Check diameter of lash adjuster.

Outer diameter:

16.980 - 16.993 mm (0.6685 - 0.6690 in)

3. Check lash adjuster guide inner diameter.

Inner diameter:

17.000 - 17.020 mm (0.6693 - 0.6701 in)

Standard clearance between lash adjuster and

adjuster guide:

0.007 - 0.040 mm (0.0003 - 0.0016 in)

SEM288A S (Out-of-square)

EM113

SEM935C

SEM936C

.SEM084D

CYLINDER HEADSR20DE

Inspection (Cont'd)

EM-96

Page 1637 of 2267

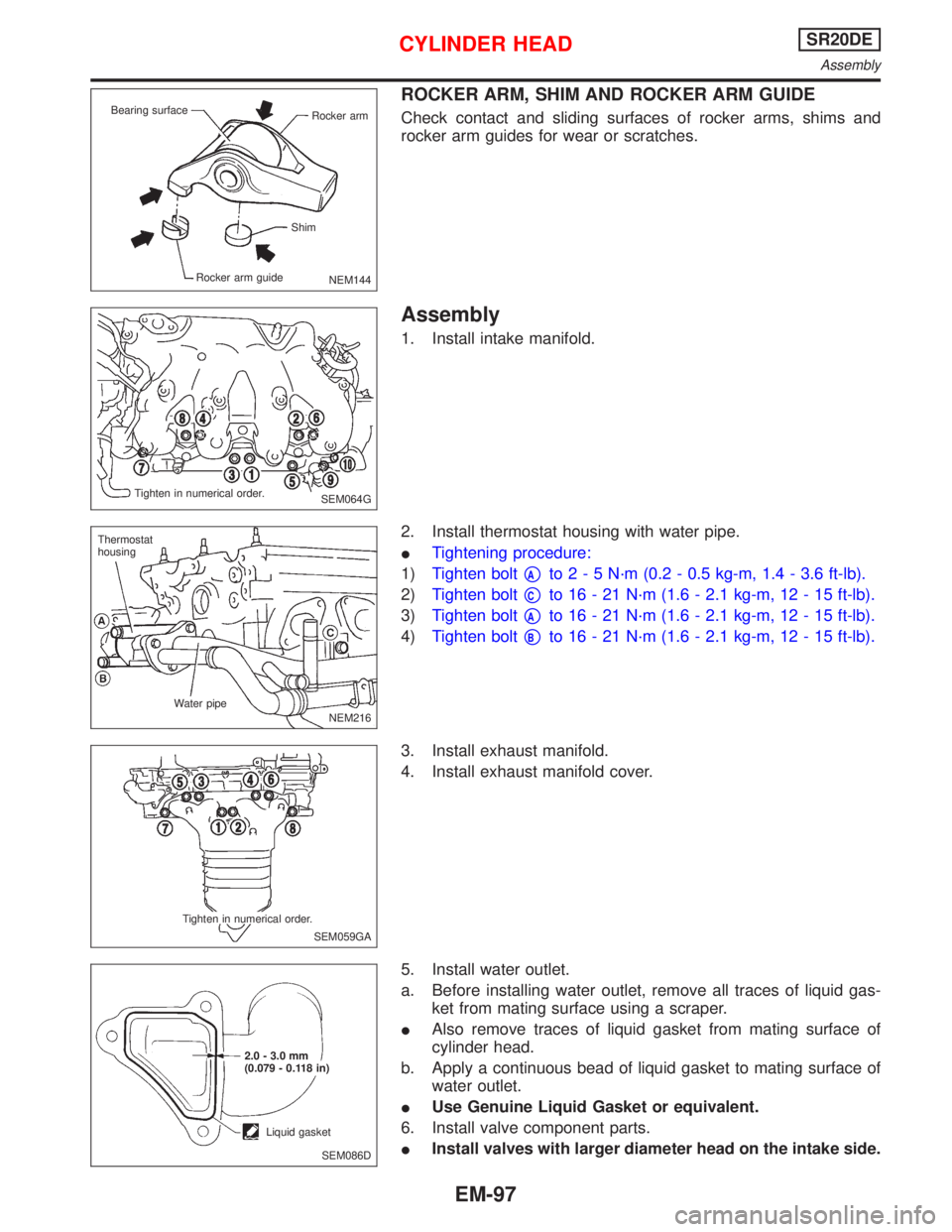

ROCKER ARM, SHIM AND ROCKER ARM GUIDE

Check contact and sliding surfaces of rocker arms, shims and

rocker arm guides for wear or scratches.

Assembly

1. Install intake manifold.

2. Install thermostat housing with water pipe.

ITightening procedure:

1)Tighten bolt

pAto2-5N´m(0.2 - 0.5 kg-m, 1.4 - 3.6 ft-lb).

2)Tighten bolt

pCto 16 - 21 N´m (1.6 - 2.1 kg-m, 12 - 15 ft-lb).

3)Tighten bolt

pAto 16 - 21 N´m (1.6 - 2.1 kg-m, 12 - 15 ft-lb).

4)Tighten bolt

pBto 16 - 21 N´m (1.6 - 2.1 kg-m, 12 - 15 ft-lb).

3. Install exhaust manifold.

4. Install exhaust manifold cover.

5. Install water outlet.

a. Before installing water outlet, remove all traces of liquid gas-

ket from mating surface using a scraper.

IAlso remove traces of liquid gasket from mating surface of

cylinder head.

b. Apply a continuous bead of liquid gasket to mating surface of

water outlet.

IUse Genuine Liquid Gasket or equivalent.

6. Install valve component parts.

IInstall valves with larger diameter head on the intake side.

NEM144 Bearing surface

Rocker arm

Shim

Rocker arm guide

SEM064G Tighten in numerical order.

NEM216 Thermostat

housing

Water pipe

SEM059GA Tighten in numerical order.

SEM086D 2.0 - 3.0 mm

(0.079 - 0.118 in)

Liquid gasket

CYLINDER HEADSR20DE

Assembly

EM-97

Page 1638 of 2267

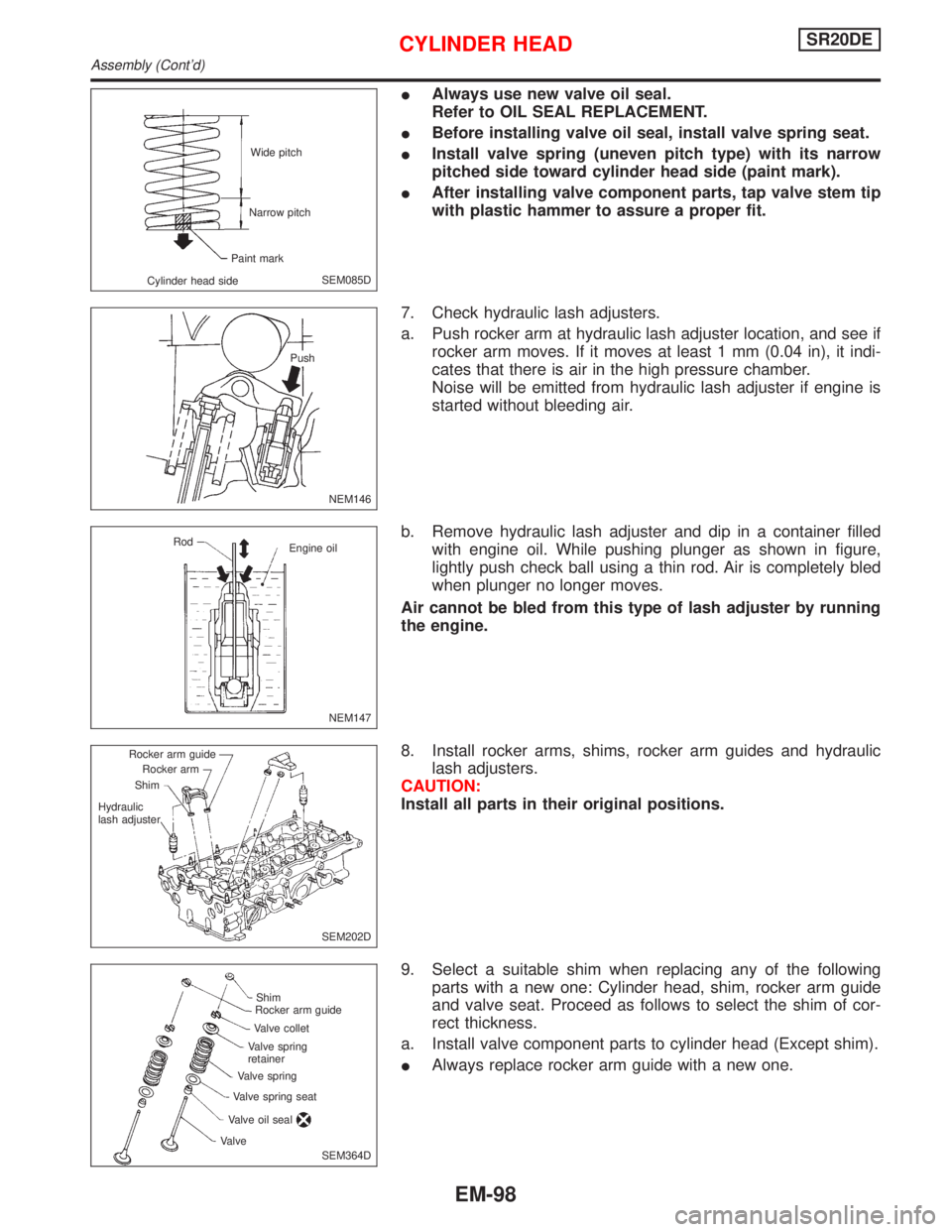

IAlways use new valve oil seal.

Refer to OIL SEAL REPLACEMENT.

IBefore installing valve oil seal, install valve spring seat.

IInstall valve spring (uneven pitch type) with its narrow

pitched side toward cylinder head side (paint mark).

IAfter installing valve component parts, tap valve stem tip

with plastic hammer to assure a proper fit.

7. Check hydraulic lash adjusters.

a. Push rocker arm at hydraulic lash adjuster location, and see if

rocker arm moves. If it moves at least 1 mm (0.04 in), it indi-

cates that there is air in the high pressure chamber.

Noise will be emitted from hydraulic lash adjuster if engine is

started without bleeding air.

b. Remove hydraulic lash adjuster and dip in a container filled

with engine oil. While pushing plunger as shown in figure,

lightly push check ball using a thin rod. Air is completely bled

when plunger no longer moves.

Air cannot be bled from this type of lash adjuster by running

the engine.

8. Install rocker arms, shims, rocker arm guides and hydraulic

lash adjusters.

CAUTION:

Install all parts in their original positions.

9. Select a suitable shim when replacing any of the following

parts with a new one: Cylinder head, shim, rocker arm guide

and valve seat. Proceed as follows to select the shim of cor-

rect thickness.

a. Install valve component parts to cylinder head (Except shim).

IAlways replace rocker arm guide with a new one.

SEM085D Wide pitch

Narrow pitch

Paint mark

Cylinder head side

NEM146 Push

NEM147 Rod

Engine oil

SEM202D Rocker arm guide

Rocker arm

Shim

Hydraulic

lash adjuster

SEM364D Shim

Rocker arm guide

Valve collet

Valve spring

retainer

Valve spring

Valve spring seat

Valve oil sealValve

CYLINDER HEADSR20DE

Assembly (Cont'd)

EM-98

Page 1639 of 2267

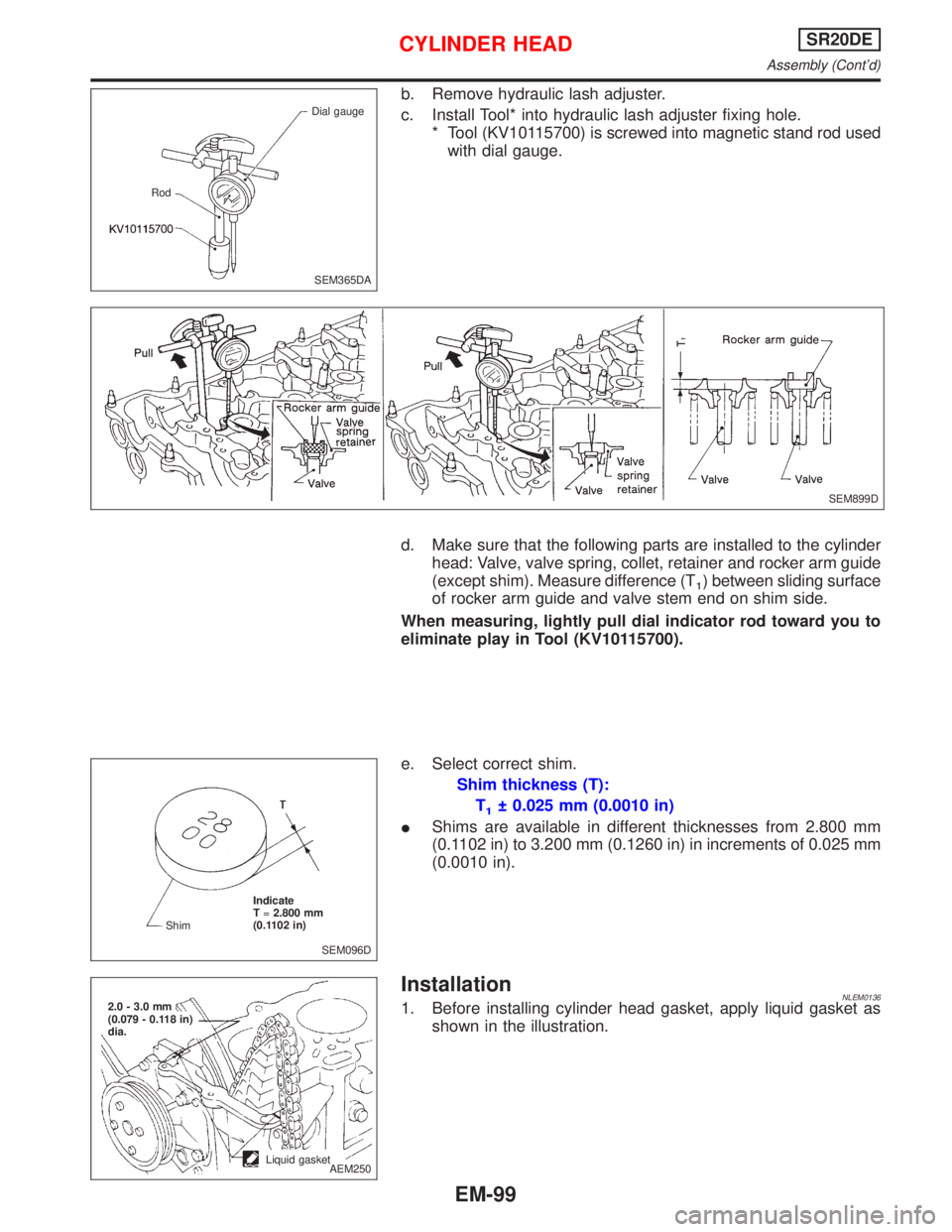

b. Remove hydraulic lash adjuster.

c. Install Tool* into hydraulic lash adjuster fixing hole.

* Tool (KV10115700) is screwed into magnetic stand rod used

with dial gauge.

d. Make sure that the following parts are installed to the cylinder

head: Valve, valve spring, collet, retainer and rocker arm guide

(except shim). Measure difference (T

1) between sliding surface

of rocker arm guide and valve stem end on shim side.

When measuring, lightly pull dial indicator rod toward you to

eliminate play in Tool (KV10115700).

e. Select correct shim.

Shim thickness (T):

T

1 0.025 mm (0.0010 in)

IShims are available in different thicknesses from 2.800 mm

(0.1102 in) to 3.200 mm (0.1260 in) in increments of 0.025 mm

(0.0010 in).

InstallationNLEM01361. Before installing cylinder head gasket, apply liquid gasket as

shown in the illustration.

SEM365DA Dial gauge

Rod

SEM899D

SEM096D ShimIndicate

T=2.800 mm

(0.1102 in)

AEM250 2.0 - 3.0 mm

(0.079 - 0.118 in)

dia.Liquid gasket

CYLINDER HEADSR20DE

Assembly (Cont'd)

EM-99

Page 1640 of 2267

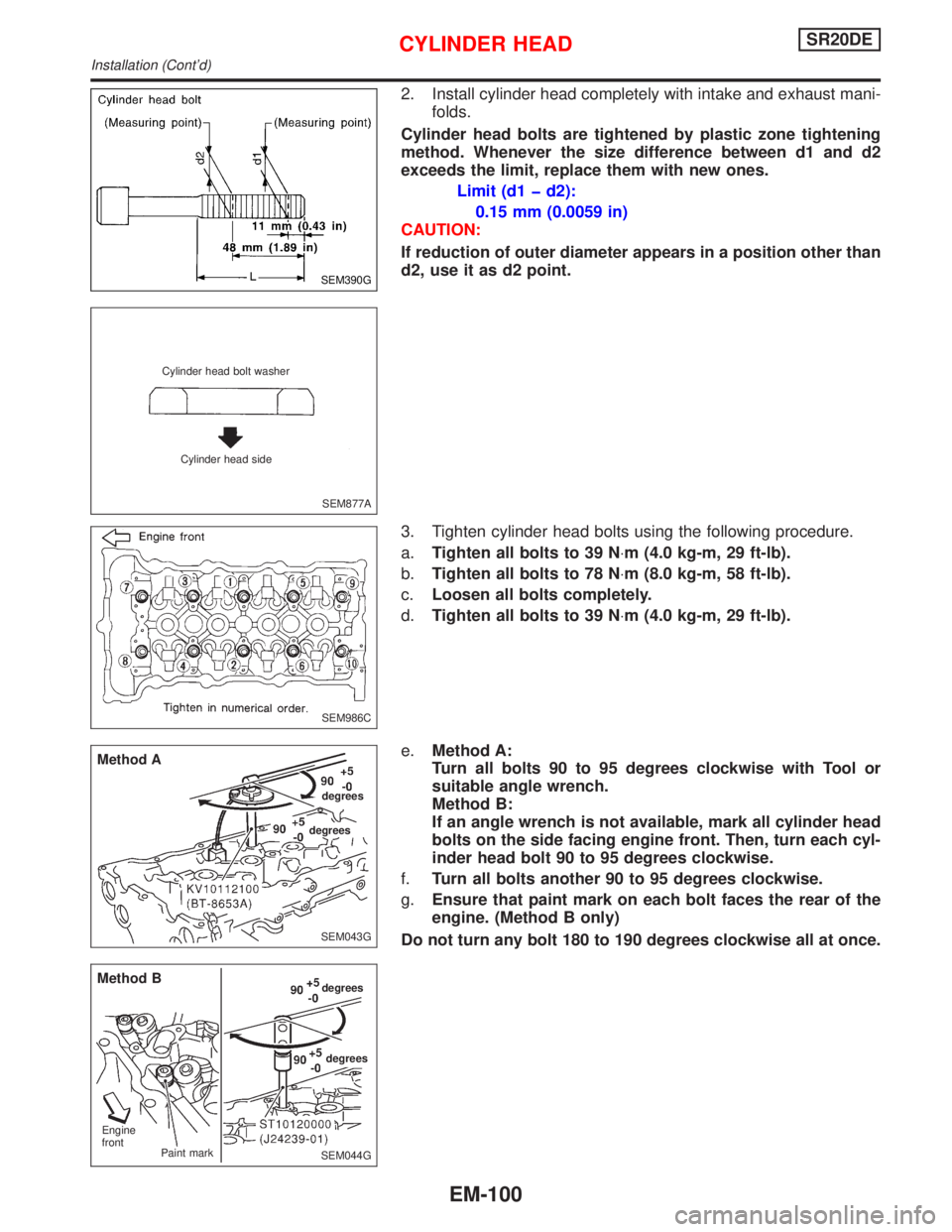

2. Install cylinder head completely with intake and exhaust mani-

folds.

Cylinder head bolts are tightened by plastic zone tightening

method. Whenever the size difference between d1 and d2

exceeds the limit, replace them with new ones.

Limit (d1 þ d2):

0.15 mm (0.0059 in)

CAUTION:

If reduction of outer diameter appears in a position other than

d2, use it as d2 point.

3. Tighten cylinder head bolts using the following procedure.

a.Tighten all bolts to 39 N×m (4.0 kg-m, 29 ft-lb).

b.Tighten all bolts to 78 N×m (8.0 kg-m, 58 ft-lb).

c.Loosen all bolts completely.

d.Tighten all bolts to 39 N×m (4.0 kg-m, 29 ft-lb).

e.Method A:

Turn all bolts 90 to 95 degrees clockwise with Tool or

suitable angle wrench.

Method B:

If an angle wrench is not available, mark all cylinder head

bolts on the side facing engine front. Then, turn each cyl-

inder head bolt 90 to 95 degrees clockwise.

f.Turn all bolts another 90 to 95 degrees clockwise.

g.Ensure that paint mark on each bolt faces the rear of the

engine. (Method B only)

Do not turn any bolt 180 to 190 degrees clockwise all at once.

SEM390G

SEM877A Cylinder head bolt washer

Cylinder head side

SEM986C

SEM043G

Method A

degrees

degrees

SEM044G

Method Bdegrees

degrees

Engine

front

Paint mark

CYLINDER HEADSR20DE

Installation (Cont'd)

EM-100