RENAULT KANGOO 1997 KC / 1.G Engine And Peripherals Workshop Manual

KANGOO 1997 KC / 1.G

RENAULT

RENAULT

https://www.carmanualsonline.info/img/7/1731/w960_1731-0.png

RENAULT KANGOO 1997 KC / 1.G Engine And Peripherals Workshop Manual

Trending: fuel filter, weight, tow, oil filter, fuse, air bleeding, wheel torque

Page 131 of 208

ANTIPOLLUTION

Fuel vapour rebreathing

14

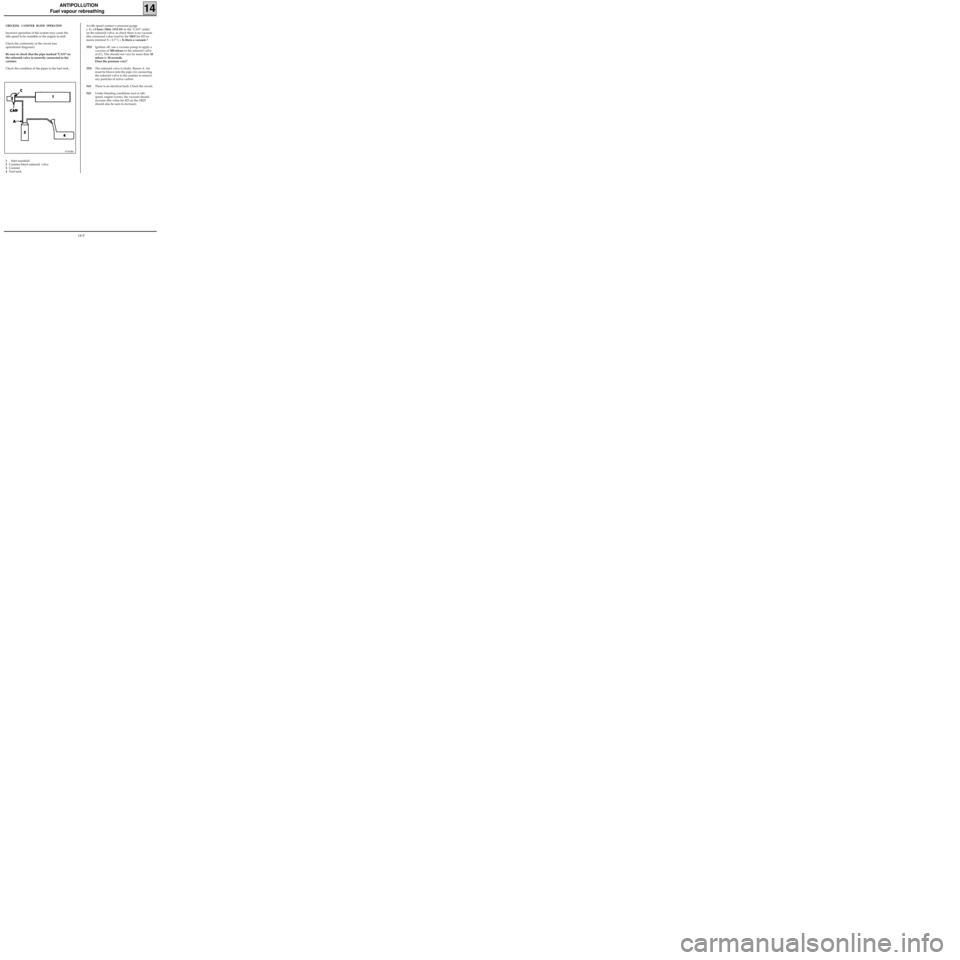

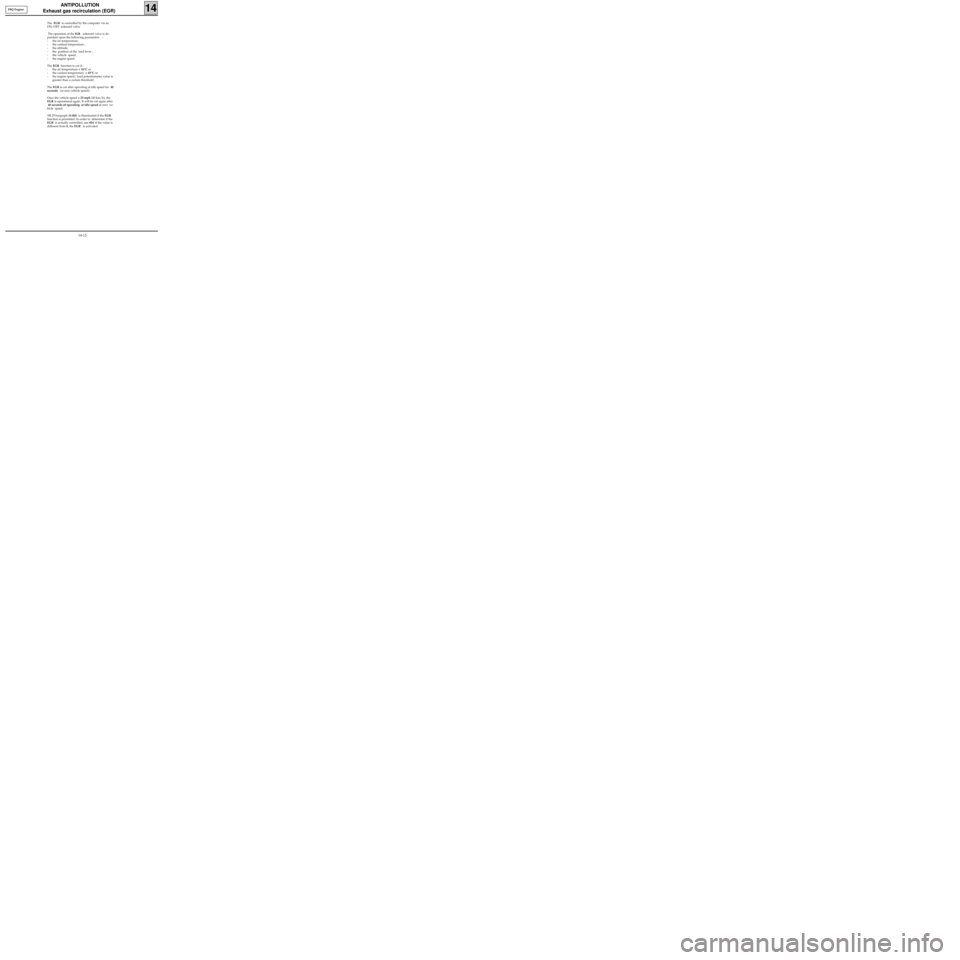

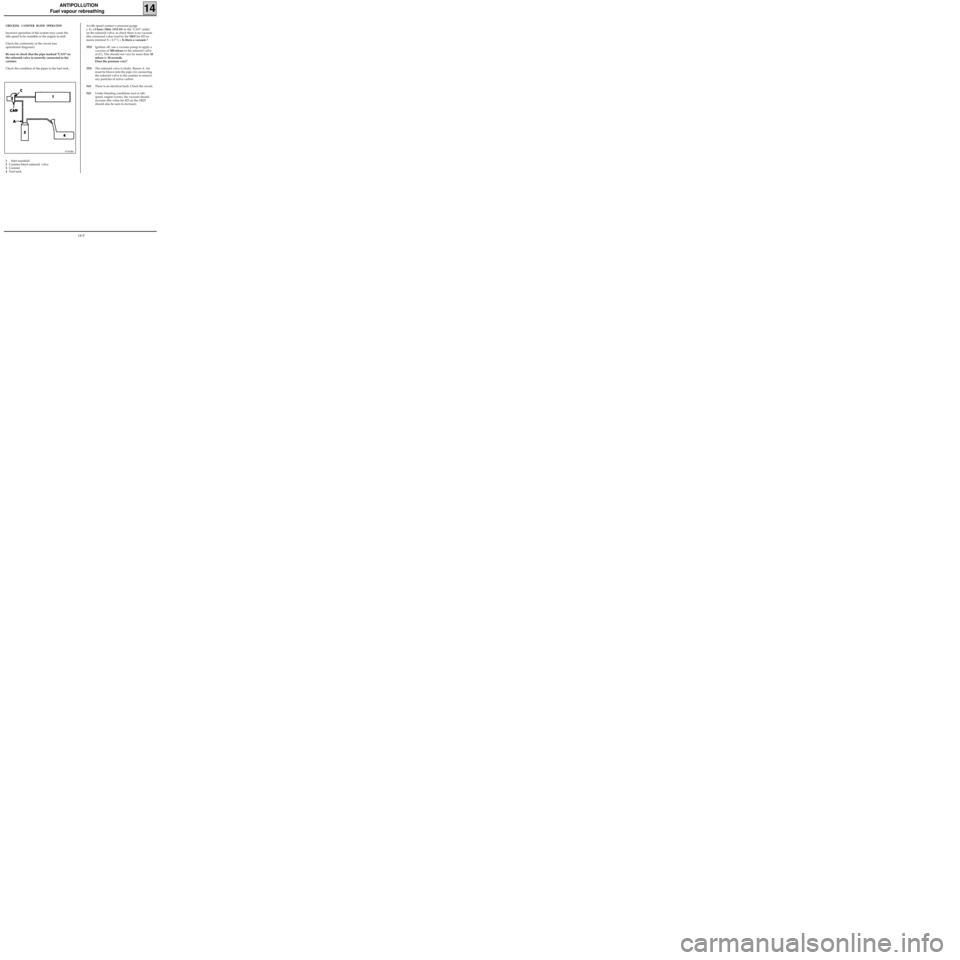

CHECKING CANISTER BLEED OPERATION

Incorrect operation of the system may cause the

idle speed to be unstable or the engine to stall.

Check the conformity of the circuit (see

operational diagrams)

Be sure to check that the pipe marked "CAN" on

the solenoid valve is correctly connected to the

canister.

Check the condition of the pipes to the fuel tank.

97393R6

1Inlet manifold

2Canister bleed solenoid valve

3Canister

4Fuel tankAt idle speed connect a pressure gauge

(- 3 ; +3 bars) (Mot. 1311-01) to the "CAN" outlet

on the solenoid valve, to check there is no vacuum

(the command value read by the

XR25 for #23 re-

mains minimal X = 0.7 % ). Is there a vacuum ?

YESIgnition off, use a vacuum pump to apply a

vacuum of 500 mbars to the solenoid valve

at (C). This should not vary by more than 10

mbars in 30 seconds.

Does the pressure vary?

YESThe solenoid valve is faulty. Renew it. Air

must be blown into the pipe (A) connecting

the solenoid valve to the canister to remove

any particles of active carbon.

NOThere is an electrical fault. Check the circuit.

NOUnder bleeding conditions (not at idle

speed, engine warm), the vacuum should

increase (the value for #23 on the XR25

should also be seen to increase).

14-5

Page 132 of 208

ANTIPOLLUTION

Fuel vapour rebreathing

14

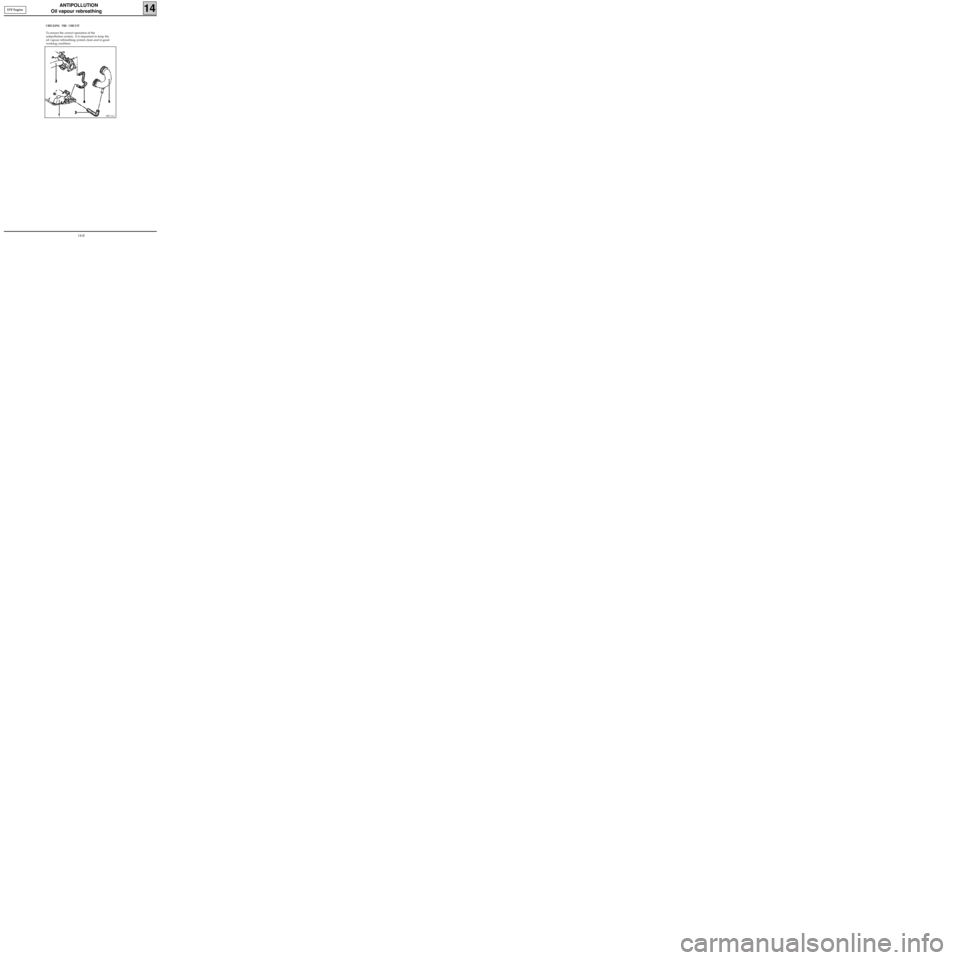

LOCATION-REMOVAL OF COMPONENTS

CANISTER BLEED SOLENOID VALVE

(1)

E7J Engine

It is mounted above the inlet manifold,

underneath the cover

D7F Engine

It is mounted at the front, on the lifting bracket.

13242R2

99939-1R3

REMOVAL OF THE FUEL VAPOUR ABSORBER (1)

This is located in the front right hand wheel arch.

REMOVAL

Disconnect the pipe connecting the canister to the

inlet manifold, from the top of the vehicle.

From the bottom, remove the wheel arch .

Disconnect the pipe at (2) connecting the

canister to the fuel tank.

Remove the three bolts at (3) mounting the

canister (1) then extract it.

13049R

14-6

Page 133 of 208

ANTIPOLLUTION

Oil vapour rebreathing

14

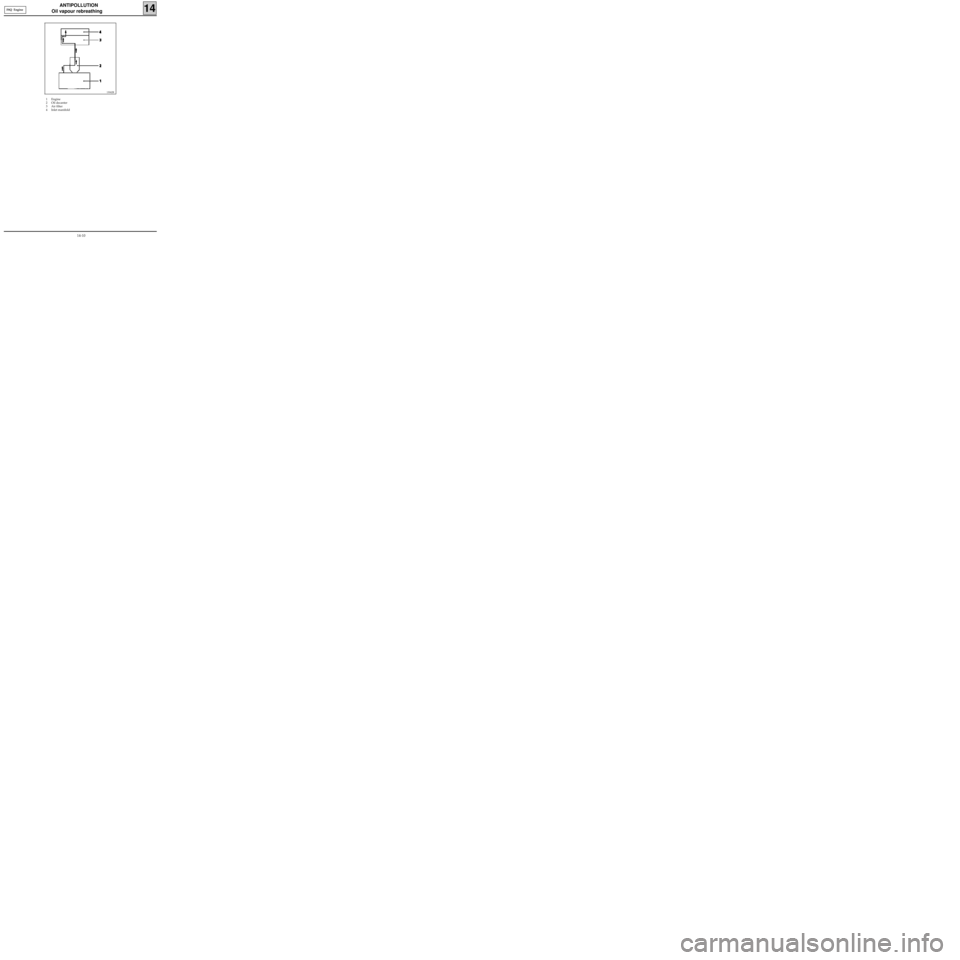

CIRCUIT DIAGRAM

1 Cylinder head cover

2 Inlet manifold

3 Oil vapour rebreathing pipe connected upstream from the throttle body (the circuit is used

for medium and high loads)

4 Oil vapour rebreathing pipe connected downstream from the throttle body

5 Air pipe

6 Throttle body

99932R

D7F Engine

14-7

Page 134 of 208

ANTIPOLLUTION

Oil vapour rebreathing

14

CHECKING THE CIRCUIT

To ensure the correct operation of the

antipollution system, it is important to keep the

oil vapour rebreathing system clean and in good

working condition.

PRC14.2

D7F Engine

14-8

Page 135 of 208

ANTIPOLLUTION

Oil vapour rebreathing

14E7J Engine

CIRCUIT DIAGRAM

1 Cylinder head

2 Inlet manifold

3 Oil vapour rebreathing pipe connected

upstream from the throttle body (the circuit is

used for medium and high loads)

4 Oil vapour rebreathing pipe connected

downstream from the throttle body

CHECKING

To ensure the correct operation of the

antipollution system, it is important to keep the

oil vapour rebreathing system clean and in good

working condition.

13335R

14-9

Page 136 of 208

ANTIPOLLUTION

Oil vapour rebreathing

14

1 Engine

2 Oil decanter

3 Air filter

4 Inlet manifold

13042R

F8Q Engine

14-10

Page 137 of 208

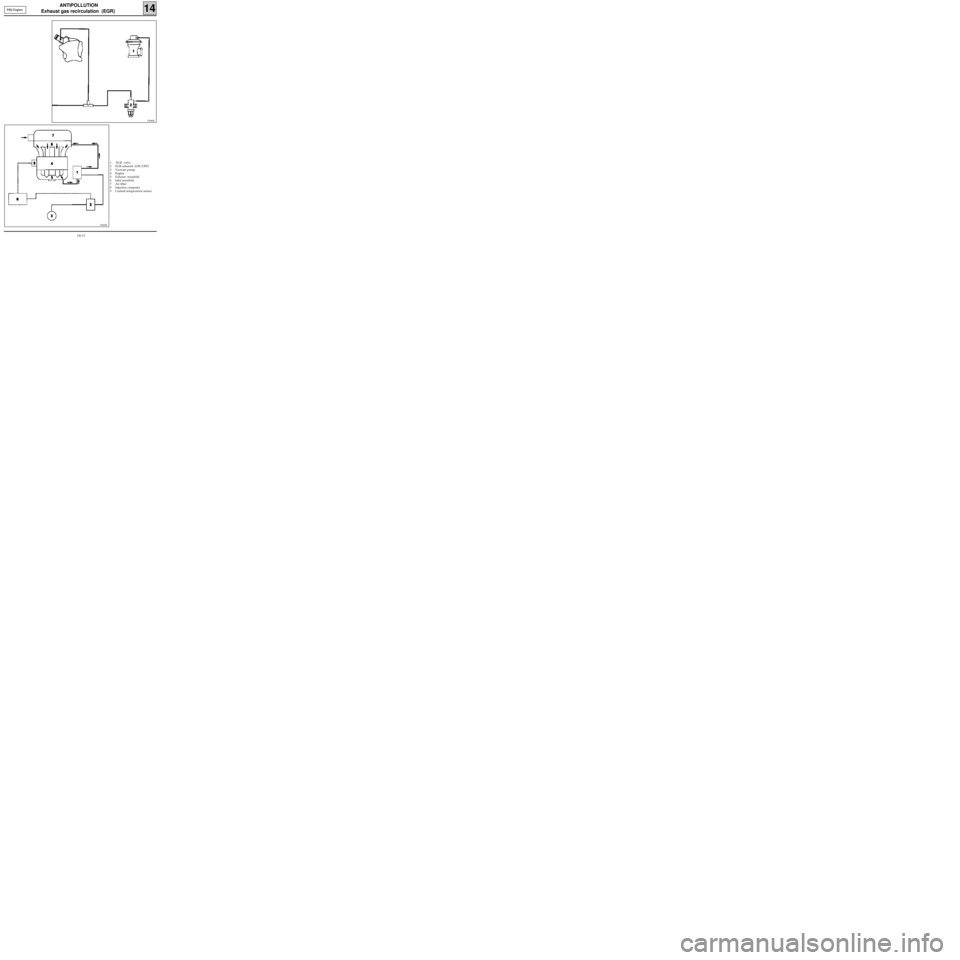

ANTIPOLLUTION

Exhaust gas recirculation (EGR)

14

1 EGR valve

2 EGR solenoid (ON/OFF)

3 Vacuum pump

4 Engine

5 Exhaust manifold

6 Inlet manifold

7 Air filter

8 Injection computer

9 Coolant temperature sensor

13046R

F8Q Engine

13045R

14-11

Page 138 of 208

ANTIPOLLUTION

Exhaust gas recirculation (EGR)

14

SPECIAL NOTES

In order to remove the steel pipe connecting the

EGR valve to the air filter, it is necessary to

remove the

EGR valve .

12871R1

F8Q Engine

13047-1R2

To remove the EGR solenoid (2), remove the air

filter .

To remove the

EGR valve (1), remove the air filter

first, and replace the seal between the solenoid

valve and the inlet manifold after each removal

operation.

14-12

Page 139 of 208

ANTIPOLLUTION

Exhaust gas recirculation (EGR)

14

The EGR is controlled by the computer via an

ON/OFF solenoid valve.

The operation of the

EGR solenoid valve is de-

pendent upon the following parameters :

- the air temperature,

- the coolant temperature ,

- the altitude,

- the position of the load lever ,

- the vehicle speed ,

- the engine speed .

The EGR function is cut if :

- the air temperature < 16°C or

- the coolant temperature < 45°C or

- the engine speed/ load potentiometer value is

greater than a certain threshold .

The EGR is cut after operating at idle speed for 40

seconds (at zero vehicle speed).

Once the vehicle speed > 25 mph (40 km/h), the

EGR is operational again. It will be cut again after

40 seconds of operating at idle speed at zero ve-

hicle speed.

XR 25 bargraph 14 RH is illuminated if the EGR

function is permitted. In order to determine if the

EGR is actually controlled, use #24. if the value is

different from 0, the EGR is activated . F8Q Engine

14-13

Page 140 of 208

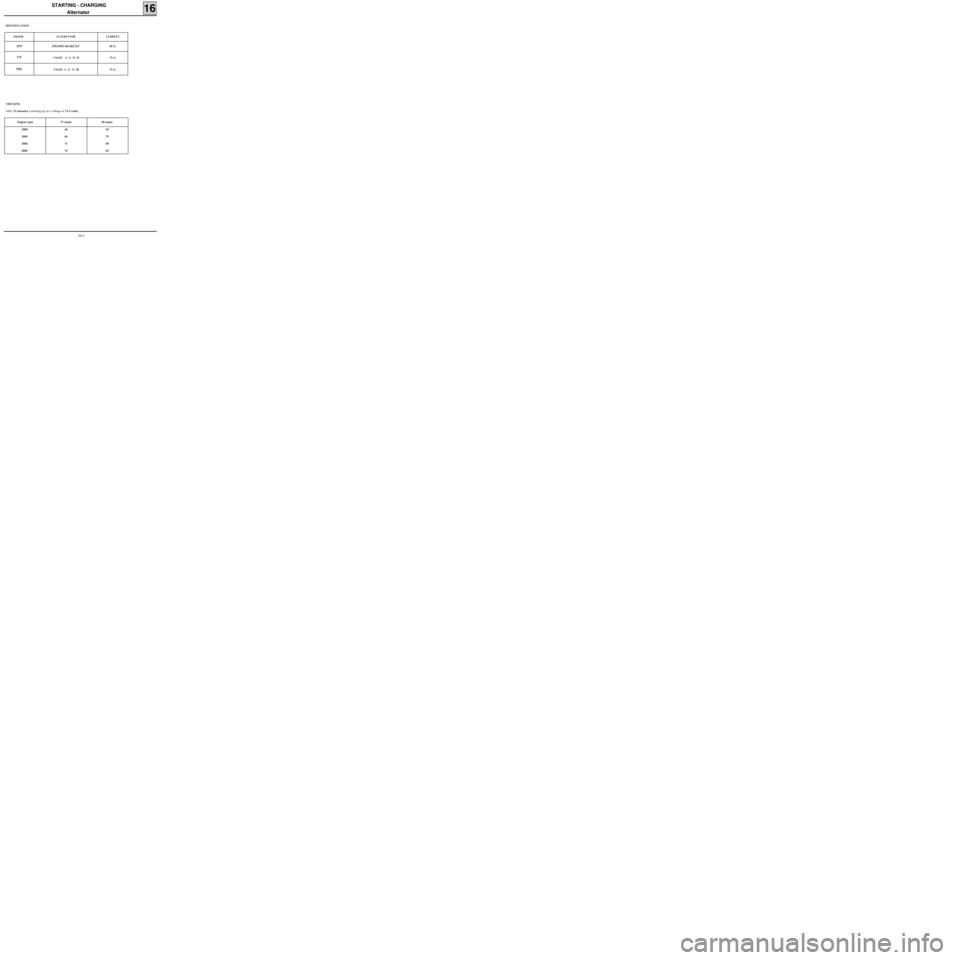

CHECKING

After 15 minutes warming up at a voltage of 13.5 volts.

STARTING - CHARGING

Alternator

16

IDENTIFICATION

ENGINE ALTERNATOR CURRENT

D7F DELPHI 104 802 215 80 A

E7J

VALEO A 11 VI 8775 A

F8Q

VALEO A 11 VI 8875 A

Engine rpm 75 amps 80 amps

1000

2000

3000

400046

68

71

7254

75

80

82

16-1

Trending: fuel filter, steering, fuel consumption, transmission oil, air conditioning, transmission, fuel pump