RENAULT KANGOO 1997 KC / 1.G Chassis Manual Online

KANGOO 1997 KC / 1.G

RENAULT

RENAULT

https://www.carmanualsonline.info/img/7/1734/w960_1734-0.png

RENAULT KANGOO 1997 KC / 1.G Chassis Manual Online

Trending: inflation pressure, traction control, ECO mode, diagram, technical specifications, warning light, wheel bolt torque

Page 81 of 105

12865-1R

MECHANICAL ELEMENT CONTROLS

Braking compensator

37

Carry out the same operation on the other circuit:

- one at the front left hand side,

- one at the rear right hand side.

If there is a large difference (values exceed

tolerance ranges), replace the compensator since

no repair is permitted.ADJUSTMENT

The method for adjusting the compensators used

today in After Sales is simple and only involves

using two pressure gauges which must be

connected to the braking circuit (front right

wheel and rear left wheel, then front left wheel

and rear right wheel).

Checking and adjustment is carried out with the

vehicle unladen, the fuel tank full and the driver

on board.

After imposing a certain pressure at the front by

pressing the brake pedal, just read off the

pressure at the rear and compare the value with

that given in section 07. Then move the

compensator rod by releasing the bolt ( 1 ), so rod

( 2 ) may be adjusted.

NOTE : do not alter the position of nut (3).

This method is difficult to carry out when the

vehicle is loaded, as is often the case for a utility

vehicle fitted out with shelves full of spare parts

and tools.

The special case of utility vehicles has led to the

development of a different method for

adjustment which uses a deflection calculation

(index of crushing) for the tyres (this is

inexpensive but must be carried out with care).

The graphs for rear pressure as a function of tyre

deflection must be consulted.

37-13

Page 82 of 105

MECHANICAL ELEMENT CONTROLS

Braking compensator

37

Tooling required:

- one measuring tape mounted on a base (used

for measuring underbody heights),

- an accurate pressure gauge.

1• Preparation of the vehicle:

- the vehicle must be left loaded,

- the person in charge of pressing the brake

pedal when the compensator is being adjusted

must be in the vehicle when the radius under

load is measured at the rear wheels,

- the vehicle must be on a flat horizontal surface,

which is smooth and clean (use a four post lift if

possible).

2• Marking the centre of the rear wheels:

- lift the rear of the vehicle so the rear wheels

may be turned,

- apply a chalk stick to the hub cover or the

wheel embellisher at the approximate centre of

the wheel,

- turn the wheel by hand fairly quickly, pressing

hard on the chalk. This allows concentric circles

to be drawn around the real rotation centre of

the wheel,

- mark the centre using a pencil on the chalk,

- carry out the same operation on the second

rear wheel.3• Adjusting the rear tyre pressure:

- the pressure must be adjusted with the wheels

on the ground and one person in the driver’s

seat,

- deflate the two rear wheels so that the pressure

is brought to 1.2 bar (use an accurate pressure

gauge which has been correctly calibrated),

- wait a few minutes for the air in the tyres to

return to ambient temperature since it is

cooled when the tyres are deflated and the

pressure will therefore have changed,

- adjust the pressure to 1.2 bar as accurately as

possible.

4• Measuring the radius with the vehicle

unladen:

- lift the rear wheels so that the tyres are no

longer crushed by the load on the axle (as soon

as the wheels leave the ground),

- measure the distance between the ground and

the wheel centre using the measuring tape.

5• Measuring the radius with the rear wheels

loaded:

- return the vehicle to its wheels,

- measure the distance between the ground and

the wheel centre using the measuring tape.

37-14

Page 83 of 105

MECHANICAL ELEMENT CONTROLS

Braking compensator

37

6• Calculating the tyre deflection:

- subtract the two measurements made to obtain

the tyre deflection.

7• Carry out stages 4, 5 and 6 for the other rear

wheel.

8• Calculate the average deflection for both

tyres:

- add the two values for the two deflections

noted for the two rear wheels and divide the

result by two to give the average deflection.

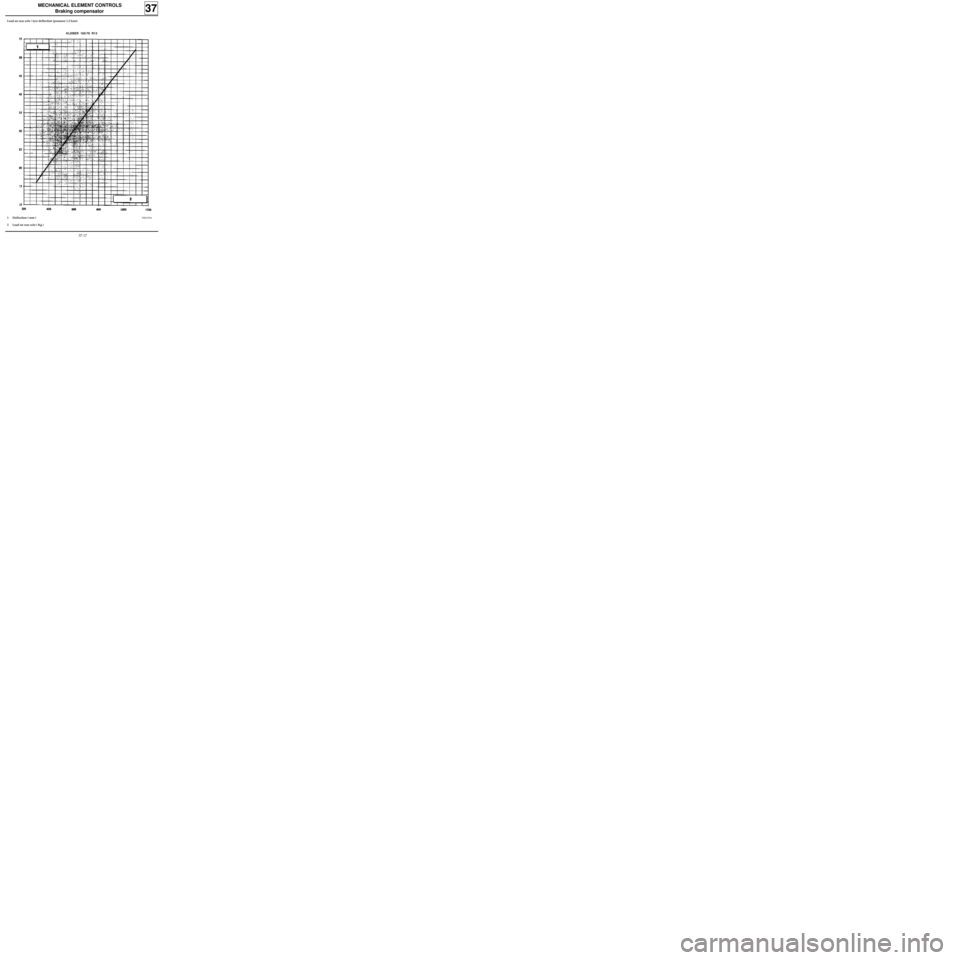

9• Reading the graphs:

- On the first graph, read off the load on the rear

axle as a function of the average deflection

noted.

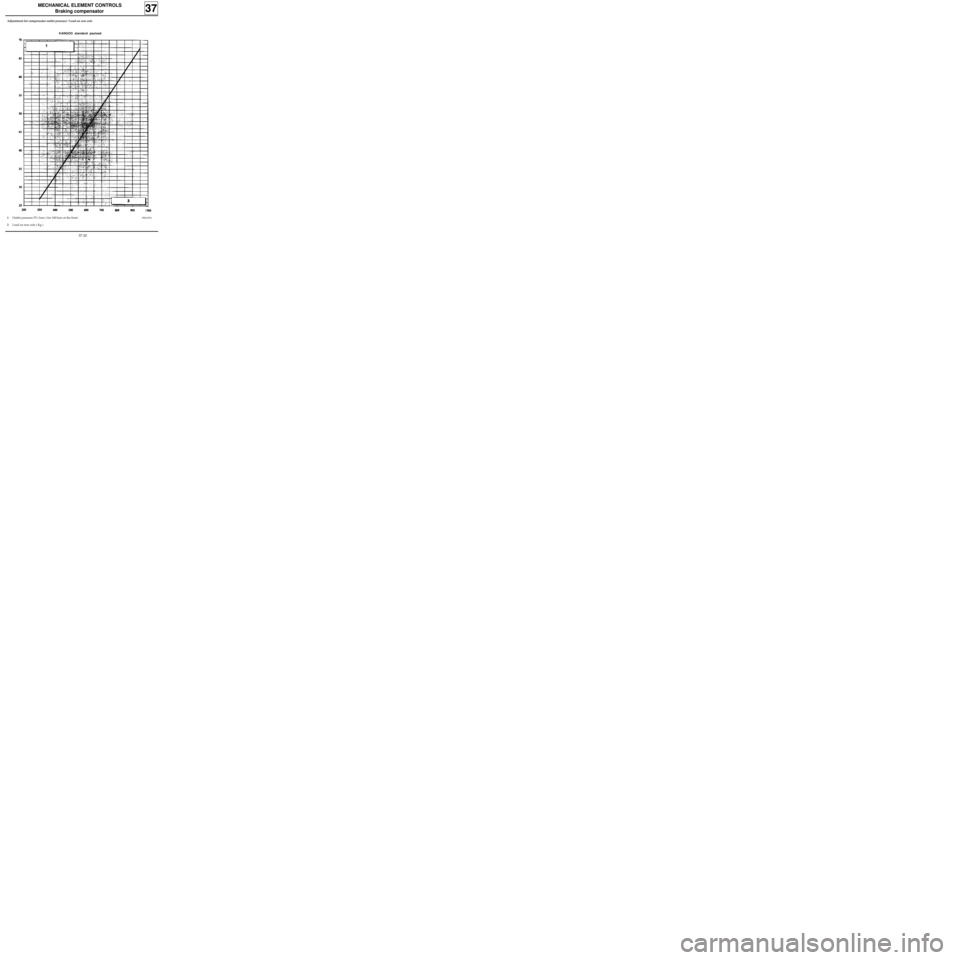

- On the second graph, read off the output

pressure P2 (corresponds to the pressure

applied to each rear wheel) as a function of the

load value noted from the first graph.

IMPORTANT: each graph corresponds to a

particular make and type of tyre.

10 • Adjusting the compensator :

- Follow the current method described for After

Sales if the compensator is incorrectly set.

37-15

Page 84 of 105

MECHANICAL ELEMENT CONTROLS

Braking compensator

37

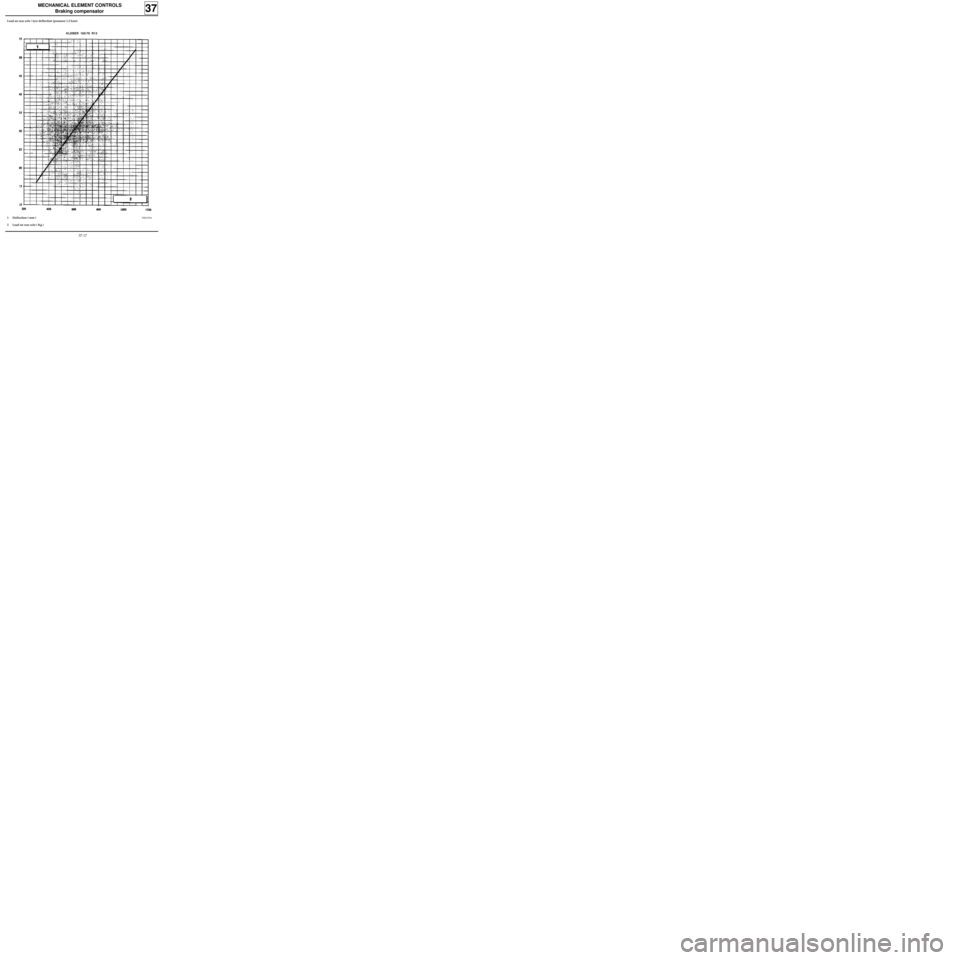

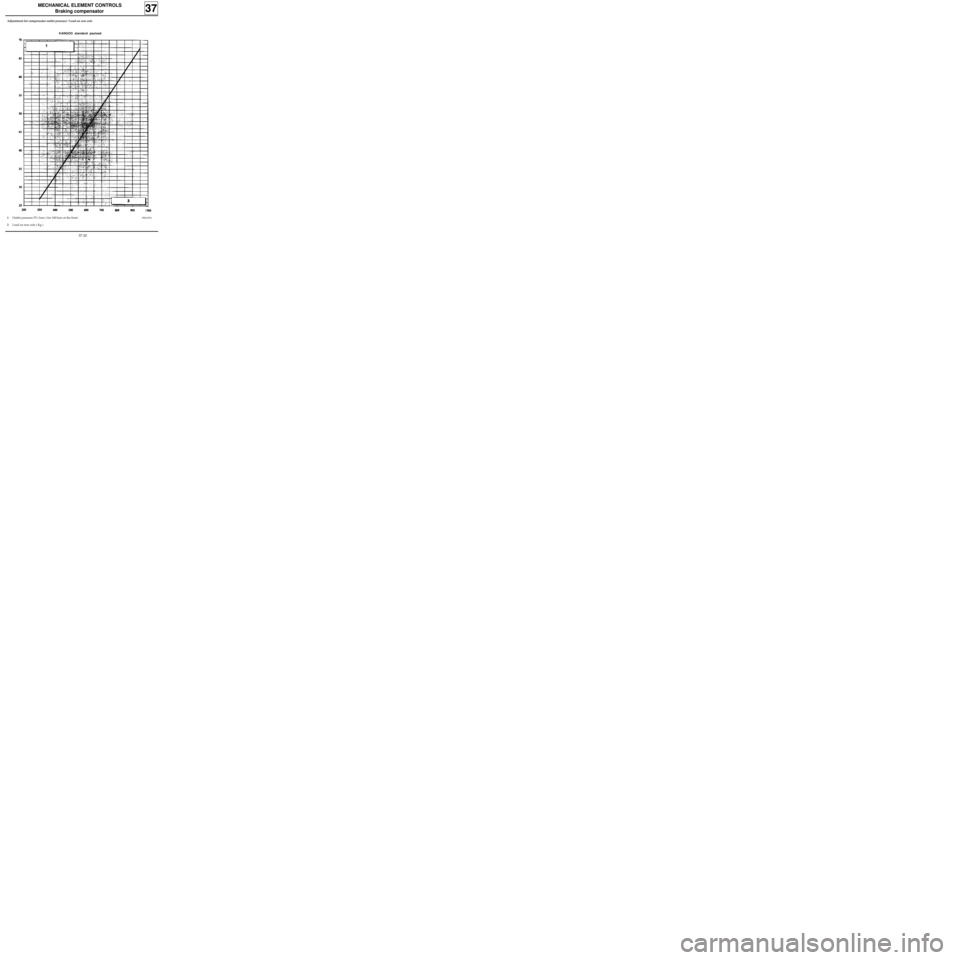

Load on rear axle / tyre deflection (pressure 1.2 bars)

DUNLOP 165/70 R13C

PRN37001 Deflection ( mm )

2 Load on rear axle ( Kg )

37-16

Page 85 of 105

MECHANICAL ELEMENT CONTROLS

Braking compensator

37

Load on rear axle / tyre deflection (pressure 1.2 bars)

KLEBER 165/70 R13

PRN37041 Deflection ( mm )

2 Load on rear axle ( Kg )

37-17

Page 86 of 105

MECHANICAL ELEMENT CONTROLS

Braking compensator

37

Load on rear axle / tyre deflection (pressure 1.2 bars)

MICHELIN 165/70 R13C XC4S

PRN37001 Deflection ( mm )

2 Load on rear axle ( Kg )

37-18

Page 87 of 105

MECHANICAL ELEMENT CONTROLS

Braking compensator

37

Load on rear axle / tyre deflection (pressure 1.2 bars)

MICHELIN 165/70 R13C Agilis 61

PRN37001 Deflection ( mm )

2 Load on rear axle ( Kg )

37-19

Page 88 of 105

MECHANICAL ELEMENT CONTROLS

Braking compensator

37

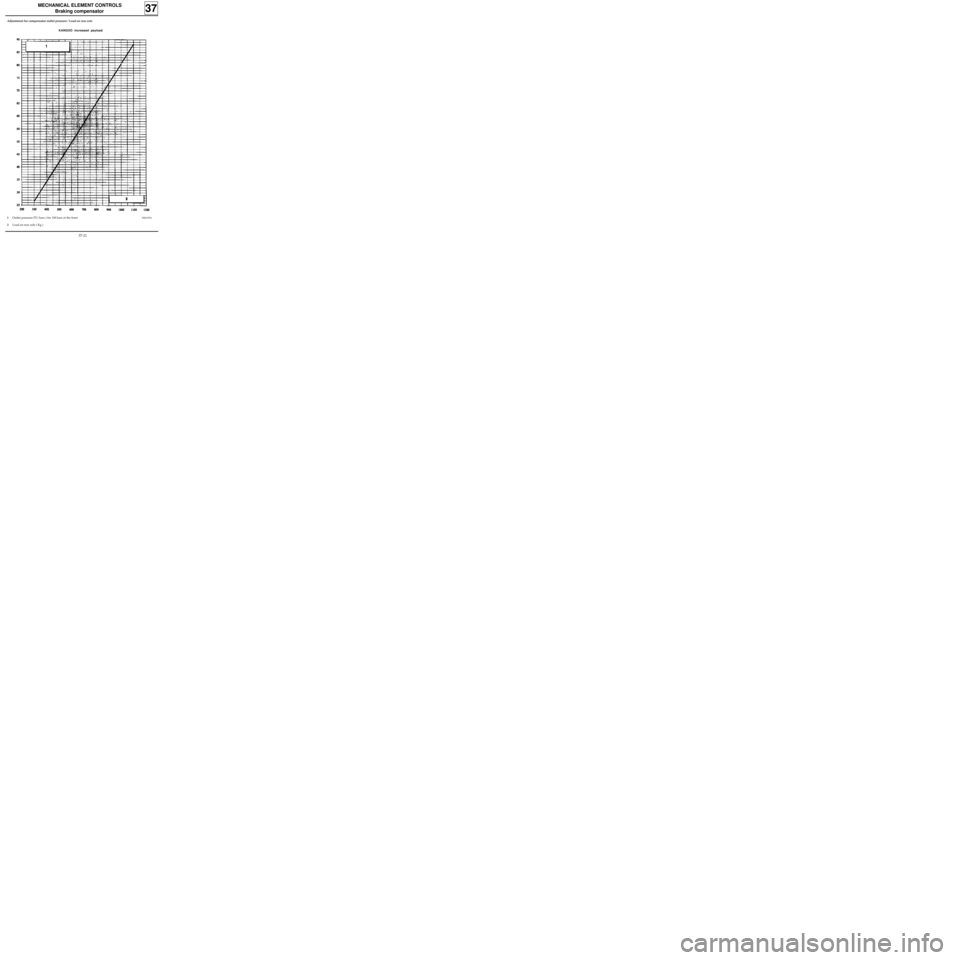

Adjustment for compensator outlet pressure / Load on rear axle

KANGOO standard payload

PRN37021 Outlet pressure P2 ( bars ) for 100 bars at the front

2 Load on rear axle ( Kg )

37-20

Page 89 of 105

MECHANICAL ELEMENT CONTROLS

Braking compensator

37

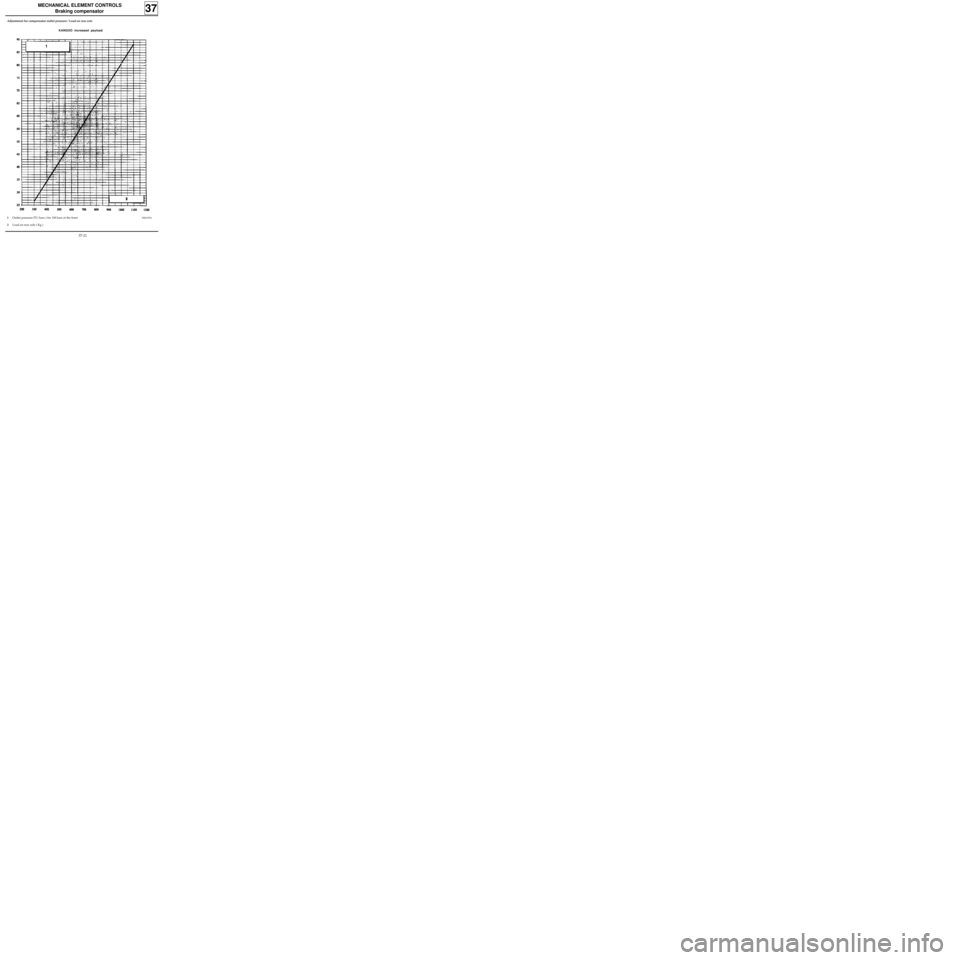

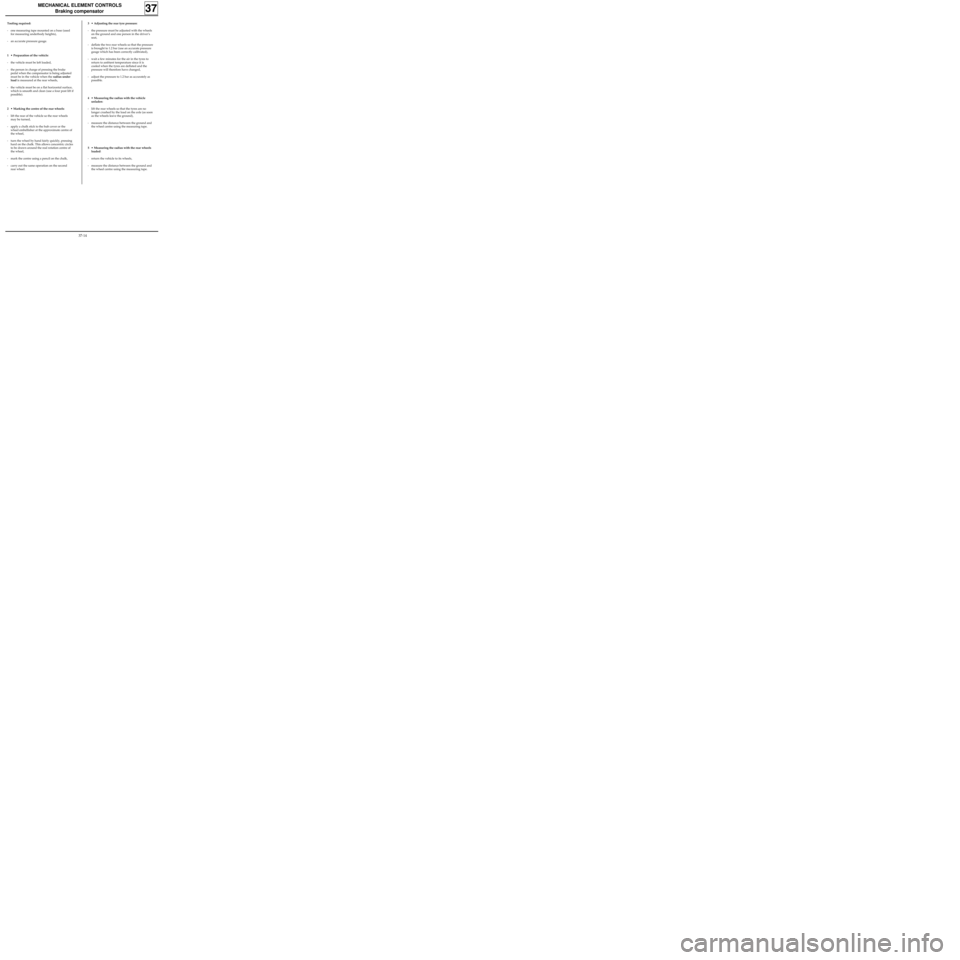

PRN37031 Outlet pressure P2 ( bars ) for 100 bars at the front

2 Load on rear axle ( Kg )

Adjustment for compensator outlet pressure / Load on rear axle

KANGOO increased payload

37-21

Page 90 of 105

MECHANICAL ELEMENT CONTROLS

Clutch control cable

37

REMOVAL

In the engine compartment, disconnect the cable

from the fork.

89204S

12986R

Remove the end of the cable from its location on

the wear compensation sector.

Remove the cable sleeve stop from the bulkhead.

Remove the complete cable via the engine

compartment.

REFITTING

From the engine compartment, thread the cable

through the bulkhead.

Fit the cable end piece into position on the wear

compensation sector.

Refit the clutch pedal.

Check the wear compensation ratchets return to

the rest position.

In the engine compartment, fit the cable onto the

clutch fork.

Check the cable sleeve stop is correctly aligned on

the bulkhead.

Press the clutch pedal to clip the cable sleeve stop

into position on the bulkhead. The adjustment is

carried out automatically.

Press the pedal to pull the cable through.

In the passenger compartment, remove:

- the bolt ( 1 ),

- the stiffener ( 2 ),

- the nut from the pedal mounting shaft ( 3 ).

37-22

Trending: power steering, fuse box diagram, brake fluid, ignition, check engine, four wheel drive, width