Ext NISSAN TIIDA 2007 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2007, Model line: TIIDA, Model: NISSAN TIIDA 2007Pages: 5883, PDF Size: 78.95 MB

Page 4214 of 5883

![NISSAN TIIDA 2007 Service Repair Manual ENGINE OIL

LU-7

< ON-VEHICLE MAINTENANCE >[HR16DE]

C

D

E

F

G

H

I

J

K

L

MA

LU

N

P O

2. Disconnect harness connector at oil pressure switch (2), and

remove oil pressure switch (2) from the cylinder bloc NISSAN TIIDA 2007 Service Repair Manual ENGINE OIL

LU-7

< ON-VEHICLE MAINTENANCE >[HR16DE]

C

D

E

F

G

H

I

J

K

L

MA

LU

N

P O

2. Disconnect harness connector at oil pressure switch (2), and

remove oil pressure switch (2) from the cylinder bloc](/img/5/57395/w960_57395-4213.png)

ENGINE OIL

LU-7

< ON-VEHICLE MAINTENANCE >[HR16DE]

C

D

E

F

G

H

I

J

K

L

MA

LU

N

P O

2. Disconnect harness connector at oil pressure switch (2), and

remove oil pressure switch (2) from the cylinder block (1) using

a deep socket (commercial service tool).

CAUTION:

Never drop or shock oil pressure switch.

3. Install oil pressure gauge and hose (SST).

4. Start engine and warm it up to normal operating temperature.

5. Check oil pressure with engine running under no-load.

NOTE:

When engine oil temperature is low, engine oil pressure becomes high.

If difference is extreme, check oil passage and oil pump for oil leaks.

6. After the inspections, install oil pressure switch as follows:

a. Remove old liquid gasket adhering to oil pressure switch and engine.

b. Apply liquid gasket and tighten oil pressure switch to specification.

Use Genuine Liquid Gasket or equivalent.

c. Check engine oil level. Refer to LU-6, "

Inspection".

d. After warming up engine, make sure there is no leaks of engine oil with running engine.

DrainingINFOID:0000000001381528

WARNING:

Be careful not to get burned, as engine oil may be hot.

Prolonged and repeated contact with used engine oil may cause skin cancer. Try to avoid direct skin

contact with used engine oil. If skin contact is made, wash thoroughly with soap or hand cleaner as

soon as possible.

1. Warm up the engine, and check for engine oil leakage from engine components. Refer to LU-6, "

Inspec-

tion".

2. Stop the engine and wait for 10 minutes.

3. Loosen oil filler cap.

4. Remove drain plug and then drain engine oil.

PBIC3817E

SLC926ZA

Engine oil pressure : Refer to LU-10, "Engine Oil Pressure".

Oil pressure switch : Refer to EM-100, "

Exploded View".

Page 4223 of 5883

![NISSAN TIIDA 2007 Service Repair Manual LU-16

< ON-VEHICLE MAINTENANCE >[MR18DE]

ENGINE OIL

2. Install oil pressure gauge and hose.

3. Check engine oil level. Refer to LU-15, "

Inspection".

4. Start engine and warm it up to normal operating NISSAN TIIDA 2007 Service Repair Manual LU-16

< ON-VEHICLE MAINTENANCE >[MR18DE]

ENGINE OIL

2. Install oil pressure gauge and hose.

3. Check engine oil level. Refer to LU-15, "

Inspection".

4. Start engine and warm it up to normal operating](/img/5/57395/w960_57395-4222.png)

LU-16

< ON-VEHICLE MAINTENANCE >[MR18DE]

ENGINE OIL

2. Install oil pressure gauge and hose.

3. Check engine oil level. Refer to LU-15, "

Inspection".

4. Start engine and warm it up to normal operating temperature.

5. Check oil pressure with engine running under no-load.

NOTE:

When engine oil temperature is low, engine oil pressure becomes high.

Engine oil pressure [Engine oil temperature at 80°C (176°F)]

If difference is extreme, check oil passage and oil pump for oil leaks.

6. After the inspections, install oil pressure switch as follows:

a. Remove old liquid gasket adhering to oil pressure switch and engine.

b. Apply liquid gasket and tighten oil pressure switch to specification.

Use Genuine Silicone RTV Sealant or equivalent. Refer to GI-27, "

Recommended Chemical Prod-

ucts and Sealants".

c. Check engine oil level. Refer to LU-15, "

Inspection".

d. After warming up engine, make sure there are no engine leaks of oil with running engine.

Changing Engine OilINFOID:0000000001337828

WARNING:

Be careful not to burn yourself, as engine oil may be hot.

Prolonged and repeated contact with used engine oil may cause skin cancer; try to avoid direct skin

contact with used engine oil. If skin contact is made, wash thoroughly with soap or hand cleaner as

soon as possible.

1. Warm up engine, park vehicle on a level surface and check for engine oil leakage from engine compo-

nents. Refer to LU-15, "

Inspection".

2. Stop engine and wait for 10 minutes.Tool number : ST25051001 (J-25695-1)

: ST25052000 (J-25695-2)

WBIA0571E

Engine speed

rpm Approximate discharge pressure

kPa (bar, kg/cm2, psi)

Idle speed More than 71.5 (0.70, 0.70, 10)

2,000 More than 200 (2.0, 2.0, 29)

Oil pressure switch : 14.7 N·m (1.5 kg-m, 11 ft-lb)

Page 4237 of 5883

![NISSAN TIIDA 2007 Service Repair Manual LU-30

< ON-VEHICLE REPAIR >[K9K]

OIL COOLER

OIL COOLER

Exploded ViewINFOID:0000000001381543

Removal and InstallationINFOID:0000000001381544

CAUTION:

Be careful not to get burned when the engine and NISSAN TIIDA 2007 Service Repair Manual LU-30

< ON-VEHICLE REPAIR >[K9K]

OIL COOLER

OIL COOLER

Exploded ViewINFOID:0000000001381543

Removal and InstallationINFOID:0000000001381544

CAUTION:

Be careful not to get burned when the engine and](/img/5/57395/w960_57395-4236.png)

LU-30

< ON-VEHICLE REPAIR >[K9K]

OIL COOLER

OIL COOLER

Exploded ViewINFOID:0000000001381543

Removal and InstallationINFOID:0000000001381544

CAUTION:

Be careful not to get burned when the engine and engine oil are hot.

When removing, prepare a shop cloth to absorb any oil leakage or spillage.

Completely wipe off any oil that adhere to the engine and the vehicle.

REMOVAL

1. Remove engine undercover using power tool.

2. Drain engine coolant. Refer to CO-58, "

Draining".

CAUTION:

Perform when engine is cold.

3. Remove RH front wheel. Refer to WT-6, "

Rotation".

4. Remove RH fender protector. Refer to EXT-22, "

Removal and Installation".

5. Remove drive belt. Refer to EM-263, "

Removal and Installation".

6. Remove generator and position aside. Refer to CHG-43, "

Removal and Installation".

7. Remove A/C compressor and position aside. Refer to HA-35, "

Removal and Installation of Compressor -

K9K".

8. Remove oil filter and oil filter bracket. Refer to LU-28, "

Replacement".

1. Cylinder block 2. Water pipe 3. O-ring

4. O-ring 5. O-ring 6. Oil cooler

7. Connecting stud 8. O-ring 9. Oil filter bracket

10. Oil pressure switch 11. Oil filter 12. O-ring

13. Connecting bolt

A. To radiator lower hose B. To water pump

E1BIA0011GB

Page 4239 of 5883

![NISSAN TIIDA 2007 Service Repair Manual LU-32

< ON-VEHICLE REPAIR >[K9K]

OIL PUMP

OIL PUMP

Exploded ViewINFOID:0000000001381546

Removal and InstallationINFOID:0000000001381547

REMOVAL

1. Remove the battery negative cable.

2. Remove the engi NISSAN TIIDA 2007 Service Repair Manual LU-32

< ON-VEHICLE REPAIR >[K9K]

OIL PUMP

OIL PUMP

Exploded ViewINFOID:0000000001381546

Removal and InstallationINFOID:0000000001381547

REMOVAL

1. Remove the battery negative cable.

2. Remove the engi](/img/5/57395/w960_57395-4238.png)

LU-32

< ON-VEHICLE REPAIR >[K9K]

OIL PUMP

OIL PUMP

Exploded ViewINFOID:0000000001381546

Removal and InstallationINFOID:0000000001381547

REMOVAL

1. Remove the battery negative cable.

2. Remove the engine undercover.

3. Remove the RH front wheel and tire. Refer to WT-6, "

Rotation".

4. Remove RH fender protector. Refer to EXT-22, "

Removal and Installation".

5. Remove front driveshaft assembly RH. Refer to FA X - 11 , "

Removal and Installation (Right Side)".

6. Remove driveshaft center bearing bracket.

7. Remove lower torque rod. Refer to EM-302, "

Exploded View".

8. Remove oil pan. Refer to EM-284, "

Removal and Installation".

9. Remove oil pump drive chain.

10. Remove oil pump assembly.

INSTALLATION

Installation is in the reverse order of removal.

1. Oil pump drive chain 2. Crankshaft sprocket (oil pump drive

chain)3. Oil pump

E1BIA0028GB

Page 4245 of 5883

PREPARATION

MA-5

< PREPARATION >

C

D

E

F

G

H

I

J

K

L

MB

MAN

OA

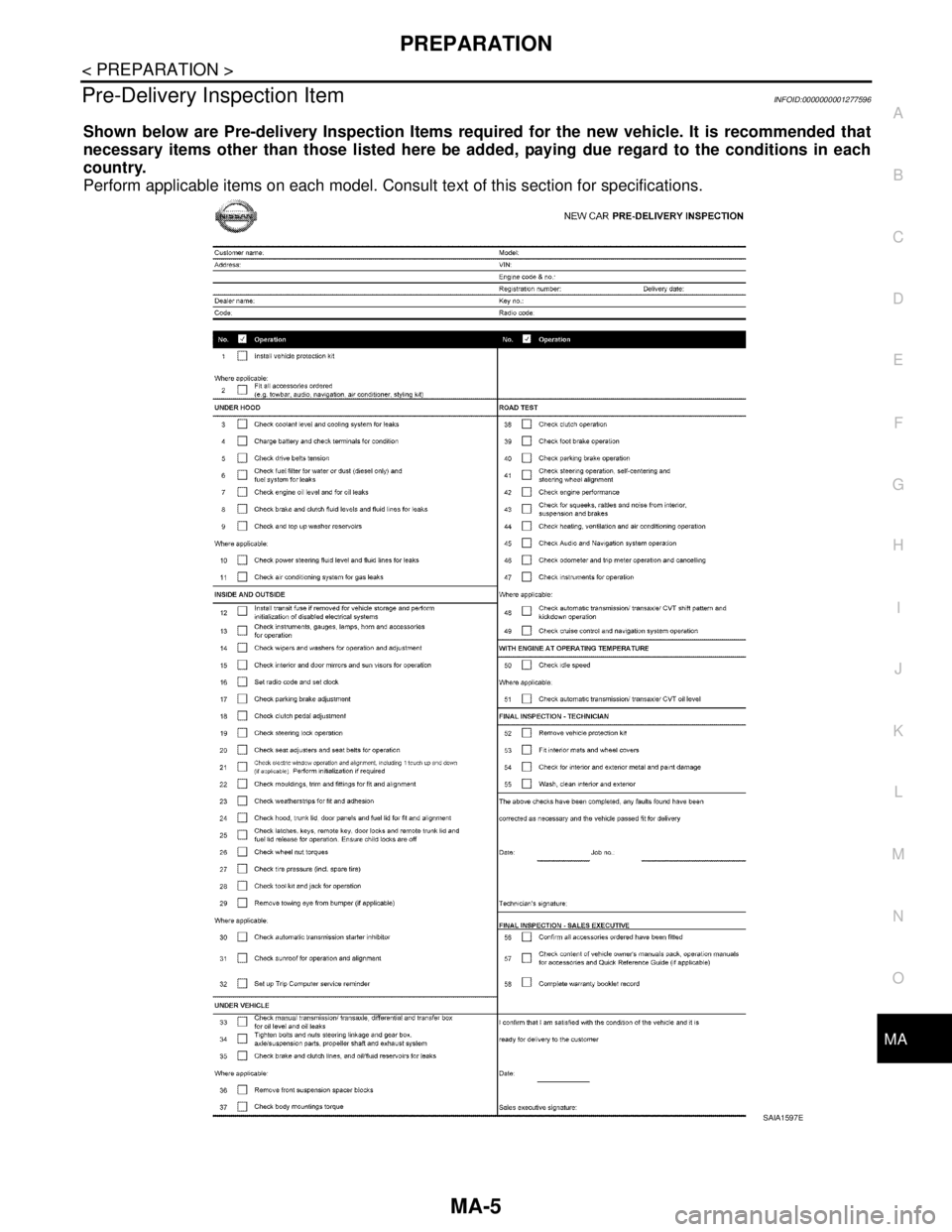

Pre-Delivery Inspection ItemINFOID:0000000001277596

Shown below are Pre-delivery Inspection Items required for the new vehicle. It is recommended that

necessary items other than those listed here be added, paying due regard to the conditions in each

country.

Perform applicable items on each model. Consult text of this section for specifications.

SAIA1597E

Page 4251 of 5883

PERIODIC MAINTENANCE

MA-11

< ON-VEHICLE MAINTENANCE >

C

D

E

F

G

H

I

J

K

L

MB

MAN

OA

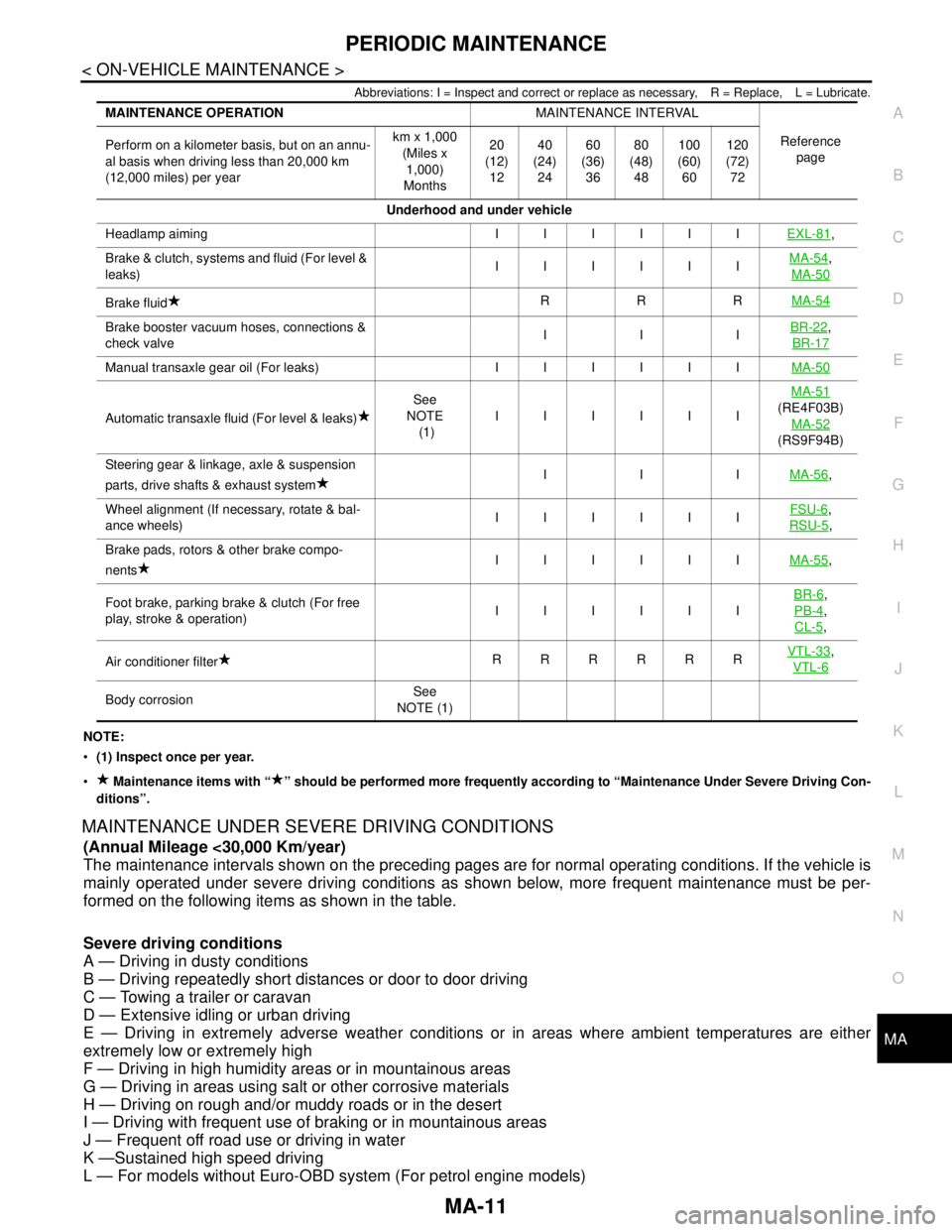

Abbreviations: I = Inspect and correct or replace as necessary, R = Replace, L = Lubricate.

NOTE:

(1) Inspect once per year.

Maintenance items with “ ” should be performed more frequently according to “Maintenance Under Severe Driving Con-

ditions”.

MAINTENANCE UNDER SEVERE DRIVING CONDITIONS

(Annual Mileage <30,000 Km/year)

The maintenance intervals shown on the preceding pages are for normal operating conditions. If the vehicle is

mainly operated under severe driving conditions as shown below, more frequent maintenance must be per-

formed on the following items as shown in the table.

Severe driving conditions

A — Driving in dusty conditions

B — Driving repeatedly short distances or door to door driving

C — Towing a trailer or caravan

D — Extensive idling or urban driving

E — Driving in extremely adverse weather conditions or in areas where ambient temperatures are either

extremely low or extremely high

F — Driving in high humidity areas or in mountainous areas

G — Driving in areas using salt or other corrosive materials

H — Driving on rough and/or muddy roads or in the desert

I — Driving with frequent use of braking or in mountainous areas

J — Frequent off road use or driving in water

K —Sustained high speed driving

L — For models without Euro-OBD system (For petrol engine models)

MAINTENANCE OPERATIONMAINTENANCE INTERVAL

Reference

page Perform on a kilometer basis, but on an annu-

al basis when driving less than 20,000 km

(12,000 miles) per yearkm x 1,000

(Miles x

1,000)

Months20

(12)

1240

(24)

2460

(36)

3680

(48)

48100

(60)

60120

(72)

72

Underhood and under vehicle

Headlamp aiming IIIIIIEXL-81

,

Brake & clutch, systems and fluid (For level &

leaks)IIIIIIMA-54

,

MA-50

Brake fluidRRRMA-54

Brake booster vacuum hoses, connections &

check valveIIIBR-22,

BR-17

Manual transaxle gear oil (For leaks) IIIIIIMA-50

Automatic transaxle fluid (For level & leaks)See

NOTE

(1)IIIIIIMA-51(RE4F03B)

MA-52

(RS9F94B)

Steering gear & linkage, axle & suspension

parts, drive shafts & exhaust systemIIIMA-56

,

Wheel alignment (If necessary, rotate & bal-

ance wheels)IIIIIIFSU-6

,

RSU-5

,

Brake pads, rotors & other brake compo-

nentsIIIIIIMA-55

,

Foot brake, parking brake & clutch (For free

play, stroke & operation)IIIIIIBR-6

,

PB-4

,

CL-5

,

Air conditioner filterRRRRRRVTL-33

,

VTL-6

Body corrosionSee

NOTE (1)

Page 4257 of 5883

PERIODIC MAINTENANCE

MA-17

< ON-VEHICLE MAINTENANCE >

C

D

E

F

G

H

I

J

K

L

MB

MAN

OA

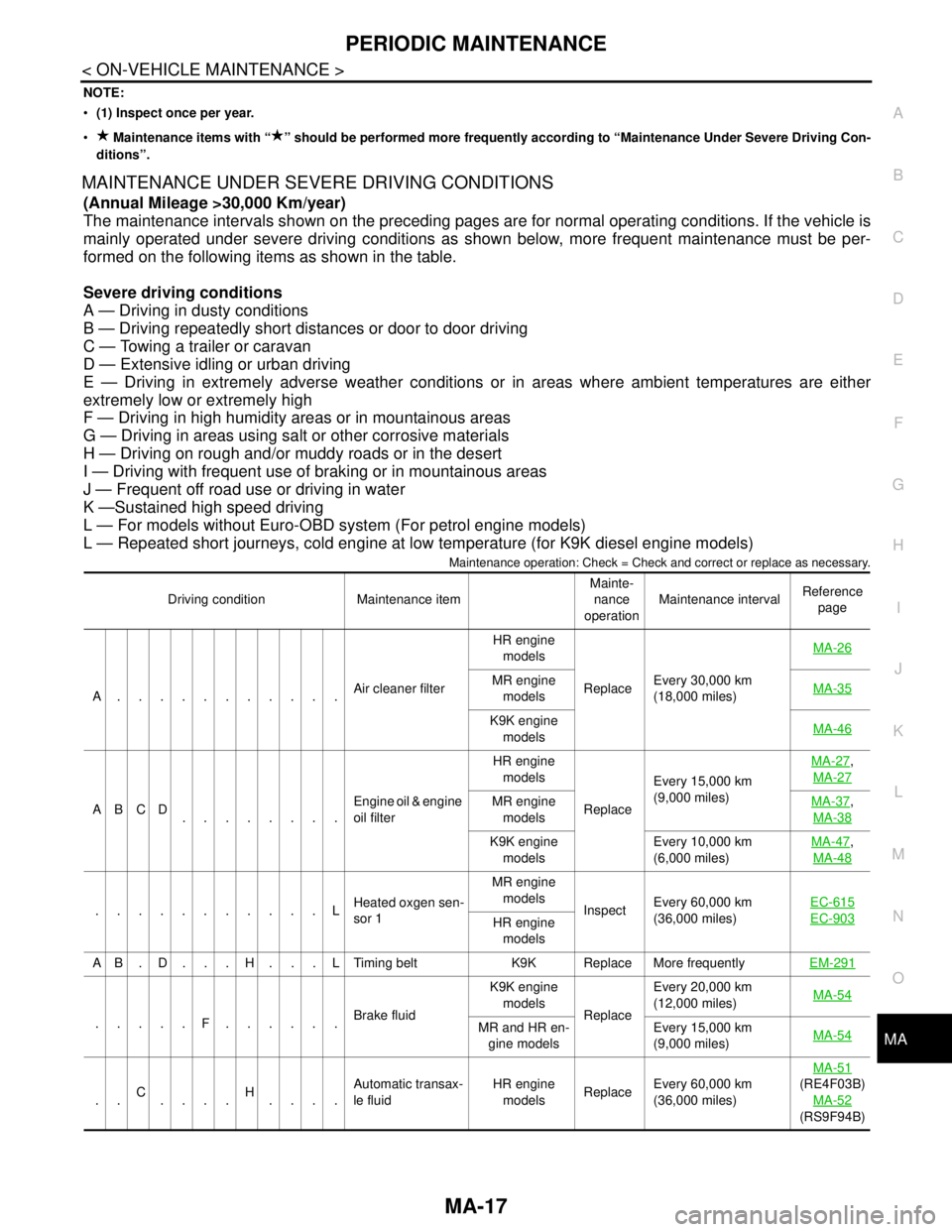

NOTE:

(1) Inspect once per year.

Maintenance items with “ ” should be performed more frequently according to “Maintenance Under Severe Driving Con-

ditions”.

MAINTENANCE UNDER SEVERE DRIVING CONDITIONS

(Annual Mileage >30,000 Km/year)

The maintenance intervals shown on the preceding pages are for normal operating conditions. If the vehicle is

mainly operated under severe driving conditions as shown below, more frequent maintenance must be per-

formed on the following items as shown in the table.

Severe driving conditions

A — Driving in dusty conditions

B — Driving repeatedly short distances or door to door driving

C — Towing a trailer or caravan

D — Extensive idling or urban driving

E — Driving in extremely adverse weather conditions or in areas where ambient temperatures are either

extremely low or extremely high

F — Driving in high humidity areas or in mountainous areas

G — Driving in areas using salt or other corrosive materials

H — Driving on rough and/or muddy roads or in the desert

I — Driving with frequent use of braking or in mountainous areas

J — Frequent off road use or driving in water

K —Sustained high speed driving

L — For models without Euro-OBD system (For petrol engine models)

L — Repeated short journeys, cold engine at low temperature (for K9K diesel engine models)

Maintenance operation: Check = Check and correct or replace as necessary.

Driving condition Maintenance itemMainte-

nance

operationMaintenance intervalReference

page

A...........Air cleaner filterHR engine

models

ReplaceEvery 30,000 km

(18,000 miles) MA-26

MR engine

modelsMA-35

K9K engine

modelsMA-46

ABCD

........Engine oil & engine

oil filter HR engine

models

ReplaceEvery 15,000 km

(9,000 miles) MA-27

,

MA-27

MR engine

modelsMA-37,

MA-38

K9K engine

modelsEvery 10,000 km

(6,000 miles) MA-47,

MA-48

...........LHeated oxgen sen-

sor 1MR engine

models

InspectEvery 60,000 km

(36,000 miles) EC-615EC-903HR engine

models

A B . D . . . H . . . L Timing belt K9K Replace More frequentlyEM-291

.....F......Brake fluidK9K engine

models

ReplaceEvery 20,000 km

(12,000 miles) MA-54MR and HR en-

gine modelsEvery 15,000 km

(9,000 miles) MA-54

..C

....H

....Automatic transax-

le fluidHR engine

modelsReplaceEvery 60,000 km

(36,000 miles) MA-51

(RE4F03B)

MA-52

(RS9F94B)

Page 4259 of 5883

RECOMMENDED FLUIDS AND LUBRICANTS

MA-19

< ON-VEHICLE MAINTENANCE >

C

D

E

F

G

H

I

J

K

L

MB

MAN

OA

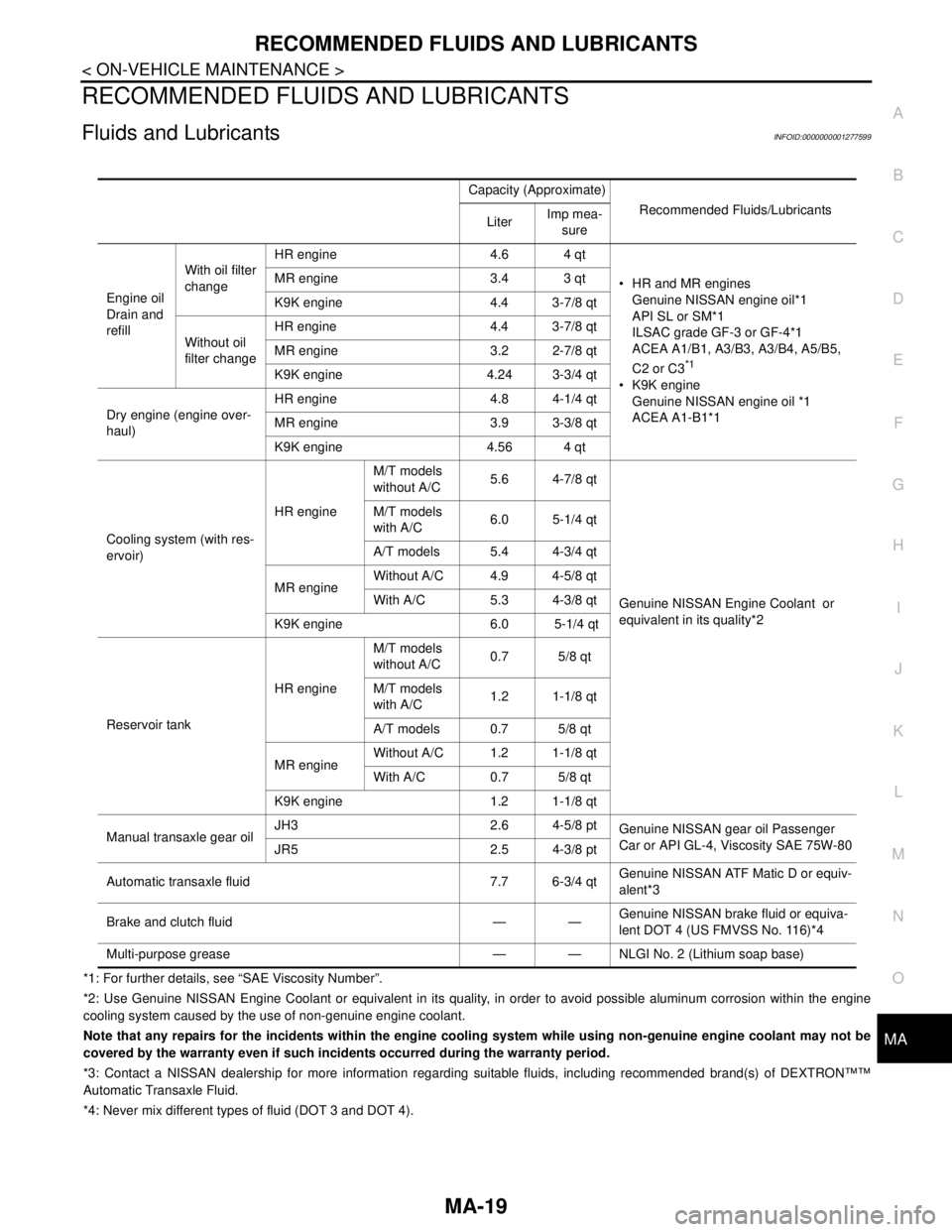

RECOMMENDED FLUIDS AND LUBRICANTS

Fluids and LubricantsINFOID:0000000001277599

*1: For further details, see “SAE Viscosity Number”.

*2: Use Genuine NISSAN Engine Coolant or equivalent in its quality, in order to avoid possible aluminum corrosion within the engine

cooling system caused by the use of non-genuine engine coolant.

Note that any repairs for the incidents within the engine cooling system while using non-genuine engine coolant may not be

covered by the warranty even if such incidents occurred during the warranty period.

*3: Contact a NISSAN dealership for more information regarding suitable fluids, including recommended brand(s) of DEXTRON™™

Automatic Transaxle Fluid.

*4: Never mix different types of fluid (DOT 3 and DOT 4).Capacity (Approximate)

Recommended Fluids/Lubricants

LiterImp mea-

sure

Engine oil

Drain and

refillWith oil filter

changeHR engine 4.6 4 qt

HR and MR engines

Genuine NISSAN engine oil*1

API SL or SM*1

ILSAC grade GF-3 or GF-4*1

ACEA A1/B1, A3/B3, A3/B4, A5/B5,

C2 or C3

*1

K9K engine

Genuine NISSAN engine oil *1

ACEA A1-B1*1 MR engine 3.4 3 qt

K9K engine 4.4 3-7/8 qt

Without oil

filter changeHR engine 4.4 3-7/8 qt

MR engine 3.2 2-7/8 qt

K9K engine 4.24 3-3/4 qt

Dry engine (engine over-

haul)HR engine 4.8 4-1/4 qt

MR engine 3.9 3-3/8 qt

K9K engine 4.56 4 qt

Cooling system (with res-

ervoir)HR engineM/T models

without A/C5.6 4-7/8 qt

Genuine NISSAN Engine Coolant or

equivalent in its quality*2 M/T models

with A/C6.0 5-1/4 qt

A/T models 5.4 4-3/4 qt

MR engineWithout A/C 4.9 4-5/8 qt

With A/C 5.3 4-3/8 qt

K9K engine 6.0 5-1/4 qt

Reservoir tankHR engineM/T models

without A/C0.7 5/8 qt

M/T models

with A/C1.2 1-1/8 qt

A/T models 0.7 5/8 qt

MR engineWithout A/C 1.2 1-1/8 qt

With A/C 0.7 5/8 qt

K9K engine 1.2 1-1/8 qt

Manual transaxle gear oilJH3 2.6 4-5/8 pt

Genuine NISSAN gear oil Passenger

Car or API GL-4, Viscosity SAE 75W-80

JR5 2.5 4-3/8 pt

Automatic transaxle fluid 7.7 6-3/4 qtGenuine NISSAN ATF Matic D or equiv-

alent*3

Brake and clutch fluid — —Genuine NISSAN brake fluid or equiva-

lent DOT 4 (US FMVSS No. 116)*4

Multi-purpose grease — — NLGI No. 2 (Lithium soap base)

Page 4261 of 5883

RECOMMENDED FLUIDS AND LUBRICANTS

MA-21

< ON-VEHICLE MAINTENANCE >

C

D

E

F

G

H

I

J

K

L

MB

MAN

OA

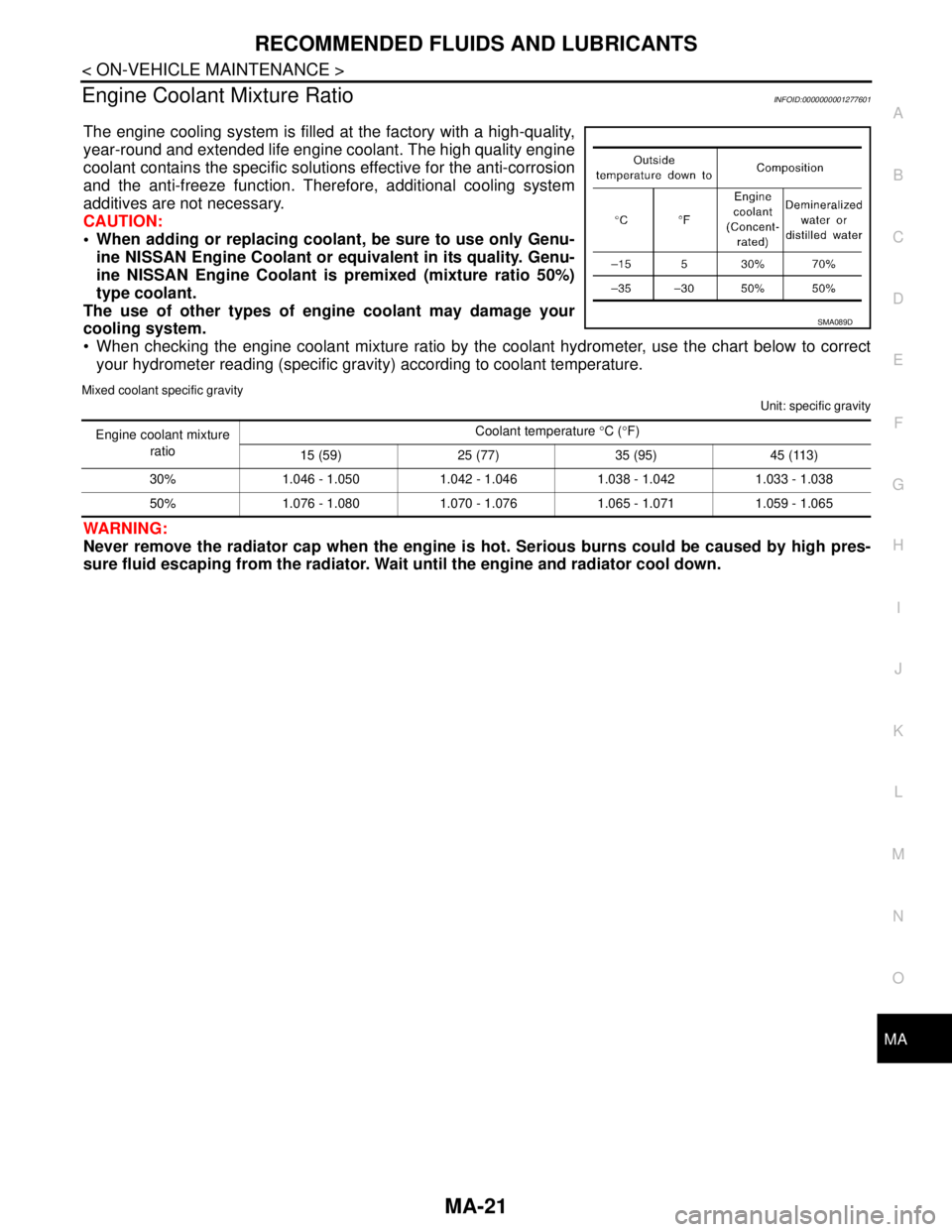

Engine Coolant Mixture RatioINFOID:0000000001277601

The engine cooling system is filled at the factory with a high-quality,

year-round and extended life engine coolant. The high quality engine

coolant contains the specific solutions effective for the anti-corrosion

and the anti-freeze function. Therefore, additional cooling system

additives are not necessary.

CAUTION:

When adding or replacing coolant, be sure to use only Genu-

ine NISSAN Engine Coolant or equivalent in its quality. Genu-

ine NISSAN Engine Coolant is premixed (mixture ratio 50%)

type coolant.

The use of other types of engine coolant may damage your

cooling system.

When checking the engine coolant mixture ratio by the coolant hydrometer, use the chart below to correct

your hydrometer reading (specific gravity) according to coolant temperature.

Mixed coolant specific gravity

Unit: specific gravity

WARNING:

Never remove the radiator cap when the engine is hot. Serious burns could be caused by high pres-

sure fluid escaping from the radiator. Wait until the engine and radiator cool down.

SMA089D

Engine coolant mixture

ratioCoolant temperature °C (°F)

15 (59) 25 (77) 35 (95) 45 (113)

30% 1.046 - 1.050 1.042 - 1.046 1.038 - 1.042 1.033 - 1.038

50% 1.076 - 1.080 1.070 - 1.076 1.065 - 1.071 1.059 - 1.065

Page 4274 of 5883

MA-34

< ON-VEHICLE MAINTENANCE >

ENGINE MAINTENANCE (MR18DE)

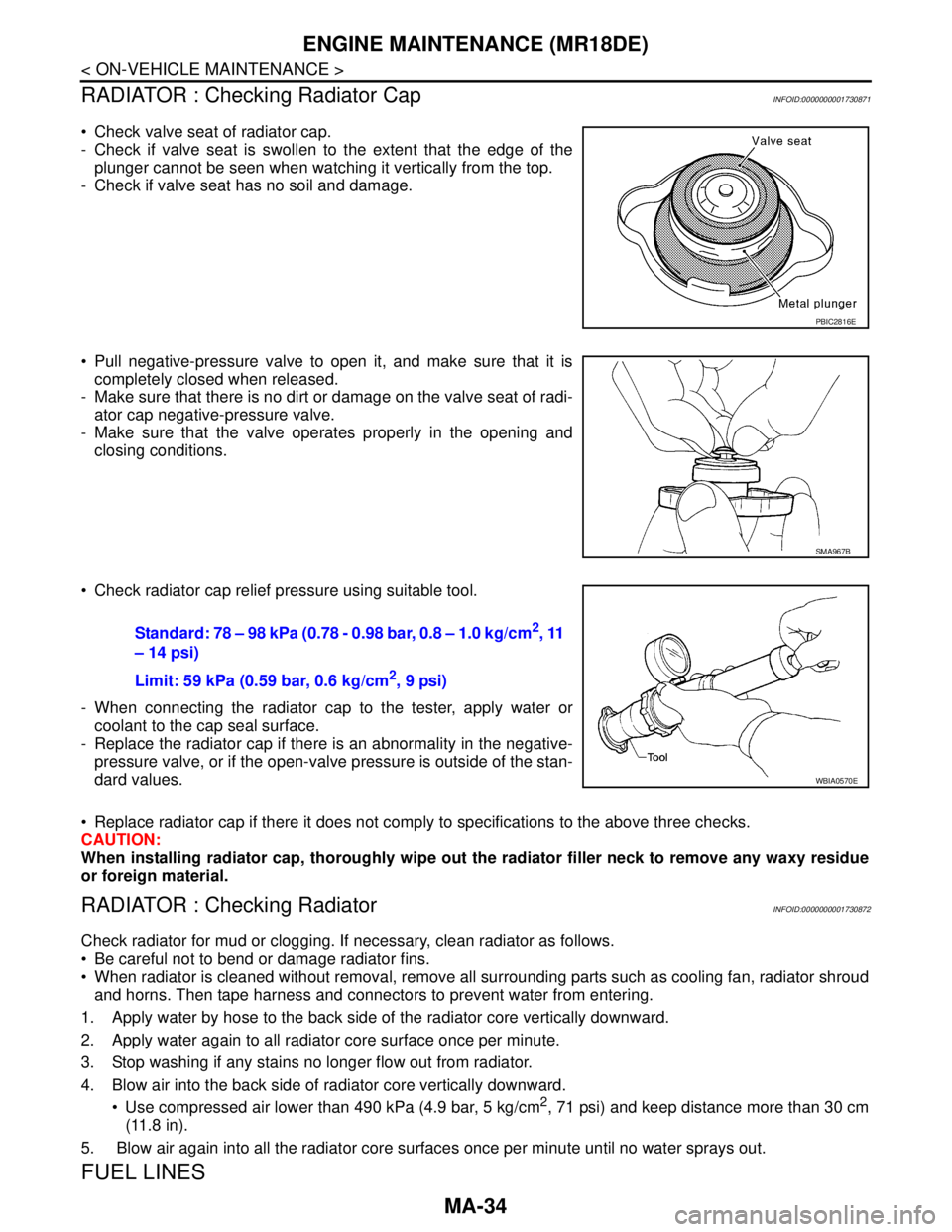

RADIATOR : Checking Radiator Cap

INFOID:0000000001730871

Check valve seat of radiator cap.

- Check if valve seat is swollen to the extent that the edge of the

plunger cannot be seen when watching it vertically from the top.

- Check if valve seat has no soil and damage.

Pull negative-pressure valve to open it, and make sure that it is

completely closed when released.

- Make sure that there is no dirt or damage on the valve seat of radi-

ator cap negative-pressure valve.

- Make sure that the valve operates properly in the opening and

closing conditions.

Check radiator cap relief pressure using suitable tool.

- When connecting the radiator cap to the tester, apply water or

coolant to the cap seal surface.

- Replace the radiator cap if there is an abnormality in the negative-

pressure valve, or if the open-valve pressure is outside of the stan-

dard values.

Replace radiator cap if there it does not comply to specifications to the above three checks.

CAUTION:

When installing radiator cap, thoroughly wipe out the radiator filler neck to remove any waxy residue

or foreign material.

RADIATOR : Checking RadiatorINFOID:0000000001730872

Check radiator for mud or clogging. If necessary, clean radiator as follows.

Be careful not to bend or damage radiator fins.

When radiator is cleaned without removal, remove all surrounding parts such as cooling fan, radiator shroud

and horns. Then tape harness and connectors to prevent water from entering.

1. Apply water by hose to the back side of the radiator core vertically downward.

2. Apply water again to all radiator core surface once per minute.

3. Stop washing if any stains no longer flow out from radiator.

4. Blow air into the back side of radiator core vertically downward.

Use compressed air lower than 490 kPa (4.9 bar, 5 kg/cm

2, 71 psi) and keep distance more than 30 cm

(11.8 in).

5. Blow air again into all the radiator core surfaces once per minute until no water sprays out.

FUEL LINES

PBIC2816E

SMA967B

Standard: 78 – 98 kPa (0.78 - 0.98 bar, 0.8 – 1.0 kg/cm2, 11

– 14 psi)

Limit: 59 kPa (0.59 bar, 0.6 kg/cm

2, 9 psi)

WBIA0570E