sensor SUBARU TRIBECA 2009 1.G Service Owners Manual

[x] Cancel search | Manufacturer: SUBARU, Model Year: 2009, Model line: TRIBECA, Model: SUBARU TRIBECA 2009 1.GPages: 2453, PDF Size: 46.32 MB

Page 415 of 2453

AC(diag)-38

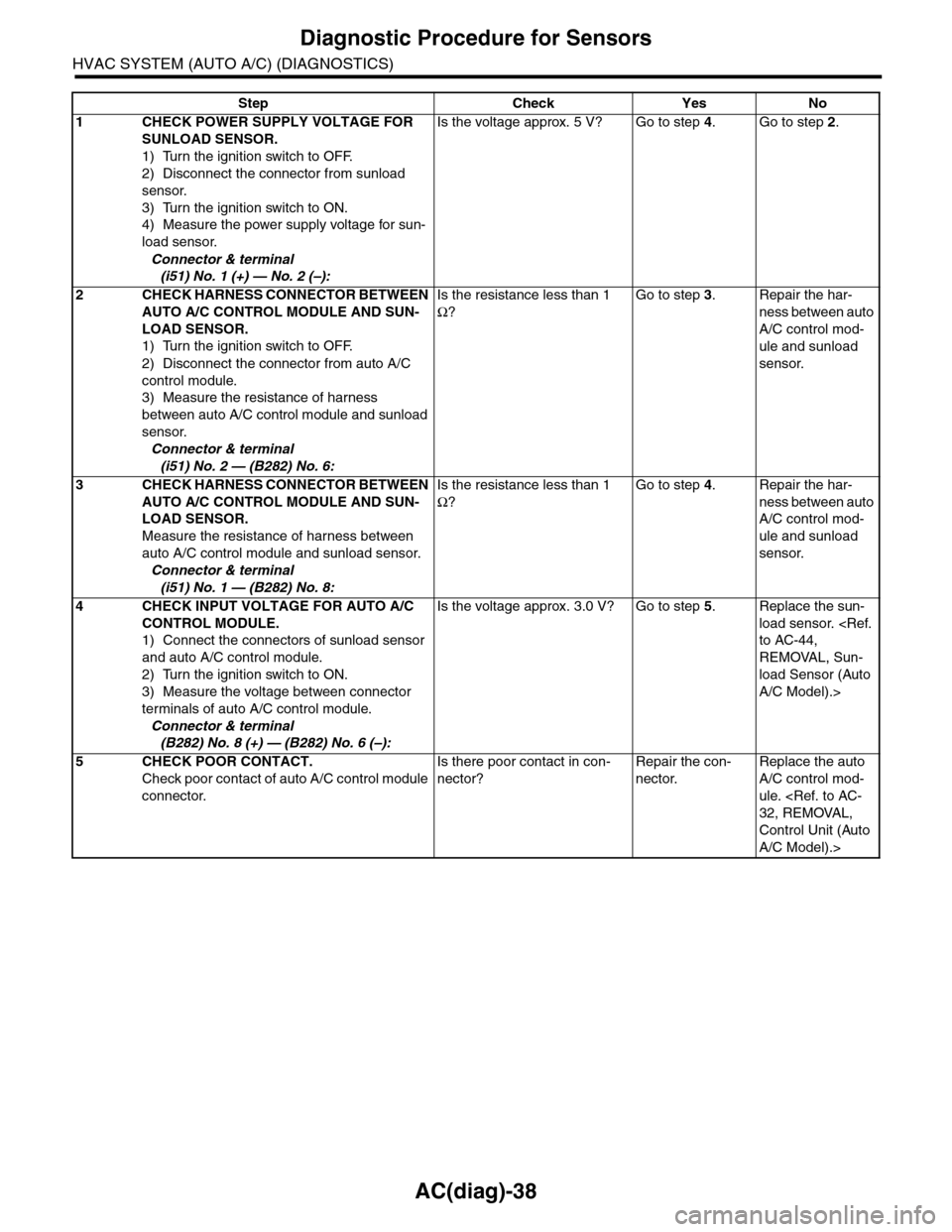

Diagnostic Procedure for Sensors

HVAC SYSTEM (AUTO A/C) (DIAGNOSTICS)

Step Check Yes No

1CHECK POWER SUPPLY VOLTAGE FOR

SUNLOAD SENSOR.

1) Turn the ignition switch to OFF.

2) Disconnect the connector from sunload

sensor.

3) Turn the ignition switch to ON.

4) Measure the power supply voltage for sun-

load sensor.

Connector & terminal

(i51) No. 1 (+) — No. 2 (–):

Is the voltage approx. 5 V? Go to step 4.Go to step 2.

2CHECK HARNESS CONNECTOR BETWEEN

AUTO A/C CONTROL MODULE AND SUN-

LOAD SENSOR.

1) Turn the ignition switch to OFF.

2) Disconnect the connector from auto A/C

control module.

3) Measure the resistance of harness

between auto A/C control module and sunload

sensor.

Connector & terminal

(i51) No. 2 — (B282) No. 6:

Is the resistance less than 1

Ω?

Go to step 3.Repair the har-

ness between auto

A/C control mod-

ule and sunload

sensor.

3CHECK HARNESS CONNECTOR BETWEEN

AUTO A/C CONTROL MODULE AND SUN-

LOAD SENSOR.

Measure the resistance of harness between

auto A/C control module and sunload sensor.

Connector & terminal

(i51) No. 1 — (B282) No. 8:

Is the resistance less than 1

Ω?

Go to step 4.Repair the har-

ness between auto

A/C control mod-

ule and sunload

sensor.

4CHECK INPUT VOLTAGE FOR AUTO A/C

CONTROL MODULE.

1) Connect the connectors of sunload sensor

and auto A/C control module.

2) Turn the ignition switch to ON.

3) Measure the voltage between connector

terminals of auto A/C control module.

Connector & terminal

(B282) No. 8 (+) — (B282) No. 6 (–):

Is the voltage approx. 3.0 V? Go to step 5.Replace the sun-

load sensor.

REMOVAL, Sun-

load Sensor (Auto

A/C Model).>

5CHECK POOR CONTACT.

Check poor contact of auto A/C control module

connector.

Is there poor contact in con-

nector?

Repair the con-

nector.

Replace the auto

A/C control mod-

ule.

Control Unit (Auto

A/C Model).>

Page 416 of 2453

AC(diag)-39

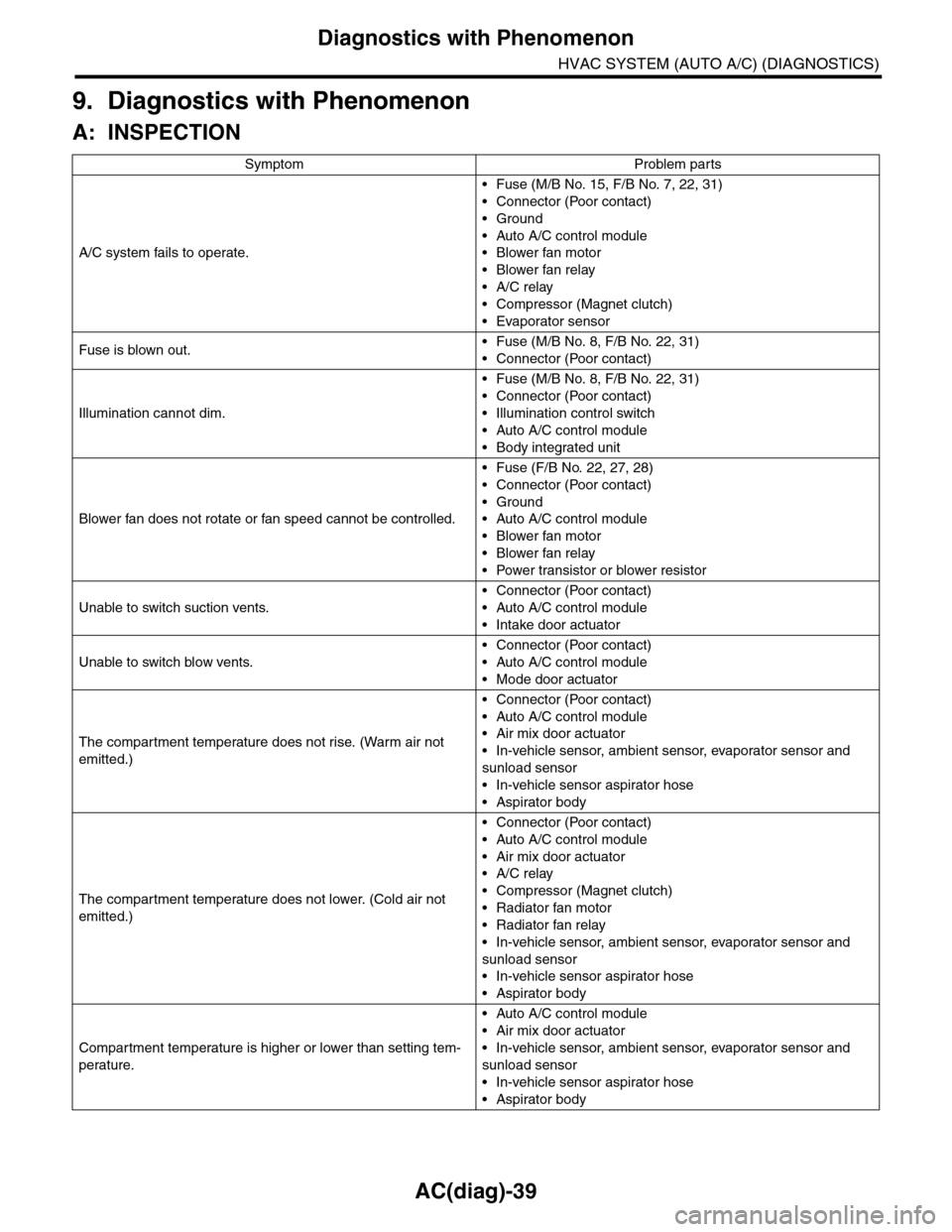

Diagnostics with Phenomenon

HVAC SYSTEM (AUTO A/C) (DIAGNOSTICS)

9. Diagnostics with Phenomenon

A: INSPECTION

Symptom Problem parts

A/C system fails to operate.

•Fuse (M/B No. 15, F/B No. 7, 22, 31)

•Connector (Poor contact)

•Ground

•Auto A/C control module

•Blower fan motor

•Blower fan relay

•A/C relay

•Compressor (Magnet clutch)

•Evaporator sensor

Fuse is blown out.•Fuse (M/B No. 8, F/B No. 22, 31)

•Connector (Poor contact)

Illumination cannot dim.

•Fuse (M/B No. 8, F/B No. 22, 31)

•Connector (Poor contact)

•Illumination control switch

•Auto A/C control module

•Body integrated unit

Blower fan does not rotate or fan speed cannot be controlled.

•Fuse (F/B No. 22, 27, 28)

•Connector (Poor contact)

•Ground

•Auto A/C control module

•Blower fan motor

•Blower fan relay

•Power transistor or blower resistor

Unable to switch suction vents.

•Connector (Poor contact)

•Auto A/C control module

•Intake door actuator

Unable to switch blow vents.

•Connector (Poor contact)

•Auto A/C control module

•Mode door actuator

The compar tment temperature does not rise. (Warm air not

emitted.)

•Connector (Poor contact)

•Auto A/C control module

•Air mix door actuator

•In-vehicle sensor, ambient sensor, evaporator sensor and

sunload sensor

•In-vehicle sensor aspirator hose

•Aspirator body

The compar tment temperature does not lower. (Cold air not

emitted.)

•Connector (Poor contact)

•Auto A/C control module

•Air mix door actuator

•A/C relay

•Compressor (Magnet clutch)

•Radiator fan motor

•Radiator fan relay

•In-vehicle sensor, ambient sensor, evaporator sensor and

sunload sensor

•In-vehicle sensor aspirator hose

•Aspirator body

Compartment temperature is higher or lower than setting tem-

perature.

•Auto A/C control module

•Air mix door actuator

•In-vehicle sensor, ambient sensor, evaporator sensor and

sunload sensor

•In-vehicle sensor aspirator hose

•Aspirator body

Page 417 of 2453

AC(diag)-40

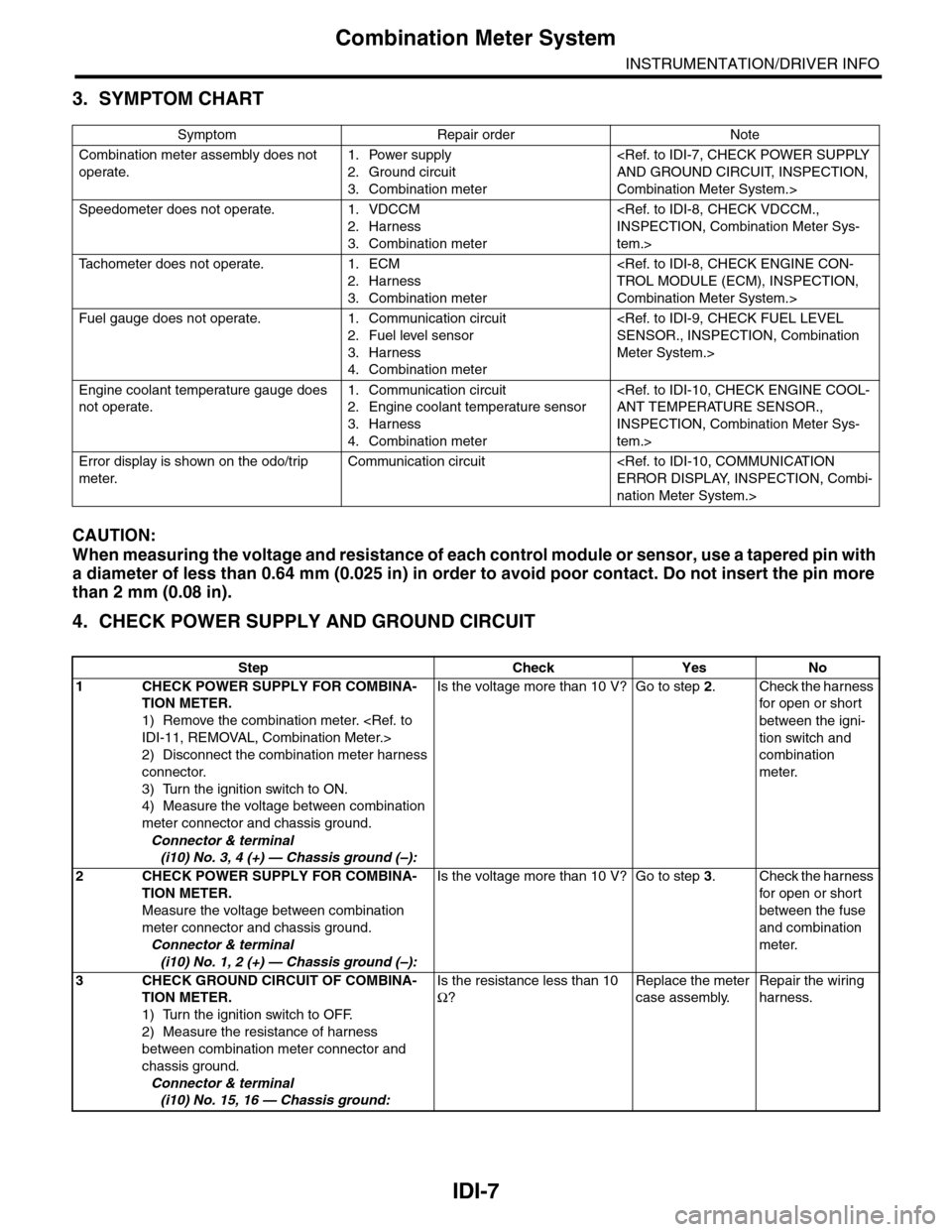

Diagnostics with Phenomenon

HVAC SYSTEM (AUTO A/C) (DIAGNOSTICS)

Compartment temperature does not quickly respond to setting

temperature.

•Air mix door actuator

•In-vehicle sensor, ambient sensor, evaporator sensor and

sunload sensor

•In-vehicle sensor aspirator hose

•Aspirator body

Radiator fan does not rotate during A/C operation.•Radiator fan motor

•Radiator fan relay

Seat heater does not run.

•Seat thermistor

•Seat heater relay

•Seat heater

•Auto A/C control module

•Front control panel

Symptom Problem parts

Page 446 of 2453

IDI-7

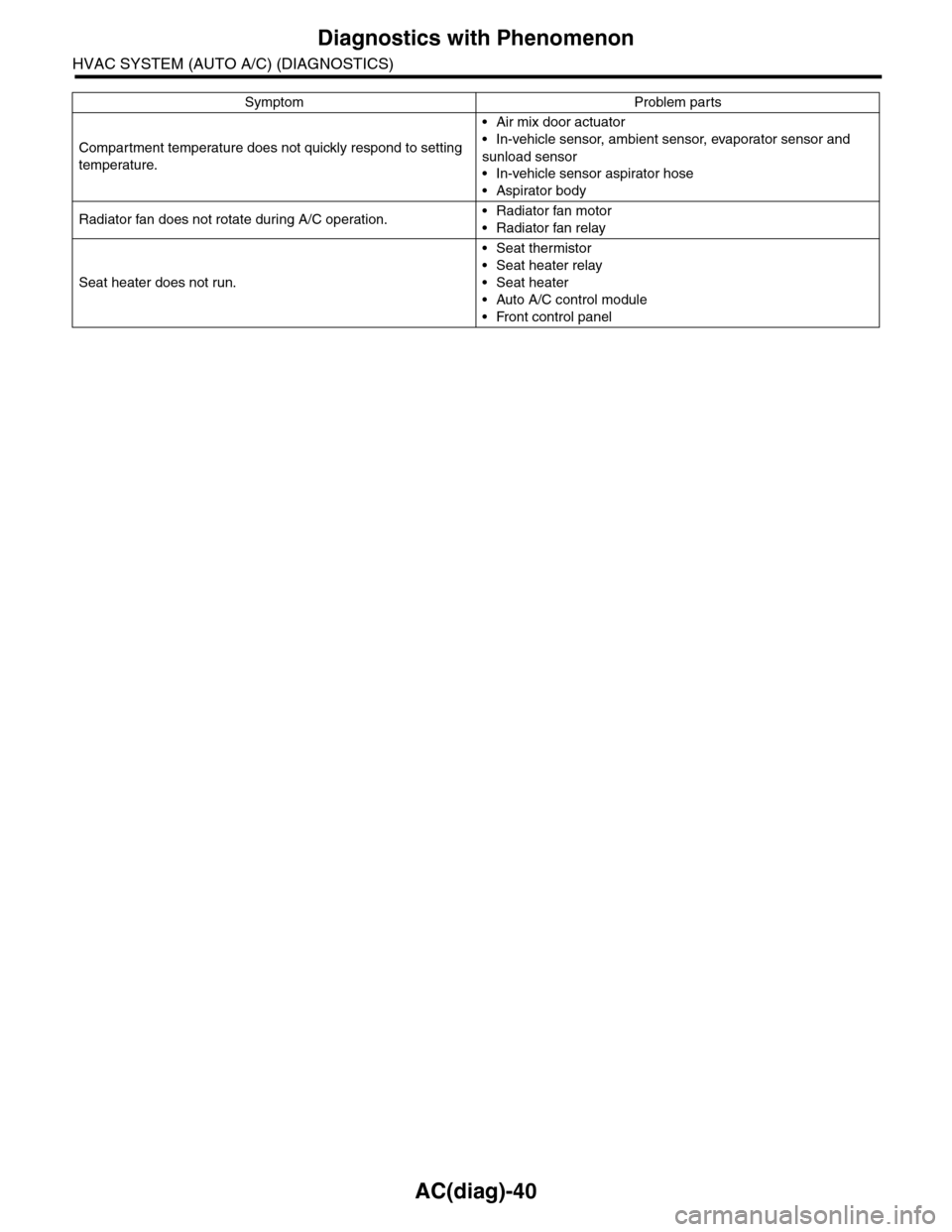

Combination Meter System

INSTRUMENTATION/DRIVER INFO

3. SYMPTOM CHART

CAUTION:

When measuring the voltage and resistance of each control module or sensor, use a tapered pin with

a diameter of less than 0.64 mm (0.025 in) in order to avoid poor contact. Do not insert the pin more

than 2 mm (0.08 in).

4. CHECK POWER SUPPLY AND GROUND CIRCUIT

Symptom Repair order Note

Combination meter assembly does not

operate.

1. Power supply

2. Ground circuit

3. Combination meter

Combination Meter System.>

Speedometer does not operate. 1. VDCCM

2. Harness

3. Combination meter

tem.>

Ta c h o m e t e r d o e s n o t o p e r a t e . 1 . E C M

2. Harness

3. Combination meter

Combination Meter System.>

Fuel gauge does not operate. 1. Communication circuit

2. Fuel level sensor

3. Harness

4. Combination meter

Meter System.>

Engine coolant temperature gauge does

not operate.

1. Communication circuit

2. Engine coolant temperature sensor

3. Harness

4. Combination meter

INSPECTION, Combination Meter Sys-

tem.>

Error display is shown on the odo/trip

meter.

Communication circuit

nation Meter System.>

Step Check Yes No

1CHECK POWER SUPPLY FOR COMBINA-

TION METER.

1) Remove the combination meter.

2) Disconnect the combination meter harness

connector.

3) Turn the ignition switch to ON.

4) Measure the voltage between combination

meter connector and chassis ground.

Connector & terminal

(i10) No. 3, 4 (+) — Chassis ground (–):

Is the voltage more than 10 V? Go to step 2.Check the harness

for open or shor t

between the igni-

tion switch and

combination

meter.

2CHECK POWER SUPPLY FOR COMBINA-

TION METER.

Measure the voltage between combination

meter connector and chassis ground.

Connector & terminal

(i10) No. 1, 2 (+) — Chassis ground (–):

Is the voltage more than 10 V? Go to step 3.Check the harness

for open or shor t

between the fuse

and combination

meter.

3CHECK GROUND CIRCUIT OF COMBINA-

TION METER.

1) Turn the ignition switch to OFF.

2) Measure the resistance of harness

between combination meter connector and

chassis ground.

Connector & terminal

(i10) No. 15, 16 — Chassis ground:

Is the resistance less than 10

Ω?

Replace the meter

case assembly.

Repair the wiring

harness.

Page 448 of 2453

IDI-9

Combination Meter System

INSTRUMENTATION/DRIVER INFO

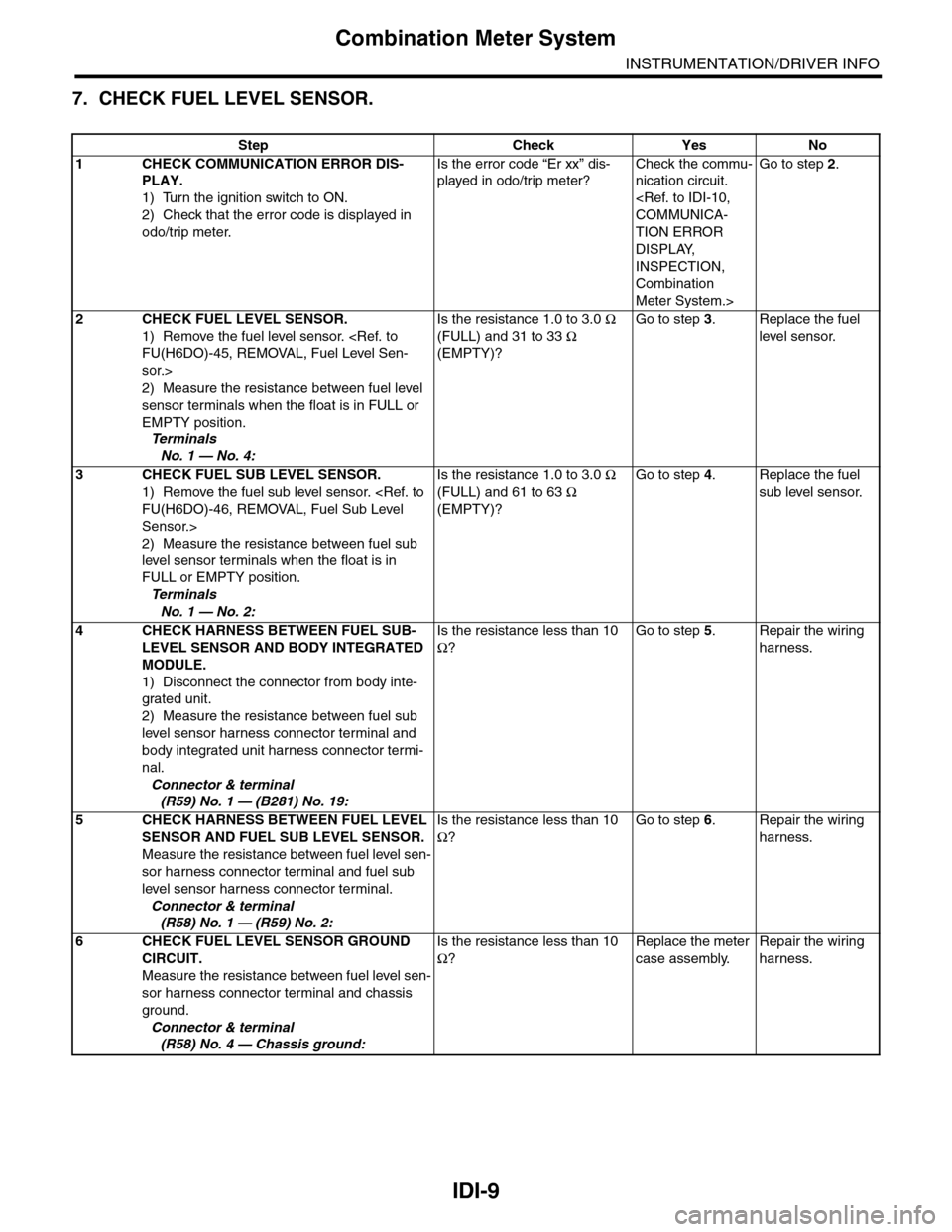

7. CHECK FUEL LEVEL SENSOR.

Step Check Yes No

1CHECK COMMUNICATION ERROR DIS-

PLAY.

1) Turn the ignition switch to ON.

2) Check that the error code is displayed in

odo/trip meter.

Is the error code “Er xx” dis-

played in odo/trip meter?

Check the commu-

nication circuit.

TION ERROR

DISPLAY,

INSPECTION,

Combination

Meter System.>

Go to step 2.

2CHECK FUEL LEVEL SENSOR.

1) Remove the fuel level sensor.

sor.>

2) Measure the resistance between fuel level

sensor terminals when the float is in FULL or

EMPTY position.

Te r m i n a l s

No. 1 — No. 4:

Is the resistance 1.0 to 3.0 Ω

(FULL) and 31 to 33 Ω

(EMPTY)?

Go to step 3.Replace the fuel

level sensor.

3CHECK FUEL SUB LEVEL SENSOR.

1) Remove the fuel sub level sensor.

Sensor.>

2) Measure the resistance between fuel sub

level sensor terminals when the float is in

FULL or EMPTY position.

Te r m i n a l s

No. 1 — No. 2:

Is the resistance 1.0 to 3.0 Ω

(FULL) and 61 to 63 Ω

(EMPTY)?

Go to step 4.Replace the fuel

sub level sensor.

4CHECK HARNESS BETWEEN FUEL SUB-

LEVEL SENSOR AND BODY INTEGRATED

MODULE.

1) Disconnect the connector from body inte-

grated unit.

2) Measure the resistance between fuel sub

level sensor harness connector terminal and

body integrated unit harness connector termi-

nal.

Connector & terminal

(R59) No. 1 — (B281) No. 19:

Is the resistance less than 10

Ω?

Go to step 5.Repair the wiring

harness.

5CHECK HARNESS BETWEEN FUEL LEVEL

SENSOR AND FUEL SUB LEVEL SENSOR.

Measure the resistance between fuel level sen-

sor harness connector terminal and fuel sub

level sensor harness connector terminal.

Connector & terminal

(R58) No. 1 — (R59) No. 2:

Is the resistance less than 10

Ω?

Go to step 6.Repair the wiring

harness.

6CHECK FUEL LEVEL SENSOR GROUND

CIRCUIT.

Measure the resistance between fuel level sen-

sor harness connector terminal and chassis

ground.

Connector & terminal

(R58) No. 4 — Chassis ground:

Is the resistance less than 10

Ω?

Replace the meter

case assembly.

Repair the wiring

harness.

Page 449 of 2453

IDI-10

Combination Meter System

INSTRUMENTATION/DRIVER INFO

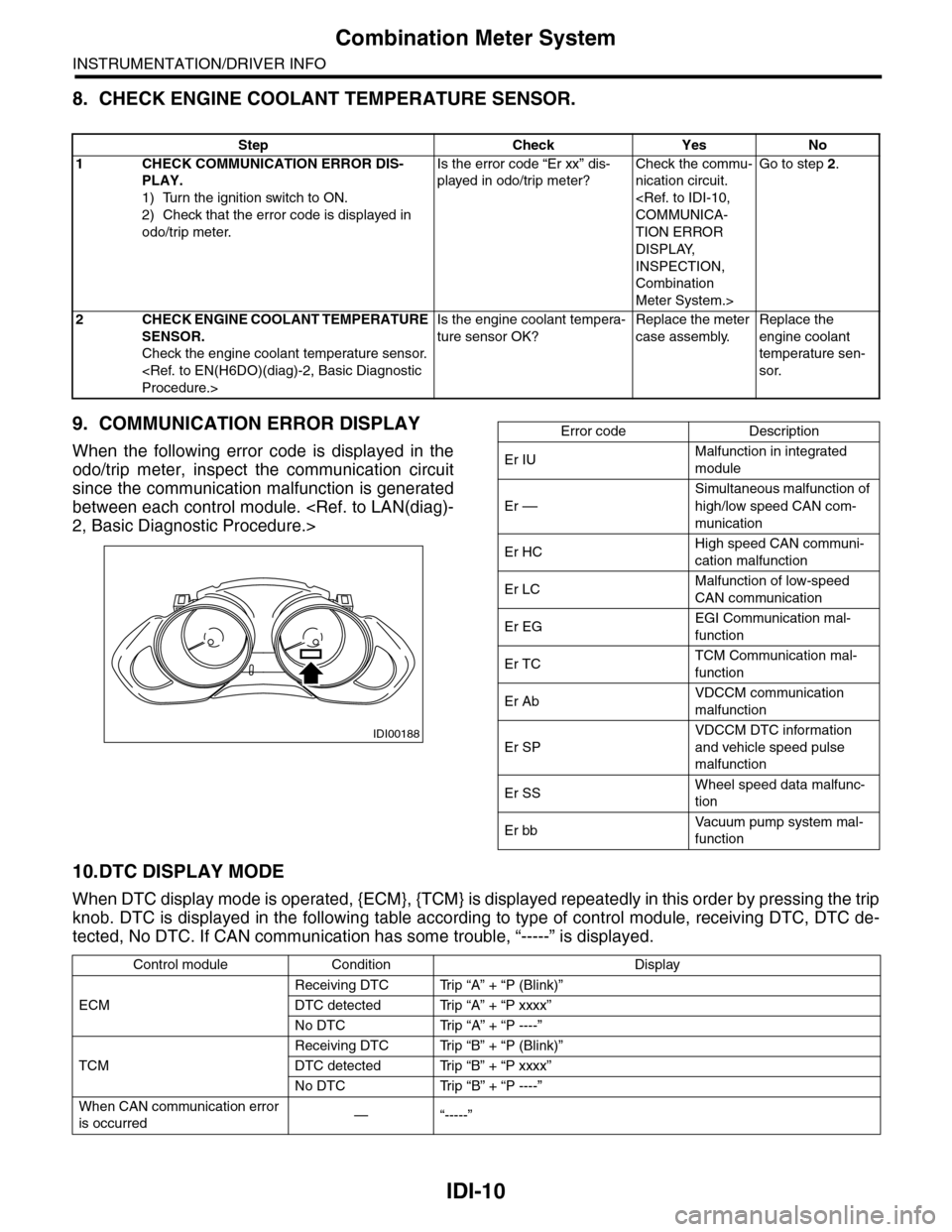

8. CHECK ENGINE COOLANT TEMPERATURE SENSOR.

9. COMMUNICATION ERROR DISPLAY

When the following error code is displayed in the

odo/trip meter, inspect the communication circuit

since the communication malfunction is generated

between each control module.

10.DTC DISPLAY MODE

When DTC display mode is operated, {ECM}, {TCM} is displayed repeatedly in this order by pressing the trip

knob. DTC is displayed in the following table according to type of control module, receiving DTC, DTC de-

tected, No DTC. If CAN communication has some trouble, “-----” is displayed.

Step Check Yes No

1CHECK COMMUNICATION ERROR DIS-

PLAY.

1) Turn the ignition switch to ON.

2) Check that the error code is displayed in

odo/trip meter.

Is the error code “Er xx” dis-

played in odo/trip meter?

Check the commu-

nication circuit.

TION ERROR

DISPLAY,

INSPECTION,

Combination

Meter System.>

Go to step 2.

2CHECK ENGINE COOLANT TEMPERATURE

SENSOR.

Check the engine coolant temperature sensor.

Is the engine coolant tempera-

ture sensor OK?

Replace the meter

case assembly.

Replace the

engine coolant

temperature sen-

sor.

IDI00188

Error code Description

Er IUMalfunction in integrated

module

Er ––

Simultaneous malfunction of

high/low speed CAN com-

munication

Er HCHigh speed CAN communi-

cation malfunction

Er LCMalfunction of low-speed

CAN communication

Er EGEGI Communication mal-

function

Er TCTCM Communication mal-

function

Er AbVDCCM communication

malfunction

Er SP

VDCCM DTC information

and vehicle speed pulse

malfunction

Er SSWheel speed data malfunc-

tion

Er bbVa c u u m p u m p s y s t e m m a l -

function

Control module Condition Display

ECM

Receiving DTC Trip “A” + “P (Blink)”

DTC detected Trip “A” + “P xxxx”

No DTC Trip “A” + “P ----”

TCM

Receiving DTC Trip “B” + “P (Blink)”

DTC detected Trip “B” + “P xxxx”

No DTC Trip “B” + “P ----”

When CAN communication error

is occurred—“-----”

Page 463 of 2453

LAN(diag)-7

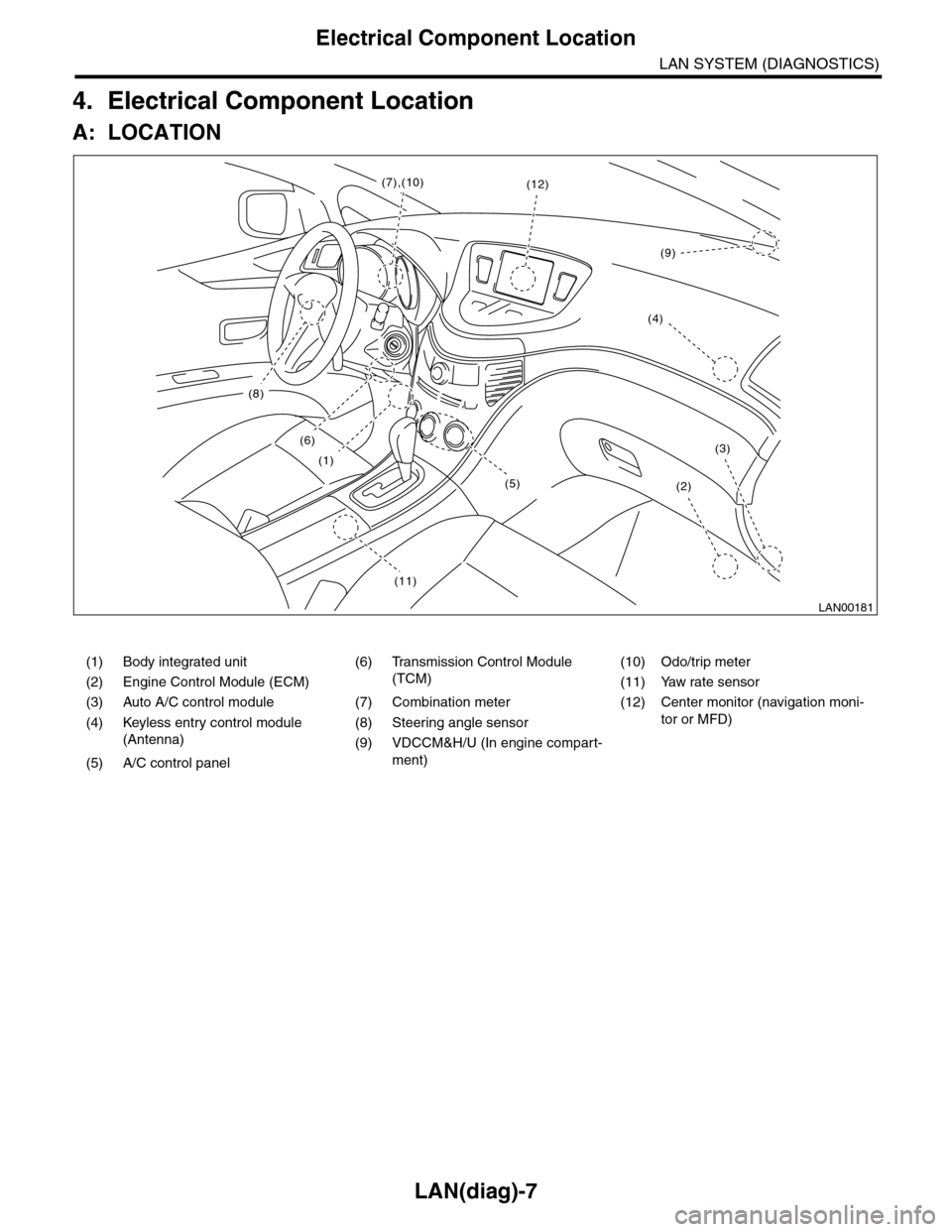

Electrical Component Location

LAN SYSTEM (DIAGNOSTICS)

4. Electrical Component Location

A: LOCATION

(1) Body integrated unit (6) Transmission Control Module

(TCM)

(10) Odo/trip meter

(2) Engine Control Module (ECM) (11) Yaw rate sensor

(3) Auto A/C control module (7) Combination meter (12) Center monitor (navigation moni-

tor or MFD)(4) Keyless entry control module

(Antenna)

(8) Steering angle sensor

(9) VDCCM&H/U (In engine compart-

ment)(5) A/C control panel

LAN00181

(8)

(6)

(1)

(11)

(2)

(3)

(12)(7),(10)

(4)

(9)

(5)

Page 466 of 2453

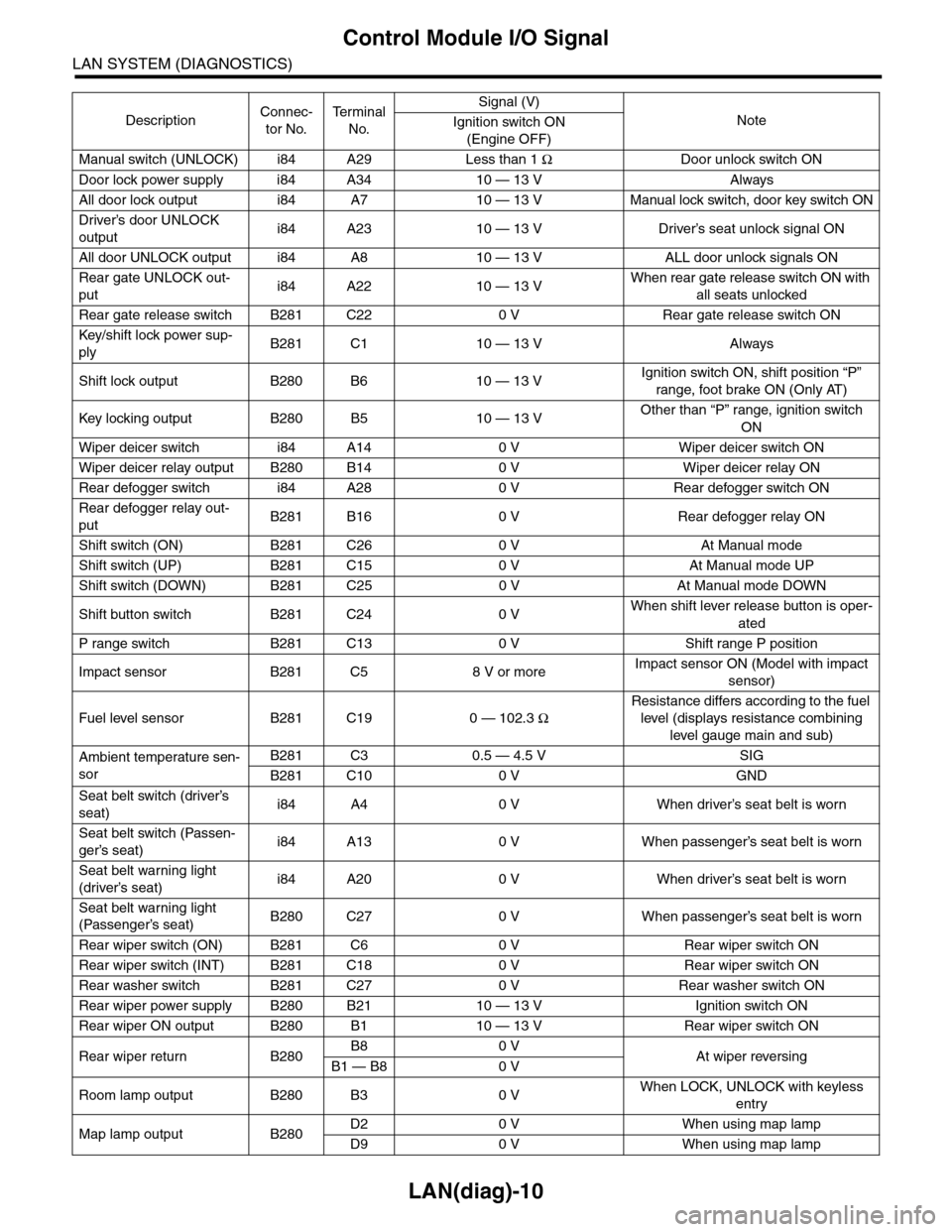

LAN(diag)-10

Control Module I/O Signal

LAN SYSTEM (DIAGNOSTICS)

Manual switch (UNLOCK) i84 A29 Less than 1 ΩDoor unlock switch ON

Door lock power supply i84 A34 10 — 13 V Always

All door lock output i84 A7 10 — 13 V Manual lock switch, door key switch ON

Driver’s door UNLOCK

outputi84 A23 10 — 13 V Driver’s seat unlock signal ON

All door UNLOCK output i84 A8 10 — 13 V ALL door unlock signals ON

Rear gate UNLOCK out-

puti84 A22 10 — 13 VWhen rear gate release switch ON with

all seats unlocked

Rear gate release switch B281 C22 0 V Rear gate release switch ON

Key/shift lock power sup-

plyB281 C1 10 — 13 V Always

Shift lock output B280 B6 10 — 13 VIgnition switch ON, shift position “P”

range, foot brake ON (Only AT)

Key locking output B280 B5 10 — 13 VOther than “P” range, ignition switch

ON

Wiper deicer switch i84 A14 0 V Wiper deicer switch ON

Wiper deicer relay output B280 B14 0 V Wiper deicer relay ON

Rear defogger switch i84 A28 0 V Rear defogger switch ON

Rear defogger relay out-

putB281 B16 0 V Rear defogger relay ON

Shift switch (ON) B281 C26 0 V At Manual mode

Shift switch (UP) B281 C15 0 V At Manual mode UP

Shift switch (DOWN) B281 C25 0 V At Manual mode DOWN

Shift button switch B281 C24 0 VWhen shift lever release button is oper-

ated

P range switch B281 C13 0 V Shift range P position

Impact sensor B281 C5 8 V or moreImpact sensor ON (Model with impact

sensor)

Fuel level sensor B281 C19 0 — 102.3 Ω

Resistance differs according to the fuel

level (displays resistance combining

level gauge main and sub)

Ambient temperature sen-

sor

B281 C3 0.5 — 4.5 V SIG

B281 C10 0 V GND

Seat belt switch (driver’s

seat)i84 A4 0 V When driver’s seat belt is worn

Seat belt switch (Passen-

ger’s seat)i84 A13 0 V When passenger’s seat belt is worn

Seat belt warning light

(driver’s seat)i84 A20 0 V When driver’s seat belt is worn

Seat belt warning light

(Passenger’s seat)B280 C27 0 V When passenger’s seat belt is worn

Rear wiper switch (ON) B281 C6 0 V Rear wiper switch ON

Rear wiper switch (INT) B281 C18 0 V Rear wiper switch ON

Rear washer switch B281 C27 0 V Rear washer switch ON

Rear wiper power supply B280 B21 10 — 13 V Ignition switch ON

Rear wiper ON output B280 B1 10 — 13 V Rear wiper switch ON

Rear wiper return B280B8 0 VAt wiper reversingB1 — B8 0 V

Room lamp output B280 B3 0 VWhen LOCK, UNLOCK with keyless

entry

Map lamp output B280D2 0 V When using map lamp

D9 0 V When using map lamp

DescriptionConnec-

tor No.

Te r m i n a l

No.

Signal (V)

NoteIgnition switch ON

(Engine OFF)

Page 469 of 2453

![SUBARU TRIBECA 2009 1.G Service Owners Manual LAN(diag)-13

Subaru Select Monitor

LAN SYSTEM (DIAGNOSTICS)

2. READ CURRENT DATA

1) On the «Main Menu» display screen, select the {Each System Check} and press the [YES] key.

2) On the «System Sele SUBARU TRIBECA 2009 1.G Service Owners Manual LAN(diag)-13

Subaru Select Monitor

LAN SYSTEM (DIAGNOSTICS)

2. READ CURRENT DATA

1) On the «Main Menu» display screen, select the {Each System Check} and press the [YES] key.

2) On the «System Sele](/img/17/7322/w960_7322-468.png)

LAN(diag)-13

Subaru Select Monitor

LAN SYSTEM (DIAGNOSTICS)

2. READ CURRENT DATA

1) On the «Main Menu» display screen, select the {Each System Check} and press the [YES] key.

2) On the «System Selection Menu» display screen, select the {Integ. Unit mode} and press the [YES] key.

3) On the «Integ. unit mode failure diag» display screen, select the {Current Data Display & Save} and press

the [YES] key.

4) On the «Current Data Display & Save» display screen, select the {12 Data Display} and press the [YES]

key.

5) Using the scroll key, scroll the display screen up or down until the desired data is shown.

•A support list contains both of analog and digital data, and they are shown in the following table.

3. DISPLAY OF ANALOG DATA

Items to be displayed Unit of measure Description Note

BATT Voltage (Control) 10 — 15 VBody integrated unit input

valueAlways

BATT Voltage (BACK UP) 10 — 15 VBody integrated unit input

valueAlways

IG power supply voltage 10 — 15 VBody integrated unit input

valueIgnition switch ON

ACC voltage 10 — 15 VBody integrated unit input

valueIgnition switch ACC

Illumination VR voltage 0 — 5 VBody integrated unit out-

put valueSmall light switch ON

Illumi. output d-ratio 0 — 100%Body integrated unit input

value

Small light ON

Illumination volume is other than bright.

Ambient temp sensor V 0 — 5 VBody integrated unit out-

put valueIgnition switch ON

Ambient temperature –40 — 87.5°CBody integrated unit out-

put valueIgnition switch ON

Fuel level voltage 0 — 8 VBody integrated unit input

valueIgnition switch ON

Fuel level resistance 0 — 102.3 ΩBody integrated unit input

valueIgnition switch ON

key-lock solenoid V 6 — 12 VBody integrated unit out-

put value

Other than parking range

Ignition ON

number of regist. 0 — 4 Key No. to register

Fr o nt W he e l S p ee d km / h C A N d a t a i np u t val u e R ec ep t io n f r o m V DC u ni t

VDC/ABS latest f-codeDTC display (Tempo-

rarily)CAN data input value

It is normal when DTC is not been input

even if this code is displayed.

Reception from VDC

Blower fan steps 0 — 2 levels CAN data input value0: OFF, 1: Low, 2: 2 levels or more

Reception from air conditioner ECM

Fuel level resistance2 0 — 102.3 ΩCAN data output value Reception from body integrated unit

Fuel consumption cc/s CAN data input valueReception from ECM and transmission to

center monitor

Coolant Temp. 40 — 130°C CAN data input value Reception from ECM

Ve h i c l e l a t e r a l Gm/s2CAN data input value Reception from VDC unit

SPORT Shift Stages 0 — 7 levels CAN data input value

(0: Light OFF; 1 — 5: Gear display; 6: Fail; 7:

AT F t e m p e r a t u r e H i g h / L o w )

Reception from TCM

Shift Position 0 — 7 levels CAN data input value

0: 1; 1: 2; 2: 3; 3: 4; 4: D; 5: N; 6: R; 7: P shift

position (There is no 8 input.)

Reception from TCM

Off delay timeOFF, Short, Normal,

Long

Body integrated unit set-

ting itemsCustomize setting

Auto lock time20, 30, 40, 50, 60 sec-

onds

Body integrated unit set-

ting itemsCustomize setting

Page 473 of 2453

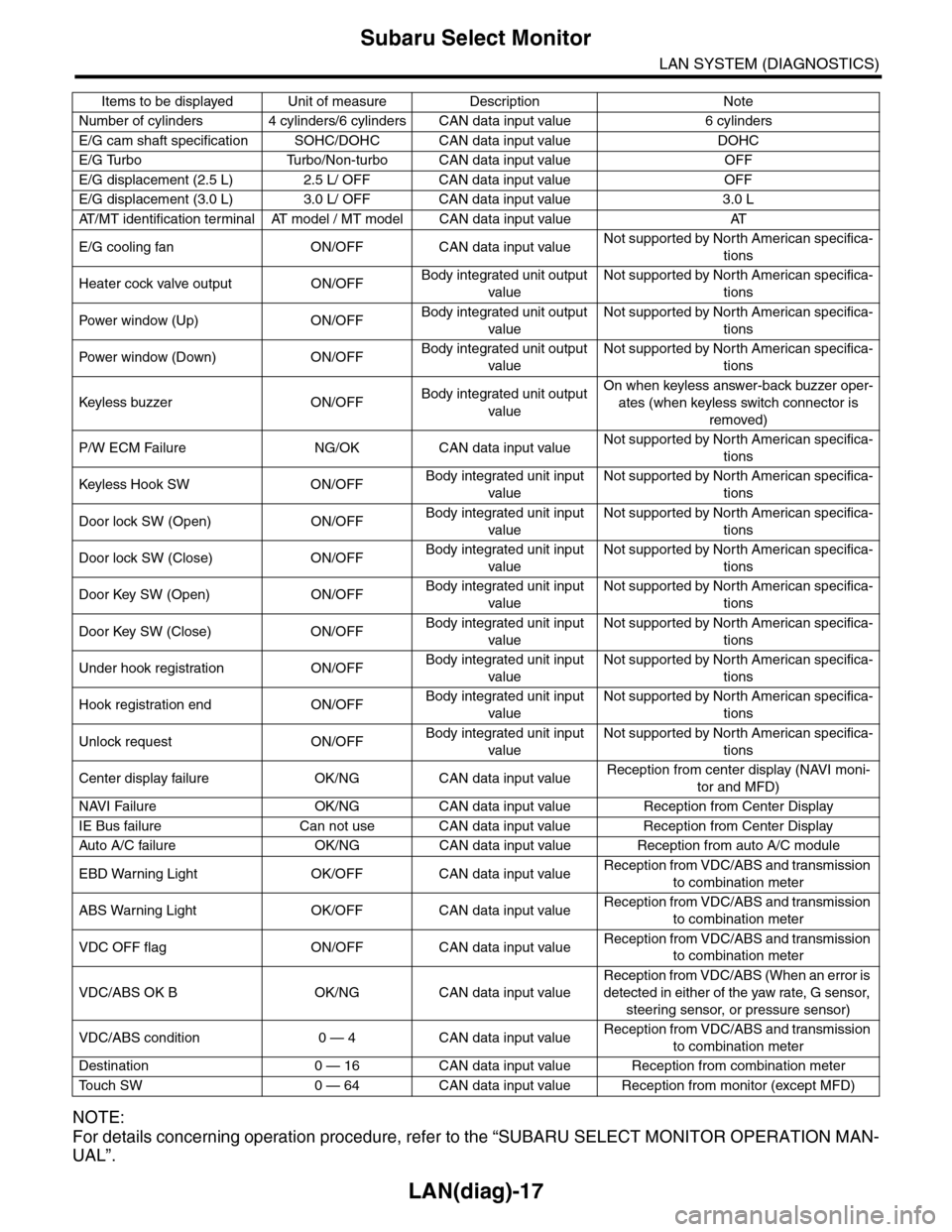

LAN(diag)-17

Subaru Select Monitor

LAN SYSTEM (DIAGNOSTICS)

NOTE:

For details concerning operation procedure, refer to the “SUBARU SELECT MONITOR OPERATION MAN-

UAL”.

Number of cylinders 4 cylinders/6 cylinders CAN data input value 6 cylinders

E/G cam shaft specification SOHC/DOHC CAN data input value DOHC

E/G Turbo Turbo/Non-turbo CAN data input value OFF

E/G displacement (2.5 L) 2.5 L/ OFF CAN data input value OFF

E/G displacement (3.0 L) 3.0 L/ OFF CAN data input value 3.0 L

AT / M T i d e n t i f i c a t i o n t e r m i n a l AT m o d e l / M T m o d e l C A N d a t a i n p u t v a l u e AT

E/G cooling fan ON/OFF CAN data input valueNot supported by North American specifica-

tions

Heater cock valve output ON/OFFBody integrated unit output

value

Not supported by North American specifica-

tions

Pow er w i nd ow (U p) O N /O FFBody integrated unit output

value

Not supported by North American specifica-

tions

Pow er w i nd ow (D ow n ) O N /O FFBody integrated unit output

value

Not supported by North American specifica-

tions

Keyless buzzer ON/OFFBody integrated unit output

value

On when keyless answer-back buzzer oper-

ates (when keyless switch connector is

removed)

P/W ECM Failure NG/OK CAN data input valueNot supported by North American specifica-

tions

Keyless Hook SW ON/OFFBody integrated unit input

value

Not supported by North American specifica-

tions

Door lock SW (Open) ON/OFFBody integrated unit input

value

Not supported by North American specifica-

tions

Door lock SW (Close) ON/OFFBody integrated unit input

value

Not supported by North American specifica-

tions

Door Key SW (Open) ON/OFFBody integrated unit input

value

Not supported by North American specifica-

tions

Door Key SW (Close) ON/OFFBody integrated unit input

value

Not supported by North American specifica-

tions

Under hook registration ON/OFFBody integrated unit input

value

Not supported by North American specifica-

tions

Hook registration end ON/OFFBody integrated unit input

value

Not supported by North American specifica-

tions

Unlock request ON/OFFBody integrated unit input

value

Not supported by North American specifica-

tions

Center display failure OK/NG CAN data input valueReception from center display (NAVI moni-

tor and MFD)

NAVI Failure OK/NG CAN data input value Reception from Center Display

IE Bus failure Can not use CAN data input value Reception from Center Display

Auto A/C failure OK/NG C AN data input value Reception from auto A/C module

EBD Warning Light OK/OFF CAN data input valueReception from VDC/ABS and transmission

to combination meter

ABS Warning Light OK/OFF CAN data input valueReception from VDC/ABS and transmission

to combination meter

VDC OFF flag ON/OFF CAN data input valueReception from VDC/ABS and transmission

to combination meter

VDC/ABS OK B OK/NG CAN data input value

Reception from VDC/ABS (When an error is

detected in either of the yaw rate, G sensor,

steering sensor, or pressure sensor)

VDC/ABS condition 0 — 4 CAN data input valueReception from VDC/ABS and transmission

to combination meter

Destination 0 — 16 CAN data input value Reception from combination meter

To u c h S W 0 — 6 4 C A N d a t a i n p u t v a l u e R e c e p t i o n f r o m m o n i t o r ( e x c e p t M F D )

Items to be displayed Unit of measure Description Note