sensor SUBARU TRIBECA 2009 1.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUBARU, Model Year: 2009, Model line: TRIBECA, Model: SUBARU TRIBECA 2009 1.GPages: 2453, PDF Size: 46.32 MB

Page 511 of 2453

LAN(diag)-55

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

LAN SYSTEM (DIAGNOSTICS)

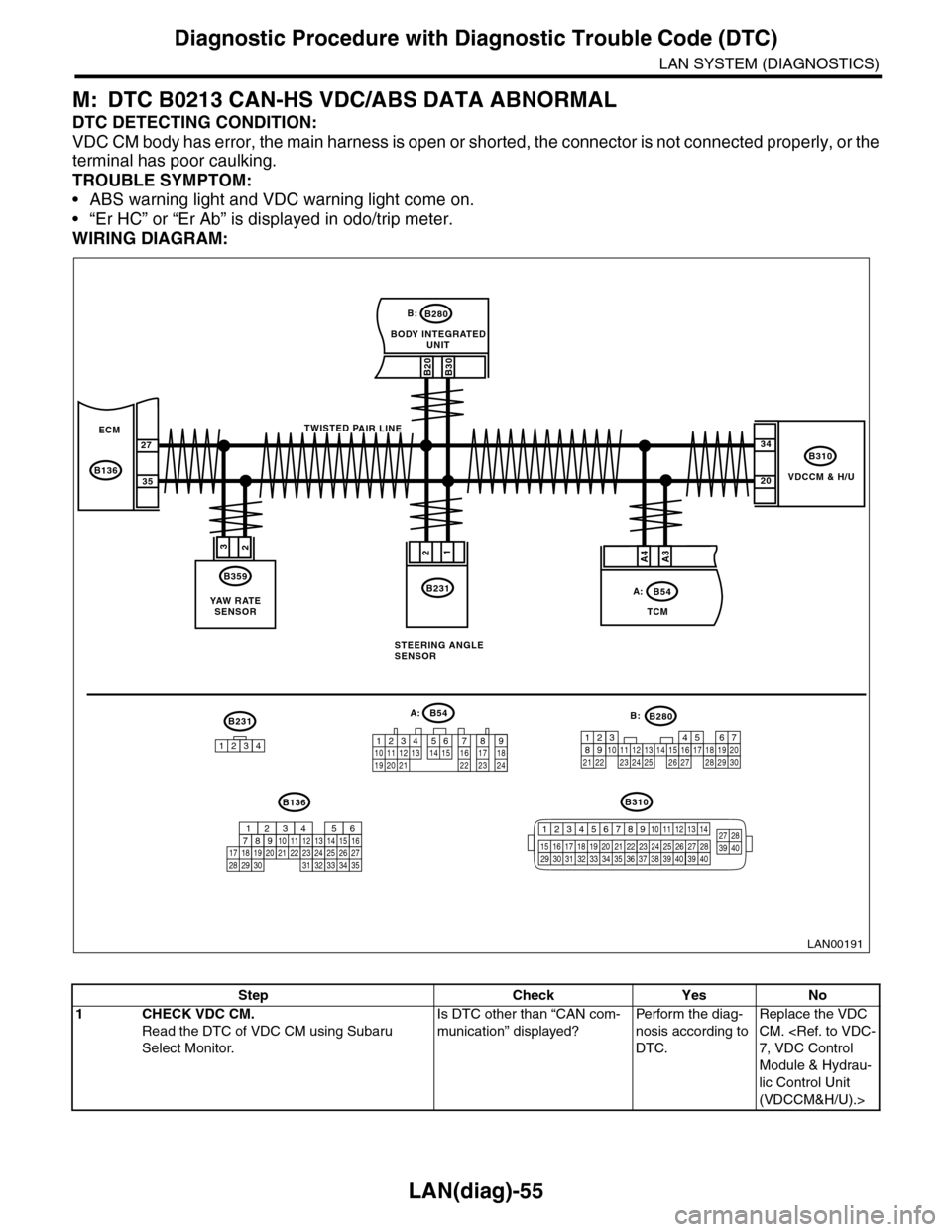

M: DTC B0213 CAN-HS VDC/ABS DATA ABNORMAL

DTC DETECTING CONDITION:

VDC CM body has error, the main harness is open or shorted, the connector is not connected properly, or the

terminal has poor caulking.

TROUBLE SYMPTOM:

•ABS warning light and VDC warning light come on.

•“Er HC” or “Er Ab” is displayed in odo/trip meter.

WIRING DIAGRAM:

VDCCM & H/U

B310

B20B30

BODY INTEGRATEDUNIT

B280B:

TCM

B54A:

23

B359

YAW R AT ESENSOR

34

20

B231

21

STEERING ANGLESENSOR

B231

1234

B54A:

12 7 8 9563410 11 1219 20 2113 14 15 16 17 1822 23 24

B136B310

B280B:

5467821931022 23111213141524 25 26 2716171828 29192021 30

ECM

B136

27

35

A3A4

TWISTED PAIR LINE

12345678910 11 12 13 14

15 16 17 18 19 2021 22 23 24 25 26 27 2829 30 31 32 33 3435 36 37 38 39403940

27 28394016101112131415252430

9871718192028212223293231

123456

2726333435

LAN00191

Step Check Yes No

1CHECK VDC CM.

Read the DTC of VDC CM using Subaru

Select Monitor.

Is DTC other than “CAN com-

munication” displayed?

Pe r for m t h e d ia g -

nosis according to

DTC.

Replace the VDC

CM.

Module & Hydrau-

lic Control Unit

(VDCCM&H/U).>

Page 512 of 2453

LAN(diag)-56

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

LAN SYSTEM (DIAGNOSTICS)

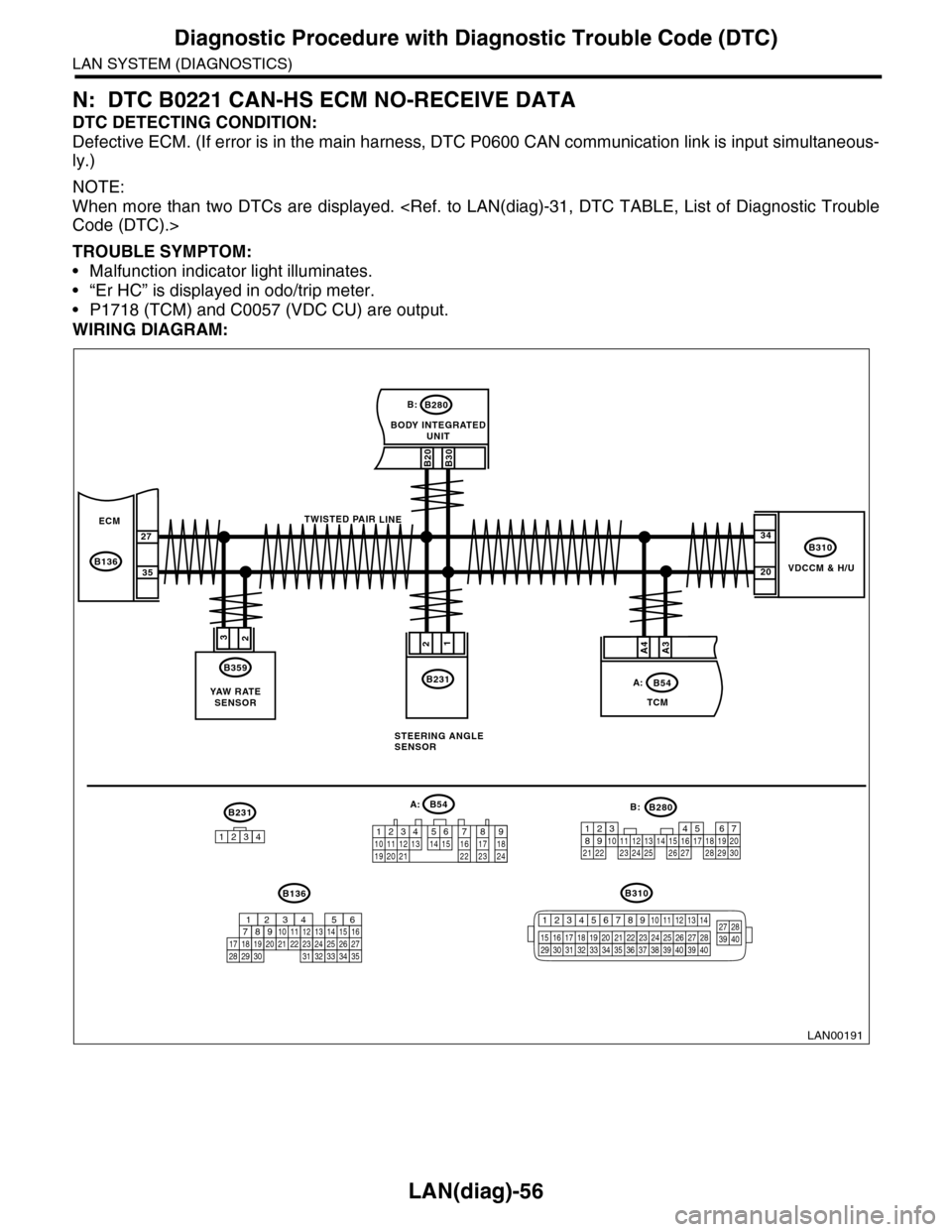

N: DTC B0221 CAN-HS ECM NO-RECEIVE DATA

DTC DETECTING CONDITION:

Defective ECM. (If error is in the main harness, DTC P0600 CAN communication link is input simultaneous-

ly.)

NOTE:

When more than two DTCs are displayed.

TROUBLE SYMPTOM:

•Malfunction indicator light illuminates.

•“Er HC” is displayed in odo/trip meter.

•P1718 (TCM) and C0057 (VDC CU) are output.

WIRING DIAGRAM:

VDCCM & H/U

B310

B20B30

BODY INTEGRATEDUNIT

B280B:

TCM

B54A:

23

B359

YAW R AT ESENSOR

34

20

B231

21

STEERING ANGLESENSOR

B231

1234

B54A:

12 7 8 9563410 11 1219 20 2113 14 15 16 17 1822 23 24

B136B310

B280B:

5467821931022 23111213141524 25 26 2716171828 29192021 30

ECM

B136

27

35

A3A4

TWISTED PAIR LINE

12345678910 11 12 13 14

15 16 17 18 19 2021 22 23 24 25 26 27 2829 30 31 32 33 3435 36 37 38 39403940

27 28394016101112131415252430

9871718192028212223293231

123456

2726333435

LAN00191

Page 515 of 2453

LAN(diag)-59

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

LAN SYSTEM (DIAGNOSTICS)

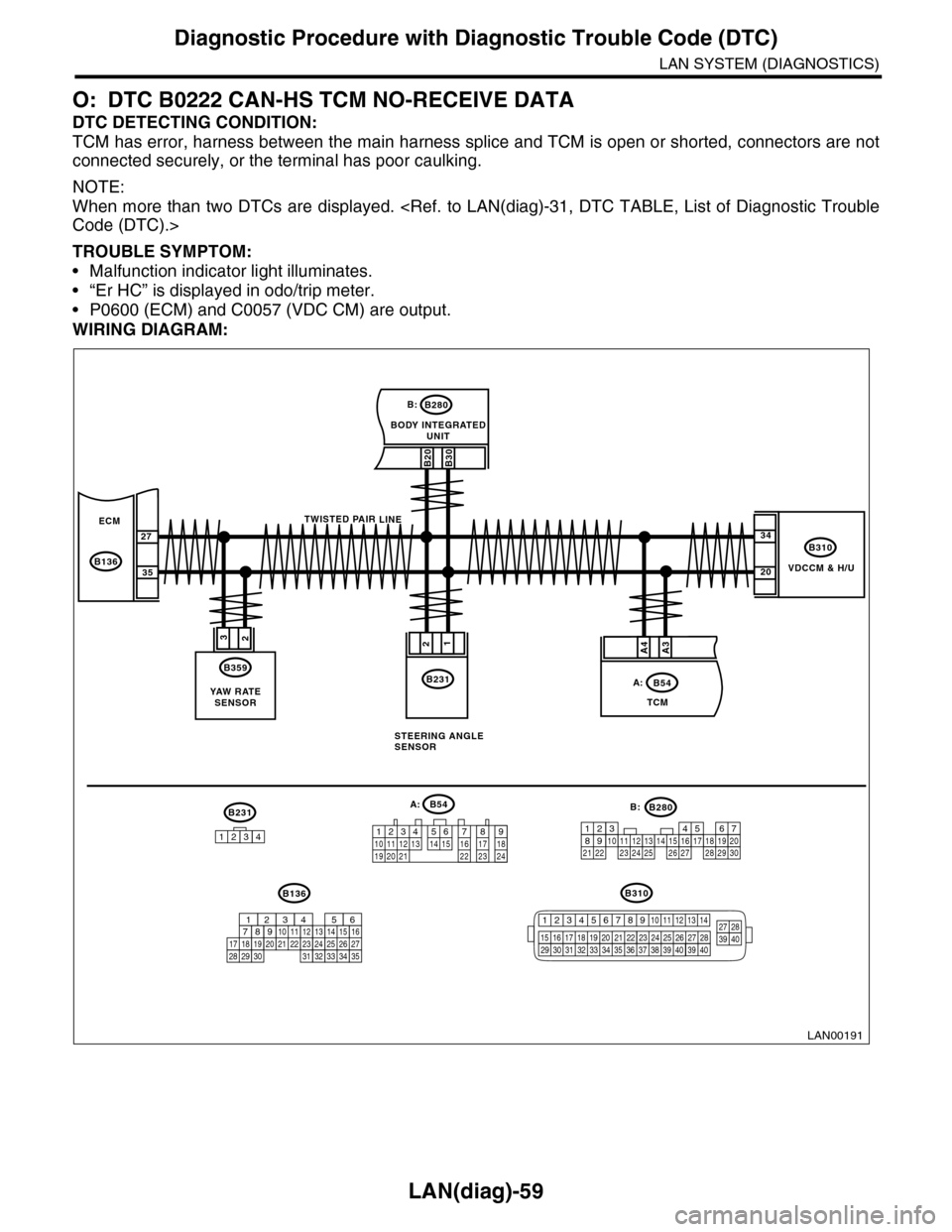

O: DTC B0222 CAN-HS TCM NO-RECEIVE DATA

DTC DETECTING CONDITION:

TCM has error, harness between the main harness splice and TCM is open or shorted, connectors are not

connected securely, or the terminal has poor caulking.

NOTE:

When more than two DTCs are displayed.

TROUBLE SYMPTOM:

•Malfunction indicator light illuminates.

•“Er HC” is displayed in odo/trip meter.

•P0600 (ECM) and C0057 (VDC CM) are output.

WIRING DIAGRAM:

VDCCM & H/U

B310

B20B30

BODY INTEGRATEDUNIT

B280B:

TCM

B54A:

23

B359

YAW R AT ESENSOR

34

20

B231

21

STEERING ANGLESENSOR

B231

1234

B54A:

12 7 8 9563410 11 1219 20 2113 14 15 16 17 1822 23 24

B136B310

B280B:

5467821931022 23111213141524 25 26 2716171828 29192021 30

ECM

B136

27

35

A3A4

TWISTED PAIR LINE

12345678910 11 12 13 14

15 16 17 18 19 2021 22 23 24 25 26 27 2829 30 31 32 33 3435 36 37 38 39403940

27 28394016101112131415252430

9871718192028212223293231

123456

2726333435

LAN00191

Page 517 of 2453

LAN(diag)-61

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

LAN SYSTEM (DIAGNOSTICS)

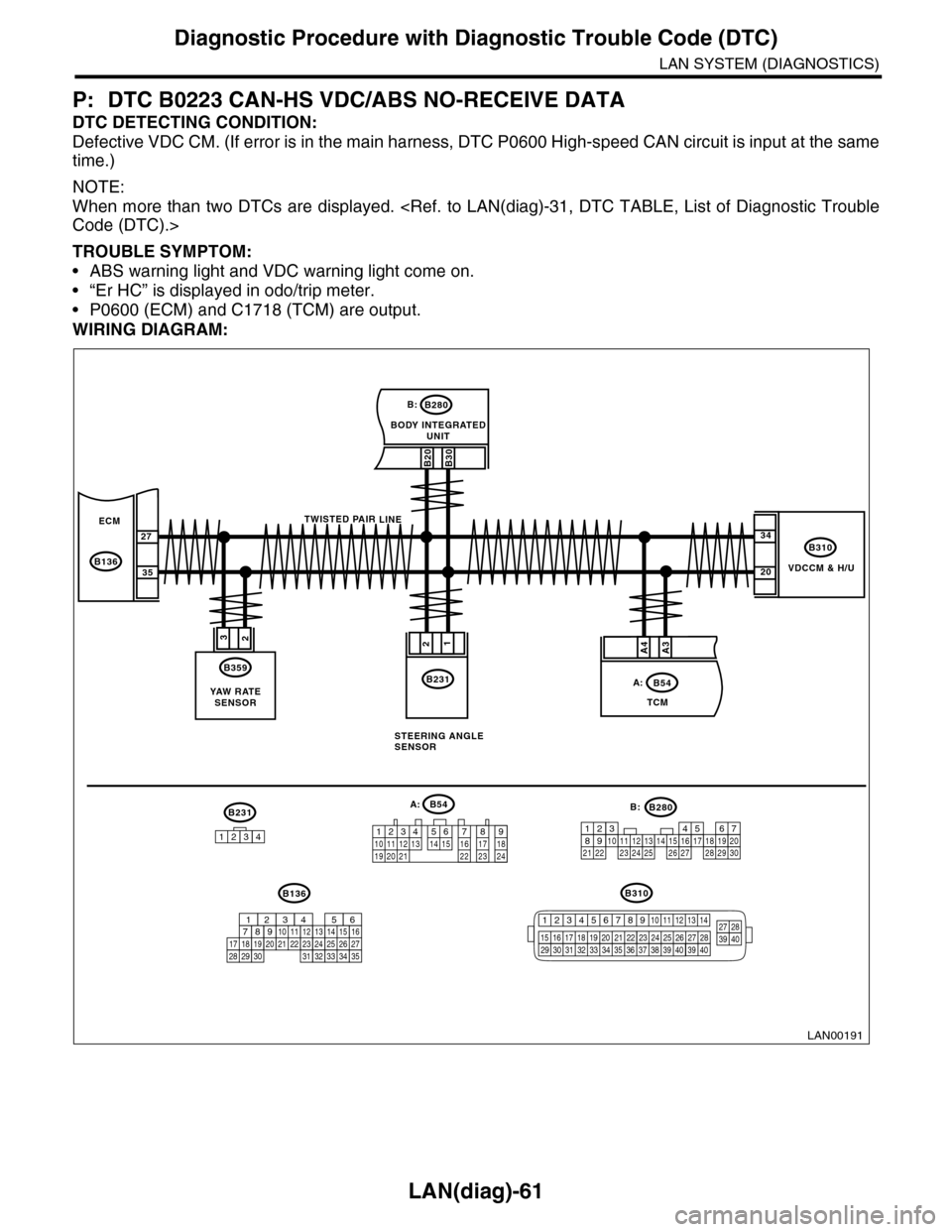

P: DTC B0223 CAN-HS VDC/ABS NO-RECEIVE DATA

DTC DETECTING CONDITION:

Defective VDC CM. (If error is in the main harness, DTC P0600 High-speed CAN circuit is input at the same

time.)

NOTE:

When more than two DTCs are displayed.

TROUBLE SYMPTOM:

•ABS warning light and VDC warning light come on.

•“Er HC” is displayed in odo/trip meter.

•P0600 (ECM) and C1718 (TCM) are output.

WIRING DIAGRAM:

VDCCM & H/U

B310

B20B30

BODY INTEGRATEDUNIT

B280B:

TCM

B54A:

23

B359

YAW R AT ESENSOR

34

20

B231

21

STEERING ANGLESENSOR

B231

1234

B54A:

12 7 8 9563410 11 1219 20 2113 14 15 16 17 1822 23 24

B136B310

B280B:

5467821931022 23111213141524 25 26 2716171828 29192021 30

ECM

B136

27

35

A3A4

TWISTED PAIR LINE

12345678910 11 12 13 14

15 16 17 18 19 2021 22 23 24 25 26 27 2829 30 31 32 33 3435 36 37 38 39403940

27 28394016101112131415252430

9871718192028212223293231

123456

2726333435

LAN00191

Page 532 of 2453

LAN(diag)-76

General Diagnostic Table

LAN SYSTEM (DIAGNOSTICS)

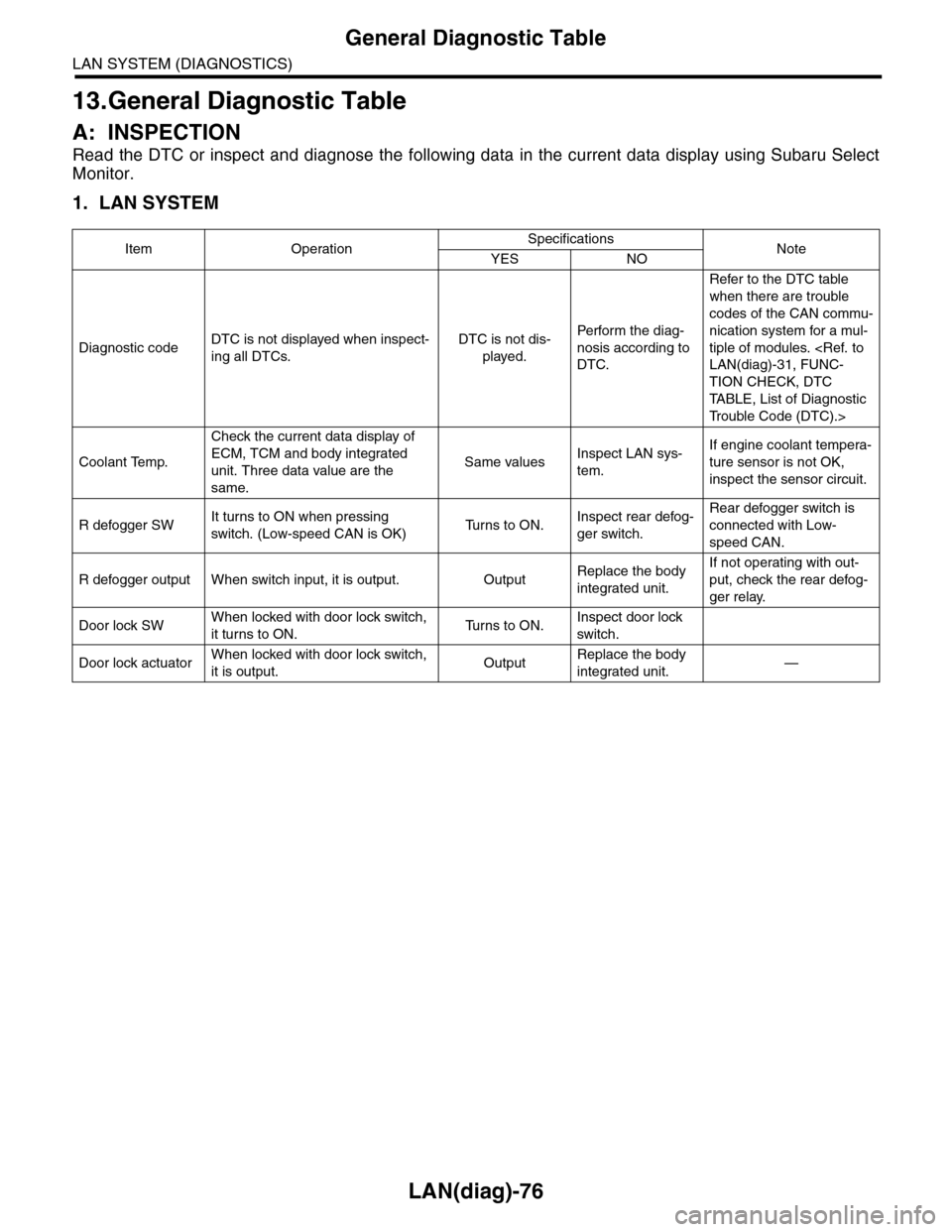

13.General Diagnostic Table

A: INSPECTION

Read the DTC or inspect and diagnose the following data in the current data display using Subaru Select

Monitor.

1. LAN SYSTEM

Item OperationSpecificationsNoteYES NO

Diagnostic codeDTC is not displayed when inspect-

ing all DTCs.

DTC is not dis-

played.

Perfor m the diag-

nosis according to

DTC.

Refer to the DTC table

when there are trouble

codes of the CAN commu-

nication system for a mul-

tiple of modules.

TION CHECK, DTC

TA B L E , L i s t o f D i a g n o s t i c

Tr o u b l e C o d e ( D T C ) . >

Coolant Temp.

Check the current data display of

ECM, TCM and body integrated

unit. Three data value are the

same.

Same valuesInspect LAN sys-

tem.

If engine coolant tempera-

ture sensor is not OK,

inspect the sensor circuit.

R defogger SWIt turns to ON when pressing

switch. (Low-speed CAN is OK)Tu r n s t o O N .Inspect rear defog-

ger switch.

Rear defogger switch is

connected with Low-

speed CAN.

R defogger output When switch input, it is output. OutputReplace the body

integrated unit.

If not operating with out-

put, check the rear defog-

ger relay.

Door lock SWWhen locked with door lock switch,

it turns to ON.Tu r n s t o O N .Inspect door lock

switch.

Door lock actuatorWhen locked with door lock switch,

it is output.OutputReplace the body

integrated unit.—

Page 572 of 2453

OD(diag)-4

General Description

OCCUPANT DETECTION SYSTEM (DIAGNOSTICS)

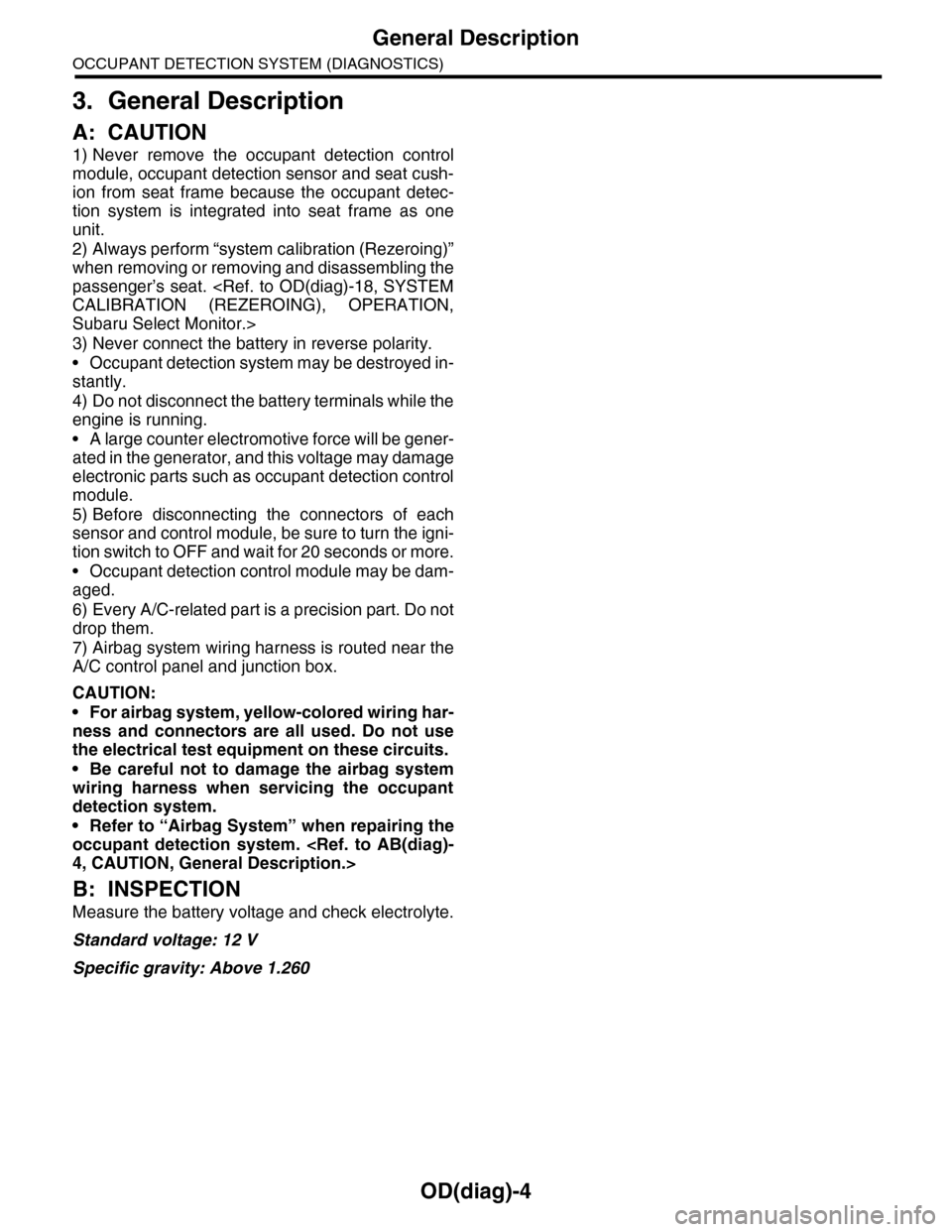

3. General Description

A: CAUTION

1) Never remove the occupant detection control

module, occupant detection sensor and seat cush-

ion from seat frame because the occupant detec-

tion system is integrated into seat frame as one

unit.

2) Always perform “system calibration (Rezeroing)”

when removing or removing and disassembling the

passenger’s seat.

Subaru Select Monitor.>

3) Never connect the battery in reverse polarity.

•Occupant detection system may be destroyed in-

stantly.

4) Do not disconnect the battery terminals while the

engine is running.

•A large counter electromotive force will be gener-

ated in the generator, and this voltage may damage

electronic parts such as occupant detection control

module.

5) Before disconnecting the connectors of each

sensor and control module, be sure to turn the igni-

tion switch to OFF and wait for 20 seconds or more.

•Occupant detection control module may be dam-

aged.

6) Every A/C-related part is a precision part. Do not

drop them.

7) Airbag system wiring harness is routed near the

A/C control panel and junction box.

CAUTION:

•For airbag system, yellow-colored wiring har-

ness and connectors are all used. Do not use

the electrical test equipment on these circuits.

•Be careful not to damage the airbag system

wiring harness when servicing the occupant

detection system.

•Refer to “Airbag System” when repairing the

occupant detection system.

B: INSPECTION

Measure the battery voltage and check electrolyte.

Standard voltage: 12 V

Specific gravity: Above 1.260

Page 580 of 2453

OD(diag)-12

General Description

OCCUPANT DETECTION SYSTEM (DIAGNOSTICS)

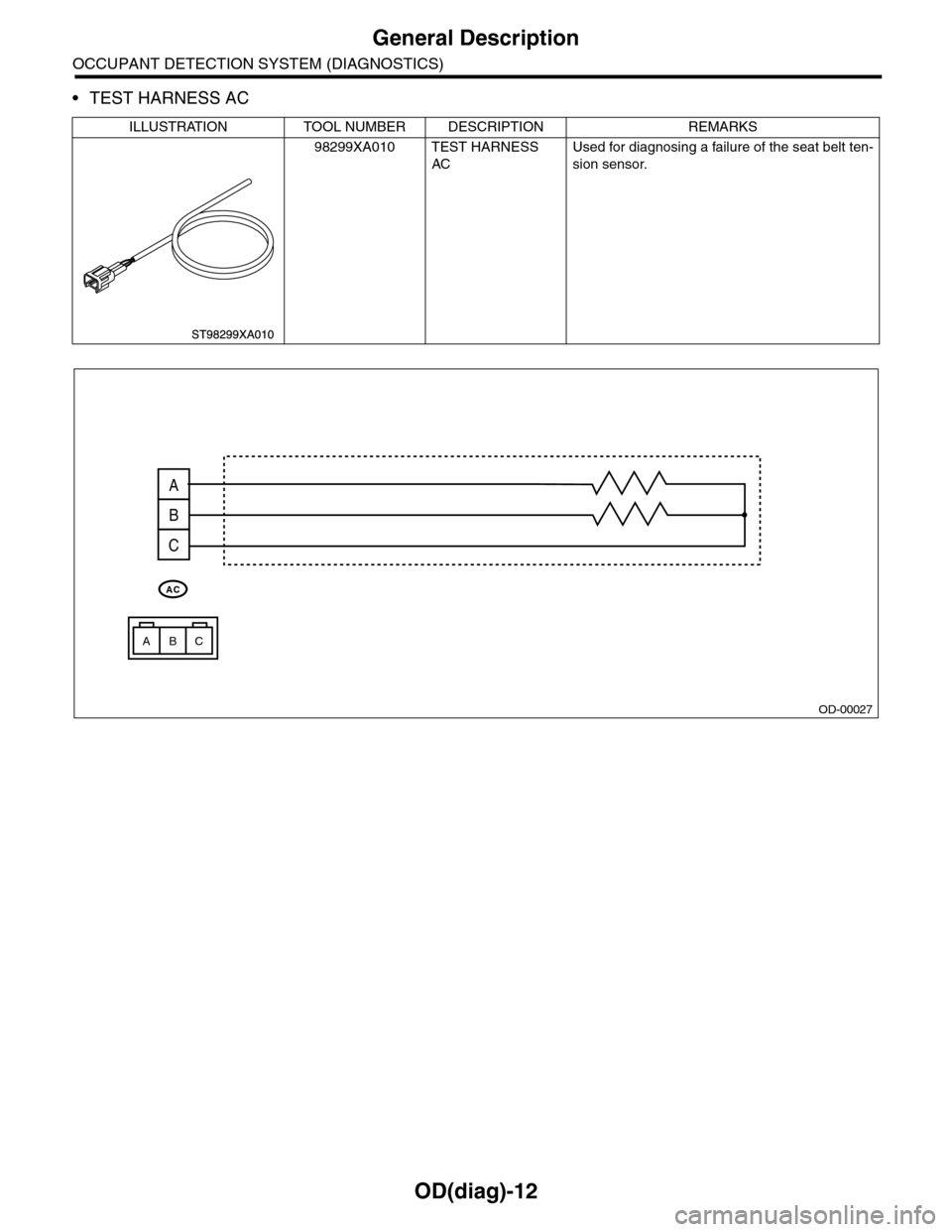

•TEST HARNESS AC

ILLUSTRATION TOOL NUMBER DESCRIPTION REMARKS

98299XA010 TEST HARNESS

AC

Used for diagnosing a failure of the seat belt ten-

sion sensor.

OD-00027

A

B

C

ACB

AC

Page 581 of 2453

OD(diag)-13

General Description

OCCUPANT DETECTION SYSTEM (DIAGNOSTICS)

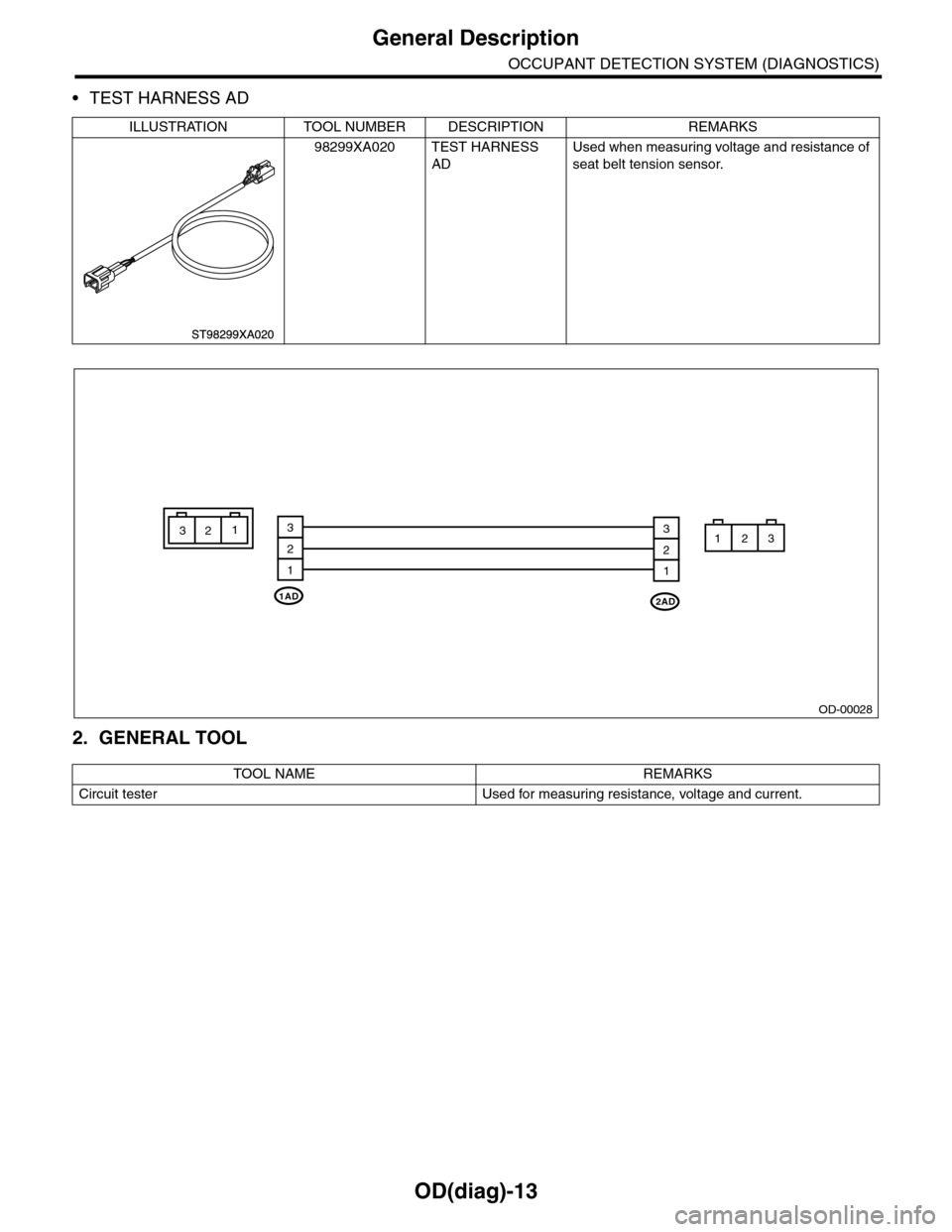

•TEST HARNESS AD

2. GENERAL TOOL

ILLUSTRATION TOOL NUMBER DESCRIPTION REMARKS

98299XA020 TEST HARNESS

AD

Used when measuring voltage and resistance of

seat belt tension sensor.

TOOL NAME REMARKS

Circuit tester Used for measuring resistance, voltage and current.

OD-00028

1AD2AD

3

2

1

3123

2

1

312

Page 582 of 2453

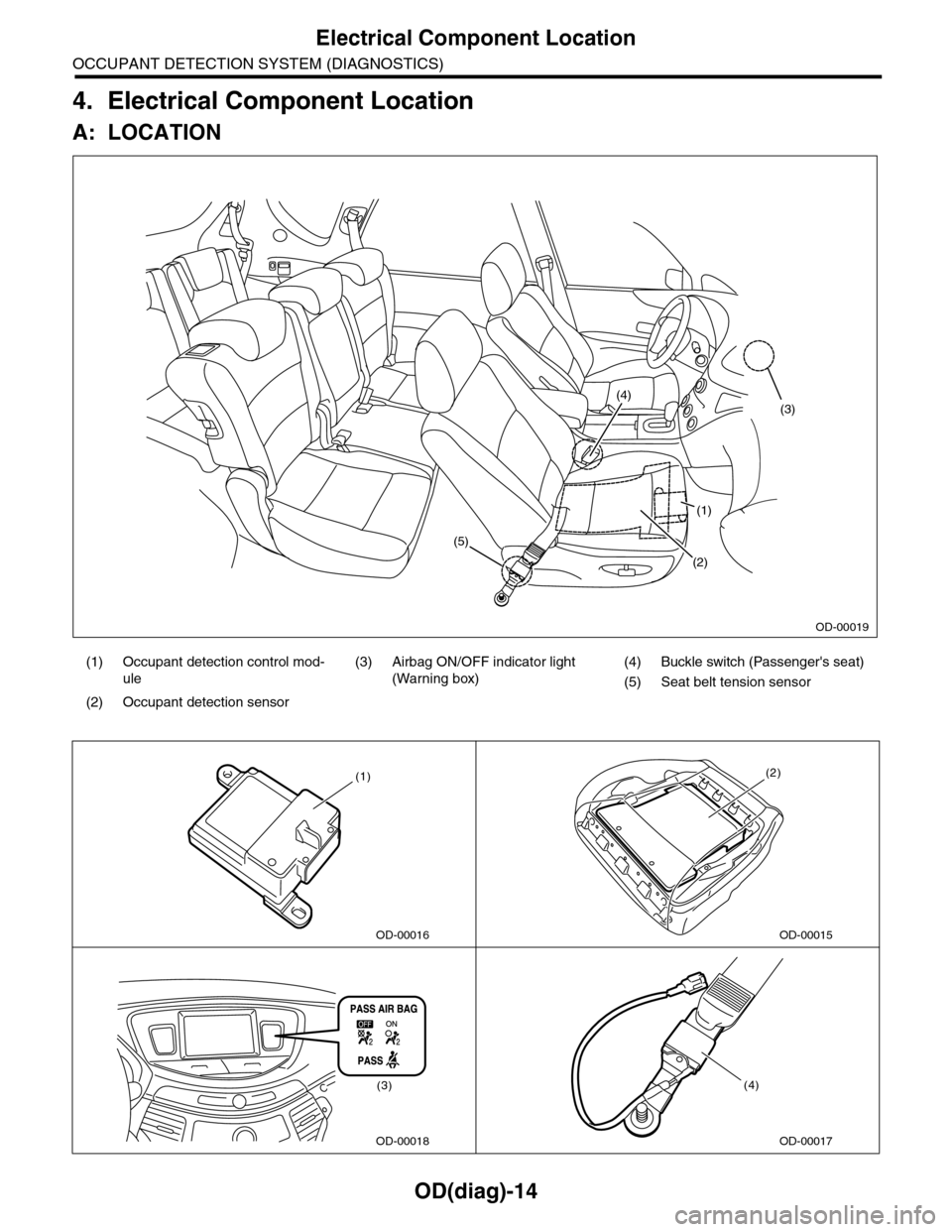

OD(diag)-14

Electrical Component Location

OCCUPANT DETECTION SYSTEM (DIAGNOSTICS)

4. Electrical Component Location

A: LOCATION

(1) Occupant detection control mod-

ule

(3) Airbag ON/OFF indicator light

(Warning box)

(4) Buckle switch (Passenger's seat)

(5) Seat belt tension sensor

(2) Occupant detection sensor

(1)

(2)

(5)

(4)(3)

OD-00019

OD-00016

(1)

OD-00015

(2)

OD-00018

(3)

OD-00017

(4)

Page 584 of 2453

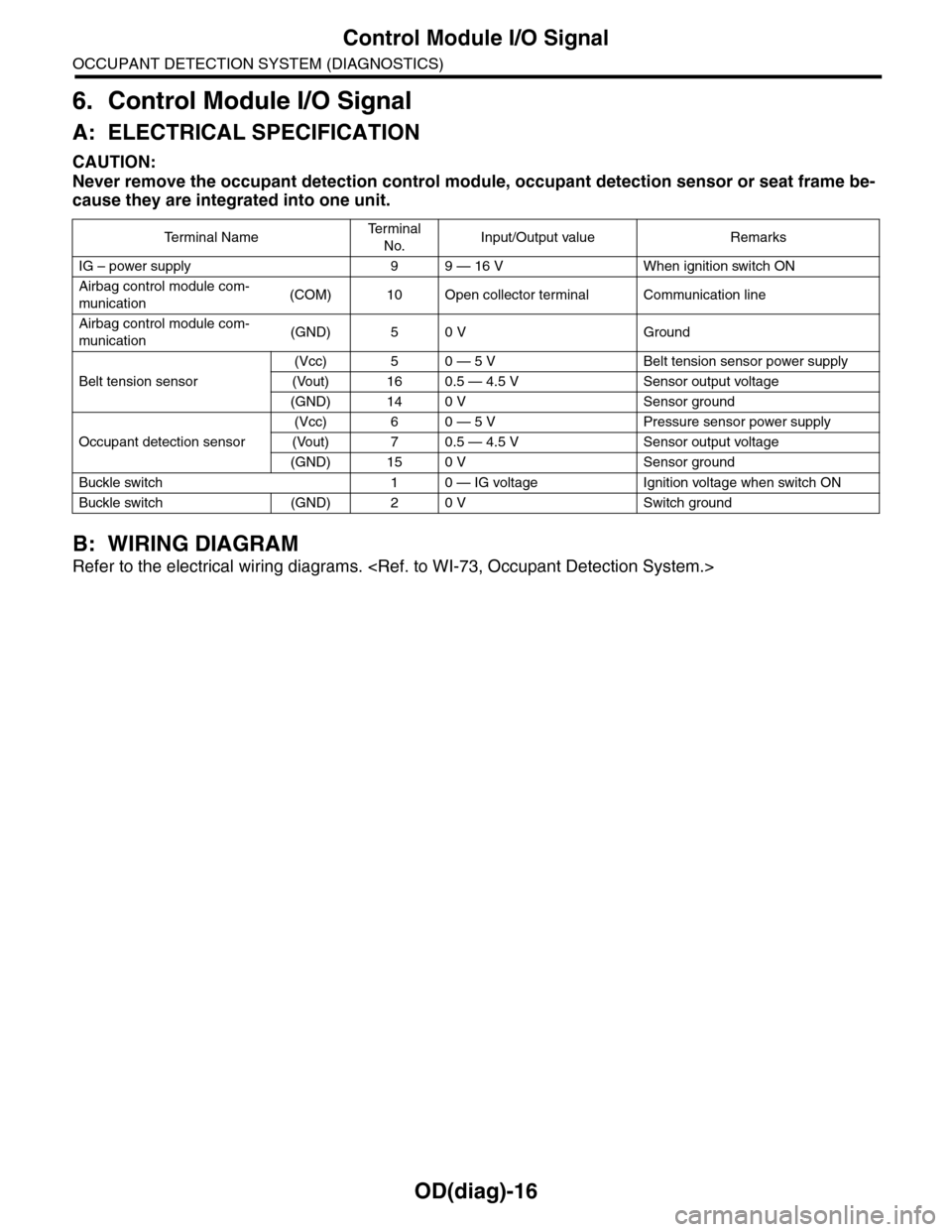

OD(diag)-16

Control Module I/O Signal

OCCUPANT DETECTION SYSTEM (DIAGNOSTICS)

6. Control Module I/O Signal

A: ELECTRICAL SPECIFICATION

CAUTION:

Never remove the occupant detection control module, occupant detection sensor or seat frame be-

cause they are integrated into one unit.

B: WIRING DIAGRAM

Refer to the electrical wiring diagrams.

Te r m i n a l N a m eTe r m i n a l

No.Input/Output value Remarks

IG – power supply 9 9 — 16 V When ignition switch ON

Airbag control module com-

munication(COM) 10 Open collector terminal Communication line

Airbag control module com-

munication(GND) 5 0 V Ground

Belt tension sensor

(Vcc) 5 0 — 5 V Belt tension sensor power supply

(Vout) 16 0.5 — 4.5 V Sensor output voltage

(GND) 14 0 V Sensor ground

Occupant detection sensor

(Vcc) 6 0 — 5 V Pressure sensor power supply

(Vout) 7 0.5 — 4.5 V Sensor output voltage

(GND) 15 0 V Sensor ground

Buckle switch 1 0 — IG voltage Ignition voltage when switch ON

Buckle switch (GND) 2 0 V Switch ground