NISSAN TEANA 2008 Service Manual

Manufacturer: NISSAN, Model Year: 2008, Model line: TEANA, Model: NISSAN TEANA 2008Pages: 5121, PDF Size: 69.03 MB

Page 4421 of 5121

POWER STEERING OIL PUMP

ST-31

< ON-VEHICLE REPAIR >

C

D

E

F

H

I

J

K

L

MA

B

ST

N

O

P

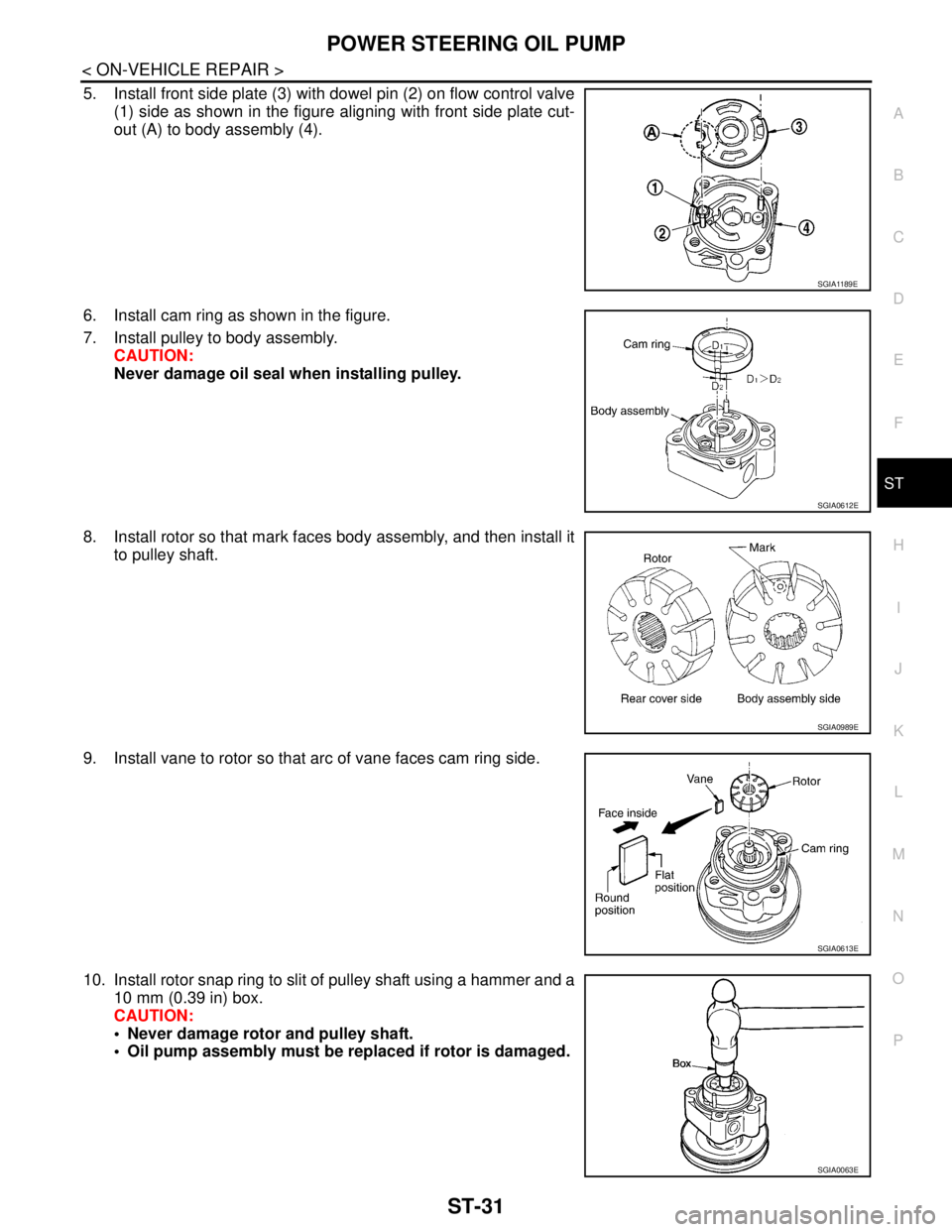

5. Install front side plate (3) with dowel pin (2) on flow control valve

(1) side as shown in the figure aligning with front side plate cut-

out (A) to body assembly (4).

6. Install cam ring as shown in the figure.

7. Install pulley to body assembly.

CAUTION:

Never damage oil seal when installing pulley.

8. Install rotor so that mark faces body assembly, and then install it

to pulley shaft.

9. Install vane to rotor so that arc of vane faces cam ring side.

10. Install rotor snap ring to slit of pulley shaft using a hammer and a

10 mm (0.39 in) box.

CAUTION:

Never damage rotor and pulley shaft.

Oil pump assembly must be replaced if rotor is damaged.

SGIA1189E

SGIA0612E

SGIA0989E

SGIA0613E

SGIA0063E

Page 4422 of 5121

ST-32

< ON-VEHICLE REPAIR >

POWER STEERING OIL PUMP

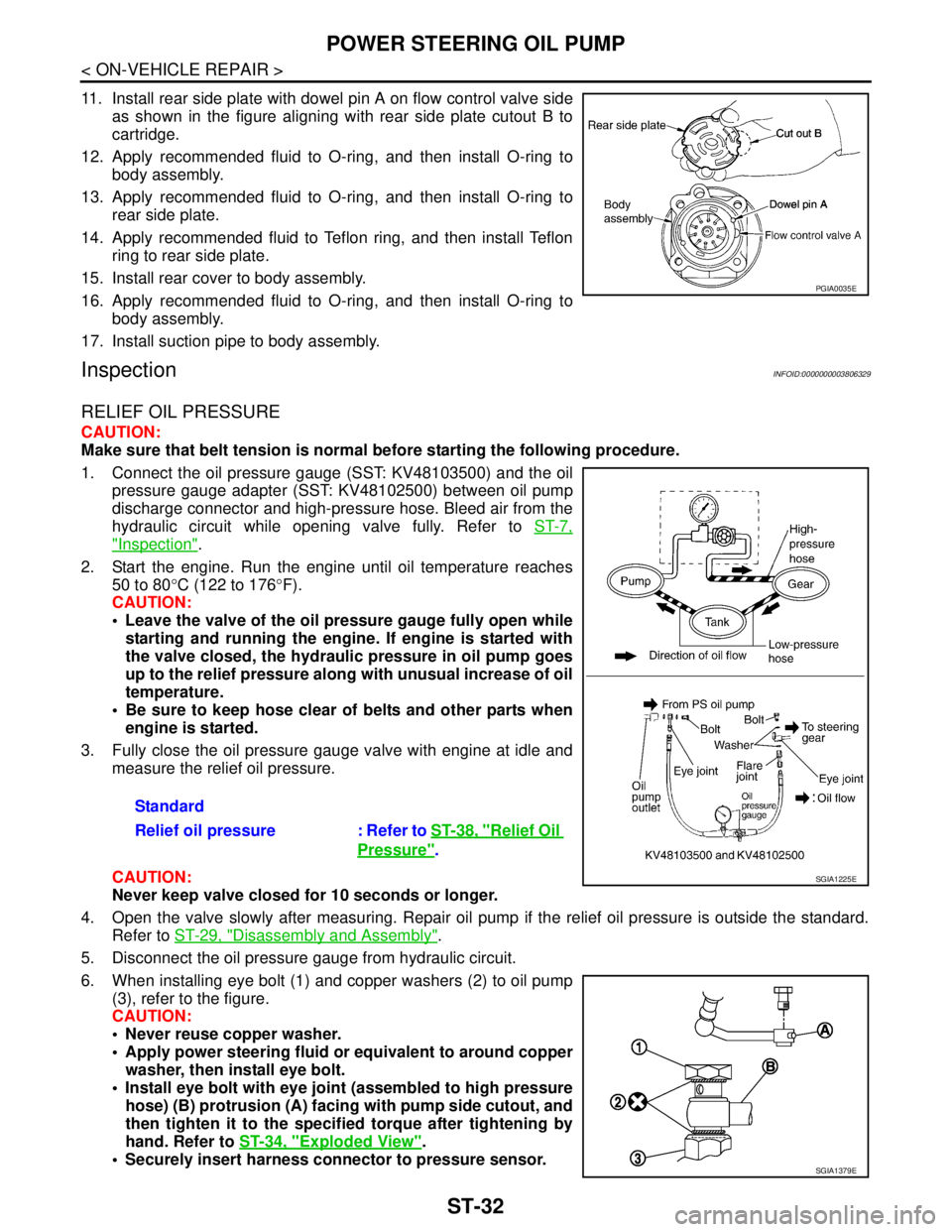

11. Install rear side plate with dowel pin A on flow control valve side

as shown in the figure aligning with rear side plate cutout B to

cartridge.

12. Apply recommended fluid to O-ring, and then install O-ring to

body assembly.

13. Apply recommended fluid to O-ring, and then install O-ring to

rear side plate.

14. Apply recommended fluid to Teflon ring, and then install Teflon

ring to rear side plate.

15. Install rear cover to body assembly.

16. Apply recommended fluid to O-ring, and then install O-ring to

body assembly.

17. Install suction pipe to body assembly.

InspectionINFOID:0000000003806329

RELIEF OIL PRESSURE

CAUTION:

Make sure that belt tension is normal before starting the following procedure.

1. Connect the oil pressure gauge (SST: KV48103500) and the oil

pressure gauge adapter (SST: KV48102500) between oil pump

discharge connector and high-pressure hose. Bleed air from the

hydraulic circuit while opening valve fully. Refer to ST-7,

"Inspection".

2. Start the engine. Run the engine until oil temperature reaches

50 to 80°C (122 to 176°F).

CAUTION:

Leave the valve of the oil pressure gauge fully open while

starting and running the engine. If engine is started with

the valve closed, the hydraulic pressure in oil pump goes

up to the relief pressure along with unusual increase of oil

temperature.

Be sure to keep hose clear of belts and other parts when

engine is started.

3. Fully close the oil pressure gauge valve with engine at idle and

measure the relief oil pressure.

CAUTION:

Never keep valve closed for 10 seconds or longer.

4. Open the valve slowly after measuring. Repair oil pump if the relief oil pressure is outside the standard.

Refer to ST-29, "

Disassembly and Assembly".

5. Disconnect the oil pressure gauge from hydraulic circuit.

6. When installing eye bolt (1) and copper washers (2) to oil pump

(3), refer to the figure.

CAUTION:

Never reuse copper washer.

Apply power steering fluid or equivalent to around copper

washer, then install eye bolt.

Install eye bolt with eye joint (assembled to high pressure

hose) (B) protrusion (A) facing with pump side cutout, and

then tighten it to the specified torque after tightening by

hand. Refer to ST-34, "

Exploded View".

Securely insert harness connector to pressure sensor.

PGIA0035E

Standard

Relief oil pressure : Refer to ST-38, "

Relief Oil

Pressure".

SGIA1225E

SGIA1379E

Page 4423 of 5121

POWER STEERING OIL PUMP

ST-33

< ON-VEHICLE REPAIR >

C

D

E

F

H

I

J

K

L

MA

B

ST

N

O

P

7. Check fluid level, fluid leakage and air bleeding hydraulic system after the installation. Refer to ST-7,

"Inspection".

BEFORE DISASSEMBLY

Disassemble oil pump only when the following malfunctions occur.

If oil leakage is found on oil pump.

Oil pump pulley is damaged or deformed.

Performance of oil pump is low.

AFTER DISASSEMBLY

Body Assembly and Rear Cover Inspection

Check body assembly and rear cover for internal damage. Replace rear cover if it is damaged. Replace oil

pump assembly if body assembly is damaged.

Cartridge Assembly Inspection

Check cam ring, rotor and vane for damage. Replace cartridge assembly if necessary.

Side Plate Inspection

Check side plate for damage. Replace side plate if necessary.

Flow Control Valve Inspection

Check flow control valve and spring for damage. Replace if necessary.

Page 4424 of 5121

ST-34

< ON-VEHICLE REPAIR >

HYDRAULIC LINE

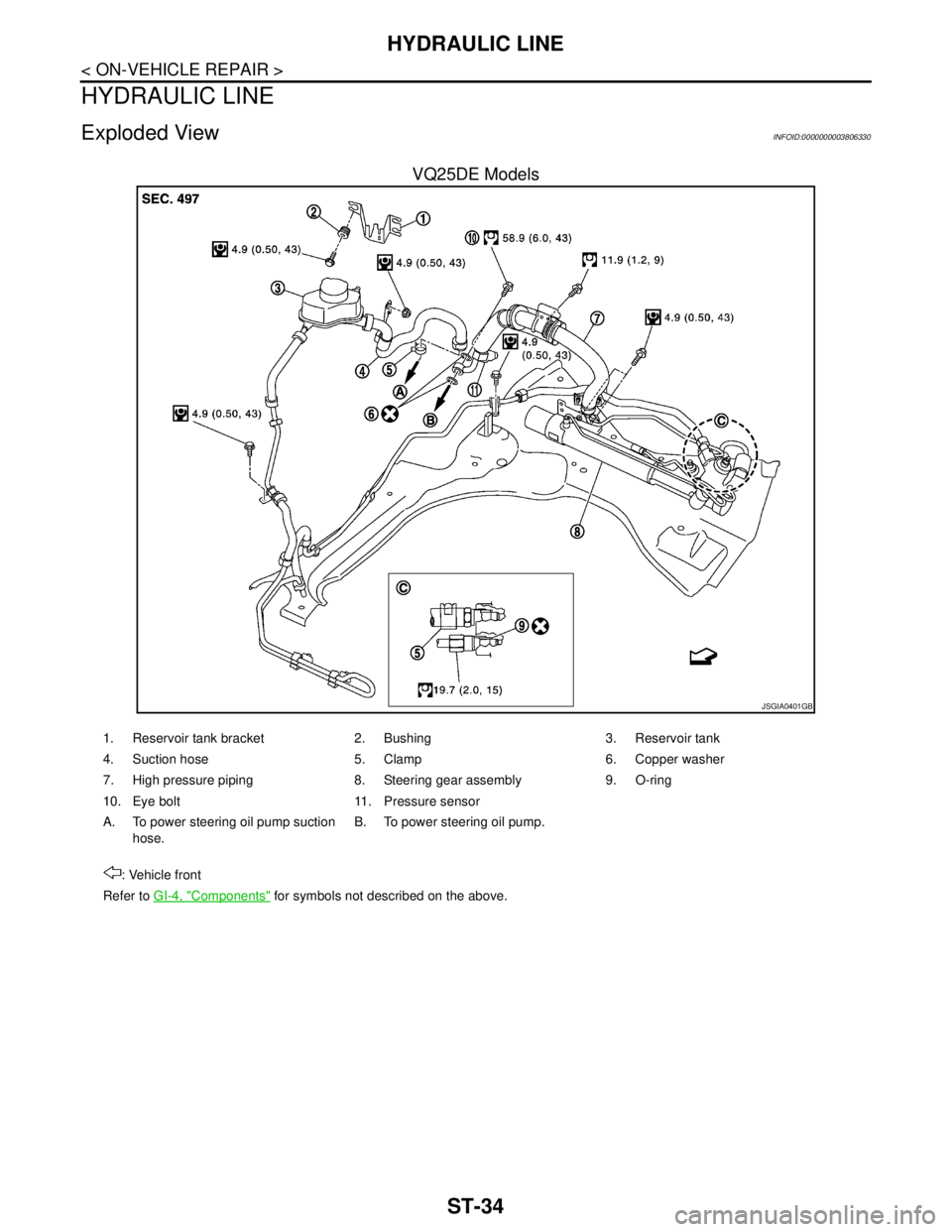

HYDRAULIC LINE

Exploded ViewINFOID:0000000003806330

VQ25DE Models

JSGIA0401GB

1. Reservoir tank bracket 2. Bushing 3. Reservoir tank

4. Suction hose 5. Clamp 6. Copper washer

7. High pressure piping 8. Steering gear assembly 9. O-ring

10. Eye bolt 11. Pressure sensor

A. To power steering oil pump suction

hose.B. To power steering oil pump.

: Vehicle front

Refer to GI-4, "

Components" for symbols not described on the above.

Page 4425 of 5121

HYDRAULIC LINE

ST-35

< ON-VEHICLE REPAIR >

C

D

E

F

H

I

J

K

L

MA

B

ST

N

O

P

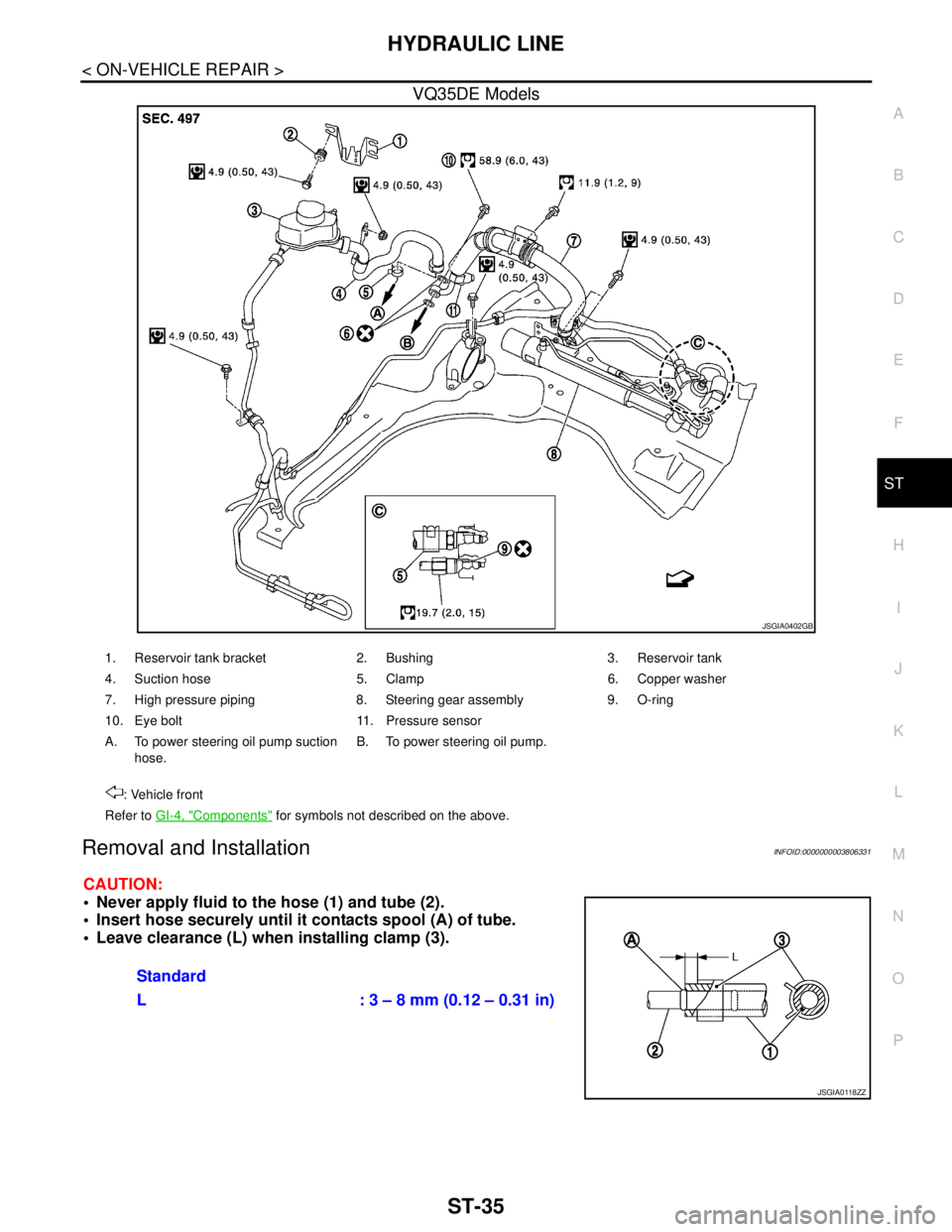

VQ35DE Models

Removal and InstallationINFOID:0000000003806331

CAUTION:

Never apply fluid to the hose (1) and tube (2).

Insert hose securely until it contacts spool (A) of tube.

Leave clearance (L) when installing clamp (3).

JSGIA0402GB

1. Reservoir tank bracket 2. Bushing 3. Reservoir tank

4. Suction hose 5. Clamp 6. Copper washer

7. High pressure piping 8. Steering gear assembly 9. O-ring

10. Eye bolt 11. Pressure sensor

A. To power steering oil pump suction

hose.B. To power steering oil pump.

: Vehicle front

Refer to GI-4, "

Components" for symbols not described on the above.

Standard

L : 3 – 8 mm (0.12 – 0.31 in)

JSGIA0118ZZ

Page 4426 of 5121

ST-36

< ON-VEHICLE REPAIR >

HYDRAULIC LINE

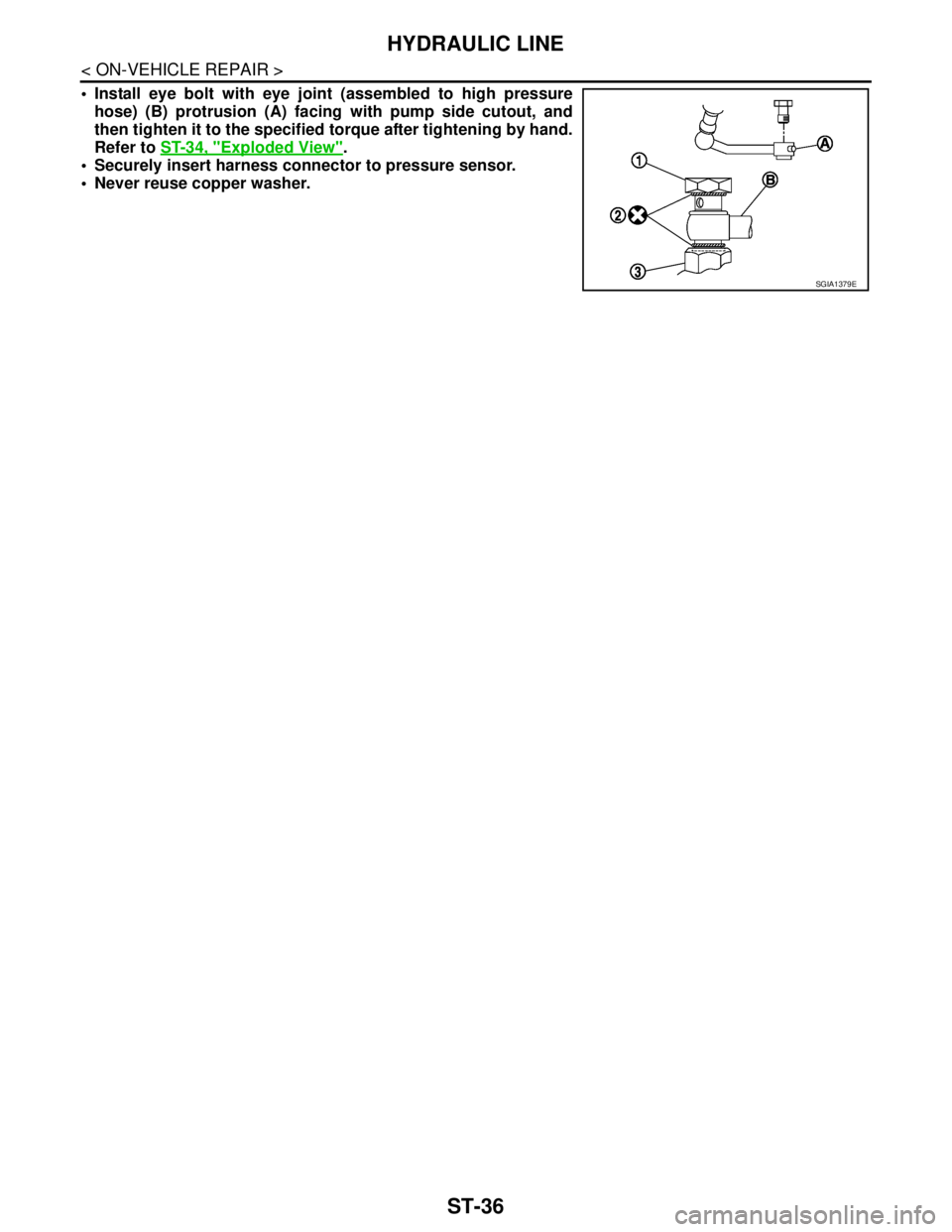

Install eye bolt with eye joint (assembled to high pressure

hose) (B) protrusion (A) facing with pump side cutout, and

then tighten it to the specified torque after tightening by hand.

Refer to ST-34, "

Exploded View".

Securely insert harness connector to pressure sensor.

Never reuse copper washer.

SGIA1379E

Page 4427 of 5121

SERVICE DATA AND SPECIFICATIONS (SDS)

ST-37

< SERVICE DATA AND SPECIFICATIONS (SDS)

C

D

E

F

H

I

J

K

L

MA

B

ST

N

O

P

SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

General SpecificationsINFOID:0000000003806332

Steering Wheel Axial End Play and PlayINFOID:0000000003806333

Unit: mm (in)

Steering Wheel Turning ForceINFOID:0000000003806334

Unit: N·m (kg-m, in-lb)

Steering AngleINFOID:0000000003806335

Unit: Degree minute (Decimal degree)

Steering Column LengthINFOID:0000000003826226

Unit: mm (in)

Steering Column Mounting DimensionsINFOID:0000000003826227

Unit: mm (in)

Steering Column Operating RangeINFOID:0000000003806336

Steering gear modelPR26AF

Fluid capacity (Approx.)

(lmp qt)1.0 (7/8)

Item Standard

Steering wheel axial end play 0 (0)

Steering wheel play on the outer circumference 0 – 35 (0 – 1.38)

Item Standard

Steering wheel turning force 7.45 (0.76, 66)

ItemStandard

Tire size: 205/65R16 Tire size: 215/55R17

Inner wheelMinimum 38°00′ (38.0°)34°00′ (34.0°)

Nominal 41°00′ (41.0°)37°00′ (37.0°)

Maximum 42°30′ (42.5°)38°30′ (38.5°)

Outer wheel Nominal 33°00′ (31.0°)31°00′ (31.0°)

Item Standard

Column length484 – 486 (19.06 – 19.13)

Item Standard

Mounting dimension 19.5 (0.768) or less

Item Standard

Tilt operating range 37 mm (1.46 in)

Rotating torque 0.49 N·m (0.05 kg-m, 4 in-lb)

Page 4428 of 5121

ST-38

< SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

Lower Shaft Sliding Range

INFOID:0000000003806337

Unit: mm (in)

Rack Sliding ForceINFOID:0000000003806338

Unit: N (kg, lb)

Rack StrokeINFOID:0000000003806339

Unit: mm (in)

Socket Swing Force and Rotating TorqueINFOID:0000000003806340

SWING FORCE

Unit: N (kg, lb)

ROTATING TORQUE

Unit: N·m (kg-m, in-lb)

Socket Axial End PlayINFOID:0000000003806341

Unit: mm (in)

Inner Socket LengthINFOID:0000000003806342

Unit: mm (in)

Relief Oil PressureINFOID:0000000003806343

Unit: kPa (bar, kg/cm2, psi)

Item Standard

Sliding range422.2 – 423.2 (16.62 – 16.66)

Item Standard

Rack sliding force 225.6 – 284.4 (23 – 29, 50.7 – 63.9)

ItemStandard

Tire size: 205/65R16 Tire size: 215/55R17

Rack stroke 74.5 (2.933) 69.0 (2.720)

Item Standard

Outer socket 4.81 – 45.7 (0.5 – 4.6, 1.1 – 10.2)

Inner socket 8.9 – 64 (0.91 – 6.5, 2.01 – 14.3)

Item Standard

Outer socket 0.3 – 2.9 (0.03 – 0.29, 3 – 25)

Item Standard

Outer socket0.5 (0.02) or less

Inner socket0.2 (0.008) or less

Item Standard

Rack neutral position84.3 (3.32)

Item Standard

Relief oil pressure 9,300 – 10,300 (93 – 103, 94.9 – 105.1, 1,349 – 1,494)

Page 4429 of 5121

STC-1

STEERING

C

DE

F

H I

J

K L

M

SECTION STC

A

B

STC

N

O P

CONTENTS

STEERING CONTROL SYSTEM

BASIC INSPECTION ....... .............................2

DIAGNOSIS AND REPAIR WORK FLOW .... .....2

Work Flow ........................................................... ......2

FUNCTION DIAGNOSIS ...............................3

EPS SYSTEM ... .............................................. .....3

System Diagram .................................................. ......3

System Description ...................................................3

Component Parts Location ........................................5

Component Description .............................................5

COMPONENT DIAGNOSIS ..........................6

POWER SUPPLY AND GROUND CIRCUIT .. .....6

Description .......................................................... ......6

Diagnosis Procedure .................................................6

POWER STEERING SOLENOID VALVE ...........7

Description .......................................................... ......7

Diagnosis Procedure .................................................7

Component Inspection ..............................................8

ENGINE SPEED SIGNAL CIRCUIT ............... .....9

Description .......................................................... ......9

Diagnosis Procedure .................................................9

VEHICLE SPEED SIGNAL CIRCUIT .................11

Description .......................................................... ....11

Diagnosis Procedure ...............................................11

ECU DIAGNOSIS .........................................13

POWER STEERING CONTROL UNIT ..............13

Reference Value .................................................. ....13

Wiring Diagram - ELECTRONICALLY CON-

TROLLED POWER STEERING SYSTEM - ............

14

Fail-Safe .............................................................. ....15

SYMPTOM DIAGNOSIS ..............................17

UNBALANCE STEERING WHEEL TURNING

FORCE (TORQUE VARIATION) .......................

17

Description ........................................................... ....17

Diagnosis Procedure ...............................................17

PRECAUTION ..............................................18

PRECAUTIONS .................................................18

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ....

18

Precaution Necessary for Steering Wheel Rota-

tion after Battery Disconnect ...................................

18

ON-VEHICLE REPAIR .................................19

POWER STEERING CONTROL UNIT ..............19

Exploded View ..................................................... ....19

Removal and Installation .........................................19

Page 4430 of 5121

STC-2

< BASIC INSPECTION >

DIAGNOSIS AND REPAIR WORK FLOW

BASIC INSPECTION

DIAGNOSIS AND REPAIR WORK FLOW

Work FlowINFOID:0000000003893521

DETAILED FLOW

1.COLLECT THE INFORMATION FROM THE CUSTOMER

It is also important to clarify customer complaints before inspection. First of all, reproduce symptoms and

understand them fully. Ask customer about his/her complaints carefully. In some cases, it is necessary to

check symptoms by driving vehicle with customer.

CAUTION:

Customers are not professional. It is dangerous to make an easy guess like “maybe the customer

means that...,” or “maybe the customer mentions this symptom”.

>> GO TO 2.

2.CHECK THE STATUS

1. Check the power steering fluid leakage and power steering fluid level. Refer to ST-7, "

Inspection".

2. Check the drive belt tension. Refer to EM-12, "

Checking".

3. Check the power steering gear for damages, cracks and fluid leakage. Refer to ST-26, "

Inspection".

4. Check the relief oil pressure. Refer to ST-32, "

Inspection".

>> GO TO 3.

3.DIAGNOSIS CHART BY SYMPTOM

Perform the diagnosis by symptom. Refer to STC-17, "

Diagnosis Procedure".

>> GO TO 4.

4.FINAL CHECK

Check the input/output standard values for the power steering control unit.

Are the power steering control unit input/output values within standard ranges respectively?

YES >> INSPECTION END

NO >> GO TO 2.