PONTIAC FIERO 1988 Service Repair Manual

Manufacturer: PONTIAC, Model Year: 1988, Model line: FIERO, Model: PONTIAC FIERO 1988Pages: 1825, PDF Size: 99.44 MB

Page 201 of 1825

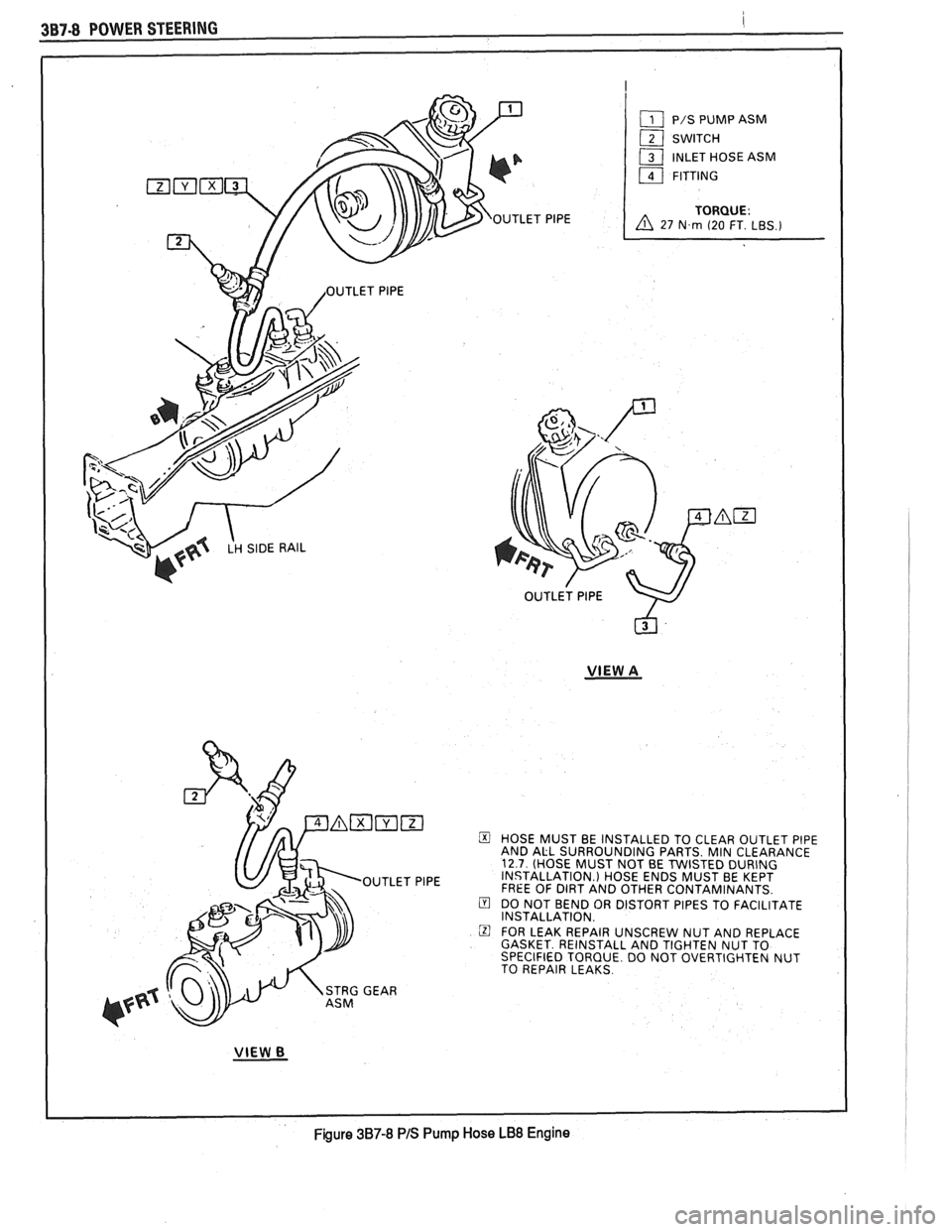

3B7-8 POWER STEERING I

I

OUTLET PlPE

OUTLET PlPE

VlEW A

OUTLET PlPE HOSE

MUST BE INSTALLED TO CLEAR OUTLET PlPE

AND ALL SURROUNDING PARTS. MIN CLEARANCE

12.7 (HOSE MUST NOT BE TWISTED DURING

INSTALLATION.) HOSE ENDS MUST BE KEPT

FREE OF

DIRT AND OTHER CONTAMINANTS. DO NOT BEND OR DISTORT PIPES TO FACILITATE

INSTALLATION.

@ FOR LEAK REPAIR UNSCREW NUT AND REPLACE

GASKET REINSTALL AND TIGHTEN NUT TO

SPECIFIED TORQUE DO NOT OVERTIGHTEN NUT

TO REPAIR LEAKS

VlEW B

Figure 387-8 PIS Pump Hose LB8 Engine

Page 202 of 1825

I - SWIFT. DRIVE 14 - RING, PUMP 2 - SEAL. DRIVE SHAFT 15 .- PLATE, PRESSURE 3 - SEAL "0 RING (HOUSING) 18 - SPRING, PRESSURE PLATE 4 - MOUSIMG ASSY., PUMP 17 - PLATE. END 5 - SPRING, FLOW CONTROL 18 - RING, END PLATE RETAINING 6 - 4ALVE ASSV.. CONTROL' 19 - SEAL "0" RING (HOUSING TO STUD)* 7 - SEAL "0 RING (MOUSING) 20 - RESERVOIR ASSY.. PUMP* 8 - SEAL "0" RlMQ (PRESSURE END

PLATE) 21 - CAP ASSY., RESERVOIR * s - PIN. DOWEL n - STUD OR BOLT* 10 - L'LATE. TMRUST 23 - SEAL "0 RING (FITTING ASSY.) 11 - AOTOR, PUMP 24 - FITTING ASSY., CONNECTOR I 12 - RING. SHAFT RETAINING 25 - MAGNET ' 13 - VANE, PUMP

Figure 387-1 0 Power Steering Pump Assembly

Page 203 of 1825

3B7-10 POWER STEERING

I. REMOVE AND INSTALL DRlVE SHAFT SEAL W l THOUT DISASSEMBL ING THE PUMP.

REMOVE It6TALL

I PROTECT DRlVE SHAFT I COAT DRIVE SHAFT SEAL WITH SHIM STOCK WITH HYDRAULIC PVMP 2 USE Ch 5EL TO CUT FLUID. REFER TO INSET FOR

SEAL AND REMOVE DRIVE SHAFT SEAL INSTALLATION

DRAUCIC WMP ASSEMBLY

TOOL J-7728

1

i

j

I

2. REMOVE AND INSTALL PUMP RESERVOIR ASSEMBLY I REMOVE INSTALL I I. DRAIN OIL FROM RESERVOIR I. USE ALL NEW SEALS AND LUBRICATE

ASSEMBLY BEFORE REMOVAL. WlTH

POWER STEERING FLUID BEFORE 2. REMOVE PARTS AS SHOWN. INSTALLAT

ION. 2. INSTALL PARTS AS SHOWN.

TORQUE TO SJ N m

FITTING ASSEMBLY

TORQUE TO 50 N m

UMP REYRVOIR ASSEMBLY *

O-RING SEALS * . NOT USED ON

HOUSING ASSEMBLY 125-N SERIES

1 1 I

REFER TO INSET FOR I. LLleRlCATE EN) PLATE AND I RETAINING RING. INSTALL

PARTS AS WOWN. REFER TO

INSET FOR POSITIONING

OF I

I RETAINING RING 1

- - - - - - - LOCATE RlNG GAP I REMOVE RETAINING RING AT POSITION WOWN I

POSITIONING OF RETAINING

ATE RETAINING RlNG

VALVE

ASSEWY

OW CONTROL SPRING

LWTI(X : BEFORE PROCEEDING. EXAMIN THIS

PART Of TM DRIVE WAFT. IF IT IS C CROCUS CLOTH BEFORE REMOVING. THIS WILL PREVENT DAMAGE TO TM WAFT WING WHICH MIGHT REWIRE RERACEMNT OF 1% ENTIRE HOUSING.

-- J RING.

4. REMOVE AND INSTALL ROTATING GROUP.

REMOVE INSTALL

1. USING A RUBBER MALLET. I. INSTALL PARTS AS SHOWN ON

TAP LIGHTLY ON DRIVE

DRIVE WAFT. INSTALL NEW

WAFT UNTIL

PRESSVRE RETAINING RING ON DRIVE

PLATE IS FREE. SHAFT AND INSTALL IN PW 2. REMOVE RETAINING RING HOUSING.

FROM DRlVE WAFT AM 2, REFER TO INSET FOR POSITIONING

DISCARD. REMOVE PARTS OF PUMP RING IN HOUSING.

AS SHOWN.

7 VANES r------I T PRESSURE PLATE '1 NOTICE: INSTALL WITH

ROUNDED EDGE OF VANES OVTWARD.

WAFT. ROTOR AN) TWST PLATE ASSEMBLY

PUIAP RING.

C

\- HOUSING ASSEMLY

TpW ROTOR

WAFT RETAINING

I RETAINING RlNG REMOVAL I

5. REMOVE AND INSTALL DRIVE SHAFT AND

O-RING SEALS.

I RLAOM INSTML

I. REMOVE PARTS 1. REFER TO TM INSET FOR DRlVE

AS WOWN WAFT SEAL INSTALLATION

USE ALL NW SEALS AND 1 LVBRlCATE SEALS WlTH POWER J-7728 STEERING FLUID BEFORE

INSTALLATION

! 2. INSTALL PARTS AS WOWN .

I

INSTALL DRIVE SHAFT

HOUSING ASSEMBLY

I LDRIVE WAFT SEAL

BENCH REPAIR

Figure 3B7-11 Power Steering Pump Overhaul

Page 204 of 1825

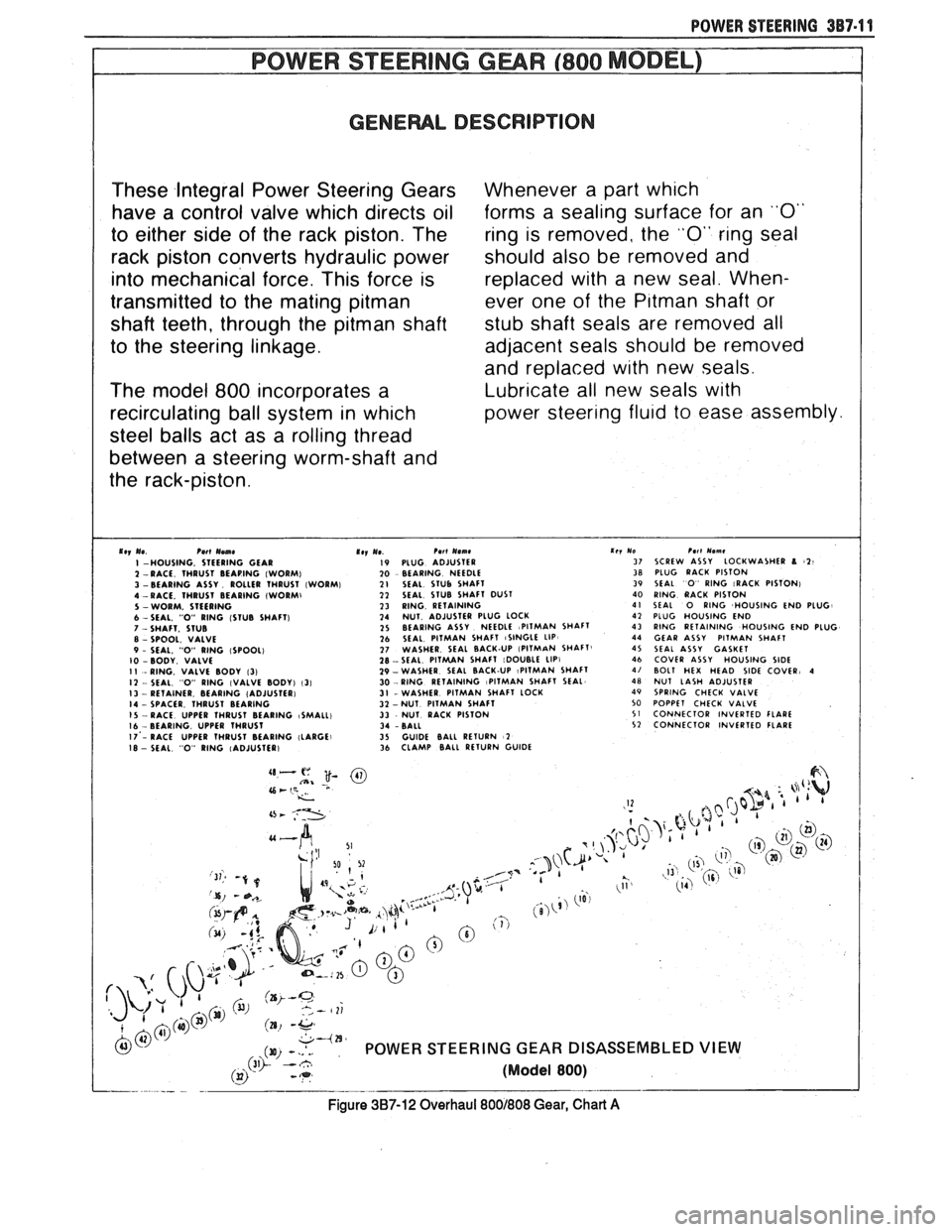

POWER STEERING 387.1 "1

GENEML DESCRIPTION

These Integral Power Steering Gears

have a control valve which directs oil

to either side of the rack piston. The

rack piston converts hydraulic power

into mechanical force. This force is

transmitted to the mating

pitman

shaft teeth, through the pitman shaft

to the steering linkage.

The model

800 incorporates a

recirculating ball system in which

steel balls act as a rolling thread

between a steering worm-shaft and

the rack-piston.

I., U.. Per1 *.a. I -HOUSING. STEERING GEAR 1 -RACE, THRUST BEAPING (WORM)

3 -BEARING ASSY. ROLLER THRUST IWORMI 4 -RACE. IHRUST BEARING (WOWMI 5 -WORM. SlEERlNG 6 -SEAL. "0" WING (STUB SHAFT) 7 - SHAFT. STUB 8 - SPOOL. VALVE

9 - SEAL. "0 RING ISPOOL) I0 -BODY. VALVE I I - RING. VALVE BODY 13) I2 -SEAL. "0" RlNG [VALVE BODY) 131 13 - RETAINER. BEARING (ADJUSIERI I4 - SPACER, THRUST BEARING

I5 -RACE UPPER THRUST BEARING ISMALLI 16.- BEARING. UPPER THRUST I7 - RACE UPPER THRUST BEARING ILARGEI IB - SEAL. "0" RlNG IADJUSTER)

Whenever a part wh~ch

forms a sealing surface for an "0"

ring is removed, the "0" rlng seal

should also be removed and

replaced with a new seal. When-

ever one of the

P~tman shaft or

stub shaft seals are removed all

adjacent seals should be removed

and replaced

w~th new seals.

Lubr~cate all new seals w~th

power steer~ng flu~d to ease assembly

I,, Ue Pet1 Were I9 PLUG ADJUSTER 10 BEARING NEEDLE ?I SEAL SIUb SHAFT ?I SEAL SlUB SHAFT DUST

23 RlNG RETAINING

24 NUT ADJUSTER PLUG LOCK

IS BEARING ASSY NEEDLE PITMAN SHAFT

16 SEAL PITMAN SHAFT ISINGLE LIP 17 WASHER SEAL BACK-UP [PlTMnN SHAFT! 18 -SEAL PITMAN SHAFT [DOUBLE LIP1 29 -WASHER SEAL BACK-UP \PITMAN SHAFT

30 -RING RETAINING iPlTMAN SHAFT SEAL

31 -WASHER PITMAN SHAFT LOCK

32 - NUT PITMAN SHAFT

33 NUT RACK PISTON

34 -BALL

35

GUIDE BALL RETURN 2 36 CLAMP BALL RETURN GUIDE

tar1 Yemr SCREW ASSY LOCKWA5HER L It PLUG RACK PISTON

SEAL 0 RlNG IRACK PISTONI RlNG RACK PISTON

SEAL 0 RING HOUSING END PLUG

PLUG HOUSING END

RlNG RETAINING HOUSING END PLUG

GEAR ASSY

PITMAN SHAFT SEAL ASSY GASKET

COVER ASSY HOUSING SIDE BOLT HEX HEAD SIDE COVER, 4 NUT LASH ADJUSTER

SPRING CHECK VALVE

POPPET CHECK VALVE

CONNECTOR INVERTED FLARE

CONNECTOR INVERTED FLARE

--- - I

Figure 387-12 Overhaul 8001808 Gear, Chart A

Page 205 of 1825

1 -HOUSING. STEERING GEAR 2 --RACE. THRUST BEAPING (WORM) 3 -BEARING ASSY . ROLLER THRUST (WORM) 4 -RACE. THRUST BEARING IWORMI 5 ~-WORM. STEERING 6 - SEAL. "0" RlNG lSTUB SHAFTI 7 SHAFT. STUB 8 - SPOOL. VALVE 9 SEAL. "0" RlNG ISPOOL) I0 - BODY. VALVE I I - RING. VALVE 80DY (3) 12 -SEAL. "0" RlNG (VALVE BODY) (31 I3 - RETAINER. BEARING (ADJUSTER)

I4 - SPACER. THRUST BEARING

IS - RACE. UPPER THRIJST BEARING (SMALL) I6 -BEARING. UPPER THRUST

Ti I7 - RACE. UPPER THRUST BEARING (LARGE)

5- I8 -- SEAL, "0" RlNG IADIUSTERI C

Krv Ue Pert Nemc I9 - PLUG. ADJUSTER 20 - BEARING. NEEDLE 21 -- SEAL. STUB SHAFT 21 - SEAL. STUB SHAFT DUST 23 - RING. RETAINING 24 - NUT. ADJUSTER PLUG LOCK 25 - BEARiNG ASSY . NEEDLE (PITMAN SHAFT) 26 - SEAL. PITMAN SHAFT (SINGLE LIP) 27 - WASHER, SEAL BACK-UP (PITMAN SHAFT)

28-SEAL. PITMAN SHAFT (DOUBLE LIP) 29 - VtASHER. SEAL BACK-UP (PITMAN SHAFT) 30 -RING RETAINING (PITMAN SHAFT SEAL)

31 -WASHER. PITMAN SHAFT LOCK 32 -NUT. PITMAN SHAFT 33 - NUT RACK PISTON 34 - BALL 35 -GUIDE. BALL RETURN (21 36 -CLAMP BALL RETURN GUIDE

Key No Pan Nrme 37 SCREW ASSY LOCKWASHER 8 (21 38 PLUG RACK PISTON 39 SEAL 0 RING (RACK PISTON) 40 RlNG RACK PISTON 41 SEAL 0 RlNG (HOUSING END PLUG, 42 PLUG HOUSING END 43 RING RETAINING iHOULlNG END PLUG 44 GEAR ASSY PITMAN SHAFT

45 SEAL ASSY GASKET

46 COVER ASSY HOUSING SlDE 4/ BOLT HEX HEAD ISIDE COVER) 14 48 NUT LASh ADJUSTER 49 SPRING CHECK VALVE 50 POPPET CHECK VALVE 51 -CONNECTOR INVERTED FLARE 52 -CONNECTOR INVERTED FLARE 53 BOLT COUPLING PINCH 54 COUPLING STEERING SHAFT

Page 206 of 1825

SEALS IN CAR

1 Clean exposed end 1 Install parts as shown 1 Remove parts 1 Install parts as shown of p~tman shaft and Open end of retalnlng end of houslng after rlng to

be approx 25 mm removlng p~tman arm HOUSING ASSEMBLY (1 ~nch) from access hole

2 Remove

retacnlng Inspect for burrs

Reta~ntng rlng rlng pl~ers J-4245

3 Start englne and

turn wheels fully SEAL (SINGLE LIP)

to the left to

force seals and

SEAL (DOUBLE LIP)

4 Turn off

englne

5 Inspect houslng

PITMAN SHAFT

Inspect seal sur

250 Newton Meters 1185 Ft. Lbs.) OUSING ASSEMBLY

HOUSING END PLUG

0 RING SEAL

HOUSING END PLUG

INSTALL

1 Remove parts as shown 1 Install parts as shown 1 If p~tman shaft and 1 If removed ~nstall s~de cover are to be gasket seal

by

separated remove bend~ng tabs around

When ~nstalllng rack.

preload adjuster nut cover edges

care should be taken not

2 Rotate stub shaft to

2 Install parts to cut teflon seal rack

center gear then as shown

remove parts as shown

SIDE COVER BOLTS

GASKET SEAL

PITMAN SHAFT

Insert ball retalner J-21552 Hold 1001 tightly agalnst worm whlle turnlng stub shaft counter-clockw~se The rack-p~ston will be forced

shaft

to asslst in removal. retalner from the gear

seal

from s~de houslng together

cover

lf requ~red

POWER STEERING 387.13

~

I

I

I

I

1

I I

I I

!

I

I

I

I

Figure 3B7-14 Overhaul 8001808 Gear, Chad C

Page 207 of 1825

387-14 POWER STEERING

5. REMOVE AND INSTALL ADJUSTER PLUG

ASSEMBLY

REMOVE INSTALL

1 Loosen lock nut 1 Install parts

Use punch agalnst as shown

edge of slots

1 2. Remove adjuster fi plug using spanner

wrench J-7624.

ADJUSTEfi PLIJG

LOCK NUT

,

When installing adjuster

plug care should be taken

not to cut seals.

1 6. DISASSEMBLE AND ASSEMBLE ADJUSTER

PLUG ASSEMBLY

DISASSEMBLE ASSEMBLE

1 D~sassemble arts 1 Assemble Darts

as shown as shown ' a

CRETAINING RING STUB SHAFT

DUST SEAL

*STUB SHAFT SEAL

NEEDLE BEARING

ADJUSTER PLUG

-\\\\\\ILL 0 RINGSEAL

UPPER THRUST BEARING

UPPER BEARING RACE (SMALL)

THRUST BEARING SPACER

1 - -------, BEARING RETAINER

RETAINER

* Use stub shaft seal protector J-29810 on stub shaft when

installing stub shaft seal

Screwc:

lver

I ''C> - Pry bear~ng retatner E- -- - -- -A at ra~sed area

Use

suttable slze arbor to

press bearlng In place

Bear~ng to be pressed 16 mm ($,n mch) Into adjuster w,th stamped

I D end up and from d~rect~on of

arrow

/

4--.---- .A

Install bear~ng

7. REMOVE AND INSTALL BEARiNG, WORM,

I AND VALVE ASSEMBLY I

I REMOVE INSTALL I 1. Grasp stub shaft and 1. Install parts as

remove valve and worm shown.

assembly as a

unlt. '

Separate the valve from the worm

Note how the pln In the wo f~ts the slot In the valve

THRUST BEARING

WORM ASSEMBLY

reassembling gear make

sure angle of thrust races are

as shown

I 8. DISASSEMBLE AND ASSEMBLE VALVE

DISASSEMBLE ASSEMBLE

1 D~sassemble parts 1 Assemble parts

as shown as shown

VALVE BODY

0 RIN

VALVE BODY

VALVE SPOO

RING (teflon) *

SPOOL TO BODY 0 RING * To ease assemblv, soak

I-

- - - -- - - - -- , teflon rings in warm water. _ A Loosen shaft cap I B Remove and ~nstall stub shaft

I I PUII cap out approx G mrn(1/sv) I

Lap l~ghtly on

wood block I k~ln on shaft and hole In I spool (Disengage to remove) --C- - ----------

I C Remove and ~nstall spool ! D Engage stub shaft I

Rotate wh~le removlng LI

~nstalltng 1

Lubr~cate spool and body I Notch must fully engage w~th power steer~ng flu~d I pln and cap must seat I aga~nst shoulder

I 1

Figure 387-1 5 Overhaul 1 8001808 Gear, Chart D

Page 208 of 1825

POWER STEERING 387-1 6

7 1 1 9. DISASSEMBLE AND ASSEMBLE RACK

1 PISTON

I DISASSEMBLE ASSEMBLE

1 Disassemble parts 1 Assemble parts

as shown as shown

2 Clean and Inspect all parts for excessive wear The black balls are smaller than

the silver balls. The black and

silver balls must

be installed

alternately into the rack-piston

and return guide to maintain

rack piston to worm gear

praloed.

TEFLON SEAL AN0 0 RING--

If replaced lubricate new seal

and 0 rlng wlth power steerlng fluid

Turn worm until worm groove IS al~gned w~th the lower

I \ WORM-Slide all the way

I \

Into the ra~k-~lston

1

v Lubr~cate balls wlth

I / oower steerlno fluid install balls th;ough Before assembling rack

ball return gulde hole In houslng. ball retalner whlle rotatlng worm J-21552 must be lnserted counterclockw~se Into rack to allow

removal of worm

- GUIDE-Alternately ~nstall rema~nder of

balls and retaln w~th grease at each

end of gu~de

to 5 Newton Metres (4 Ft Lbs )

10. REMOVE AND INSTALL PITMAN SHAR

SEALS AND BEARING

REMOVE INSTALL

1 Clean end of 1 Coat seal Ilp and washer face houslng thoroughly with anhydrous calclum grease

to prevent dlrt from enterlng and be 2. Install parts as shown

extremelv careful not

to score

(he houslng

bore HOUSING ASSEMBLY

Inspect for burrs

2 Remove retalnlng rlng wlth snap rlng pllers J-4245

3 Uslng screw drlver. pry seals and washers

from bore

PITMAN SHAFT SEAL

(SINGLE LIP)

PITMAN SHAFT SEAL

(DOUBLE LIP)

RETAINING

RING 2

SEAL BACK UP WASHER NEEDLE BEARING

Remove onlv 11 ~t I - - - - - .- - - - . - . - . -. . - - 1 needs replacing.

I

When tool bottoms on

fully Installed

I I

L ------------ J L ----------- J

Install Pltman shaft bearlng Install Pttman shaft seals

CI I J

Figure 387-16 Overhaul 800f808 Gear, Chart E

Page 209 of 1825

387-16 POWER STEERING

11. REMOVE AND INSTALL CHECK VALVE

REMOVE INSTALL

1. Remove parts as shown. 1. Install parts as shown. I

/'-

With small screwdriver, pry

check valve from housing.

Care

should be taken not to

damage threads when prying

on edge of housing.

3/8 tubing, 4 inches

A Uslng spanner wrench

J-7624, tlghten adjuster

plug until thrust bearlng IS flrmly bottomed. 27 Newton

Metres (20 Ft Lbs )

Mark housing and

I I Measure back I counterclockw~se I 13 mm (l/zl') and place a f se~ond mark on housing 1

tlghten lock nut securely

Hold adjuster plug to J

malntain alignment of

I

Figure 387-1 7 Overhaul

13. PITMAN SHAR "OVER-CENTER"

SECTOR ADJUSTMENT

normally on same side as.

and parallel with, slde cover.

The block tooth on the

Pltman shaft IS In llne w~th the

over-center preload adjuster - /

B Back off preload adjuster I C Turn adjuster In unt~l untll ~t stops, then turn I torque to turn stub shaft ~t ~n one full turn 1 IS 0 6 to 1 2 Newton Metres 1 (6 to 10 In Lbs ) 1 more than readlng At1

1 I 7

L

1

With gear at center f Torque adjuster lock

of travel, check torque I nut to 27

to turn stub shaft 1 (20 Ft Lbs ) (readlng XI) I I Prevent adjuster screw I from turnlng whlle I torquelng lock nut

I I I

8001808 Gear, Chart F

Page 210 of 1825

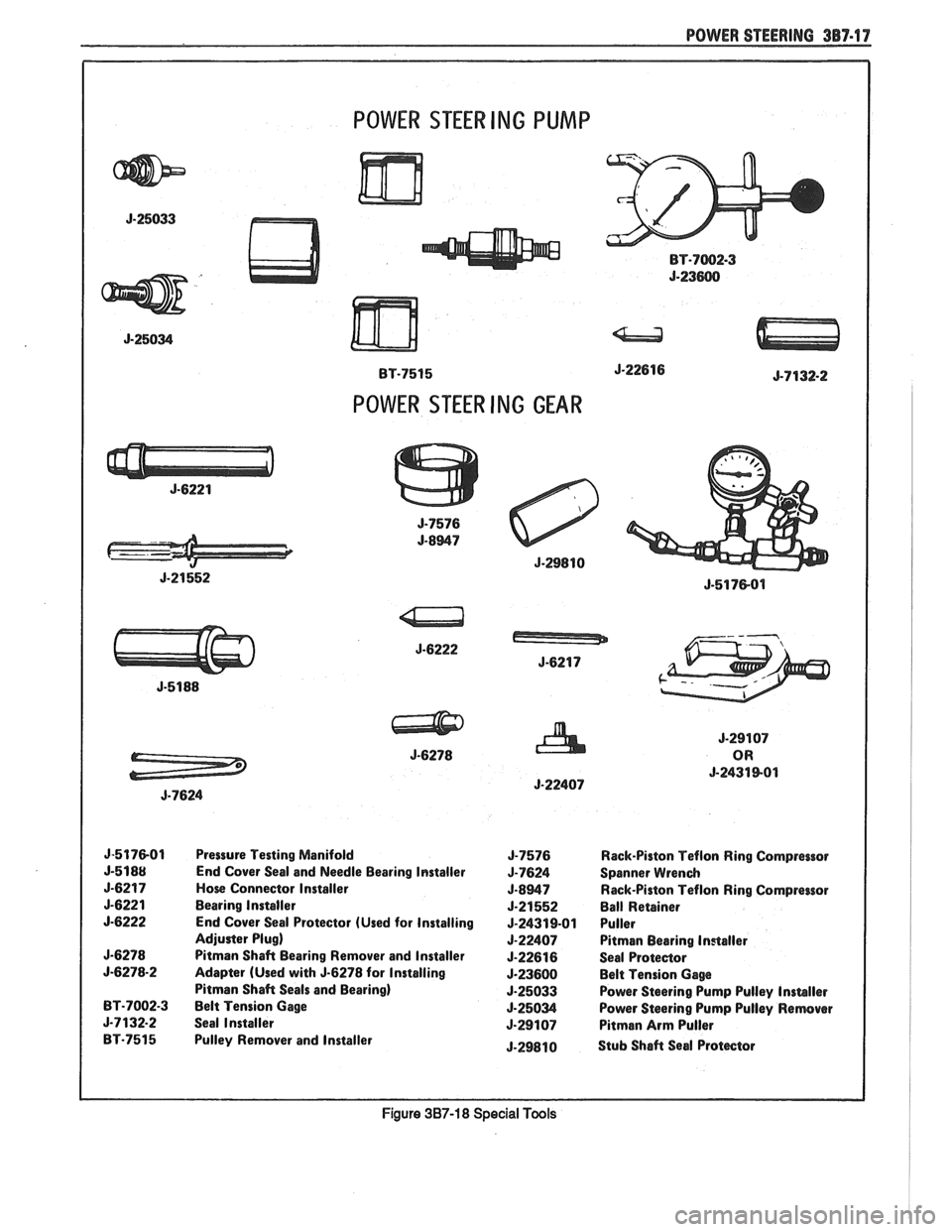

POWER STEERING 387-17

POWER STEER ING PUMP

BT-7002-3

BT-7515

POWER STEER ING GEAR

5-2431 801 J-22407

J-517801 Pressure Testing Manifold J-7576 Rack-Piston Teflon Ring Compressor

End Cover Seal and Needle Bearing Installer

J-7624 Spanner Wrench

Hose Connector Installer

J-8947 Rack-Piston Teflon Ring Compreaor

Bearing Installer

5-21552 Ball Retainer

End Cover Seal Protector (Used for Installing

J-24319-01 Puller

Adjuster Plug)

5-22407 Pitman Bearing Installer

Pitman Shaft Bearing Remover and Installer J-22616 Seal Proteaor

5-6278-2 Adapter (Used with 5-6278 for Installing J-23600 Belt Tension Gage

Pitman Shaft Seals and Bearing)

J-25033 Power Steering Pump Pulley Insmller BT-7002-3 Belt Tension Gage 5-25034 Power Steering Pump Pulley Remover

5-7132.2 Seal Installer 5-29107 Pitman Arm Puller

BT-7515 Pulley Remover and lnstaller

J-29810 Stub Shaft Seal Protector

Figure 387-1 8 Special Tools