NISSAN TERRANO 2004 Service Repair Manual

Manufacturer: NISSAN, Model Year: 2004, Model line: TERRANO, Model: NISSAN TERRANO 2004Pages: 1833, PDF Size: 53.42 MB

Page 541 of 1833

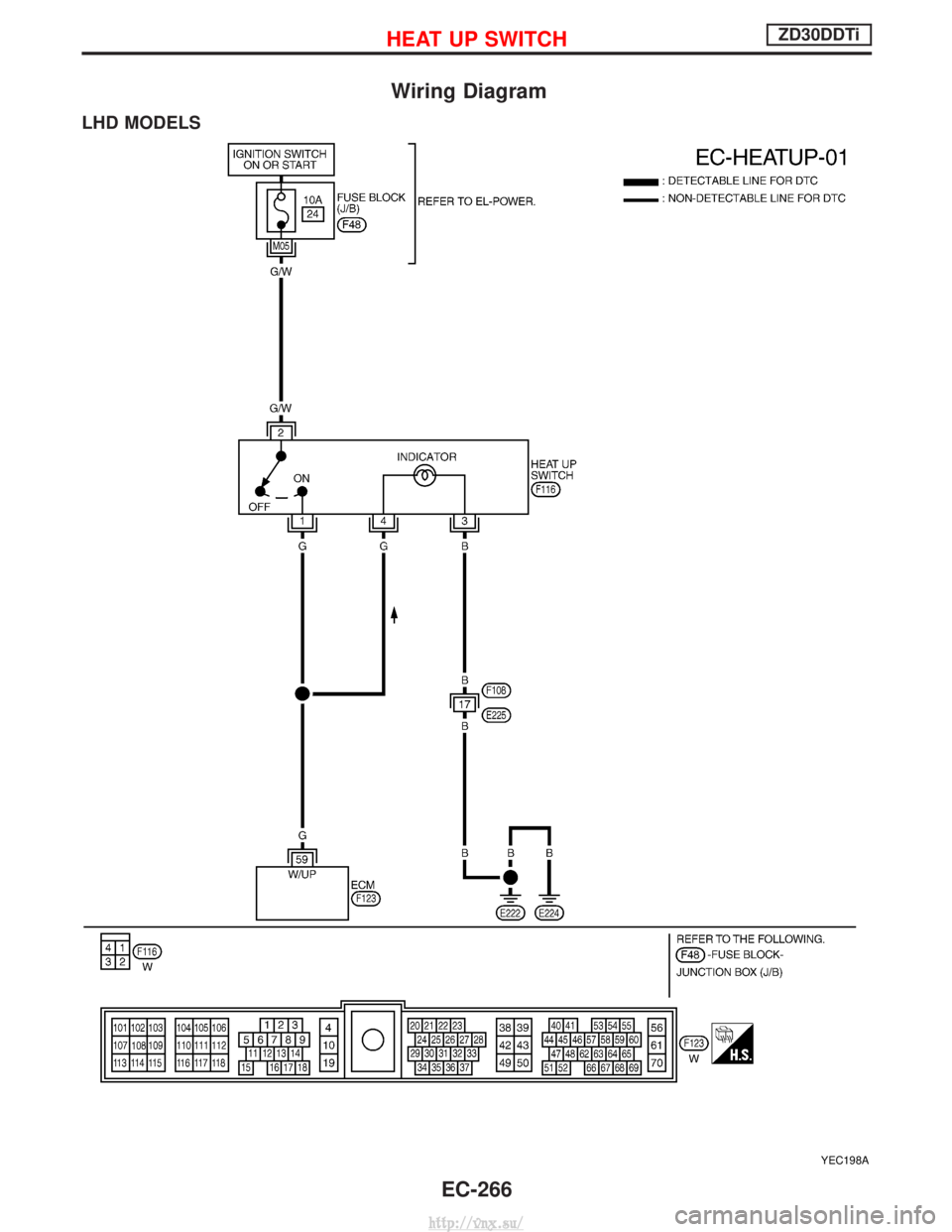

Wiring Diagram

LHD MODELS

YEC198A

HEAT UP SWITCHZD30DDTi

EC-266

http://vnx.su/

Page 542 of 1833

Diagnostic Procedure

1 INSPECTION START

Do you have CONSULT-II?YesorNo

Ye s EGO TO 2.

No EGO TO 3.

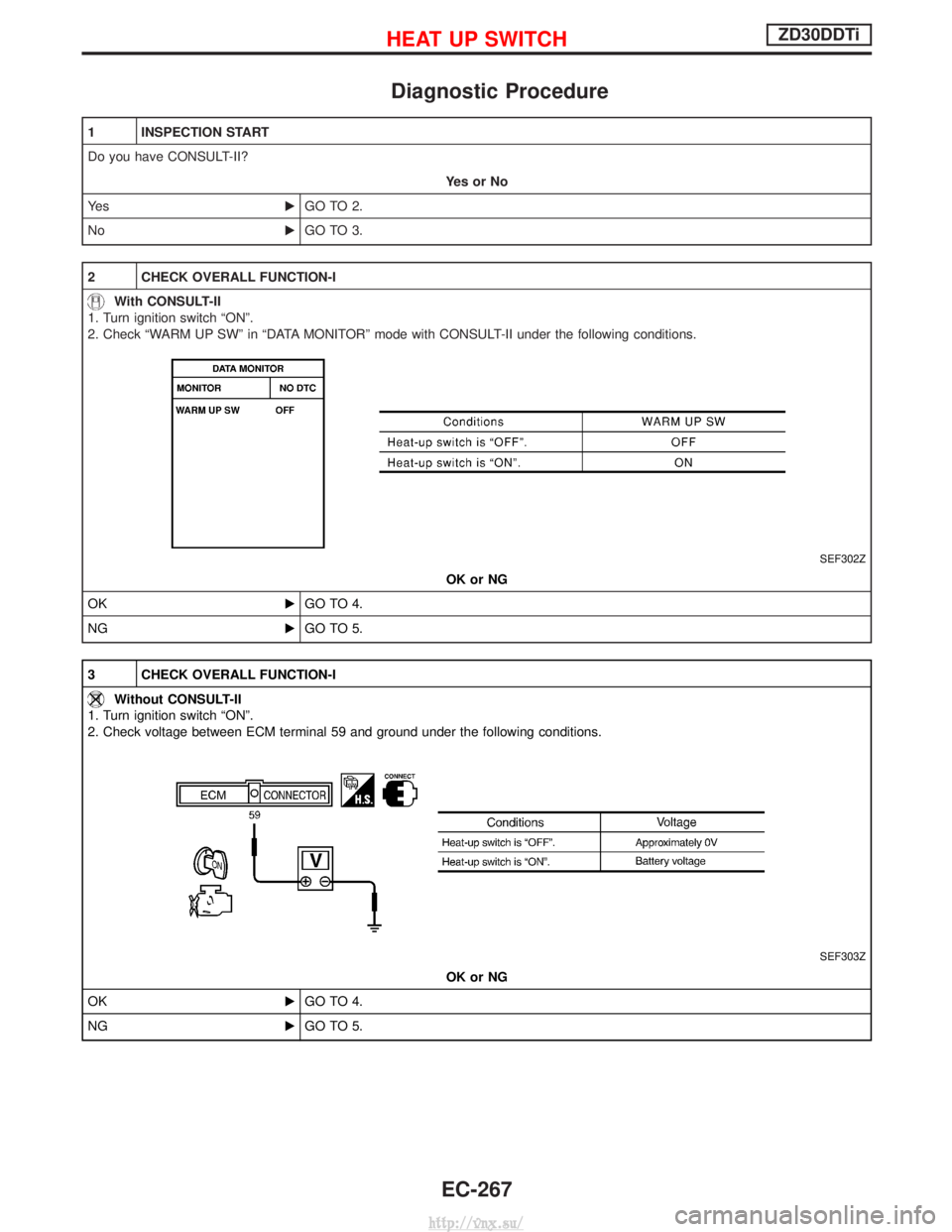

2 CHECK OVERALL FUNCTION-I

With CONSULT-II

1. Turn ignition switch ªONº.

2. Check ªWARM UP SWº in ªDATA MONITORº mode with CONSULT-II under the following conditions.

SEF302Z

OK or NG

OK EGO TO 4.

NG EGO TO 5.

3 CHECK OVERALL FUNCTION-I

Without CONSULT-II

1. Turn ignition switch ªONº.

2. Check voltage between ECM terminal 59 and ground under the following conditions.

SEF303Z

OK or NG

OK EGO TO 4.

NG EGO TO 5.

HEAT UP SWITCHZD30DDTi

EC-267

http://vnx.su/

Page 543 of 1833

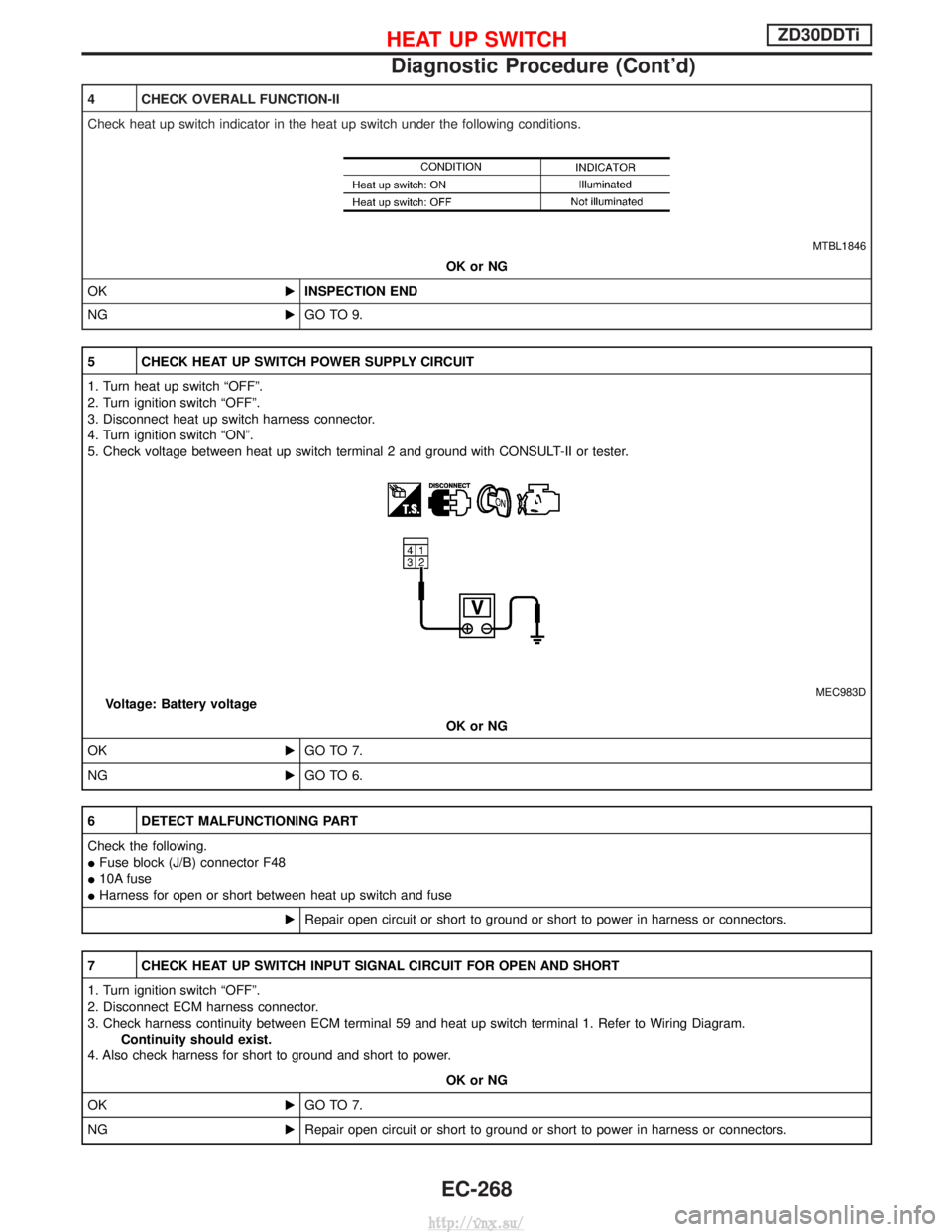

4 CHECK OVERALL FUNCTION-II

Check heat up switch indicator in the heat up switch under the following conditions.

MTBL1846

OK or NG

OK EINSPECTION END

NG EGO TO 9.

5 CHECK HEAT UP SWITCH POWER SUPPLY CIRCUIT

1. Turn heat up switch ªOFFº.

2. Turn ignition switch ªOFFº.

3. Disconnect heat up switch harness connector.

4. Turn ignition switch ªONº.

5. Check voltage between heat up switch terminal 2 and ground with CONSULT-II or tester.

MEC983DVoltage: Battery voltage

OK or NG

OK EGO TO 7.

NG EGO TO 6.

6 DETECT MALFUNCTIONING PART

Check the following.

IFuse block (J/B) connector F48

I 10A fuse

I Harness for open or short between heat up switch and fuse

ERepair open circuit or short to ground or short to power in harness or connectors.

7 CHECK HEAT UP SWITCH INPUT SIGNAL CIRCUIT FOR OPEN AND SHORT

1. Turn ignition switch ªOFFº.

2. Disconnect ECM harness connector.

3. Check harness continuity between ECM terminal 59 and heat up switch terminal 1. Refer to Wiring Diagram.

Continuity should exist.

4. Also check harness for short to ground and short to power.

OK or NG

OK EGO TO 7.

NG ERepair open circuit or short to ground or short to power in harness or connectors.

HEAT UP SWITCHZD30DDTi

Diagnostic Procedure (Cont'd)

EC-268

http://vnx.su/

Page 544 of 1833

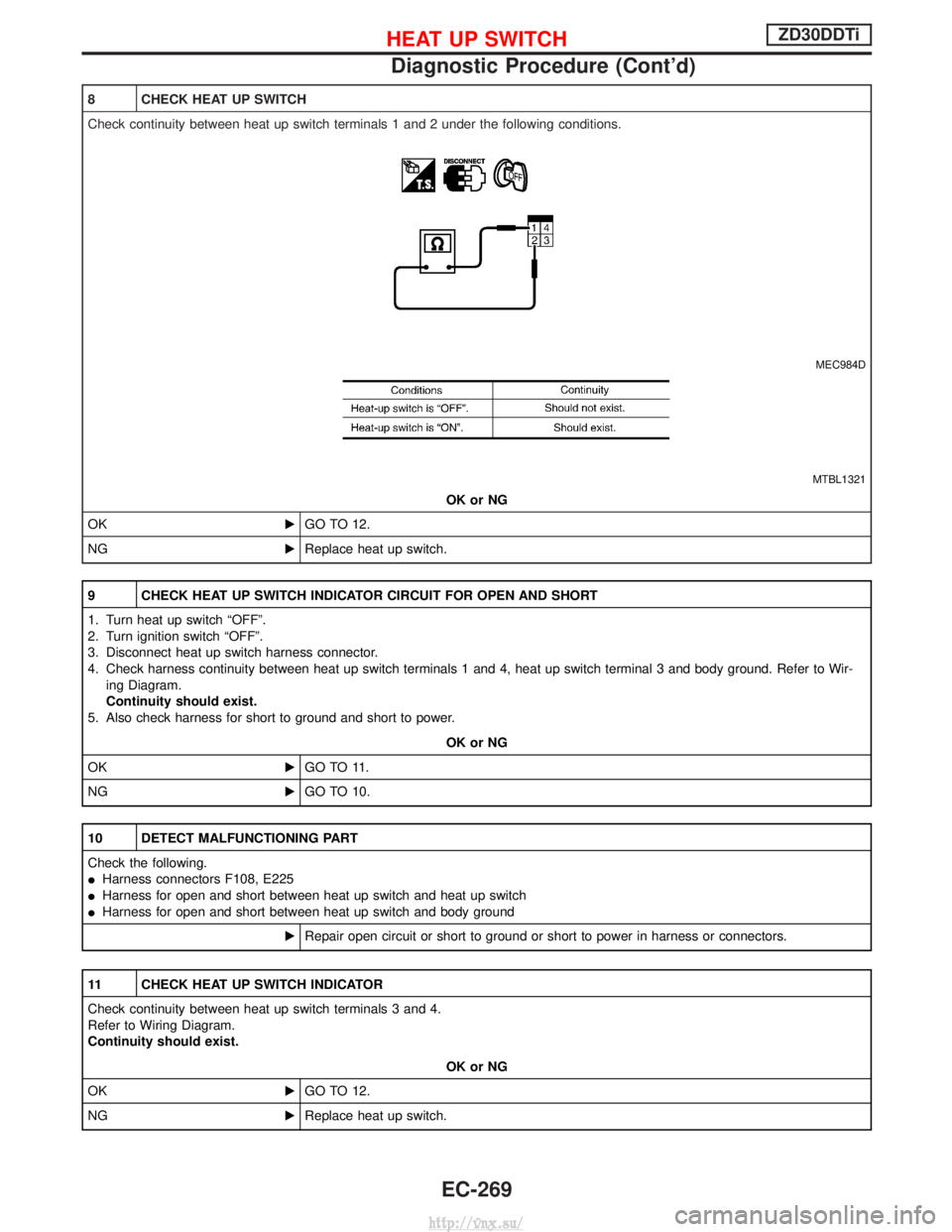

8 CHECK HEAT UP SWITCH

Check continuity between heat up switch terminals 1 and 2 under the following conditions.

MEC984D

MTBL1321

OK or NG

OK EGO TO 12.

NG EReplace heat up switch.

9 CHECK HEAT UP SWITCH INDICATOR CIRCUIT FOR OPEN AND SHORT

1. Turn heat up switch ªOFFº.

2. Turn ignition switch ªOFFº.

3. Disconnect heat up switch harness connector.

4. Check harness continuity between heat up switch terminals 1 and 4, heat up switch terminal 3 and body ground. Refer to Wir-

ing Diagram.

Continuity should exist.

5. Also check harness for short to ground and short to power.

OK or NG

OK EGO TO 11.

NG EGO TO 10.

10 DETECT MALFUNCTIONING PART

Check the following.

IHarness connectors F108, E225

I Harness for open and short between heat up switch and heat up switch

I Harness for open and short between heat up switch and body ground

ERepair open circuit or short to ground or short to power in harness or connectors.

11 CHECK HEAT UP SWITCH INDICATOR

Check continuity between heat up switch terminals 3 and 4.

Refer to Wiring Diagram.

Continuity should exist.

OK or NG

OK EGO TO 12.

NG EReplace heat up switch.

HEAT UP SWITCHZD30DDTi

Diagnostic Procedure (Cont'd)

EC-269

http://vnx.su/

Page 545 of 1833

12 CHECK INTERMITTENT INCIDENT

Refer to ªTROUBLE DIAGNOSIS FOR INTERMITTENT INCIDENTº, EC-78.EINSPECTION END

HEAT UP SWITCHZD30DDTi

Diagnostic Procedure (Cont'd)

EC-270

http://vnx.su/

Page 546 of 1833

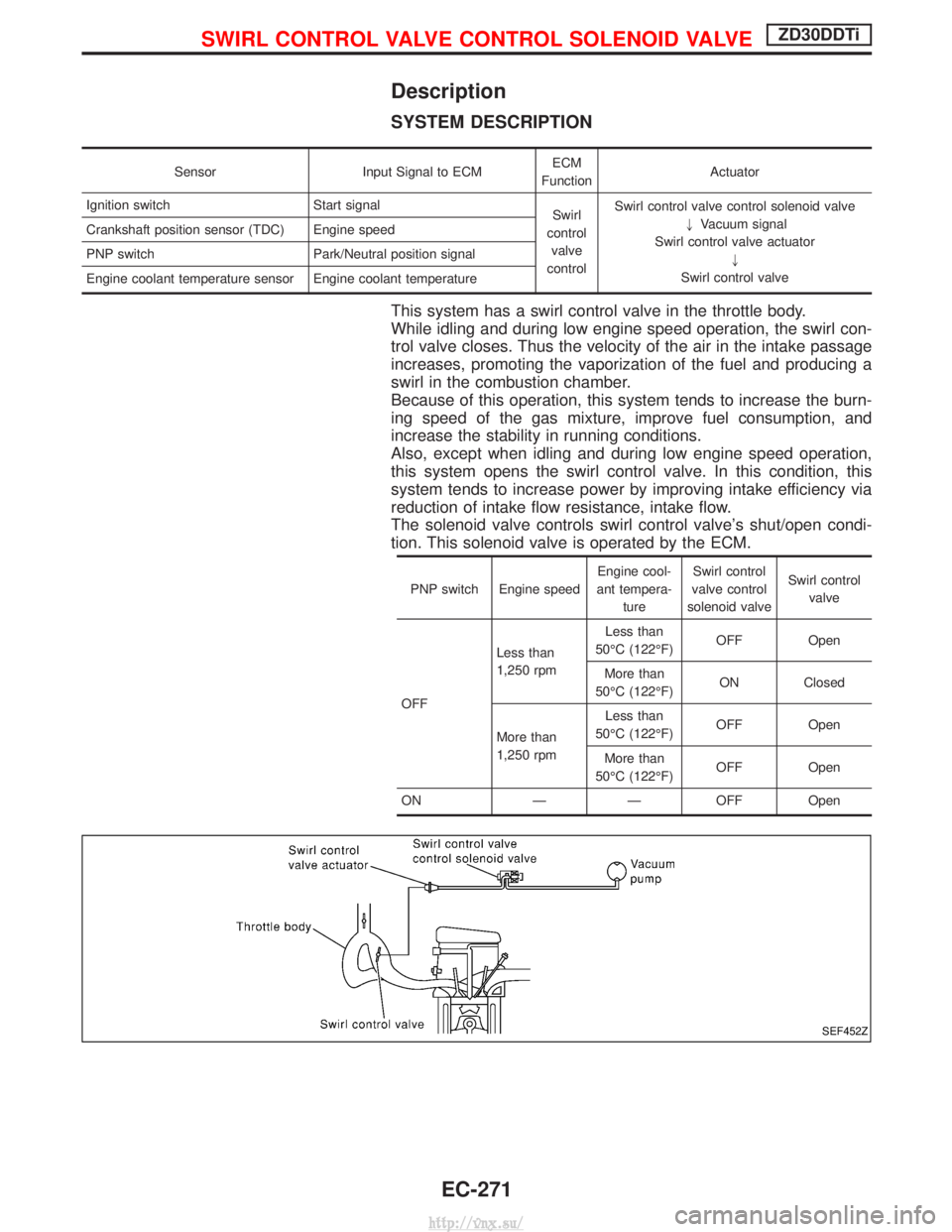

Description

SYSTEM DESCRIPTION

SensorInput Signal to ECM ECM

Function Actuator

Ignition switch Start signal Swirl

control valve

control Swirl control valve control solenoid valve

"Vacuum signal

Swirl control valve actuator "

Swirl control valve

Crankshaft position sensor (TDC) Engine speed

PNP switch Park/Neutral position signal

Engine coolant temperature sensor Engine coolant temperature

This system has a swirl control valve in the throttle body.

While idling and during low engine speed operation, the swirl con-

trol valve closes. Thus the velocity of the air in the intake passage

increases, promoting the vaporization of the fuel and producing a

swirl in the combustion chamber.

Because of this operation, this system tends to increase the burn-

ing speed of the gas mixture, improve fuel consumption, and

increase the stability in running conditions.

Also, except when idling and during low engine speed operation,

this system opens the swirl control valve. In this condition, this

system tends to increase power by improving intake efficiency via

reduction of intake flow resistance, intake flow.

The solenoid valve controls swirl control valve's shut/open condi-

tion. This solenoid valve is operated by the ECM.

PNP switch Engine speed

Engine cool-

ant tempera- ture Swirl control

valve control

solenoid valve Swirl control

valve

OFF Less than

1,250 rpm

Less than

50ÉC (122ÉF) OFF Open

More than

50ÉC (122ÉF) ON Closed

More than

1,250 rpm Less than

50ÉC (122ÉF) OFF Open

More than

50ÉC (122ÉF) OFF Open

ON Ð Ð OFF Open

SEF452Z

SWIRL CONTROL VALVE CONTROL SOLENOID VALVEZD30DDTi

EC-271

http://vnx.su/

Page 547 of 1833

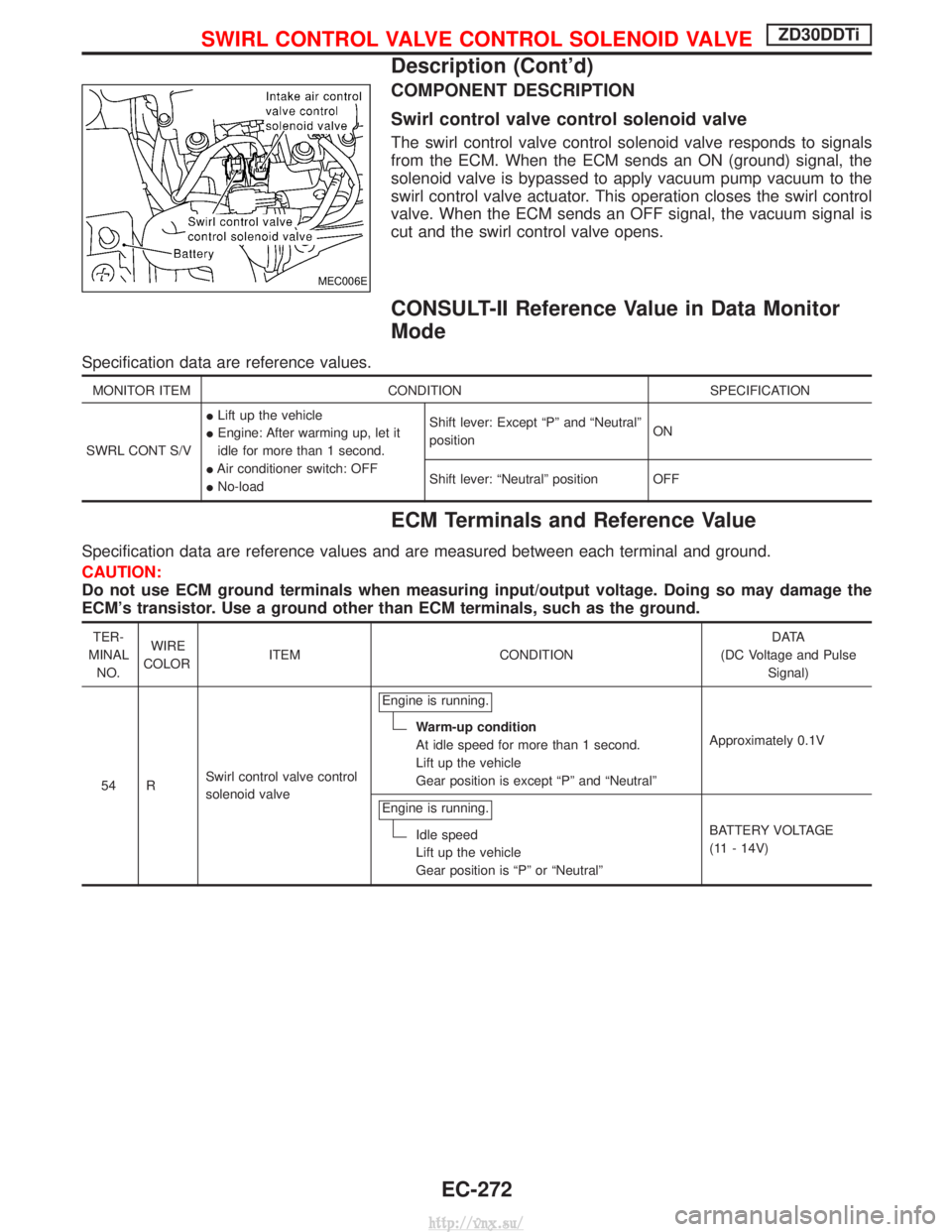

COMPONENT DESCRIPTION

Swirl control valve control solenoid valve

The swirl control valve control solenoid valve responds to signals

from the ECM. When the ECM sends an ON (ground) signal, the

solenoid valve is bypassed to apply vacuum pump vacuum to the

swirl control valve actuator. This operation closes the swirl control

valve. When the ECM sends an OFF signal, the vacuum signal is

cut and the swirl control valve opens.

CONSULT-II Reference Value in Data Monitor

Mode

Specification data are reference values.

MONITOR ITEMCONDITION SPECIFICATION

SWRL CONT S/V I

Lift up the vehicle

I Engine: After warming up, let it

idle for more than 1 second.

I Air conditioner switch: OFF

I No-load Shift lever: Except ªPº and ªNeutralº

position

ON

Shift lever: ªNeutralº position OFF

ECM Terminals and Reference Value

Specification data are reference values and are measured between each terminal and ground.

CAUTION:

Do not use ECM ground terminals when measuring input/output voltage. Doing so may damage the

ECM's transistor. Use a ground other than ECM terminals, such as the ground.

TER-

MINAL NO. WIRE

COLOR ITEM CONDITION D ATA

(DC Voltage and Pulse Signal)

54 R Swirl control valve control

solenoid valve Engine is running.

Warm-up condition

At idle speed for more than 1 second.

Lift up the vehicle

Gear position is except ªPº and ªNeutralº

Approximately 0.1V

Engine is running.

Idle speed

Lift up the vehicle

Gear position is ªPº or ªNeutralº BATTERY VOLTAGE

(11 - 14V)

MEC006E

SWIRL CONTROL VALVE CONTROL SOLENOID VALVEZD30DDTi

Description (Cont'd)

EC-272

http://vnx.su/

Page 548 of 1833

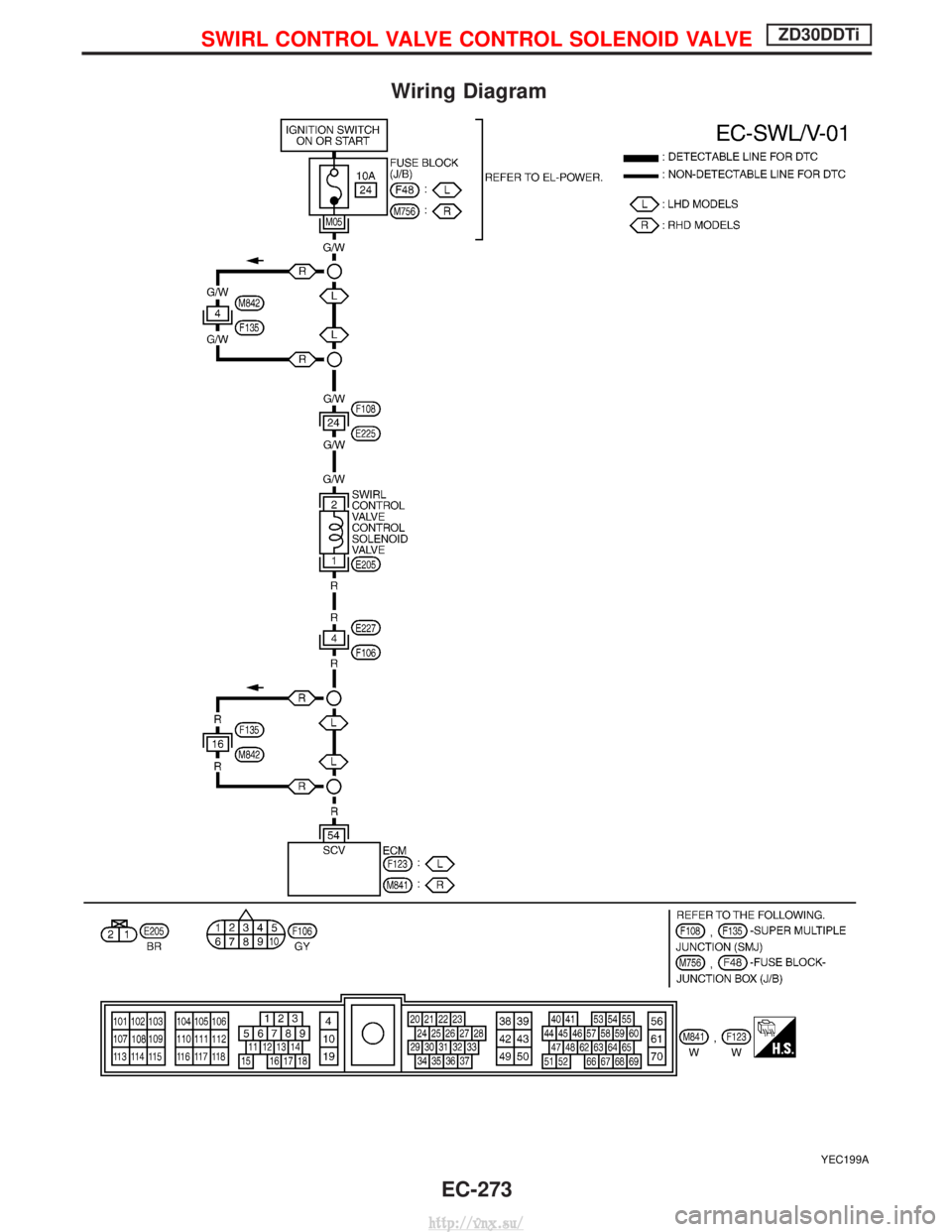

Wiring Diagram

YEC199A

SWIRL CONTROL VALVE CONTROL SOLENOID VALVEZD30DDTi

EC-273

http://vnx.su/

Page 549 of 1833

Diagnostic Procedure

1 INSPECTION START

Do you have CONSULT-II?YesorNo

Ye s EGO TO 2.

No EGO TO 3.

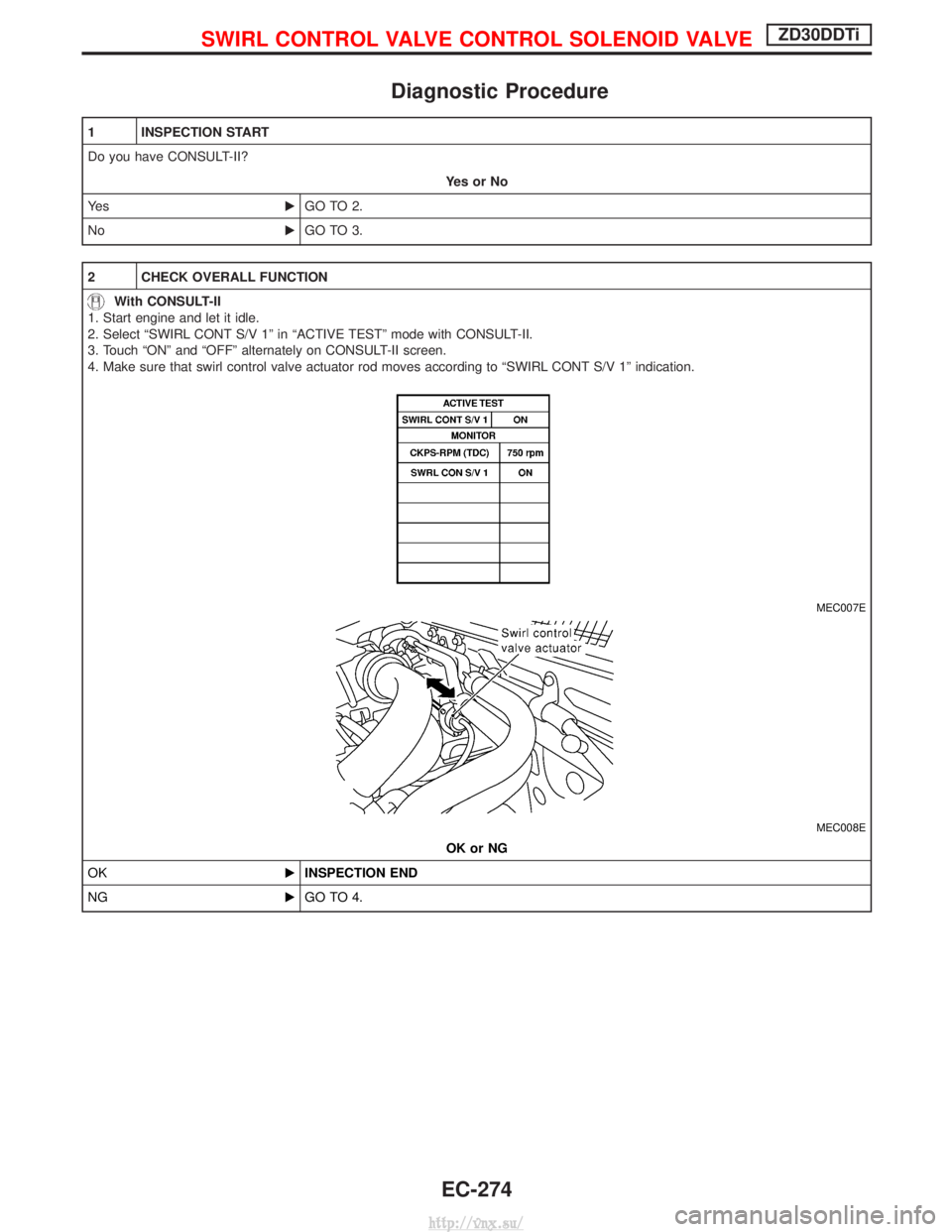

2 CHECK OVERALL FUNCTION

With CONSULT-II

1. Start engine and let it idle.

2. Select ªSWIRL CONT S/V 1º in ªACTIVE TESTº mode with CONSULT-II.

3. Touch ªONº and ªOFFº alternately on CONSULT-II screen.

4. Make sure that swirl control valve actuator rod moves according to ªSWIRL CONT S/V 1º indication.

MEC007E

MEC008E

OK or NG

OK EINSPECTION END

NG EGO TO 4.

SWIRL CONTROL VALVE CONTROL SOLENOID VALVEZD30DDTi

EC-274

http://vnx.su/

Page 550 of 1833

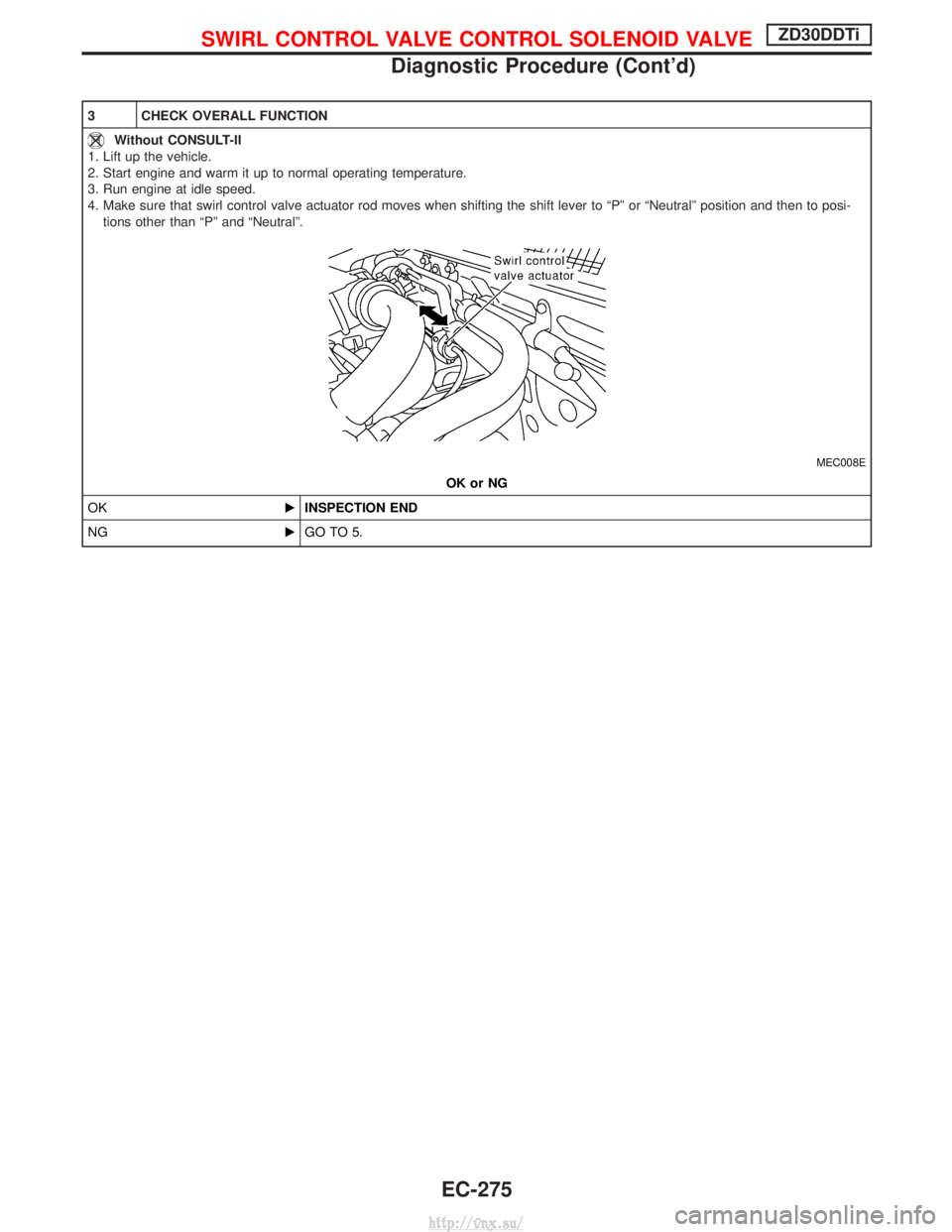

3 CHECK OVERALL FUNCTION

Without CONSULT-II

1. Lift up the vehicle.

2. Start engine and warm it up to normal operating temperature.

3. Run engine at idle speed.

4. Make sure that swirl control valve actuator rod moves when shifting the shift lever to ªPº or ªNeutralº position and then to posi- tions other than ªPº and ªNeutralº.

MEC008E

OK or NG

OK EINSPECTION END

NG EGO TO 5.

SWIRL CONTROL VALVE CONTROL SOLENOID VALVEZD30DDTi

Diagnostic Procedure (Cont'd)

EC-275

http://vnx.su/