PONTIAC FIERO 1988 Service Repair Manual

Manufacturer: PONTIAC, Model Year: 1988, Model line: FIERO, Model: PONTIAC FIERO 1988Pages: 1825, PDF Size: 99.44 MB

Page 411 of 1825

Page 412 of 1825

ENGINE COOLING 6B-1

SECTION 6B

NE COOL

General Description ................................ 6B- 1 Off-Vehicle Leak Testing ............................... 6B-9

Radiator

...................................................... 6B- 1 Repairable Leaks ........................ ... .......... 6B- 10

Radiator Cap

......................... .. ............... 6B- 1 Repair Methods ................................................ 6B- 10

Recovery Bottle ......................................... 6B-2 Cooling Fin Removal ................................ 6B- 10 - ............................................. Fans ............................................................... 6B-2 Tube Blocking 6B- 1 1 ............ Header Repair ....................... .... 6B- 1 1 Temperature Switch ..................................... 6B-2 General Core Repair 6B- 1 1 ....................................

........................... Coolant Temperature Fan Switch ................ 6B-2 Tank

Gasket ~eik Repair 6B- 12

................... Thermostat .. 6B-3 Oil

Cooler Gasket Replacement

6B- 13 ............... ................................

...........................................................

Coolant Recovery System 6B-3 Recore 6B- 14 ............................. Special Tools ..................................................... 6B- 14 Diagnosis ..................................................... 6B-3

.............................. ..................................... Service Procedures 6B-3 On-Vehicle Service 6B-14

Cooling System Care

............................... 6B-3 Thermostat ....................................... 6B-14

Draining and Refilling the Cooling Electric Cooling Fan ............................. 6B-15

System

................................................... 6B-7 Water Pump .................... .... ......... 6B-15

Drive Belt

...................... .. .......................... 6B-7 Coolant Recovery Bottle ........................ 6B-16

.......................................... Aluminum Radiator Service .................... 6B-8 Radiator 6B-17

Diagnosis .................................................... 6B-8

Leak Testing

.............................................. 6B-8

On-Vehicle Pressure Testing

...................... .... 6B-9

GENERAL DESCRIPnIBN

The cooling system maintains engine temperature

5" below the filler neck which reads, "Important - for

at an efficient level during all engine operating repair see Harrison Service Manual". Service

conditions. When the engine is cold the system cools procedures for the aluminum plastic radiator are

slowly, or not at all, to allow the engine to warm up described in that manual and in this section.

quickly.

The cooling system includes a radiator and

Radiator Cap

recovery sub-system, cooling fan, thermostat and

housing, water pump, and drive belts.

Operation of the cooling system requires proper

functioning of all components. Coolant is drawn from

the radiator by the water pump and circulated through

water jackets in the engine block, intake manifold, and

cylinder

head(s), and then directed back to the radiator

where it's cooled.

This system directs some coolant through hoses

to the heater core, to provide for heating and

defrosting. A recovery bottle is connected to the

radiator to recover coolant displaced by expansion

from high temperatures and maintain correct coolant

level. As the coolant cools and contracts it is drawn

back into the radiator by vacuum.

RADIATOR

A cross-flow radiator is used on all models. Tanks

in this type radiator are located to the right and left of

the core, instead of above and below.

Radiators used with automatic transmissions

have oil coolers with inlet and outlet fittings for

transmission fluid circulation. Cars with manual

transmissions use radiators without oil coolers.

Vehicles equipped with air conditioning use a radiator

with extra cooling capability.

An aluminum-plastic radiator, used on some

models, can be identified by a note on the outlet tank A pressure-vent

cap is used on the cross-flow

radiator to allow a buildup of

103 kPa (15 psi) in the

cooling system. This pressure raises the boiling point

of coolant to approximately 125°C (262°F) at sea level.

Do not remove radiator cap to check engine

coolant level; check coolant visually at the

see-through coolant reservoir. Coolant should

be added only

to the reservoir.

CAUTION: As long as there

is

pressure in the cooling system, the

temperature can be considerably

higher than the boiling temperature

of

the solution in the radiator without

causing the solution to boil. Removal

of the radiator cap while engine is hot

and pressure is high will cause

the

solution to boil instantaneously and

possibly with explosive

force, spewing

the solution over engine, fenders and

person removing cap. If the solution

contains flammable antifreeze, such

as alcohol (not recommended for use

at any time), there is also the

possibility

of causing a serious fire.

The pressure-type radiator filler cap contains a

blow off or pressure valve and a vacuum or

atmospheric valve (Figure

1). The pressure valve is

held against its seat by a spring of pre-determined

Page 413 of 1825

BB-2 ENGINE COOLING

strength, which protects the radiator by relieving

pressure if it exceeds design limits. The vacuum valve

is held against its seat by a light spring, which permits

opening of the valve to relieve vacuum created in the

system when it cools off and which otherwise might

cause the radiator to collapse.

VACUUM RELIEF PRESSURE RELIEF

Fig. 1 Pressure-Type Radiator Cap

The radiator cap is designed to discourage

inadvertent removal. The finger grips have been

removed so the cap is round in shape. It also must be

pushed downward before it can be removed. A rubber

asbestos gasket is added to the diaphragm spring at the

top of the cap. Embossed on the cap is a caution against

its being opened and arrows indicating the proper

closed position.

Every vehicle has a radiator cap. Also,

J, N and

P Series vehicles with 2.5L engines have a thermostat

housing cap. For these engines, add coolant through

the thermostat housing (with the thermostat and cap

removed).

Recovery Bottle

A "see-through" plastic reservoir, similar to the

familiar windshield washer jar, is connected to the

radiator by a hose. As the car is driven, the coolant is

heated and expands. The portion of the fluid displaced

by this expansion flows from the radiator into the

recovery bottle. When the engine is stopped and the

coolant cools and contracts, the displaced coolant is

drawn back into the radiator by vacuum. Thus, the

radiator is kept filled with coolant to the desired level

at all times, resulting in increased cooling efficiency.

Coolant level should be between "ADD" and

"FULL"

marks on recovery bottle. These marks are

approximately two quarts apart so that a

50/50

mixture can be added (one quart of ethylene glycol

anti-freeze and one quart of water).

FAN

Electric Fan

Fans range in sizes from 290mm (11.6 in) to

422mm (16.9 in) with 4 to 7 blades to aid air flow

through the

radiator/condenser. The fan is driven by

an electric motor which is attached to the radiator

support.

The fan motor is activated by a coolant

temperature switch. If the vehicle is equipped with

Fig. 2 Coolant Recovery Bottle

A/C, a second switch can activate the circuit,

depending upon

A/C compressor head pressure to the

condenser.

CAUTION: If a fan blade is bent or

damaged in any way, no attempt

should be made to repair and reuse the

damaged part.

A bent or damaged fan

assembly should always be replaced

with a new fan assembly. It is

essential that fan assemblies remain

in proper balance and proper balance

cannot be assured once a fan

assembly has been bent or damaged.

A fan assembly that is not in proper

balance could fail and fly apart during

subsequent use, creating an

extremely dangerous condition.

The majority of non-A/C cars use a fan with four

blades which are unevenly spaced and have curled tips

to provide minimum noise.

A fan shroud is used to

prevent recirculation of air around the fan on most

cars.

Thermostatically Controlled Fluid Clutch Fan

A thermostatically controlled fluid clutch fan is

used on some air conditioned vehicles. It operates only

when additional air flow is required to reduce radiator

coolant temperatures. This clutch is of a simple,

functional design. It is made of lightweight metal filled

with silicone oil and is hermetically sealed. The finned

(rear) housing contains a hub assembly (secured to the

housing bearing) which attaches to the engine water

pump. Four bosses with tapped holes in the rear face

provide for attachment of the engine fan. The front

surface of the housing has six deep circular grooves

which index with six matching bosses on the rear face

of a floating clutch. A separator plate and front cover,

with thermostatic coil control, complete the clutch

assembly.

During periods of operation when radiator

discharge air temperature is low, below approximately

66°C (150°F), the clutch limits the fan speed to

800- 1400 rpm. In this position, the clutch is disengaged

Page 414 of 1825

ENGINE COOLING 88.3

since a small oil pump driven by the separator plate

forces the silicone oil into a reservoir between the

separator plate and the front cover assembly. In this

position, the passage from this cavity to the clutch area

is closed by a slide valve. As operating conditions

produce a high radiator air temperature discharge,

above approximately 66°C

(150"F), the temperature

sensitive bi-metal coil tightens to move the slide valve

(attached to the coil) which opens a port in the

separator plate. This allows a flow of silicone oil into

the clutch chamber to engage the clutch, providing a

maximum fan speed of approximately 2200 rpm. The

clutch coil is calibrated so that, with a road load at an

ambient temperature of approximately 32°C

(90T), the

clutch is just at a point of shift between high and low

fan speed. No attempt should be made to disturb the

calibration of the engine clutch fan assembly as each

assembly is individually calibrated at the time of

manufacture. Under certain temperature conditions

there is a lateral movement at the fan tip which should

not be considered as a hub or bearing failure. This

condition is a design feature of the clutch assembly

which allows up to approximately

1/4" lateral

movement measured at the fan tip.

Testing a clutch fan by holding the small hub

with one hand and rotating the aluminum housing in

a

clockwise/counter-clockwise motion will cause the

clutch to freewheel, which is a normal condition when

operated in this manner. This should not be considered

a test by which replacement is determined.

Temperature Switch

This switch activates a warning lamp in the

instrument cluster if the engine overheats. With

optional instrumentation, a temperature gage replaces

the warning lamp and the temperature switch is

replaced with a transducer. See Section

8A for

Temperature Switch location and diagnosis.

Coolant Temperature Fan Switch

This switch regulates voltage to the coolant fan

relay, which operates the fan whenever the engine

coolant temperature exceeds 230"

F (110" C). For

location and diagnosis see Section 8A for Coolant

Temperature Fan Switch.

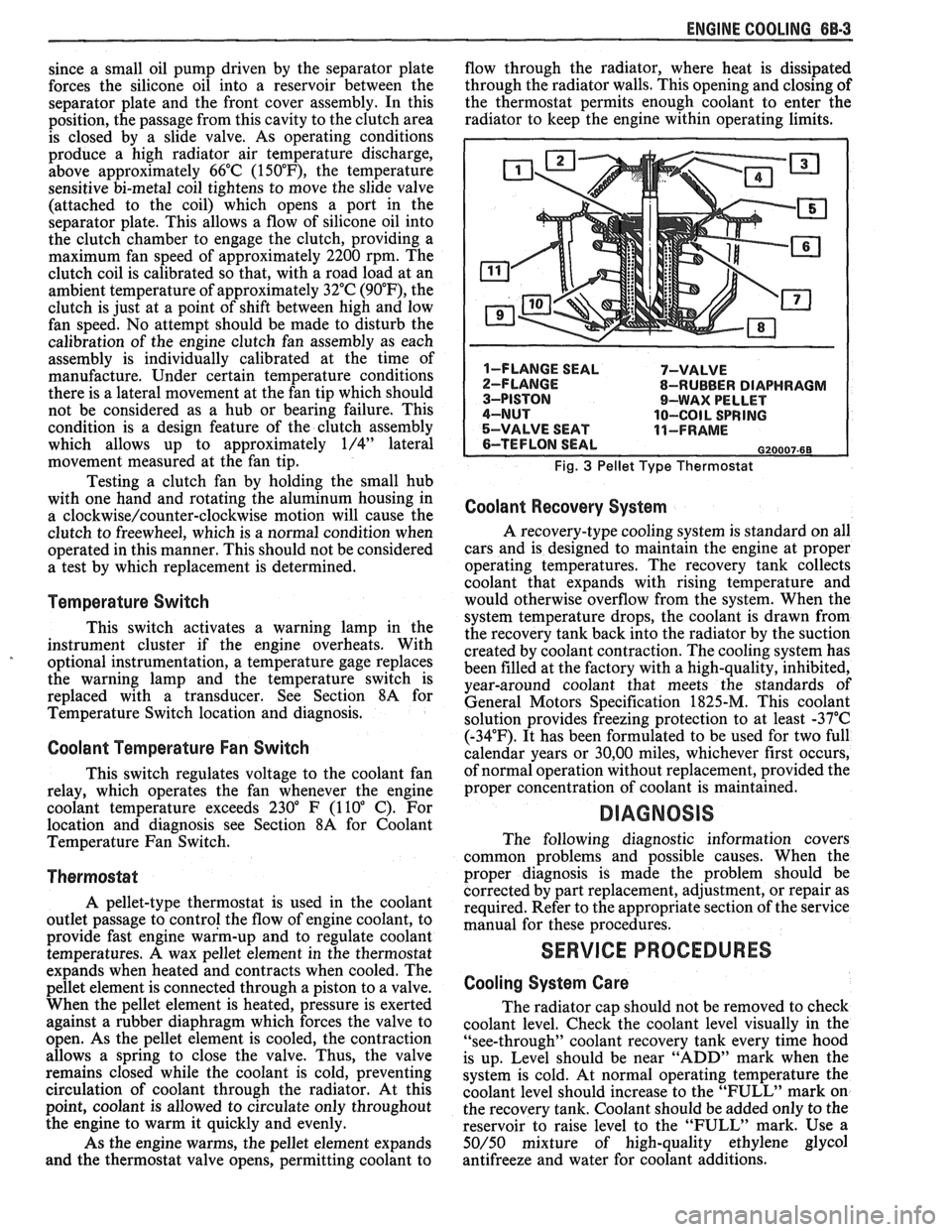

Thermostat

A pellet-type thermostat is used in the coolant

outlet passage to control the flow of engine coolant, to

provide fast engine warm-up and to regulate coolant

temperatures.

A wax pellet element in the thermostat

expands when heated and contracts when cooled. The

pellet element is connected through a piston to a valve.

When the pellet element is heated, pressure is exerted

against a rubber diaphragm which forces the valve to

open. As the pellet element is cooled, the contraction

allows a spring to close the valve. Thus, the valve

remains closed while the coolant is cold, preventing

circulation of coolant through the radiator. At this

point, coolant is allowed to circulate only throughout

the engine to warm it quickly and evenly.

As the engine warms, the pellet element expands

and the thermostat valve opens, permitting coolant to flow

through the radiator, where heat is dissipated

through the radiator walls. This opening and closing of

the thermostat permits enough coolant to enter the

radiator to keep the engine within operating limits.

Fig. 3 Pellet Type Thermostat

Coolant Recovery System

A recovery-type cooling system is standard on all

cars and is designed to maintain the engine at proper

operating temperatures. The recovery tank collects

coolant that expands with rising temperature and

would otherwise overflow from the system. When the

system temperature drops, the coolant is drawn from

the recovery tank back into the radiator by the suction

created by coolant contraction. The cooling system has

been filled at the factory with a high-quality, inhibited,

year-around coolant that meets the standards of

General Motors Specification 1825-M. This coolant

solution provides freezing protection to at least -37°C

(-34°F). It has been formulated to be used for two full

calendar years or

30,OO miles, whichever first occurs,

of normal operation without replacement, provided the

proper concentration of coolant is maintained.

DIAGNOSIS

The following diagnostic information covers

common problems and possible causes. When the

proper diagnosis is made the problem should be

corrected by part replacement, adjustment, or repair as

required. Refer to the appropriate section of the service

manual for these procedures.

SERVICE PROCEDURES

Cooling System Care

The radiator cap should not be removed to check

coolant level. Check the coolant level visually in the

"see-through" coolant recovery tank every time hood

is up. Level should be near "ADD" mark when the

system is cold. At normal operating temperature the

coolant level should increase to the "FULL" mark on

the recovery tank. Coolant should be added only to the

reservoir to raise level to the "FULL" mark. Use a

50/50 mixture of high-quality ethylene glycol

antifreeze and water for coolant additions.

Page 415 of 1825

BB.4 ENGINE COOLING

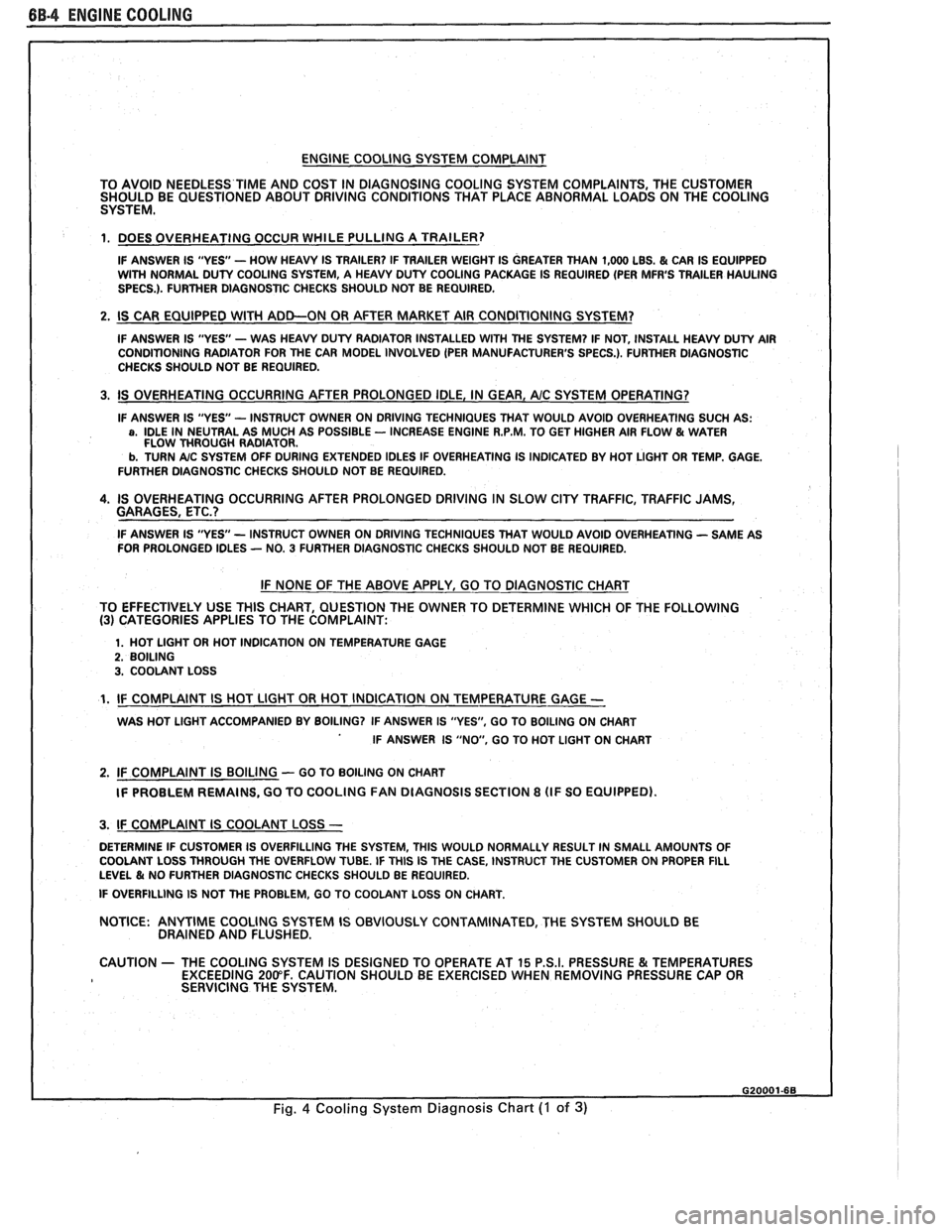

ENGINE COOLING SYSTEM COMPLAINT

TO AVOID NEEDLESS

TIME AND COST IN DIAGNOSING COOLING SYSTEM COMPLAINTS, THE CUSTOMER

SHOULD BE QUESTIONED ABOUT DRIVING CONDITIONS THAT PLACE ABNORMAL LOADS ON THE COOLING

SYSTEM.

1. DOES OVERHEATING OCCUR WHILE PULLING A TRAILER?

IF ANSWER IS "YES'- HOW HEAVY IS TRAILER? IF TRAILER WEIGHT IS GREATER THAN 1,000 LBS. & CAR IS EQUIPPED

WITH NORMAL DUTY COOLING SYSTEM, A HEAVY DUTY COOLING PACKAGE IS REQUIRED (PER MFR'S TRAILER HAULING

SPECS.). FURTHER DIAGNOSTIC CHECKS SHOULD NOT BE REQUIRED.

2. IS CAR EQUIPPED WlTH ADD-ON OR AFTER MARKET AIR CONDITIONING SYSTEM?

IF ANSWER IS "YES"- WAS HEAVY DUTY RADIATOR INSTALLED WITH THE SYSTEM? IF NOT, INSTALL HEAVY DUTY AIR

CONDITIONING RADIATOR FOR THE CAR MODEL INVOLVED (PER MANUFACTURER'S SPECS.). FURTHER DlAGNOSTlC

CHECKS SHOULD NOT BE REQUIRED.

3. IS OVERHEATING OCCURRING AFTER PROLONGED IDLE, IN GEAR, AIC SYSTEM OPERATING?

IF ANSWER IS "YES - INSTRUCT OWNER ON DRIVING TECHNIQUES THAT WOULD AVOID OVERHEATING SUCH AS: a, IDLE IN NEUTRAL AS MUCH AS POSSIBLE - INCREASE ENGINE R.P.M. TO GET HIGHER AIR FLOW & WATER

FLOW THROUGH RADIATOR.

b. TURN A/C SYSTEM OFF DURING EXTENDED IDLES IF OVERHEATING IS INDICATED BY HOT LIGHT OR TEMP. GAGE.

FURTHER DIAGNOSTIC CHECKS SHOULD NOT BE REQUIRED.

4. IS OVERHEATING OCCURRING AFTER PROLONGED DRIVING IN SLOW CITY TRAFFIC, TRAFFIC JAMS,

GARAGES, ETC.?

IF ANSWER IS "YES - INSTRUCT OWNER ON DRIVING TECHNIQUES THAT WOULD AVOID OVERHEATING - SAME AS

FOR PROLONGED IDLES - NO. 3 FURTHER DIAGNOSTIC CHECKS SHOULD NOT BE REQUIRED.

IF NONE OF THE ABOVE APPLY, GO TO DIAGNOSTIC CHART

TO EFFECTIVELY USE THlS CHART, QUESTION THE OWNER TO DETERMINE WHICH OF THE FOLLOWING

(3) CATEGORIES APPLIES TO THE COMPLAINT:

1. HOT LlGHT OR HOT INDICATION ON TEMPERATURE GAGE 2. BOILING 3. COOLANT LOSS

1. IF COMPLAINT IS HOT LlGHT OR HOT INDICATION ON TEMPERATURE GAGE -

WAS HOT LlGHT ACCOMPANIED BY BOILING? IF ANSWER IS "YES", GO TO BOILING ON CHART

IF ANSWER IS "NO, GO TO HOT LlGHT ON CHART

2. IF COMPLAINT IS BOILING - GO TO BOILING ON CHART

IF PROBLEM REMAINS, GO TO COOLING

FAN DIAGNOSIS SECTION 8 (IF SO EQUIPPED).

I 3. IF COMPLAINT IS COOLANT LOSS -

DETERMINE IF CUSTOMER IS OVERFILLING THE SYSTEM, THlS WOULD NORMALLY RESULT IN SMALL AMOUNTS OF

I COOLANT LOSS THROUGH THE OVERFLOW TUBE. IF THlS IS THE CASE, INSTRUCT THE CUSTOMER ON PROPER FILL LEVEL & NO FURTHER DIAGNOSTIC CHECKS SHOULD BE REQUIRED.

I IF OVERFILLING IS NOT THE PROBLEM, GO TO COOLANT LOSS ON CHART.

NOTICE:

ANYTIME COOLING SYSTEM IS OBVIOUSLY CONTAMINATED, THE SYSTEM SHOULD BE

DRAINED AND FLUSHED.

1 CAUTION - THE COOLING SYSTEM IS DESIGNED TO OPERATE AT 15 P.S.I. PRESSURE & TEMPERATURES

EXCEEDING 200°F. CAUTION SHOULD BE EXERCISED WHEN REMOVING PRESSURE CAP OR

I SERVICING THE SYSTEM.

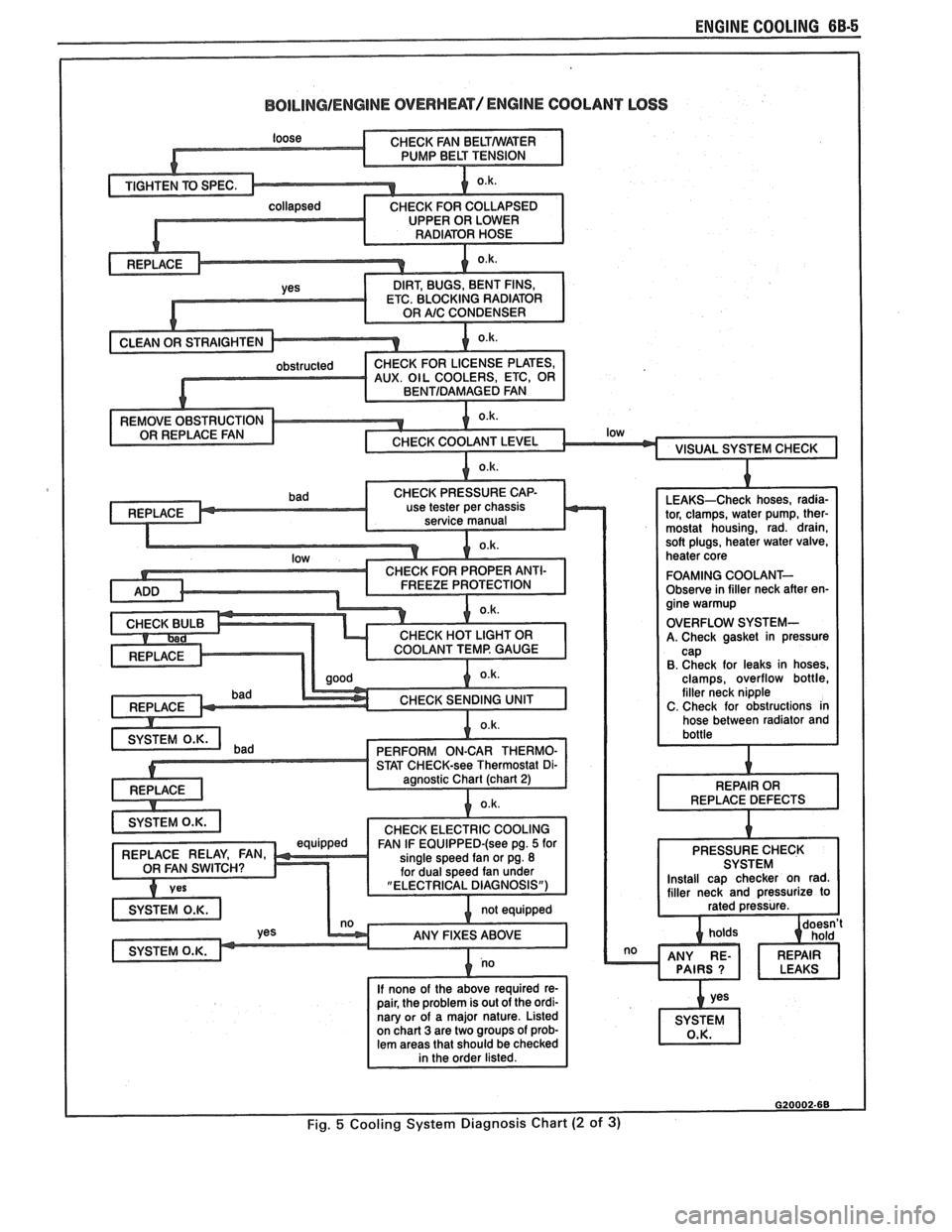

Fig. 4 Cooling System Diagnosis Chart (I of 3)

Page 416 of 1825

ENGINE COOLING 6B-5

BOILINGIENGINE OVERHEAT/ ENGINE COOLANT LOSS

FOAMING COOLANT- Observe in filler neck after en-

for leaks in hoses. , overflow bottle,

for obstructions in

on chart

3 are two groups of prob-

Page 417 of 1825

6B-8 ENGINE COOLING

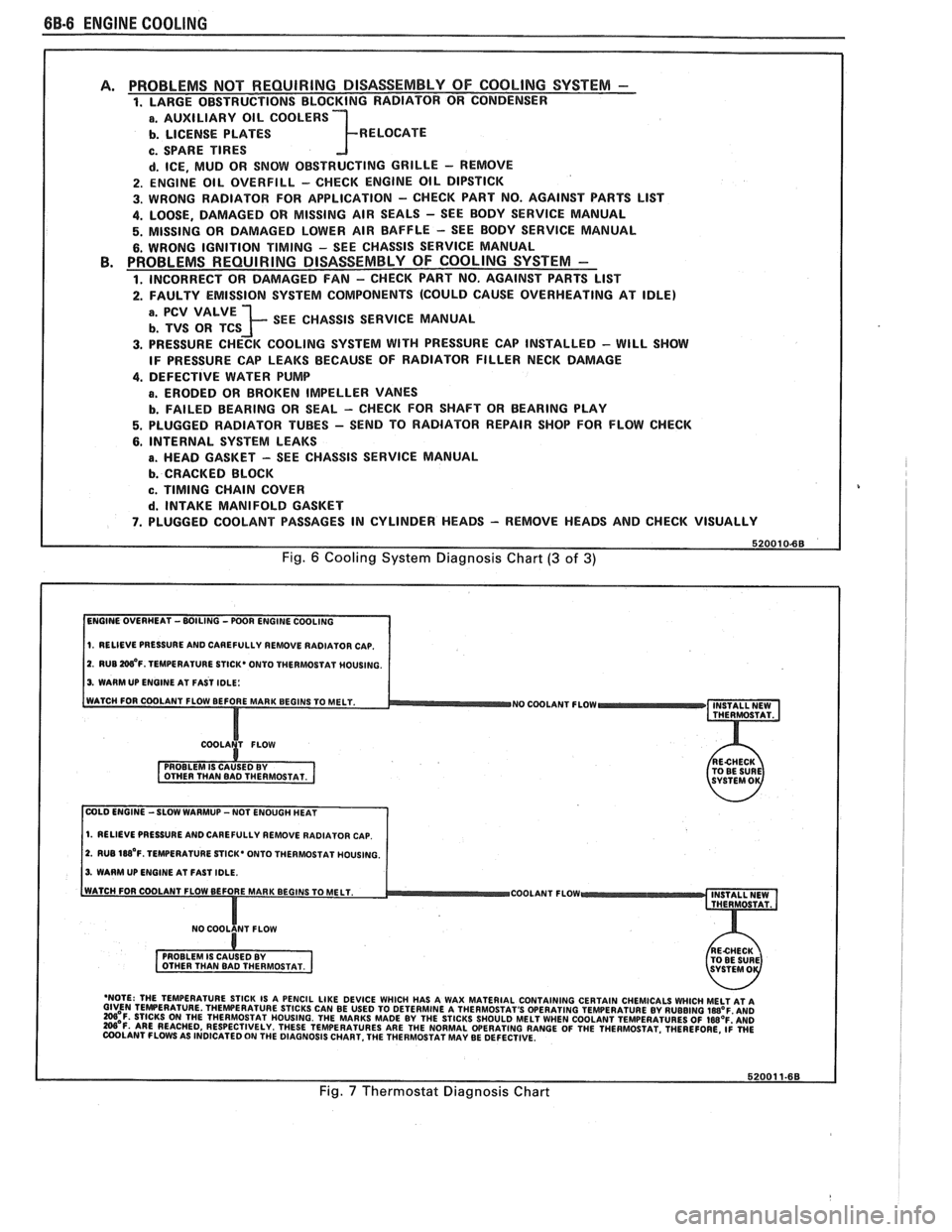

PROBLEMS NOT REQUIRING DISASSEMBLY OF COOLING SYSTEM - 1. LARGE OBSTRUCTIONS BLOCKING RADIATOR OR CONDENSER

a. AUXILIARY OIL COOLERS

b. LICENSE PLATES R ELOCATE

c. SPARE TIRES

d. ICE, MUD OR SNOW OBSTRUCTING GRILLE - REMOVE

2. ENGINE OIL OVERFILL - CHECK ENGINE OIL DIPSTICK

3. WRONG RADIATOR FOR

APPLICATION - CHECK PART NO. AGAINST PARTS LlST

4. LOOSE, DAMAGED OR MISSING AIR SEALS - SEE BODY SERVICE MANUAL

5. MISSING OR DAMAGED LOWER AIR BAFFLE - SEE BODY SERVICE MANUAL

6. WRONG IGNITION TIMING - SEE CHASSIS SERVICE MANUAL PROBLEMS REQUIRING DISASSEMBLY OF COOLING SYSTEM -

1. INCORRECT OR DAMAGED FAN - CHECK PART NO. AGAINST PARTS LlST

2. FAULTY EMISSION SYSTEM COMPONENTS (COULD CAUSE OVERHEATING AT IDLE)

; SEE CHASSIS SERVICE MANUAL

3. PRESSURE CHECK COOLING SYSTEM WITH PRESSURE CAP INSTALLED - WILL SHOW

IF PRESSURE CAP LEAKS BECAUSE OF RADIATOR FILLER NECK DAMAGE

4. DEFECTIVE WATER PUMP

a. ERODED OR BROKEN IMPELLER VANES

b. FAILED BEARING OR SEAL - CHECK FOR SHAFT OR BEARING PLAY

5. PLUGGED RADIATOR TUBES - SEND TO RADIATOR REPAIR SHOP FOR FLOW CHECK

6. INTERNAL SYSTEM LEAKS

B. HEAD GASKET - SEE CHASSIS SERVICE MANUAL

b. CRACKED BLOCK

c. TIMING CHAIN COVER

d. INTAKE MANIFOLD GASKET

7. PLUGGED COOLANT PASSAGES IN CYLINDER HEADS - REMOVE HEADS AND CHECK VISUALLY

Fig. 6 Cooling System Diagnosis Chart (3 of 3)

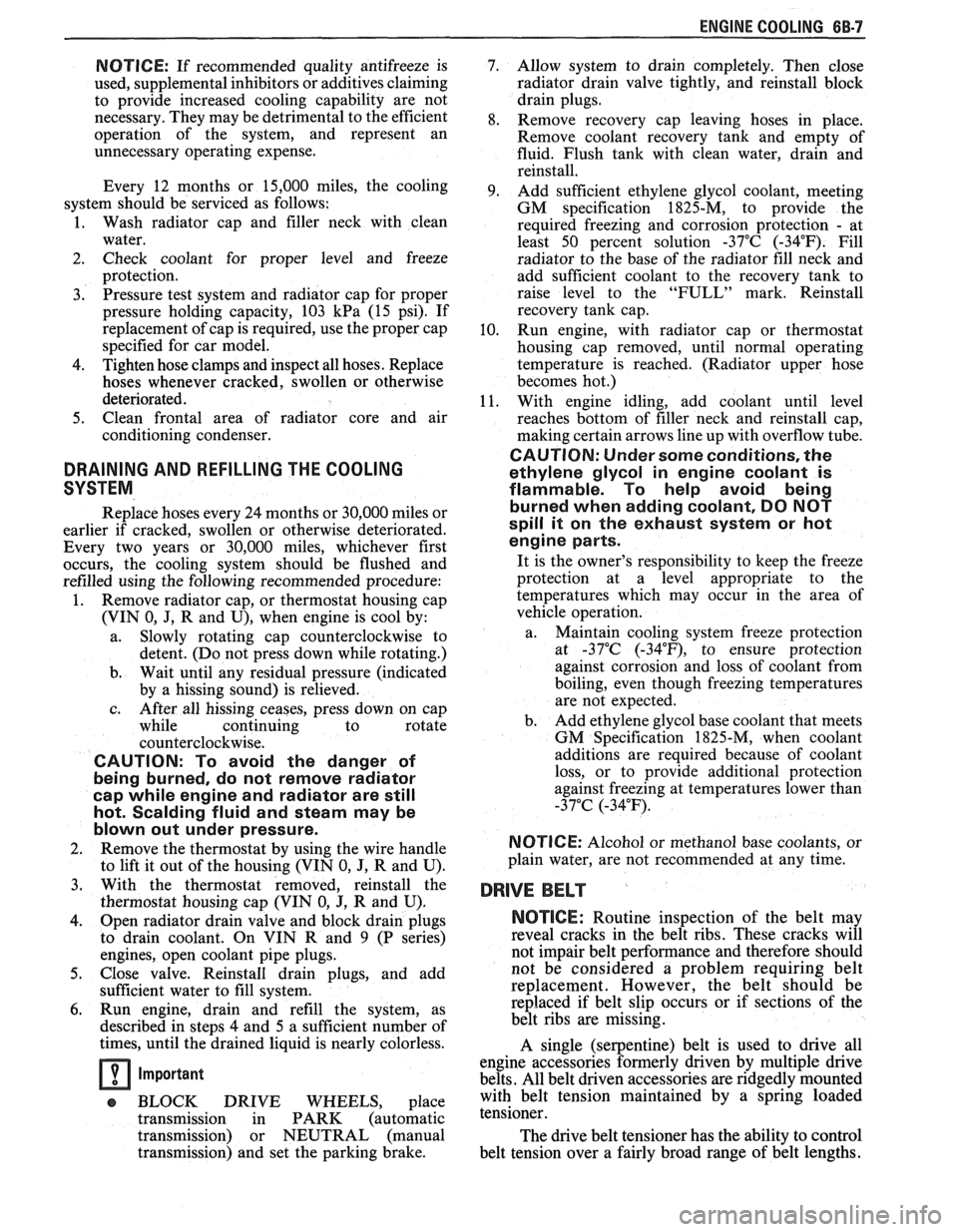

1. RELIEVE PRESSURE AND CAREFULLY REMOVE RADIATOR CAP.

2. RUB W'F. TEMPERATURE STICK* ONTO THERMOSTAT MOUSING.

3. WARM UP ENGINE AT FAST IDLE:

WATCH FOR COOLANT FLOW BEFORE MAR

NO COOLANT FLOW INSTALL NEW

THERMOSTAT.

COLD ENGINE -SLOW WARMUP -NOT ENOUGH HEAT

1. RELIEVE PRESSURE AND CAREFULLY REMOVE RADIATOR CAP.

2. RUB 188'~. TEMPERATURE STICK' ONTO THERMOSTAT HOUSING.

3. WARM UP ENGINE AT FAST IDLE.

COOLANT FLOW

- 'NOTE: THE TEMPERATURE STICK IS A PENCIL LIKE DEVICE WHICH HAS A WAX MATERIAL CONTAINING CERTAIN CHEMICALS WHICH MELT AT A GIVEN TEMPERATURE THEWERATURE STICKS CAN BE USED TO DETERMINE A THERMOSTAT'S OPERATING TEMPERATURE BY RUBBING laB°F AN0 =OF. STICKS ON THE THERMOSTAT HOUSING. THE MARKS MADE BY THE STICKS SHOULD MELT WHEN COOLANT TEMPERATURES OF IWOF'AND W'F. ARE REACHED, RESPECTIVELY. THESE TEMPERATURES ARE THE NORMAL WERATING RANGE OF THE THERMOSTAT. THEREFORE, ~i WE COOLANT FLOWS AS INDICATED ON THE DIAGNOSIS CHART. THE THERMOSTAT MAY BE DEFECTIVE.

Fig. 7 Thermostat Diagnosis Chart

Page 418 of 1825

ENGINE COOLING BB-7

NOTICE: If recommended quality antifreeze is

used, supplemental inhibitors or additives claiming

to provide increased cooling capability are not

necessary. They may be detrimental to the efficient

operation of the system, and represent an

unnecessary operating expense.

Every 12 months or 15,000 miles, the cooling

system should be serviced as follows;

1. Wash radiator cap and filler neck with clean

water.

2. Check coolant for proper level and freeze

protection.

3. Pressure test system and radiator cap for proper

pressure holding capacity, 103

kPa (15 psi). If

replacement of cap is required, use the proper cap

specified for car model.

4. Tighten hose clamps and inspect all hoses. Replace

hoses whenever cracked, swollen or otherwise

deteriorated.

5. Clean frontal area of radiator core and air

conditioning condenser.

DRAINING AND REFILLING THE COOLING

SYSTEM

Replace hoses every 24 months or 30,000 miles or

earlier if cracked, swollen or otherwise deteriorated.

Every two years or 30,000 miles, whichever first

occurs, the cooling system should be flushed and

refilled using the following recommended procedure:

1. Remove radiator cap, or thermostat housing cap

(VIN

0, J, R and U), when engine is cool by:

a. Slowly

rotating cap counterclockwise to

detent. (Do not press down while rotating.)

b. Wait until any

residual pressure (indicated

by a hissing sound) is relieved.

c. After all hissing ceases, press down on cap

while continuing to rotate

counterclockwise.

CAUTION: To avoid the danger of

being burned, do not remove radiator

cap while engine and radiator are still

hot. Scalding fluid and steam may be

blown out under pressure.

2. Remove the thermostat by using the wire handle

to lift it out of the housing (VIN

0, J, R and U).

3. With the thermostat removed, reinstall the

thermostat housing cap (VIN

0, J, R and U).

4. Open radiator drain valve and block drain plugs

to drain coolant. On VIN R and

9 (P series)

engines, open coolant pipe plugs.

5. Close valve. Reinstall drain plugs, and add

sufficient water to fill system.

6. Run engine, drain and refill the system, as

described in steps

4 and 5 a sufficient number of

times, until the drained liquid is nearly colorless.

Important

BLOCK DRIVE WHEELS, place

transmission in PARK (automatic

transmission) or NEUTRAL (manual

transmission) and set the parking brake. 7.

Allow system to drain completely. Then close

radiator drain valve tightly, and reinstall block

drain plugs.

8. Remove recovery cap leaving hoses in place.

Remove coolant recovery tank and empty of

fluid. Flush tank with clean water, drain and

reinstall.

9. Add sufficient ethylene glycol coolant, meeting

GM specification 1825-M, to provide the

required freezing and corrosion protection

- at

least 50 percent solution -37°C (-34°F). Fill

radiator to the base of the radiator fill neck and

add sufficient coolant to the recovery tank to

raise level to the "FULL" mark. Reinstall

recovery tank cap.

10. Run engine, with radiator cap or thermostat

housing cap removed, until normal operating

temperature is reached. (Radiator upper hose

becomes hot.)

11. With engine idling, add coolant until level

reaches bottom of filler neck and reinstall cap,

making certain arrows line up with overflow tube.

CAUTION: Under some conditions, the

ethylene glycol in engine coolant is

flammable. To help avoid being

burned when adding coolant, DO NOT

spill

it on the exhaust system or hat

engine parts.

It is the owner's responsibility to keep the freeze

protection at a level appropriate to the

temperatures which may occur in the area of

vehicle operation.

a. Maintain

cooling system freeze protection

at

-37°C (-34"F), to ensure protection

against corrosion and loss of coolant from

boiling, even though freezing temperatures

are not expected.

b. Add ethylene glycol base coolant that meets

GM Specification 1825-M, when coolant

additions are required because of coolant

loss, or to provide additional protection

against

freezing at temperatures lower than

-37°C (-34°F).

NOTICE: Alcohol or methanol base coolants, or

plain water, are not recommended at any time.

DRlVE BELT

NOTICE: Routine inspection of the belt may

reveal cracks in the belt ribs. These cracks will

not impair belt performance and therefore should

not be considered a problem requiring belt

replacement. However, the belt should be

replaced if belt slip occurs or if sections of the

belt ribs are missing.

A single (serpentine) belt is used to drive all

engine accessories formerly driven by multiple drive

belts. All belt driven accessories are ridgedly mounted

with belt tension maintained by a spring loaded

tensioner.

The drive belt tensioner has the ability to control

belt tension over a fairly broad range of belt lengths.

Page 419 of 1825

68-8 ENGINE COOLING

However, there are limits to the tensioner's ability to

The tensioner has rovisions for a visual check to

compensate for varying lengths of belts. With the

ten- verify that it is in t e "operating range" (see Figures

sioner outside of its operating range, poor tension

608 and 609). R

control andlor damage to the tensioner may result.

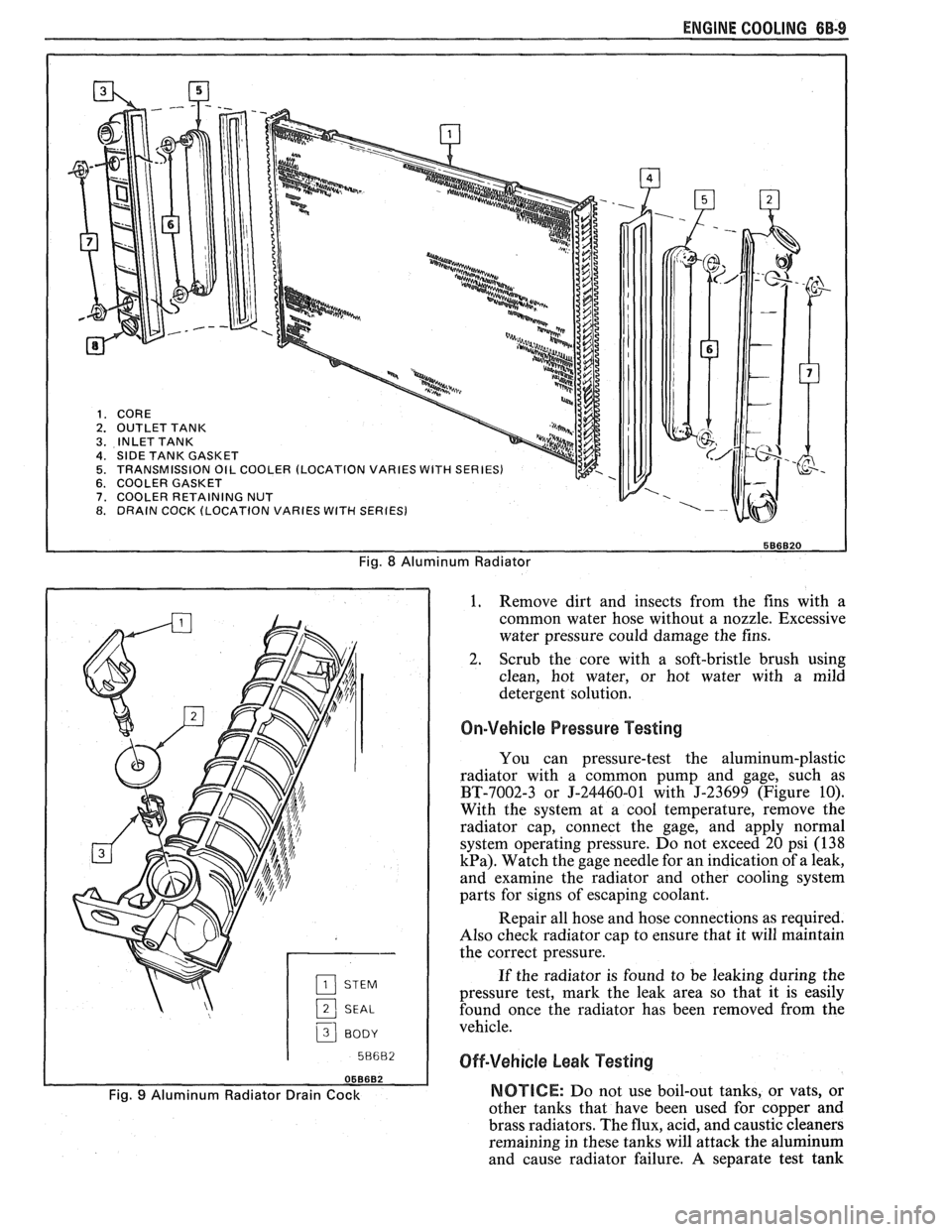

ALUMINUM RADIATOR REPAIR

This radiator utilizes an aluminum core with

plastic side tanks. The core and side tanks can be

replaced separately and core repair is easily made with

the hot melt adhesive method. A transaxle oil cooler

is located in one of the side tanks. The oil cooler can

be replaced. The drain cock is located on the lower part

of one of the tanks. The drain cock is also serviceable.

Core

The core is made of aluminum and is of the

crossflow design. It utilizes large tubes that resist

plugging, and repairs to the tubes and core are easily

made using the hot melt adhesive method.

The core is attached to the tanks by clinched tabs

on the core that can be bent back if tank or core

replacement is required.

If the damage to a tube is too severe, a tube can

be blocked or plugged as explained in "Tube Blocking.

" No more than two tubes should ever be blocked on

a core. Also replace the core if more than three tabs are

broken on one side, or if two adjacent tabs are broken.

Tanks

The tanks are attached to the core by the use of

clinched tabs. The clinched tabs can be bent back if the

tanks need to be removed from the core. Bend the tabs

back only enough to remove the tank. Overbending

will weaken the tabs.

A high temperature rubber gasket is used to seal

the mating surface between the core and the tank. (See

Fig. 8). The gasket must be replaced any time a tank

is removed from the core.

Transaxle Oil Cooler

The transaxle oil cooler is located in one of the

radiator side tanks. The oil cooler can be replaced by

removing the tank from the core.

A leaking oil cooler gasket can be replaced

without removing the tank from the core.

Drain Cock

The aluminum/plastic radiator utilizes a two

piece plastic drain cock and a rubber seal. The drain

cock is serviceable (See Fig.

9).

ALUMINUM RADIATOR SERVICE

The aluminum-plastic radiator can be repaired at

the dealership. The following components are easily

replaced:

e Core

e Tanks and gaskets

o Oil coolers and gaskets

e Drain cock and gasket The

tanks cannot be repaired if broken or

cracked. The radiator core can be replaced and the new

core used with the original tanks and oil cooler.

Precautions

As with all cooling system service, take measures

to prevent personal injury and damage to the system.

CAUTION: To help avoid the danger of

being burned, do not remove the

radiator cap while the engine and

radiator are

still hot. Scalding fluid

and steam can be blown out under

pressure if the

cap is taken off too

soon.

NOTICE: DO NOT USE "BOIL OUT" TANKS

OR VATS. Common service methods may

actually destroy an aluminum radiator. Caustic or

lye cleaning solutions must NOT be used for

aluminum radiators.

e Do not open the hood if you can see, or hear,

steam or coolant escaping from the engine

compartment.

e Do not remove radiator cap if radiator feels

warm.

e Do not remove the radiator cap or coolant

recovery tank cap if the coolant in the recovery

tank looks like it is boiling.

Wear eye protection.

e Wear gloves to protect your hands against

excessive heat, or the effects of chemicals on your

skin.

o Prevent dirt and water from entering the

transmission oil cooler.

e Do not use boil-out tanks, or vats, or other tanks

that have been used for copper and brass

radiators. The flux, acid, and caustic cleaners

remaining in these tanks will attack the

aluminum and cause radiator failure.

A separate

test tank containing clean water is strongly

recommended for servicing aluminum-plastic

radiators.

RIOTICE: Never use shop air that is not regulated

at

20 psi (138 kPa) to pressure test radiator.

Pressures over

20 psi (138 kPa) will damage the

radiator.

DIAGNOSIS

Leak Testing

Some core leaks can be detected by merely adding

water to the radiator. It is helpful to clean the core so

that the damaged area can be more easily found.

Page 420 of 1825

ENGINE COOLING 6B-9

Fig. 8 Aluminum Radiator

2 SEAL

3 BODY I

1. Remove

dirt and insects from the fins with a

common water hose without a nozzle. Excessive

water pressure could damage the fins.

2. Scrub the core with a soft-bristle brush using

clean, hot water, or hot water with a mild

detergent solution.

On-Vehicle Pressure Testing

You can pressure-test the aluminum-plastic

radiator with a common pump and gage, such as

BT-7002-3 or J-24460-01 with J-23699 (Figure 10).

With the system at a cool temperature, remove the

radiator cap, connect the gage, and apply normal

system operating pressure. Do not exceed 20 psi (138

kPa). Watch the gage needle for an indication of a leak,

and examine the radiator and other cooling system

parts for signs of escaping coolant.

Repair all hose and hose connections as required.

Also check radiator cap to ensure that it will maintain

the correct pressure.

If the radiator is found to be leaking during the

pressure test, mark the leak area so that it is easily

found once the radiator has been removed from the

vehicle.

Off-Vehicle beak Testing

Fig. 9 Aluminum Radiator Drain Cock NOTICE: Do not use boil-out tanks, or vats, or

other tanks that have been used for

couuer and

brass radiators. The flux, acid, and

caustiE cleaners

remaining in these tanks will attack the aluminum

and cause radiator failure. A separate test tank