OPEL FRONTERA 1998 Workshop Manual

Manufacturer: OPEL, Model Year: 1998, Model line: FRONTERA, Model: OPEL FRONTERA 1998Pages: 6000, PDF Size: 97 MB

Page 5731 of 6000

7A–42

AUTOMATIC TRANSMISSION (4L30–E)

8. Connect wiring harness to band control and shift

solenoids.

9. Install roller and spring assembly to manual detent.

Install two 13 mm screws, and tighten them to the

specified torque.

Torque: 20 N

m (2.0 kgꞏm/15 lb ft)

10. Install oil filter and three 13 mm screws. Tighten the

screws to the specified torque.

Torque : 20 N

m (2.0 kgꞏm/15 lb ft)

11. Install oil pan gasket, magnet, oil pan and sixteen 10

mm screws. Tighten the screws to the specified

torque.

Torque: 11 N

m (1.1 kgꞏm/96 lb in)

12. Install third crossmember and rear mount. Tighten the

bolts and nuts to the specified torque.

Torque

Third crossmember bolt:

76 N

m (7.8 kgꞏm/56 lb ft)

Rear mount nut: 50 N

m(5.1kgꞏm/37lbft)

13. Install exhaust pipe and connect oxygen sensor

connector. Tighten the bolts to the specified torque.

Exhaust pipe flange bolt torque:

43 N

m (4.4 kgꞏm/32 lb ft)

14. Install transfer and exhaust protectors. Tighten the

bolts to the specified torque.

Torque: 37 N

m (3.8 kgꞏm/27 lb ft)

15. Fill transmission through overfill screw hole of oil pan,

using ATF DEXRON

–III, refer to Changing

Transmission Fluid in this section.

16. Connect battery ground cable.

Page 5732 of 6000

7A–43 AUTOMATIC TRANSMISSION (4L30–E)

Valve Body Assembly (Adapter Case)

Removal

1. Raise the vehicle and support it on jack stands.

2. Disconnect battery ground cable.

3. Drain fluid.

4. Remove transfer and exhaust protectors.

5. Remove exhaust pipe and disconnect oxygen sensor

connector.

6. Remove twelve 10 mm adapter case oil pan fixing

screws, adapter case oil pan, and gasket.

NOTE: Oil pan still contains transmission fluid. Place a

large drain container under the oil pan.

Drain the fluid carefully.

7. Disconnect wiring harness from force motor solenoid

and converter clutch solenoid. Pull only on

connectors, not on wiring harness.

8. Remove seven 13 mm screws from adapter case

valve body assembly, then remove transfer plate, two

gaskets, and adapter case valve body.

Installation

1. Inspect electrical 5 pin connector and seal of adapter

case. Replace if necessary.2. Install gasket, transfer plate, and gasket.

3. Install adapter case valve body and seven 13 mm

screws. Tighten the screws to the specified torque.

To r q u e : 2 0 N

m (2.0 kgꞏm/15 lb ft)

4. Connect wiring harness assembly to converter clutch

solenoid and force motor.

5. Install oil pan gasket, oil pan, and twelve 10 mm

screws. Tighten the screws to the specified torque.

To r q u e : 11 N

m (1.1 kgꞏm/96 lb in)

6. Install exhaust pipe and connect oxygen sensor

connector. Tighten the bolts to the specified torque.

Exhaust pipe flange bolt torque:

43 N

m(4.4kgꞏm/32lbft)

7. Install transfer and exhaust protectors. Tighten the

bolts to the specified torque.

To r q u e : 3 7 N

m(3.8kgꞏm/27lbft)

8. Fill transmission through the overfill screw hole of oil

pan, using ATF DEXRON

–III. Refer to Changing

Transmission Fluid in this section.

9. Connect battery ground cable.

Powertrain Control Module (PCM)

Removal

1. Disconnect battery ground cable.

2. Remove front console.

3. Disconnect PCM wiring harness connectors from

PCM.

4. Remove three PCM retaining screws.

5. Remove two brackets from PCM.

826RV006

Installation

1. Install two brackets to PCM.

2. Install three PCM retaining screws.

3. Connect PCM wiring harness connectors to PCM.

4. Install front console.

5. Connect battery ground cable.

Page 5733 of 6000

7A–44

AUTOMATIC TRANSMISSION (4L30–E)

Speed Sensor (Extension Housing)

Removal

1. Disconnect battery ground cable.

2. Remove front console.

3. Remove selector lever assembly.

4. Disconnect speed sensor harness connector from

speed sensor.

5. Remove one 10 mm screw and speed sensor with

O–ring.

241RW007

Installation

1. Inspect the speed sensor O–ring, and replace it if

necessary.

2. Install speed sensor assembly and 10 mm screw.

To r q u e : 9 N

m (0.9 kgꞏm/78 lb in)

3. Connect speed sensor harness connector to speed

sensor.

4. Install selector lever assembly.

Adjust shift lock cable. Refer to Selector Lever in

this section.

5. Install front console.

6. Connect battery ground cable.

Transmission Oil Temperature Sensor (Adapter Case)

Removal

1. Raise the vehicle and support it on jack stands.

2. Disconnect battery ground cable.

3. Drain fluid.

4. Remove transfer and exhaust protectors.

5. Remove exhaust pipe and disconnect oxygen sensor

connector.

6. Remove twelve 10 mm adapter case oil pan fixing

screws, adapter case oil pan, and gasket.

NOTE: Oil pan still contains transmission fluid. Place a

large drain container under the oil pan, and drain the fluid

carefully.

7. Disconnect wiring harness from force motor solenoid,

converter clutch solenoid, and 5 pin connector of

adapter case. Pull only on connectors, not on wiring

harness.

8. Disconnect ground wire from converter clutch

solenoid wiring harness connector.9. Remove wiring harness assembly (transmission oil

temperature sensor).

243RW002

Page 5734 of 6000

7A–45 AUTOMATIC TRANSMISSION (4L30–E)

Installation

1. Connect ground wire to converter clutch solenoid

wiring harness connector of the wiring harness

assembly.

2. Install wiring harness assembly to converter clutch

solenoid, force motor, and 5 pin connector of adapter

case.

3. Install oil pan gasket, oil pan, and twelve 10 mm fixing

screws. Tighten the screws to the specified torque.

Torque: 11 N

m (1.1 kgꞏm/96 lb in)4. Install exhaust pipe and connect oxygen sensor

connector. Tighten the bolts to the specified torque.

Exhaust pipe flange bolt torque:

43 N

m(4.4kgꞏm/32lbft)

5. Install transfer and exhaust protectors. Tighten the

bolts to the specified torque.

To r q u e : 3 7 N

m (3.8 kgꞏm/27 lb ft)

6. Fill transmission through the overfill screw hole of oil

pan, using ATF DEXRON

–III.

Refer to Changing Transmission Fluid in this section.

7. Connect battery ground cable.

Front Oil Seal (Converter Housing)

Removal

1. Remove transmission assembly with transfer case

from the vehicle. Refer to Transmission (with Transfer

Case) in this section.

2. Remove torque converter from converter housing.

3. Remove three screws and oil seal ring from converter

housing.

241RW008

Installation

1. Apply clean ATF to the new oil seal ring lip.

Install oil seal ring to converter housing. Tighten the

screws to the specified torque.

To r q u e : 3 N

m (0.3 kgꞏm/26 lb in)

2. Install torque converter to converter housing.

3. Install transmission assembly with transfer case to

the vehicle. Refer to Transmission (with Transfer

Case) in this section.

Page 5735 of 6000

7A–46

AUTOMATIC TRANSMISSION (4L30–E)

Rear Oil Seal (Extension Housing)

Removal

1. Remove transfer case assembly from the vehicle.

Refer to Transfer Case in Drive Line/Axle section.

2. Remove rear oil seal from transmission extension

housing.

241RW005

Installation

1. Use 5–8840–2282–0 (J–36797) extension housing

oil seal installer, and install the rear oil seal to the

transmission extension housing.

2. Install the transfer case assembly to the vehicle.

Refer to Transfer Case in Drive Line/Axle section.

Transmission (4L30–E)

Disassembly

NOTE: During the disassembly and reassembly, perform

the following:

Wash each part thoroughly, and blow air through each

oil passage and groove to eliminate blockage.

Seal rings, roll pins, and gaskets should be replaced.

When assembling the components, apply

DEXRON

–III Automatic Transmission Fluid (ATF)

to each seal, rotating part, and sliding part.

Do not dip part facings, such as clutch or brake drive

plates, in cleaner when washing it.

Also, always coat parts with new ATF two or three

times after cleaning with solvent.

1. Remove torque converter (1).

Drain fluid from torque converter.

Attach 5–8840–2278–0 (J–8763–02) holding

fixture to the transmission and set it on

5–8840–0003–0 (J–3289–20) holding fixture base.

NOTE: Do not overtighten the tool, as case damage may

result.

420RW019

2. Remove O–ring (2) from turbine shaft.

3. Remove two 10mm mode switch screws, selector

lever nut, cover, and mode switch (3).

4. Remove twelve 10mm adapter case oil pan (4) fixing

screws, adapter oil pan, and gasket.

5. Disconnect electrical wiring connections (5) from

solenoids and 5 pin connector of adapter case. Pull

on connectors only, not on wiring harness.

Page 5736 of 6000

7A–47 AUTOMATIC TRANSMISSION (4L30–E)

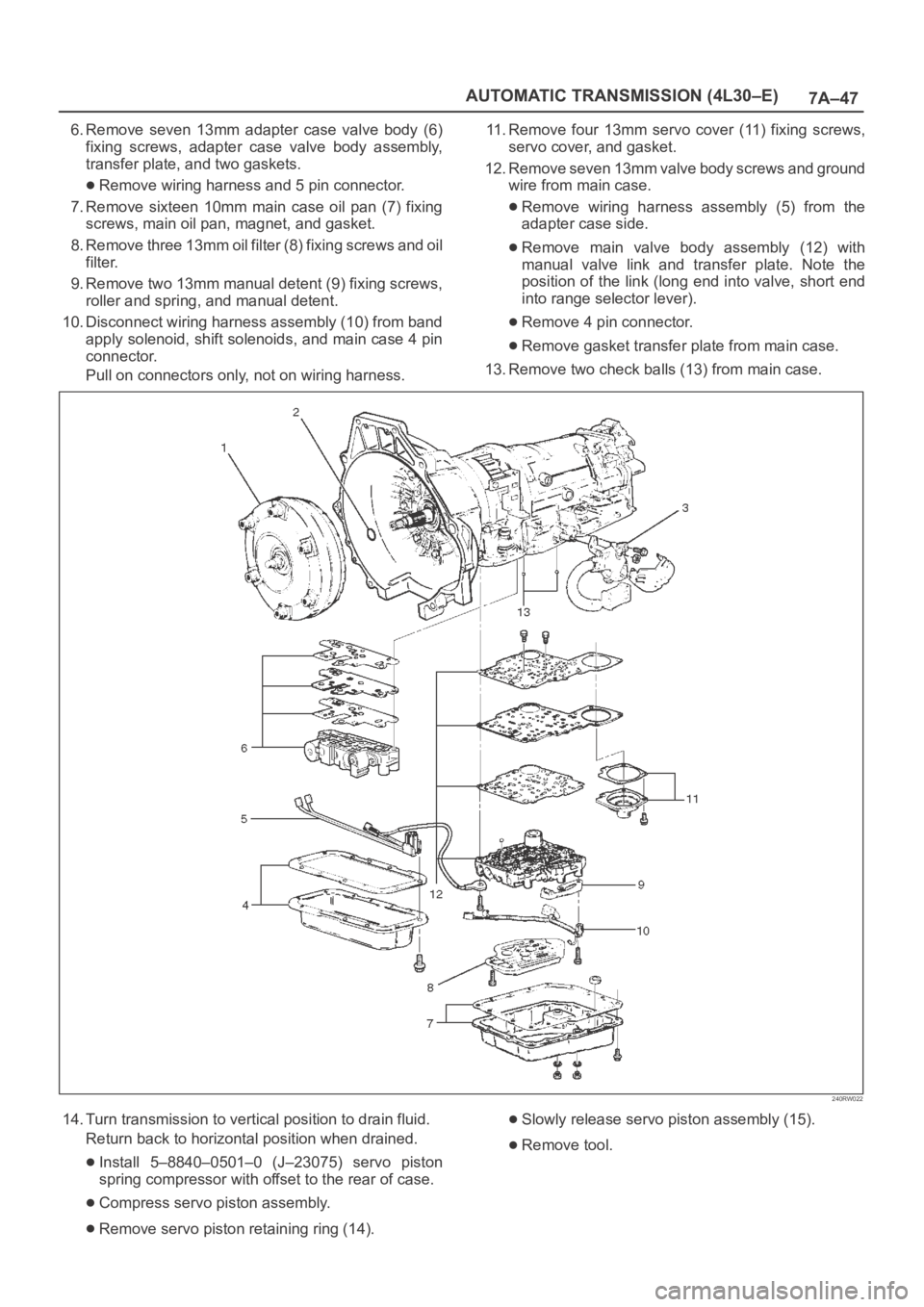

6. Remove seven 13mm adapter case valve body (6)

fixing screws, adapter case valve body assembly,

transfer plate, and two gaskets.

Remove wiring harness and 5 pin connector.

7. Remove sixteen 10mm main case oil pan (7) fixing

screws, main oil pan, magnet, and gasket.

8. Remove three 13mm oil filter (8) fixing screws and oil

filter.

9. Remove two 13mm manual detent (9) fixing screws,

roller and spring, and manual detent.

10. Disconnect wiring harness assembly (10) from band

apply solenoid, shift solenoids, and main case 4 pin

connector.

Pull on connectors only, not on wiring harness.11. Remove four 13mm servo cover (11) fixing screws,

servo cover, and gasket.

12. Remove seven 13mm valve body screws and ground

wire from main case.

Remove wiring harness assembly (5) from the

adapter case side.

Remove main valve body assembly (12) with

manual valve link and transfer plate. Note the

position of the link (long end into valve, short end

into range selector lever).

Remove 4 pin connector.

Remove gasket transfer plate from main case.

13. Remove two check balls (13) from main case.

240RW022

14. Turn transmission to vertical position to drain fluid.

Return back to horizontal position when drained.

Install 5–8840–0501–0 (J–23075) servo piston

spring compressor with offset to the rear of case.

Compress servo piston assembly.

Remove servo piston retaining ring (14).

Slowly release servo piston assembly (15).

Remove tool.

Page 5737 of 6000

7A–48

AUTOMATIC TRANSMISSION (4L30–E)

15. Remove servo piston assembly (15), return spring

(16), and servo apply rod (17).

242RW006

16. Rotate transmission to horizontal position, pan side

down.

Remove one 10mm screw, and speed sensor (18)

with “O” ring.

17. Remove seven 8mm extension housing hexagon

socket head screws, extension housing assembly

(19), and gasket.

18. Remove retaining ring (20).

NOTE: Use extra long, needle- nose pliers.19. Remove speed wheel (21).

20. Remove wheel parking lock (with seal ring) (22).

241RS002

21. Rotate transmission to vertical position, converter

housing up.

Loosen the converter housing and oil pump

assembly fixing screws, but do not remove the five

13 mm inner screws if oil pump disassembly is

required.

Remove seven outer screws.

Remove converter housing and oil pump assembly

(23).

22. Remove gasket (24).

Page 5738 of 6000

7A–49 AUTOMATIC TRANSMISSION (4L30–E)

23. Remove selective thrust washer (25).

241RW004

24. Remove fourth clutch retainer (26).

25. Grasp turbine shaft and lift out the overrun clutch

housing assembly (27) and fourth clutch plates (28).

26. Remove thrust bearing assembly (29).

27. Remove overdrive internal gear (30).28. Remove thrust washer (31).

252RS001

29. Remove adapter case and center support assembly

(with fourth clutch piston) (32).

30. Remove seal ring (33).

31. Remove selective thrust washer (34) and two O–ring

seals (35) from main case.

32. Use 5–8840–0195–0 (J–23327) and 5–8840–2263–0

(J–23327–90) compressor to compress the fourth

clutch spring retainer and springs (37).

Release snap ring (36) from groove.

Remove clutch compressor and snap ring (36).

33. Remove retainer and spring assembly (37).

34. Insert two converter housing/main case screws to

hold adapter case while pulling out fourth clutch

piston (38).

Remove fourth clutch piston assembly (38) from the

adapter case.

Remove converter housing/main case screws.

35. Grasp intermediate shaft, twist and pull out the

second and third clutch drum assemblies with reverse

clutch plates while holding onto output shaft (39).

Page 5739 of 6000

7A–50

AUTOMATIC TRANSMISSION (4L30–E)

36. Separate second (40) and third clutch (41)

assemblies.

37. Remove thrust washer (42).

38. Remove reverse clutch plates (43 and 44) and

reverse clutch pressure plate (45).

39. Remove bearing (46) and washer (47).

40. Remove planetary carrier assembly (48).

41. Remove thrust bearing (49).

42. Remove reaction sun gear (50)

43. Remove needle bearing (51).

44. Remove brake drum (52).

45. Remove brake band (53).

46. Remove thrust bearing (54).

242RS003

47. Rotate case to horizontal position, valve body side

facing up.

Remove spring pin (55), using cutting pliers, then

remove parking lock and selector lever assembly

(56).NOTE: Insert wire in the center of the spring pin to

prevent it from collapsing during removal. Be aware of pin

height. Protect machined face of main case.

48. Remove parking lock and range selector lever 17 mm

nut (57).

49. Remove parking lock and range selector lever (56),

and actuator assembly.

50. Remove selector shaft (58).

NOTE: Inspect the shaft for burrs before removing to

prevent damaging seal. If necessary, remove burrs by

lightly sanding with an oilstone.

249RS004

Reassembly

1. Inspect selector shaft seal, and replace it if

necessary.

NOTE: Use a seal installer when replacing the seal.

Install selector shaft.

NOTE: Spring pin groove must be positioned inside the

case.

2. Install spring pin. Be sure the selector shaft can move

freely. Do not push the pin flush with the case surface.

Leave enough height for removal.

3. Install actuator assembly (1).

4. Install parking lock and range selector lever (2) and

new 17 mm nut. Tighten the nut to the specified

torque.

To r q u e : 2 2 N

m (2.2 kgꞏm/16 lb ft)

Page 5740 of 6000

7A–51 AUTOMATIC TRANSMISSION (4L30–E)

249RS005

5. Rotate main case to vertical position, extension end

facing down.

Install brake band assembly (3).

NOTE: Be sure to align servo pin area with the servo hole.

6. Install thrust bearing (4).

NOTE: The case bushing acts as a guide for the thrust

bearing.

7. Install brake drum (5).

8. Install reaction sun gear (6).

9. Install needle bearing (7).

10. Inspect planetary carrier assembly (8) for wear and

damage. If necessary replace it.

Measure pinion end play clearance with a feeler

gauge.

Clearance: 0.13mm–0.89mm (0.005 in–0.035 in)

If clearance is outside specified value, replace the

planetary carrier assembly.

248RS001

11. Install the thrust bearing (9) on the output shaft.

NOTE: Use petroleum jelly to hold the thrust bearing in

place.

12. Align planetary pinions. Each pinion is marked with

double points to indicate the master tooth space and

exactly opposite with a single point to indicate the

master tooth. The markings on the planetary carrier

consist of double lines which are to be lined up with

the double points on two opposite pinions; the single

lines are to be lined up with the single points on the

other two pinions.

After all four pinions are lined up, slide on the third

clutch assembly. Rotate third clutch and check

mark alignment. Considering that the ring gear

tooth between the double points of one planetary

pinion is tooth number 1, count the teeth to check

that the single points on the two adjacent pinions

are between teeth 23 and 24 of the ring gear, and

that the ring gear tooth between the double points of

the opposite pinion is tooth number 46. If the ring

gear and pinions are not lined up, remove, and

realign them.

13. Install planetary carrier (8) with third clutch (12).

NOTE: Do not force. When properly aligned, the parts will

fit together easily.

248RS002

14. Remove the third clutch (12).

15. Install bearing (11) and washer (10).