RENAULT KANGOO 1997 KC / 1.G Chassis Repair Manual

Manufacturer: RENAULT, Model Year: 1997, Model line: KANGOO, Model: RENAULT KANGOO 1997 KC / 1.GPages: 105

Page 61 of 105

STEERING ASSEMBLY

Manual steering assistance pump

36

SPECIAL TOOLING REQUIRED

Mot. 453-01Hose clamp pliers

T. Ar. 1094Extractor

Put the vehicle on a two post lift.

REMOVAL

Remove:

- the PAS pump belt,

- the pulley.

Fit a clamp Mot. 453-01 to the supply pipe.

Disconnect the supply and high pressure pipes.

Take precautions to catch the PAS fluid (protect

the alternator).

Remove the three pump mounting bolts and

remove the pump.

REFITTING

Refitting is the reverse of removal. Observe the

procedure for tensioning the belt (see section 07).

Fill and bleed the circuit, moving the steering

from lock to lock.

D7F engine

without AC

36-9

Page 62 of 105

STEERING ASSEMBLY

Manual steering assistance pump

36

SPECIAL TOOLING REQUIRED

Mot. 453-01Hose clamp pliers

Put the vehicle on a two post lift.

REMOVAL

Remove:

- the right hand wheel,

- the right hand mudguard,

- the bumper (10 bolts).

- the accessories belt,

- the pulley.

Fit a clamp Mot. 453-01 to the supply pipe.

Disconnect the supply and high pressure pipes.

Take precautions to catch the PAS fluid.

Remove the three pump mounting bolts and

remove the pump.

REFITTING

Refitting is the reverse of removal. Observe the

procedure for tensioning the belt (see section 07).

Fill and bleed the circuit, moving the steering

from lock to lock.

F8Q engine

without AC

36-10

Page 63 of 105

STEERING ASSEMBLY

Manual steering assistance pump

36

SPECIAL TOOLING REQUIRED

Mot. 453-01Hose clamp pliers

Put the vehicle on a two post lift.

REMOVAL

Remove:

- the alternator belt,

- the PAS pump belt,

- the alternator.

Fit a clamp Mot. 453-01 to the supply pipe.

Disconnect the supply and high pressure pipes.

Take precautions to catch the PAS fluid.

Remove the three pump mounting bolts and

remove the pump.

REFITTING

Refitting is the reverse of removal. Observe the

procedure for tensioning the belt (see section 07).

Fill and bleed the circuit, moving the steering

from lock to lock.

13296R

E7J engine

without AC

36-11

Page 64 of 105

STEERING ASSEMBLY

Steering column

36

TIGHTENING TORQUES (in daN.m)

REMOVAL

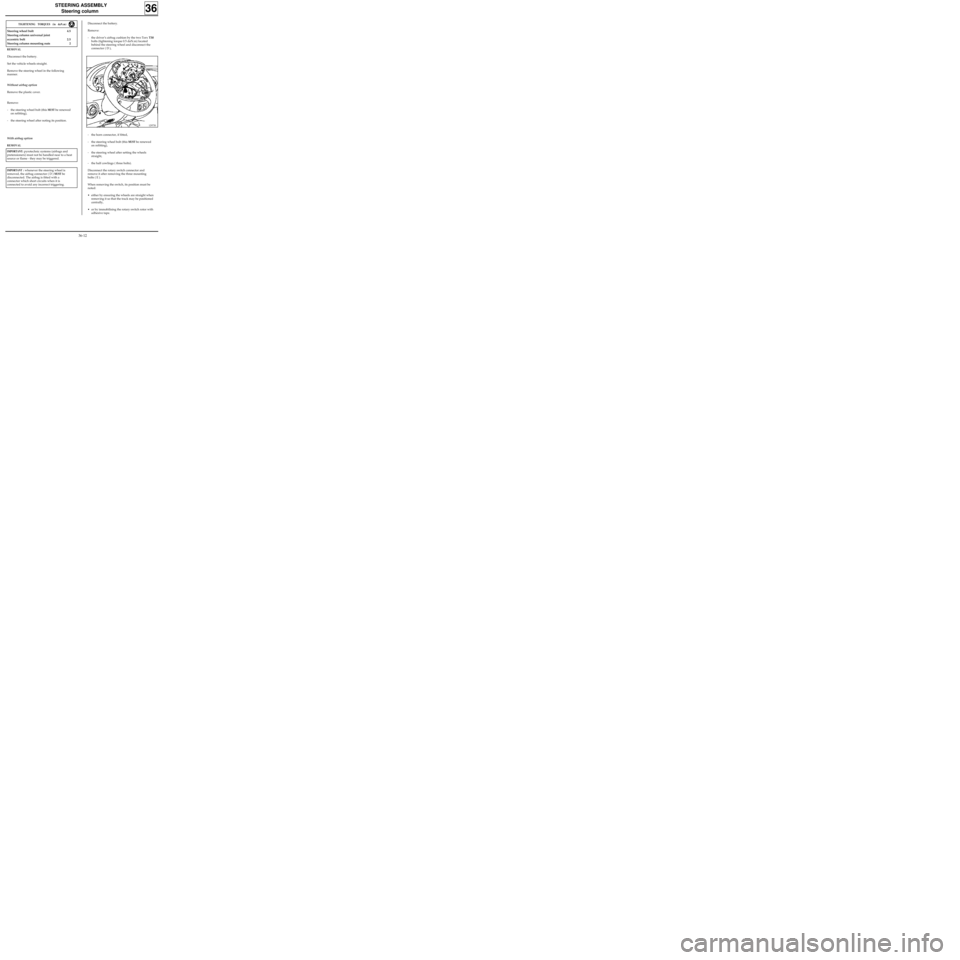

Disconnect the battery.

Set the vehicle wheels straight.

Remove the steering wheel in the following

manner.

Without airbag option

Remove the plastic cover.

Remove:

- the steering wheel bolt (this

MUST be renewed

on refitting),

- the steering wheel after noting its position.

With airbag option

REMOVAL

Disconnect the battery.

Remove:

- the driver’s airbag cushion by the two Torx T30

bolts (tightening torque 0.5 daN.m) located

behind the steering wheel and disconnect the

connector ( D ),

IMPORTANT: pyrotechnic systems (airbags and

pretensioners) must not be handled near to a heat

source or flame - they may be triggered.

IMPORTANT : whenever the steering wheel is

removed, the airbag connector ( D )

MUST be

disconnected. The airbag is fitted with a

connector which short circuits when it is

connected to avoid any incorrect triggering.

12973S

- the horn connector, if fitted,

- the steering wheel bolt (this

MUST be renewed

on refitting),

- the steering wheel after setting the wheels

straight,

- the half cowlings ( three bolts).

Disconnect the rotary switch connector and

remove it after removing the three mounting

bolts ( E ).

When removing the switch, its position must be

noted:

• either by ensuring the wheels are straight when

removing it so that the track may be positioned

centrally,

• or by immobilising the rotary switch rotor with

adhesive tape.

Steering wheel bolt 4.5

Steering column universal joint

eccentric bolt 2.5

Steering column mounting nuts 2

36-12

Page 65 of 105

STEERING ASSEMBLY

Steering column

36

If the switch is being replaced, the new part is

supplied ready-centred, held in place by an

adhesive label which tears off when the steering

wheel is moved for the first time (fit with the

wheels straight).

12970S

Remove:

- the half cowlings (three bolts),

- the stalk - switch assembly (one bolt).

12967-1R

12971R

Disconnect the connectors.

36-13

Page 66 of 105

STEERING ASSEMBLY

Steering column

36

Remove:

- the instrument panel visor ( six bolts).

12970-1R1

- the four mounting bolts for the instrument

panel and disconnect the connectors.

12969-1R1

12968S

- the lower protector ( four bolts).

12966R

36-14

Page 67 of 105

STEERING ASSEMBLY

Steering column

36

Under the vehicle, cut the retaining clip for the

rubber gaiter and push it back towards the

bulkhead.

Remove the eccentric bolt from the universal

joint.

Remove the two bolts and the two nuts mounting

the steering column.

12964R2

12965-1R2

Release:

- the steering column after disconnecting the

ignition switch,

- the gaiter from the bulkhead ( 1 ) and remove

it with the steering column.

REFITTING

Refit the steering column.

Fit the gaiter on the bulkhead, having tied the

flaps and the universal joint together with string.

Refitting is then the reverse of removal.

Check the instrument panel connectors are

correctly reconnected.

13116S

Remove the mounting bolts for the dashboard on

the steering column.

36-15

Page 68 of 105

STEERING ASSEMBLY

Steering column

36

IMPORTANT : if these instructions are not

followed exactly the system may not operate

normally and could even be triggered incorrectly.

IMPORTANT

Before reconnecting the driver’s airbag cushion,

check to see if the system is operating correctly as

follows:

•check the airbag warning light on the

instrument panel is illuminated when the

ignition is on,

•connect a dummy ignition module to the

driver’s airbag connector and check that the

warning light extinguishes,

•switch the ignition off, connect the airbag

cushion in place of the dummy ignition module

and secure the cushion to the steering wheel,

•switch the ignition on. Check the warning light

illuminates for three seconds when the ignition

is switched on then extinguishes and remains

extinguished.

If the warning light does not operate as described

above, refer to the fault finding section and check

the system using the

XRBAG (Elé. 1288).

SPECIAL NOTES FOR VEHICLES FITTED WITH A

DRIVER’S AIRBAG

Ensure that the wheels are still straight.

Check that the rotary switch is still immobilised

before refitting.

If it is not, follow the method for centring

described in section 88 "driver’s airbag".

Renew the steering wheel bolt each time it is

removed ( pre-bonded bolt).

Observe the correct tightening torque ( 4.5

daN.m).

36-16

Page 69 of 105

MECHANICAL ELEMENT CONTROLS

Master cylinder

37

Hydraulic pipe unions 1.7

Mounting nut on brake servo 1.8

REMOVAL

Disconnect the battery.

Disconnect the brake fluid level detector

connector.

Remove the injection computer (depending on

version).

Release the PAS reservoir and move it to the side,

towards the engine.

Drain and remove, by pulling up, the brake fluid

reservoir (take care to catch the fluid which will

run out).

Remove:

- the pipes and note their positions,

- the two mounting nuts on the brake servo.

REFITTING

Refitting is the reverse of removal.

Check the length of the pushrod.

Dimension X = 22.3 mm.

Depending on model, adjust using pin (P).

91101R

NOTE : these vehicles have a master cylinder

which is integral to the brake servo. Sealing of the

brake servo is directly linked to that of the master

cylinder. During any operation, a new seal (A)

must be fitted.

Fit the master cylinder in alignment with the

brake servo so that pushrod pin (P) enters

correctly into the master cylinder housing.

TIGHTENING TORQUES (in daN.m)

DI3718

37-1

Page 70 of 105

MECHANICAL ELEMENT CONTROLS

Master cylinder

37

Fill the brake fluid reservoir and bleed the brake

circuit.

MASTER CYLINDER (EXCHANGE)

The kit sold by the Parts Department comprises :

- one master cylinder (4 outlets or 2 outlets for

ABS),

- two plugs (A),

- two mounting nuts (B).

DI3719

37-2