sensor SUBARU TRIBECA 2009 1.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUBARU, Model Year: 2009, Model line: TRIBECA, Model: SUBARU TRIBECA 2009 1.GPages: 2453, PDF Size: 46.32 MB

Page 474 of 2453

![SUBARU TRIBECA 2009 1.G Service Workshop Manual LAN(diag)-18

Subaru Select Monitor

LAN SYSTEM (DIAGNOSTICS)

5. CONFIRMATION OF CURRENT SETTING

1) On the «Main Menu» display screen, select the {Each System Check} and press the [YES] key.

2) On the SUBARU TRIBECA 2009 1.G Service Workshop Manual LAN(diag)-18

Subaru Select Monitor

LAN SYSTEM (DIAGNOSTICS)

5. CONFIRMATION OF CURRENT SETTING

1) On the «Main Menu» display screen, select the {Each System Check} and press the [YES] key.

2) On the](/img/17/7322/w960_7322-473.png)

LAN(diag)-18

Subaru Select Monitor

LAN SYSTEM (DIAGNOSTICS)

5. CONFIRMATION OF CURRENT SETTING

1) On the «Main Menu» display screen, select the {Each System Check} and press the [YES] key.

2) On the «System Selection Menu» display screen, select the {Integ. Unit mode} and press the [YES] key.

3) On the «Integ. unit mode failure diag» display screen, select the {Current Data Display & Save} and press

the [YES] key.

4) On the «Current Data Display & Save» display screen, select the {12 Data Display} and press the [YES]

key.

5) Using the scroll key, scroll the display screen up or down until the desired data is shown.

6) Display the following item and record the settings.

Required items for new registration (Except for system not equipped)

Item Item to confirm Remarks

Key No. to register 1 2 3 4 Registered ID type

Off delay OFF Long Normal Short Setting for lighting off time

Auto-lock 60, 50 40, 30, 20 OFF Not suppor ted by Nor th Amer ican specifications (Unit sec.)

Rr defogger op. mode Normal ContinuousNormal: Off at 15 minutes of operation

Continuous: Operations from switch on to off

Wiper deicer op. mode Normal Continuous

Normal: Off at 15 minutes of operation

Continuous: Operations from switch ON to OFF, repeats ON

for 15 minutes, OFF for 2 minutes

Security Alarm Setup ON OFFON: Warning device operation possible

OFF: Warning device does not operate

Impact Sensor Setup ON OFF

ON: Impact sensor operation possible

OFF: Impact sensor does not operate

Tu r n O F F f o r v e h i c l e s n o t e q u i p p e d w i t h a n I m p a c t S e n s o r

Alarm monitor delay set-

tingON OFF

ON: Monitor after a fixed period of time from reception of the

keyless lock signal

OFF: Monitor after reception of the keyless lock signal

Lockout prevention ON OFFON: Lockout prevention operation

OFF: Lockout prevention not operated

Impact Sensor Yes No

Ye s : I m p a c t s e n s o r e q u i p p e d

No: Impact sensor not equipped

Always set to no for vehicles not equipped with the impact sen-

sor.

Siren setting Yes No

Ye s : V e h i c l e e q u i p p e d w i t h s i r e n

No: Vehicle not equipped with siren

The horn does not honk when the warning operates if the vehi-

cle not equipped with a siren is set to ‘Yes’.

Answer-back buzzer

setupON OFFON: Answer-back buzzer operation possible

OFF: Answer-back buzzer not operated

Hazard answer-back

setupON OFFON: Hazard answer-back buzzer operation possible

OFF: Hazard answer-back buzzer not operated

Automatic locking setup ON OFF Not suppor ted by Nor th Amer ican specifications

Ans.-back Buzzer Yes NoYe s : V e h i c l e e q u i p p e d w i t h a n s w e r - b a c k b u z z e r

No: Vehicle not equipped with answer-back buzzer

Auto locking Yes No Not suppor ted by Nor th Amer ican specifications

Door open warning (pre-

vention of batter y run-

out)

Ye s N o

Ye s : D o o r i n t e r l o c k e d r o o m l i g h t g o e s o f f w h e n o n f o r 1 0 m i n -

utes consecutively when door is open.

No: Room light remains illuminated until door is closed.

A/C ECM setting Yes No Model with auto A/C (Set to ‘Yes’)

P/W ECM setting Yes No Not supported by North American specifications

Center display failure Yes NoYe s : V e h i c l e e q u i p p e d w i t h M F D a n d n a v i g a t i o n d i s p l a y

No: Vehicle not equipped with MFD nor navigation display

Wiper deicer Yes NoYe s : V e h i c l e e q u i p p e d w i t h w i p e r d e i c e r

No: Vehicle not equipped with wiper deicer

Rear fog light setting Yes No Not supported by North American specifications

Fac t or y in i ti a l s et t i ng Fa ct o r y M ar ke tDo not change to the factory mode. Set to market when using

normally.

Page 478 of 2453

![SUBARU TRIBECA 2009 1.G Service Workshop Manual LAN(diag)-22

Subaru Select Monitor

LAN SYSTEM (DIAGNOSTICS)

9. FUNCTION SETTING (ECM CUSTOMIZING)

1) On the «Main Menu» display screen, select the {Each System Check} and press the [YES] key.

2) On SUBARU TRIBECA 2009 1.G Service Workshop Manual LAN(diag)-22

Subaru Select Monitor

LAN SYSTEM (DIAGNOSTICS)

9. FUNCTION SETTING (ECM CUSTOMIZING)

1) On the «Main Menu» display screen, select the {Each System Check} and press the [YES] key.

2) On](/img/17/7322/w960_7322-477.png)

LAN(diag)-22

Subaru Select Monitor

LAN SYSTEM (DIAGNOSTICS)

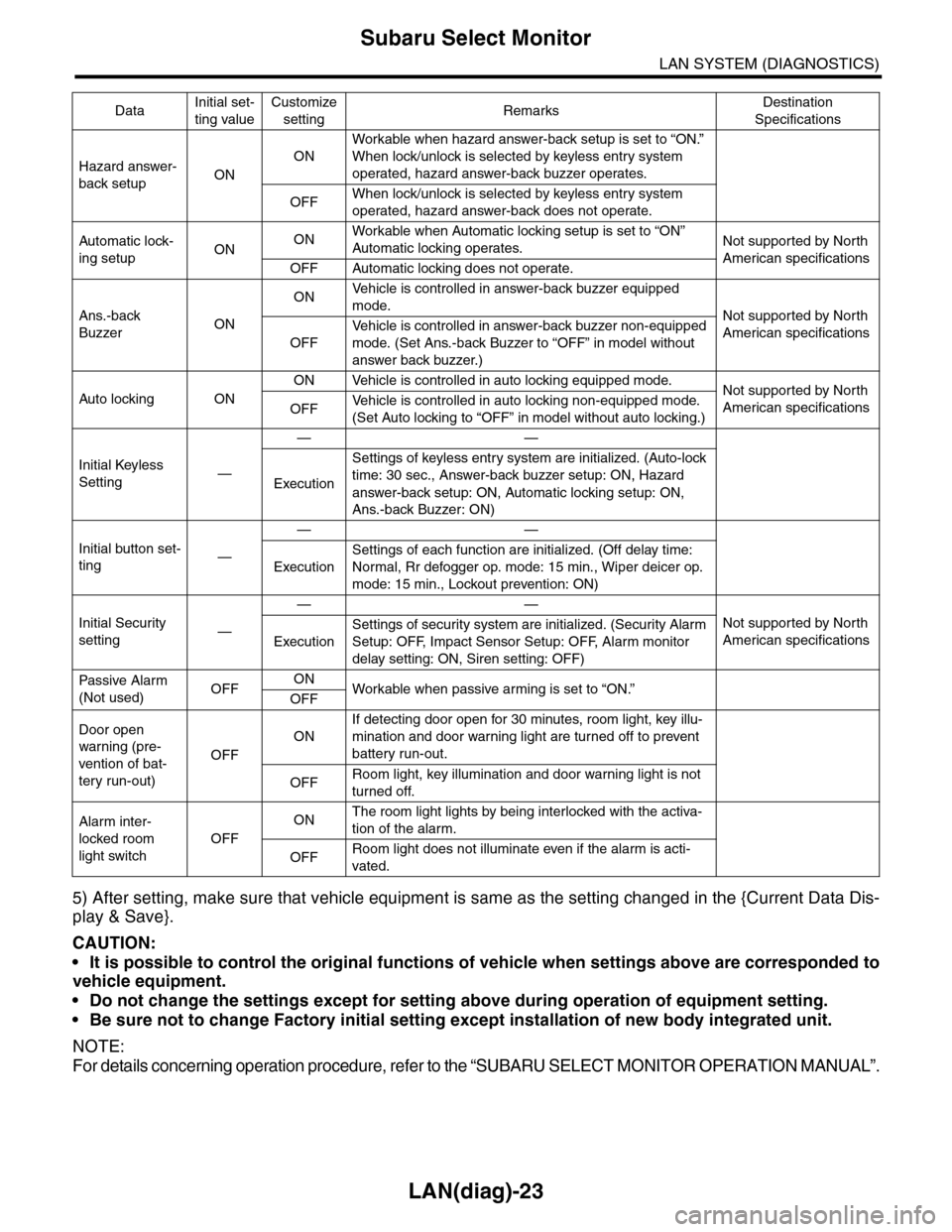

9. FUNCTION SETTING (ECM CUSTOMIZING)

1) On the «Main Menu» display screen, select the {Each System Check} and press the [YES] key.

2) On the «System Selection Menu» display screen, select the {Integ. Unit mode} and press the [YES] key.

3) On the «Integ. Unit mode failure diag» display screen, select the {ECM customizing} and press the [YES] key.

4) Change the setting with UP/DOWN key and press the [YES] key.

•List of function setting item (ECM customizing)

NOTE:

Even if changes are made to items that are not equipped, the contents are not confirmed and do not operate.

DataInitial set-

ting value

Customize

settingRemarksDestination

Specifications

Off delay time Normal

Delay time below can be selected by setting.

After door closed After key unlock

OFF 0 sec. 0 sec.

Short 3 sec. 10 sec.

Normal 5 sec. 20 sec.

Long 8 sec. 30 sec.

Auto lock time 30 sec.0 — 60

sec.

Workable when Auto locking is set to “ON” and Automatic

locking setup is “ON”. Time can be changed by 10 sec-

onds: 0 (OFF) — 60 (maximum).

Not supported by North

American specifications

Rr defogger op.

mode15 min.

15 min.Rear defogger stops in 15 minutes automatically after

switch is turned to ON.

ContinuousRear defogger repeats active condition for 15 minutes and

inactive condition for 2 minutes until switch is turned to OFF.

Wiper deicer op.

mode15 min.

15 min.Wiper deicer stops in 15 minutes automatically after

switch is turned to ON.

ContinuousWiper deicer repeats active condition for 15 minutes and

inactive condition for 2 minutes until switch is turned to OFF.

Security Alarm

SetupONON Security alarm (hazard, horn or siren) in active condition

OFF Security alarm in inactive condition

Impact Sensor

SetupOFF

ONWorkable when Impact Sensor Setup is set to “ON”

Impact sensor in active condition

OFFImpact sensor in inactive condition (Set Impact Sensor

Setup of model without impact sensor to “OFF”.)

Alarm monitor

delay settingON

After doors are locked by keyless entry system operated,

Alarm monitor starts in following time.

ON Delay time is 30 seconds.

OFF Delay time is 0 seconds.

Lockout preven-

tionONONLockout prevention in inactive condition (Lockout preven-

tion does not operate if safety knob is locked by hand.)

OFF Lockout prevention in inactive condition

Impact Sensor OFFON

Ve h i c l e i s c o n t r o l l e d i n i m p a c t s e n s o r e q u i p p e d m o d e .

(Set impact sensor to “OFF” in model without impact sen-

sor. If impact sensor is set to “ON”, hazard, horn or siren

operate after doors are locked by keyless entry system

operated (Alarm monitor starting).

Set to “ON” when an

optional impact sensor

is installed.

OFF Vehicle is controlled in impact sensor no-equipped mode.

Siren setting OFFON

Siren sounds when alarm operates. (Set siren setting to

“OFF” in model without siren. Horn does not sound if siren

setting is set to “ON”.)

Set to “ON” when an

optional siren is

installed.OFF Horn sounds when alarm operates.

Answer-back

buzzer setupON

ON

Workable when answer-back buzzer setup is set to “ON”.

When lock/unlock is selected by keyless entry system

operated, hazard answer-back buzzer operates.

OFFWhen lock/unlock is selected by keyless entry system

operated, answer-back buzzer does not sound.

Page 479 of 2453

LAN(diag)-23

Subaru Select Monitor

LAN SYSTEM (DIAGNOSTICS)

5) After setting, make sure that vehicle equipment is same as the setting changed in the {Current Data Dis-

play & Save}.

CAUTION:

•It is possible to control the original functions of vehicle when settings above are corresponded to

vehicle equipment.

•Do not change the settings except for setting above during operation of equipment setting.

•Be sure not to change Factory initial setting except installation of new body integrated unit.

NOTE:

For details concerning operation procedure, refer to the “SUBARU SELECT MONITOR OPERATION MANUAL”.

Hazard answer-

back setupON

ON

Workable when hazard answer-back setup is set to “ON.”

When lock/unlock is selected by keyless entry system

operated, hazard answer-back buzzer operates.

OFFWhen lock/unlock is selected by keyless entry system

operated, hazard answer-back does not operate.

Automatic lock-

ing setupONONWorkable when Automatic locking setup is set to “ON”

Automatic locking operates.Not supported by North

American specificationsOFF Automatic locking does not operate.

Ans.-back

BuzzerON

ONVe h i c l e i s c o n t r o l l e d i n a n sw e r - b a c k b u z z e r e q u i p p e d

mode.Not supported by North

American specificationsOFF

Ve h i c l e i s c o n t r o l l e d i n a n sw e r - b a c k b u z z e r n o n - e q u i p p e d

mode. (Set Ans.-back Buzzer to “OFF” in model without

answer back buzzer.)

Auto locking ON

ON Vehicle is controlled in auto locking equipped mode.Not supported by North

American specificationsOFFVe h i c l e i s c o n t r o l l e d i n a u t o l o c k i n g n o n - e q u i p p e d m o d e .

(Set Auto locking to “OFF” in model without auto locking.)

Initial Keyless

Setting—

——

Execution

Settings of keyless entry system are initialized. (Auto-lock

time: 30 sec., Answer-back buzzer setup: ON, Hazard

answer-back setup: ON, Automatic locking setup: ON,

Ans.-back Buzzer: ON)

Initial button set-

ting—

——

Execution

Settings of each function are initialized. (Off delay time:

Normal, Rr defogger op. mode: 15 min., Wiper deicer op.

mode: 15 min., Lockout prevention: ON)

Initial Security

setting—

——

Not supported by North

American specificationsExecution

Settings of security system are initialized. (Security Alarm

Setup: OFF, Impact Sensor Setup: OFF, Alarm monitor

delay setting: ON, Siren setting: OFF)

Passive Alar m

(Not used)OFFONWorkable when passive ar ming is set to “ON.”

OFF

Door open

warning (pre-

vention of bat-

tery run-out)

OFF

ON

If detecting door open for 30 minutes, room light, key illu-

mination and door warning light are turned off to prevent

battery run-out.

OFFRoom light, key illumination and door warning light is not

turned off.

Alarm inter-

locked room

light switch

OFF

ONThe room light lights by being interlocked with the activa-

tion of the alarm.

OFFRoom light does not illuminate even if the alarm is acti-

vated.

DataInitial set-

ting value

Customize

settingRemarksDestination

Specifications

Page 502 of 2453

LAN(diag)-46

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

LAN SYSTEM (DIAGNOSTICS)

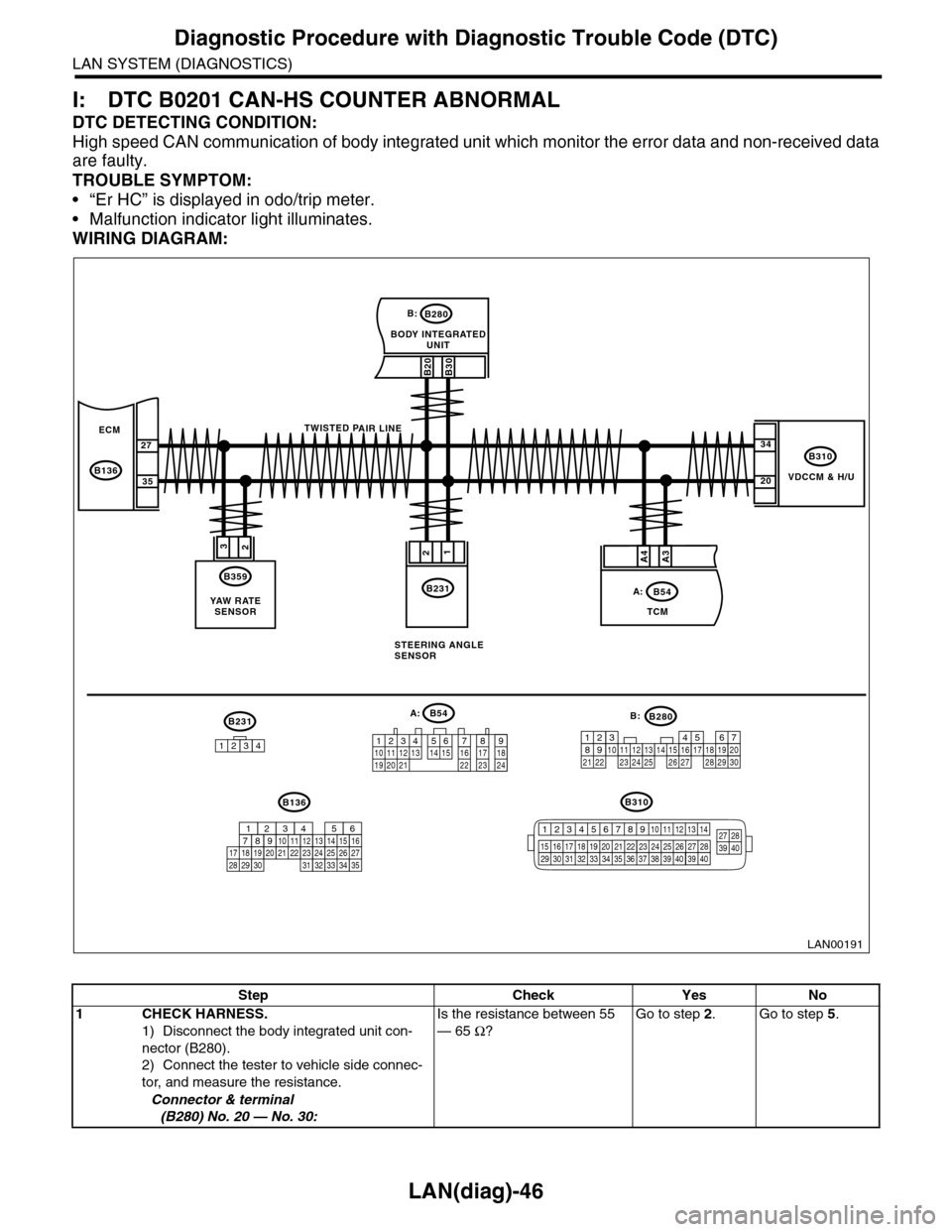

I: DTC B0201 CAN-HS COUNTER ABNORMAL

DTC DETECTING CONDITION:

High speed CAN communication of body integrated unit which monitor the error data and non-received data

are faulty.

TROUBLE SYMPTOM:

•“Er HC” is displayed in odo/trip meter.

•Malfunction indicator light illuminates.

WIRING DIAGRAM:

VDCCM & H/U

B310

B20B30

BODY INTEGRATEDUNIT

B280B:

TCM

B54A:

23

B359

YAW R AT ESENSOR

34

20

B231

21

STEERING ANGLESENSOR

B231

1234

B54A:

12 7 8 9563410 11 1219 20 2113 14 15 16 17 1822 23 24

B136B310

B280B:

5467821931022 23111213141524 25 26 2716171828 29192021 30

ECM

B136

27

35

A3A4

TWISTED PAIR LINE

12345678910 11 12 13 14

15 16 17 18 19 2021 22 23 24 25 26 27 2829 30 31 32 33 3435 36 37 38 39403940

27 28394016101112131415252430

9871718192028212223293231

123456

2726333435

LAN00191

Step Check Yes No

1CHECK HARNESS.

1) Disconnect the body integrated unit con-

nector (B280).

2) Connect the tester to vehicle side connec-

tor, and measure the resistance.

Connector & terminal

(B280) No. 20 — No. 30:

Is the resistance between 55

— 65 Ω?

Go to step 2.Go to step 5.

Page 503 of 2453

LAN(diag)-47

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

LAN SYSTEM (DIAGNOSTICS)

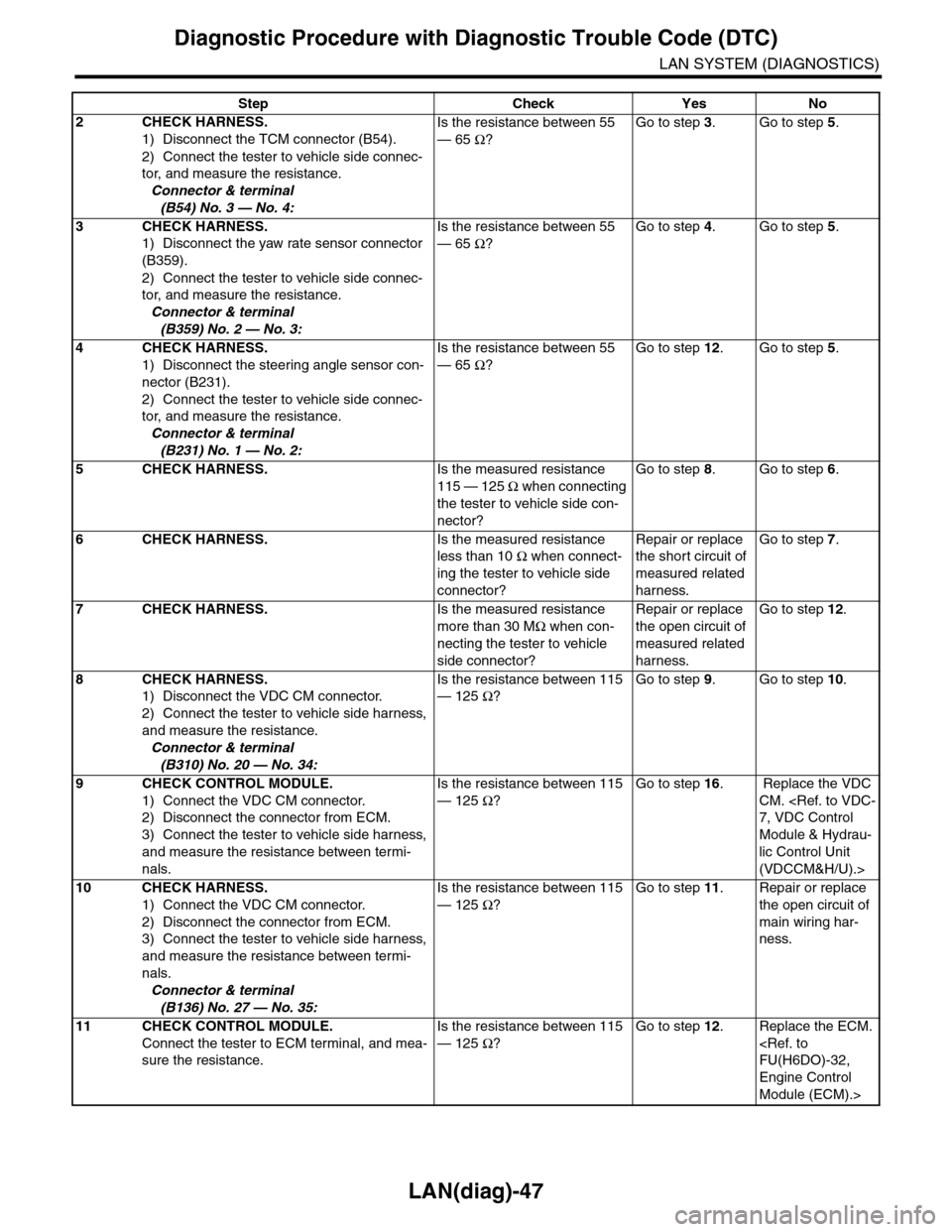

2CHECK HARNESS.

1) Disconnect the TCM connector (B54).

2) Connect the tester to vehicle side connec-

tor, and measure the resistance.

Connector & terminal

(B54) No. 3 — No. 4:

Is the resistance between 55

— 65 Ω?

Go to step 3.Go to step 5.

3CHECK HARNESS.

1) Disconnect the yaw rate sensor connector

(B359).

2) Connect the tester to vehicle side connec-

tor, and measure the resistance.

Connector & terminal

(B359) No. 2 — No. 3:

Is the resistance between 55

— 65 Ω?

Go to step 4.Go to step 5.

4CHECK HARNESS.

1) Disconnect the steering angle sensor con-

nector (B231).

2) Connect the tester to vehicle side connec-

tor, and measure the resistance.

Connector & terminal

(B231) No. 1 — No. 2:

Is the resistance between 55

— 65 Ω?

Go to step 12.Go to step 5.

5CHECK HARNESS.Is the measured resistance

115 — 125 Ω when connecting

the tester to vehicle side con-

nector?

Go to step 8.Go to step 6.

6CHECK HARNESS.Is the measured resistance

less than 10 Ω when connect-

ing the tester to vehicle side

connector?

Repair or replace

the short circuit of

measured related

harness.

Go to step 7.

7CHECK HARNESS.Is the measured resistance

more than 30 MΩ when con-

necting the tester to vehicle

side connector?

Repair or replace

the open circuit of

measured related

harness.

Go to step 12.

8CHECK HARNESS.

1) Disconnect the VDC CM connector.

2) Connect the tester to vehicle side harness,

and measure the resistance.

Connector & terminal

(B310) No. 20 — No. 34:

Is the resistance between 115

— 125 Ω?

Go to step 9.Go to step 10.

9CHECK CONTROL MODULE.

1) Connect the VDC CM connector.

2) Disconnect the connector from ECM.

3) Connect the tester to vehicle side harness,

and measure the resistance between termi-

nals.

Is the resistance between 115

— 125 Ω?

Go to step 16. Replace the VDC

CM.

Module & Hydrau-

lic Control Unit

(VDCCM&H/U).>

10 CHECK HARNESS.

1) Connect the VDC CM connector.

2) Disconnect the connector from ECM.

3) Connect the tester to vehicle side harness,

and measure the resistance between termi-

nals.

Connector & terminal

(B136) No. 27 — No. 35:

Is the resistance between 115

— 125 Ω?

Go to step 11.Repair or replace

the open circuit of

main wiring har-

ness.

11 CHECK CONTROL MODULE.

Connect the tester to ECM terminal, and mea-

sure the resistance.

Is the resistance between 115

— 125 Ω?

Go to step 12.Replace the ECM.

Engine Control

Module (ECM).>

Step Check Yes No

Page 504 of 2453

LAN(diag)-48

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

LAN SYSTEM (DIAGNOSTICS)

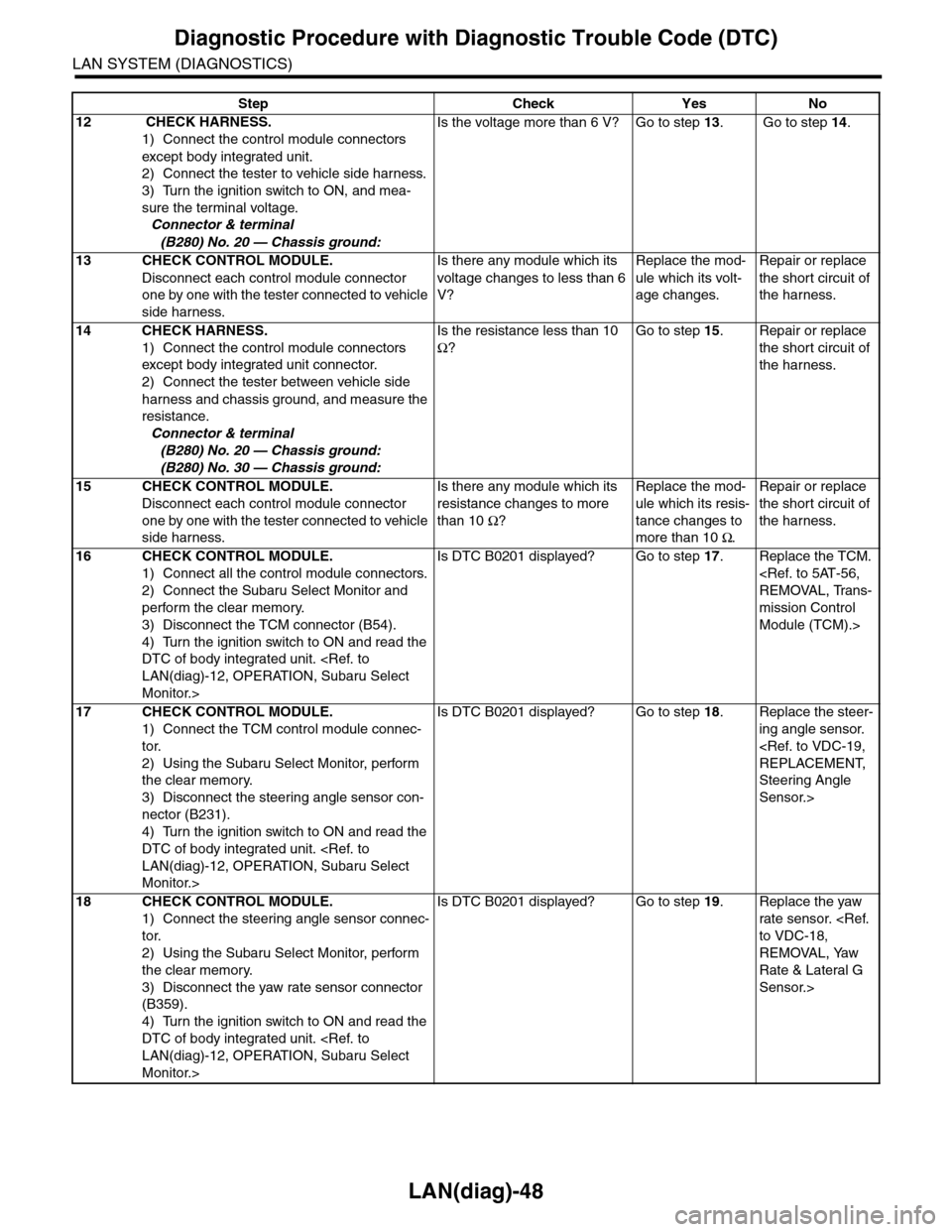

12 CHECK HARNESS.

1) Connect the control module connectors

except body integrated unit.

2) Connect the tester to vehicle side harness.

3) Turn the ignition switch to ON, and mea-

sure the terminal voltage.

Connector & terminal

(B280) No. 20 — Chassis ground:

Is the voltage more than 6 V? Go to step 13. Go to step 14.

13 CHECK CONTROL MODULE.

Disconnect each control module connector

one by one with the tester connected to vehicle

side harness.

Is there any module which its

voltage changes to less than 6

V?

Replace the mod-

ule which its volt-

age changes.

Repair or replace

the shor t circuit of

the harness.

14 CHECK HARNESS.

1) Connect the control module connectors

except body integrated unit connector.

2) Connect the tester between vehicle side

harness and chassis ground, and measure the

resistance.

Connector & terminal

(B280) No. 20 — Chassis ground:

(B280) No. 30 — Chassis ground:

Is the resistance less than 10

Ω?

Go to step 15.Repair or replace

the shor t circuit of

the harness.

15 CHECK CONTROL MODULE.

Disconnect each control module connector

one by one with the tester connected to vehicle

side harness.

Is there any module which its

resistance changes to more

than 10 Ω?

Replace the mod-

ule which its resis-

tance changes to

more than 10 Ω.

Repair or replace

the shor t circuit of

the harness.

16 CHECK CONTROL MODULE.

1) Connect all the control module connectors.

2) Connect the Subaru Select Monitor and

perform the clear memory.

3) Disconnect the TCM connector (B54).

4) Turn the ignition switch to ON and read the

DTC of body integrated unit.

Monitor.>

Is DTC B0201 displayed? Go to step 17.Replace the TCM.

mission Control

Module (TCM).>

17 CHECK CONTROL MODULE.

1) Connect the TCM control module connec-

tor.

2) Using the Subaru Select Monitor, perform

the clear memory.

3) Disconnect the steering angle sensor con-

nector (B231).

4) Turn the ignition switch to ON and read the

DTC of body integrated unit.

Monitor.>

Is DTC B0201 displayed? Go to step 18.Replace the steer-

ing angle sensor.

Steering Angle

Sensor.>

18 CHECK CONTROL MODULE.

1) Connect the steering angle sensor connec-

tor.

2) Using the Subaru Select Monitor, perform

the clear memory.

3) Disconnect the yaw rate sensor connector

(B359).

4) Turn the ignition switch to ON and read the

DTC of body integrated unit.

Monitor.>

Is DTC B0201 displayed? Go to step 19.Replace the yaw

rate sensor.

REMOVAL, Yaw

Rate & Lateral G

Sensor.>

Step Check Yes No

Page 506 of 2453

LAN(diag)-50

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

LAN SYSTEM (DIAGNOSTICS)

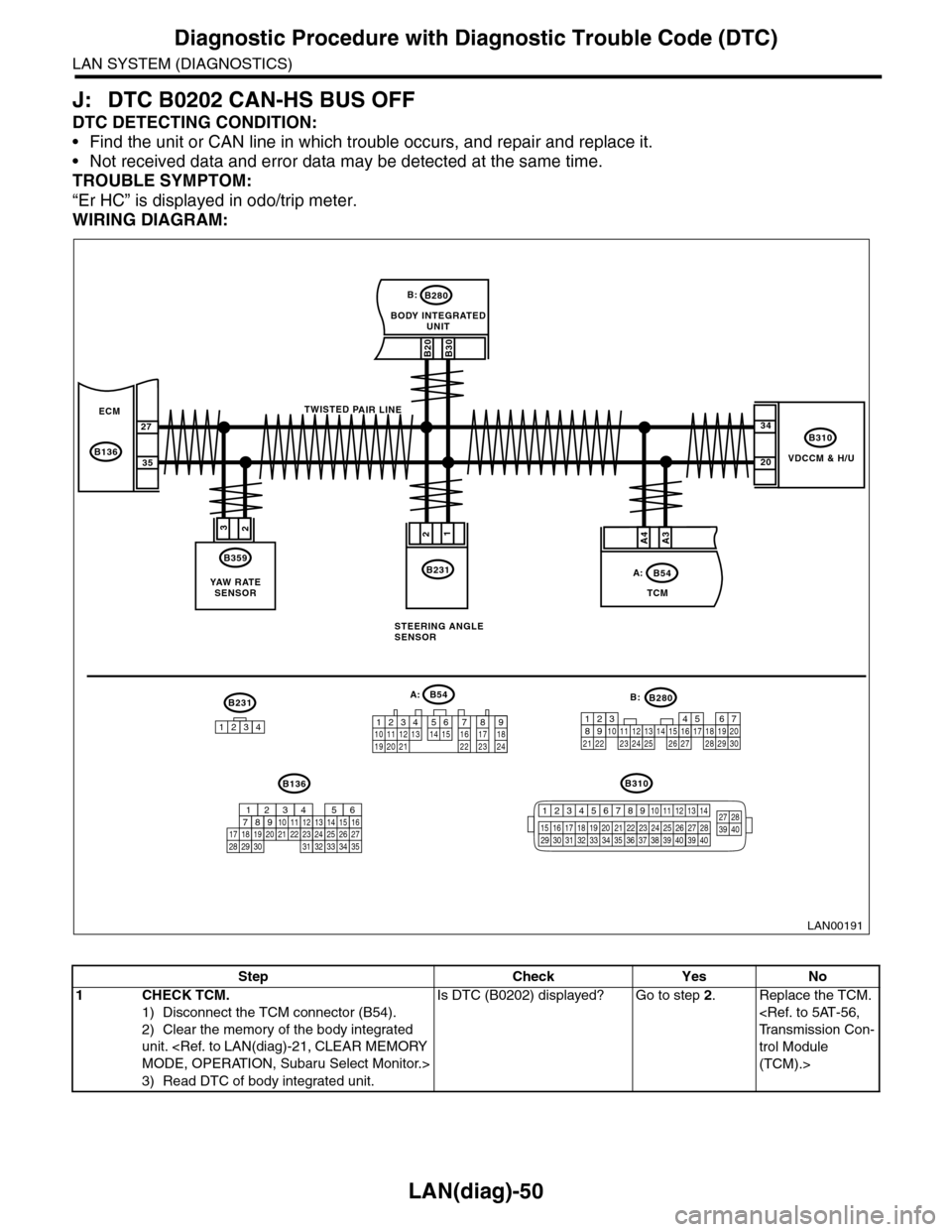

J: DTC B0202 CAN-HS BUS OFF

DTC DETECTING CONDITION:

•Find the unit or CAN line in which trouble occurs, and repair and replace it.

•Not received data and error data may be detected at the same time.

TROUBLE SYMPTOM:

“Er HC” is displayed in odo/trip meter.

WIRING DIAGRAM:

VDCCM & H/U

B310

B20B30

BODY INTEGRATEDUNIT

B280B:

TCM

B54A:

23

B359

YAW R AT ESENSOR

34

20

B231

21

STEERING ANGLESENSOR

B231

1234

B54A:

12 7 8 9563410 11 1219 20 2113 14 15 16 17 1822 23 24

B136B310

B280B:

5467821931022 23111213141524 25 26 2716171828 29192021 30

ECM

B136

27

35

A3A4

TWISTED PAIR LINE

12345678910 11 12 13 14

15 16 17 18 19 2021 22 23 24 25 26 27 2829 30 31 32 33 3435 36 37 38 39403940

27 28394016101112131415252430

9871718192028212223293231

123456

2726333435

LAN00191

Step Check Yes No

1CHECK TCM.

1) Disconnect the TCM connector (B54).

2) Clear the memory of the body integrated

unit.

3) Read DTC of body integrated unit.

Is DTC (B0202) displayed? Go to step 2.Replace the TCM.

trol Module

(TCM).>

Page 507 of 2453

LAN(diag)-51

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

LAN SYSTEM (DIAGNOSTICS)

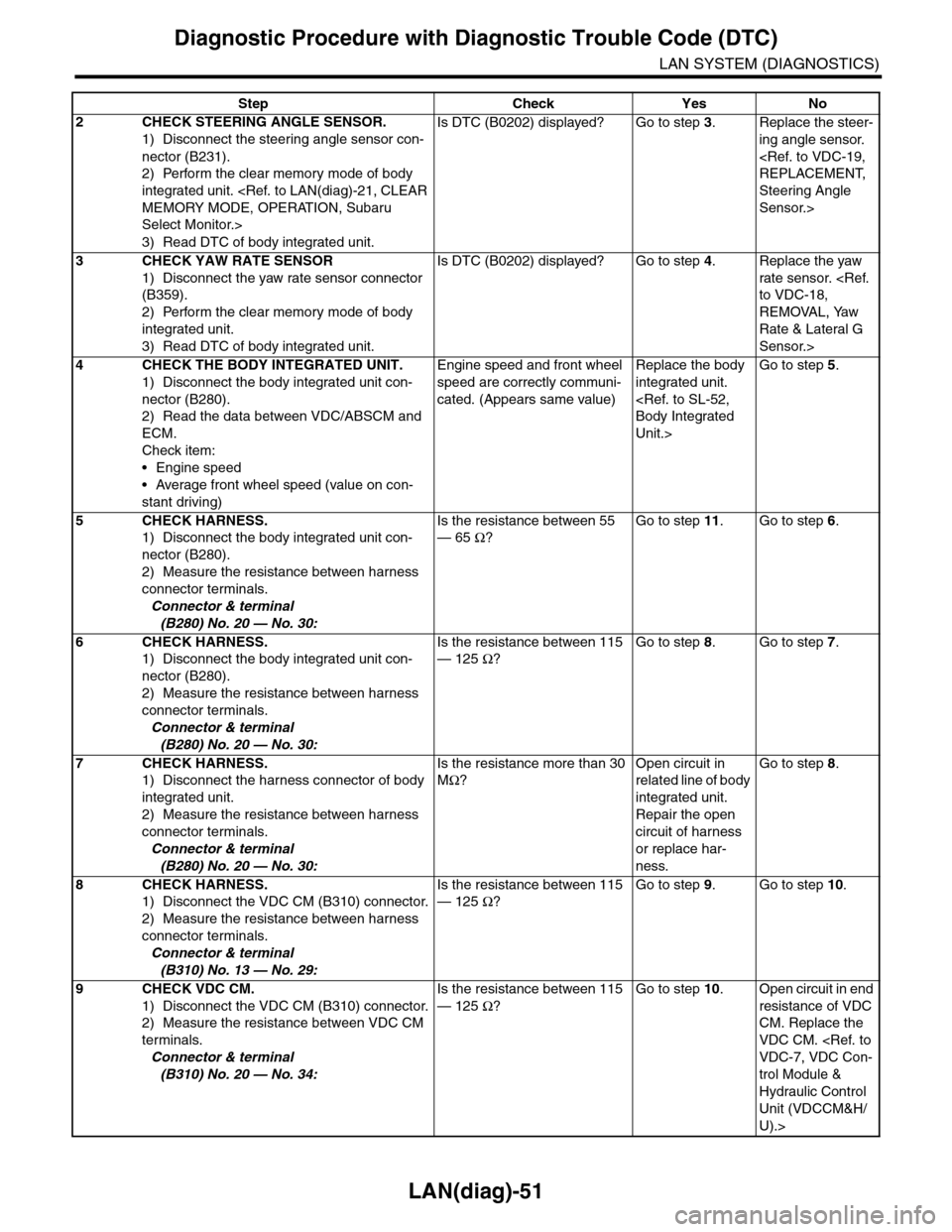

2CHECK STEERING ANGLE SENSOR.

1) Disconnect the steering angle sensor con-

nector (B231).

2) Perform the clear memory mode of body

integrated unit.

Select Monitor.>

3) Read DTC of body integrated unit.

Is DTC (B0202) displayed? Go to step 3.Replace the steer-

ing angle sensor.

Steering Angle

Sensor.>

3CHECK YAW RATE SENSOR

1) Disconnect the yaw rate sensor connector

(B359).

2) Perform the clear memory mode of body

integrated unit.

3) Read DTC of body integrated unit.

Is DTC (B0202) displayed? Go to step 4.Replace the yaw

rate sensor.

REMOVAL, Yaw

Rate & Lateral G

Sensor.>

4CHECK THE BODY INTEGRATED UNIT.

1) Disconnect the body integrated unit con-

nector (B280).

2) Read the data between VDC/ABSCM and

ECM.

Check item:

•Engine speed

•Average front wheel speed (value on con-

stant driving)

Engine speed and front wheel

speed are correctly communi-

cated. (Appears same value)

Replace the body

integrated unit.

Unit.>

Go to step 5.

5CHECK HARNESS.

1) Disconnect the body integrated unit con-

nector (B280).

2) Measure the resistance between harness

connector terminals.

Connector & terminal

(B280) No. 20 — No. 30:

Is the resistance between 55

— 65 Ω?

Go to step 11.Go to step 6.

6CHECK HARNESS.

1) Disconnect the body integrated unit con-

nector (B280).

2) Measure the resistance between harness

connector terminals.

Connector & terminal

(B280) No. 20 — No. 30:

Is the resistance between 115

— 125 Ω?

Go to step 8.Go to step 7.

7CHECK HARNESS.

1) Disconnect the harness connector of body

integrated unit.

2) Measure the resistance between harness

connector terminals.

Connector & terminal

(B280) No. 20 — No. 30:

Is the resistance more than 30

MΩ?

Open circuit in

related line of body

integrated unit.

Repair the open

circuit of harness

or replace har-

ness.

Go to step 8.

8CHECK HARNESS.

1) Disconnect the VDC CM (B310) connector.

2) Measure the resistance between harness

connector terminals.

Connector & terminal

(B310) No. 13 — No. 29:

Is the resistance between 115

— 125 Ω?

Go to step 9.Go to step 10.

9CHECK VDC CM.

1) Disconnect the VDC CM (B310) connector.

2) Measure the resistance between VDC CM

terminals.

Connector & terminal

(B310) No. 20 — No. 34:

Is the resistance between 115

— 125 Ω?

Go to step 10.Open circuit in end

resistance of VDC

CM. Replace the

VDC CM.

trol Module &

Hydraulic Control

Unit (VDCCM&H/

U).>

Step Check Yes No

Page 509 of 2453

LAN(diag)-53

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

LAN SYSTEM (DIAGNOSTICS)

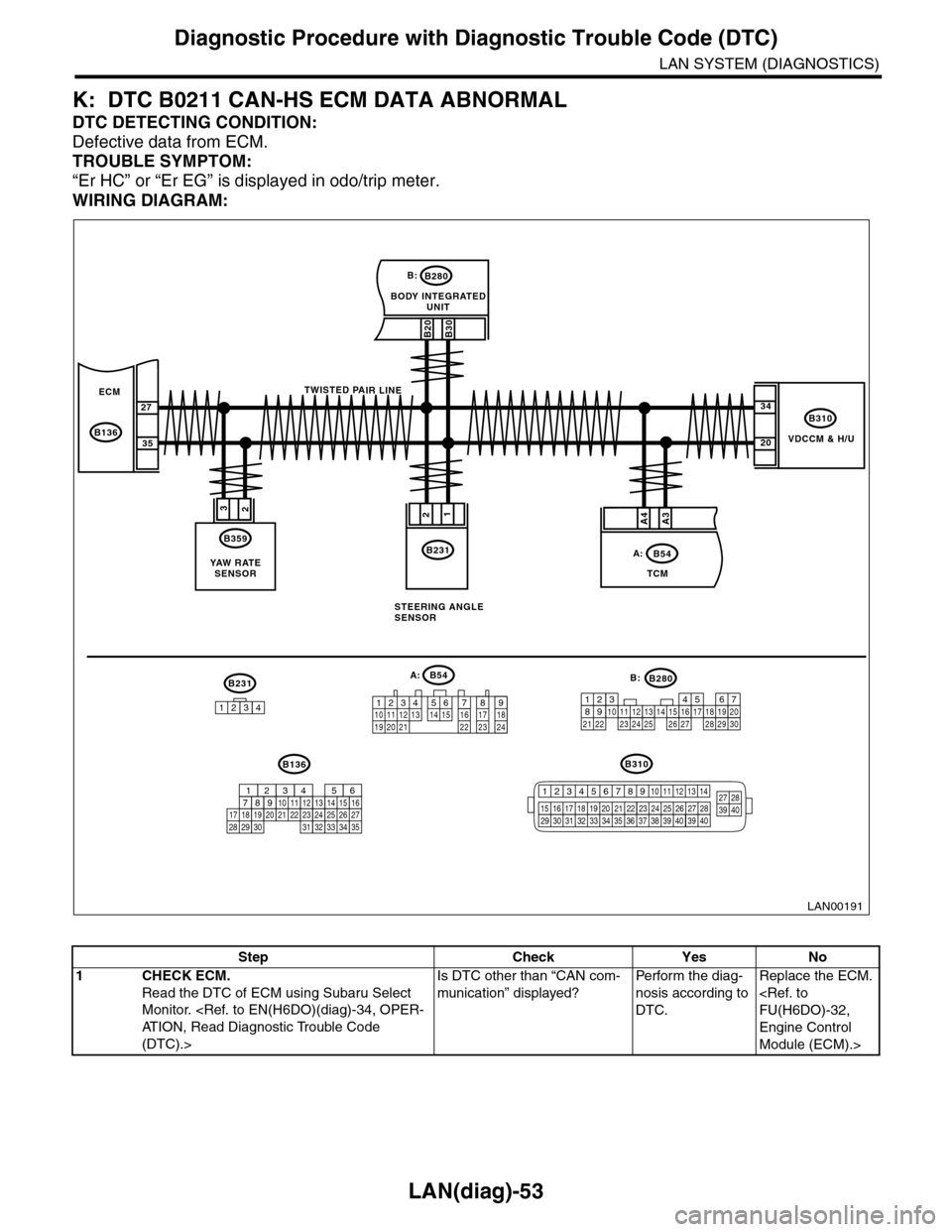

K: DTC B0211 CAN-HS ECM DATA ABNORMAL

DTC DETECTING CONDITION:

Defective data from ECM.

TROUBLE SYMPTOM:

“Er HC” or “Er EG” is displayed in odo/trip meter.

WIRING DIAGRAM:

VDCCM & H/U

B310

B20B30

BODY INTEGRATEDUNIT

B280B:

TCM

B54A:

23

B359

YAW R AT ESENSOR

34

20

B231

21

STEERING ANGLESENSOR

B231

1234

B54A:

12 7 8 9563410 11 1219 20 2113 14 15 16 17 1822 23 24

B136B310

B280B:

5467821931022 23111213141524 25 26 2716171828 29192021 30

ECM

B136

27

35

A3A4

TWISTED PAIR LINE

12345678910 11 12 13 14

15 16 17 18 19 2021 22 23 24 25 26 27 2829 30 31 32 33 3435 36 37 38 39403940

27 28394016101112131415252430

9871718192028212223293231

123456

2726333435

LAN00191

Step Check Yes No

1CHECK ECM.

Read the DTC of ECM using Subaru Select

Monitor.

(DTC).>

Is DTC other than “CAN com-

munication” displayed?

Pe r for m t h e d ia g -

nosis according to

DTC.

Replace the ECM.

Engine Control

Module (ECM).>

Page 510 of 2453

LAN(diag)-54

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

LAN SYSTEM (DIAGNOSTICS)

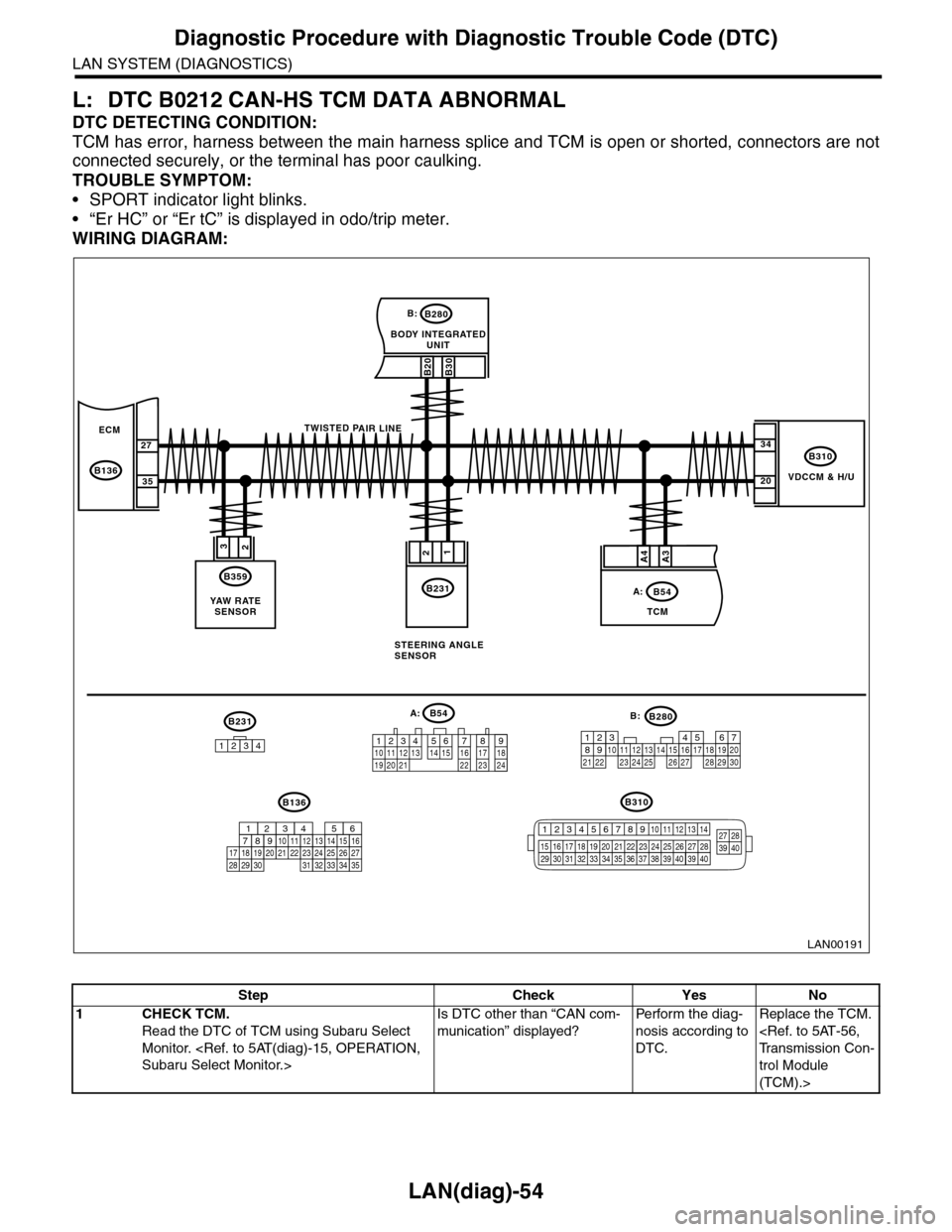

L: DTC B0212 CAN-HS TCM DATA ABNORMAL

DTC DETECTING CONDITION:

TCM has error, harness between the main harness splice and TCM is open or shorted, connectors are not

connected securely, or the terminal has poor caulking.

TROUBLE SYMPTOM:

•SPORT indicator light blinks.

•“Er HC” or “Er tC” is displayed in odo/trip meter.

WIRING DIAGRAM:

VDCCM & H/U

B310

B20B30

BODY INTEGRATEDUNIT

B280B:

TCM

B54A:

23

B359

YAW R AT ESENSOR

34

20

B231

21

STEERING ANGLESENSOR

B231

1234

B54A:

12 7 8 9563410 11 1219 20 2113 14 15 16 17 1822 23 24

B136B310

B280B:

5467821931022 23111213141524 25 26 2716171828 29192021 30

ECM

B136

27

35

A3A4

TWISTED PAIR LINE

12345678910 11 12 13 14

15 16 17 18 19 2021 22 23 24 25 26 27 2829 30 31 32 33 3435 36 37 38 39403940

27 28394016101112131415252430

9871718192028212223293231

123456

2726333435

LAN00191

Step Check Yes No

1CHECK TCM.

Read the DTC of TCM using Subaru Select

Monitor.

Is DTC other than “CAN com-

munication” displayed?

Pe r for m t h e d ia g -

nosis according to

DTC.

Replace the TCM.

trol Module

(TCM).>