NISSAN PRIMERA 1999 Electronic Repair Manual

PRIMERA 1999

NISSAN

NISSAN

https://www.carmanualsonline.info/img/5/57377/w960_57377-0.png

NISSAN PRIMERA 1999 Electronic Repair Manual

Trending: wiper fluid, check oil, clutch, odometer, airbag off, manual transmission, fuel cap

Page 1771 of 2267

INSPECTION

Shock absorber assembly

lCheck for smooth operation through a full stroke, both com-

pression and extension.

lCheck for oil leakage occurring on welded or gland packing

portions.

lCheck piston rod for cracks, deformation or other damage.

Replace if necessary.

Mounting insulator and rubber parts

lCheck cemented rubber-to-metal portion for separation or

cracks.

lCheck rubber parts for deterioration. Replace if necessary.

Coil spring

lCheck for cracks, deformation or other damage. Replace if

necessary.

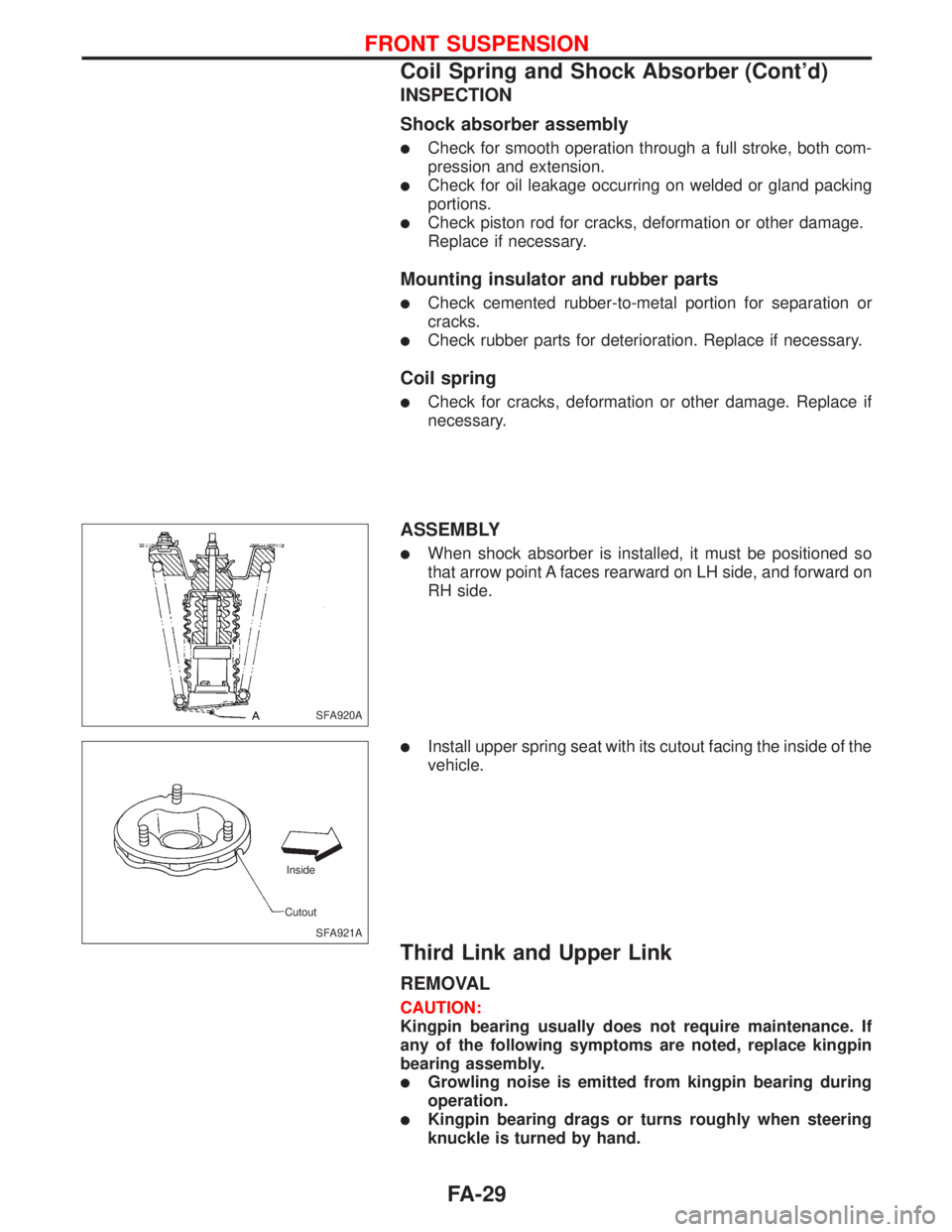

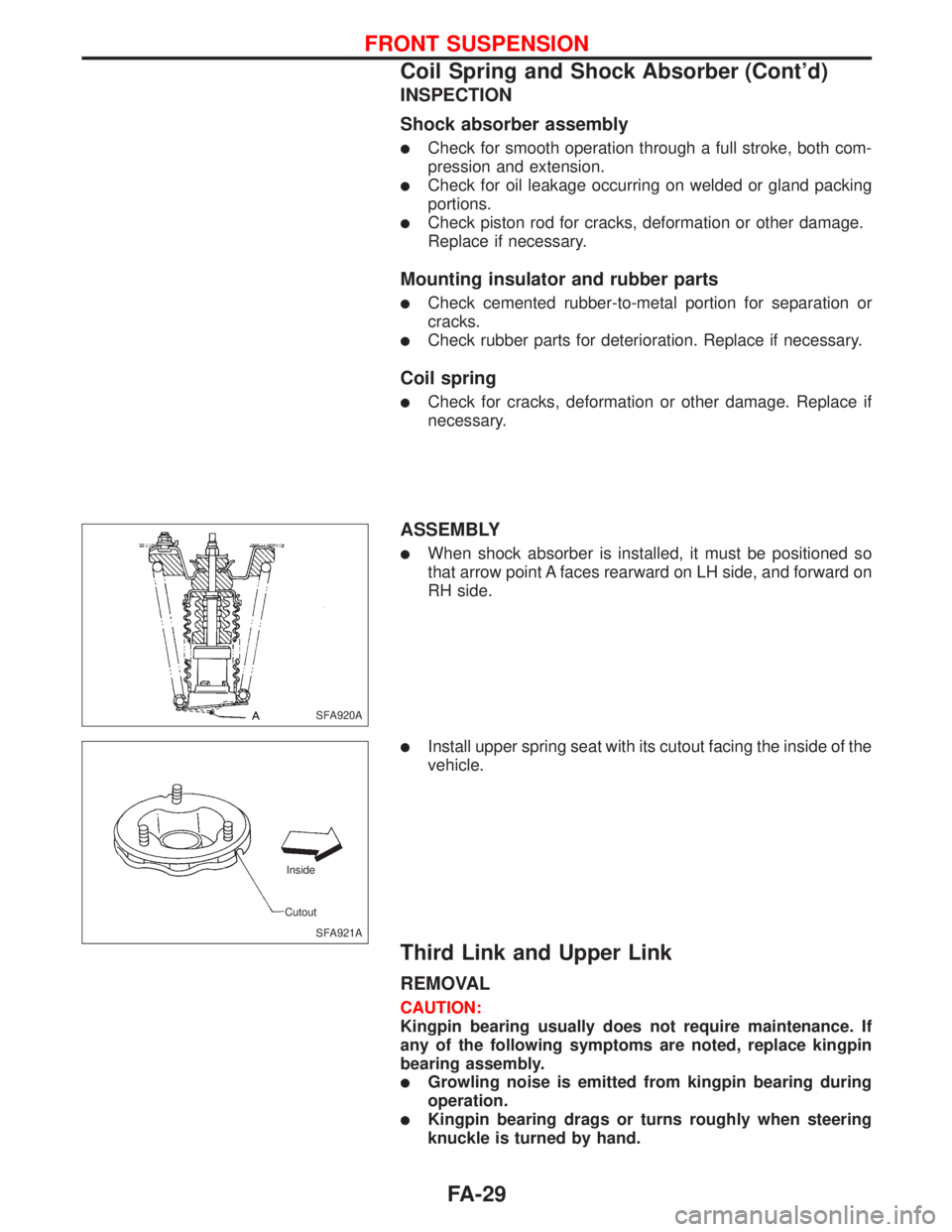

ASSEMBLY

lWhen shock absorber is installed, it must be positioned so

that arrow point A faces rearward on LH side, and forward on

RH side.

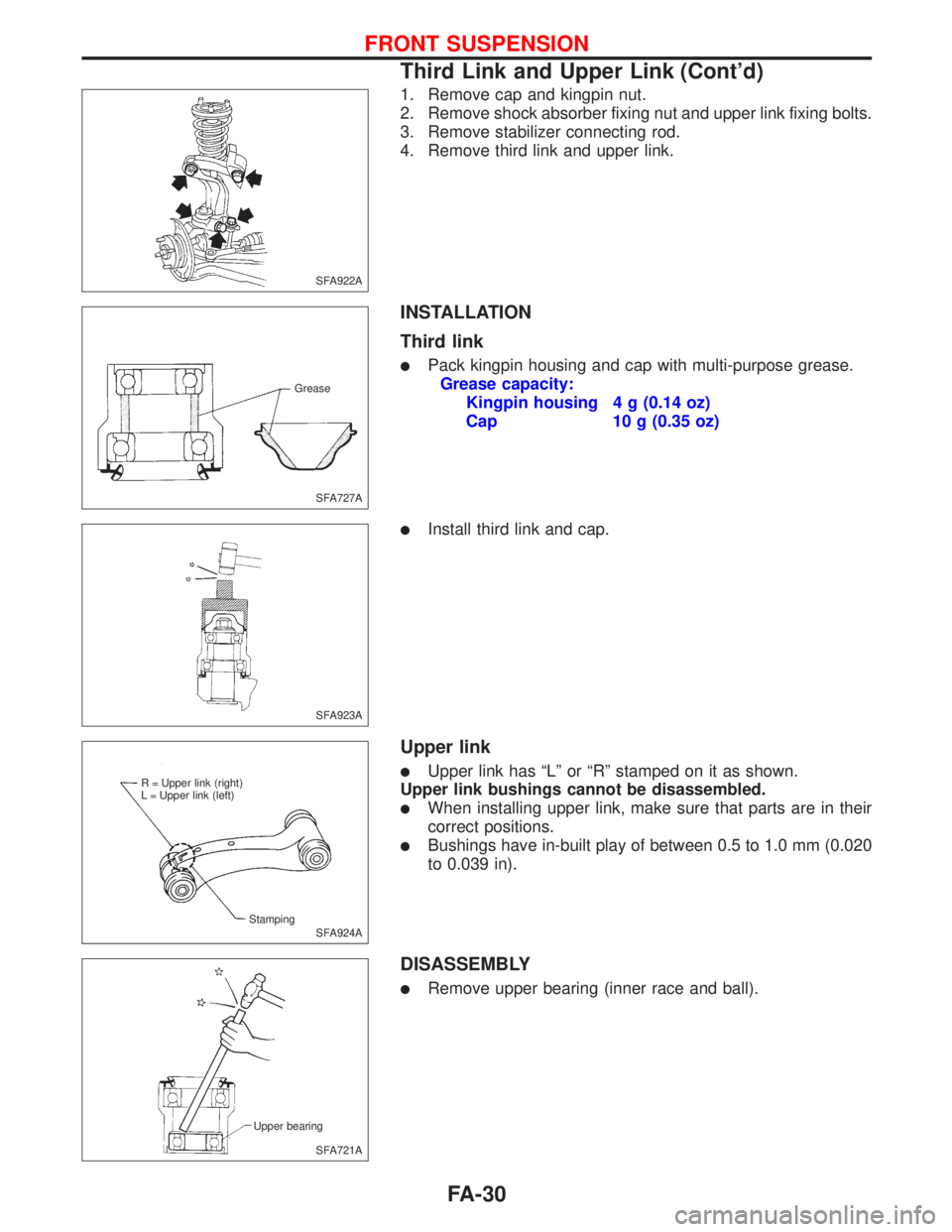

lInstall upper spring seat with its cutout facing the inside of the

vehicle.

Third Link and Upper Link

REMOVAL

CAUTION:

Kingpin bearing usually does not require maintenance. If

any of the following symptoms are noted, replace kingpin

bearing assembly.

lGrowling noise is emitted from kingpin bearing during

operation.

lKingpin bearing drags or turns roughly when steering

knuckle is turned by hand.

SFA920A

SFA921A Inside

Cutout

FRONT SUSPENSION

Coil Spring and Shock Absorber (Cont'd)

FA-29

Page 1772 of 2267

1. Remove cap and kingpin nut.

2. Remove shock absorber fixing nut and upper link fixing bolts.

3. Remove stabilizer connecting rod.

4. Remove third link and upper link.

INSTALLATION

Third link

lPack kingpin housing and cap with multi-purpose grease.

Grease capacity:

Kingpin housing 4 g (0.14 oz)

Cap 10 g (0.35 oz)

lInstall third link and cap.

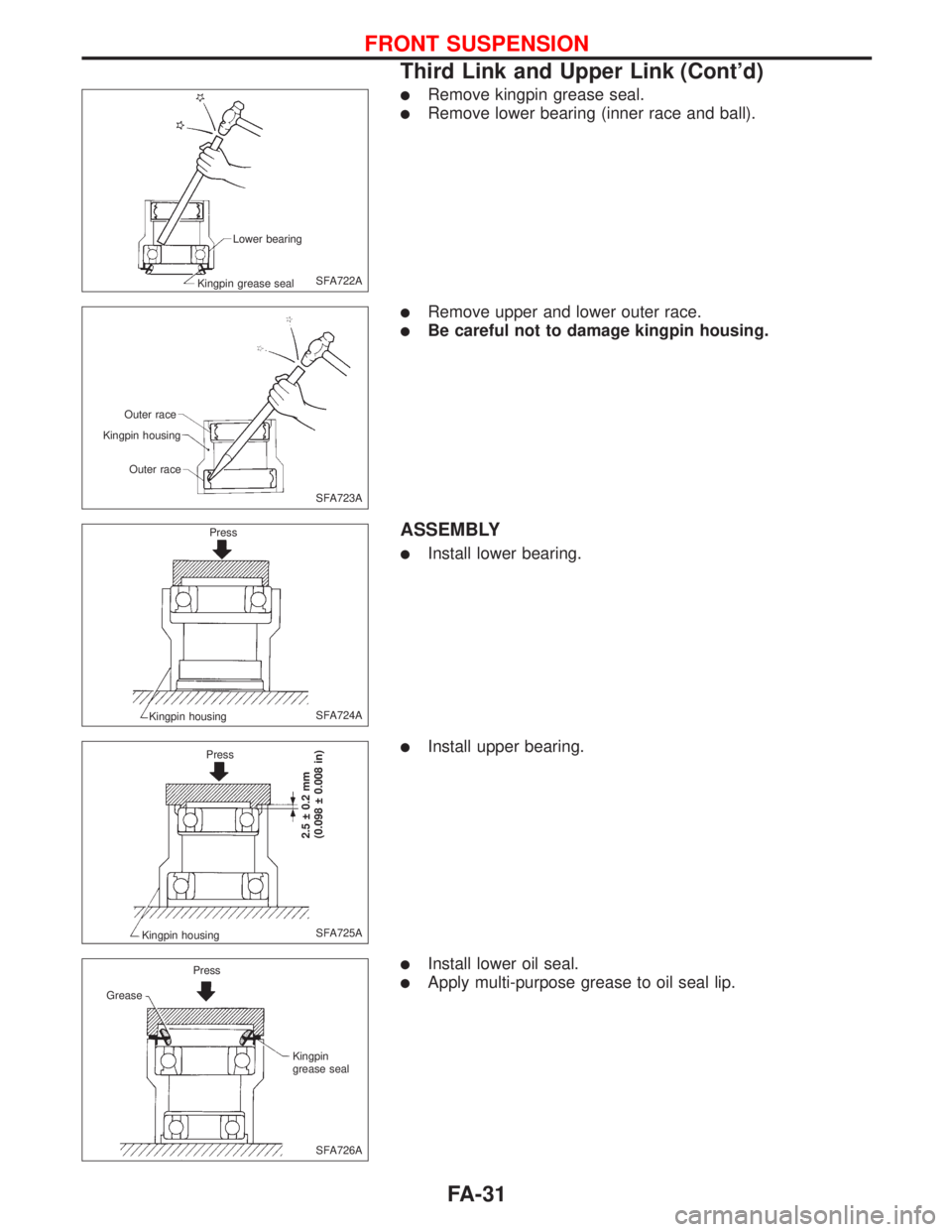

Upper link

lUpper link has ªLº or ªRº stamped on it as shown.

Upper link bushings cannot be disassembled.

lWhen installing upper link, make sure that parts are in their

correct positions.

lBushings have in-built play of between 0.5 to 1.0 mm (0.020

to 0.039 in).

DISASSEMBLY

lRemove upper bearing (inner race and ball).

SFA922A

SFA727A Grease

SFA923A

SFA924A R = Upper link (right)

L = Upper link (left)

Stamping

SFA721A Upper bearing

FRONT SUSPENSION

Third Link and Upper Link (Cont'd)

FA-30

Page 1773 of 2267

lRemove kingpin grease seal.

lRemove lower bearing (inner race and ball).

lRemove upper and lower outer race.

lBe careful not to damage kingpin housing.

ASSEMBLY

lInstall lower bearing.

lInstall upper bearing.

lInstall lower oil seal.

lApply multi-purpose grease to oil seal lip.

SFA722A Lower bearing

Kingpin grease seal

SFA723A Outer race

Kingpin housing

Outer race

SFA724A Press

Kingpin housing

SFA725A Press

Kingpin housing

2.5 0.2 mm

(0.098 0.008 in)

SFA726A Press

Grease

Kingpin

grease seal

FRONT SUSPENSION

Third Link and Upper Link (Cont'd)

FA-31

Page 1774 of 2267

Transverse Link and Lower Ball Joint

REMOVAL AND INSTALLATION

lRemove tension rod, ball joint and transverse link assembly.

lDuring installation, final tightening must be done at curb

weight with tires on ground.

lAfter installation, check wheel alignment.

Refer to ªFront Wheel Alignmentº, ªON-VEHICLE SER-

VICEº, FA-6.

INSPECTION

Transverse link

lCheck transverse link for damage, cracks or deformation.

Replace it if necessary.

lCheck rubber bushing for damage, cracks and deformation.

Replace transverse link if necessary.

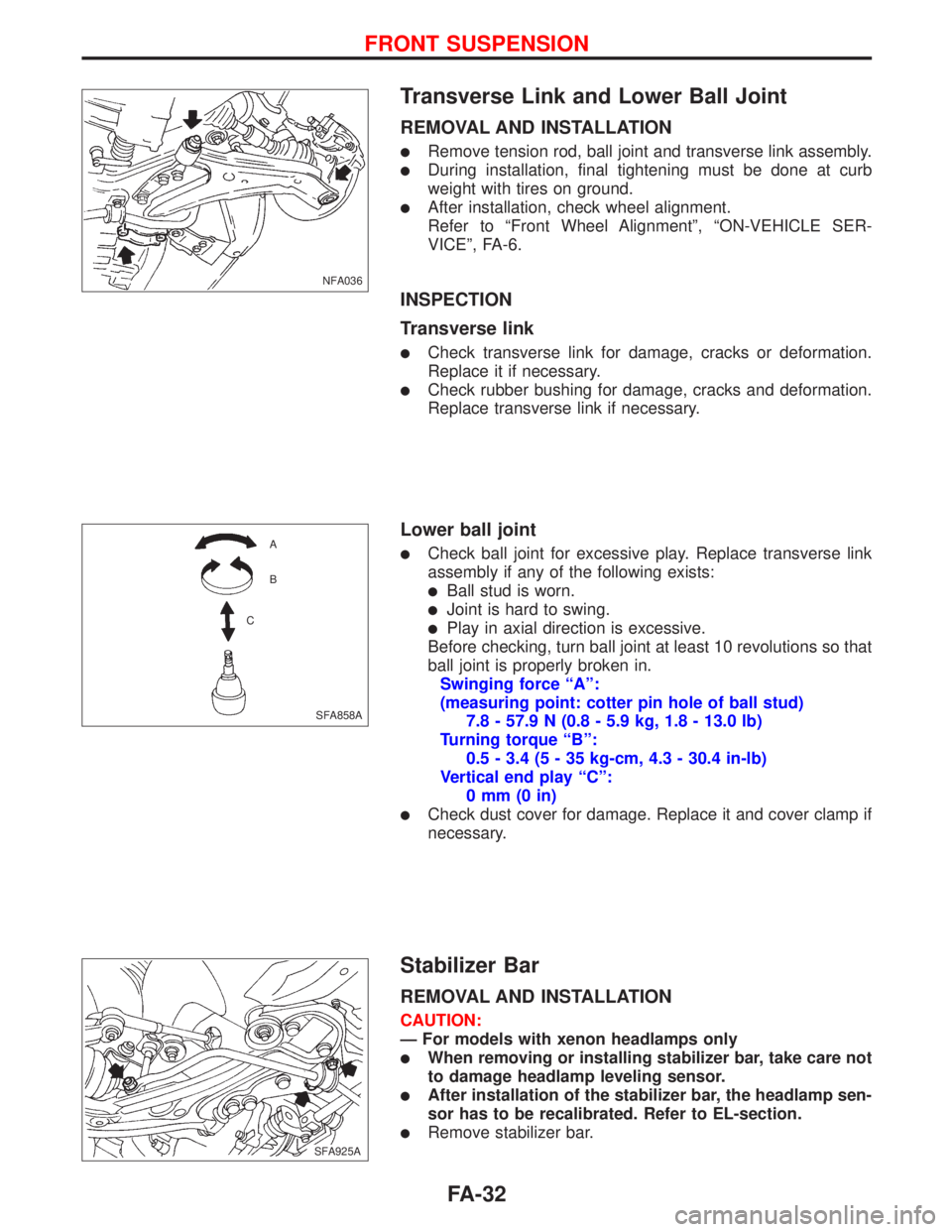

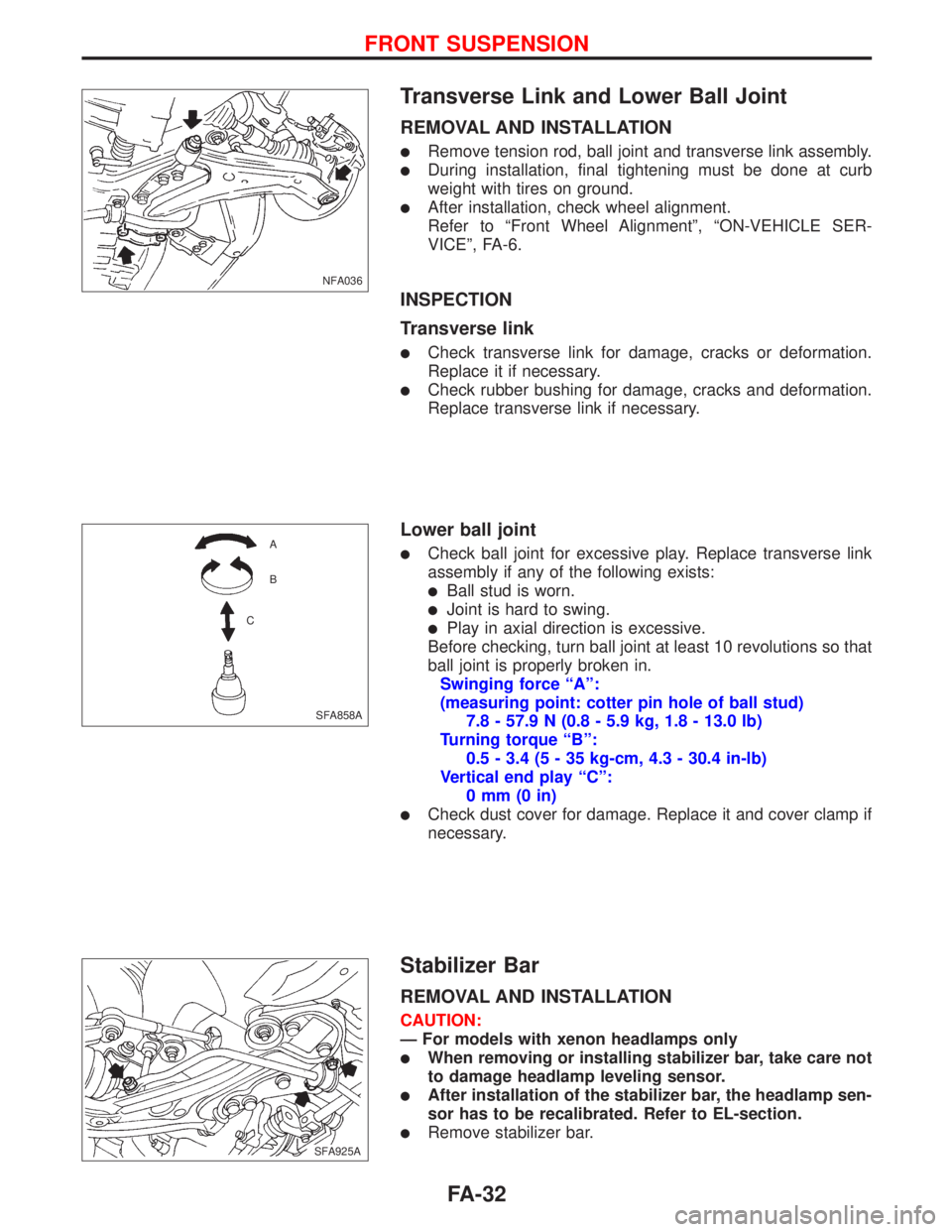

Lower ball joint

lCheck ball joint for excessive play. Replace transverse link

assembly if any of the following exists:

lBall stud is worn.

lJoint is hard to swing.

lPlay in axial direction is excessive.

Before checking, turn ball joint at least 10 revolutions so that

ball joint is properly broken in.

Swinging force ªAº:

(measuring point: cotter pin hole of ball stud)

7.8 - 57.9 N (0.8 - 5.9 kg, 1.8 - 13.0 lb)

Turning torque ªBº:

0.5 - 3.4 (5 - 35 kg-cm, 4.3 - 30.4 in-lb)

Vertical end play ªCº:

0mm(0in)

lCheck dust cover for damage. Replace it and cover clamp if

necessary.

Stabilizer Bar

REMOVAL AND INSTALLATION

CAUTION:

Ð For models with xenon headlamps only

lWhen removing or installing stabilizer bar, take care not

to damage headlamp leveling sensor.

lAfter installation of the stabilizer bar, the headlamp sen-

sor has to be recalibrated. Refer to EL-section.

lRemove stabilizer bar.

NFA036

SFA858A A

B

C

.SFA925A

FRONT SUSPENSION

FA-32

Page 1775 of 2267

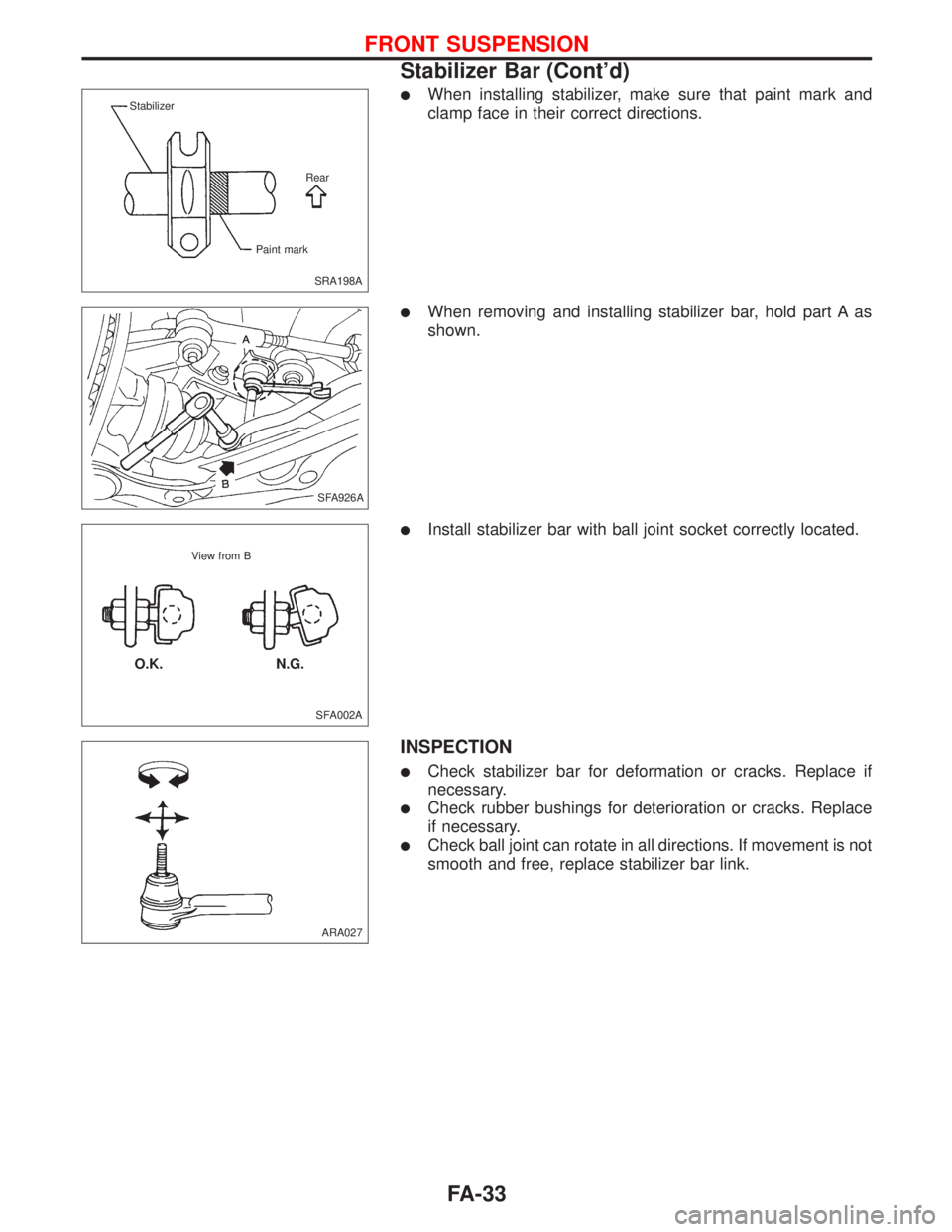

lWhen installing stabilizer, make sure that paint mark and

clamp face in their correct directions.

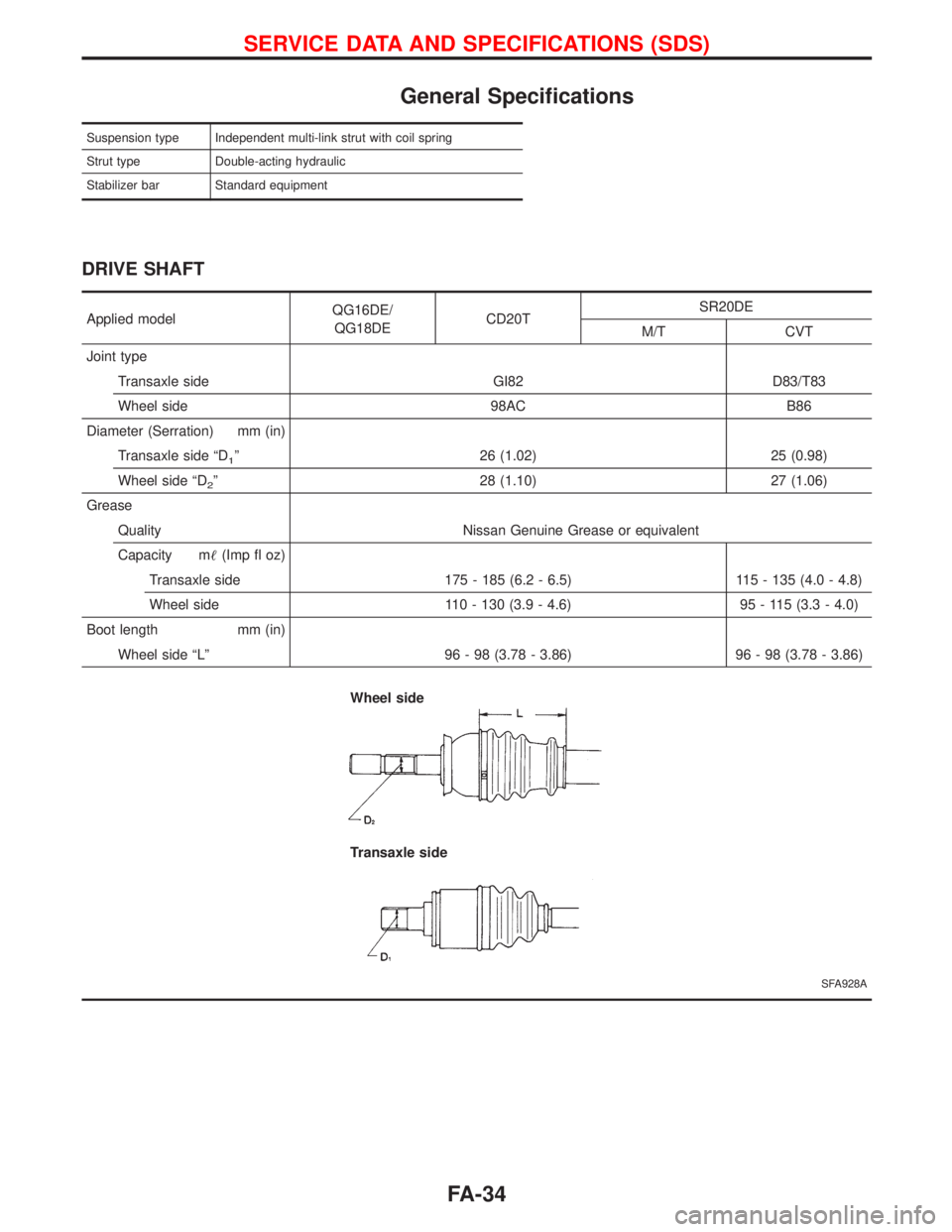

lWhen removing and installing stabilizer bar, hold part A as

shown.

lInstall stabilizer bar with ball joint socket correctly located.

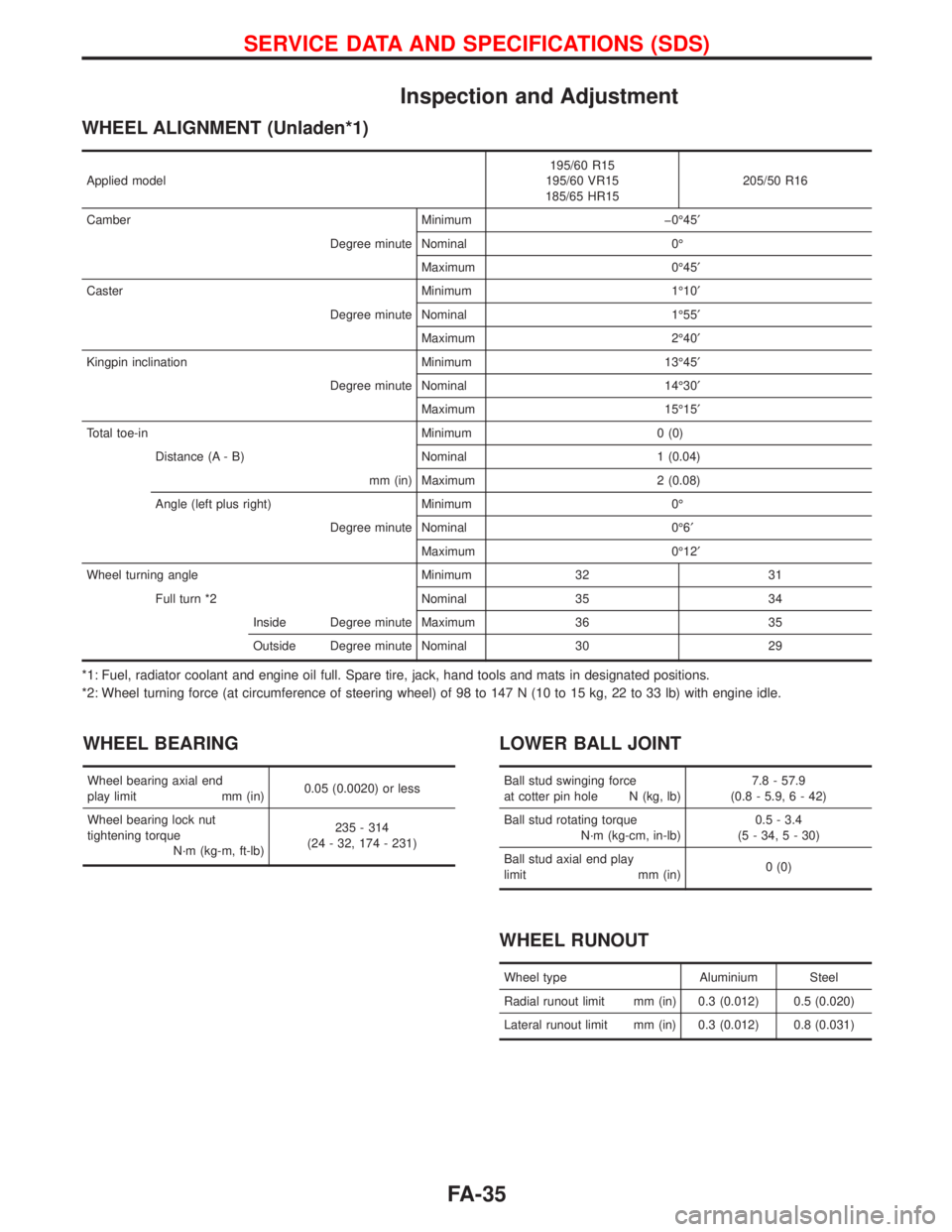

INSPECTION

lCheck stabilizer bar for deformation or cracks. Replace if

necessary.

lCheck rubber bushings for deterioration or cracks. Replace

if necessary.

lCheck ball joint can rotate in all directions. If movement is not

smooth and free, replace stabilizer bar link.

SRA198A Stabilizer

Rear

Paint mark

.SFA926A

SFA002A View from B

O.K. N.G.

ARA027

FRONT SUSPENSION

Stabilizer Bar (Cont'd)

FA-33

Page 1776 of 2267

General Specifications

Suspension type Independent multi-link strut with coil spring

Strut type Double-acting hydraulic

Stabilizer bar Standard equipment

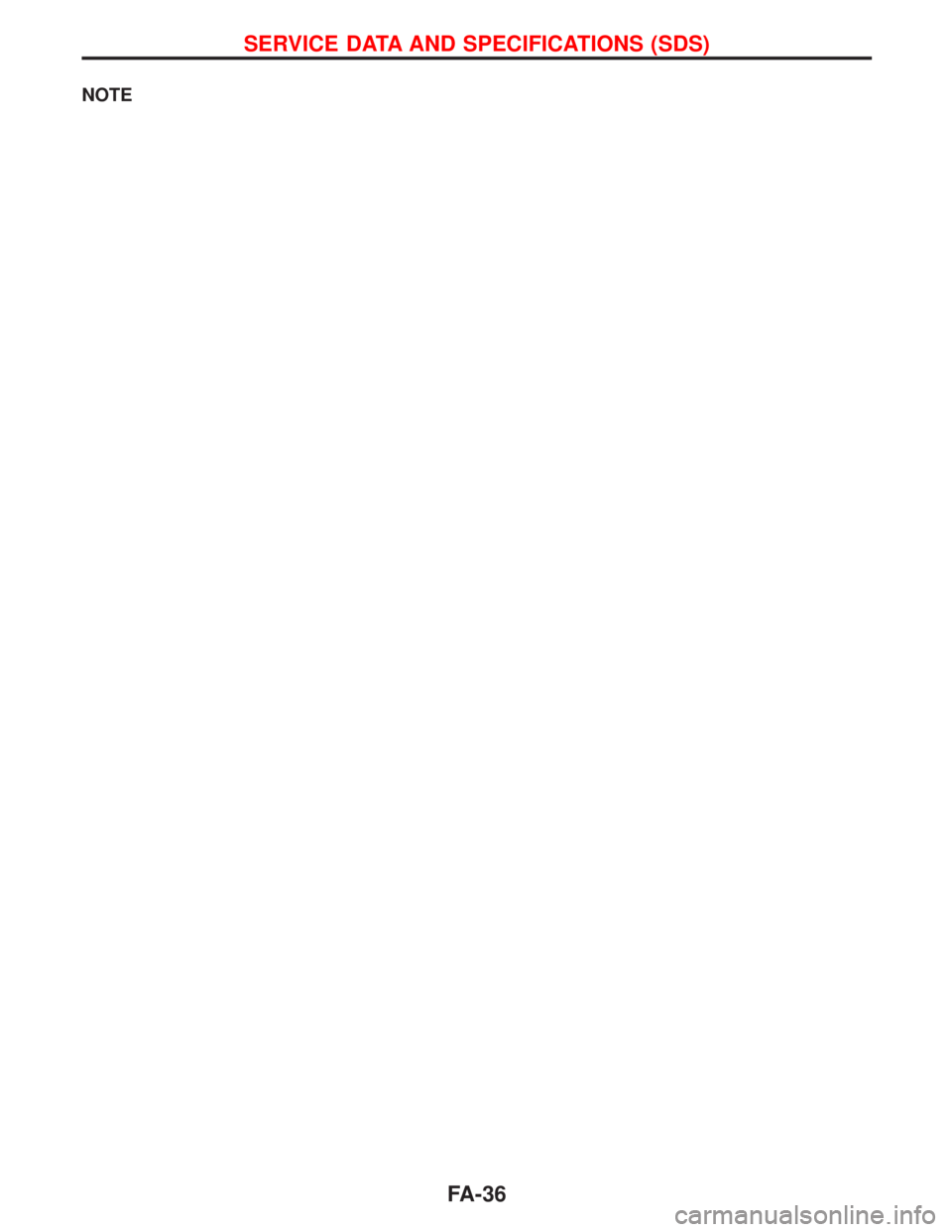

DRIVE SHAFT

Applied modelQG16DE/

QG18DECD20TSR20DE

M/T CVT

Joint type

Transaxle side GI82 D83/T83

Wheel side 98AC B86

Diameter (Serration) mm (in)

Transaxle side ªD

1º 26 (1.02) 25 (0.98)

Wheel side ªD

2º 28 (1.10) 27 (1.06)

Grease

Quality Nissan Genuine Grease or equivalent

Capacity m(Imp fl oz)

Transaxle side 175 - 185 (6.2 - 6.5) 115 - 135 (4.0 - 4.8)

Wheel side 110 - 130 (3.9 - 4.6) 95 - 115 (3.3 - 4.0)

Boot length mm (in)

Wheel side ªLº 96 - 98 (3.78 - 3.86) 96 - 98 (3.78 - 3.86)

SFA928A

Wheel side

Transaxle side

SERVICE DATA AND SPECIFICATIONS (SDS)

FA-34

Page 1777 of 2267

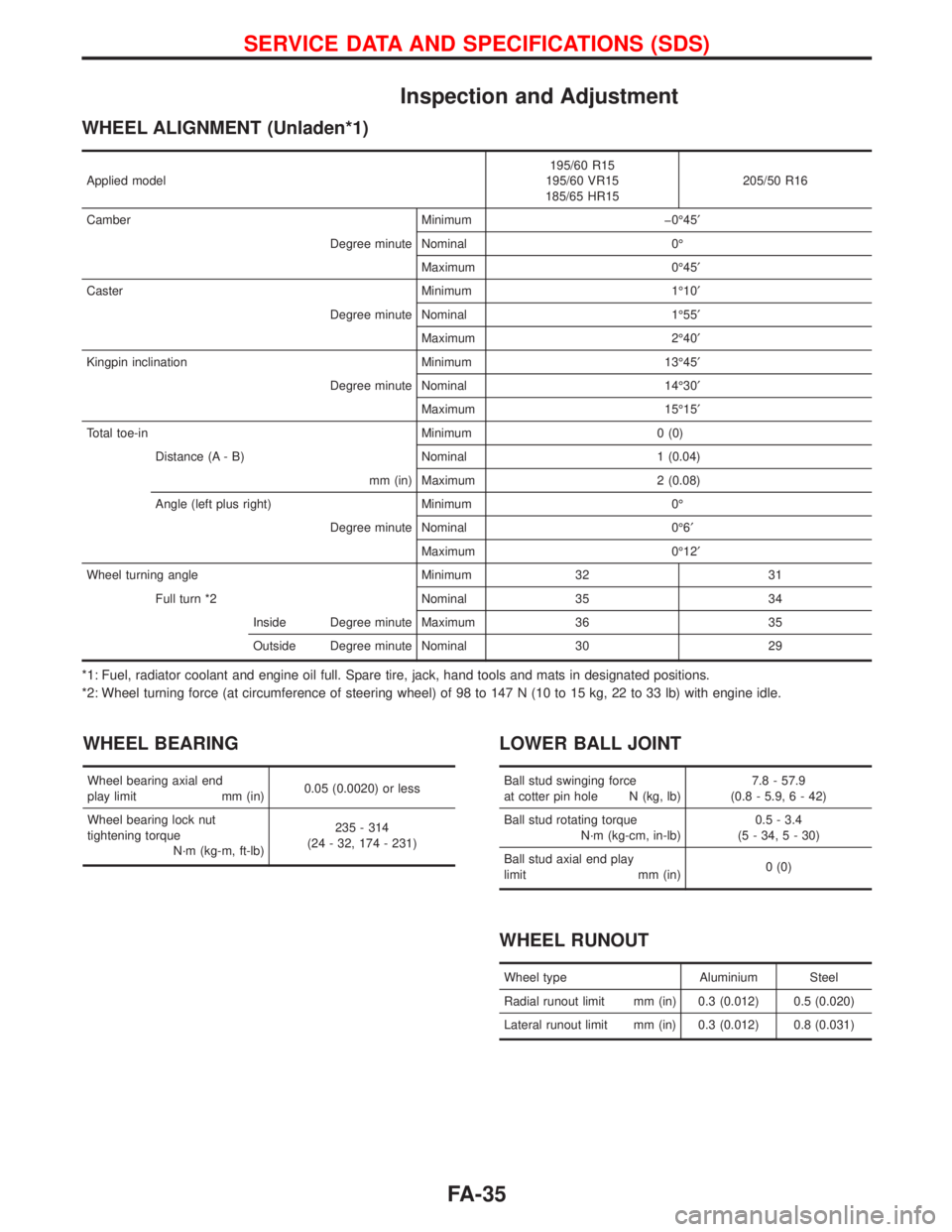

Inspection and Adjustment

WHEEL ALIGNMENT (Unladen*1)

Applied model195/60 R15

195/60 VR15

185/65 HR15205/50 R16

Camber Minimum þ0É45¢

Degree minute Nominal 0É

Maximum 0É45¢

Caster Minimum 1É10¢

Degree minute Nominal 1É55¢

Maximum 2É40¢

Kingpin inclination Minimum 13É45¢

Degree minute Nominal 14É30¢

Maximum 15É15¢

Total toe-in Minimum 0 (0)

Distance (A - B) Nominal 1 (0.04)

mm (in) Maximum 2 (0.08)

Angle (left plus right) Minimum 0É

Degree minute Nominal 0É6¢

Maximum 0É12¢

Wheel turning angle Minimum 32 31

Full turn *2 Nominal 35 34

Inside Degree minute Maximum 36 35

Outside Degree minute Nominal 30 29

*1: Fuel, radiator coolant and engine oil full. Spare tire, jack, hand tools and mats in designated positions.

*2: Wheel turning force (at circumference of steering wheel) of 98 to 147 N (10 to 15 kg, 22 to 33 lb) with engine idle.

WHEEL BEARING

Wheel bearing axial end

play limit mm (in)0.05 (0.0020) or less

Wheel bearing lock nut

tightening torque

N´m (kg-m, ft-lb)235 - 314

(24 - 32, 174 - 231)

LOWER BALL JOINT

Ball stud swinging force

at cotter pin hole N (kg, lb)7.8 - 57.9

(0.8 - 5.9, 6 - 42)

Ball stud rotating torque

N´m (kg-cm, in-lb)0.5 - 3.4

(5 - 34, 5 - 30)

Ball stud axial end play

limit mm (in)0 (0)

WHEEL RUNOUT

Wheel type Aluminium Steel

Radial runout limit mm (in) 0.3 (0.012) 0.5 (0.020)

Lateral runout limit mm (in) 0.3 (0.012) 0.8 (0.031)

SERVICE DATA AND SPECIFICATIONS (SDS)

FA-35

Page 1778 of 2267

NOTE

SERVICE DATA AND SPECIFICATIONS (SDS)

FA-36

Page 1779 of 2267

ACCELERATOR CONTROL, FUEL &

EXHAUST SYSTEMS

SECTION

FE

CONTENTS

PREPARATION.............................................................. 2

Special Service Tool .................................................. 2

QG16DE, QG18DE, SR20DE

ACCELERATOR CONTROL SYSTEM......................... 3

Adjusting Accelerator Cable ...................................... 4

CD20T

ACCELERATOR CONTROL SYSTEM......................... 5

QG16DE, QG18DE, SR20De, CD20T

FUEL SYSTEM.............................................................. 6

Fuel Pump and Gauge .............................................. 7

EXHAUST SYSTEM...................................................... 9

FE

Page 1780 of 2267

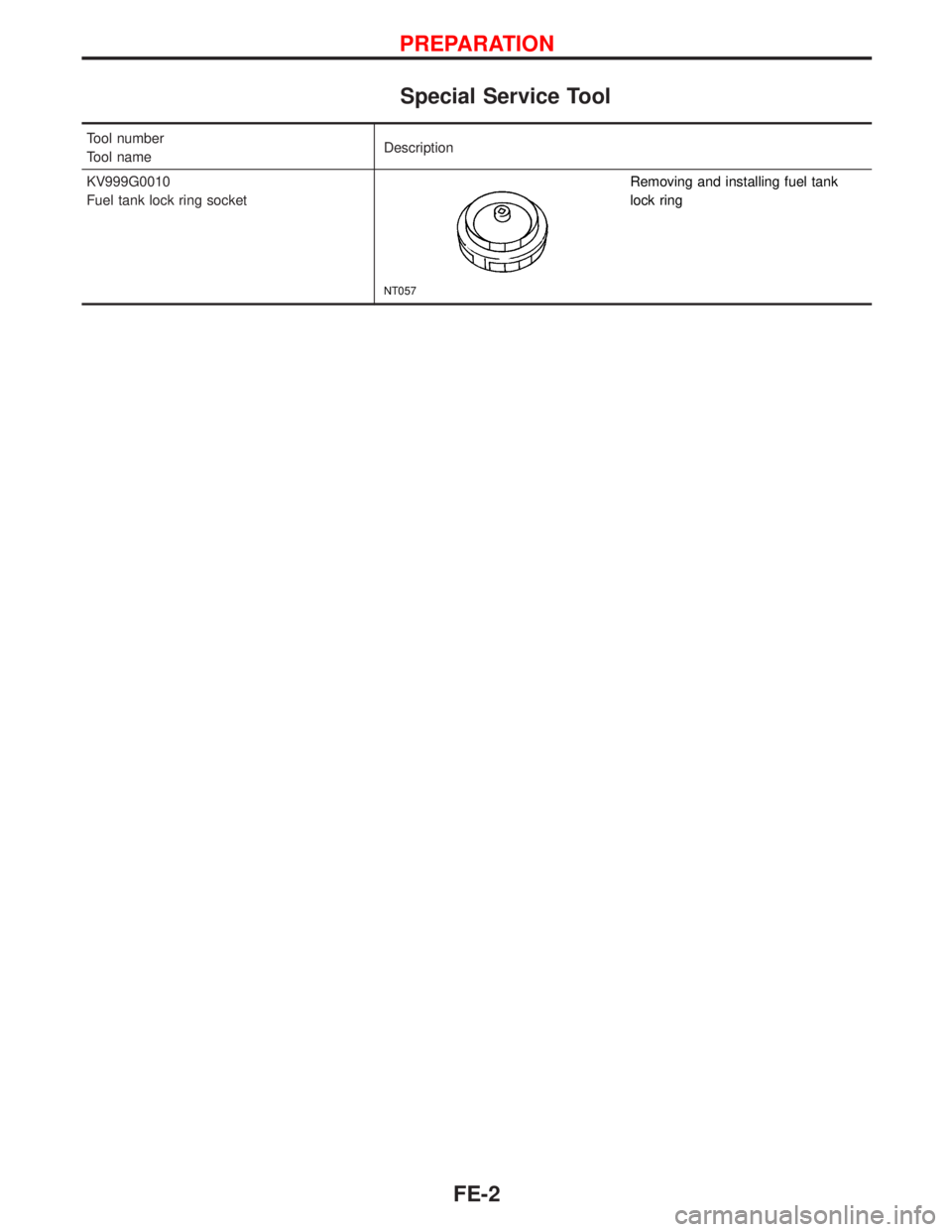

Special Service Tool

Tool number

Tool nameDescription

KV999G0010

Fuel tank lock ring socket

NT057

Removing and installing fuel tank

lock ring

PREPARATION

FE-2

Trending: catalytic converter, jump cable, fuel pressure, air condition, auxiliary battery, rear view mirror, clutch