NISSAN TEANA 2008 Service Manual

Manufacturer: NISSAN, Model Year: 2008, Model line: TEANA, Model: NISSAN TEANA 2008Pages: 5121, PDF Size: 69.03 MB

Page 4391 of 5121

ST-1

STEERING

C

DE

F

H I

J

K L

M

SECTION ST

A

B

ST

N

O P

CONTENTS

STEERING SYSTEM

SYMPTOM DIAGNOSIS ..... ..........................2

NOISE, VIBRATION AND HARSHNESS

(NVH) TROUBLESHOOTING ........................ .....

2

NVH Troubleshooting Chart ................................ ......2

PRECAUTION ...............................................3

PRECAUTIONS .............................................. .....3

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ......

3

Precaution Necessary for Steering Wheel Rota-

tion after Battery Disconnect .....................................

3

Service Notice or Precautions for Steering System

......

3

PREPARATION ............................................5

PREPARATION .............................................. .....5

Special Service Tools .......................................... ......5

ON-VEHICLE MAINTENANCE .....................7

POWER STEERING FLUID ........................... .....7

Inspection ............................................................ ......7

STEERING WHEEL .............................................9

Inspection ............................................................ ......9

ON-VEHICLE REPAIR .................................12

STEERING WHEEL ........................................ ....12

Exploded View .................................................... ....12

Removal and Installation .........................................12

STEERING COLUMN .........................................13

Exploded View .................................................... ....13

Removal and Installation .........................................13

Inspection ................................................................14

LOWER SHAFT ................................................16

Exploded View ..................................................... ....16

Removal and Installation .........................................16

Inspection ................................................................17

STEERING GEAR AND LINKAGE ...................18

Exploded View .........................................................18

Removal and Installation .........................................19

Disassembly and Assembly .....................................20

Inspection ................................................................26

POWER STEERING OIL PUMP .......................28

Exploded View .........................................................28

Removal and Installation .........................................29

Disassembly and Assembly .....................................29

Inspection ................................................................32

HYDRAULIC LINE ............................................34

Exploded View .........................................................34

Removal and Installation .........................................35

SERVICE DATA AND SPECIFICATIONS

(SDS) ............... .............................................

37

SERVICE DATA AND SPECIFICATIONS

(SDS) .................................................................

37

General Specifications ......................................... ....37

Steering Wheel Axial End Play and Play .................37

Steering Wheel Turning Force .................................37

Steering Angle .........................................................37

Steering Column Length ..........................................37

Steering Column Mounting Dimensions ..................37

Steering Column Operating Range .........................37

Lower Shaft Sliding Range ......................................38

Rack Sliding Force ..................................................38

Rack Stroke .............................................................38

Socket Swing Force and Rotating Torque ...............38

Socket Axial End Play .............................................38

Inner Socket Length ................................................38

Relief Oil Pressure ...................................................38

Page 4392 of 5121

ST-2

< SYMPTOM DIAGNOSIS >

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTING

SYMPTOM DIAGNOSIS

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTING

NVH Troubleshooting ChartINFOID:0000000003806305

Use the chart below to find the cause of the symptom. If necessary, repair or replace these parts.

×: ApplicableReference

ST-7, "

Inspection

"

ST-7, "

Inspection

"

ST-26, "

Inspection

"

ST-26, "

Inspection

"

ST-26, "

Inspection

"

ST-7, "

Inspection

"

ST-9, "

Inspection

"

ST-9, "

Inspection

"

EM-12, "

Checking

"

ST-9, "

Inspection

"—

ST-18, "

Exploded View

"

ST-14, "

Inspection

"

ST-13, "

Exploded View

"

ST-18, "

Exploded View

"

NVH in DLN section.

NVH in DLN section.

NVH in FAX, RAX, FSU, RSU section.

NVH in WT section.

NVH in WT section.

NVH in FAX section.

NVH in BR section.

Possible cause and SUSPECTED PARTS

Fluid level

Air in hydraulic system

Outer/inner socket ball joint swinging torque

Outer/inner socket ball joint rotating torque

Outer/inner socket ball joint end play

Steering fluid leakage

Steering wheel play

Steering gear rack sliding force

Drive belt looseness

Improper steering wheel

Improper installation or looseness of tilt lock lever

Mounting looseness

Steering column deformation or damage

Improper installation or looseness of steering column

Steering linkage looseness

PROPELLER SHAFT

DIFFERENTIAL

AXLE and SUSPENSION

TIRE

ROAD WHEEL

DRIVE SHAFT

BRAKE

Symptom SteeringNoise××××××××× ×× ×××××××

Shake× × × ×××××

Vibration××××××××

Shimmy×× × ××××

Judder××××××

Page 4393 of 5121

PRECAUTIONS

ST-3

< PRECAUTION >

C

D

E

F

H

I

J

K

L

MA

B

ST

N

O

P

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000003971958

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. Information necessary to service the system safely is included in the “SRS AIRBAG” and

“SEAT BELT” of this Service Manual.

WARNING:

• To avoid rendering the SRS inoperative, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

Improper maintenance, including incorrect removal and installation of the SRS, can lead to personal

injury caused by unintentional activation of the system. For removal of Spiral Cable and Air Bag

Module, see the “SRS AIRBAG”.

Never use electrical test equipment on any circuit related to the SRS unless instructed to in this Ser-

vice Manual. SRS wiring harnesses can be identified by yellow and/or orange harnesses or harness

connectors.

Precaution Necessary for Steering Wheel Rotation after Battery Disconnect

INFOID:0000000003806307

NOTE:

Before removing and installing any control units, first turn the push-button ignition switch to the LOCK posi-

tion, then disconnect both battery cables.

After finishing work, confirm that all control unit connectors are connected properly, then re-connect both

battery cables.

Always use CONSULT-III to perform self-diagnosis as a part of each function inspection after finishing work.

If a DTC is detected, perform trouble diagnosis according to self-diagnosis results.

This vehicle is equipped with a push-button ignition switch and a steering lock unit.

If the battery is disconnected or discharged, the steering wheel will lock and cannot be turned.

If turning the steering wheel is required with the battery disconnected or discharged, follow the procedure

below before starting the repair operation.

OPERATION PROCEDURE

1. Connect both battery cables.

NOTE:

Supply power using jumper cables if battery is discharged.

2. Carry the Intelligent Key or insert it to the key slot and turn the push-button ignition switch to ACC position.

(At this time, the steering lock will be released.)

3. Disconnect both battery cables. The steering lock will remain released with both battery cables discon-

nected and the steering wheel can be turned.

4. Perform the necessary repair operation.

5. When the repair work is completed, re-connect both battery cables. With the brake pedal released, turn

the push-button ignition switch from ACC position to ON position, then to LOCK position. (The steering

wheel will lock when the push-button ignition switch is turned to LOCK position.)

6. Perform self-diagnosis check of all control units using CONSULT-III.

Service Notice or Precautions for Steering SystemINFOID:0000000003806308

CAUTION:

In case of removing steering gear assembly, make the final tightening with grounded and unloaded

vehicle condition, and then check wheel alignment.

Observe the following precautions when disassembling.

- Before disassembly, thoroughly clean the outside of the unit.

- Disassembly should be done in a clean work area. It is important to prevent the internal parts from

becoming contaminated by dirt or other foreign matter.

Page 4394 of 5121

ST-4

< PRECAUTION >

PRECAUTIONS

- For easier and proper assembly, place disassembled parts in order on a parts rack.

- Use nylon cloth or paper towels to clean the parts; common shop rags can leave lint that might inter-

fere with their operation.

- Never reuse non-reusable parts.

- Before assembling, apply the specified grease to the directed parts.

Page 4395 of 5121

PREPARATION

ST-5

< PREPARATION >

C

D

E

F

H

I

J

K

L

MA

B

ST

N

O

P

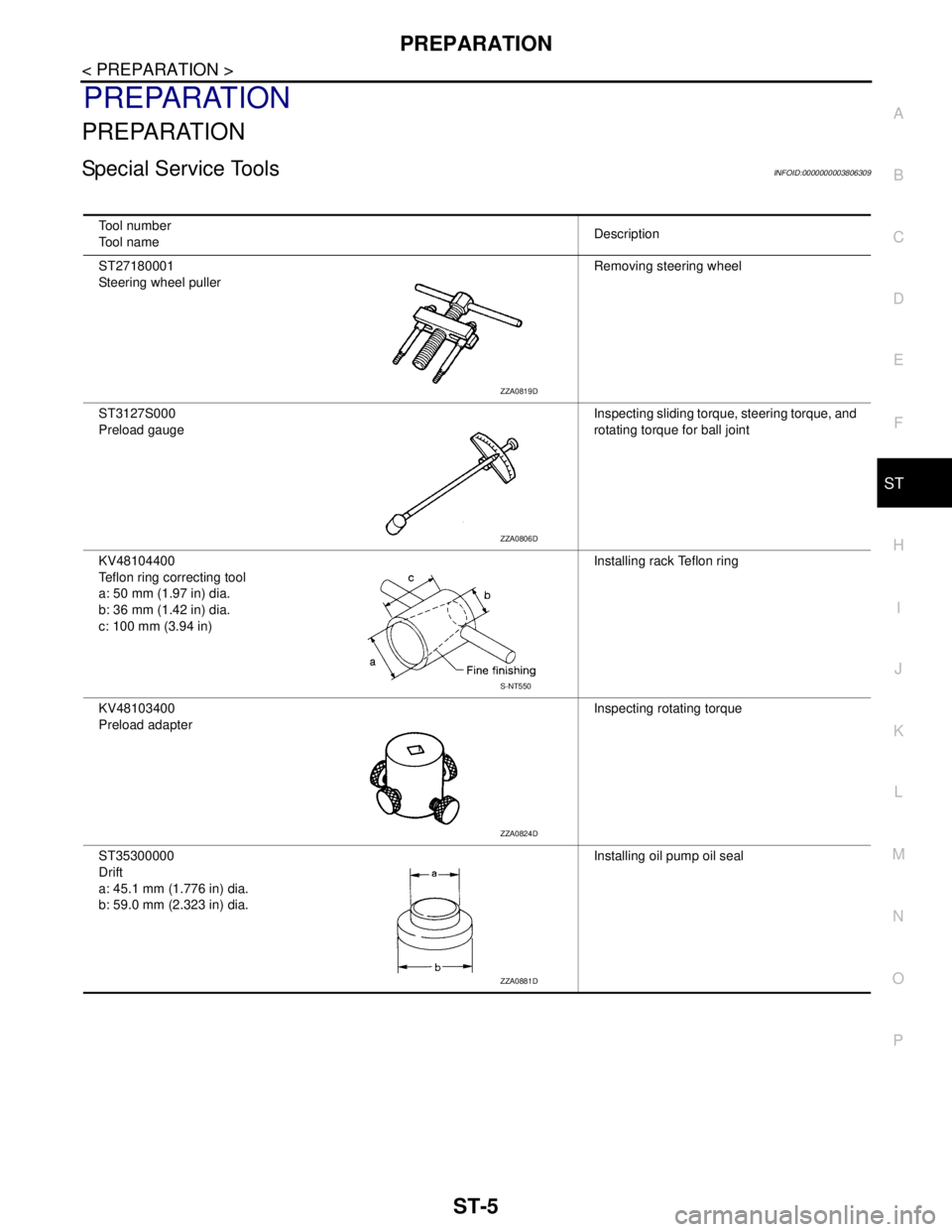

PREPARATION

PREPARATION

Special Service ToolsINFOID:0000000003806309

Tool number

Tool nameDescription

ST27180001

Steering wheel pullerRemoving steering wheel

ST3127S000

Preload gaugeInspecting sliding torque, steering torque, and

rotating torque for ball joint

KV48104400

Teflon ring correcting tool

a: 50 mm (1.97 in) dia.

b: 36 mm (1.42 in) dia.

c: 100 mm (3.94 in)Installing rack Teflon ring

KV48103400

Preload adapterInspecting rotating torque

ST35300000

Drift

a: 45.1 mm (1.776 in) dia.

b: 59.0 mm (2.323 in) dia.Installing oil pump oil seal

ZZA0819D

ZZA0806D

S-NT550

ZZA0824D

ZZA0881D

Page 4396 of 5121

ST-6

< PREPARATION >

PREPARATION

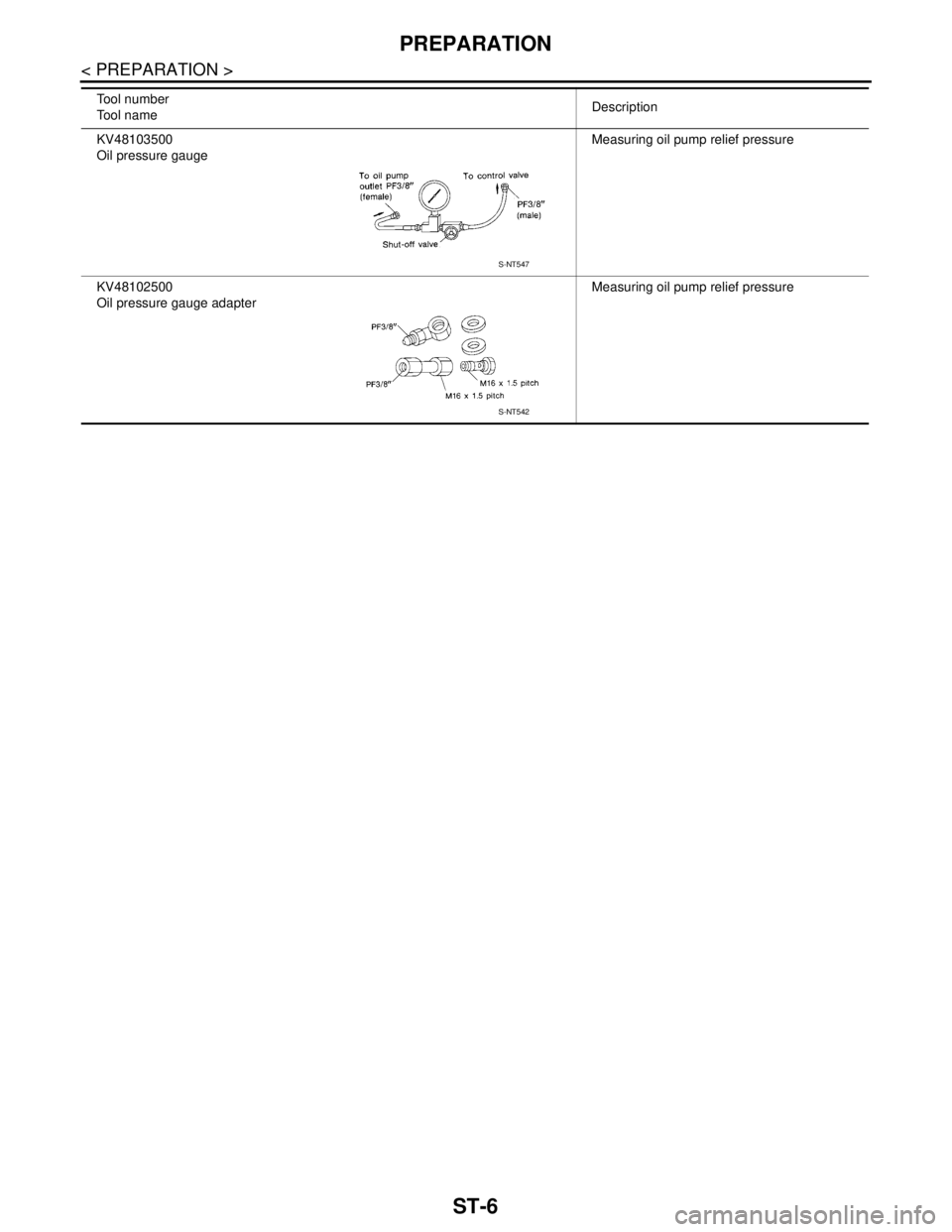

KV48103500

Oil pressure gaugeMeasuring oil pump relief pressure

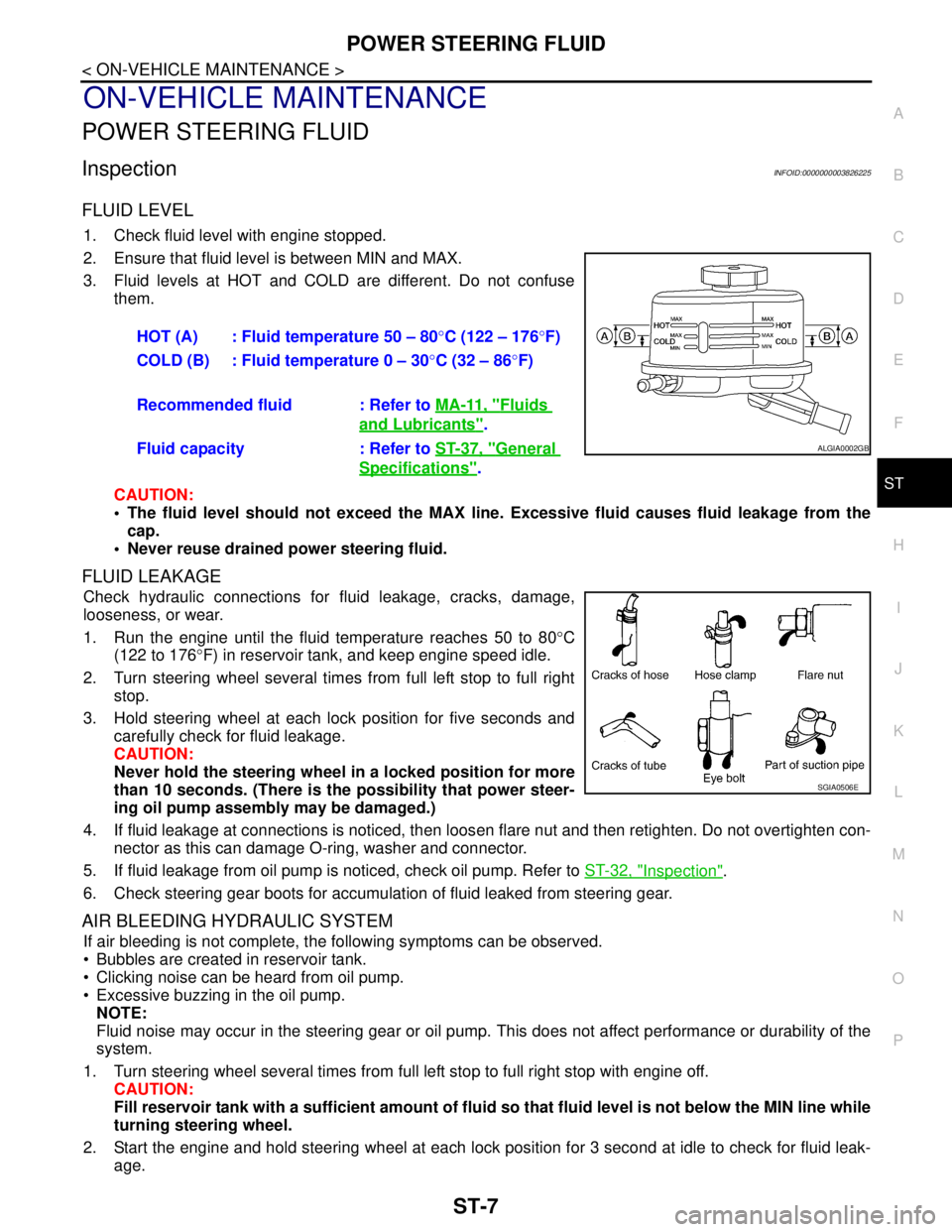

KV48102500

Oil pressure gauge adapterMeasuring oil pump relief pressure Tool number

Tool nameDescription

S-NT547

S-NT542

Page 4397 of 5121

POWER STEERING FLUID

ST-7

< ON-VEHICLE MAINTENANCE >

C

D

E

F

H

I

J

K

L

MA

B

ST

N

O

P

ON-VEHICLE MAINTENANCE

POWER STEERING FLUID

InspectionINFOID:0000000003826225

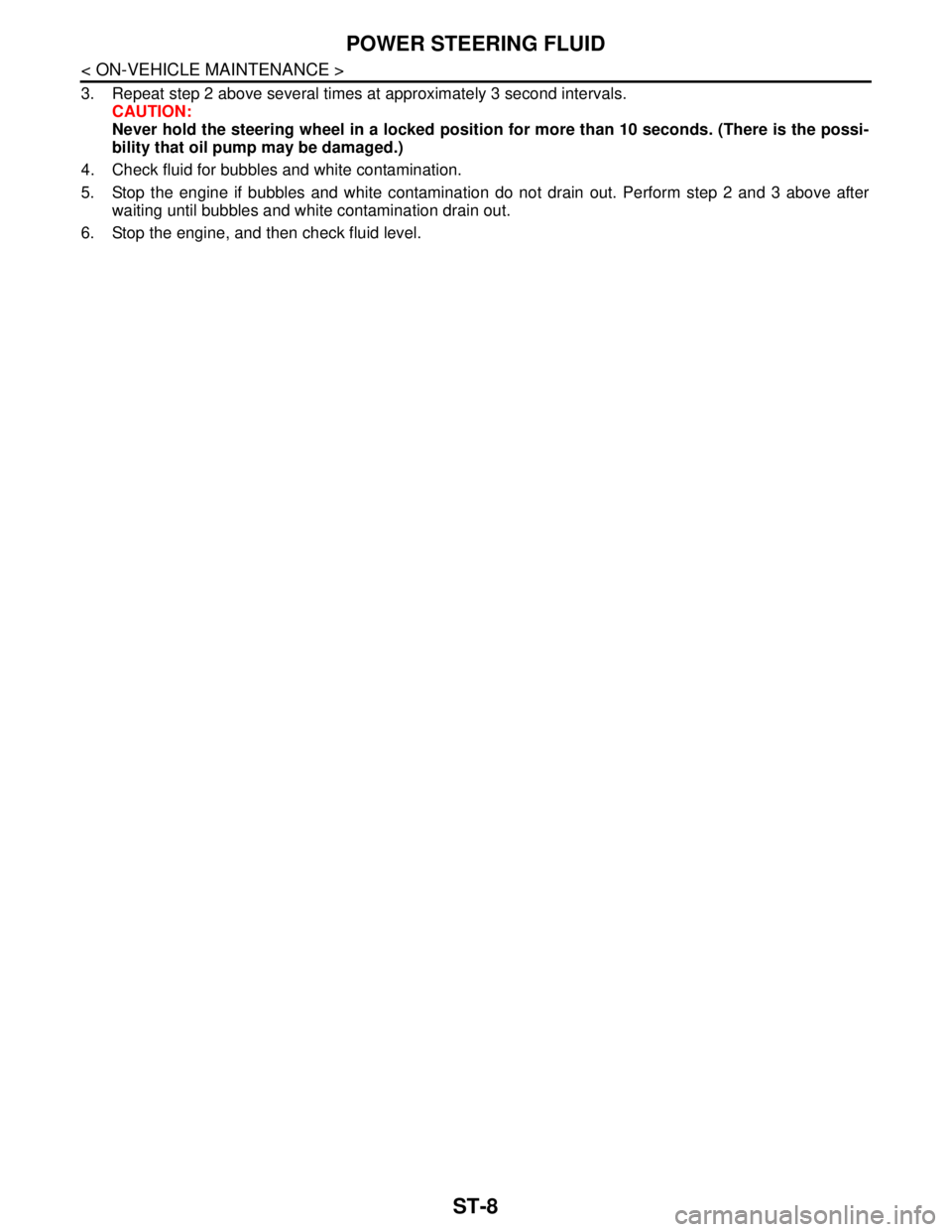

FLUID LEVEL

1. Check fluid level with engine stopped.

2. Ensure that fluid level is between MIN and MAX.

3. Fluid levels at HOT and COLD are different. Do not confuse

them.

CAUTION:

The fluid level should not exceed the MAX line. Excessive fluid causes fluid leakage from the

cap.

Never reuse drained power steering fluid.

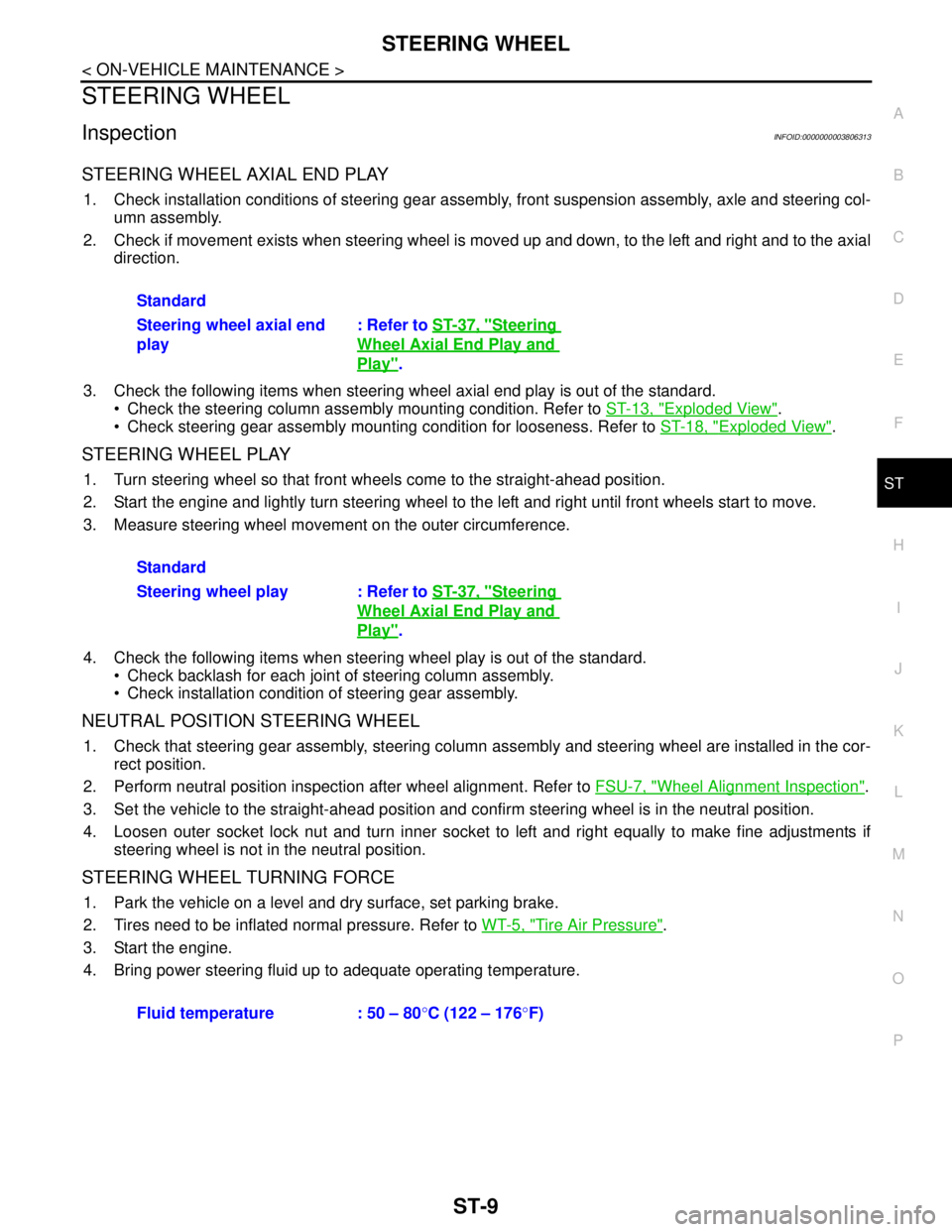

FLUID LEAKAGE

Check hydraulic connections for fluid leakage, cracks, damage,

looseness, or wear.

1. Run the engine until the fluid temperature reaches 50 to 80°C

(122 to 176°F) in reservoir tank, and keep engine speed idle.

2. Turn steering wheel several times from full left stop to full right

stop.

3. Hold steering wheel at each lock position for five seconds and

carefully check for fluid leakage.

CAUTION:

Never hold the steering wheel in a locked position for more

than 10 seconds. (There is the possibility that power steer-

ing oil pump assembly may be damaged.)

4. If fluid leakage at connections is noticed, then loosen flare nut and then retighten. Do not overtighten con-

nector as this can damage O-ring, washer and connector.

5. If fluid leakage from oil pump is noticed, check oil pump. Refer to ST-32, "

Inspection".

6. Check steering gear boots for accumulation of fluid leaked from steering gear.

AIR BLEEDING HYDRAULIC SYSTEM

If air bleeding is not complete, the following symptoms can be observed.

Bubbles are created in reservoir tank.

Clicking noise can be heard from oil pump.

Excessive buzzing in the oil pump.

NOTE:

Fluid noise may occur in the steering gear or oil pump. This does not affect performance or durability of the

system.

1. Turn steering wheel several times from full left stop to full right stop with engine off.

CAUTION:

Fill reservoir tank with a sufficient amount of fluid so that fluid level is not below the MIN line while

turning steering wheel.

2. Start the engine and hold steering wheel at each lock position for 3 second at idle to check for fluid leak-

age.HOT (A) : Fluid temperature 50 – 80°C (122 – 176°F)

COLD (B) : Fluid temperature 0 – 30°C (32 – 86°F)

Recommended fluid : Refer to MA-11, "

Fluids

and Lubricants".

Fluid capacity : Refer to ST-37, "

General

Specifications".

ALGIA0002GB

SGIA0506E

Page 4398 of 5121

ST-8

< ON-VEHICLE MAINTENANCE >

POWER STEERING FLUID

3. Repeat step 2 above several times at approximately 3 second intervals.

CAUTION:

Never hold the steering wheel in a locked position for more than 10 seconds. (There is the possi-

bility that oil pump may be damaged.)

4. Check fluid for bubbles and white contamination.

5. Stop the engine if bubbles and white contamination do not drain out. Perform step 2 and 3 above after

waiting until bubbles and white contamination drain out.

6. Stop the engine, and then check fluid level.

Page 4399 of 5121

STEERING WHEEL

ST-9

< ON-VEHICLE MAINTENANCE >

C

D

E

F

H

I

J

K

L

MA

B

ST

N

O

P

STEERING WHEEL

InspectionINFOID:0000000003806313

STEERING WHEEL AXIAL END PLAY

1. Check installation conditions of steering gear assembly, front suspension assembly, axle and steering col-

umn assembly.

2. Check if movement exists when steering wheel is moved up and down, to the left and right and to the axial

direction.

3. Check the following items when steering wheel axial end play is out of the standard.

Check the steering column assembly mounting condition. Refer to ST-13, "

Exploded View".

Check steering gear assembly mounting condition for looseness. Refer to ST-18, "

Exploded View".

STEERING WHEEL PLAY

1. Turn steering wheel so that front wheels come to the straight-ahead position.

2. Start the engine and lightly turn steering wheel to the left and right until front wheels start to move.

3. Measure steering wheel movement on the outer circumference.

4. Check the following items when steering wheel play is out of the standard.

Check backlash for each joint of steering column assembly.

Check installation condition of steering gear assembly.

NEUTRAL POSITION STEERING WHEEL

1. Check that steering gear assembly, steering column assembly and steering wheel are installed in the cor-

rect position.

2. Perform neutral position inspection after wheel alignment. Refer to FSU-7, "

Wheel Alignment Inspection".

3. Set the vehicle to the straight-ahead position and confirm steering wheel is in the neutral position.

4. Loosen outer socket lock nut and turn inner socket to left and right equally to make fine adjustments if

steering wheel is not in the neutral position.

STEERING WHEEL TURNING FORCE

1. Park the vehicle on a level and dry surface, set parking brake.

2. Tires need to be inflated normal pressure. Refer to WT-5, "

Tire Air Pressure".

3. Start the engine.

4. Bring power steering fluid up to adequate operating temperature.Standard

Steering wheel axial end

play: Refer to ST-37, "

Steering

Wheel Axial End Play and

Play".

Standard

Steering wheel play : Refer to ST-37, "

Steering

Wheel Axial End Play and

Play".

Fluid temperature : 50 – 80°C (122 – 176°F)

Page 4400 of 5121

ST-10

< ON-VEHICLE MAINTENANCE >

STEERING WHEEL

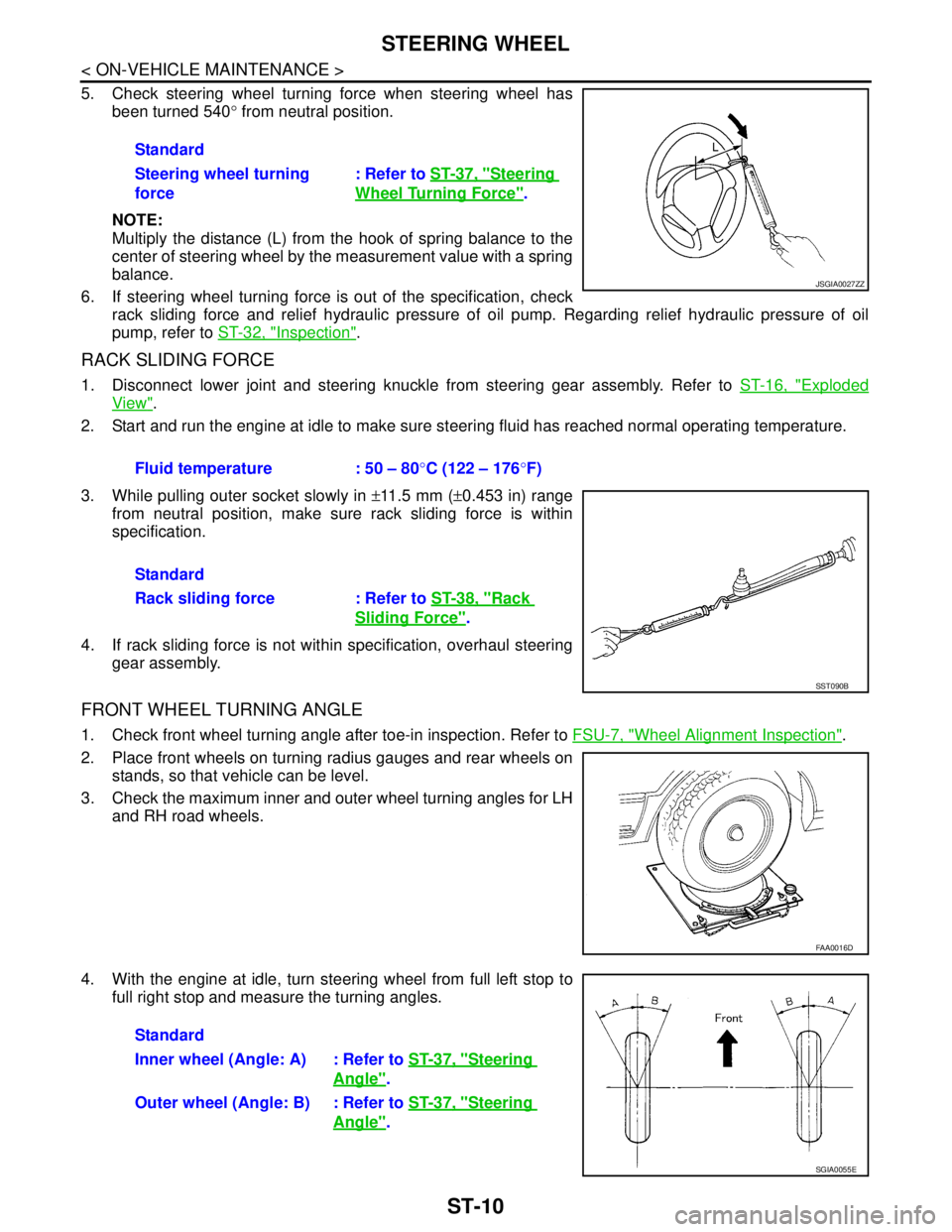

5. Check steering wheel turning force when steering wheel has

been turned 540° from neutral position.

NOTE:

Multiply the distance (L) from the hook of spring balance to the

center of steering wheel by the measurement value with a spring

balance.

6. If steering wheel turning force is out of the specification, check

rack sliding force and relief hydraulic pressure of oil pump. Regarding relief hydraulic pressure of oil

pump, refer to ST-32, "

Inspection".

RACK SLIDING FORCE

1. Disconnect lower joint and steering knuckle from steering gear assembly. Refer to ST-16, "Exploded

View".

2. Start and run the engine at idle to make sure steering fluid has reached normal operating temperature.

3. While pulling outer socket slowly in ±11.5 mm (±0.453 in) range

from neutral position, make sure rack sliding force is within

specification.

4. If rack sliding force is not within specification, overhaul steering

gear assembly.

FRONT WHEEL TURNING ANGLE

1. Check front wheel turning angle after toe-in inspection. Refer to FSU-7, "Wheel Alignment Inspection".

2. Place front wheels on turning radius gauges and rear wheels on

stands, so that vehicle can be level.

3. Check the maximum inner and outer wheel turning angles for LH

and RH road wheels.

4. With the engine at idle, turn steering wheel from full left stop to

full right stop and measure the turning angles.Standard

Steering wheel turning

force: Refer to ST-37, "

Steering

Wheel Turning Force".

JSGIA0027ZZ

Fluid temperature : 50 – 80°C (122 – 176°F)

Standard

Rack sliding force : Refer to ST-38, "

Rack

Sliding Force".

SST090B

FAA0016D

Standard

Inner wheel (Angle: A) : Refer to ST-37, "

Steering

Angle".

Outer wheel (Angle: B) : Refer to ST-37, "

Steering

Angle".

SGIA0055E