SUBARU LEGACY 1999 Service Repair Manual

Manufacturer: SUBARU, Model Year: 1999, Model line: LEGACY, Model: SUBARU LEGACY 1999Pages: 1456, PDF Size: 59.93 MB

Page 1271 of 1456

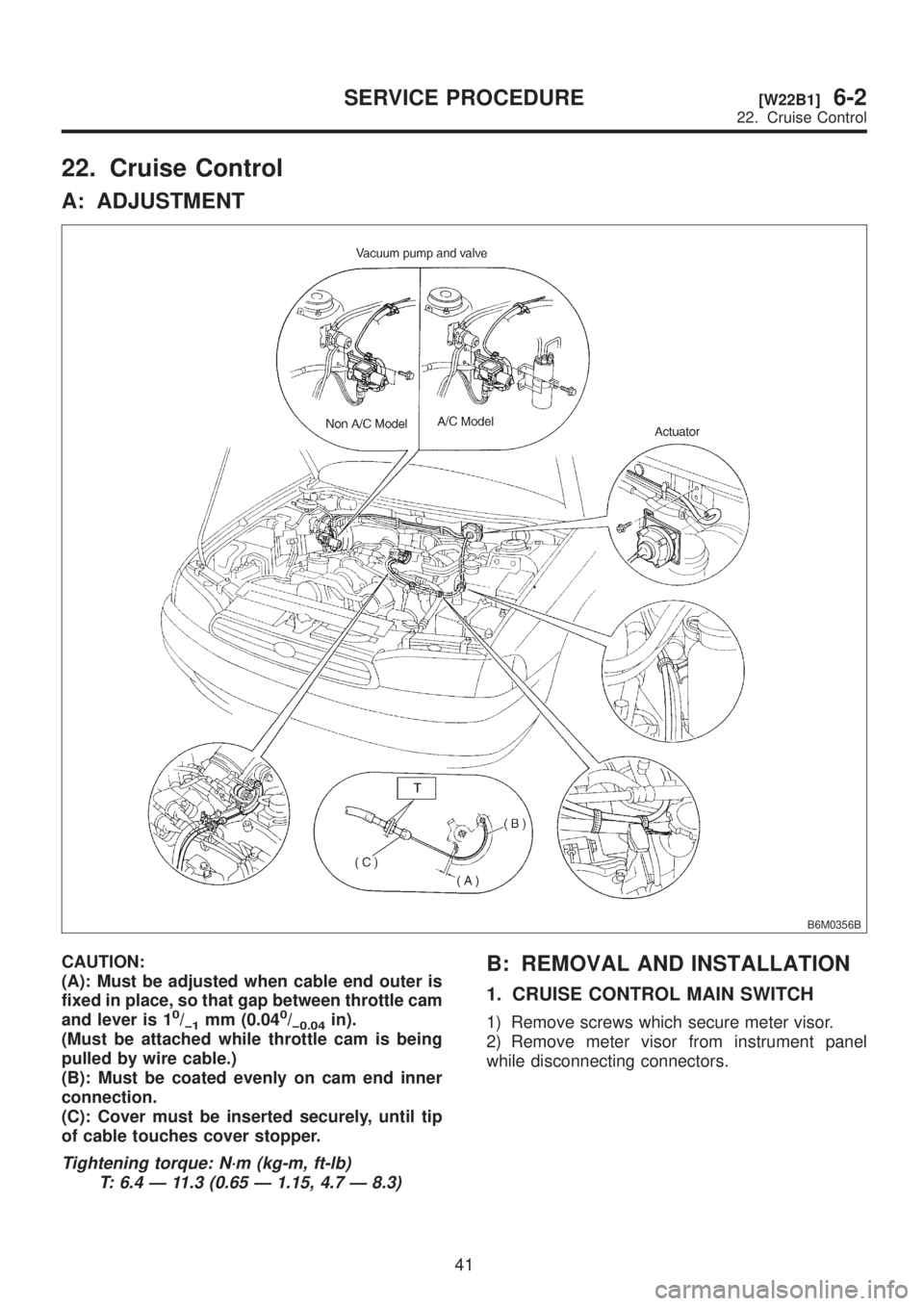

22. Cruise Control

A: ADJUSTMENT

B6M0356B

CAUTION:

(A): Must be adjusted when cable end outer is

fixed in place, so that gap between throttle cam

and lever is 1

0/þ1mm (0.040/þ0.04in).

(Must be attached while throttle cam is being

pulled by wire cable.)

(B): Must be coated evenly on cam end inner

connection.

(C): Cover must be inserted securely, until tip

of cable touches cover stopper.

Tightening torque: N´m (kg-m, ft-lb)

T: 6.4 Ð 11.3 (0.65 Ð 1.15, 4.7 Ð 8.3)

B: REMOVAL AND INSTALLATION

1. CRUISE CONTROL MAIN SWITCH

1) Remove screws which secure meter visor.

2) Remove meter visor from instrument panel

while disconnecting connectors.

41

[W22B1]6-2SERVICE PROCEDURE

22. Cruise Control

Page 1272 of 1456

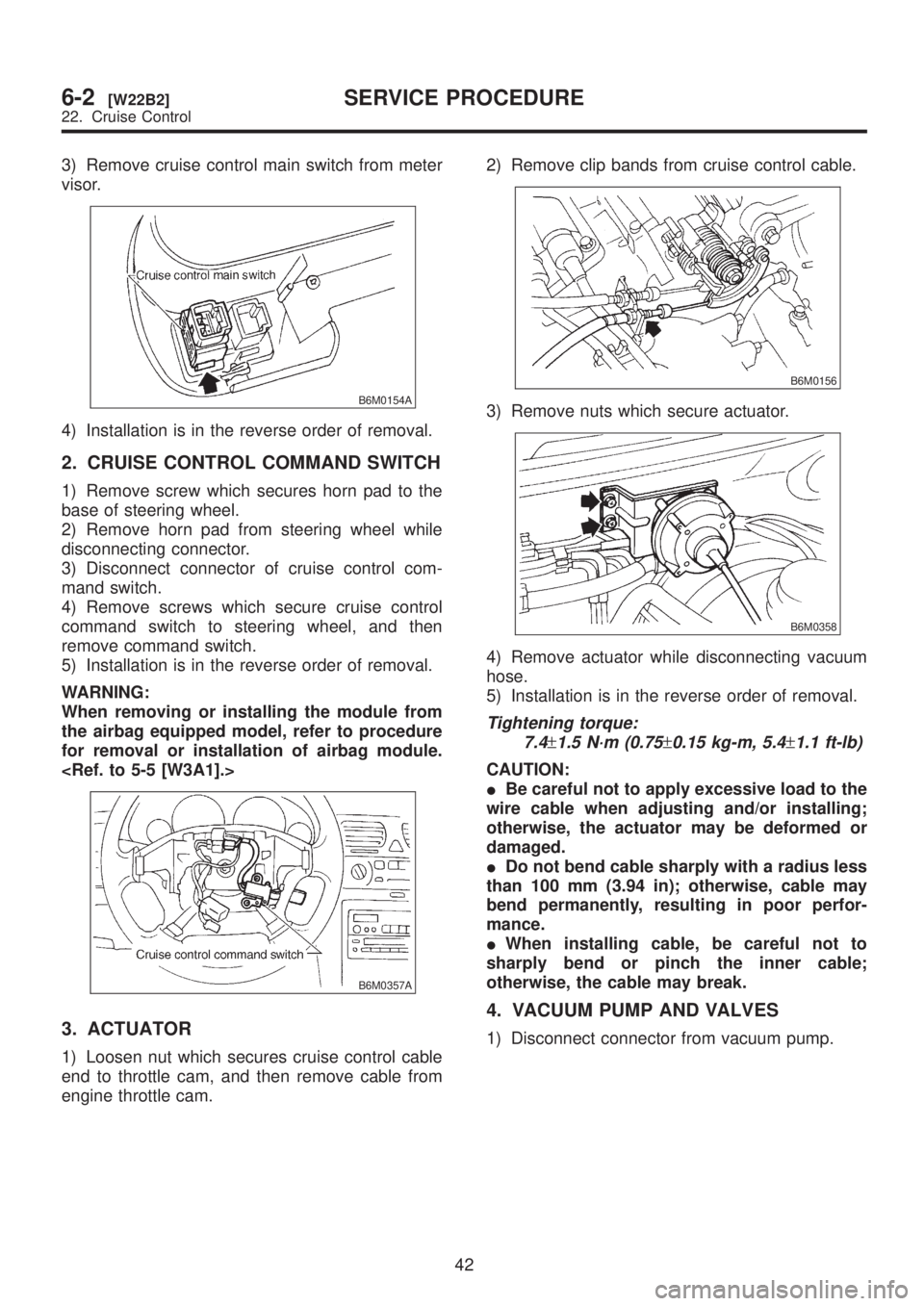

3) Remove cruise control main switch from meter

visor.

B6M0154A

4) Installation is in the reverse order of removal.

2. CRUISE CONTROL COMMAND SWITCH

1) Remove screw which secures horn pad to the

base of steering wheel.

2) Remove horn pad from steering wheel while

disconnecting connector.

3) Disconnect connector of cruise control com-

mand switch.

4) Remove screws which secure cruise control

command switch to steering wheel, and then

remove command switch.

5) Installation is in the reverse order of removal.

WARNING:

When removing or installing the module from

the airbag equipped model, refer to procedure

for removal or installation of airbag module.

B6M0357A

3. ACTUATOR

1) Loosen nut which secures cruise control cable

end to throttle cam, and then remove cable from

engine throttle cam.2) Remove clip bands from cruise control cable.

B6M0156

3) Remove nuts which secure actuator.

B6M0358

4) Remove actuator while disconnecting vacuum

hose.

5) Installation is in the reverse order of removal.

Tightening torque:

7.4

±1.5 N´m (0.75±0.15 kg-m, 5.4±1.1 ft-lb)

CAUTION:

IBe careful not to apply excessive load to the

wire cable when adjusting and/or installing;

otherwise, the actuator may be deformed or

damaged.

IDo not bend cable sharply with a radius less

than 100 mm (3.94 in); otherwise, cable may

bend permanently, resulting in poor perfor-

mance.

IWhen installing cable, be careful not to

sharply bend or pinch the inner cable;

otherwise, the cable may break.

4. VACUUM PUMP AND VALVES

1) Disconnect connector from vacuum pump.

42

6-2[W22B2]SERVICE PROCEDURE

22. Cruise Control

Page 1273 of 1456

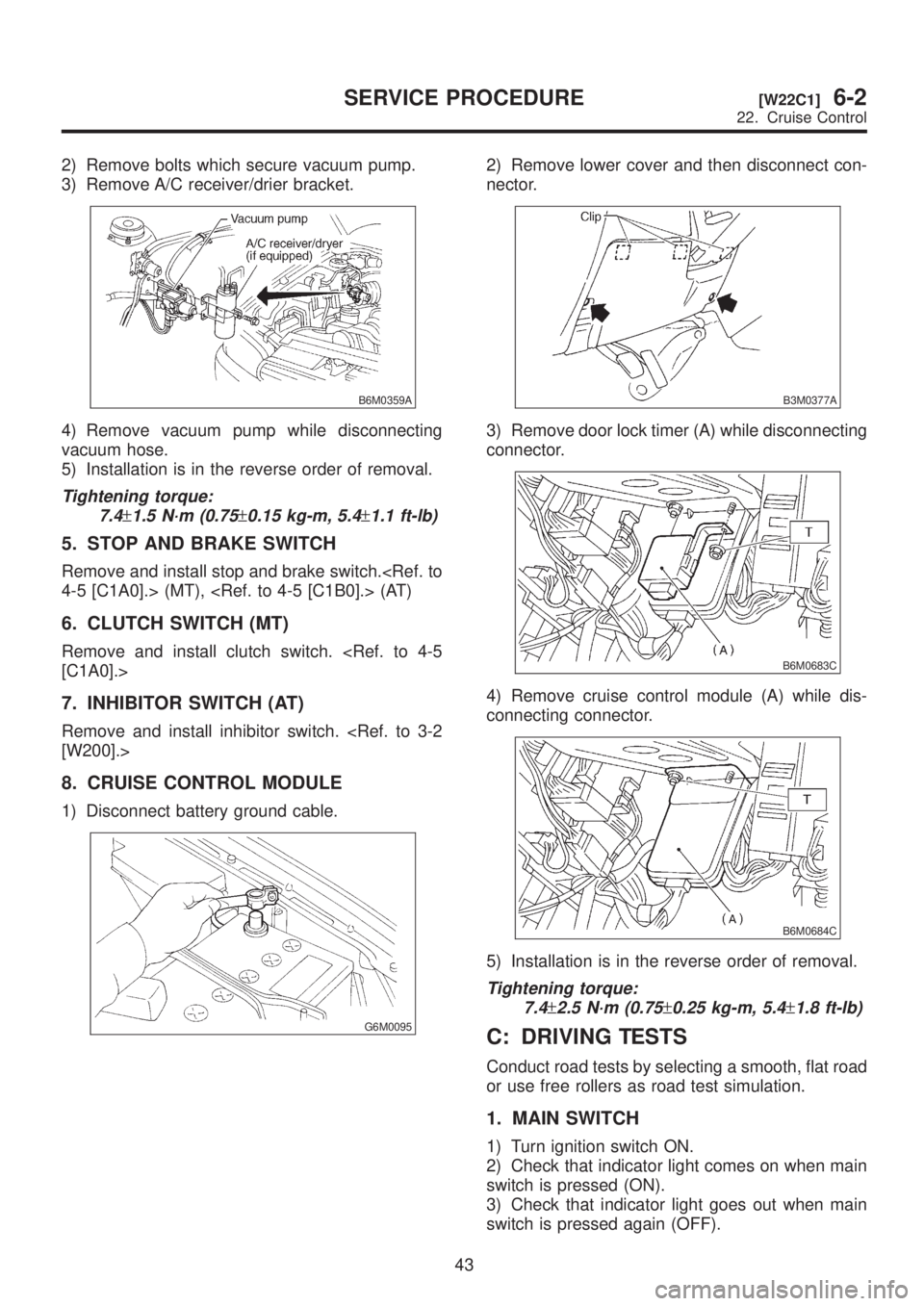

2) Remove bolts which secure vacuum pump.

3) Remove A/C receiver/drier bracket.

B6M0359A

4) Remove vacuum pump while disconnecting

vacuum hose.

5) Installation is in the reverse order of removal.

Tightening torque:

7.4

±1.5 N´m (0.75±0.15 kg-m, 5.4±1.1 ft-lb)

5. STOP AND BRAKE SWITCH

Remove and install stop and brake switch.

6. CLUTCH SWITCH (MT)

Remove and install clutch switch.

7. INHIBITOR SWITCH (AT)

Remove and install inhibitor switch.

8. CRUISE CONTROL MODULE

1) Disconnect battery ground cable.

G6M0095

2) Remove lower cover and then disconnect con-

nector.

B3M0377A

3) Remove door lock timer (A) while disconnecting

connector.

B6M0683C

4) Remove cruise control module (A) while dis-

connecting connector.

B6M0684C

5) Installation is in the reverse order of removal.

Tightening torque:

7.4

±2.5 N´m (0.75±0.25 kg-m, 5.4±1.8 ft-lb)

C: DRIVING TESTS

Conduct road tests by selecting a smooth, flat road

or use free rollers as road test simulation.

1. MAIN SWITCH

1) Turn ignition switch ON.

2) Check that indicator light comes on when main

switch is pressed (ON).

3) Check that indicator light goes out when main

switch is pressed again (OFF).

43

[W22C1]6-2SERVICE PROCEDURE

22. Cruise Control

Page 1274 of 1456

4) Turn ignition switch OFF with main switch ON

(which is indicated by illumination.).

5) Turn ignition switch ON again to ensure that

indicator light remains OFF.

2. COMMAND SWITCH

1) Check that command switch is properly set in

ªSET/COASTº, ªRESUME/ACCELº or ªCANCELº

mode.

2) Also check that command switch returns to the

original position when released.

3. CONSTANT SPEED TEST

1) Turn main switch ON.

2) Drive vehicle at speed greater than 40 km/h (25

MPH).

3) Press command switch to set in ªSET/COASTº

mode.

4) Ensure that vehicle is maintained at the speed

set when command switch was pressed.

4. ACCELERATION TEST

1) Set vehicle speed at speed greater than 40

km/h (25 MPH).

2) Ensure that vehicle continues to accelerate

while holding command switch in RESUME/

ACCEL mode, and that vehicle maintains that

optional speed when command switch is released.

5. DECELERATION TEST

1) Set vehicle speed at optional speed greater

than 40 km/h (25 MPH).

2) Ensure that vehicle continues to decelerate

while holding command switch in SET/COAST

mode, and that it maintains that optional speed

when command switch is released.

NOTE:

When vehicle speed reaches the lower speed limit

of 30 km/h (19 MPH) during deceleration, cruise

control will be released.

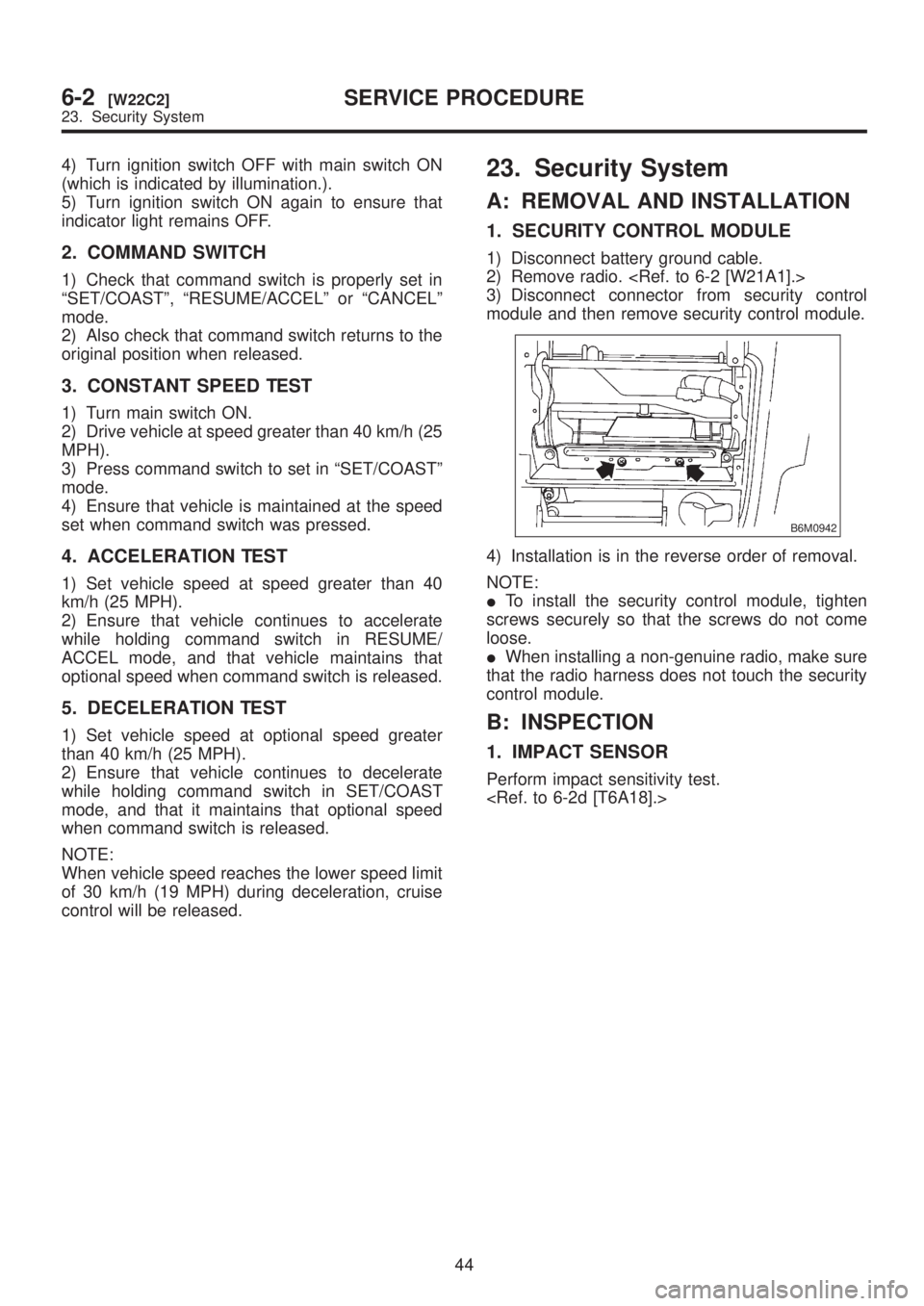

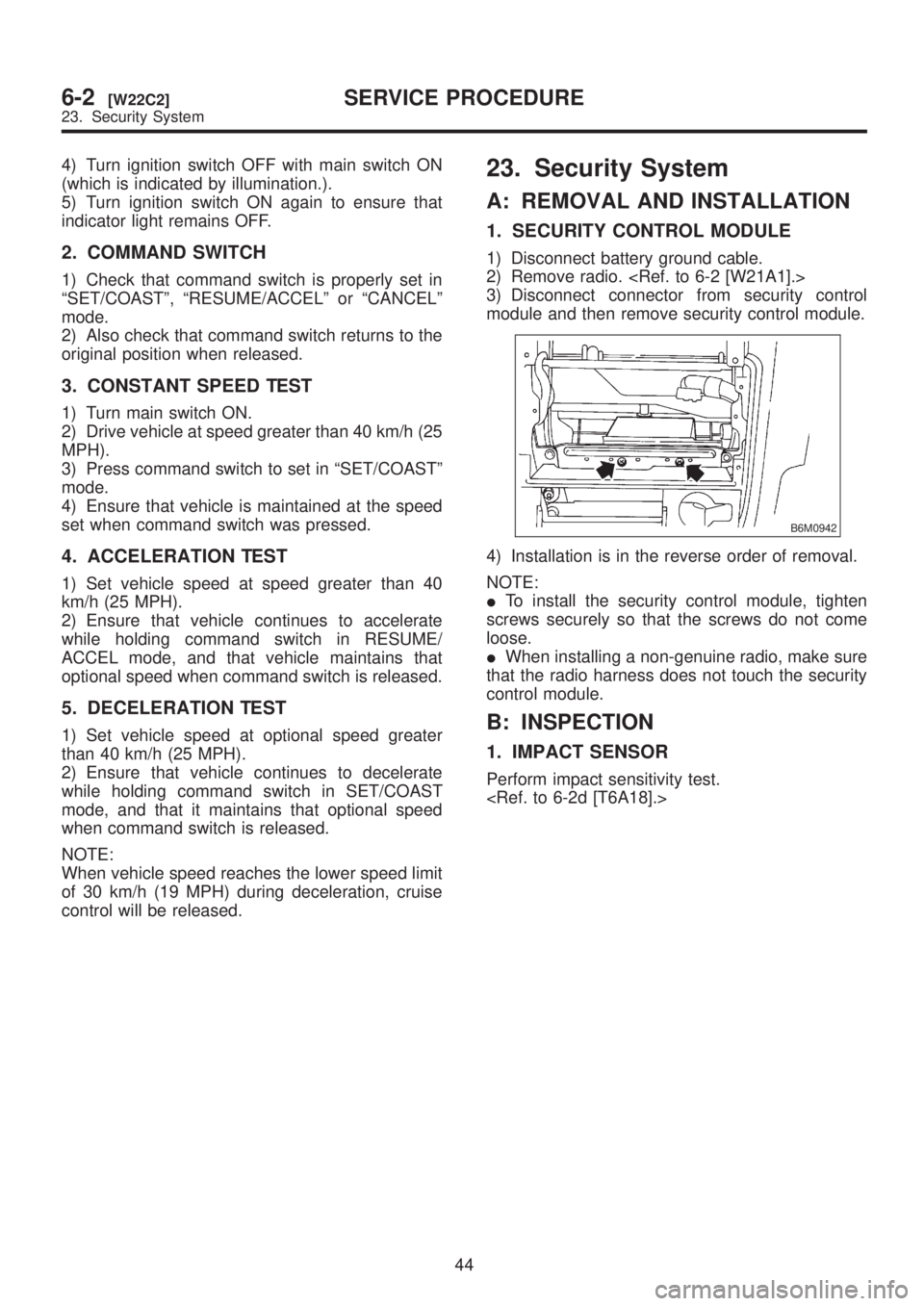

23. Security System

A: REMOVAL AND INSTALLATION

1. SECURITY CONTROL MODULE

1) Disconnect battery ground cable.

2) Remove radio.

3) Disconnect connector from security control

module and then remove security control module.

B6M0942

4) Installation is in the reverse order of removal.

NOTE:

ITo install the security control module, tighten

screws securely so that the screws do not come

loose.

IWhen installing a non-genuine radio, make sure

that the radio harness does not touch the security

control module.

B: INSPECTION

1. IMPACT SENSOR

Perform impact sensitivity test.

44

6-2[W22C2]SERVICE PROCEDURE

23. Security System

Page 1275 of 1456

4) Turn ignition switch OFF with main switch ON

(which is indicated by illumination.).

5) Turn ignition switch ON again to ensure that

indicator light remains OFF.

2. COMMAND SWITCH

1) Check that command switch is properly set in

ªSET/COASTº, ªRESUME/ACCELº or ªCANCELº

mode.

2) Also check that command switch returns to the

original position when released.

3. CONSTANT SPEED TEST

1) Turn main switch ON.

2) Drive vehicle at speed greater than 40 km/h (25

MPH).

3) Press command switch to set in ªSET/COASTº

mode.

4) Ensure that vehicle is maintained at the speed

set when command switch was pressed.

4. ACCELERATION TEST

1) Set vehicle speed at speed greater than 40

km/h (25 MPH).

2) Ensure that vehicle continues to accelerate

while holding command switch in RESUME/

ACCEL mode, and that vehicle maintains that

optional speed when command switch is released.

5. DECELERATION TEST

1) Set vehicle speed at optional speed greater

than 40 km/h (25 MPH).

2) Ensure that vehicle continues to decelerate

while holding command switch in SET/COAST

mode, and that it maintains that optional speed

when command switch is released.

NOTE:

When vehicle speed reaches the lower speed limit

of 30 km/h (19 MPH) during deceleration, cruise

control will be released.

23. Security System

A: REMOVAL AND INSTALLATION

1. SECURITY CONTROL MODULE

1) Disconnect battery ground cable.

2) Remove radio.

3) Disconnect connector from security control

module and then remove security control module.

B6M0942

4) Installation is in the reverse order of removal.

NOTE:

ITo install the security control module, tighten

screws securely so that the screws do not come

loose.

IWhen installing a non-genuine radio, make sure

that the radio harness does not touch the security

control module.

B: INSPECTION

1. IMPACT SENSOR

Perform impact sensitivity test.

44

6-2[W22C2]SERVICE PROCEDURE

23. Security System

Page 1276 of 1456

![SUBARU LEGACY 1999 Service Repair Manual 24. Seat Heater

A: REMOVAL AND INSTALLATION

1. SEAT HEATER

Remove and install front seat (including heater

system). <Ref. to 5-3 [W1A0].>

2. SEAT HEATER SWITCH

1) Remove screws which secure rear conso SUBARU LEGACY 1999 Service Repair Manual 24. Seat Heater

A: REMOVAL AND INSTALLATION

1. SEAT HEATER

Remove and install front seat (including heater

system). <Ref. to 5-3 [W1A0].>

2. SEAT HEATER SWITCH

1) Remove screws which secure rear conso](/img/17/57435/w960_57435-1275.png)

24. Seat Heater

A: REMOVAL AND INSTALLATION

1. SEAT HEATER

Remove and install front seat (including heater

system).

2. SEAT HEATER SWITCH

1) Remove screws which secure rear console

cover, and then remove rear console cover.

2) Remove seat heater switch from console cover.

B6M0150A

3) Installation is in the reverse order of removal.

B: INSPECTION

1. SEAT HEATER

Check continuity between terminals of seat heater

connector:

IBetween terminals No. 1 and No. 3

IBetween terminals No. 1 and No. 4

IBetween terminals No. 3 and No. 4

B6M0151A

2. SEAT HEATER SWITCH

Set switch to each position and check continuity

between terminals.

B6M0845A

45

[W24B2]6-2SERVICE PROCEDURE

24. Seat Heater

Page 1277 of 1456

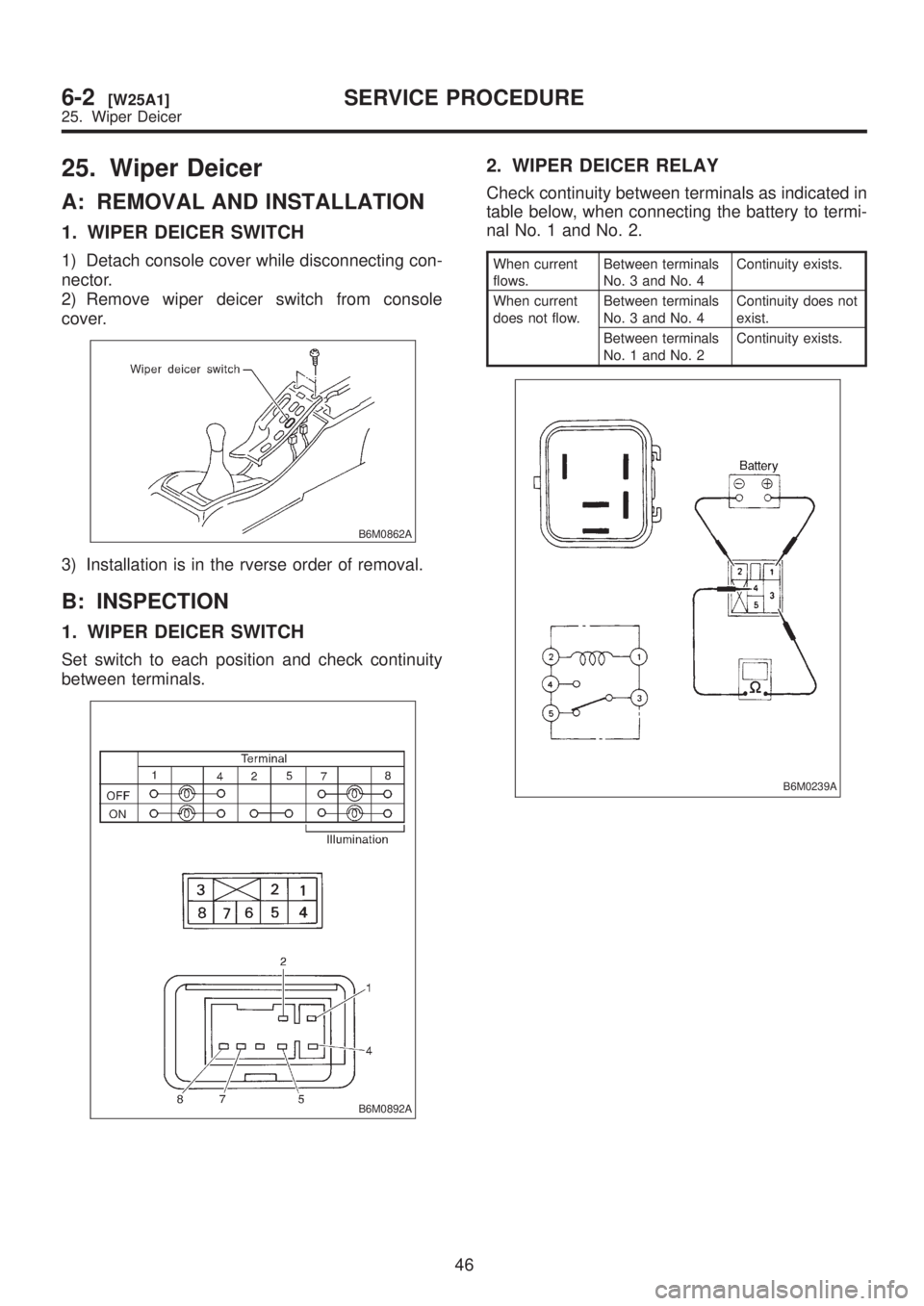

25. Wiper Deicer

A: REMOVAL AND INSTALLATION

1. WIPER DEICER SWITCH

1) Detach console cover while disconnecting con-

nector.

2) Remove wiper deicer switch from console

cover.

B6M0862A

3) Installation is in the rverse order of removal.

B: INSPECTION

1. WIPER DEICER SWITCH

Set switch to each position and check continuity

between terminals.

B6M0892A

2. WIPER DEICER RELAY

Check continuity between terminals as indicated in

table below, when connecting the battery to termi-

nal No. 1 and No. 2.

When current

flows.Between terminals

No. 3 and No. 4Continuity exists.

When current

does not flow.Between terminals

No. 3 and No. 4Continuity does not

exist.

Between terminals

No. 1 and No. 2Continuity exists.

B6M0239A

46

6-2[W25A1]SERVICE PROCEDURE

25. Wiper Deicer

Page 1278 of 1456

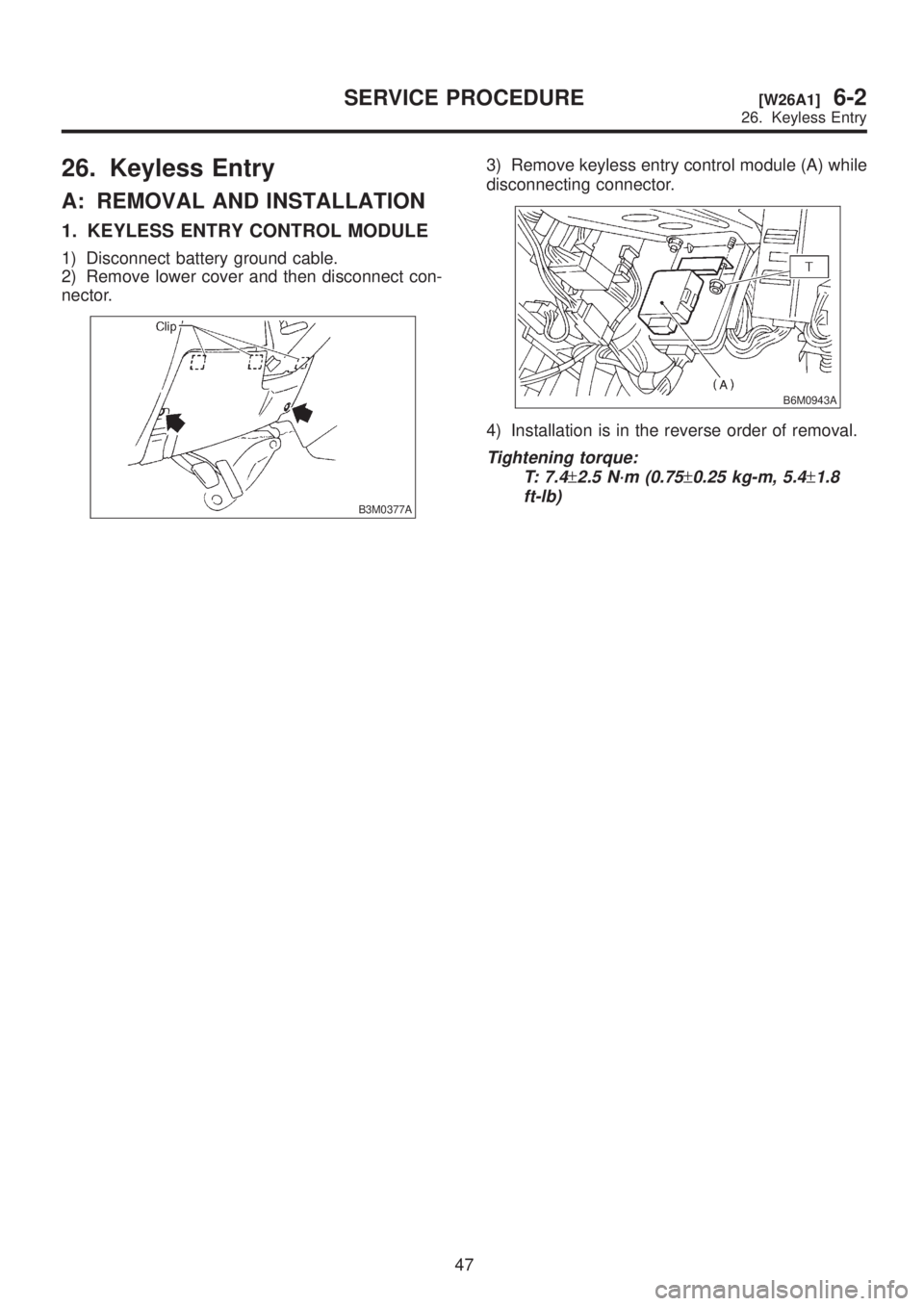

26. Keyless Entry

A: REMOVAL AND INSTALLATION

1. KEYLESS ENTRY CONTROL MODULE

1) Disconnect battery ground cable.

2) Remove lower cover and then disconnect con-

nector.

B3M0377A

3) Remove keyless entry control module (A) while

disconnecting connector.

B6M0943A

4) Installation is in the reverse order of removal.

Tightening torque:

T: 7.4

±2.5 N´m (0.75±0.25 kg-m, 5.4±1.8

ft-lb)

47

[W26A1]6-2SERVICE PROCEDURE

26. Keyless Entry

Page 1279 of 1456

MEMO:

48

6-2SERVICE PROCEDURE

Page 1280 of 1456

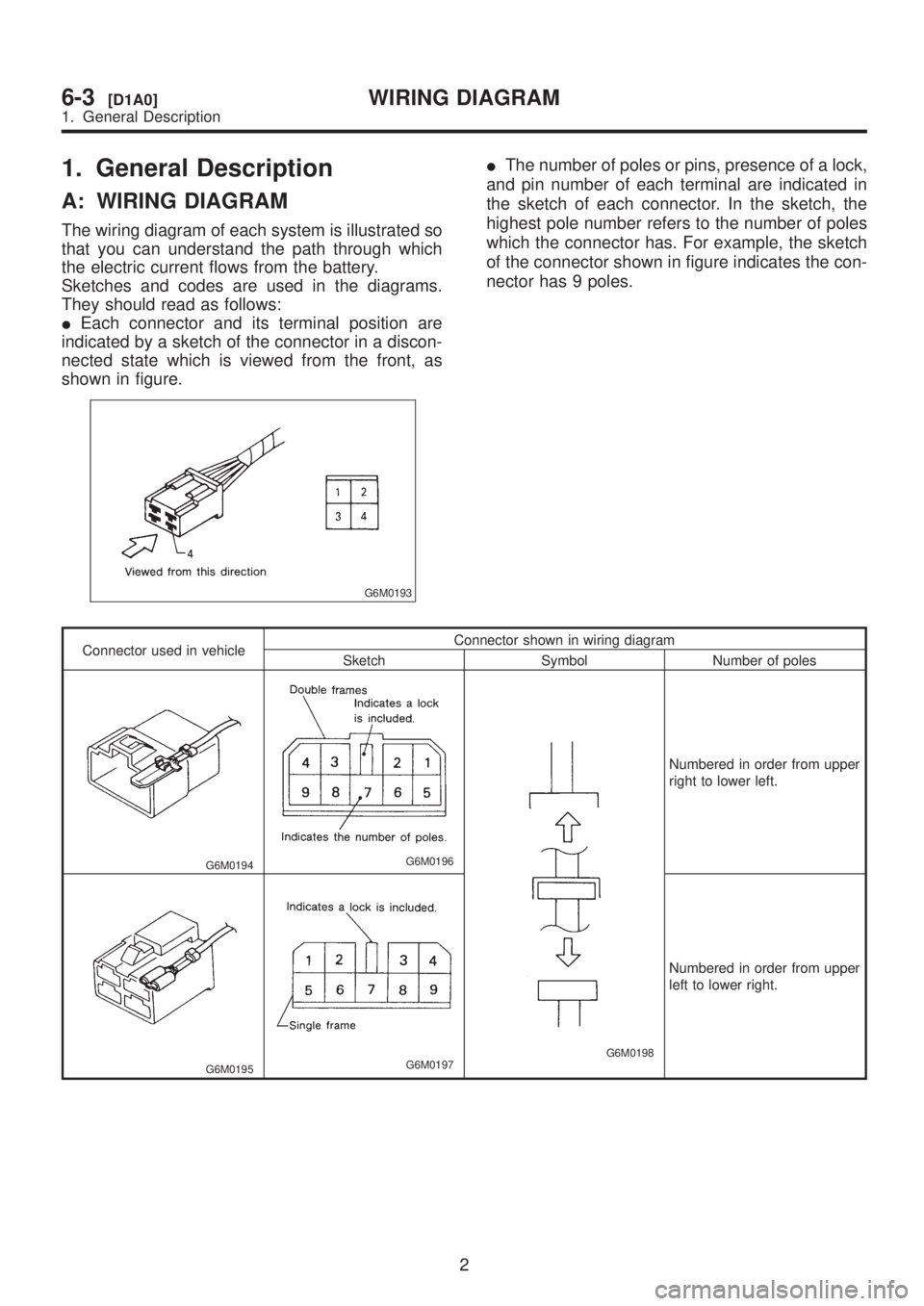

1. General Description

A: WIRING DIAGRAM

The wiring diagram of each system is illustrated so

that you can understand the path through which

the electric current flows from the battery.

Sketches and codes are used in the diagrams.

They should read as follows:

IEach connector and its terminal position are

indicated by a sketch of the connector in a discon-

nected state which is viewed from the front, as

shown in figure.

G6M0193

IThe number of poles or pins, presence of a lock,

and pin number of each terminal are indicated in

the sketch of each connector. In the sketch, the

highest pole number refers to the number of poles

which the connector has. For example, the sketch

of the connector shown in figure indicates the con-

nector has 9 poles.

Connector used in vehicleConnector shown in wiring diagram

Sketch Symbol Number of poles

G6M0194G6M0196

G6M0198

Numbered in order from upper

right to lower left.

G6M0195G6M0197

Numbered in order from upper

left to lower right.

2

6-3[D1A0]WIRING DIAGRAM

1. General Description