RENAULT KANGOO 1997 KC / 1.G Engine And Peripherals Workshop Manual

Manufacturer: RENAULT, Model Year: 1997, Model line: KANGOO, Model: RENAULT KANGOO 1997 KC / 1.GPages: 208

Page 101 of 208

DIESEL EQUIPMENT

Advance solenoid valve

13

ITB191917

REFITTING

It is VITAL to remove the small filter (3) situated at

the bottom of the system, using a pair of thin-

nose pliers, and replace with a new filter.

The outer part serves as a seal and locks on

tightening the actuator.

Replace, in the following order : the seal at (4) of

the "banjo" return connection (5) ; the new

activator (1) fitted with an external filter, along

with the the two seals at (6) and (7).

Tighten the actuator to a torque of 3 daN.m

using socket Mot. 997-01.

Place the new protective cover (2)on the actuator.

Reconnect the two terminals to the connector.

Reconnect the connector itself.

Replace the protective sheath on the wiring,

along with the retaining clip.Bleed the diesel circuit using the priming pump

before starting the engine.

It is IMPERATIVE to erase the computer memory

by pressing G0**.

It is vital to road test the vehicle after the

operation.

13127R

13-21

Page 102 of 208

DIESEL EQUIPMENT

Altimetric corrector

13

13129R

SPECIAL TOOLING REQUIRED

Mot. 997-01 Tool for removing injector

Mot. 1140 Tool for removing altimetric

corrector

Altimetric corrector 3

TIGHTENING TORQUES (in daN.m)

REMOVAL

Remove the high pressure pipes.

Remove the injector with sensor(cylinder n° 3),

using tool Mot. 997-01.

Remove the electrical connector from the pump.

Remove the two terminals for the altimetric cor-

rector from the 10 track pump connector. F8Q 662

13-22

Page 103 of 208

DIESEL EQUIPMENT

Altimetric corrector

13

13342R

To remove the terminals for the pump

connector:

1) Pull the yellow guide to release it from the

terminals, then press the two tabs on either

side of the connector.

2) Extract the yellow guide.

3) Pull the wire to be removed.

4) The terminal is held in place by two small tabs,

one on each side; using a screwdriver, move

one of the tabs to one side (the action of

pulling on the wire prevents the tab from

going back into place.

5) Using a screwdriver move the other tab to one

side.

The terminal may now be removed from the

connector.Remove the protective sheath grouping the pump

actuators.

Remove the protective cover from the solenoid

valve.

Remove the altimetric corrector (1) using tool

Mot. 1440.

10579R2

AConnector passage

F8Q 662

13-23

Page 104 of 208

DIESEL EQUIPMENT

Altimetric corrector

13

REFITTING

It is VITAL to remove the small filter (2) situated at

the bottom of the system using a pair of thin -

nosed pliers, and replace it with a new one.

Tighten the actuator (1) to a torque of 3 daN.m

using the socket Mot. 1440.

Place a new protective cover on the actuator.

Reconnect the two terminals to the connector.Reconnect the connector.

Replace the protective sheath on the wiring,

along with the retaining clip.

Bleed the diesel circuit using the priming pump

before starting the engine.

It is IMPERATIVE to erase the computer memory

by pressing G0**.

It is vital to road test the vehicle after this

operation.

13128R

F8Q 662

FUNCTION : it acts on the flow in proportion to altitude ; if the vehicle is running at

an altitude greater than or equal to 1 000 metres, the computer reduces the flow by

3 mm

3/stroke. The conventional flow is reestablished if the vehicle runs at an alti-

tude lower than 900 metres.

13-24

Page 105 of 208

DIESEL EQUIPMENT

Fast idle speed LDA

13

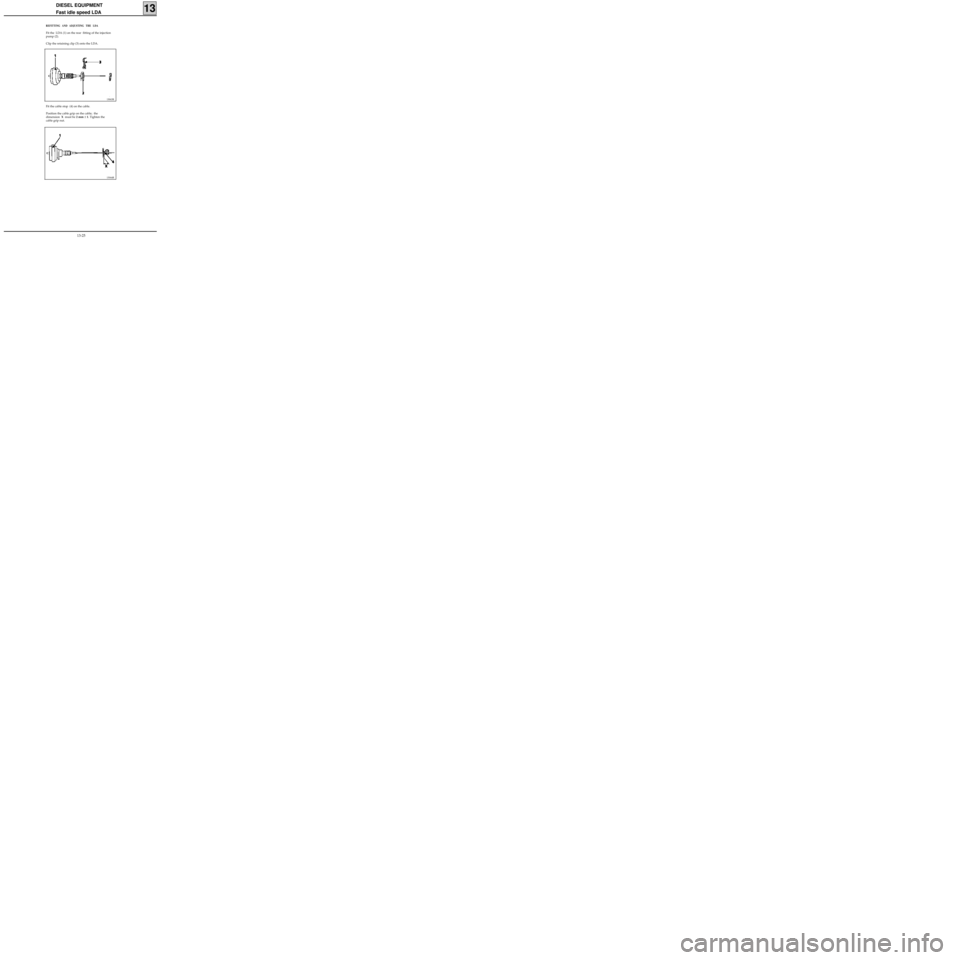

REFITTING AND ADJUSTING THE LDA

Fit the LDA (1) on the rear fitting of the injection

pump (2).

Clip the retaining clip (3) onto the LDA.

13043R

Fit the cable stop (4) on the cable.

Position the cable grip on the cable; the

dimension X must be 2 mm ± 1. Tighten the

cable grip nut.

13044R

13-25

Page 106 of 208

DIESEL EQUIPMENT

Coded solenoid valve

13

10713R1 10314R3

10315R2

99780-1R

13-26

Page 107 of 208

DIESEL EQUIPMENT

Coded solenoid valve

13

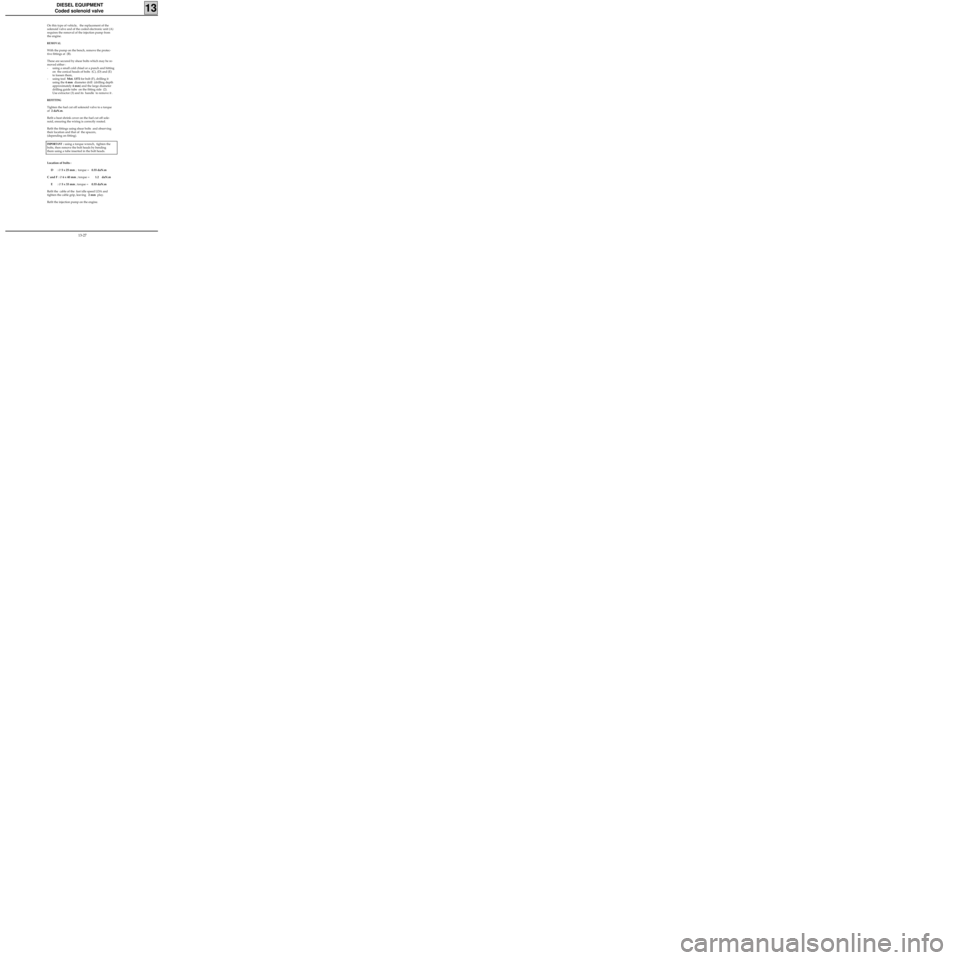

On this type of vehicle, the replacement of the

solenoid valve and of the coded electronic unit (A)

requires the removal of the injection pump from

the engine.

REMOVAL

With the pump on the bench, remove the protec-

tive fittings at (B).

These are secured by shear bolts which may be re-

moved either :

- using a small cold chisel or a punch and hitting

on the conical heads of bolts (C), (D) and (E)

to loosen them,

- using tool Mot. 1372 for bolt (F), drilling it

using the 4 mm diameter drill (drilling depth

approximately 4 mm) and the large diameter

drilling guide tube on the fitting side (2).

Use extractor (3) and its handle to remove it .

REFITTING

Tighten the fuel cut off solenoid valve to a torque

of 2 daN.m.

Refit a heat shrink cover on the fuel cut off sole-

noid, ensuring the wiring is correctly routed.

Refit the fittings using shear bolts and observing

their location and that of the spacers,

(depending on fitting).

IMPORTANT : using a torque wrench, tighten the

bolts, then remove the bolt heads by bending

them using a tube inserted in the bolt heads.

Location of bolts :

D :

∅ 5 x 25 mm ; torque =0.55 daN.m

C and F :

∅ 6 x 40 mm ; torque =1.2 daN.m

E :

∅ 5 x 33 mm ; torque =0.55 daN.m

Refit the cable of the fast idle speed LDA and

tighten the cable grip, leaving 2 mm play.

Refit the injection pump on the engine.

13-27

Page 108 of 208

DIESEL EQUIPMENT

Load potentiometer

13

In the factory, vehicles are programmed with the full load position. (memorising the voltage delivered by the

potentiometer in the full load position). This value is used to adjust the load potentiometer after it has been

replaced. It is therefore essential, if the diesel injection computer has to be replaced during the vehicle’s li-

fetime , to carry out this programming (G31*).

If it is necessary to replace the load potentiometer, in order to adjust it we compare the voltage delivered by

the potentiometer in full load position, with the value memorised. The new potentiometer is said to be cor-

rectly adjusted when the two voltages are equal. This is displayed on the

XR25. G32* indicates the diffe-

rence in voltage between the value memorised and the one from the potentiometer. The adjustment is cor-

rect if this value is equal to 0 in the full load position.

The potentiometer and the computer cannot be replaced at the same time (if necessary, replace the poten-

tiometer first and then the computer).

REPLACEMENT OF THE LOAD POTENTIOMETER (operation to be carried out by two people)

Remove the three terminals for the load potentiometer from the 10 track pump connector (see method

described in section 13 "Advance solenoid valve").

Remove the two bolts mounting the faulty potentiometer, extract this, and fit the new potentiometer .

Hand tighten the two bolts mounting the potentiometer but do not lock them - it should be possible to turn

the potentiometer body .

Connect the

XR25, and switch on the ignition.

Set the selector to S8.

Enter code

Press down on the accelerator pedal (full load position). Do not act directly on the load lever.

Holding the full load position, turn the potentiometer body until the value 0 appears on the XR25 display (if

you are too far from the 0 value, the screen will display HL , which means "Hors Limite"= "Off limits". Just

to turn the potentiometer body to obtain the display of a decimal value).

Tighten the two bolts mounting the potentiometer in the full load position, when the value read is 0. D

34then

G32*

13-28

Page 109 of 208

DIESEL EQUIPMENT

Computer configuration

13

PROGRAMMING THE FULL LOAD POSITION

Switch the ignition off.

Replace the computer.

Carry out the programming of the full load position; in order to do this :

Switch the ignition on.

Connect the

XR25.

Set the selector to S8.

Enter code

Enter code

When the display flashes "PF", press the accelerator pedal down as far as it will go.

The programming is complete when

the screen displays the following

wording: D

34

G31*

Bargraph N.12 on the right hand side should now be extinguished.

Switch the ignition off.

DPCN LUCAS injection computers are configured before sale to "with air conditioning". If the vehicle is not

fitted with an air conditioning system, use command G50*4* on the

XR25 to carry out the "no air conditio-

ning " programming.

DPCN LUCAS "injection computers are configured before sale to "with power assisted steering " (power as-

sisted steering with pump assembly). If the vehicle is not fitted with a power assisted steering pump as-

sembly, use command G50*9* on the

XR25 to carry out the "no power assisted steering pump assembly"

programming.then

13-29

Page 110 of 208

DIESEL EQUIPMENT

Computer configuration

13

COMPUTER CONFIGURATION IN RELATION TO AIR CONDITIONING.

For vehicles equipped with air conditioning , enter G50*3* on the XR25

For vehicles without air conditioning , enter G50*4* on the XR25 .

COMPUTER CONFIGURATION IN RELATION TO THE PAS (POWER ASSISTED STEERING PUMP ASSEMBLY)

The vehicle may have two types of PAS assembly :

-a

PAS assembly including a high pressure pump driven by a belt. In this case, the computer must be

configured without PAS : enter G50*9* on the

XR25,

-a

PAS assembly with a pump assembly which is driven electrically and controlled by the injection compu-

ter. ( this type of

PAS is fitted in all vehicles which are also equipped with AC). In this case, the computer

must be configured with PAS : enter G50*8* on the XR25.

IMPORTANT : according to the above explanations, only two types of combination are possible for the illumi-

nation of bargraphs 18 and 19.

Vehicle with AC

and PAS pump assemblyVehicle without AC and PAS pump assembly

(with conventional PAS)

18

19

18

19

DA CA

NOTE : if the computer has been replaced, remember to carry out the programming of the load potentio-

meter full load position (see "Load potentiometer " section ).

13-30