NISSAN TIIDA 2007 Service Repair Manual

Manufacturer: NISSAN, Model Year: 2007, Model line: TIIDA, Model: NISSAN TIIDA 2007Pages: 5883, PDF Size: 78.95 MB

Page 4451 of 5883

![NISSAN TIIDA 2007 Service Repair Manual PCS

POWER SUPPLY AND GROUND CIRCUIT

PCS-37

< COMPONENT DIAGNOSIS >[POWER DISTRIBUTION SYSTEM]

C

D

E

F

G

H

I

J

K

L B A

O

P N

POWER SUPPLY AND GROUND CIRCUIT

BCM

BCM : Diagnosis ProcedureINFOID:00000000 NISSAN TIIDA 2007 Service Repair Manual PCS

POWER SUPPLY AND GROUND CIRCUIT

PCS-37

< COMPONENT DIAGNOSIS >[POWER DISTRIBUTION SYSTEM]

C

D

E

F

G

H

I

J

K

L B A

O

P N

POWER SUPPLY AND GROUND CIRCUIT

BCM

BCM : Diagnosis ProcedureINFOID:00000000](/img/5/57395/w960_57395-4450.png)

PCS

POWER SUPPLY AND GROUND CIRCUIT

PCS-37

< COMPONENT DIAGNOSIS >[POWER DISTRIBUTION SYSTEM]

C

D

E

F

G

H

I

J

K

L B A

O

P N

POWER SUPPLY AND GROUND CIRCUIT

BCM

BCM : Diagnosis ProcedureINFOID:0000000001697613

Refer to BCS-30, "Diagnosis Procedure".

BCM : Special Repair RequirementINFOID:0000000001697614

1.REQUIRED WORK WHEN REPLACING BCM

Initialize control unit. Refer to CONSULT-III Operation Manual.

>> Work end.

IPDM E/R (INTELLIGENT POWER DISTRIBUTION MODULE ENGINE ROOM)

IPDM E/R (INTELLIGENT POWER DISTRIBUTION MODULE ENGINE ROOM) : Di-

agnosis Procedure

INFOID:0000000001697615

Refer to PCS-16, "Diagnosis Procedure".

Page 4452 of 5883

![NISSAN TIIDA 2007 Service Repair Manual PCS-38

< ECU DIAGNOSIS >[POWER DISTRIBUTION SYSTEM]

BCM (BODY CONTROL MODULE)

ECU DIAGNOSIS

BCM (BODY CONTROL MODULE)

Reference ValueINFOID:0000000001697616

Refer to BCS-35, "Reference Value".

Termina NISSAN TIIDA 2007 Service Repair Manual PCS-38

< ECU DIAGNOSIS >[POWER DISTRIBUTION SYSTEM]

BCM (BODY CONTROL MODULE)

ECU DIAGNOSIS

BCM (BODY CONTROL MODULE)

Reference ValueINFOID:0000000001697616

Refer to BCS-35, "Reference Value".

Termina](/img/5/57395/w960_57395-4451.png)

PCS-38

< ECU DIAGNOSIS >[POWER DISTRIBUTION SYSTEM]

BCM (BODY CONTROL MODULE)

ECU DIAGNOSIS

BCM (BODY CONTROL MODULE)

Reference ValueINFOID:0000000001697616

Refer to BCS-35, "Reference Value".

Terminal LayoutINFOID:0000000001697617

Refer to BCS-38, "Terminal Layout".

Physical ValuesINFOID:0000000001697618

Refer to BCS-39, "Physical Values".

Wiring DiagramINFOID:0000000001697619

Refer to BCS-50, "Wiring Diagram".

DTC Inspection Priority ChartINFOID:0000000001697620

Refer to BCS-53, "DTCInspectionPriorityChart".

DTC IndexINFOID:0000000001697621

Refer to BCS-54, "DTCIndex".

Page 4453 of 5883

![NISSAN TIIDA 2007 Service Repair Manual PCS

IPDM E/R (INTELLIGENT POWER DISTRIBUTION MODULE ENGINE ROOM)

PCS-39

< ECU DIAGNOSIS >[POWER DISTRIBUTION SYSTEM]

C

D

E

F

G

H

I

J

K

L B A

O

P N

IPDM E/R (INTELLIGENT POWER DISTRIBUTION MODULE ENGIN NISSAN TIIDA 2007 Service Repair Manual PCS

IPDM E/R (INTELLIGENT POWER DISTRIBUTION MODULE ENGINE ROOM)

PCS-39

< ECU DIAGNOSIS >[POWER DISTRIBUTION SYSTEM]

C

D

E

F

G

H

I

J

K

L B A

O

P N

IPDM E/R (INTELLIGENT POWER DISTRIBUTION MODULE ENGIN](/img/5/57395/w960_57395-4452.png)

PCS

IPDM E/R (INTELLIGENT POWER DISTRIBUTION MODULE ENGINE ROOM)

PCS-39

< ECU DIAGNOSIS >[POWER DISTRIBUTION SYSTEM]

C

D

E

F

G

H

I

J

K

L B A

O

P N

IPDM E/R (INTELLIGENT POWER DISTRIBUTION MODULE ENGINE

ROOM)

Reference ValueINFOID:0000000001697622

Refer to PCS-17, "Reference Value".

Terminal LayoutINFOID:0000000001697623

Refer to PCS-19, "Terminal Layout".

Physical ValuesINFOID:0000000001697624

Refer to PCS-19, "Physical Values".

Wiring DiagramINFOID:0000000001697625

Refer to PCS-23, "Wiring Diagram".

Fail SafeINFOID:0000000001697626

Refer to PCS-26, "FailSafe".

DTC IndexINFOID:0000000001697627

Refer to PCS-28, "DTCIndex".

Page 4454 of 5883

![NISSAN TIIDA 2007 Service Repair Manual PCS-40

< ON-VEHICLE MAINTENANCE >[POWER DISTRIBUTION SYSTEM]

PRE-INSPECTION FOR DIAGNOSTIC

ON-VEHICLE MAINTENANCE

PRE-INSPECTION FOR DIAGNOSTIC

Basic InspectionINFOID:0000000001697628

The engine start NISSAN TIIDA 2007 Service Repair Manual PCS-40

< ON-VEHICLE MAINTENANCE >[POWER DISTRIBUTION SYSTEM]

PRE-INSPECTION FOR DIAGNOSTIC

ON-VEHICLE MAINTENANCE

PRE-INSPECTION FOR DIAGNOSTIC

Basic InspectionINFOID:0000000001697628

The engine start](/img/5/57395/w960_57395-4453.png)

PCS-40

< ON-VEHICLE MAINTENANCE >[POWER DISTRIBUTION SYSTEM]

PRE-INSPECTION FOR DIAGNOSTIC

ON-VEHICLE MAINTENANCE

PRE-INSPECTION FOR DIAGNOSTIC

Basic InspectionINFOID:0000000001697628

The engine start function, door lock function, power distribution system and NATS-NVIS system are closely

related to each other regarding control. Narrow down the functional area in question by performing basic

inspection to identify which function is malfunctioning. The vehicle security function can operate only when the

door lock and power distribution system are operating normally. Therefore, it is easy to identify any factor

unique to the vehicle security system by performing the vehicle security operation check after basic inspection.

1. CHECK DOOR LOCK OPERATION

1. Check the door lock for normal operation with the keyfob or Intelligent Key (if equipped) and door request

switch.

Successful door lock operation with the keyfob or Intelligent Key (if equipped) and request SW indicates

that the remote keyless entry receiver and inside key antenna (with Intelligent Key) required for engine

start are functioning normally.

Identify the malfunctioning point by referring to the DLK section if the door cannot be unlocked.

Can the door be locked with the Intelligent Key and door request switch?

YES >> GO TO 2

NO >> Refer to DLK-191, "

DOOR LOCK AND UNLOCK SWITCH : Symptom Table" (with Intelligent Key

without super lock), DLK-420, "

DOOR LOCK AND UNLOCK SWITCH : Symptom Table" (with

Intelligent Key and super lock), DLK-567, "

DOOR LOCK AND UNLOCK SWITCH : Symptom

Table" (without Intelligent Key without super lock) or DLK-718, "DOOR LOCK AND UNLOCK

SWITCH : Symptom Table" (without Intelligent Key with super lock).

2. CHECK ENGINE STARTING

1. Checks that the engine starts.

Does the engine start?

YES >> GO TO 3

NO >> Refer to SEC-76, "

Symptom Table" (with Intelligent Key) or SEC-117, "Symptom Table" (without

Intelligent Key).

3. CHECK STEERING LOCKING (MODELS WITH INTELLIGENT KEY)

1. Does the steering lock when operating door switch after switching the power supply from ON position (or

ACC position) to LOCK position?

If door switch is malfunctioning, BCM cannot lock the steering. If BCM does not detect DTC, steering lock

unit is normal.

Does steering lock?

YES >> GO TO 4

NO >> Refer to STC-29, "

Symptom Chart".

4. CHECK VEHICLE SECURITY SYSTEM

1. Check the vehicle security system for normal operation.

The vehicle security function can operate only when the door lock and power distribution functions are

operating normally.

Therefore, it is easy to identify any factor unique to the vehicle security by performing the vehicle security

operation check after this basic inspection.

>> Refer to SEC-75, "

Symptom Table" (with Intelligent Key) or SEC-116, "Symptom Table" (without

Intelligent Key).

Page 4455 of 5883

![NISSAN TIIDA 2007 Service Repair Manual PCS

BCM (BODY CONTROL MODULE)

PCS-41

< ON-VEHICLE REPAIR >[POWER DISTRIBUTION SYSTEM]

C

D

E

F

G

H

I

J

K

L B A

O

P N

ON-VEHICLE REPAIR

BCM (BODY CONTROL MODULE)

Removal and InstallationINFOID:000000000 NISSAN TIIDA 2007 Service Repair Manual PCS

BCM (BODY CONTROL MODULE)

PCS-41

< ON-VEHICLE REPAIR >[POWER DISTRIBUTION SYSTEM]

C

D

E

F

G

H

I

J

K

L B A

O

P N

ON-VEHICLE REPAIR

BCM (BODY CONTROL MODULE)

Removal and InstallationINFOID:000000000](/img/5/57395/w960_57395-4454.png)

PCS

BCM (BODY CONTROL MODULE)

PCS-41

< ON-VEHICLE REPAIR >[POWER DISTRIBUTION SYSTEM]

C

D

E

F

G

H

I

J

K

L B A

O

P N

ON-VEHICLE REPAIR

BCM (BODY CONTROL MODULE)

Removal and InstallationINFOID:0000000001697629

Refer to BCS-57, "Removal and Installation of BCM".

Page 4456 of 5883

PG

PG-1

ELECTRICAL & POWER CONTROL

C

D

E

F

G

H

I

J

K

L B

SECTION PG

A

O

P N

CONTENTS

POWER SUPPLY, GROUND & CIRCUIT ELEMENTS

PRECAUTION ...............................................2

PRECAUTIONS ...................................................2

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ...................................................................

2

BASIC INSPECTION ....................................3

BATTERY ...........................................................3

How to Handle Battery ..............................................3

ON-VEHICLE REPAIR ..................................6

BATTERY ...........................................................6

Removal and Installation ..........................................6

Page 4457 of 5883

PG-2

< PRECAUTION >

PRECAUTIONS

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000001731064

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. Information necessary to service the system safely is included in the “SRS AIRBAG” and

“SEAT BELT” of this Service Manual.

WARNING:

• To avoid rendering the SRS inoperative, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

Improper maintenance, including incorrect removal and installation of the SRS, can lead to personal

injury caused by unintentional activation of the system. For removal of Spiral Cable and Air Bag

Module, see the “SRS AIRBAG”.

Do not use electrical test equipment on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identified by yellow and/or orange harnesses or har-

ness connectors.

Page 4458 of 5883

PG

BATTERY

PG-3

< BASIC INSPECTION >

C

D

E

F

G

H

I

J

K

L B A

O

P N

BASIC INSPECTION

BATTERY

How to Handle BatteryINFOID:0000000001723097

CAUTION:

If it becomes necessary to start the engine with a booster battery and jumper cables, use a 12-volt

booster battery.

After connecting battery cables, ensure that they are tightly clamped to battery terminals for good

contact.

Never add distilled water through the hole used to check specific gravity.

METHODS OF PREVENTING OVER-DISCHARGE

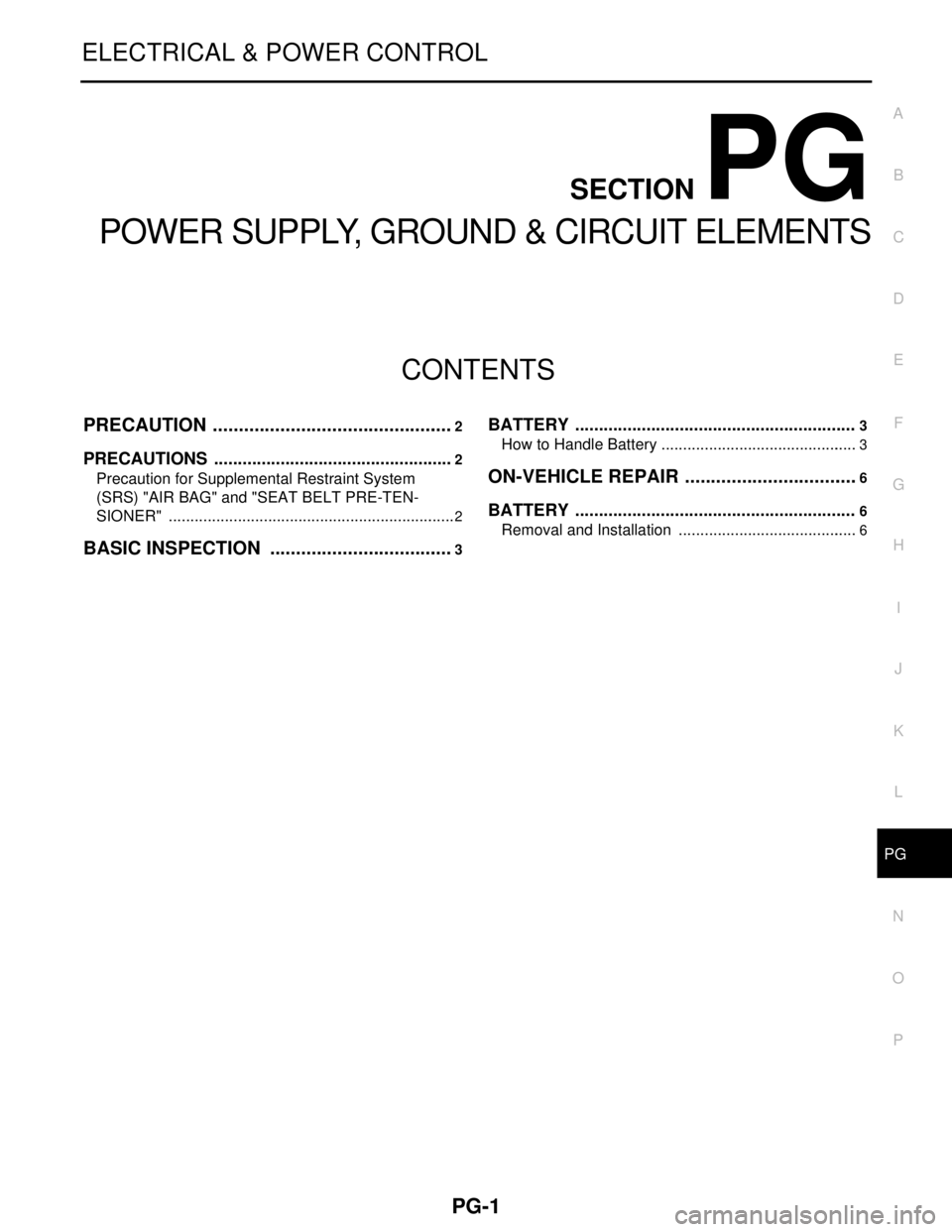

The following precautions must be taken to prevent over-discharging a battery.

The battery surface (particularly its top) should always be kept

clean and dry.

The terminal connections should be clean and tight.

At every routine maintenance, check the electrolyte level.

This also applies to batteries designated as “low maintenance” and

“maintenance-free”.

When the vehicle is not going to be used over a long period of

time, disconnect the battery cable from the negative terminal. (If

the vehicle has an extended storage switch, turn it off.)

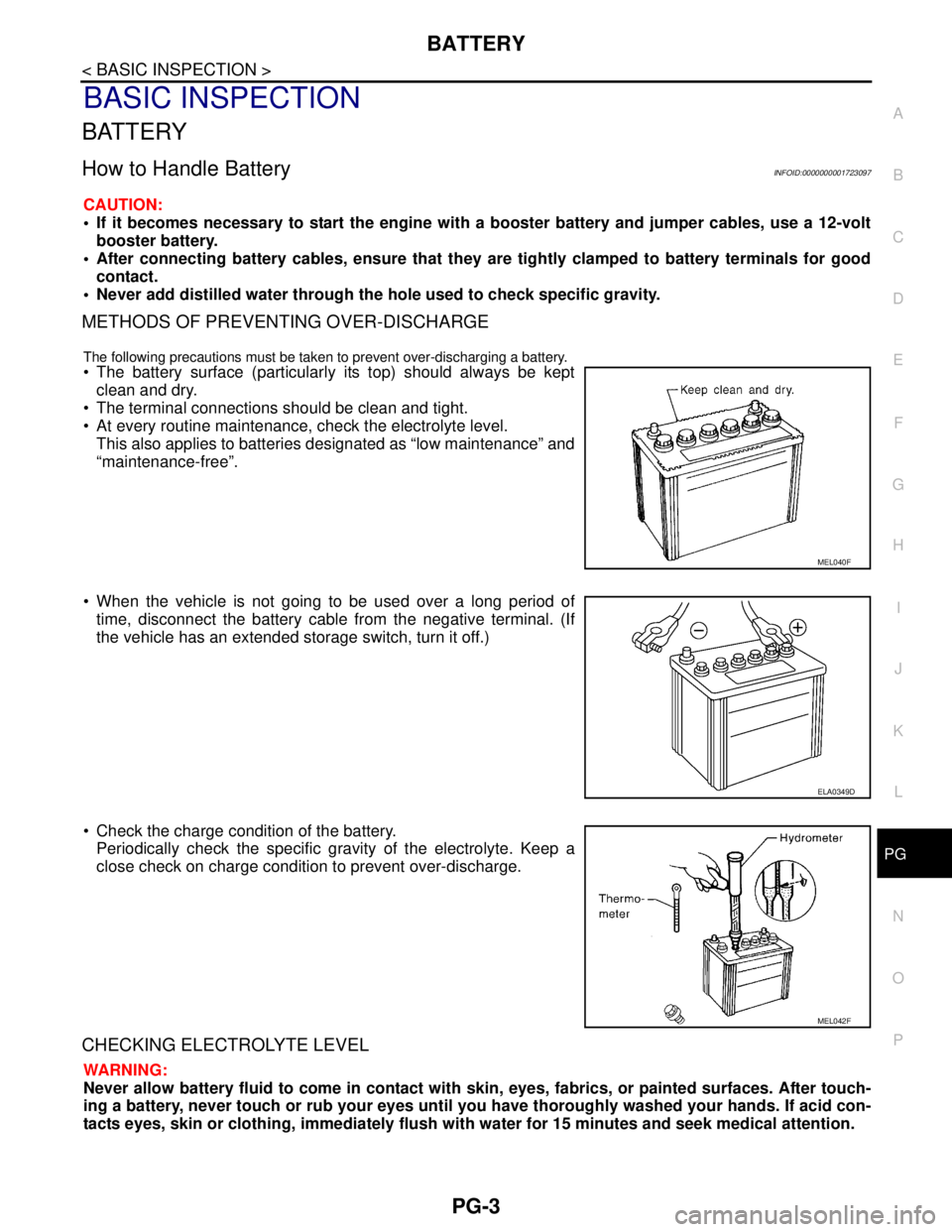

Check the charge condition of the battery.

Periodically check the specific gravity of the electrolyte. Keep a

close check on charge condition to prevent over-discharge.

CHECKING ELECTROLYTE LEVEL

WARNING:

Never allow battery fluid to come in contact with skin, eyes, fabrics, or painted surfaces. After touch-

ing a battery, never touch or rub your eyes until you have thoroughly washed your hands. If acid con-

tacts eyes, skin or clothing, immediately flush with water for 15 minutes and seek medical attention.

MEL040F

ELA0349D

MEL042F

Page 4459 of 5883

PG-4

< BASIC INSPECTION >

BATTERY

Remove the cell plug using a suitable tool.

Add distilled water up to the MAX level.

Sulphation

A battery will be completely discharged if it is left unattended

for a long time and the specific gravity will become less than

1.100. This may result in sulphation on the cell plates.

To determine if a battery has been “sulphated”, note its voltage

and current when charging it. As shown in the figure, less cur-

rent and higher voltage are observed in the initial stage of

charging sulphated batteries.

A sulphated battery may sometimes be brought back into ser-

vice by means of a long, slow charge, 12 hours or more, fol-

lowed by a battery capacity test.

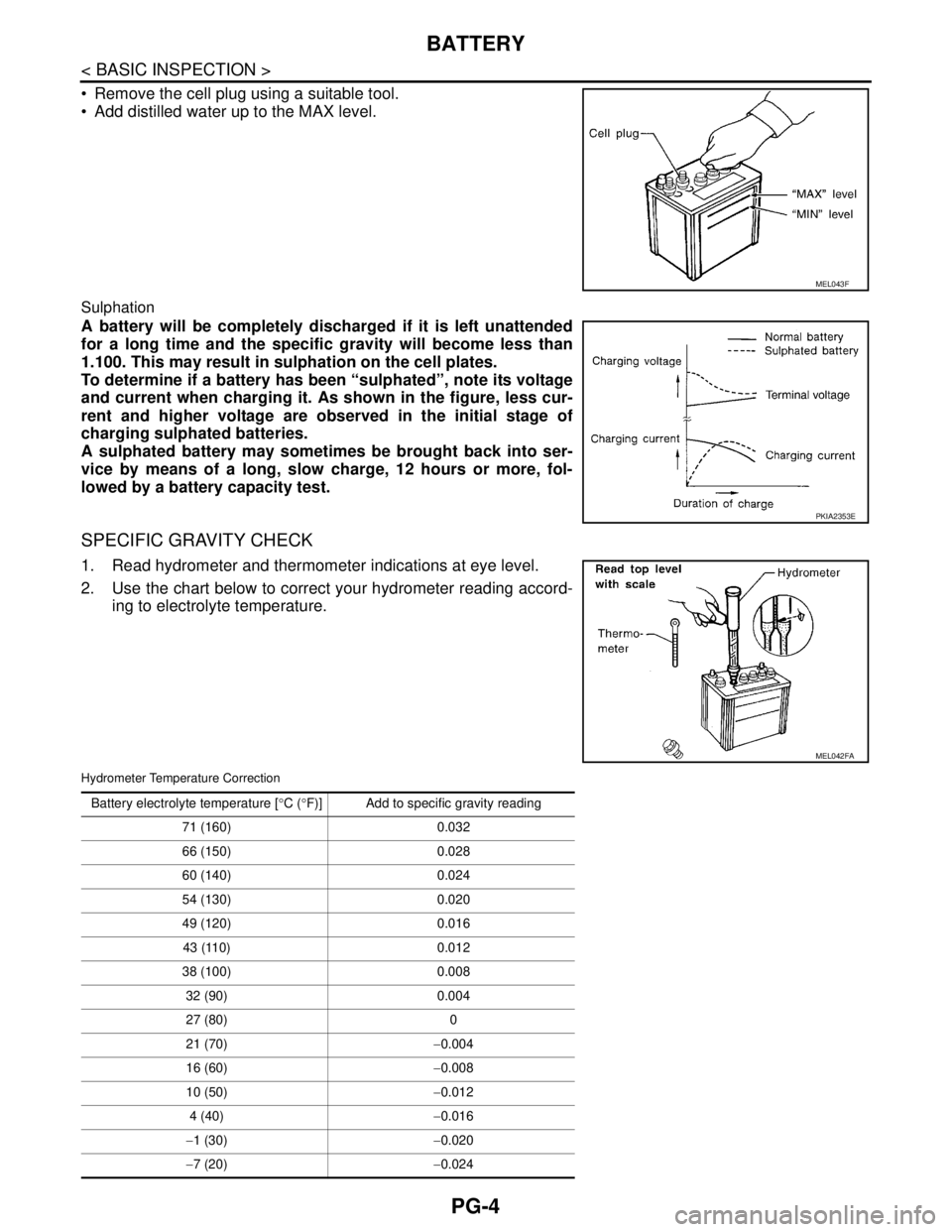

SPECIFIC GRAVITY CHECK

1. Read hydrometer and thermometer indications at eye level.

2. Use the chart below to correct your hydrometer reading accord-

ing to electrolyte temperature.

Hydrometer Temperature Correction

MEL043F

PKIA2353E

MEL042FA

Battery electrolyte temperature [°C (°F)] Add to specific gravity reading

71 (160) 0.032

66 (150) 0.028

60 (140) 0.024

54 (130) 0.020

49 (120) 0.016

43 (110) 0.012

38 (100) 0.008

32 (90) 0.004

27 (80) 0

21 (70)−0.004

16 (60)−0.008

10 (50)−0.012

4 (40)−0.016

−1 (30)−0.020

−7 (20)−0.024

Page 4460 of 5883

PG

BATTERY

PG-5

< BASIC INSPECTION >

C

D

E

F

G

H

I

J

K

L B A

O

P N

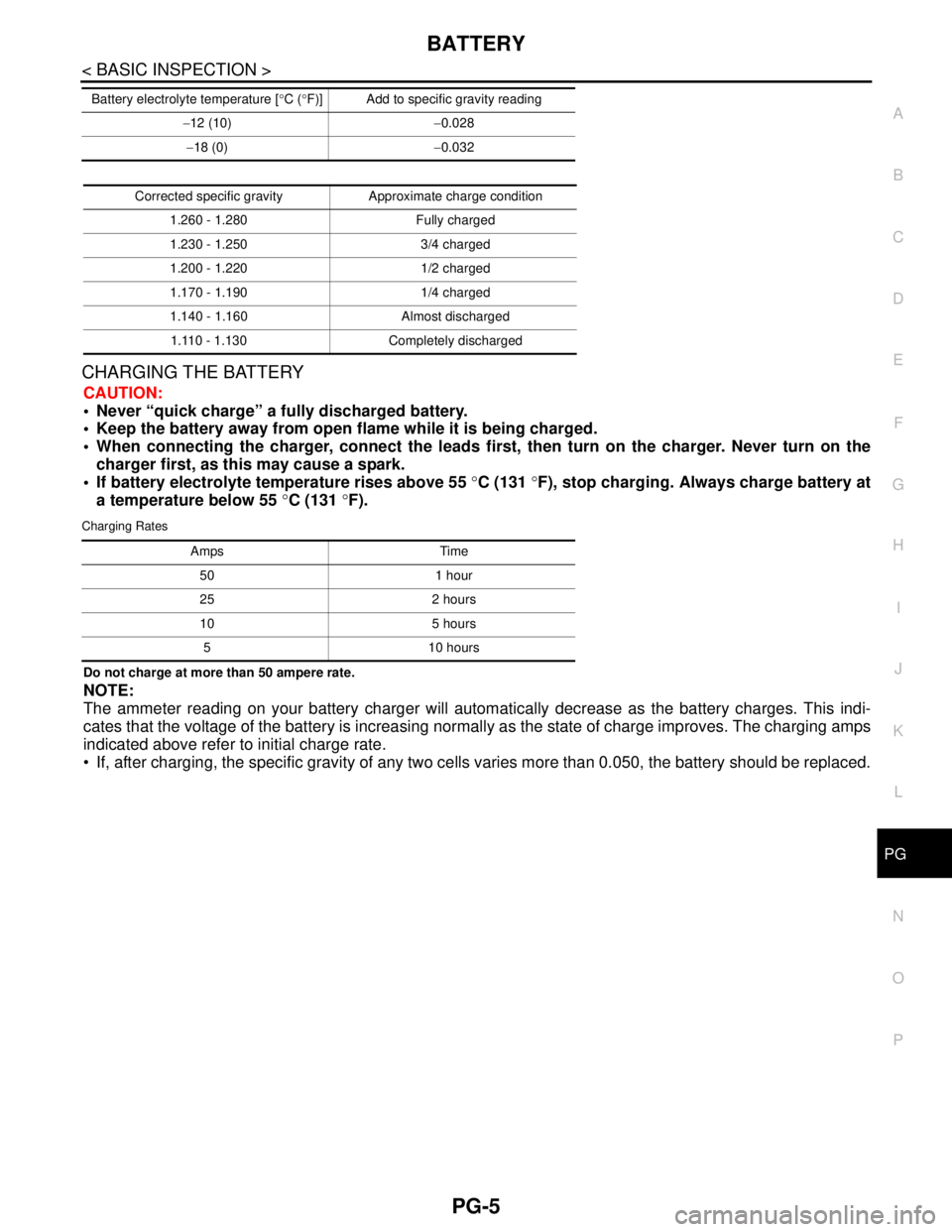

CHARGING THE BATTERY

CAUTION:

Never “quick charge” a fully discharged battery.

Keep the battery away from open flame while it is being charged.

When connecting the charger, connect the leads first, then turn on the charger. Never turn on the

charger first, as this may cause a spark.

If battery electrolyte temperature rises above 55 °C (131 °F), stop charging. Always charge battery at

a temperature below 55 °C (131 °F).

Charging Rates

Do not charge at more than 50 ampere rate.

NOTE:

The ammeter reading on your battery charger will automatically decrease as the battery charges. This indi-

cates that the voltage of the battery is increasing normally as the state of charge improves. The charging amps

indicated above refer to initial charge rate.

If, after charging, the specific gravity of any two cells varies more than 0.050, the battery should be replaced.

−12 (10)−0.028

−18 (0)−0.032 Battery electrolyte temperature [°C (°F)] Add to specific gravity reading

Corrected specific gravity Approximate charge condition

1.260 - 1.280 Fully charged

1.230 - 1.250 3/4 charged

1.200 - 1.220 1/2 charged

1.170 - 1.190 1/4 charged

1.140 - 1.160 Almost discharged

1.110 - 1.130 Completely discharged

Amps Time

50 1 hour

25 2 hours

10 5 hours

5 10 hours