PONTIAC FIERO 1988 Service Repair Manual

Manufacturer: PONTIAC, Model Year: 1988, Model line: FIERO, Model: PONTIAC FIERO 1988Pages: 1825, PDF Size: 99.44 MB

Page 441 of 1825

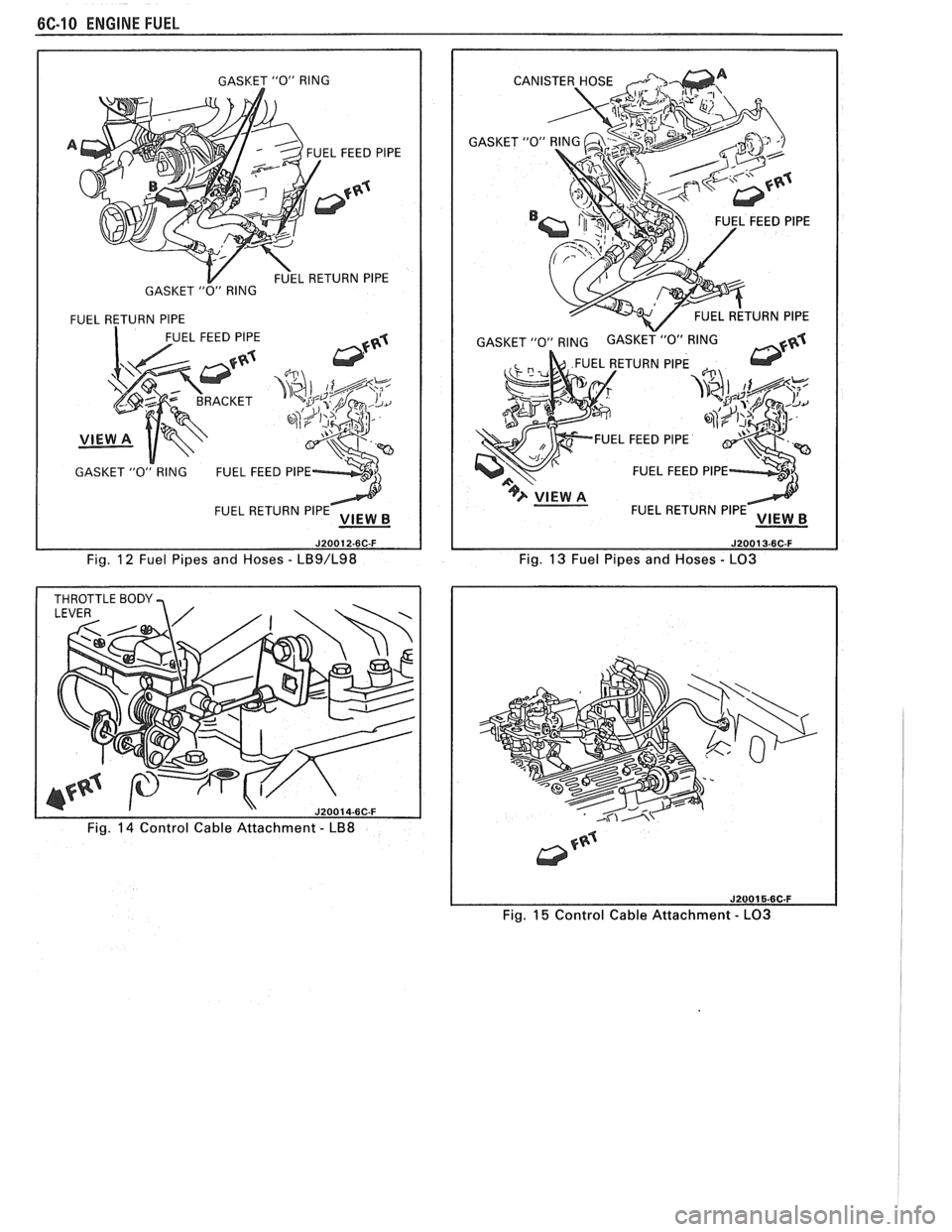

6C-1Q ENGINE FUEL

GASKET "0" RING I

A EL FEED PlPE

L RETURN PlPE

GASKET

"0" RlNG

FUEL RETURN

PIPE I

UEL FEED PlPE

GASKET

"0" RlNG FUEL FEED PIPE

FUEL RETURN PlPE

Fig. 12 Fuel Pipes and Hoses - LB9/L98

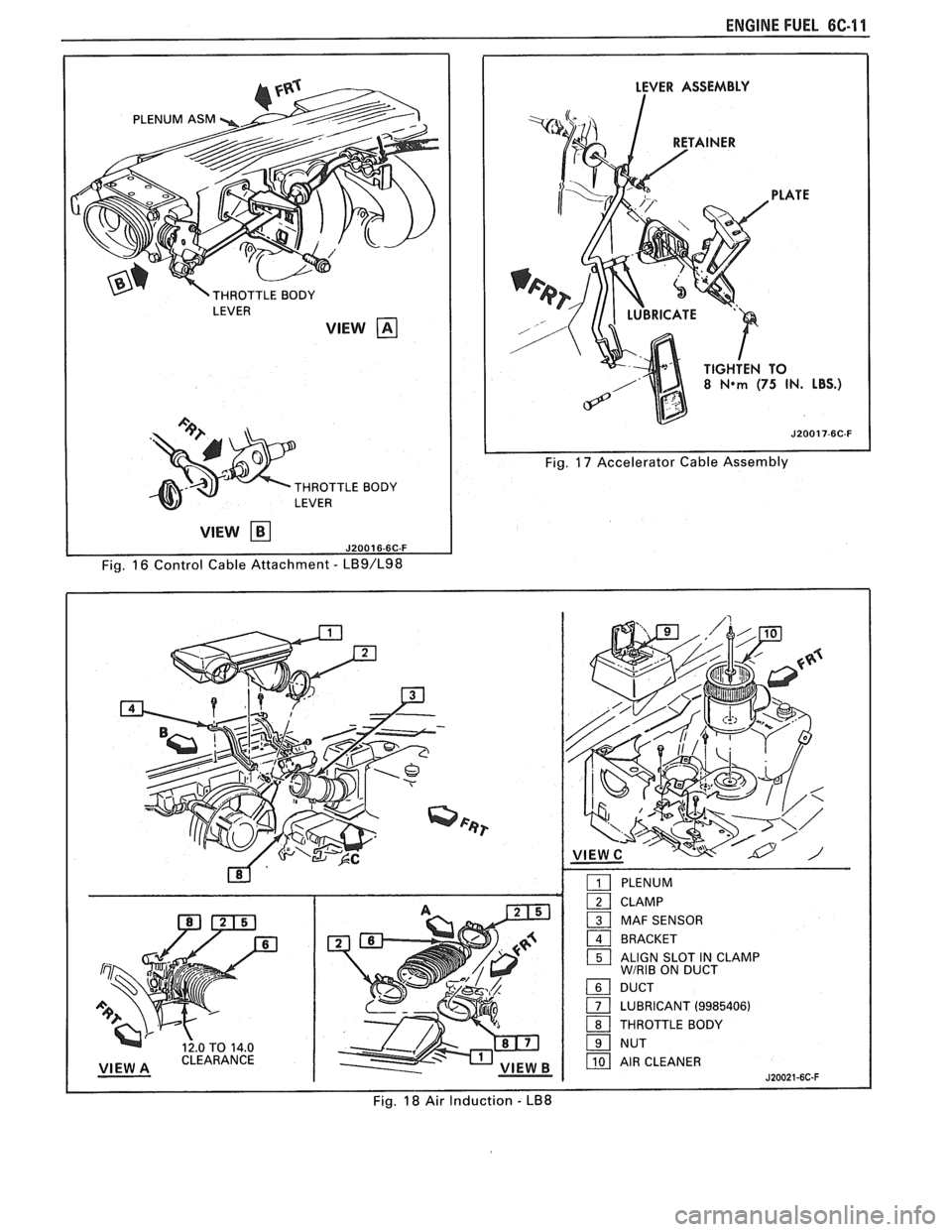

I THROTTLE BODY 9 I

Fig. 14 Control Cable Attachment - LB8

GASKET "0" RING GASKET "0" RING

FUEL FEED PlPE

FUEL FEED PlPE

FUEL RETURN PlPE

Fig. 13 Fuel Pipes and Hoses - LO3

Fig. 15 Control Cable Attachment - LO3

Page 442 of 1825

ENGINE FUEL 6C-11

LEVER

VlEW

THROTTLE BODY

LEVER

VlEW kl

Fig. 16 Control Cable Attachment - LB9/L98

LEVER ASSEMBLY

Fig. 17 Accelerator Cable Assembly

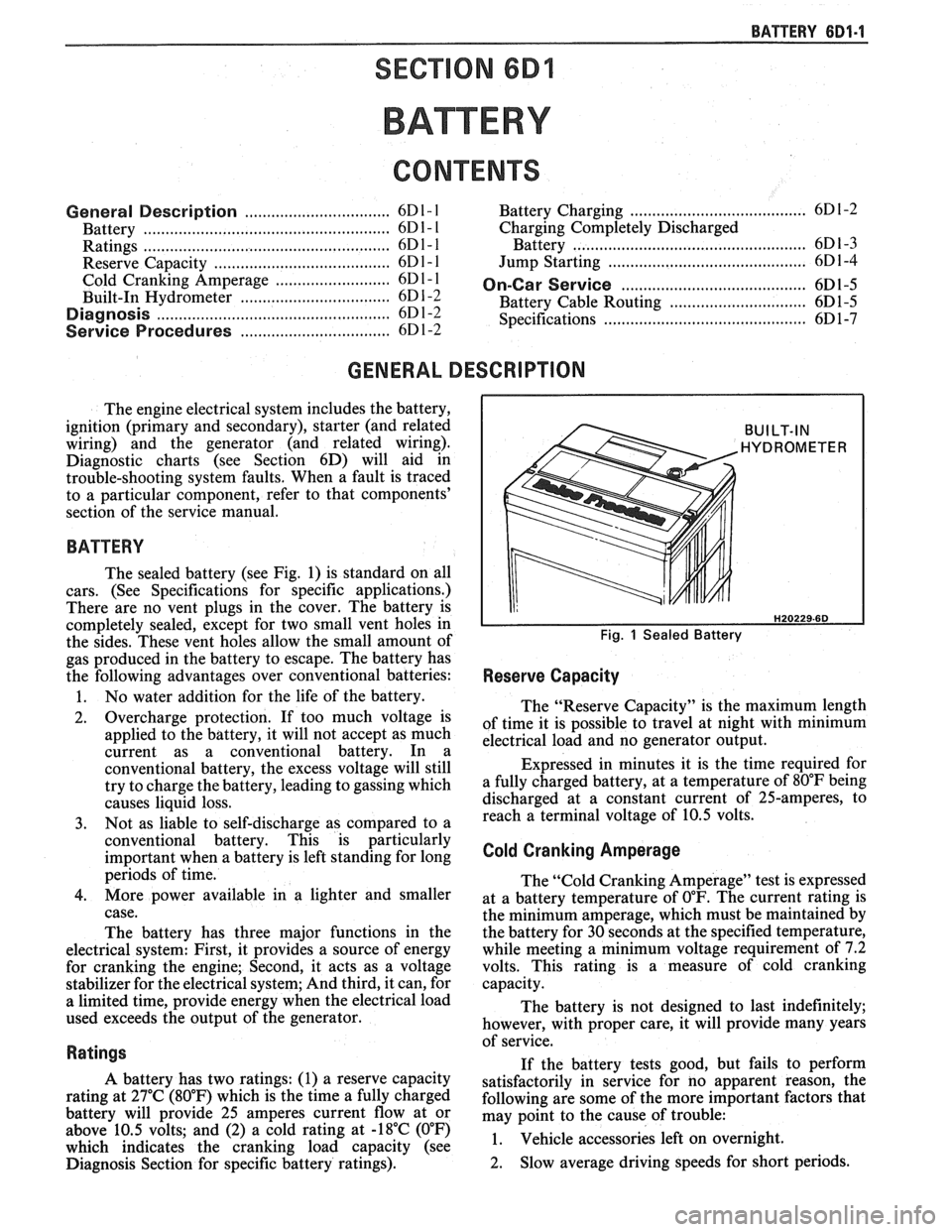

Fig.

18 Air Induction - LB8

Page 443 of 1825

![PONTIAC FIERO 1988 Service Repair Manual

6C-12 ENGINE FUEL

VIEW A

MAF SENSOR &

:~~~T

I3] DUCT

1 AIR CLEANER

1 ALIGN SLOT IN CLAMP WIRIB ON DUCT

LUBRICANT

(9985406)

1 THROTTLE BODY

Fig. 19 Air lnduction - LB9/L98

Fig. 20 Air PONTIAC FIERO 1988 Service Repair Manual

6C-12 ENGINE FUEL

VIEW A

MAF SENSOR &

:~~~T

I3] DUCT

1 AIR CLEANER

1 ALIGN SLOT IN CLAMP WIRIB ON DUCT

LUBRICANT

(9985406)

1 THROTTLE BODY

Fig. 19 Air lnduction - LB9/L98

Fig. 20 Air](/img/50/57415/w960_57415-442.png)

6C-12 ENGINE FUEL

VIEW A

MAF SENSOR &

:~~~T

I3] DUCT

1 AIR CLEANER

1 ALIGN SLOT IN CLAMP WIRIB ON DUCT

LUBRICANT

(9985406)

1 THROTTLE BODY

Fig. 19 Air lnduction - LB9/L98

Fig. 20 Air Induction - LO3

Page 444 of 1825

BATTERY 6D1.1

SECTION 6Dl

BATTERY

CONTENTS

.......................... .. General Description ................................ 6D1- 1 Battery Charging ...... 6D 1-2

Battery .......................... ... ....................... 6D 1 - 1 Charging Completely Discharged

.................................................... ............................. Ratings .................... ... 6D 1 - 1 Battery 6D 1-3

........................................... Reserve Capacity ..................................... 6D 1 - 1 Jump Starting 6D

1-4

Cranking ............a*............ 6D1-1 On-Gar Service ...................................... 6Dl-5 .................................. Built-In Hydrometer 6D 1-2 Battery Cable Routing ............................... 6D 1-5 Diagnosis ................................................... 6Dl-2

Specifications .............................................. 6D 1-7 ............................. Service Procedures ..... 6D 1-2

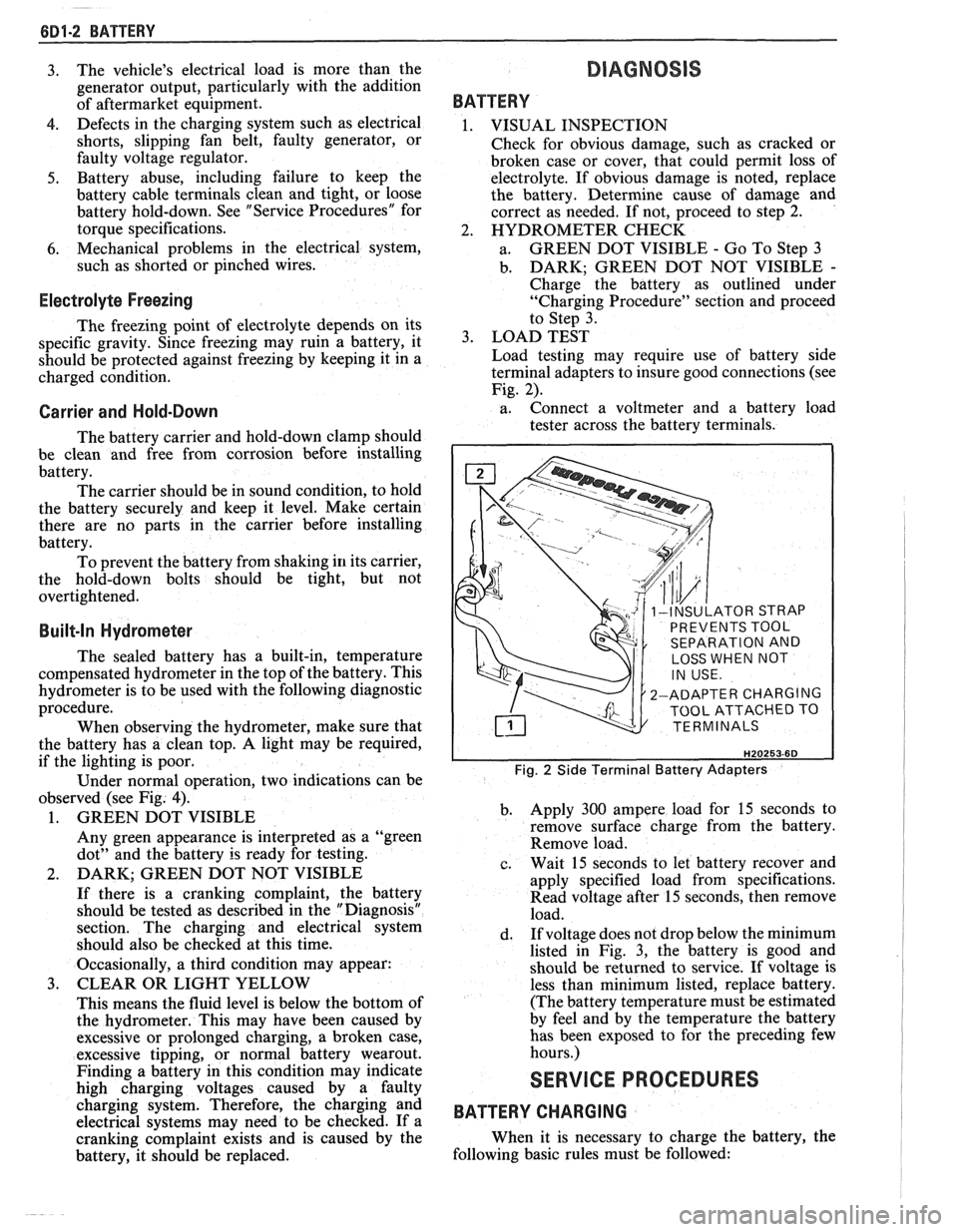

GENERAL DESCRIPTION

The engine electrical system includes the battery,

ignition (primary and secondary), starter (and related

wiring) and the generator (and related wiring).

Diagnostic charts (see Section 6D) will aid in

trouble-shooting system faults. When a fault is traced

to a particular component, refer to that components'

section of the service manual.

BATTERY

The sealed battery (see Fig. 1) is standard on all

cars. (See Specifications for specific applications.)

There are no vent plugs in the cover. The battery is

completely sealed, except for two small vent holes in

the sides. These vent holes allow the small amount of

gas produced in the battery to escape. The battery has

the following advantages over conventional batteries:

1. No water addition for the life of the battery.

2. Overcharge protection. If too much voltage is

applied to the battery, it will not accept as much

current as a conventional battery. In a

conventional battery, the excess voltage will still

try to charge the battery, leading to gassing which

causes liquid loss.

3. Not as liable to self-discharge as compared to a

conventional battery. This is particularly

important when a battery is left standing for long

periods of time.

4. More power available in a lighter and smaller

case.

The battery has three major functions in the

electrical system: First, it provides a source of energy

for cranking the engine; Second, it acts as a voltage

stabilizer for the electrical system; And third, it can, for

a limited time, provide energy when the electrical load

used exceeds the output of the generator.

Ratings

A battery has two ratings: (1) a reserve capacity

rating at 27°C (80°F) which is the time a fully charged

battery will provide 25 amperes current flow at or

above 10.5 volts; and (2) a cold rating at -18°C (0°F)

which indicates the cranking load capacity (see

Diagnosis Section for specific battery ratings).

BUILT-IN

HYDROMETER

Fig. 1 Sealed Battery

Reserve Capacity

The "Reserve Capacity" is the maximum length

of time it is possible to travel at night with minimum

electrical load and no generator output.

Expressed in minutes it is the time required for

a fully charged battery, at a temperature of 80°F being

discharged at a constant current of 25-amperes, to

reach a terminal voltage of 10.5 volts.

Cold Cranking Amperage

The "Cold Cranking Amperage" test is expressed

at a battery temperature of

0°F. The current rating is

the minimum amperage, which must be maintained by

the battery for 30 seconds at the specified temperature,

while meeting a minimum voltage requirement of 7.2

volts. This rating is a measure of cold cranking

capacity.

The battery is not designed to last indefinitely;

however, with proper care, it will provide many years

of service.

If the battery tests good, but fails to perform

satisfactorily in service for no apparent reason, the

following are some of the more important factors that

may point to the cause of trouble:

1. Vehicle

accessories left on overnight.

2. Slow

average driving speeds for short periods.

Page 445 of 1825

6D1-2 BA'TTERY

3. The

vehicle's electrical load is more than the

generator output, particularly with the addition

of aftermarket equipment.

4. Defects in the charging system such as electrical

shorts, slipping fan belt, faulty generator, or

faulty voltage regulator.

5. Battery abuse, including failure to keep the

battery cable terminals clean and tight, or loose

battery hold-down. See "Service Procedures" for

torque specifications.

6. Mechanical problems in the electrical system,

such as shorted or pinched wires.

Electrolyte Freezing

The freezing point of electrolyte depends on its

specific gravity. Since freezing may ruin a battery, it

should be protected against freezing by keeping it in a

charged condition.

Carrier and Hold-Down

The battery carrier and hold-down clamp should

be clean and free from corrosion before installing

battery.

The carrier should be in sound condition, to hold

the battery securely and keep it level. Make certain

there are no parts in the carrier before installing

battery.

To prevent the battery from shaking

in its carrier,

the hold-down bolts should be tight, but not

overtightened.

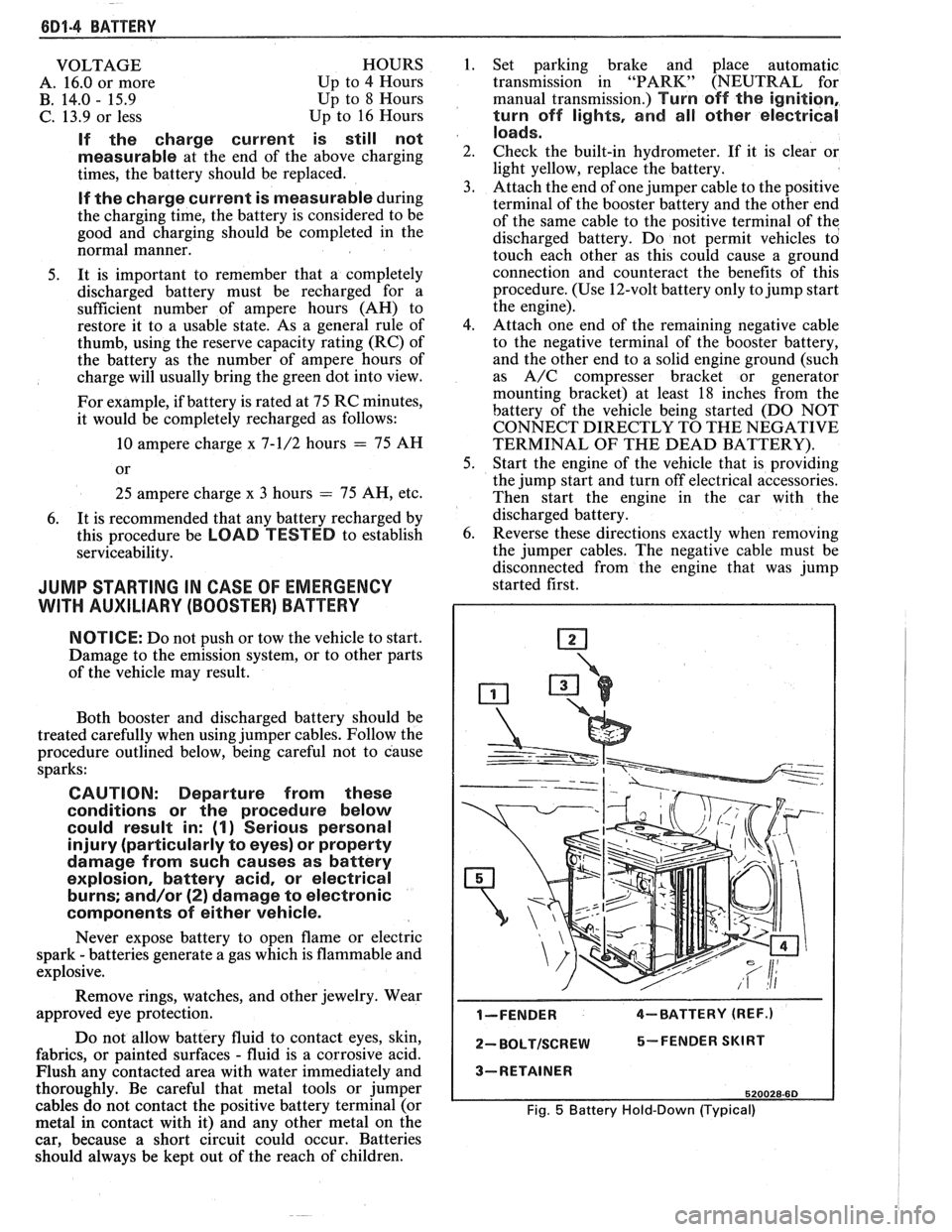

Built-In Hydrometer

The sealed battery has a built-in, temperature

compensated hydrometer in the top of the battery. This

hydrometer is to be used with the following diagnostic

procedure.

When observing the hydrometer, make sure that

the battery has a clean top. A light may be required,

if the lighting is poor.

Under normal operation, two indications can be

observed (see Fig.

4).

1. GREEN DOT VISIBLE

Any green appearance is interpreted as a "green

dot" and the battery

is ready for testing.

2. DARK; GREEN DOT NOT VISIBLE

If there is a cranking complaint, the battery

should be tested as described in the "Diagnosis"

section. The charging and electrical system

should also be checked at this time.

Occasionally, a third condition may appear:

3. CLEAR OR LIGHT YELLOW

This means the fluid level is below the bottom of

the hydrometer. This may have been caused by

excessive or prolonged charging, a broken case,

excessive tipping, or normal battery

wearout.

Finding a battery in this condition may indicate

high charging voltages caused by a faulty

charging system. Therefore, the charging and

electrical systems may need to be checked. If a

cranking complaint exists and is caused by the

battery, it should be replaced.

BATTERY

1. VISUAL INSPECTION

Check for obvious damage, such as cracked or

broken case or cover, that could permit loss of

electrolyte. If obvious damage is noted, replace

the battery. Determine cause of damage and

correct as needed. If not, proceed to step 2.

2. HYDROMETER CHECK

a. GREEN

DOT VISIBLE

- Go To Step 3

b. DARK;

GREEN DOT NOT VISIBLE -

Charge the battery as outlined under

"Charging Procedure" section and proceed

to Step 3.

3. LOAD TEST

Load testing may require use of battery side

terminal adapters to insure good connections (see

Fig. 2).

a. Connect

a voltmeter and a battery load

tester across the battery terminals.

INSULATOR STRAP

PREVENTS TOOL

SEPARATION AND

LOSS WHEN NOT

2-ADAPTER CHARGING

TOOL ATTACHED TO

TERMINALS

Fig. 2 Side Terminal Battery Adapters

b. Apply 300 ampere load for 15 seconds

to

remove surface charge from the battery.

Remove load.

c. Wait

15 seconds to let battery recover and

apply specified load from specifications.

Read voltage after 15 seconds, then remove

load.

d. If

voltage does not drop below the minimum

listed in Fig. 3, the battery is good and

should be returned to service. If voltage is

less than minimum listed, replace battery.

(The battery temperature must be estimated

by feel and by the temperature the battery

has been exposed to for the preceding few

hours.)

SERVICE PROCEDURES

BATTERY CHARGING

When it is necessary to charge the battery, the

following basic rules must be followed:

Page 446 of 1825

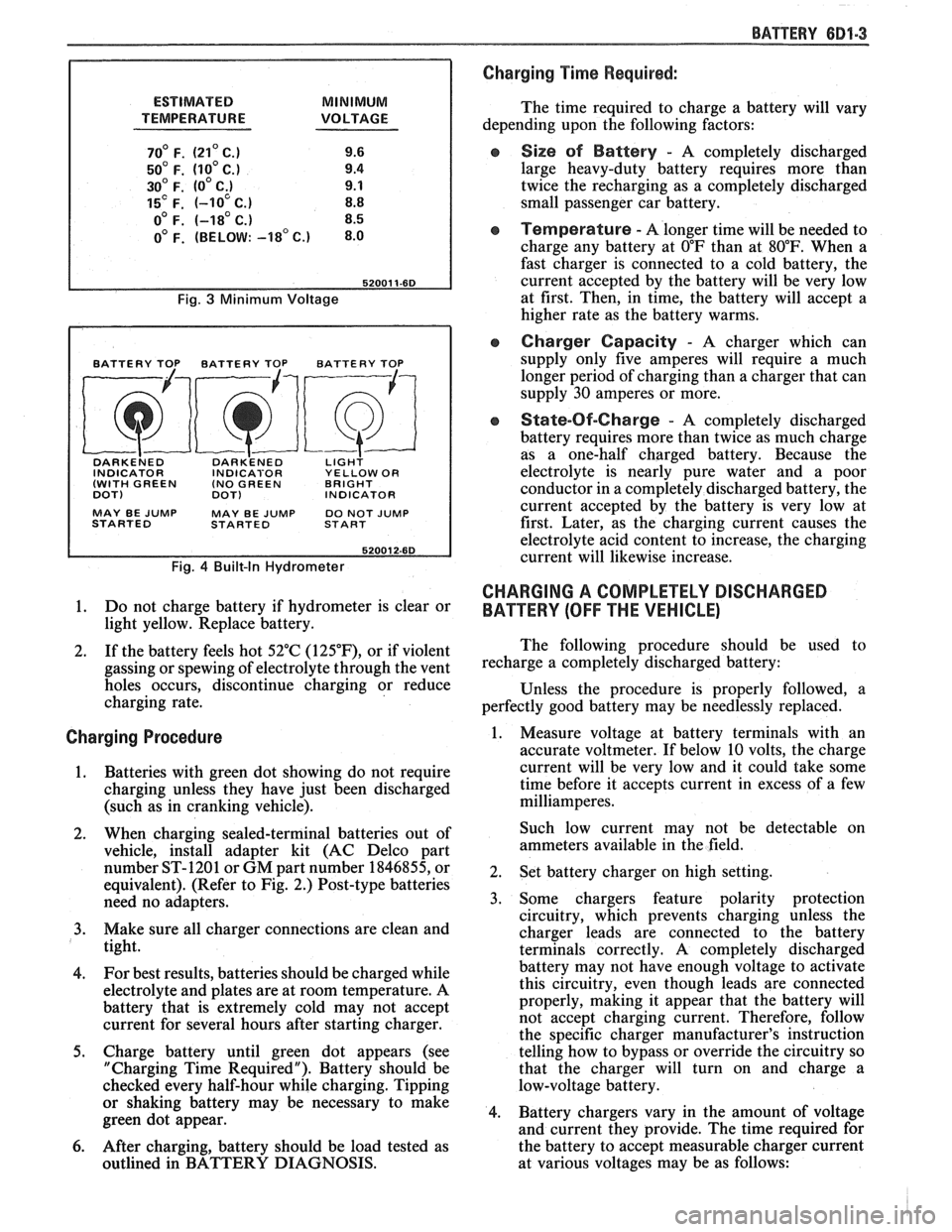

ESTIMATED MINIMUM

TEMPERATURE VOLTAGE

70' F. (21' C.) 9.6

50' F. (10' C.) 9.4

30' F. (0' C;) 9.1

15' F. (-10 C.) 8.8

o0 F. (-18' C.) 8.5

0' F. (BELOW: -18' c.) 8.0

Fig. 3 Minimum Voltage

BATTERY TOP BATTERY TOP BATTERY TOP

DARKE~ED DARK'ENED LIGH? INDICATOR INDICABOR YELLOW OR

(WITH GREEN (NO

GREEN BRIGHT

DOT)

DOT) INDICATOR

MAY BE

JUMP MAY BE JUMP DO NOT JUMP

STARTED STARTED START

Fig. 4 Built-In Hydrometer

1. Do not charge battery if hydrometer is clear or

light yellow. Replace battery.

2. If the battery feels hot 52°C

(125"F), or if violent

gassing or spewing of electrolyte through the vent

holes occurs, discontinue charging or reduce

charging rate.

Charging Procedure

1. Batteries with green

dot showing do not require

charging unless they have just been discharged

(such as in cranking vehicle).

2. When charging sealed-terminal batteries out of

vehicle, install adapter kit (AC Delco part

number ST-1201 or GM part number 1846855, or

equivalent). (Refer to Fig. 2.) Post-type batteries

need no adapters.

3. Make sure all charger connections are clean and

tight.

4. For

best results, batteries should be charged while

electrolyte and plates are at room temperature. A

battery that is extremely cold may not accept

current for several hours after starting charger.

5. Charge battery until green dot appears (see

"Charging Time Required"). Battery should be

checked every half-hour while charging. Tipping

or shaking battery may be necessary to make

green dot appear.

6. After charging, battery should be load tested as

outlined in BATTERY DIAGNOSIS.

BATTERY 681-3

Charging Time Required:

The time required to charge a battery will vary

depending upon the following factors:

e Size sf Battery - A completely discharged

large heavy-duty battery requires more than

twice the recharging as a completely discharged

small passenger car battery.

Temperature - A longer time will be needed to

charge any battery at

O"F than at 80°F. When a

fast charger is connected to a cold battery, the

current accepted by the battery will be very low

at first. Then, in time, the battery will accept a

higher rate as the battery warms.

Charger Capacity - A charger which can

supply only five amperes will require a much

longer period of charging than a charger that can

supply

30 amperes or more.

e State-Of-Charge - A completely discharged

battery requires more than twice as much charge

as a one-half charged battery. Because the

electrolyte is nearly pure water and a poor

conductor in a completely discharged battery, the

current accepted by the battery is very low at

first. Later, as the charging current causes the

electrolyte acid content to increase, the charging

current will likewise increase.

CHARGING A COMPLETELY DISCHARGED

BATTERY

(OFF THE VEHICLE)

The following procedure should be used to

recharge a completely discharged battery:

Unless the procedure is properly followed, a

perfectly good battery may be needlessly replaced.

1. Measure voltage at battery terminals with an

accurate voltmeter. If below 10 volts, the charge

current will be very low and it could take some

time before it accepts current in excess of a few

milliamperes.

Such low current may not be detectable on

ammeters available in the field.

2. Set battery charger on high setting.

3. Some chargers feature polarity protection

circuitry, which prevents charging unless the

charger leads are connected to the battery

terminals correctly. A completely discharged

battery may not have enough voltage to activate

this circuitry, even though leads are connected

properly, making it appear that the battery will

not accept charging current. Therefore, follow

the specific charger manufacturer's instruction

telling how to bypass or override the circuitry so

that the charger will turn on and charge a

low-voltage battery.

4. Battery chargers vary in the amount of voltage

and current they provide. The time required for

the battery to accept measurable charger current

at various voltages may be as follows:

Page 447 of 1825

6D1-4 BATTERY

VOLTAGE

A. 16.0 or more

B. 14.0

- 15.9

C. 13.9 or less HOURS

1. Set parking brake and place automatic

Up to 4 Hours transmission in "PARK" (NEUTRAL for

Up to 8 Hours manual transmission.) Turn off the ignition,

Up to 16 Hours turn off lights, and all other electrical

If the charge current is still not

measurable

at the end of the above charging

times, the battery should be replaced.

If the charge current is measurable during

the charging time, the battery is considered to be

good and charging should be completed in the

normal manner.

5. It

is important to remember that a completely

discharged battery must be recharged for a

sufficient number of ampere hours (AH) to

restore it to a usable state. As a general rule of

thumb, using the reserve capacity rating (RC) of

the battery as the number of ampere hours of

charge will usually bring the green dot into view.

For example, if battery is rated at 75 RC minutes,

it would be completely recharged as follows:

10 ampere charge x 7-1/2 hours

= 75 AH

25 ampere charge x 3 hours = 75 AH, etc.

6. It

is recommended that any battery recharged by

this procedure be

LOAD TESTED to establish

serviceability.

JUMP STARTING IN CASE OF EMERGENCY

WITH AUXILIARY (BOOSTER) BAVEEWY

NOTICE: Do not push or tow the vehicle to start.

Damage to the emission system, or to other parts

of the vehicle may result.

Both booster and discharged battery should be

treated carefully when using jumper cables. Follow the

procedure outlined below, being careful not to cause

sparks:

CAUTION: Departure from these

conditions or the procedure below

could result in:

(1) Serious personal

injury (particularly to eyes) or property

damage from such causes as battery

explosion, battery acid, or electrical

burns; and/or

(2) damage to electronic

components of either vehicle.

Never expose battery to open flame or electric

spark

- batteries generate a gas which is flammable and

explosive.

Remove rings, watches, and other jewelry. Wear

approved eye protection.

Do not allow battery fluid to contact eyes, skin,

fabrics, or painted surfaces

- fluid is a corrosive acid.

Flush any contacted area with water immediately and

thoroughly. Be careful that metal tools or jumper

cables do not contact the positive battery terminal (or

metal in contact with it) and any other metal on the

car, because a short circuit could occur. Batteries

should always be kept out of the reach of children.

loads.

2. Check the built-in hydrometer. If it is clear or

light yellow, replace the battery.

3. Attach the end of one jumper cable to the positive

terminal of the booster battery and the other end

of the same cable to the positive terminal of the

discharged battery. Do not permit vehicles to

touch each other as this could cause a ground

connection and counteract the benefits of this

procedure. (Use 12-volt battery only to jump start

the engine).

4. Attach one end of the remaining negative cable

to the negative terminal of the booster battery,

and the other end to a solid engine ground (such

as

A/C compresser bracket or generator

mounting bracket) at least 18 inches from the

battery of the vehicle being started (DO NOT

CONNECT DIRECTLY TO THE NEGATIVE

TERMINAL OF THE DEAD BATTERY).

5. Start the engine of the vehicle that is providing

the jump start and turn off electrical accessories.

Then start the engine in the car with the

discharged battery.

6. Reverse these directions exactly when removing

the jumper cables. The negative cable must be

disconnected from the engine that was jump

started first.

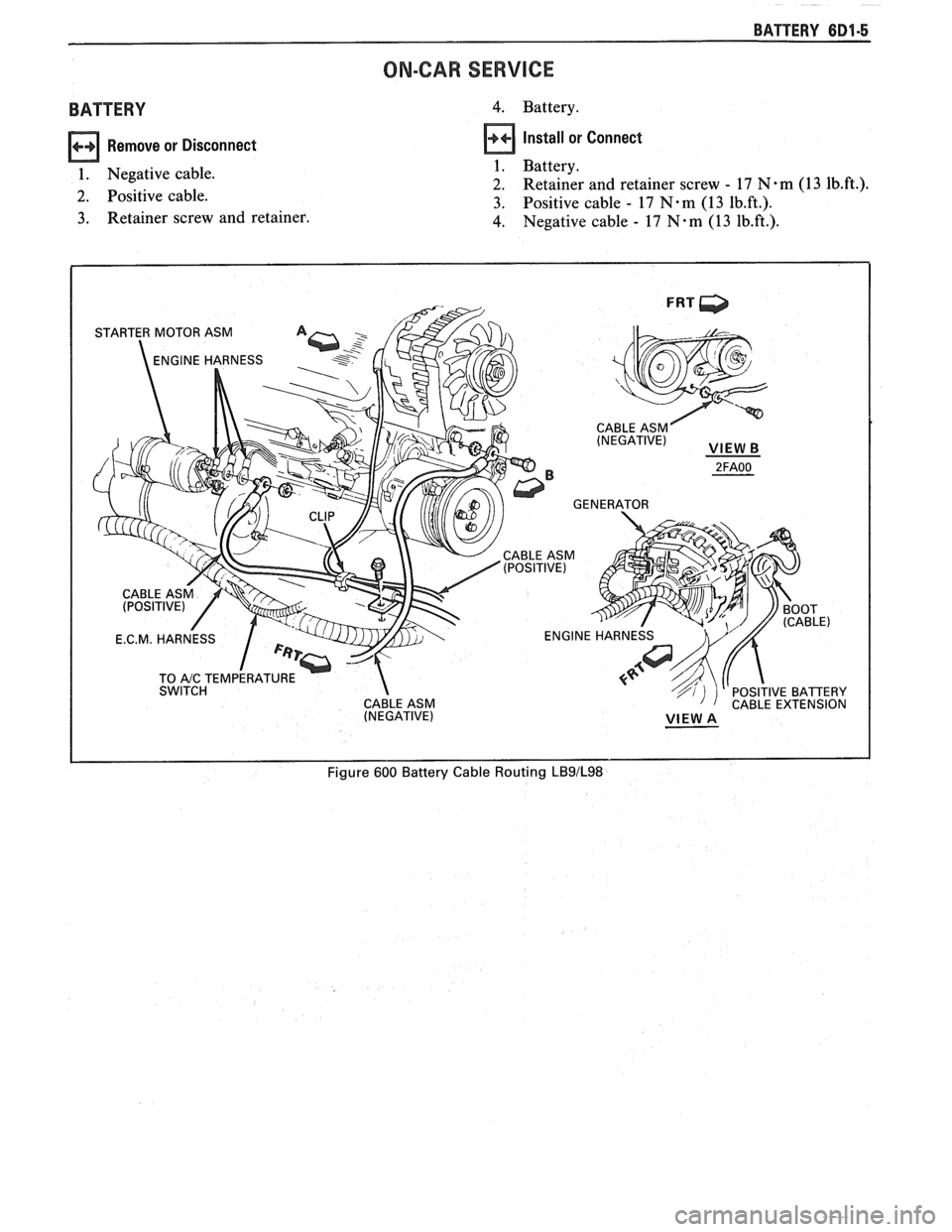

I-FENDER 4-BATTERY (REF.)

2- BOLTISCREW 5-FENDER SKIRT

3-RETAINER

520028-60

Fig. 5 Battery Hold-Down (Typical)

Page 448 of 1825

BATTERY 6D1-5

ON-CAR SERVICE

BATTERY

Remove or Disconnect

1. Negative cable.

2. Positive cable.

3. Retainer screw and retainer.

4. Battery.

Install or Connect

1. Battery.

2. Retainer and retainer screw - 17 N.m (13 1b.ft.).

3. Positive cable - 17 N.m (13 1b.ft.).

4. Negative cable - 17 N-m (13 1b.ft.).

Figure 600 Battery Cable Routing LB9lL98

Page 449 of 1825

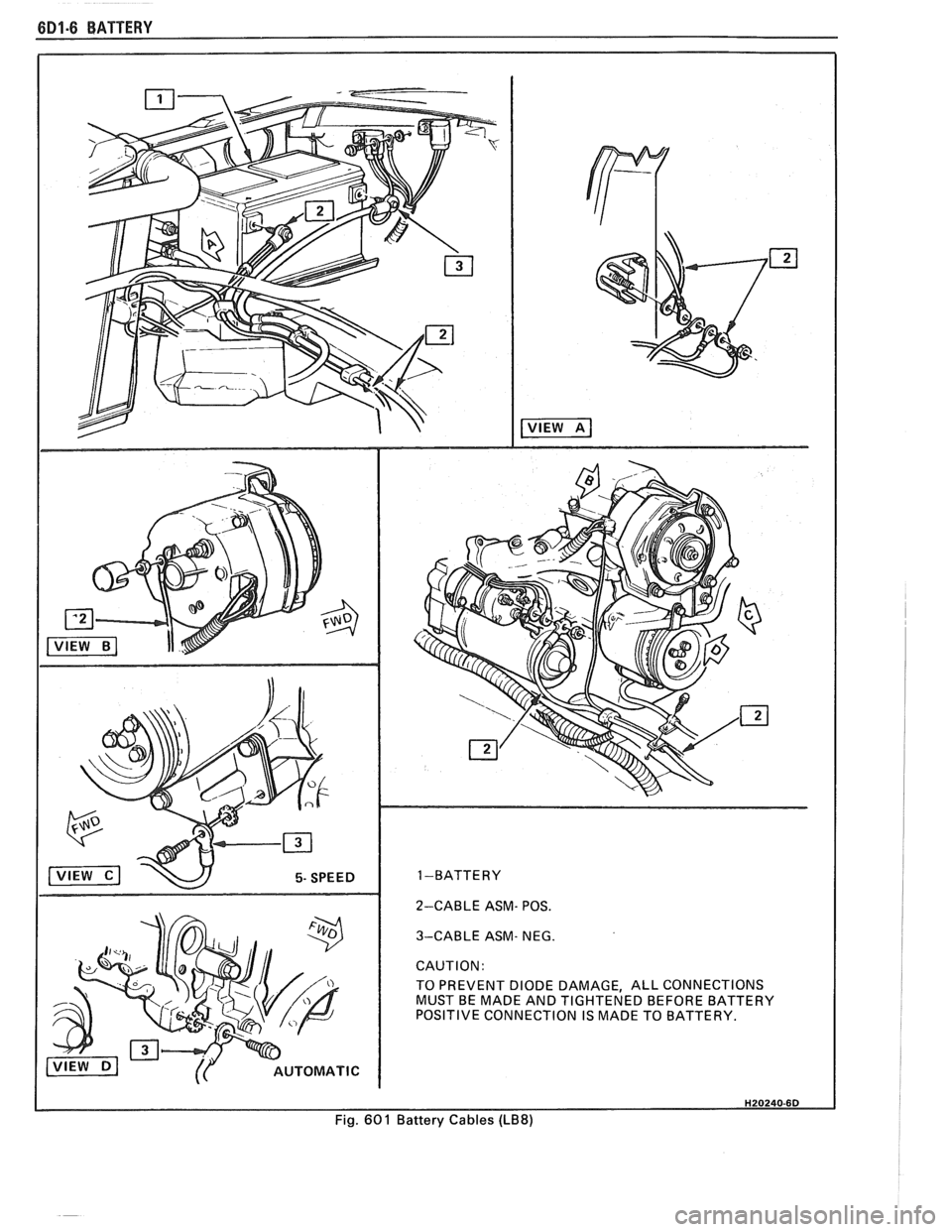

6D1-6 BATTERY

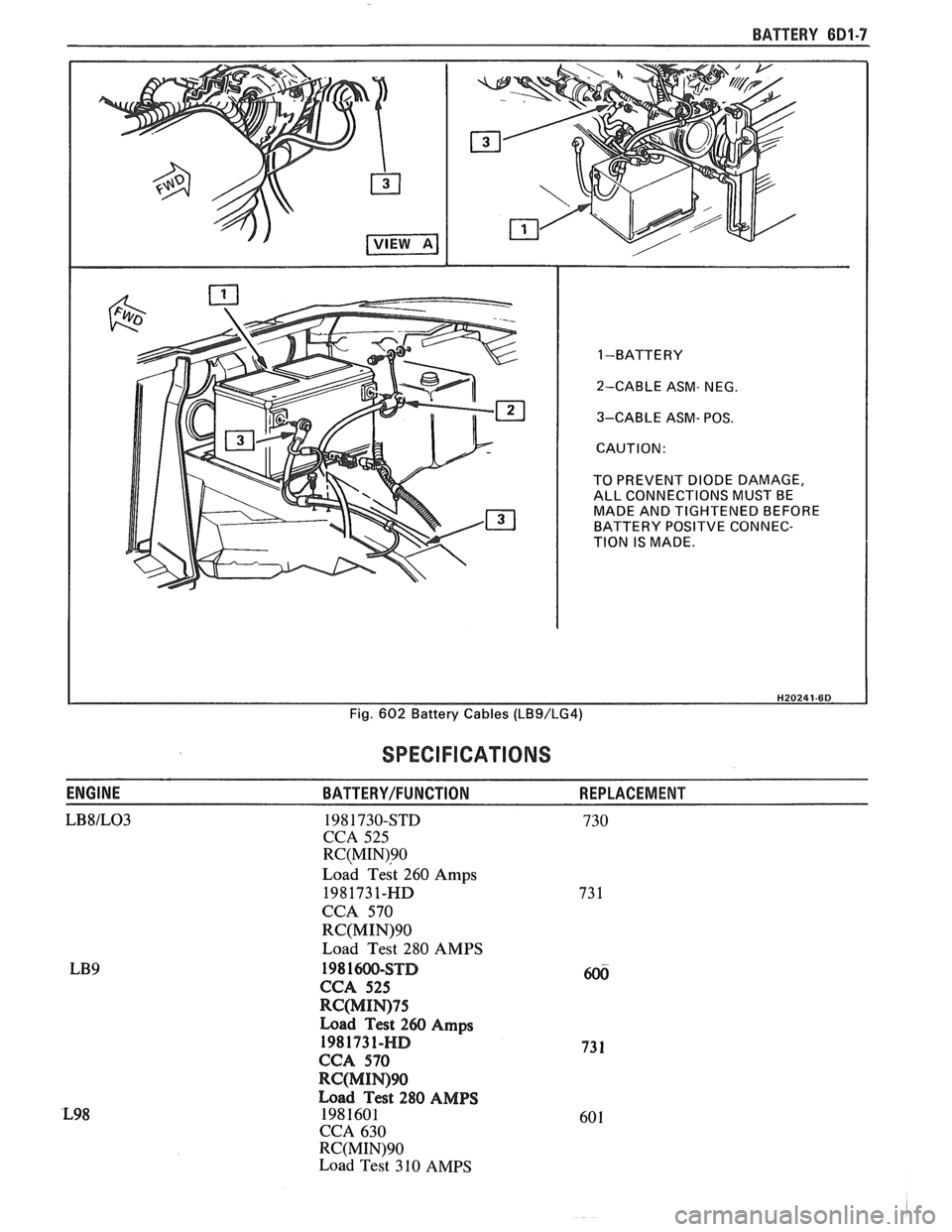

1 -BATTERY

2-CABLE ASM- POS.

3-CABLE ASM- NEG.

TO PREVENT DIODE DAMAGE, ALL CONNECTIONS

MUST BE MADE AND TIGHTENED BEFORE BATTERY

POSITIVE CONNECTION IS MADE TO BATTERY.

Fig.

60 1 Battery Cables (LB8)

Page 450 of 1825

BATTERY 801-7

1 -BATTERY

2-CABLE ASM- NEG.

3-CABLE ASM- POS.

TO PREVENT DIODE DAMAGE, ALL CONNECTIONS MUST BE

MADE AND TIGHTENED BEFORE

BATTERY

POSlTVE CONNEC-

TION IS MADE.

Fig.

602 Battery Cables (LBS/LG4)

SPECIFICATIONS

ENGINE BATTERY/FUNCTION REPLACEMENT

LB8lL03 198 1730-STD 730

CCA 525

RC(MIN)90

~oad ~est 260 Amps

1981731-HD

CCA 570

RC(MIN)90

Load Test 280 AMPS

198 1W-STD

CCA 525

RC(MIN)75

Load Test 260 Amps

1981731-HD

CCA 570

RC(MIWW

Load Test 280 AMPS

1981601

CCA 630

RC(MIN)90

Load Test 310 AMPS