Ext NISSAN TIIDA 2007 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2007, Model line: TIIDA, Model: NISSAN TIIDA 2007Pages: 5883, PDF Size: 78.95 MB

Page 4564 of 5883

RF-30

< ON-VEHICLE REPAIR >

SUNROOF SYSTEM

ON-VEHICLE REPAIR

SUNROOF SYSTEM

InspectionINFOID:0000000001724431

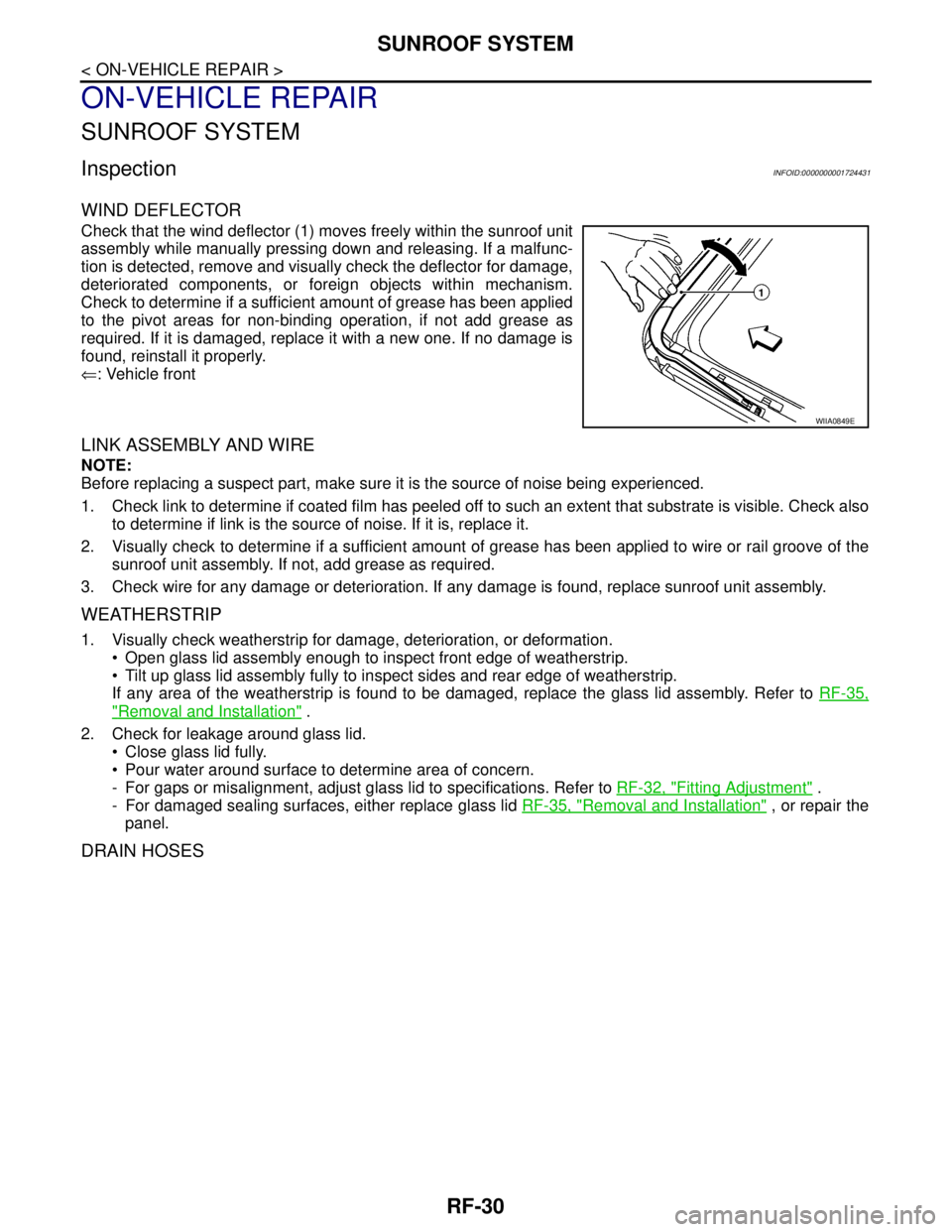

WIND DEFLECTOR

Check that the wind deflector (1) moves freely within the sunroof unit

assembly while manually pressing down and releasing. If a malfunc-

tion is detected, remove and visually check the deflector for damage,

deteriorated components, or foreign objects within mechanism.

Check to determine if a sufficient amount of grease has been applied

to the pivot areas for non-binding operation, if not add grease as

required. If it is damaged, replace it with a new one. If no damage is

found, reinstall it properly.

⇐: Vehicle front

LINK ASSEMBLY AND WIRE

NOTE:

Before replacing a suspect part, make sure it is the source of noise being experienced.

1. Check link to determine if coated film has peeled off to such an extent that substrate is visible. Check also

to determine if link is the source of noise. If it is, replace it.

2. Visually check to determine if a sufficient amount of grease has been applied to wire or rail groove of the

sunroof unit assembly. If not, add grease as required.

3. Check wire for any damage or deterioration. If any damage is found, replace sunroof unit assembly.

WEATHERSTRIP

1. Visually check weatherstrip for damage, deterioration, or deformation.

Open glass lid assembly enough to inspect front edge of weatherstrip.

Tilt up glass lid assembly fully to inspect sides and rear edge of weatherstrip.

If any area of the weatherstrip is found to be damaged, replace the glass lid assembly. Refer to RF-35,

"Removal and Installation" .

2. Check for leakage around glass lid.

Close glass lid fully.

Pour water around surface to determine area of concern.

- For gaps or misalignment, adjust glass lid to specifications. Refer to RF-32, "

Fitting Adjustment" .

- For damaged sealing surfaces, either replace glass lid RF-35, "

Removal and Installation" , or repair the

panel.

DRAIN HOSES

WIIA0849E

Page 4570 of 5883

RF-36

< ON-VEHICLE REPAIR >

SUNROOF SYSTEM

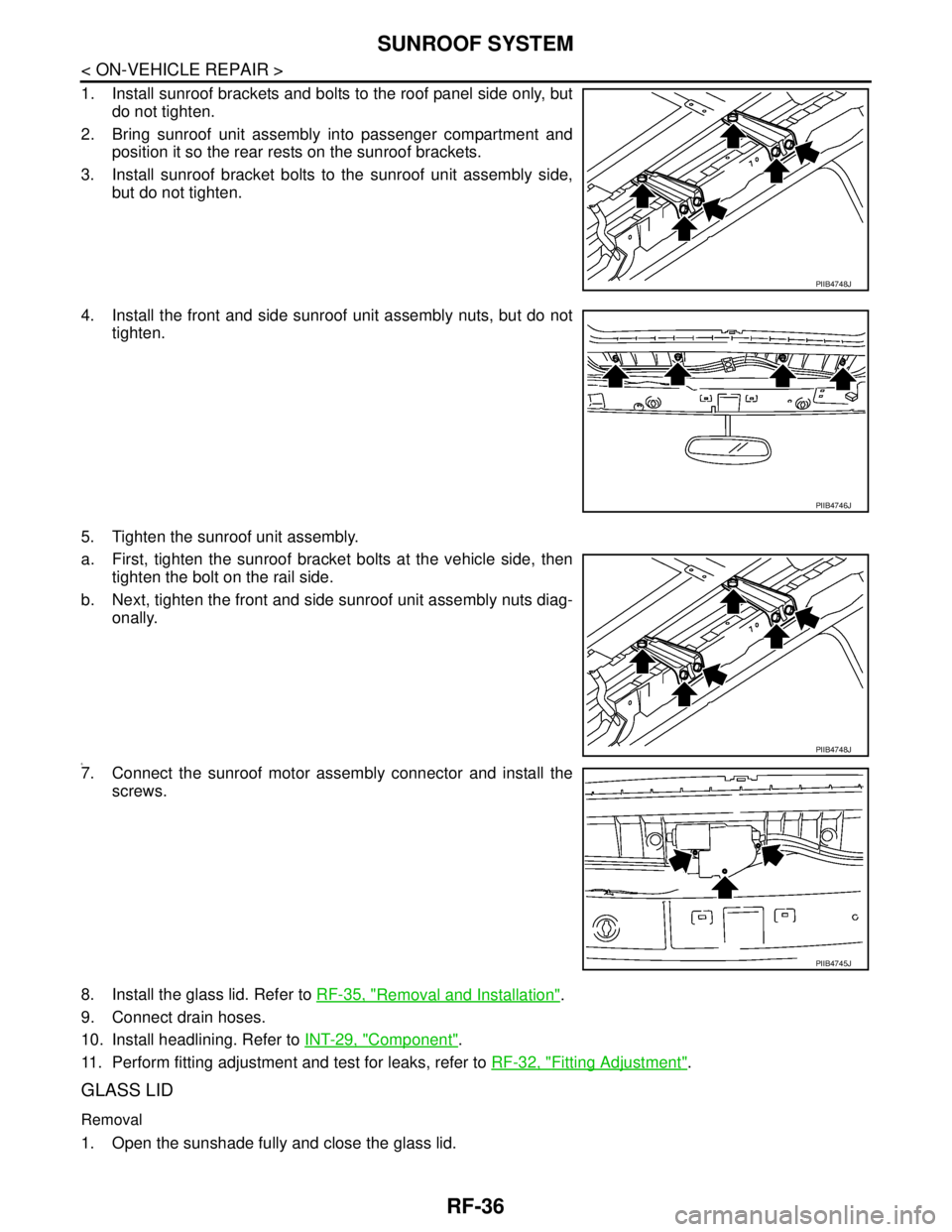

1. Install sunroof brackets and bolts to the roof panel side only, but

do not tighten.

2. Bring sunroof unit assembly into passenger compartment and

position it so the rear rests on the sunroof brackets.

3. Install sunroof bracket bolts to the sunroof unit assembly side,

but do not tighten.

4. Install the front and side sunroof unit assembly nuts, but do not

tighten.

5. Tighten the sunroof unit assembly.

a. First, tighten the sunroof bracket bolts at the vehicle side, then

tighten the bolt on the rail side.

b. Next, tighten the front and side sunroof unit assembly nuts diag-

onally.

6.7. Connect the sunroof motor assembly connector and install the

screws.

8. Install the glass lid. Refer to RF-35, "

Removal and Installation".

9. Connect drain hoses.

10. Install headlining. Refer to INT-29, "

Component".

11. Perform fitting adjustment and test for leaks, refer to RF-32, "

Fitting Adjustment".

GLASS LID

Removal

1. Open the sunshade fully and close the glass lid.

PIIB4748J

PIIB4746J

PIIB4748J

PIIB4745J

Page 4587 of 5883

INSPECTION

SB-3

< BASIC INSPECTION >

C

D

E

F

G

I

J

K

L

MA

B

SB

N

O

P

BASIC INSPECTION

INSPECTION

Seat Belt InspectionINFOID:0000000001366781

AFTER A COLLISION

WARNING:

Inspect all seat belt assemblies including retractors and attaching hardware after any collision.

NISSAN recommends that all seat belt assemblies in use during a collision be replaced unless the col-

lision was minor and the belts show no damage and continue to operate properly. Failure to do so

could result in serious personal injury in an accident. Seat belt assemblies not in use during a colli-

sion should also be replaced if either damage or improper operation is noted. Seat belt pre-tensioner

should be replaced even if the seat belts are not in use during a frontal collision in which the air bags

are deployed.

Replace any seat belt assembly (including anchor bolts) if:

The seat belt was in use at the time of a collision (except for minor collisions and the belts, retractors and

buckles show no damage and continue to operate properly).

The seat belt was damaged in an accident. (i.e. torn webbing, bent retractor or guide, etc.)

The seat belt attaching point was damaged in an accident. Inspect the seat belt attaching area for damage

or distortion and repair as necessary before installing a new seat belt assembly.

Anchor bolts are deformed or worn out.

The seat belt pre-tensioner should be replaced even if the seat belts are not in use during a frontal collision

in which the air bags are deployed.

PRELIMINARY CHECKS

1. Check the seat belt warning lamp/chime for proper operation as follows:

a. Switch ignition ON. The seat belt warning lamp should illuminate. Also, the seat belt warning chime should

sound for about seven seconds.

b. Fasten driver's seat belt. The seat belt warning lamp should go out and the chime (if sounding) should

stop.

2. If the air bag warning lamp is blinking, conduct self-diagnosis using CONSULT-III, and air bag warning

lamp. Refer to SRC-11, "

SRS Operation Check".

3. Check that the seat belt retractor, seat belt anchor and buckle bolts are securely attached.

4. Check the shoulder seat belt guide and shoulder belt height adjuster for front seats. Make sure guide

swivels freely and that webbing lays flat and does not bind in guide. Make sure height adjuster operates

properly and holds securely.

5. Check retractor operation:

a. Fully extend the seat belt webbing and check for twists, tears or other damage.

b. Allow the seat belt to retract. Make sure that webbing returns smoothly and completely into the retractor. If

the seat belt does not return smoothly, wipe the inside of the loops with a clean paper cloth. Dirt build-up

in the loops of the upper anchors can cause the seat belts to retract slowly.

c. Fasten the seat belt. Check the seat belt returns smoothly and completely to the retractor. If the webbing

does not return smoothly, the cause may be an accumulation of dust or dirt. Use the “SEAT BELT TAPE

SET” and perform the following steps.

Inspect the front seat belt though-anchor

1. Pull the seat belt out to a length of 500 mm (19.69 in) or more.

2. Use a clip or other device to attach the seat belt at the center pillar webbing opening.

3. Pass a thin wire though the D-ring anchor webbing opening. Hold both ends of the wire and pull taut

while moving it up and down several times along the webbing opening surface to remove matter stuck

there.

4. Any dirt that cannot be removed with the wire can be removed by cleaning the opening with a clean

cloth.

5. Apply tape at the point where the webbing contacts the though-anchor webbing opening.

NOTE:

Apply the tape so that there is no looseness or wrinkling.

6. Remove the clip attaching the seat belt and check that the webbing returns smoothly.

Page 4588 of 5883

SB-4

< BASIC INSPECTION >

INSPECTION

6. Repeat steps above as necessary to check the other seat belts.

SEAT BELT RETRACTOR ON-VEHICLE CHECK

Emergency Locking Retractors (ELR) and Automatic Locking Retractors (ALR)

NOTE:

All seat belt retractors are of the Emergency Locking Retractors (ELR) type. In an emergency (sudden stop)

the retractor will lock and prevent the webbing from extending any further. All 3-point type seat belt retractors

except the driver's seat belt also have an Automatic Locking Retractors (ALR) mode. The ALR mode (also

called child restraint mode) is used when installing child seats. The ALR mode is activated when the seat belt

is fully extended. When the webbing is then retracted partially, the ALR mode automatically locks the seat belt

in a specific position so the webbing cannot be extended any further. To cancel the ALR mode, allow the seat

belt to fully wind back into the retractor.

Check the seat belt retractors using the following test(s) to determine if a retractor assembly is operating prop-

erly.

ELR Function Stationary Check

Grasp the shoulder webbing and pull it forward quickly. The retractor should lock and prevent the belt from

extending further.

ALR Function Stationary Check

1. Pull out entire length of seat belt from retractor until a click is heard.

2. Retract the webbing partially. A clicking noise should be heard as the webbing retracts, indicating that the

retractor is in the Automatic Locking Retractors (ALR) mode.

3. Grasp the seat belt and try to pull out the retractor. The webbing must lock and not extend any further. If

NG, replace the retractor assembly.

4. Allow the entire length of the webbing to retract to cancel the automatic locking mode.

ELR Function Moving Check

WARNING:

Perform the following test in a safe, open area clear of other vehicles and obstructions (for example, a

large, empty parking lot). Road surface must be paved and dry. DO NOT perform the following test on

wet or gravel roads or on public streets and highways. This could result in an accident and serious

personal injury. The driver and passenger must be prepared to brace themselves in the event the

retractor does not lock.

1. Fasten driver's seat belt. Buckle a passenger into the seat for the belt that is to be tested.

2. Proceed to the designated safe area.

3. Drive the vehicle at approximately 16 km/h (10 MPH). Notify any passengers of a pending sudden stop

and the driver and passenger must be prepared to brace themselves in the event the retractor does not

lock, apply brakes firmly and make a very hard stop.

During the stop, seat belts should lock and not be extended. If the seat belt retractor assembly does not lock,

perform the retractor off-vehicle check.

SEAT BELT RETRACTOR OFF-VEHICLE CHECK

1. Remove the seat belt retractor. Refer to SB-6, "Removal and Installation of Front Seat Belt".

Page 4626 of 5883

SEC-1

BODY EXTERIOR, DOORS, ROOF & VEHICLE SECURITY

C

D

E

F

G

H

I

J

L

M

SECTION SEC

A

B

SEC

N

O

P

CONTENTS

SECURITY CONTROL SYSTEM

WITH INTELLIGENT KEY SYSTEM

BASIC INSPECTION ....................................

4

DIAGNOSIS AND REPAIR WORKFLOW ..........4

Work Flow .................................................................4

INSPECTION AND ADJUSTMENT .....................7

ADDITIONAL SERVICE WHEN REPLACING

CONTROL UNIT ..........................................................

7

ADDITIONAL SERVICE WHEN REPLACING

CONTROL UNIT : Special Repair Requirement .......

7

ECM RE-COMMUNICATING FUNCTION ...................7

ECM RE-COMMUNICATING FUNCTION : De-

scription .....................................................................

7

ECM RE-COMMUNICATING FUNCTION : Spe-

cial Repair Requirement ............................................

7

FUNCTION DIAGNOSIS ...............................8

INTELLIGENT KEY SYSTEM/ENGINE

START FUNCTION .............................................

8

System Diagram ........................................................8

System Description ...................................................8

Component Parts Location ......................................10

Component Description ...........................................10

NATS (NISSAN ANTI-THEFT SYSTEM) ...........12

System Diagram ......................................................12

System Description .................................................12

Component Parts Location ......................................14

Component Description ..........................................14

DIAGNOSIS SYSTEM (BCM) ............................15

COMMON ITEM .........................................................15

COMMON ITEM : CONSULT-III Function (BCM -

COMMON ITEM) .....................................................

15

IMMU ..........................................................................15

IMMU : CONSULT-III Function (BCM - IMMU) .......15

THEFT ALM ...............................................................16

THEFT ALM : CONSULT-III Function (BCM -

THEFT ALM) ...........................................................

16

DIAGNOSIS SYSTEM (INTELLIGENT KEY

UNIT) .................................................................

18

CONSULT-III Function (INTELLIGENT KEY) ..........18

COMPONENT DIAGNOSIS .........................21

U1000 CAN COMM CIRCUIT ...........................21

Description ...............................................................21

DTC Logic ................................................................21

Diagnosis Procedure ...............................................21

U1010 CONTROL UNIT (CAN) .........................22

Description ...............................................................22

DTC Logic ................................................................22

Diagnosis Procedure ...............................................22

Special Repair Requirement ....................................22

B2013 ID DISCORD I-KEY-STRG ....................23

Description ...............................................................23

DTC Logic ................................................................23

Diagnosis Procedure ...............................................23

B2190, P1614 NATS ANTENNA AMP. ............26

Description ...............................................................26

DTC Logic ................................................................26

Diagnosis Procedure ...............................................26

B2191, P1615 DIFFERENCE OF KEY .............29

Description ...............................................................29

DTC Logic ................................................................29

Diagnosis Procedure ...............................................29

B2192, P1611 ID DISCORD, IMMU-ECM .........30

Description ...............................................................30

DTC Logic ................................................................30

Diagnosis Procedure ...............................................30

B2193, P1612 CHAIN OF ECM-IMMU ..............32

Page 4640 of 5883

![NISSAN TIIDA 2007 Service Repair Manual DIAGNOSIS SYSTEM (BCM)

SEC-15

< FUNCTION DIAGNOSIS >[WITH INTELLIGENT KEY SYSTEM]

C

D

E

F

G

H

I

J

L

MA

B

SEC

N

O

P

DIAGNOSIS SYSTEM (BCM)

COMMON ITEM

COMMON ITEM : CONSULT-III Function (BCM - COMMON I NISSAN TIIDA 2007 Service Repair Manual DIAGNOSIS SYSTEM (BCM)

SEC-15

< FUNCTION DIAGNOSIS >[WITH INTELLIGENT KEY SYSTEM]

C

D

E

F

G

H

I

J

L

MA

B

SEC

N

O

P

DIAGNOSIS SYSTEM (BCM)

COMMON ITEM

COMMON ITEM : CONSULT-III Function (BCM - COMMON I](/img/5/57395/w960_57395-4639.png)

DIAGNOSIS SYSTEM (BCM)

SEC-15

< FUNCTION DIAGNOSIS >[WITH INTELLIGENT KEY SYSTEM]

C

D

E

F

G

H

I

J

L

MA

B

SEC

N

O

P

DIAGNOSIS SYSTEM (BCM)

COMMON ITEM

COMMON ITEM : CONSULT-III Function (BCM - COMMON ITEM)INFOID:0000000001404046

APPLICATION ITEM

CONSULT-III performs the following functions via CAN communication with BCM.

SYSTEM APPLICATION

BCM can perform the following functions for each system.

NOTE:

It can perform the diagnosis modes except the following for all sub system selection items.

IMMU

IMMU : CONSULT-III Function (BCM - IMMU)INFOID:0000000001404047

APPLICATION ITEM

CONSULT-III performs the following functions via CAN communication with BCM.

Diagnosis mode Function Description

WORK SUPPORT Changes the setting for each system function.

SELF-DIAG RESULTS Displays the diagnosis results judged by BCM. Refer to XX-XX, "*****"

.

CAN DIAG SUPPORT MNTR Monitors the reception status of CAN communication viewed from BCM.

DATA MONITOR The BCM input/output signals are displayed.

ACTIVE TEST The signals used to activate each device are forcibly supplied from BCM.

ECU IDENTIFICATION The BCM part number is displayed.

CONFIGURATION Enables to read and save the vehicle specification.

Enables to write the vehicle specification when replacing BCM.

System Sub system selection itemDiagnosis mode

WORK SUPPORT DATA MONITOR ACTIVE TEST

—BCM×

Door lock DOOR LOCK×××

Rear window defogger REAR DEFOGGER××

Warning chime BUZZER××

Interior room lamp timer INT LAMP×××

Remote keyless entry system MULTI REMOTE ENT×××

Exterior lamp HEAD LAMP×××

Wiper and washer WIPER×××

Turn signal and hazard warning lamps FLASHER××

Air conditioner AIR CONDITONER×

Intelligent Key system INTELLIGENT KEY×

Combination switch COMB SW×

Immobilizer IMMU××

Interior room lamp battery saver BATTERY SAVER×××

Trunk open TRUNK×

Vehicle security system THEFT ALM×××

Signal buffer system SIGNAL BUFFER××

PTC heater system PTC HEATER××

Page 4712 of 5883

![NISSAN TIIDA 2007 Service Repair Manual DIAGNOSIS SYSTEM (BCM)

SEC-87

< FUNCTION DIAGNOSIS >[WITHOUT INTELLIGENT KEY SYSTEM]

C

D

E

F

G

H

I

J

L

MA

B

SEC

N

O

P

DIAGNOSIS SYSTEM (BCM)

COMMON ITEM

COMMON ITEM : CONSULT-III Function (BCM - COMMO NISSAN TIIDA 2007 Service Repair Manual DIAGNOSIS SYSTEM (BCM)

SEC-87

< FUNCTION DIAGNOSIS >[WITHOUT INTELLIGENT KEY SYSTEM]

C

D

E

F

G

H

I

J

L

MA

B

SEC

N

O

P

DIAGNOSIS SYSTEM (BCM)

COMMON ITEM

COMMON ITEM : CONSULT-III Function (BCM - COMMO](/img/5/57395/w960_57395-4711.png)

DIAGNOSIS SYSTEM (BCM)

SEC-87

< FUNCTION DIAGNOSIS >[WITHOUT INTELLIGENT KEY SYSTEM]

C

D

E

F

G

H

I

J

L

MA

B

SEC

N

O

P

DIAGNOSIS SYSTEM (BCM)

COMMON ITEM

COMMON ITEM : CONSULT-III Function (BCM - COMMON ITEM)INFOID:0000000001404165

APPLICATION ITEM

CONSULT-III performs the following functions via CAN communication with BCM.

SYSTEM APPLICATION

BCM can perform the following functions for each system.

NOTE:

It can perform the diagnosis modes except the following for all sub system selection items.

IMMU

IMMU : CONSULT-III Function (BCM - IMMU)INFOID:0000000001404166

APPLICATION ITEM

CONSULT-III performs the following functions via CAN communication with BCM.

Diagnosis mode Function Description

WORK SUPPORT Changes the setting for each system function.

SELF-DIAG RESULTS Displays the diagnosis results judged by BCM. Refer to XX-XX, "*****"

.

CAN DIAG SUPPORT MNTR Monitors the reception status of CAN communication viewed from BCM.

DATA MONITOR The BCM input/output signals are displayed.

ACTIVE TEST The signals used to activate each device are forcibly supplied from BCM.

ECU IDENTIFICATION The BCM part number is displayed.

CONFIGURATION Enables to read and save the vehicle specification.

Enables to write the vehicle specification when replacing BCM.

System Sub system selection itemDiagnosis mode

WORK SUPPORT DATA MONITOR ACTIVE TEST

—BCM×

Door lock DOOR LOCK×××

Rear window defogger REAR DEFOGGER××

Warning chime BUZZER××

Interior room lamp timer INT LAMP×××

Remote keyless entry system MULTI REMOTE ENT×××

Exterior lamp HEAD LAMP×××

Wiper and washer WIPER×××

Turn signal and hazard warning lamps FLASHER××

Air conditioner AIR CONDITONER×

Combination switch COMB SW×

Immobilizer IMMU××

Interior room lamp battery saver BATTERY SAVER×××

Trunk open TRUNK×

Vehicle security system THEFT ALM×××

Signal buffer system SIGNAL BUFFER××

PTC heater system PTC HEATER××

Page 4778 of 5883

SRS AIR BAG SYSTEM

SRC-9

< FUNCTION DIAGNOSIS >

C

D

E

F

G

I

J

K

L

MA

B

SRC

N

O

P

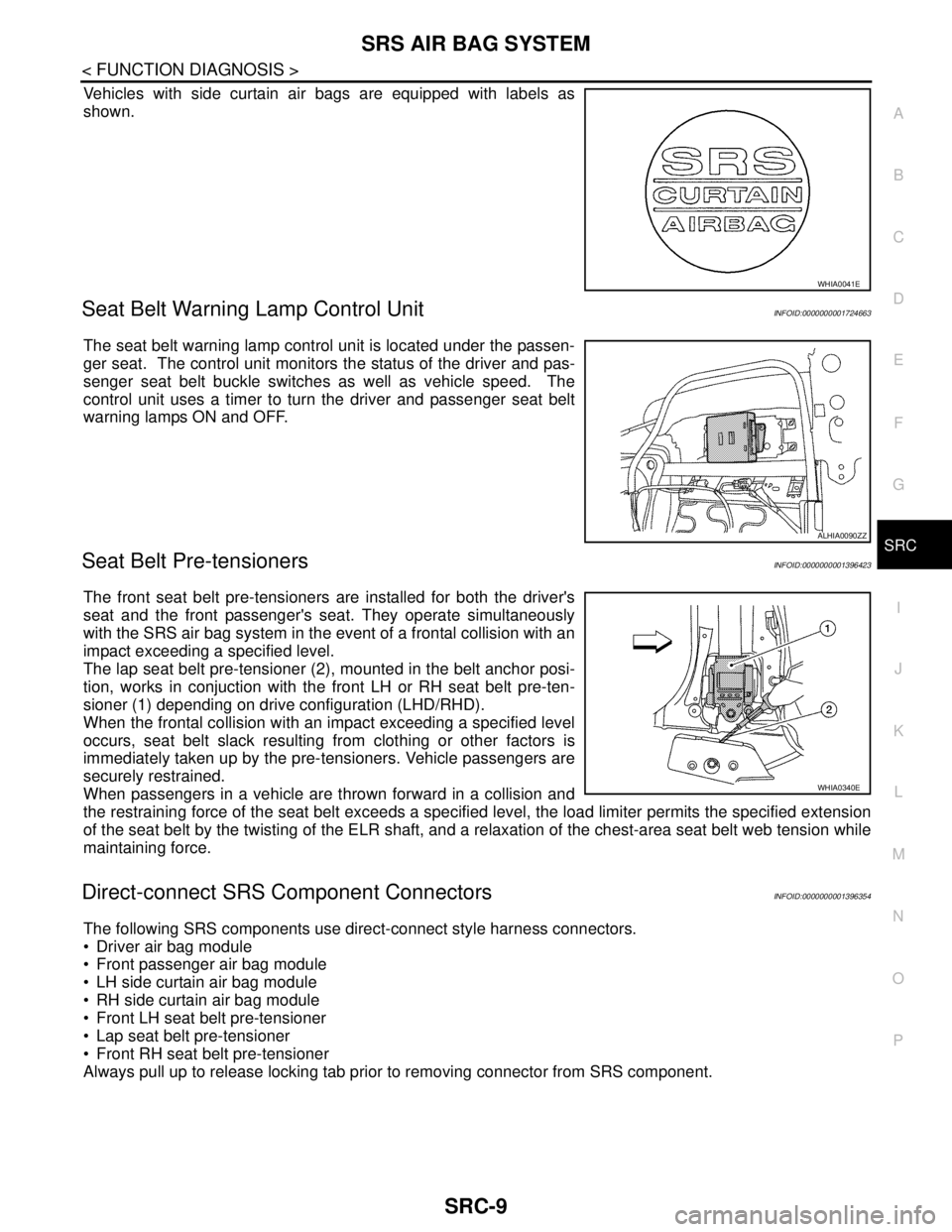

Vehicles with side curtain air bags are equipped with labels as

shown.

Seat Belt Warning Lamp Control UnitINFOID:0000000001724663

The seat belt warning lamp control unit is located under the passen-

ger seat. The control unit monitors the status of the driver and pas-

senger seat belt buckle switches as well as vehicle speed. The

control unit uses a timer to turn the driver and passenger seat belt

warning lamps ON and OFF.

Seat Belt Pre-tensionersINFOID:0000000001396423

The front seat belt pre-tensioners are installed for both the driver's

seat and the front passenger's seat. They operate simultaneously

with the SRS air bag system in the event of a frontal collision with an

impact exceeding a specified level.

The lap seat belt pre-tensioner (2), mounted in the belt anchor posi-

tion, works in conjuction with the front LH or RH seat belt pre-ten-

sioner (1) depending on drive configuration (LHD/RHD).

When the frontal collision with an impact exceeding a specified level

occurs, seat belt slack resulting from clothing or other factors is

immediately taken up by the pre-tensioners. Vehicle passengers are

securely restrained.

When passengers in a vehicle are thrown forward in a collision and

the restraining force of the seat belt exceeds a specified level, the load limiter permits the specified extension

of the seat belt by the twisting of the ELR shaft, and a relaxation of the chest-area seat belt web tension while

maintaining force.

Direct-connect SRS Component ConnectorsINFOID:0000000001396354

The following SRS components use direct-connect style harness connectors.

Driver air bag module

Front passenger air bag module

LH side curtain air bag module

RH side curtain air bag module

Front LH seat belt pre-tensioner

Lap seat belt pre-tensioner

Front RH seat belt pre-tensioner

Always pull up to release locking tab prior to removing connector from SRS component.

WHIA0041E

ALHIA0090ZZ

WHIA0340E

Page 4845 of 5883

SRC-76

< ECU DIAGNOSIS >

DIAGNOSIS SENSOR UNIT

Trouble Diagnosis with CONSULT-III

INFOID:0000000001396411

DIAGNOSTIC CODE CHART

NOTE:

Follow the procedures in numerical order when repairing malfunctioning parts. Confirm whether malfunction is

eliminated using air bag warning lamp or CONSULT-III each time repair is finished. If malfunction is still

observed, proceed to the next step. When malfunction is eliminated, further repair work is not required.

ALHIA0081GB

Page 4847 of 5883

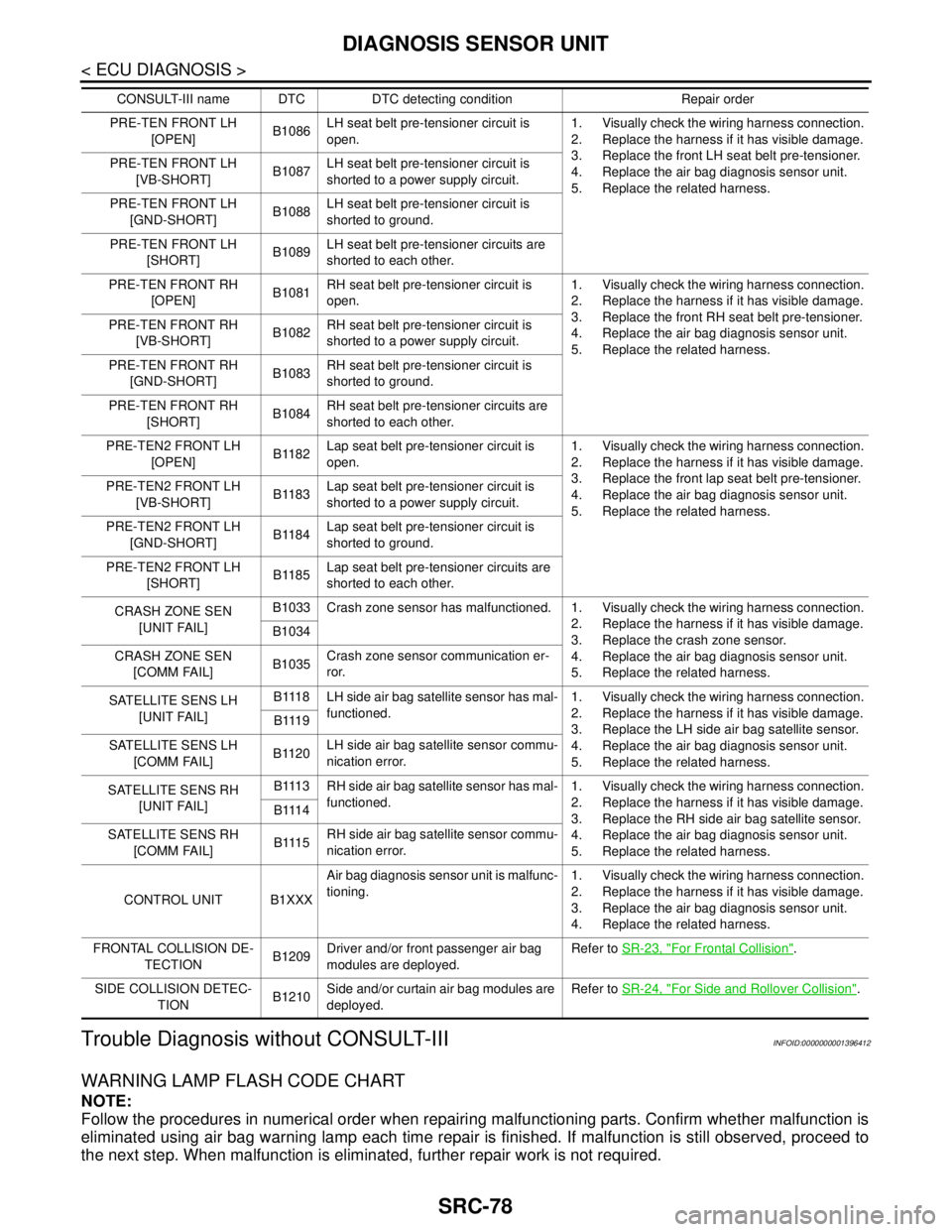

SRC-78

< ECU DIAGNOSIS >

DIAGNOSIS SENSOR UNIT

Trouble Diagnosis without CONSULT-III

INFOID:0000000001396412

WARNING LAMP FLASH CODE CHART

NOTE:

Follow the procedures in numerical order when repairing malfunctioning parts. Confirm whether malfunction is

eliminated using air bag warning lamp each time repair is finished. If malfunction is still observed, proceed to

the next step. When malfunction is eliminated, further repair work is not required.

PRE-TEN FRONT LH

[OPEN]B1086LH seat belt pre-tensioner circuit is

open.1. Visually check the wiring harness connection.

2. Replace the harness if it has visible damage.

3. Replace the front LH seat belt pre-tensioner.

4. Replace the air bag diagnosis sensor unit.

5. Replace the related harness. PRE-TEN FRONT LH

[VB-SHORT]B1087LH seat belt pre-tensioner circuit is

shorted to a power supply circuit.

PRE-TEN FRONT LH

[GND-SHORT]B1088LH seat belt pre-tensioner circuit is

shorted to ground.

PRE-TEN FRONT LH

[SHORT]B1089LH seat belt pre-tensioner circuits are

shorted to each other.

PRE-TEN FRONT RH

[OPEN]B1081RH seat belt pre-tensioner circuit is

open.1. Visually check the wiring harness connection.

2. Replace the harness if it has visible damage.

3. Replace the front RH seat belt pre-tensioner.

4. Replace the air bag diagnosis sensor unit.

5. Replace the related harness. PRE-TEN FRONT RH

[VB-SHORT]B1082RH seat belt pre-tensioner circuit is

shorted to a power supply circuit.

PRE-TEN FRONT RH

[GND-SHORT]B1083RH seat belt pre-tensioner circuit is

shorted to ground.

PRE-TEN FRONT RH

[SHORT]B1084RH seat belt pre-tensioner circuits are

shorted to each other.

PRE-TEN2 FRONT LH

[OPEN]B1182Lap seat belt pre-tensioner circuit is

open.1. Visually check the wiring harness connection.

2. Replace the harness if it has visible damage.

3. Replace the front lap seat belt pre-tensioner.

4. Replace the air bag diagnosis sensor unit.

5. Replace the related harness. PRE-TEN2 FRONT LH

[VB-SHORT]B1183Lap seat belt pre-tensioner circuit is

shorted to a power supply circuit.

PRE-TEN2 FRONT LH

[GND-SHORT]B1184Lap seat belt pre-tensioner circuit is

shorted to ground.

PRE-TEN2 FRONT LH

[SHORT]B1185Lap seat belt pre-tensioner circuits are

shorted to each other.

CRASH ZONE SEN

[UNIT FAIL]B1033 Crash zone sensor has malfunctioned. 1. Visually check the wiring harness connection.

2. Replace the harness if it has visible damage.

3. Replace the crash zone sensor.

4. Replace the air bag diagnosis sensor unit.

5. Replace the related harness. B1034

CRASH ZONE SEN

[COMM FAIL]B1035Crash zone sensor communication er-

ror.

SATELLITE SENS LH

[UNIT FAIL]B1118 LH side air bag satellite sensor has mal-

functioned.1. Visually check the wiring harness connection.

2. Replace the harness if it has visible damage.

3. Replace the LH side air bag satellite sensor.

4. Replace the air bag diagnosis sensor unit.

5. Replace the related harness. B 111 9

SATELLITE SENS LH

[COMM FAIL]B1120LH side air bag satellite sensor commu-

nication error.

SATELLITE SENS RH

[UNIT FAIL]B1113 RH side air bag satellite sensor has mal-

functioned.1. Visually check the wiring harness connection.

2. Replace the harness if it has visible damage.

3. Replace the RH side air bag satellite sensor.

4. Replace the air bag diagnosis sensor unit.

5. Replace the related harness. B 111 4

SATELLITE SENS RH

[COMM FAIL]B 111 5RH side air bag satellite sensor commu-

nication error.

CONTROL UNIT B1XXXAir bag diagnosis sensor unit is malfunc-

tioning.1. Visually check the wiring harness connection.

2. Replace the harness if it has visible damage.

3. Replace the air bag diagnosis sensor unit.

4. Replace the related harness.

FRONTAL COLLISION DE-

TECTIONB1209Driver and/or front passenger air bag

modules are deployed.Refer to SR-23, "

For Frontal Collision".

SIDE COLLISION DETEC-

TIONB1210Side and/or curtain air bag modules are

deployed.Refer to SR-24, "

For Side and Rollover Collision". CONSULT-III name DTC DTC detecting condition Repair order