OPEL GT-R 1973 Service Manual

Manufacturer: OPEL, Model Year: 1973, Model line: GT-R, Model: OPEL GT-R 1973Pages: 625, PDF Size: 17.22 MB

Page 341 of 625

6E- 501973 OPEL SERVICE MANUALMAINTENANCE AND ADJUSTMENTS

IDLE SPEED ADJUSTMENT

Note:

Idle speeds of 600 to 800 R.P.M. are normal

for engines with less than

3,ooO miles.Prior to making any adjustment to the carburetor,

the following items must be checked for proper oper-

ation and/or setting:

1. Valve Adjustment (Hydraulic lifters can be im-

properly adjusted.)

2. Dwell Angle.

3. Ignition Timing.

4. Spark Plug Gap.

5. Exhaust Gas Recirculation Valve (See “Check-

ing” under EXHAUST GAS RECIRCULATION

SYSTEM.)

After it has been ascertained that the above items are

properly adjusted and operating correctly and idle

R.P.M. is still not within specifications, proceed as

follows:

1. With air cleaner installed, run engine until normal

operating temperature is reached.

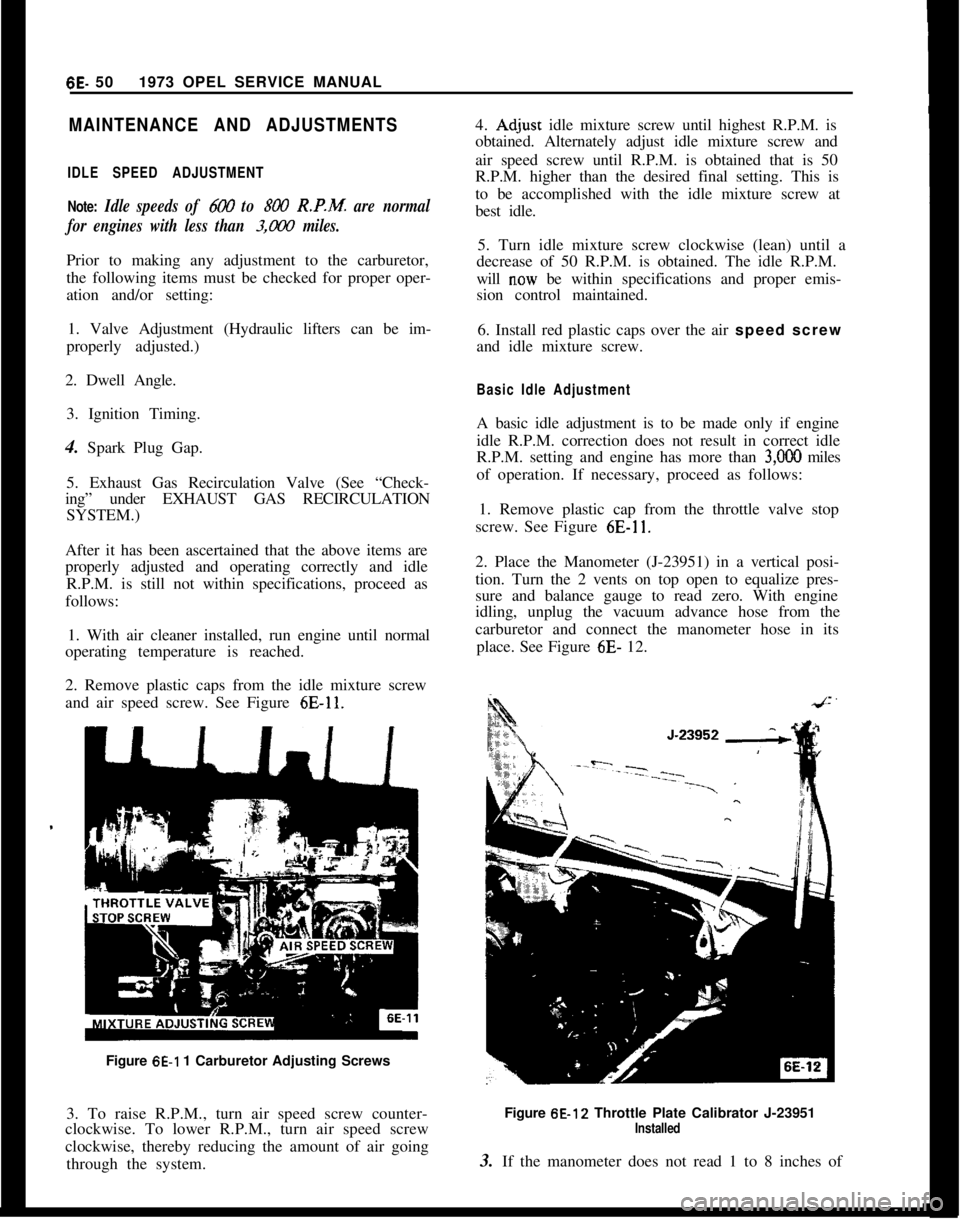

2. Remove plastic caps from the idle mixture screw

and air speed screw. See Figure

6E-11.Figure

6E-1 1 Carburetor Adjusting Screws

3. To raise R.P.M., turn air speed screw counter-

clockwise. To lower R.P.M., turn air speed screw

clockwise, thereby reducing the amount of air going

through the system.4.

Ad,just idle mixture screw until highest R.P.M. is

obtained. Alternately adjust idle mixture screw and

air speed screw until R.P.M. is obtained that is 50

R.P.M. higher than the desired final setting. This is

to be accomplished with the idle mixture screw at

best idle.

5. Turn idle mixture screw clockwise (lean) until a

decrease of 50 R.P.M. is obtained. The idle R.P.M.

will

n.ow be within specifications and proper emis-

sion control maintained.

6. Install red plastic caps over the air speed screw

and idle mixture screw.

Basic Idle AdjustmentA basic idle adjustment is to be made only if engine

idle R.P.M. correction does not result in correct idle

R.P.M. setting and engine has more than

3,OOO miles

of operation. If necessary, proceed as follows:

1. Remove plastic cap from the throttle valve stop

screw. See Figure

6E-11.2. Place the Manometer (J-23951) in a vertical posi-

tion. Turn the 2 vents on top open to equalize pres-

sure and balance gauge to read zero. With engine

idling, unplug the vacuum advance hose from the

carburetor and connect the manometer hose in its

place. See Figure 6E- 12.

Figure 6E-12 Throttle Plate Calibrator J-23951

Installed3. If the manometer does not read 1 to 8 inches of

Page 342 of 625

CARBURETOR AND THROTTLE LINKAGE6E- 51

water, adjust the throttle stop screw to read 6 inches

of water (3 inches down and 3 inches up).

4. Disconnect manometer and reconnect the vacuum

advance hose.

5. Adjust idle air speed screw and mixture screw to

obtain maximum idle at 850 to 900 R.P.M. (auto-

matic transmission) or 900 to 950 R.P.M. (manual

transmission).

6. Make final adjustment by turning idle mixture

screw in to reduce idle speed 50 R.P.M.

7. Install red plastic caps over the air speed screw

and idle mixture screw. Replace plastic cap over the

throttle valve stop screw and secure in place with

Loctite.

Fast Idle Speed Adjustment

1. Remove air cleaner cover.

2. With engine off, open the throttle halfway and

close the choke valve, release the throttle, then re-

lease the choke.

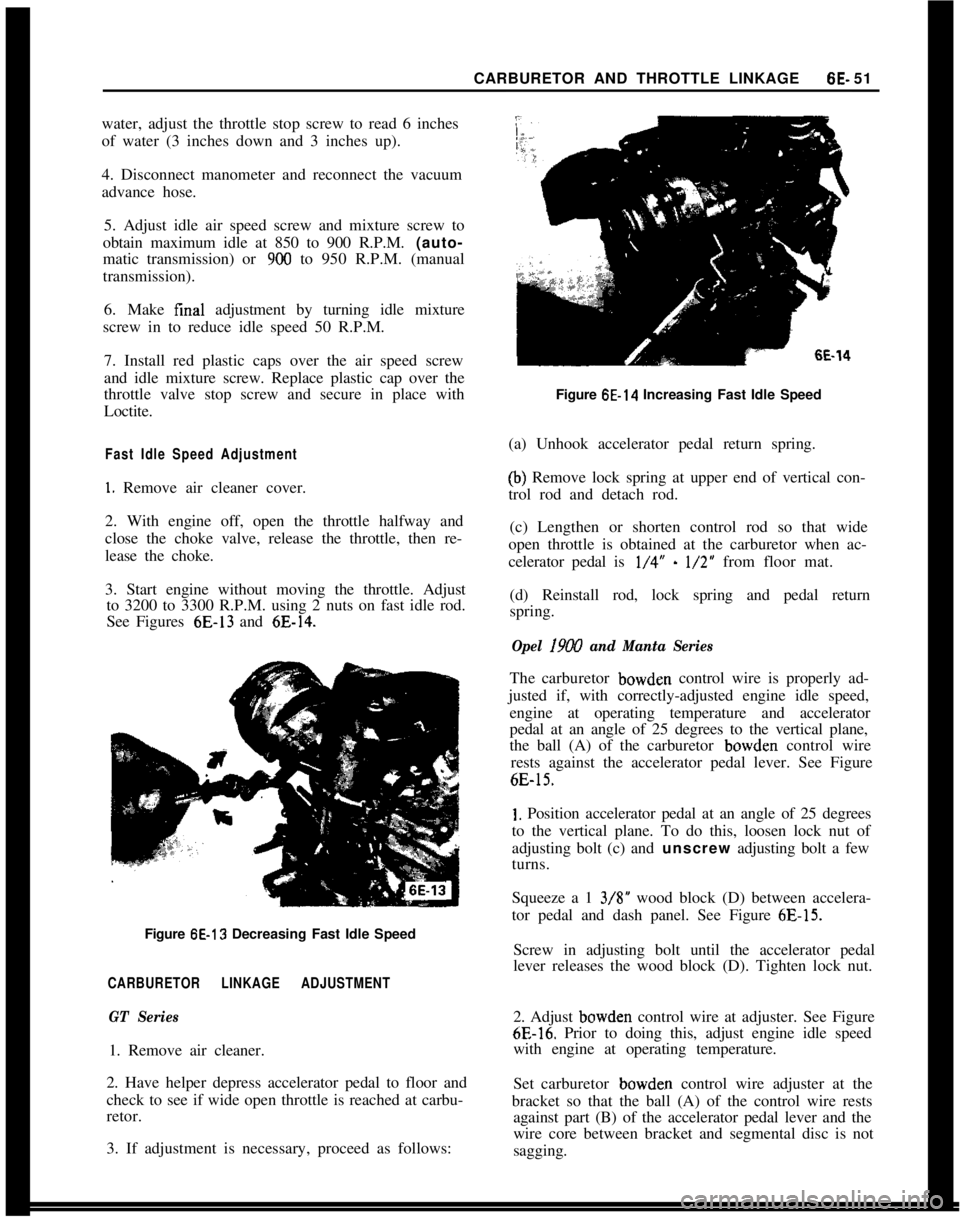

3. Start engine without moving the throttle. Adjust

to 3200 to 3300 R.P.M. using 2 nuts on fast idle rod.

See Figures 6E-13 and

6E-14.Figure

6E-13 Decreasing Fast Idle Speed

CARBURETOR LINKAGE ADJUSTMENT

GT Series1. Remove air cleaner.

2. Have helper depress accelerator pedal to floor and

check to see if wide open throttle is reached at carbu-

retor.

3. If adjustment is necessary, proceed as follows:

6E-14Figure

6E-14 Increasing Fast Idle Speed

(a) Unhook accelerator pedal return spring.

(b) Remove lock spring at upper end of vertical con-

trol rod and detach rod.

(c) Lengthen or shorten control rod so that wide

open throttle is obtained at the carburetor when ac-

celerator pedal is

l/4” - l/2” from floor mat.

(d) Reinstall rod, lock spring and pedal return

spring.

Opel 19W and Manta SeriesThe carburetor bowden control wire is properly ad-

justed if, with correctly-adjusted engine idle speed,

engine at operating temperature and accelerator

pedal at an angle of 25 degrees to the vertical plane,

the ball (A) of the carburetor bowden control wire

rests against the accelerator pedal lever. See Figure

6E-15.

1. Position accelerator pedal at an angle of 25 degrees

to the vertical plane. To do this, loosen lock nut of

adjusting bolt (c) and unscrew adjusting bolt a few

turns.

Squeeze a 1 3/S” wood block (D) between accelera-

tor pedal and dash panel. See Figure

6E-15.Screw in adjusting bolt until the accelerator pedal

lever releases the wood block (D). Tighten lock nut.

2. Adjust bowden control wire at adjuster. See Figure

6E-16. Prior to doing this, adjust engine idle speed

with engine at operating temperature.

Set carburetor bowden control wire adjuster at the

bracket so that the ball (A) of the control wire rests

against part (B) of the accelerator pedal lever and the

wire core between bracket and segmental disc is not

sagging.

Page 343 of 625

6E. 521973 OPEL SERVICE MANUAL

Figure 6E-15 Adjusting Accelerator Cable

Depress accelerator pedal until pedal lever touches

floor mat. The carburetor throttle valve must now be

completely opened.MAJOR REPAIR

REMOVE AND INSTALL CARBURETOR1. Remove air cleaner.

2. Remove fuel and vacuum hoses from carburetor

fittings.

3. Remove choke wire.Figure 6E-16

Bowden Control Wire Adjuster and

Segmental Disc

4. Disconnect throttle linkage by removing lock pin

and unsnapping ball socket from ball on end of throt-

tle shaft.

5. Remove carburetor by removing four nuts and

lockwashers.

Install in reverse order, noting the following:

1. Prior to carburetor insta!lation, place a new gasket

on intake manifold.

2. Make certain that all nuts and screws on the car-

buretor are securely tightened.

3. Make sure that choke housing is set on index and

that choke valve is nearly closed at room tempera-

ture. See Figure

6E-17. Make sure choke valve is free

in all positions.

Figure

LiE-17 Choke Housing Set on Index

Page 344 of 625

CARBURETOR AND THROTTLE LINKAGE6E- 63

4. Adjust engine idle speed and mixture

CAUTION: : Make sure choke valve opensfully before starting idle adjustment.

THROTTLE LINKAGE REMOVAL

Removal

Opel 1900 and Manta Series1. Remove control wire from bracket and unhook it

from segmental disc. See Figure

6E-16.2. In passenger compartment, unhook wire with ball

and plastic bushing from accelerator pedal lever. See

arrow in Figure 6E- 18.

Figure 6E.18 Unhook Wire in Passenger

Compartment3. In engine compartment, pull bowden control wire

out of bracket on dash panel.

If bowden control wire is kinked or damaged in any

way, it must be replaced.

1. Feed ball and plastic bushing from engine com-

partment through opening in dash panel and hook in

accelerator pedal lever. See Figure

6E-19.2. Lightly pull wire core so that the plastic bushing

slips into bore of accelerator pedal lever.

3. Hook bowden control wire in segmental disc and

attach control wire to bracket.Figure

6E-19 Installing Ball and Plastic Bushing

4. Adjust control wire.

OVERHAUL CARBURETORDisassembly

1. Remove outer nut from end of throttle lever to

choke link. See Figure

6E-20.

Figure 6E-20 Removing Choke Link

2. Pry off vacuum case connecting lever. See Figure

6E-2 1.3. Unscrew carburetor cover.

4. Screw float needle valve out of carburetor cover

and take off copper seal ring.

Page 345 of 625

6E- 541973 OPEL SERVICE MANUAL

Figure 6E-21 Removing Vacuum Case Lever

5. Unscrew vacuum diaphragm cover from choke

housing. See Figure

6E-22.Figure 6E-22 Removing Vacuum Diaphragm Cover

6. Unscrew retaining ring from automatic choke

body and take off cover.

7. Unscrew vacuum diaphragm case from carbu-

retor cover. Remove reduction jet. See Figure 6B23.

8. Take float together with spindle and leaf spring

from float chamber.

9. Pull accelerator pump discharge nozzle assemblyFigure 6E-23 Removing Vacuum Case Reduction Jet

out of carburetor housing. Nozzle is press fitted. See

Figure 6E-24.

GATOR PUMPISCHARGE NOZZLE

Figure 6E.24 Removing Accelerator Pump Discharge

10. Remove primary idle jets and secondary idle

plug. Remove primary and secondary high-speed air

jets.

11. Remove primary and secondary main metering

jets.

12. Remove cotter pin from pump connecting rod.

Remove accelerator pump.

13. Remove idle mixture adjusting screw from throt-

tle valve body. Remove idle air adjusting screw from

Page 346 of 625

CARBURETOR AND THROTTLE LINKAGE6E- 55

float chamber. Clean all parts and blow out with

compressed air. Replace gaskets and seal rings.

14. Check actuating parts in automatic choke body,

including diaphragm, for wear. Check pull rod for

free operation. See Figure 6E-25.15. Remove choke assembly by removing choke

valve and 2 choke housing

- to - carburetor screws.

Figure 6E-25 Checking Automatic Choke Parts

16. Check vacuum case assembly. If bushing is worn,

replace vacuum case assembly. See Figure 6B27.

Figure

6E-27 Checking Vacuum Case Brass Bushings

17. Install secondary vacuum diaphragm case assem-

bly. See Figure 6B28.

18. Install gasket and shield between automatic

choke cover and automatic choke body.Figure

6E-28 Installing Vacuum Case Assembly

19. Install automatic choke cover so that the catch

of the

b&metal spring is positioned onto bent end of

the intermediate lever. See Figure 6B29.

Figure 6G29 Installing Automatic Choke Cover

20. Align and tighten automatic choke cover. Choke

valve should be nearly closed at room temperature.

21. Check vent valve for free operation. Valve rod

must not be bent.

22. Screw in jets according to calibration table.

Never interchange parts of the primary and

second-

xy barrel. See Figure 6E-37.23. Install the throttle body to the bowl, using new

throttle body gasket. Adjust secondary throttle valve

gap by loosening lock nut on the secondary throttle

Page 347 of 625

6E- 561973 OPEL SERVICE MANUAL

valve stop screw. Loosen the stop screw until the

valve is completely closed. Turn the screw in l/4turn from closed position, hold, and tighten lock nut.

This is done to insure that the throttle blade will not

stick closed. See Figure

6E-30.PUMPFigure 6E-30 Adjusting Secondary Throttle Valve Gap

24. Install accelerator pump connecting rod in lower

hole of primary throttle shaft lever and cotter pin in

outboard hole at accelerator pump actuating lever

end. Paying attention to proper arrangement of cot-

ter pin and washers. See Figure

6E-2.25. With throttle plate completely closed, there

should be no clearance between the pump levei and

the pump plunger rod.

26. If a clearance is present, loosen 4 accelerator

Figure

6E-31 Accelerator Pump CoverFigure 6C32 Accelerator Pump Cover

pump cover retaining screws and allow the

dia-’phragm spring to push plunger against lever so that

a zero clearance exists. Then retighten the screws.

See Figures

6E-3 1 and 6E-32.27. Insert accelerator pump discharge nozzle so that

the bent tube end points into suction channel of the

primary barrel.

28. Fill the bowl with fuel.

29. With fuel in bowl, slowly open the throttle and

observe the accelerator pump pressure relief valve

exhaust ports and where it seats into the bowl. See

Figure

6E-33. Fuel should not be bleeding back into

the bowl from the exhaust ports or where the relief

valve seats, but a steady stream of fuel should dis-

charge from the discharge nozzle.

30. With fuel in bowl, rapidly open the throttle atid

observe the exhaust ports of the pressure relief valve.

See Figure

6E-33. Fuel should~exhaust’from the ac-

celerator pump pressure relief valve exhaust ports.

3 1. If the pressure relief valve malfunctions, remove

it and replace with a new one.

32. No float adjustment is possible, so check position

of float arm by comparing with a new float of thesame carburetor type. If float arm is bent, replace

float.

Page 348 of 625

CARBURETOR AND THROTTLE LINKAGE6E- 57

ACCELERATOR PUMP

PRESSURE RELIEF

VALVE SEAT

ALVE

VENT DISCHARGE

(AIR BUBBLES FROM THIS

HOLE

IS NORMAL)

PUMP INLET

VALVE EXHAUST

PORT

--6E-33

Figure 6E-33 Carburetor Fuel Bowl

33. Install float and pivot rod making sure rod is

seated in casting.36. Install new air horn gasket so that the holes in

the gasket coincide with the screw holes in carbu-

retor housing. See Figure

6E-35.34. Install leaf spring so that spring ends rest on float

spindle. See Figure

6E-34.37. On vent valve, pay attention to cotter pin position

and arrangement of washers.

3.5. Screw in float needle valve together with copper38. Basic adjustment of idle mixture adjusting screw

seal ring

(.08 in. thick).is 5 turns open.

Page 349 of 625

6E- 581973 OPEL SERVICE MANUAL

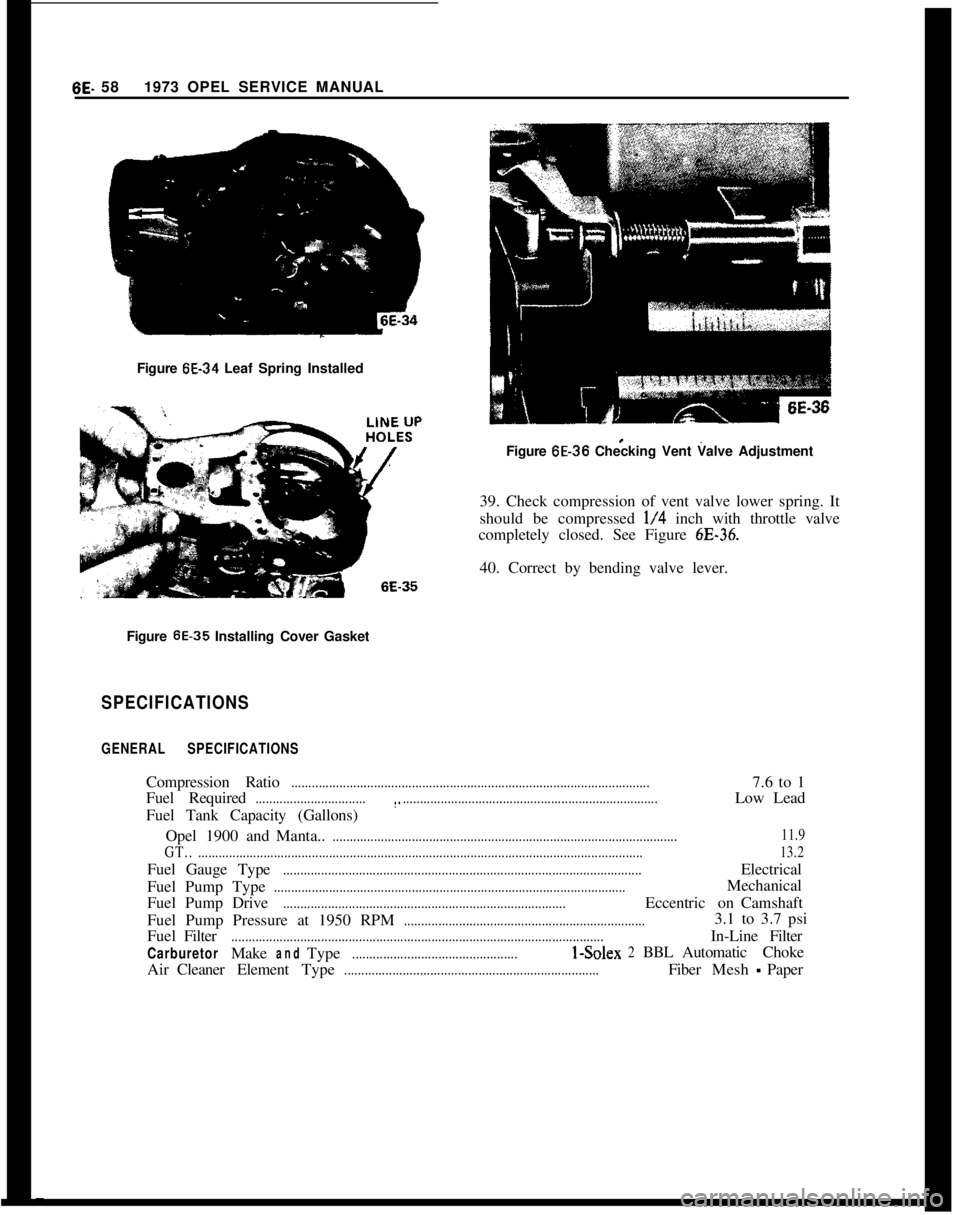

Figure 6E-34 Leaf Spring Installed

1 6E-36

Figure 6E-36 Checking Vent Valve Adjustment

39. Check compression of vent valve lower spring. It

should be compressed

l/4 inch with throttle valve

completely closed. See Figure

6E-36.40. Correct by bending valve lever.

Figure

6E-35 Installing Cover Gasket

SPECIFICATIONS

GENERAL SPECIFICATIONSCompression Ratio

........................................................................................................7.6 to 1

Fuel Required

................................(...........................................................................Low Lead

Fuel Tank Capacity (Gallons)

Opel1900andManta..

....................................................................................................11.9

GT...................................................................................................................................13.2Fuel Gauge Type

........................................................................................................Electrical

FuelPumpType

......................................................................................................Mechanical

FuelPumpDrive

..................................................................................EccentriconCamshaft

Fuel Pump Pressure at 1950 RPM

......................................................................3.1 to 3.7 psi

FuelFilter

............................................................................................................In-LineFilter

CarburetorMakeandType................................................I-Solex2BBLAutomaticChoke

AirCleanerElementType

..........................................................................FiberMesh-Paper

Page 350 of 625

CARBURETOR AND THROTTLE LINKAGE6E- 59

Figure 6E-37 Carburetor Specifications