OPEL GT-R 1973 Manual Online

Manufacturer: OPEL, Model Year: 1973, Model line: GT-R, Model: OPEL GT-R 1973Pages: 625, PDF Size: 17.22 MB

Page 81 of 625

/

I1 H- 601973 OPEL SEW& MANUAL

1. Remove headlight switch button by depressing

retaining clip on shaft and pulling back on switch

knob. See Figure lH-3.

Figure 1 H-5

- Removing Cluster Screws

Figure lH-3

- Removing Headlight Switch Knob,

2. Remove two (2) plugs on cluster panel. See FigurelH-4.301H6

-Figure 1 H-4 Removing Plugs

3. Remove two (2) sheet metal screws behind plugs

on cluster. See Figure lH-5.

4. Pull off heater control knobs toward front.

j5. On top, carefully pull instrument ‘trim plate

:to-wards steering wheel and remove plate.

6. Remove two screws for lower housing

attach&t.See Figure lH-6.Figure 1 H-6 Lower Housing Attaching Screws

7. Disconnect speed0 cable at cluster by turning cou-

pling counterclockwise.

8. If equipped, pull heated rear window or fog lamp

switch out of instrument housing and disconnect

wires from switches.

9. Pull cluster right and left sides partially out and

disconnect wires on back of cluster. See Figure lH-7.

Installation

1.

P&e instrument cluster in position and connect

wires on back of cluster.

2. Pull fog light or heated back glass switch wires

into opening, if equipped, and connect wires and

replace switch.

3. Connect two screws on lower housing attachment.

Page 82 of 625

I

I

IINSTRUMENT PANELlH- 61Figwe 1 H-7

- Disconnecting Cluster Wires

4. Install instrument cluster trim plate and replace

two screw and plugs.

5. Con&t speed0 cable by turning coupling clock-

wise. 1

6. Install light

.switch button and heater control

knobs. I

I

7. Con+ct battery cable.

Removidg Windshield Wiper Switch - Opel 1900Manta I

1.

Rem* instrument cluster trim plate.

2. Corndress retaining clips and remove switch. See

Figure iH-8.

I

Figure lH-8 . Removing Windshield Wiper Switch3. Disconnect wiring connector.

Installation1. Connect wiring to switch.

2. Snap switch back into panel.

3. Replace instrument cluster trim plate.

Removing Instrument Cluster Bulbs - Opel 1900.

Manta1. Remove instrument cluster assembly.

2. Replace bulbs from back ofcluster. See Figure

lH-

9.Figure lH-9 Removing Instrument

Clu’ster Bulbs

Installation1. Replace bulbs in cluster.

2. Replace instrument cluster assembly.

Removing and Installing Ignition SwitchRefer to Group 3, Section F.

Removal of Instrument Cluster Housing Assembly.

GTDisconnect battery before making any electrical re-

pairs.

1. Disconnect battery cable.

2. Remove right access cover and remove screw. See

Figure lH-10.

Page 83 of 625

1 H- 62 1973 OPEL SERVICE, MANUAL

4. Remove flasher unit. See Figure IH-12.

5. Position steering so that wheels are straight ahead.

6. Pull off heads of both tear bolts by first drilling a3/16 inch pilot hole and then using a stud extractor

to remove tear bolts. See Figure lH-13.

Figure 1 H-10 Removing Right Aicess Cover andSWW3. Remove left access cover and f”rnove screw. See

Figure lH-11.

Figure 1 H-l 3 Steering Column Attaching Bolts

7. Disconnect ignition (white) and directional signal

(black) wire set plugs.

8. Support steering column assembly and remove

both hex head bolts. See Figure lH-13.

9. Drop steering column assembly to floor.

10. Disconnect speedometer cable.

11. Remove six (6) screws on instrument cluster. See

Figure

lH- 14.

Figure lli-1 1 Removing Left Access Cover and

SC&Figure lH-14 Instrument Cluster Screws

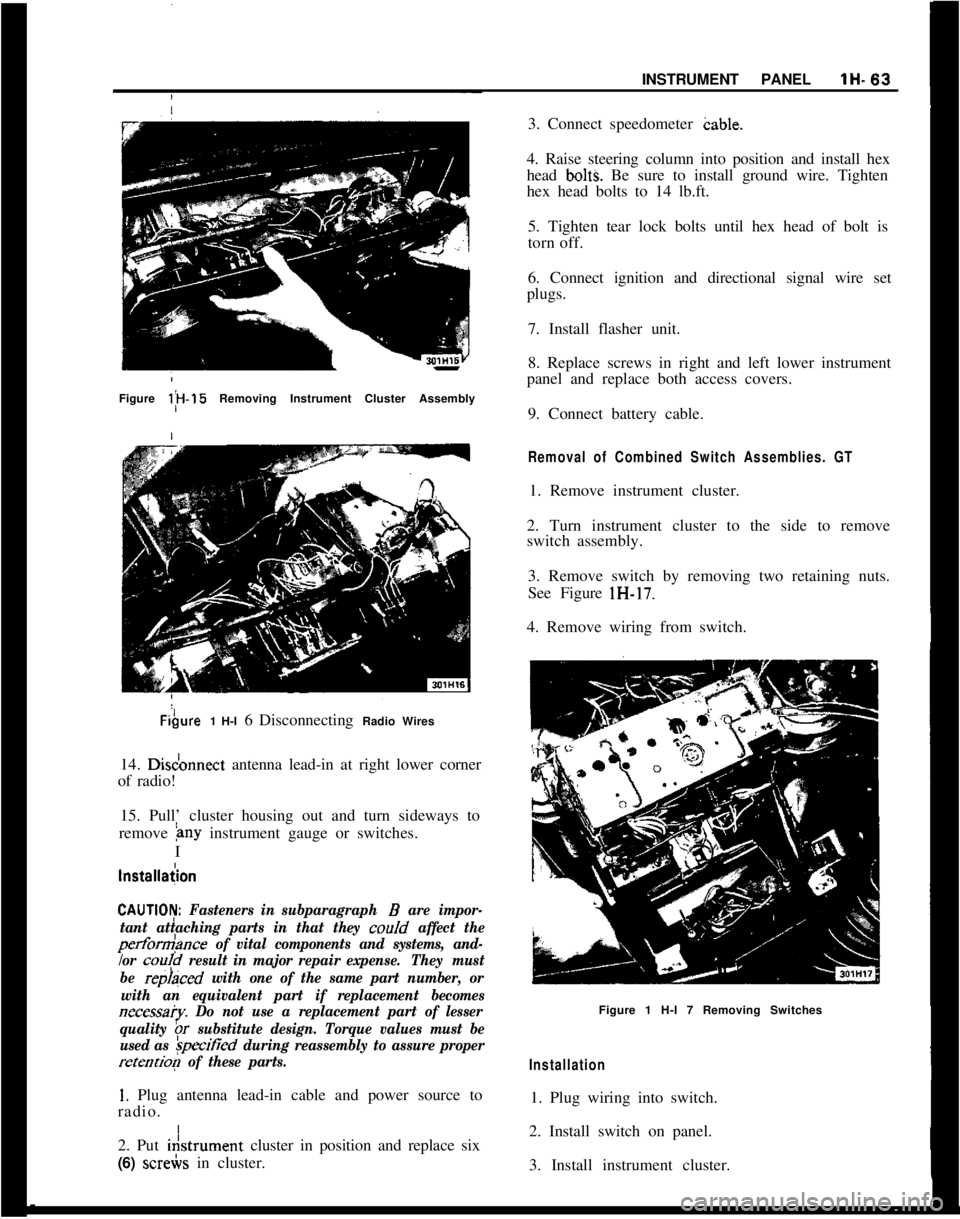

12. Pull back on instrument cluster from top to

remove. See Figure lH-15.

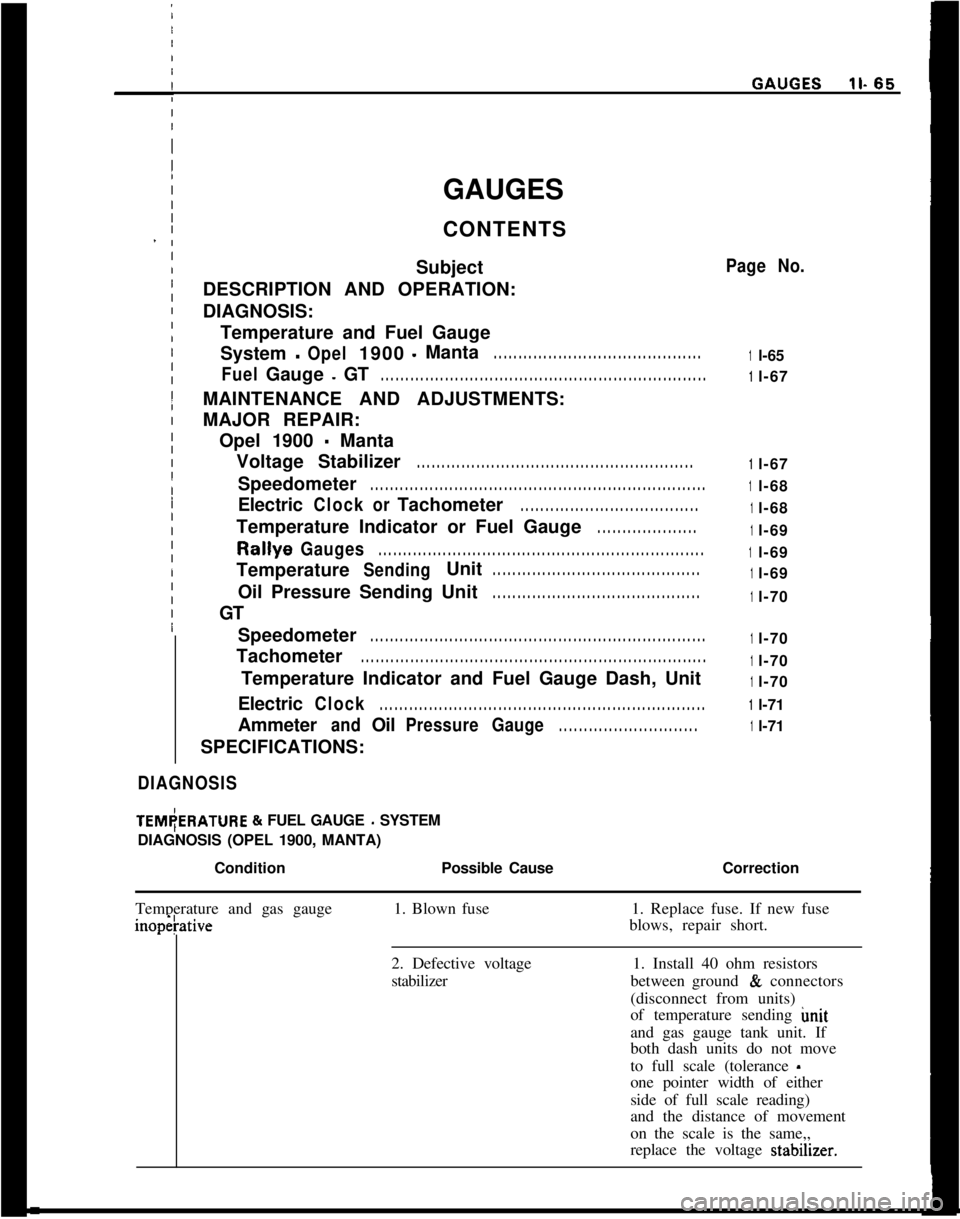

Figure l H-12 Flasher Unit Installed13. Disconnect wires on back of radio. See FigurelH-16.

Page 84 of 625

I

,INSTRUMENT PANELlH-63Figure l;H-15 Removing Instrument Cluster AssemblyFibure1 H-l 6 Disconnecting Radio Wires

14. Disdonnect antenna lead-in at right lower corner

of radio!

15. Pull’ cluster housing out and turn sideways to

remove

&~y instrument gauge or switches.

I

lnstallaiion

CAUTlOI$ Fasteners in subparagraph B are impor-

tant attaching parts in that they coo/d

affect the

perform>nce of vital components and systems, and-

/or

cou!d result in major repair expense.They must

be

repraced with one of the same part number, or

with an equivalent part if replacement becomes

necessa?y. Do not use a replacement part of lesser

quality

br substitute design. Torque values must be

used as

&ified during reassembly to assure proper

retention of these parts.

1. Plug antenna lead-in cable and power source to

radio. I

2. Put i&trument cluster in position and replace six

(6) screbs in cluster.3. Connect speedometer cable.

4. Raise steering column into position and install hex

head

bolt% Be sure to install ground wire. Tighten

hex head bolts to 14 lb.ft.

5. Tighten tear lock bolts until hex head of bolt is

torn off.

6. Connect ignition and directional signal wire set

plugs.

7. Install flasher unit.

8. Replace screws in right and left lower instrument

panel and replace both access covers.

9. Connect battery cable.

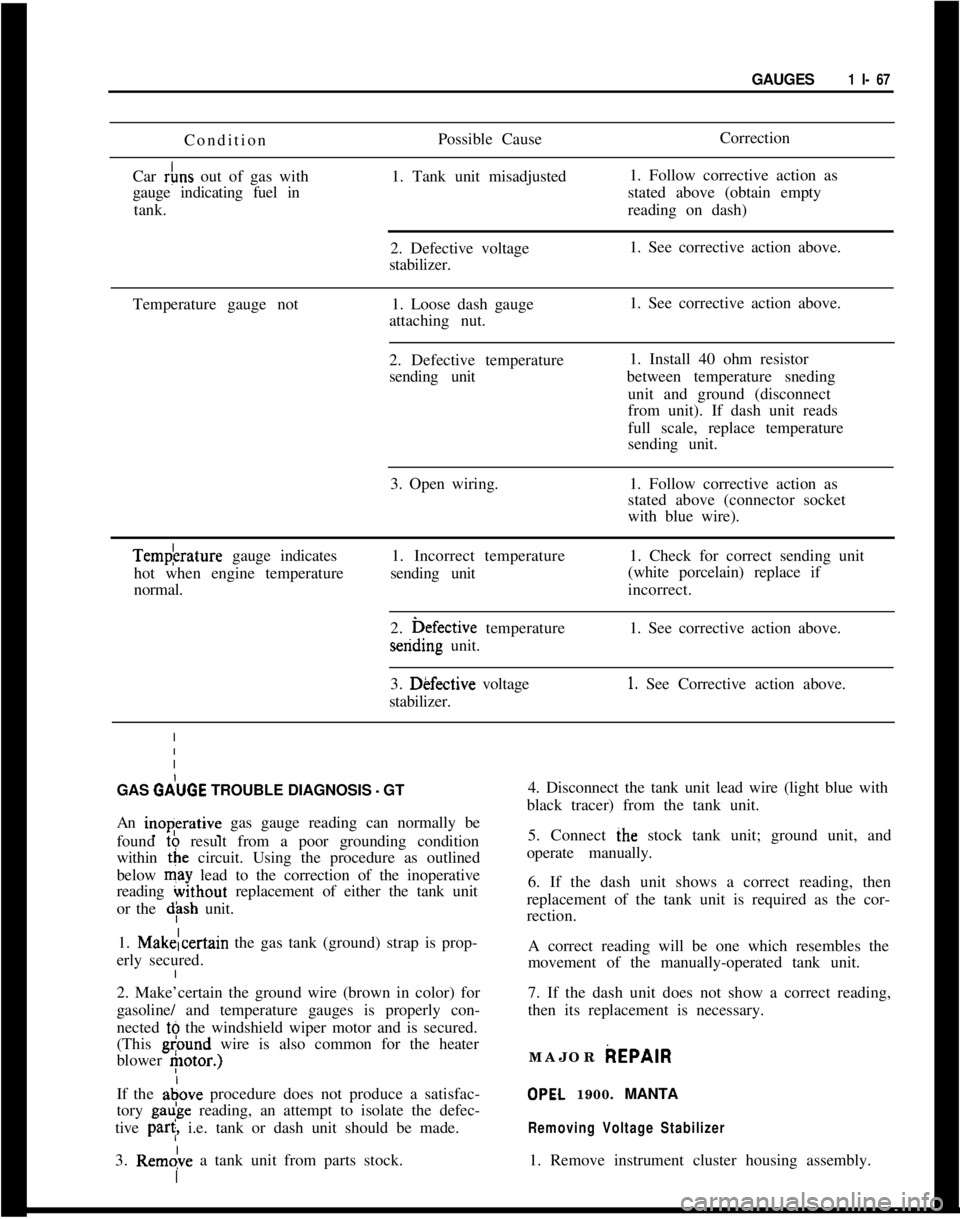

Removal of Combined Switch Assemblies. GT1. Remove instrument cluster.

2. Turn instrument cluster to the side to remove

switch assembly.

3. Remove switch by removing two retaining nuts.

See Figure lH-17.

4. Remove wiring from switch.

Figure 1 H-l 7 Removing Switches

Installation1. Plug wiring into switch.

2. Install switch on panel.

3. Install instrument cluster.

Page 85 of 625

lti- 64 1973 OPEL SERVICE MANUALj

Removal of Cigar Lighter GT/

1. Remove instrument housing.I

’ 2. Disconnect electrical wire.

3. Remove hex nut on back of cigar lighter

base’.’4. Remove cigar lighter base.

Installation1. Install cigar lighter base.

2. Install hex nut on back of lighter base.

3. Connect wire to lighter.

4. Replace instrument cluster.

Page 86 of 625

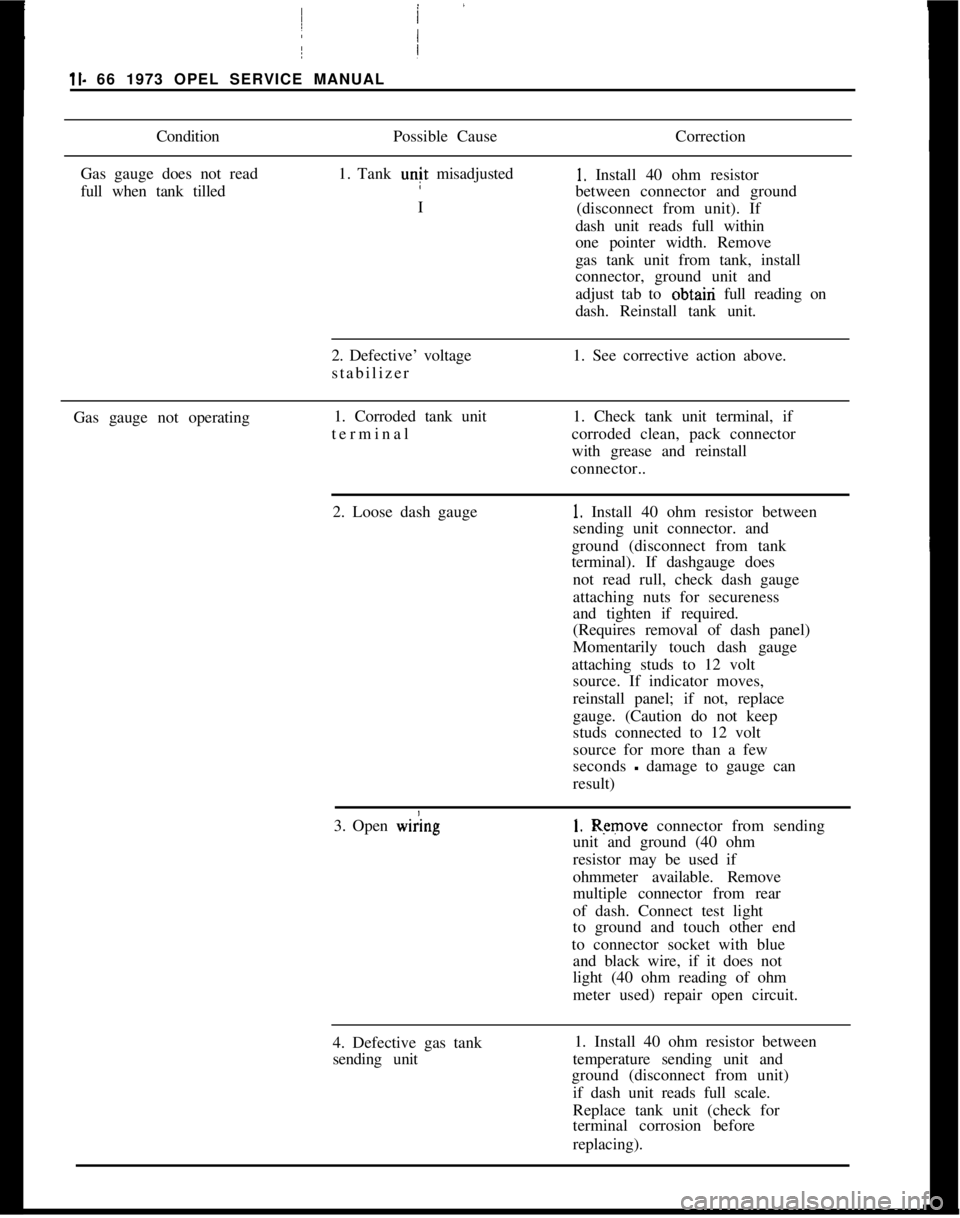

GAUGES

CONTENTS

Subject

DESCRIPTION AND OPERATION:

DIAGNOSIS:

Temperature and Fuel Gauge

System-Opel1900-Manta. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

FuelGauge-GT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .MAINTENANCE AND ADJUSTMENTS:

MAJOR REPAIR:

Opel 1900

- Manta

Voltage Stabilizer

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Speedometer

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Electric

ClockorTachometer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Temperature Indicator or Fuel Gauge

. . . . . . . . . . . . . . . . . . . .Rallye

Gauges. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Temperature

SendingUnit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Oil Pressure Sending Unit

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .GT

Speedometer

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Tachometer

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Temperature Indicator and Fuel Gauge Dash, Unit

Electric

Clock. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Ammeter

andOilPressureGauge. . . . . . . . . . . . . . . . . . . . . . . . . . . .SPECIFICATIONS:

DIAGNOSISITEM(ERATURE

& FUEL GAUGE - SYSTEM

DIAGNOSIS (OPEL 1900, MANTA)

/

ConditionPossible Cause

I

Page No.

1l-65

1l-67

1l-67

1l-68

1l-68

1l-69

1l-69

1l-69

1l-70

1l-70

1l-70

1l-70

1l-71

1l-71

Correction

Temperature and gas gaugeinopetative1. Blown fuse1. Replace fuse. If new fuse

blows, repair short.

2. Defective voltage

stabilizer1. Install 40 ohm resistors

between ground

& connectors

(disconnect from units)

of temperature sending imit

and gas gauge tank unit. If

both dash units do not move

to full scale (tolerance

-one pointer width of either

side of full scale reading)

and the distance of movement

on the scale is the same,,

replace the voltage stabdner.

Page 87 of 625

ll- 66 1973 OPEL SERVICE MANUALi

ConditionPossible CauseCorrection

Gas gauge does not read

full when tank tilled1. Tank unit misadjusted1. Install 40 ohm resistor

between connector and ground

I

(disconnect from unit). If

dash unit reads full within

one pointer width. Remove

/

Igas tank unit from tank, install

connector, ground unit and

adjust tab to obtairi full reading on

dash. Reinstall tank unit.

2. Defective’ voltage

stabilizer1. See corrective action above.

Gas gauge not operating1. Corroded tank unit

terminal I1. Check tank unit terminal, if

corroded clean, pack connector

with grease and reinstall

connector..

2. Loose dash gauge

!

1. Install 40 ohm resistor between

sending unit connector. and

ground (disconnect from tank

terminal). If dashgauge does

not read rull, check dash gauge

attaching nuts for secureness

and tighten if required.

(Requires removal of dash panel)

Momentarily touch dash gauge

attaching studs to 12 volt

source. If indicator moves,

reinstall panel; if not, replace

gauge. (Caution do not keep

studs connected to 12 volt

source for more than a few

seconds

- damage to gauge can

result)

3. Open

w&g1. Remove connector from sending

unit and ground (40 ohm

resistor may be used if

ohmmeter available. Remove

multiple connector from rear

of dash. Connect test light

to ground and touch other end

to connector socket with blue

and black wire, if it does not

light (40 ohm reading of ohm

meter used) repair open circuit.

4. Defective gas tank

sending unit1. Install 40 ohm resistor between

temperature sending unit and

ground (disconnect from unit)

if dash unit reads full scale.

Replace tank unit (check for

terminal corrosion before

replacing).

Page 88 of 625

I

GAUGES1 I- 67I

I Condition

Car

&s out of gas with

gauge indicating fuel in

tank. 1

I

I

I

I

IPossible Cause

1. Tank unit misadjusted

2. Defective voltage

stabilizer.Correction

1. Follow corrective action as

stated above (obtain empty

reading on dash)

1. See corrective action above.

Temperature gauge not1. Loose dash gauge1. See corrective action above.

Iattaching nut.

I

I

I2. Defective temperature1. Install 40 ohm resistor

Isending unitbetween temperature sneding

Iunit and ground (disconnect

I

from unit). If dash unit reads

I

full scale, replace temperature

Isending unit.

I

I

I3. Open wiring.1. Follow corrective action as

Istated above (connector socket

Iwith blue wire).Tempkrature gauge indicates

hot when engine temperature1. Incorrect temperature1. Check for correct sending unit

sending unit

normal.(white porcelain) replace if

incorrect.

2. i>efective temperaturesending unit.1. See corrective action above.

3. Dkfective voltage

stabilizer.

1. See Corrective action above.

GAS

GdUGE TROUBLE DIAGNOSIS - GT4. Disconnect the tank unit lead wire (light blue with

black tracer) from the tank unit.

An inoperative gas gauge reading can normally be

found to result from a poor grounding condition

within the circuit. Using the procedure as outlined

below may lead to the correction of the inoperative

reading without replacement of either the tank unit

or the

dph unit.5. Connect ihe stock tank unit; ground unit, and

operate manually.

6. If the dash unit shows a correct reading, then

replacement of the tank unit is required as the cor-

rection.

1. Makelcertain the gas tank (ground) strap is prop-

erly secured.A correct reading will be one which resembles the

movement of the manually-operated tank unit.

2. Make’certain the ground wire (brown in color) for

gasoline/ and temperature gauges is properly con-

nected tb the windshield wiper motor and is secured.

(This

gl?ound wire is also common for the heater

blower

etor.)7. If the dash unit does not show a correct reading,

then its replacement is necessary.

If the adove procedure does not produce a satisfac-

tory gaube reading, an attempt to isolate the defec-

tive

par<, i.e. tank or dash unit should be made.

3. Rem&e a tank unit from parts stock.MAJOR

AEPAIR

OPEL 1900. MANTA

Removing Voltage Stabilizer1. Remove instrument cluster housing assembly.

Page 89 of 625

1 I- 68 1973 OPEL SERVICE MANUAL

2. Pull voltage stabilizer of back of printed circhit.

See Figure

11-l.

!

L-_ -~~---,~. _^__, _-_~

Figure 1 l-3 - Speedometer Attaching Screws

Figure

11-l -Voltage Stabilizer

installation

2. Install six (6) screws holding instrument cluster

lens in housing.

3. Replace cluster housing.

1. Install voltage stabilizer on

back of printed circuit.

2. Install instrument cluster

ho*sing assembly. j

I

Removing Speedometer I

1. Remove instrument cluster housing.:

2. Remove six screws shown in Figure

11-2 and

remove both instrument

cluster’lens.

Figure 1 l-2 - Removing Instrument Cluster Lens

3. Remove three speedometer attaching screws. L&X

Figure 11-3.

/

Installation

1. Replace speedometer in cluster with three (3) at-

taching screws.

Removing Electric Clock or Tachometer

1. Remove instrument housing.

2. Remove six screws and remove both instrument

cluster lens, as shown in Figure

11-2.

3. Remove three screws, as shown in Figure 11-4, and

remove clock or tachometer.

L-u-.------ _._- -----G1.-A-... -.

Figure 1 l-4 - Removing Electric Clock or Tachometer

1. Install clock or tachometer in instrument cluster

with three (3) attaching screws.

2. Install six (6) screws holding instrument cluster

lens.

Page 90 of 625

I

IGAUGES1 I- 69

I

I

3. Replace instrument housing.InstallationFiemoving~Temperature Indicator or Fuel Gauge

1. Remov+ instrument cluster housing.

2. Remov; six screws and remove both instrument

cluster

le+ See Figure 11-2.3. Pull v&age stabilizer off printed circuit and

remove fohr instrument attaching screws, as shown

in Figure

111-5.Figure

11-5 Removing Four Instrument Attaching\SCWWS

4. Take temperature or fuel gauge out of clusterlnstallatidn

1. Install itemperature or fuel gauge in cluster.

2. Replack voltage stabilizer on back of printed cir-

cuit. I

3. Replack both instrument cluster lens.

I

4. Install /instrument cluster housing.

I

IRemwind Rallye Gauges

1. Removt glove compartment.

2. Remo?e radio, if equipped.

3.

Remoje screws holding instrument carrier frominstrumejf

pane!.4. Disconpect wres from instrument gauge.

5.

Removal attaching nuts from gauge and remove.I1. Replace gauge with attaching nuts on panel.

2. Hook up wires to gauges.

3. With holding screws, attach gauge cluster to in-

strument panel.

4. Replace radio.

5. Replace glove compartment.

Removal of Temperature Sending Unit

1. Drain and collect coolant.

To drain radiator, remove end of lower radiator hose

that is connected to radiator.

2. Remove wire from temperature sending unit.

3. Unscrew temperature sending unit from thermo-

stat housing. See Figure

11-6.Figure

11-S -Temperature Sending Unitlnstalletian

1. Screw temperature sending unit into thermostat

housing after sealing unit with non-hardening per-matex.

2. Install wire on sending unit.

3. Replace coolant.