NISSAN TEANA 2008 Service Manual

Manufacturer: NISSAN, Model Year: 2008, Model line: TEANA, Model: NISSAN TEANA 2008Pages: 5121, PDF Size: 69.03 MB

Page 4411 of 5121

STEERING GEAR AND LINKAGE

ST-21

< ON-VEHICLE REPAIR >

C

D

E

F

H

I

J

K

L

MA

B

ST

N

O

P

Never damage inner socket and gear housing assembly when removing boot. Inner socket and

gear housing assembly must be replaced if inner socket and gear housing assembly are damaged

because it may cause foreign material interfusion.

9. Remove inner socket and spacer from gear housing assembly.

10. Drill out the clinching part of gear housing assembly (end cover

assembly side) outer rim with a 3 mm (0.12 in) drill bit. [Drill for

approximately 1.5 mm (0.059 in) depth.]

11. Remove end cover assembly with a 36 mm (1.42 in) open head

(suitable tool).

CAUTION:

Never damage rack assembly surface when removing. Rack

assembly must be replaced if damaged because it may

cause fluid leakage.

12. Pull rack assembly together with rack oil seal (outer side) out

from gear housing assembly.

CAUTION:

Never damage cylinder inner wall when remove rack

assembly. Gear housing assembly must be replaced if dam-

aged because it may cause fluid leakage.

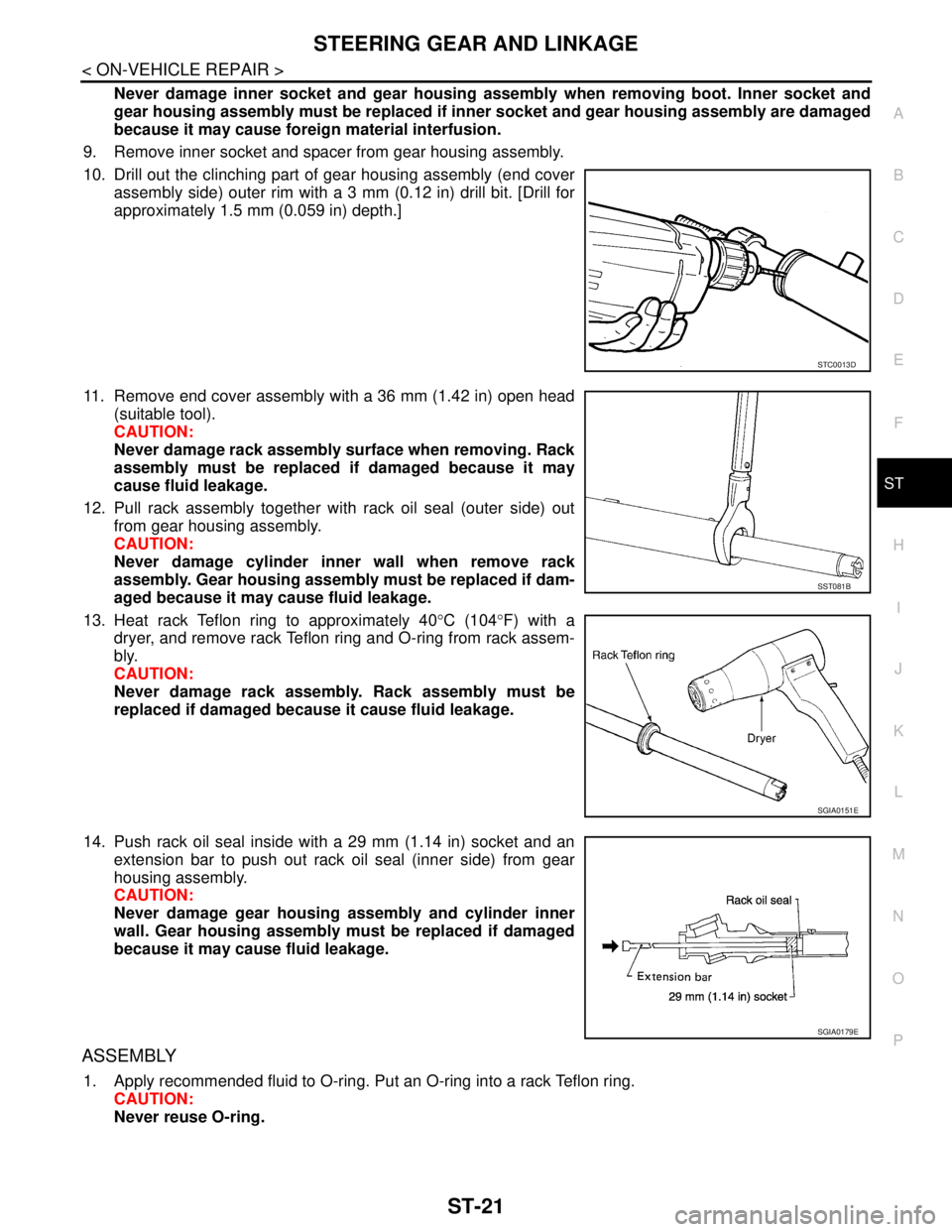

13. Heat rack Teflon ring to approximately 40°C (104°F) with a

dryer, and remove rack Teflon ring and O-ring from rack assem-

bly.

CAUTION:

Never damage rack assembly. Rack assembly must be

replaced if damaged because it cause fluid leakage.

14. Push rack oil seal inside with a 29 mm (1.14 in) socket and an

extension bar to push out rack oil seal (inner side) from gear

housing assembly.

CAUTION:

Never damage gear housing assembly and cylinder inner

wall. Gear housing assembly must be replaced if damaged

because it may cause fluid leakage.

ASSEMBLY

1. Apply recommended fluid to O-ring. Put an O-ring into a rack Teflon ring.

CAUTION:

Never reuse O-ring.

STC0013D

SST081B

SGIA0151E

SGIA0179E

Page 4412 of 5121

ST-22

< ON-VEHICLE REPAIR >

STEERING GEAR AND LINKAGE

2. Heat rack Teflon ring to approximately 40°C (104°C) with a

dryer. Assemble it to mounting groove of rack assembly.

CAUTION:

Never reuse rack Teflon ring.

3. Install the Teflon ring correcting tool (A) (SST: KV48104400)

from tooth side of rack fit rack Teflon ring (1) on rack. Compress

the with tool.

4. Apply recommended grease to rack oil seal, and then install

rack oil seal in the following procedure. Then assemble rack

assembly to gear housing assembly.

CAUTION:

Install rack oil seal in a direction so that the lip of inner oil

seal and the lip of outer oil seal face each other.

Never damage retainer sliding surface by rack assembly.

Replace gear housing assembly if damaged.

Never damage gear housing assembly inner wall by rack

assembly. Gear housing assembly must be replaced if

damaged because it may cause fluid leakage.

a. Wrap an OHP sheet [approximately 70 mm (2.76 in) × 100 mm

(3.94 in)]. Around rack assembly teeth to avoid damaging rack

oil seal (inner). Install rack oil seal over sheet. Then, pull OHP

sheet along with rack oil seal until they pass rack assembly

teeth, and remove OHP sheet.

b. Insert rack oil seal (inner) (1) into rack assembly piston (2).

c. Push retainer to adjusting screw side by hand, and move the

rack assembly inside the gear housing assembly so that the

rack oil seal (inner) can be pressed against the gear housing

assembly.

SGIA0153E

SGIA1324E

SGIA0205E

SGIA0157E

JSGIA0323ZZ

Page 4413 of 5121

![NISSAN TEANA 2008 Service Manual STEERING GEAR AND LINKAGE

ST-23

< ON-VEHICLE REPAIR >

C

D

E

F

H

I

J

K

L

MA

B

ST

N

O

P

d. Wrap an OHP sheet [approximately 70 mm (2.76 in) × 100 mm

(3.94 in)]. Around the edge to avoid damaging rack o NISSAN TEANA 2008 Service Manual STEERING GEAR AND LINKAGE

ST-23

< ON-VEHICLE REPAIR >

C

D

E

F

H

I

J

K

L

MA

B

ST

N

O

P

d. Wrap an OHP sheet [approximately 70 mm (2.76 in) × 100 mm

(3.94 in)]. Around the edge to avoid damaging rack o](/img/5/57391/w960_57391-4412.png)

STEERING GEAR AND LINKAGE

ST-23

< ON-VEHICLE REPAIR >

C

D

E

F

H

I

J

K

L

MA

B

ST

N

O

P

d. Wrap an OHP sheet [approximately 70 mm (2.76 in) × 100 mm

(3.94 in)]. Around the edge to avoid damaging rack oil seal

(outer). Install rack oil seal over sheet. Then, pull oil seal along

with OHP sheet until they pass rack edge, and remove OHP

sheet.

e. Install end cover assembly to rack edge, and move rack oil seal

(outer) until it contacts with gear housing assembly.

5. Tighten end cover assembly to specified torque using a 36 mm

(1.42 in) open head (suitable tool).

CAUTION:

Never damage rack assembly. Replace it if damaged

because it may cause fluid leakage.

6. Crimp gear housing assembly at one point using a punch as

shown in the figure so as to prevent end cover assembly from

getting loose after tightening end cover assembly.

7. Apply recommended fluid to O-ring, and then install O-ring to

gear housing assembly.

8. Install gear-sub assembly to gear housing assembly.

CAUTION:

In order to protect oil seal from any damage, insert gear-

sub assembly straightly.

9. Install inner socket and spacer to gear housing assembly with

the following procedure.

a. Apply recommended thread locking sealant into the thread of inner socket.

Use Genuine High Strength Thread Locking Sealant, Loctite 271 or equivalent.

b. Screw inner socket into rack part and tighten at the specified torque.

10. Decide on the neutral position of the rack stroke (L).

11. Install rear cover cap to gear sub-assembly.

CAUTION:

Make sure that the projection of rear cover cap is aligned

with the marking position of gear housing assembly.

SGIA0157E

SST081B

Standard

L : Refer to ST-38, "

Rack

Stroke".

SGIA0871E

SGIA0877E

Page 4414 of 5121

ST-24

< ON-VEHICLE REPAIR >

STEERING GEAR AND LINKAGE

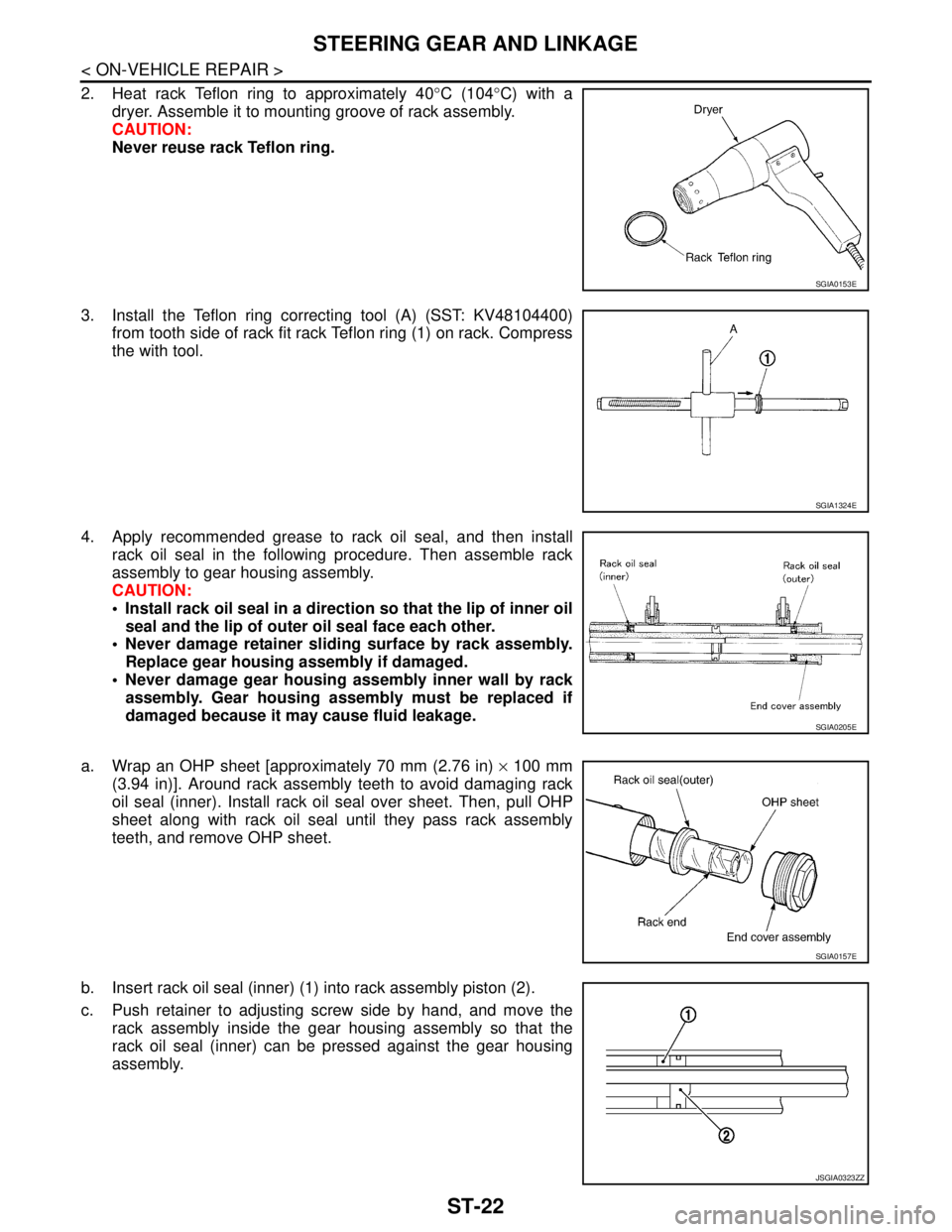

12. Apply recommended sealant into the thread of adjusting screw

(2 turns thread), and then screw in the adjusting screw until it

reaches height “H” from gear housing assembly measured

before disassembling.

Use Genuine Liquid Gasket, Three Bond 1111B or equiva-

lent.

13. Move rack assembly 10 strokes throughout the full stroke so that

the parts can fit with each other.

14. Adjust pinion rotating torque with the following procedure.

a. Measure pinion rotating torque within ±180° of neutral position

of the rack assembly using Tools. Stop the gear at the point

where highest torque is read.

b. Loosen adjusting screw and retighten to 5.4 N·m (0.55 kg-m, 48

in-lb), and then loosen by 20 to 40°.

c. Measure pinion rotating torque using Tools to make sure that the

measured value is within the standard. Readjust if the value is

outside the standard. Replace steering gear assembly, if the

value is outside the standard after readjusting, or adjusting

screw rotating torque is 5 N·m (0.51 kg-m, 44 in-lb) or less.

d. Apply recommended liquid gasket to inner socket and turn pinion fully to left with inner socket installed to

gear housing assembly.

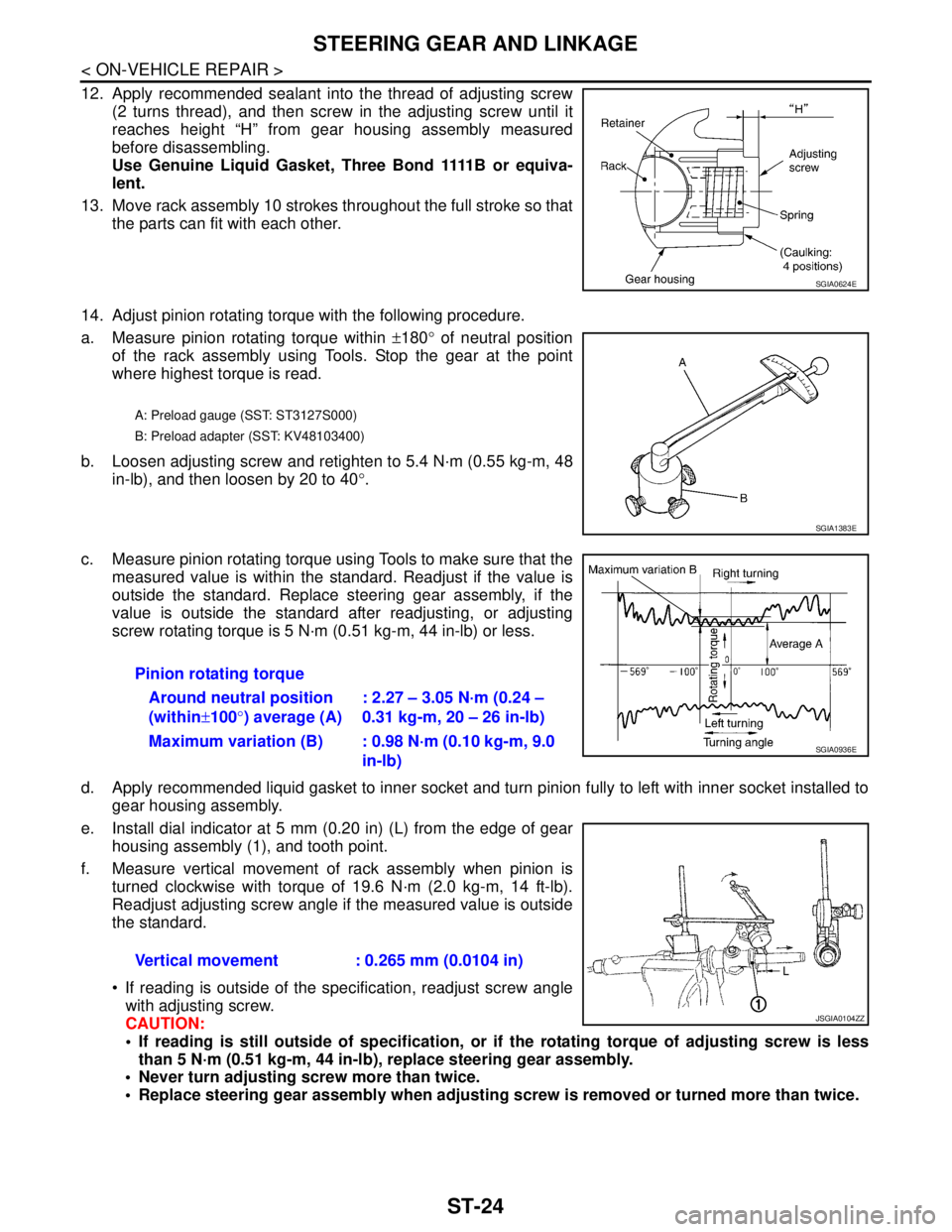

e. Install dial indicator at 5 mm (0.20 in) (L) from the edge of gear

housing assembly (1), and tooth point.

f. Measure vertical movement of rack assembly when pinion is

turned clockwise with torque of 19.6 N·m (2.0 kg-m, 14 ft-lb).

Readjust adjusting screw angle if the measured value is outside

the standard.

If reading is outside of the specification, readjust screw angle

with adjusting screw.

CAUTION:

If reading is still outside of specification, or if the rotating torque of adjusting screw is less

than 5 N·m (0.51 kg-m, 44 in-lb), replace steering gear assembly.

Never turn adjusting screw more than twice.

Replace steering gear assembly when adjusting screw is removed or turned more than twice.

SGIA0624E

A: Preload gauge (SST: ST3127S000)

B: Preload adapter (SST: KV48103400)

SGIA1383E

Pinion rotating torque

Around neutral position

(within±100°) average (A): 2.27 – 3.05 N·m (0.24 –

0.31 kg-m, 20 – 26 in-lb)

Maximum variation (B) : 0.98 N·m (0.10 kg-m, 9.0

in-lb)

Vertical movement : 0.265 mm (0.0104 in)

SGIA0936E

JSGIA0104ZZ

Page 4415 of 5121

STEERING GEAR AND LINKAGE

ST-25

< ON-VEHICLE REPAIR >

C

D

E

F

H

I

J

K

L

MA

B

ST

N

O

P

15. Install large end of boot to gear housing assembly.

16. Install small end of boot to inner socket boot mounting groove.

17. Install boot clamp to boot small end.

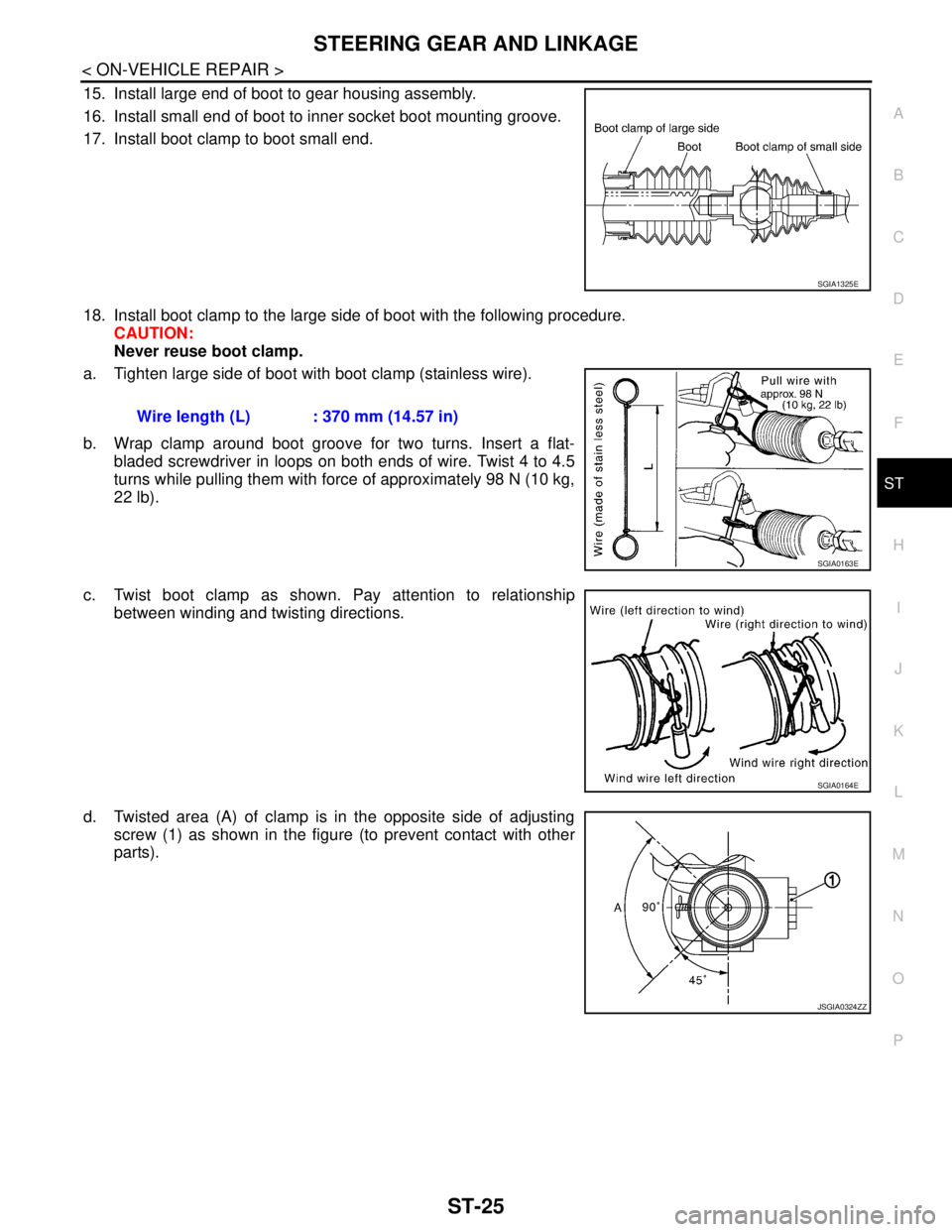

18. Install boot clamp to the large side of boot with the following procedure.

CAUTION:

Never reuse boot clamp.

a. Tighten large side of boot with boot clamp (stainless wire).

b. Wrap clamp around boot groove for two turns. Insert a flat-

bladed screwdriver in loops on both ends of wire. Twist 4 to 4.5

turns while pulling them with force of approximately 98 N (10 kg,

22 lb).

c. Twist boot clamp as shown. Pay attention to relationship

between winding and twisting directions.

d. Twisted area (A) of clamp is in the opposite side of adjusting

screw (1) as shown in the figure (to prevent contact with other

parts).

SGIA1325E

Wire length (L) : 370 mm (14.57 in)

SGIA0163E

SGIA0164E

JSGIA0324ZZ

Page 4416 of 5121

ST-26

< ON-VEHICLE REPAIR >

STEERING GEAR AND LINKAGE

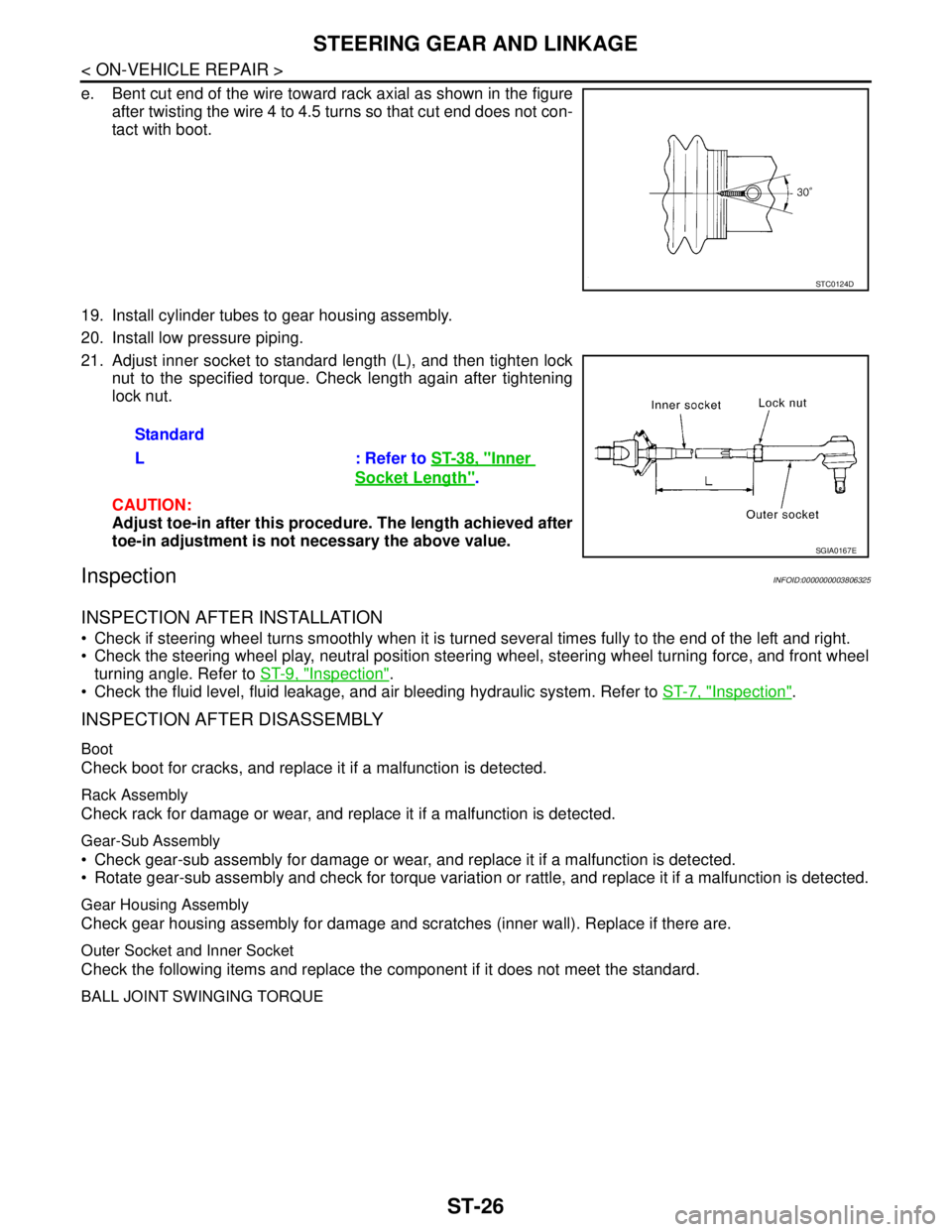

e. Bent cut end of the wire toward rack axial as shown in the figure

after twisting the wire 4 to 4.5 turns so that cut end does not con-

tact with boot.

19. Install cylinder tubes to gear housing assembly.

20. Install low pressure piping.

21. Adjust inner socket to standard length (L), and then tighten lock

nut to the specified torque. Check length again after tightening

lock nut.

CAUTION:

Adjust toe-in after this procedure. The length achieved after

toe-in adjustment is not necessary the above value.

InspectionINFOID:0000000003806325

INSPECTION AFTER INSTALLATION

Check if steering wheel turns smoothly when it is turned several times fully to the end of the left and right.

Check the steering wheel play, neutral position steering wheel, steering wheel turning force, and front wheel

turning angle. Refer to ST-9, "

Inspection".

Check the fluid level, fluid leakage, and air bleeding hydraulic system. Refer to ST-7, "

Inspection".

INSPECTION AFTER DISASSEMBLY

Boot

Check boot for cracks, and replace it if a malfunction is detected.

Rack Assembly

Check rack for damage or wear, and replace it if a malfunction is detected.

Gear-Sub Assembly

Check gear-sub assembly for damage or wear, and replace it if a malfunction is detected.

Rotate gear-sub assembly and check for torque variation or rattle, and replace it if a malfunction is detected.

Gear Housing Assembly

Check gear housing assembly for damage and scratches (inner wall). Replace if there are.

Outer Socket and Inner Socket

Check the following items and replace the component if it does not meet the standard.

BALL JOINT SWINGING TORQUE

STC0124D

Standard

L : Refer to ST-38, "

Inner

Socket Length".

SGIA0167E

Page 4417 of 5121

STEERING GEAR AND LINKAGE

ST-27

< ON-VEHICLE REPAIR >

C

D

E

F

H

I

J

K

L

MA

B

ST

N

O

P

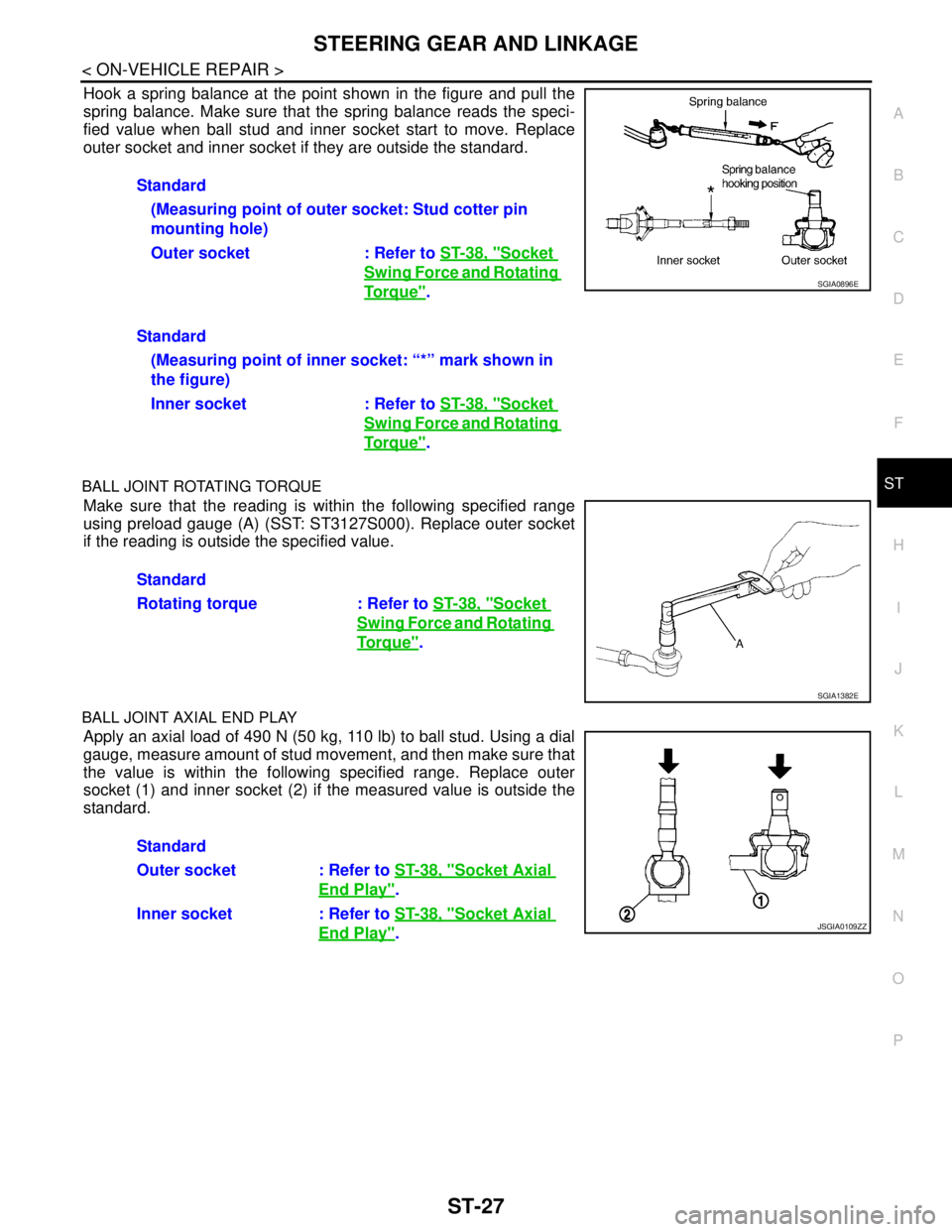

Hook a spring balance at the point shown in the figure and pull the

spring balance. Make sure that the spring balance reads the speci-

fied value when ball stud and inner socket start to move. Replace

outer socket and inner socket if they are outside the standard.

BALL JOINT ROTATING TORQUE

Make sure that the reading is within the following specified range

using preload gauge (A) (SST: ST3127S000). Replace outer socket

if the reading is outside the specified value.

BALL JOINT AXIAL END PLAY

Apply an axial load of 490 N (50 kg, 110 lb) to ball stud. Using a dial

gauge, measure amount of stud movement, and then make sure that

the value is within the following specified range. Replace outer

socket (1) and inner socket (2) if the measured value is outside the

standard.Standard

(Measuring point of outer socket: Stud cotter pin

mounting hole)

Outer socket : Refer to ST-38, "

Socket

Swing Force and Rotating

To r q u e".

Standard

(Measuring point of inner socket: “*” mark shown in

the figure)

Inner socket : Refer to ST-38, "

Socket

Swing Force and Rotating

To r q u e".

SGIA0896E

Standard

Rotating torque : Refer to ST-38, "

Socket

Swing Force and Rotating

Torque".

SGIA1382E

Standard

Outer socket : Refer to ST-38, "

Socket Axial

End Play".

Inner socket : Refer to ST-38, "

Socket Axial

End Play".JSGIA0109ZZ

Page 4418 of 5121

ST-28

< ON-VEHICLE REPAIR >

POWER STEERING OIL PUMP

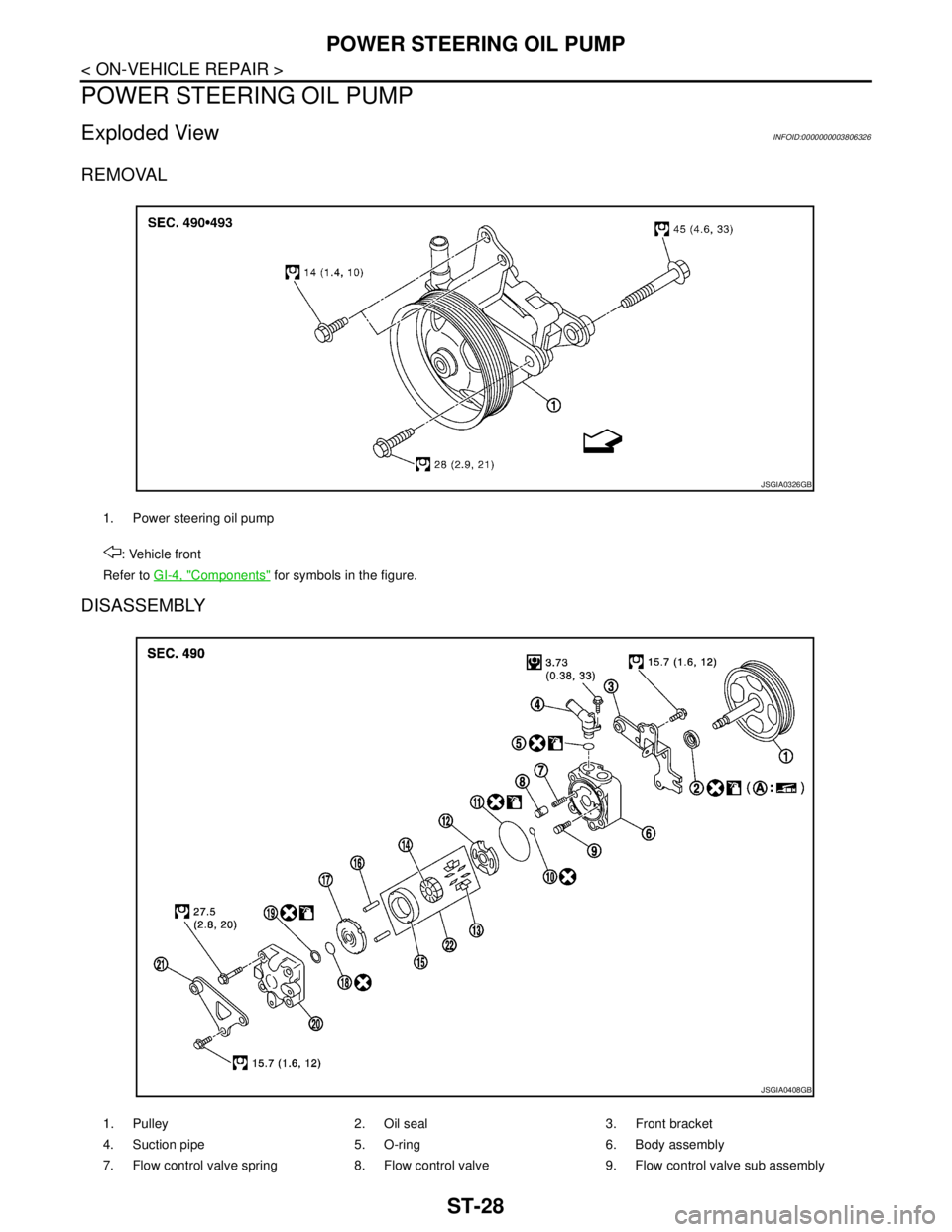

POWER STEERING OIL PUMP

Exploded ViewINFOID:0000000003806326

REMOVAL

DISASSEMBLY

1. Power steering oil pump

: Vehicle front

Refer to GI-4, "

Components" for symbols in the figure.

JSGIA0326GB

1. Pulley 2. Oil seal 3. Front bracket

4. Suction pipe 5. O-ring 6. Body assembly

7. Flow control valve spring 8. Flow control valve 9. Flow control valve sub assembly

JSGIA0408GB

Page 4419 of 5121

POWER STEERING OIL PUMP

ST-29

< ON-VEHICLE REPAIR >

C

D

E

F

H

I

J

K

L

MA

B

ST

N

O

P

Removal and InstallationINFOID:0000000003806327

REMOVAL

1. Drain power steering fluid from reservoir tank.

2. Remove front tires.

3. Remove splash guard. Refer to EXT-22, "

FENDER PROTECTOR : Exploded View".

4. Loosen drive belt. Refer to EM-12, "

Removal and Installation".

5. Remove drive belt from oil pump pulley.

6. Remove copper washers and eye bolt (drain fluid from their pipings).

7. Remove suction hose (drain fluid from their pipings).

8. Remove oil pump mounting bolts, and then remove oil pump.

CAUTION:

Never damage drive shaft boot.

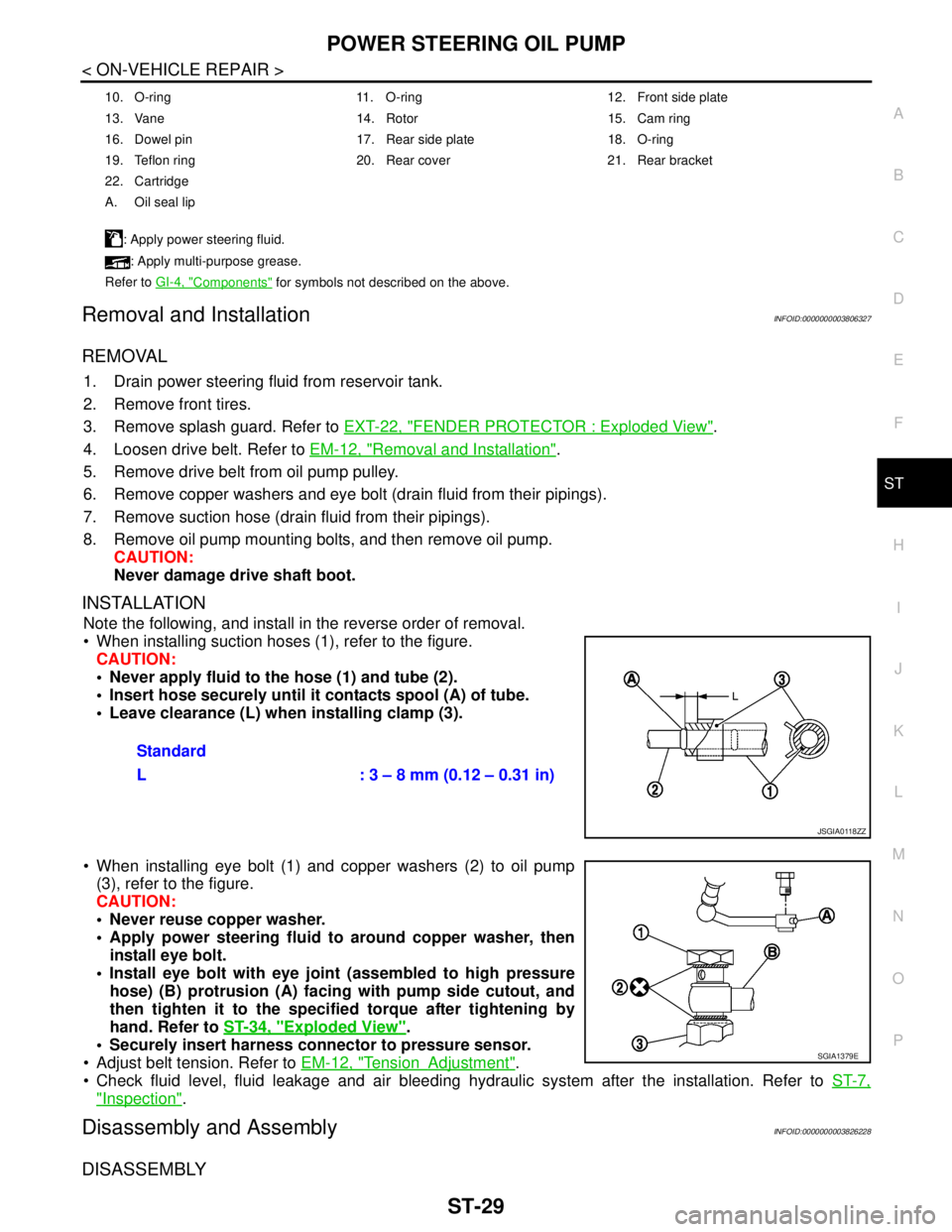

INSTALLATION

Note the following, and install in the reverse order of removal.

When installing suction hoses (1), refer to the figure.

CAUTION:

Never apply fluid to the hose (1) and tube (2).

Insert hose securely until it contacts spool (A) of tube.

Leave clearance (L) when installing clamp (3).

When installing eye bolt (1) and copper washers (2) to oil pump

(3), refer to the figure.

CAUTION:

Never reuse copper washer.

Apply power steering fluid to around copper washer, then

install eye bolt.

Install eye bolt with eye joint (assembled to high pressure

hose) (B) protrusion (A) facing with pump side cutout, and

then tighten it to the specified torque after tightening by

hand. Refer to ST-34, "

Exploded View".

Securely insert harness connector to pressure sensor.

Adjust belt tension. Refer to EM-12, "

TensionAdjustment".

Check fluid level, fluid leakage and air bleeding hydraulic system after the installation. Refer to ST-7,

"Inspection".

Disassembly and AssemblyINFOID:0000000003826228

DISASSEMBLY

10. O-ring 11. O-ring 12. Front side plate

13. Vane 14. Rotor 15. Cam ring

16. Dowel pin 17. Rear side plate 18. O-ring

19. Teflon ring 20. Rear cover 21. Rear bracket

22. Cartridge

A. Oil seal lip

: Apply power steering fluid.

: Apply multi-purpose grease.

Refer to GI-4, "

Components" for symbols not described on the above.

Standard

L : 3 – 8 mm (0.12 – 0.31 in)

JSGIA0118ZZ

SGIA1379E

Page 4420 of 5121

ST-30

< ON-VEHICLE REPAIR >

POWER STEERING OIL PUMP

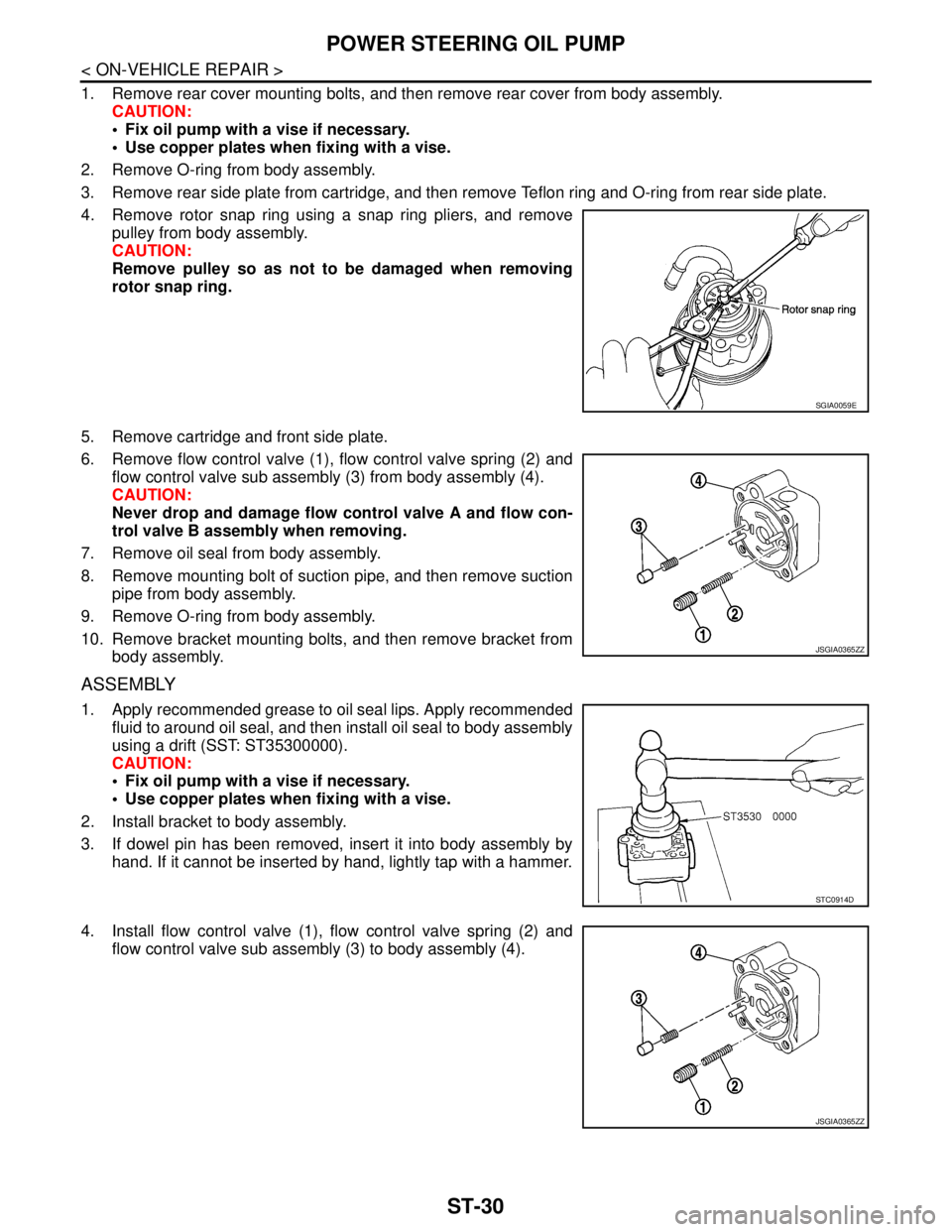

1. Remove rear cover mounting bolts, and then remove rear cover from body assembly.

CAUTION:

Fix oil pump with a vise if necessary.

Use copper plates when fixing with a vise.

2. Remove O-ring from body assembly.

3. Remove rear side plate from cartridge, and then remove Teflon ring and O-ring from rear side plate.

4. Remove rotor snap ring using a snap ring pliers, and remove

pulley from body assembly.

CAUTION:

Remove pulley so as not to be damaged when removing

rotor snap ring.

5. Remove cartridge and front side plate.

6. Remove flow control valve (1), flow control valve spring (2) and

flow control valve sub assembly (3) from body assembly (4).

CAUTION:

Never drop and damage flow control valve A and flow con-

trol valve B assembly when removing.

7. Remove oil seal from body assembly.

8. Remove mounting bolt of suction pipe, and then remove suction

pipe from body assembly.

9. Remove O-ring from body assembly.

10. Remove bracket mounting bolts, and then remove bracket from

body assembly.

ASSEMBLY

1. Apply recommended grease to oil seal lips. Apply recommended

fluid to around oil seal, and then install oil seal to body assembly

using a drift (SST: ST35300000).

CAUTION:

Fix oil pump with a vise if necessary.

Use copper plates when fixing with a vise.

2. Install bracket to body assembly.

3. If dowel pin has been removed, insert it into body assembly by

hand. If it cannot be inserted by hand, lightly tap with a hammer.

4. Install flow control valve (1), flow control valve spring (2) and

flow control valve sub assembly (3) to body assembly (4).

SGIA0059E

JSGIA0365ZZ

STC0914D

JSGIA0365ZZ