TOYOTA RAV4 2006 Service Repair Manual

Manufacturer: TOYOTA, Model Year: 2006, Model line: RAV4, Model: TOYOTA RAV4 2006Pages: 2000, PDF Size: 45.84 MB

Page 671 of 2000

EM–1442AZ-FE ENGINE MECHANICAL – ENGINE UNIT

EM

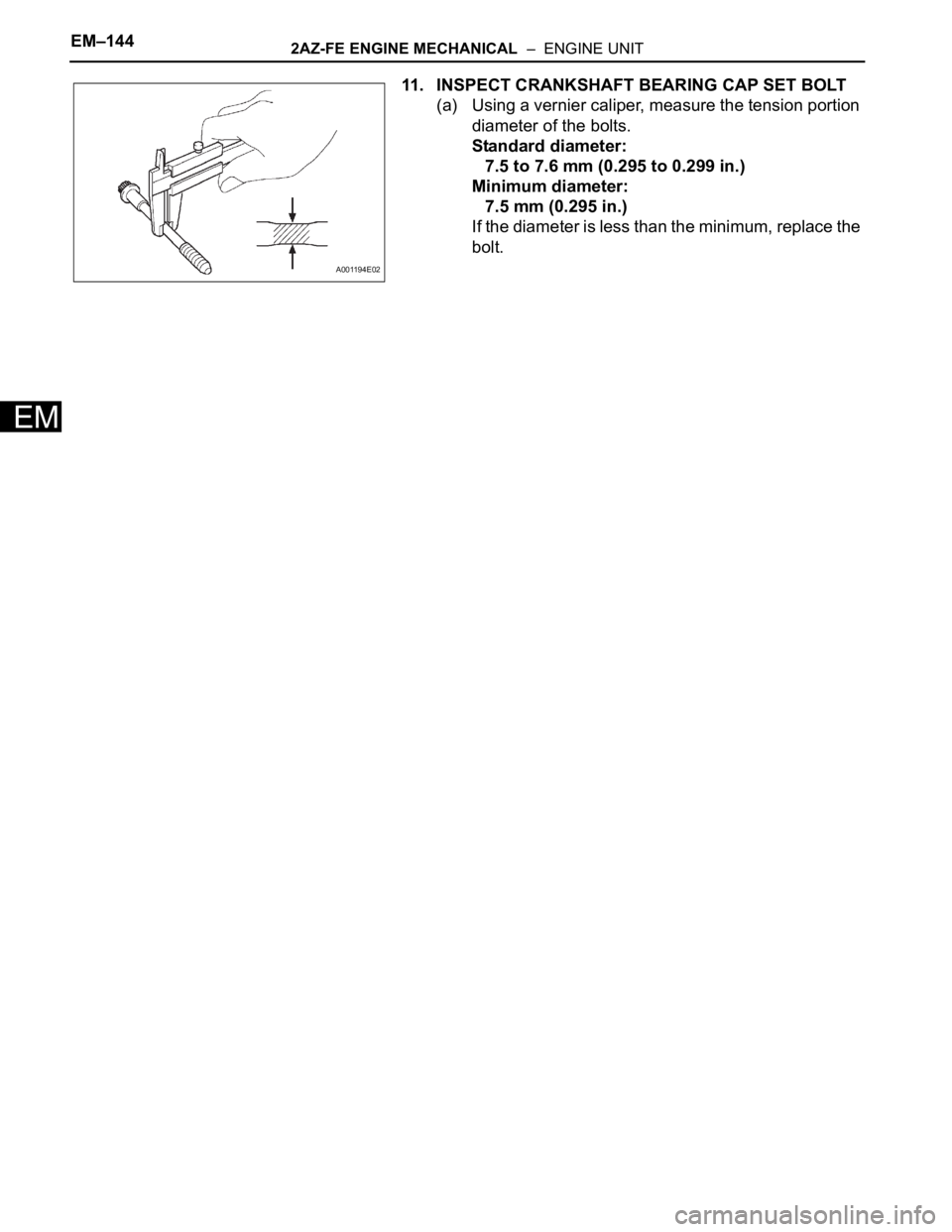

11. INSPECT CRANKSHAFT BEARING CAP SET BOLT

(a) Using a vernier caliper, measure the tension portion

diameter of the bolts.

Standard diameter:

7.5 to 7.6 mm (0.295 to 0.299 in.)

Minimum diameter:

7.5 mm (0.295 in.)

If the diameter is less than the minimum, replace the

bolt.

A001194E02

Page 672 of 2000

2AZ-FE ENGINE MECHANICAL – ENGINE UNITEM–145

EM

REPLACEMENT

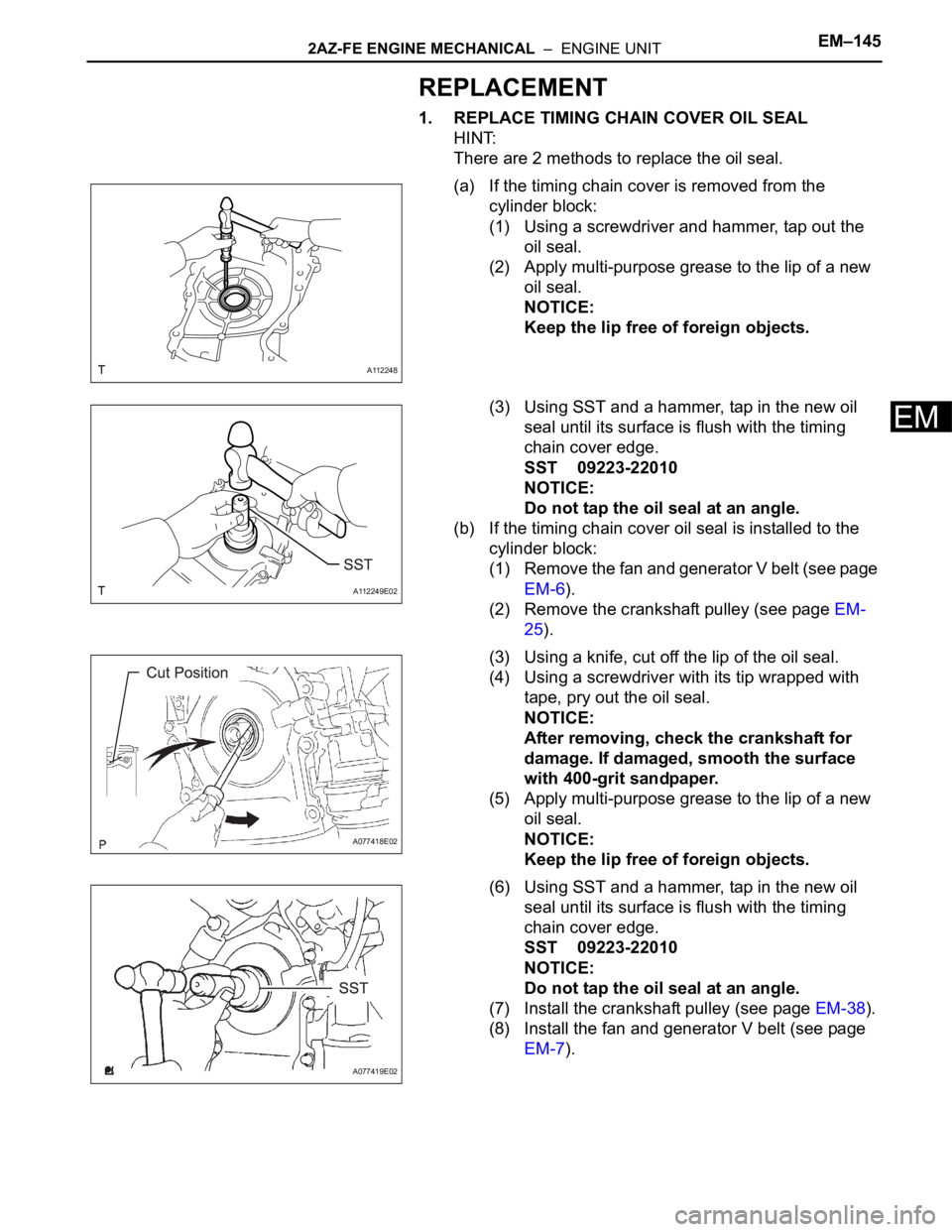

1. REPLACE TIMING CHAIN COVER OIL SEAL

HINT:

There are 2 methods to replace the oil seal.

(a) If the timing chain cover is removed from the

cylinder block:

(1) Using a screwdriver and hammer, tap out the

oil seal.

(2) Apply multi-purpose grease to the lip of a new

oil seal.

NOTICE:

Keep the lip free of foreign objects.

(3) Using SST and a hammer, tap in the new oil

seal until its surface is flush with the timing

chain cover edge.

SST 09223-22010

NOTICE:

Do not tap the oil seal at an angle.

(b) If the timing chain cover oil seal is installed to the

cylinder block:

(1) Remove the fan and generator V belt (see page

EM-6).

(2) Remove the crankshaft pulley (see page EM-

25).

(3) Using a knife, cut off the lip of the oil seal.

(4) Using a screwdriver with its tip wrapped with

tape, pry out the oil seal.

NOTICE:

After removing, check the crankshaft for

damage. If damaged, smooth the surface

with 400-grit sandpaper.

(5) Apply multi-purpose grease to the lip of a new

oil seal.

NOTICE:

Keep the lip free of foreign objects.

(6) Using SST and a hammer, tap in the new oil

seal until its surface is flush with the timing

chain cover edge.

SST 09223-22010

NOTICE:

Do not tap the oil seal at an angle.

(7) Install the crankshaft pulley (see page EM-38).

(8) Install the fan and generator V belt (see page

EM-7).

A112248

A112249E02

A077418E02

A077419E02

Page 673 of 2000

EM–1462AZ-FE ENGINE MECHANICAL – ENGINE UNIT

EM

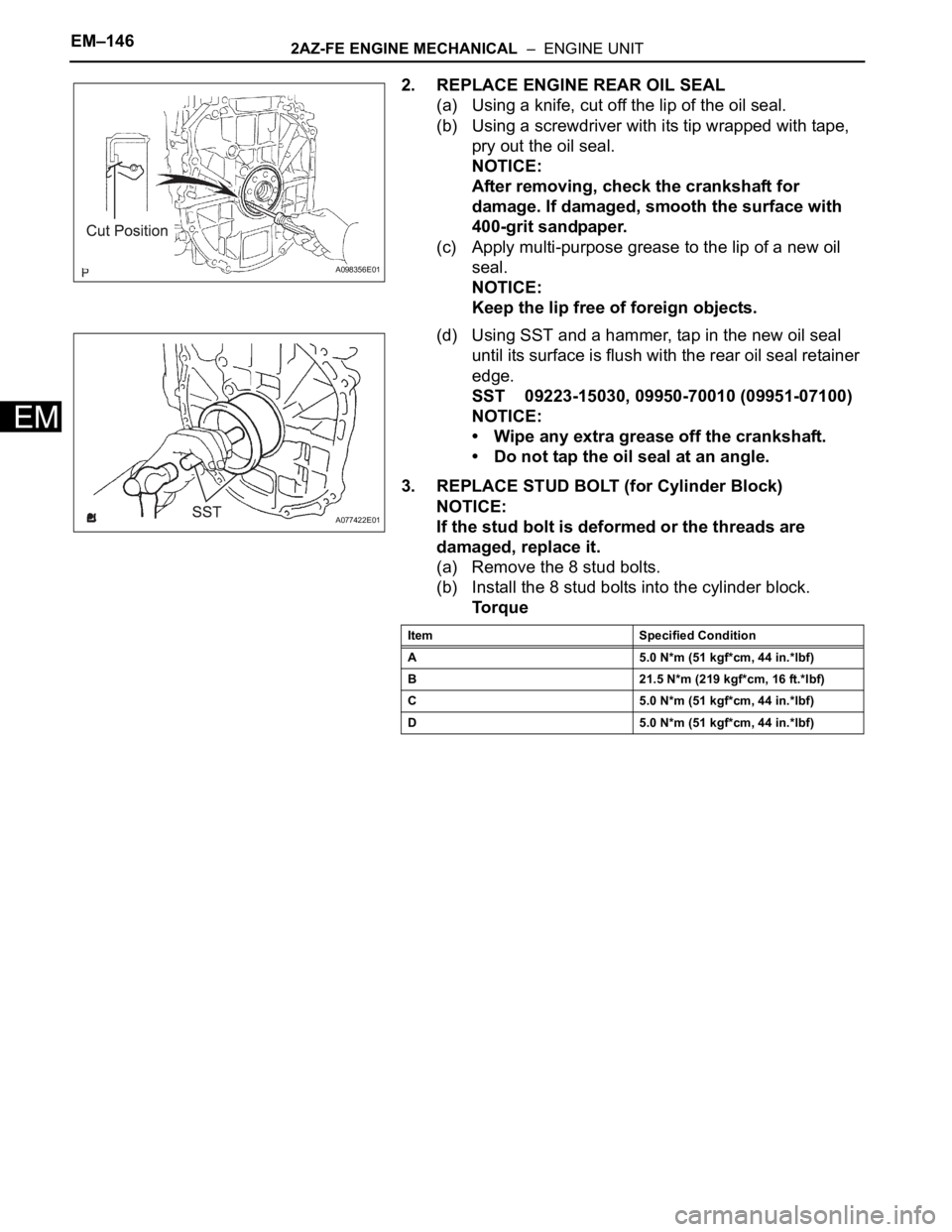

2. REPLACE ENGINE REAR OIL SEAL

(a) Using a knife, cut off the lip of the oil seal.

(b) Using a screwdriver with its tip wrapped with tape,

pry out the oil seal.

NOTICE:

After removing, check the crankshaft for

damage. If damaged, smooth the surface with

400-grit sandpaper.

(c) Apply multi-purpose grease to the lip of a new oil

seal.

NOTICE:

Keep the lip free of foreign objects.

(d) Using SST and a hammer, tap in the new oil seal

until its surface is flush with the rear oil seal retainer

edge.

SST 09223-15030, 09950-70010 (09951-07100)

NOTICE:

• Wipe any extra grease off the crankshaft.

• Do not tap the oil seal at an angle.

3. REPLACE STUD BOLT (for Cylinder Block)

NOTICE:

If the stud bolt is deformed or the threads are

damaged, replace it.

(a) Remove the 8 stud bolts.

(b) Install the 8 stud bolts into the cylinder block.

To r q u e

A098356E01

A077422E01

Item Specified Condition

A 5.0 N*m (51 kgf*cm, 44 in.*lbf)

B 21.5 N*m (219 kgf*cm, 16 ft.*lbf)

C 5.0 N*m (51 kgf*cm, 44 in.*lbf)

D 5.0 N*m (51 kgf*cm, 44 in.*lbf)

Page 674 of 2000

2AZ-FE ENGINE MECHANICAL – ENGINE UNITEM–147

EM

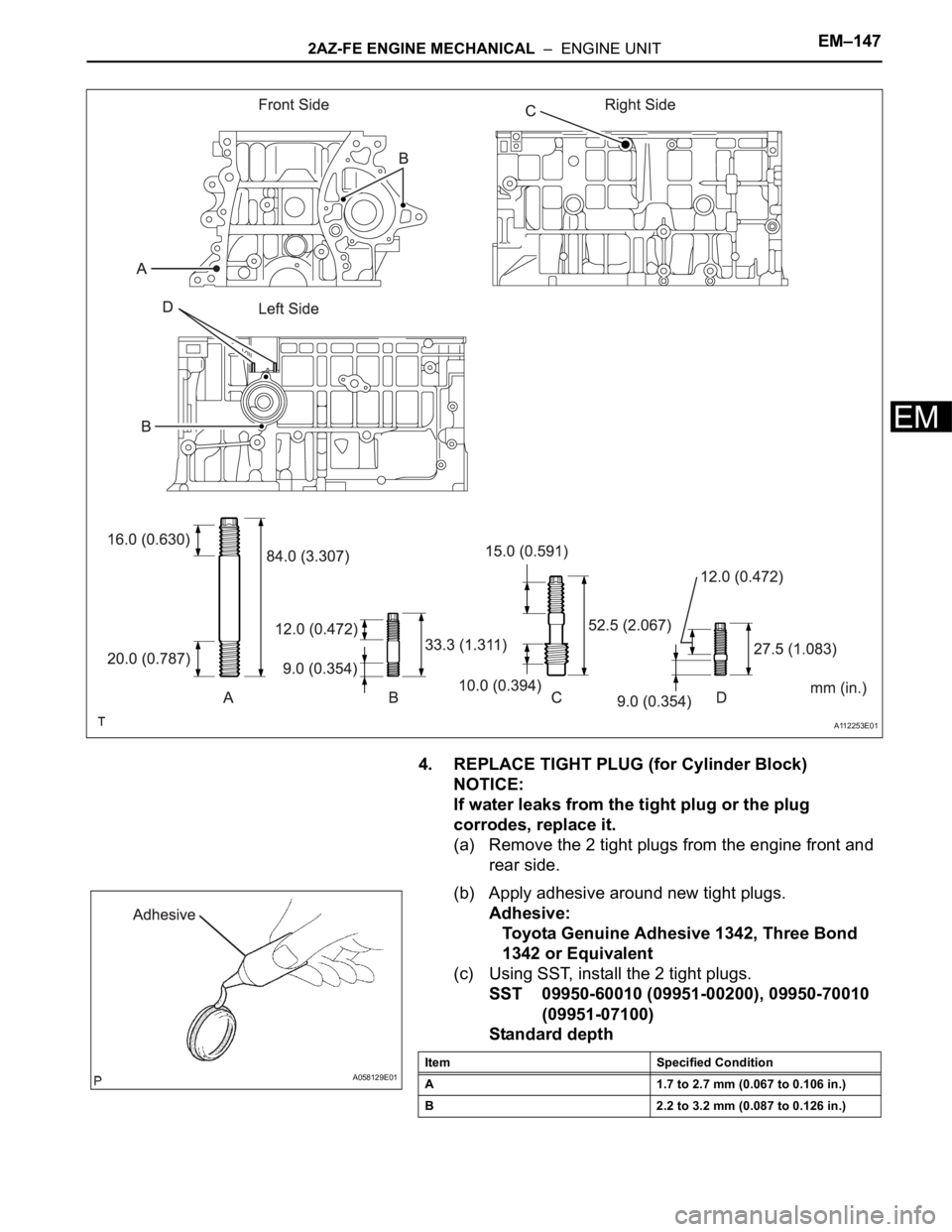

4. REPLACE TIGHT PLUG (for Cylinder Block)

NOTICE:

If water leaks from the tight plug or the plug

corrodes, replace it.

(a) Remove the 2 tight plugs from the engine front and

rear side.

(b) Apply adhesive around new tight plugs.

Adhesive:

Toyota Genuine Adhesive 1342, Three Bond

1342 or Equivalent

(c) Using SST, install the 2 tight plugs.

SST 09950-60010 (09951-00200), 09950-70010

(09951-07100)

Standard depth

A112253E01

A058129E01Item Specified Condition

A 1.7 to 2.7 mm (0.067 to 0.106 in.)

B 2.2 to 3.2 mm (0.087 to 0.126 in.)

Page 675 of 2000

EM–1482AZ-FE ENGINE MECHANICAL – ENGINE UNIT

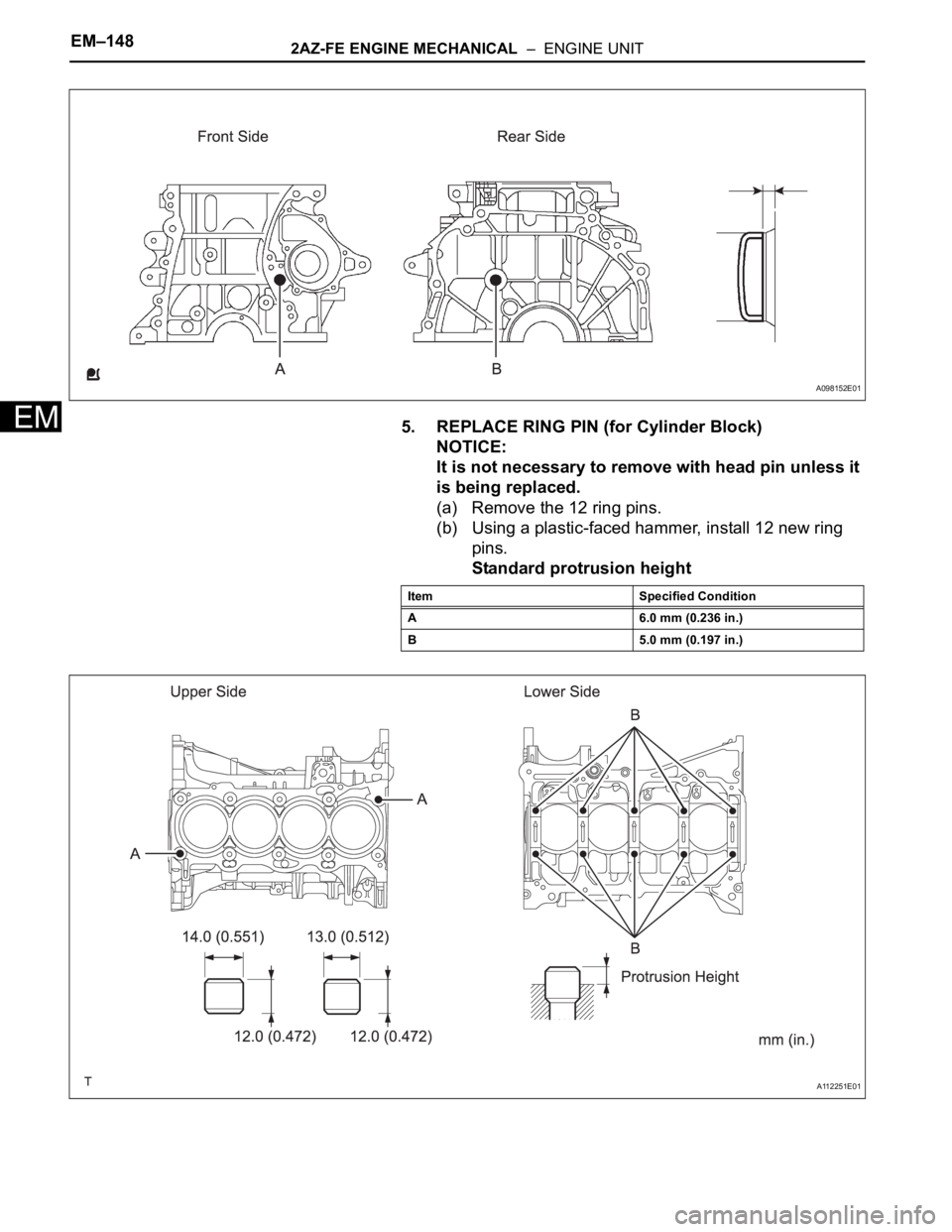

EM5. REPLACE RING PIN (for Cylinder Block)

NOTICE:

It is not necessary to remove with head pin unless it

is being replaced.

(a) Remove the 12 ring pins.

(b) Using a plastic-faced hammer, install 12 new ring

pins.

Standard protrusion height

A098152E01

Item Specified Condition

A 6.0 mm (0.236 in.)

B 5.0 mm (0.197 in.)

A112251E01

Page 676 of 2000

2AZ-FE ENGINE MECHANICAL – ENGINE UNITEM–149

EM

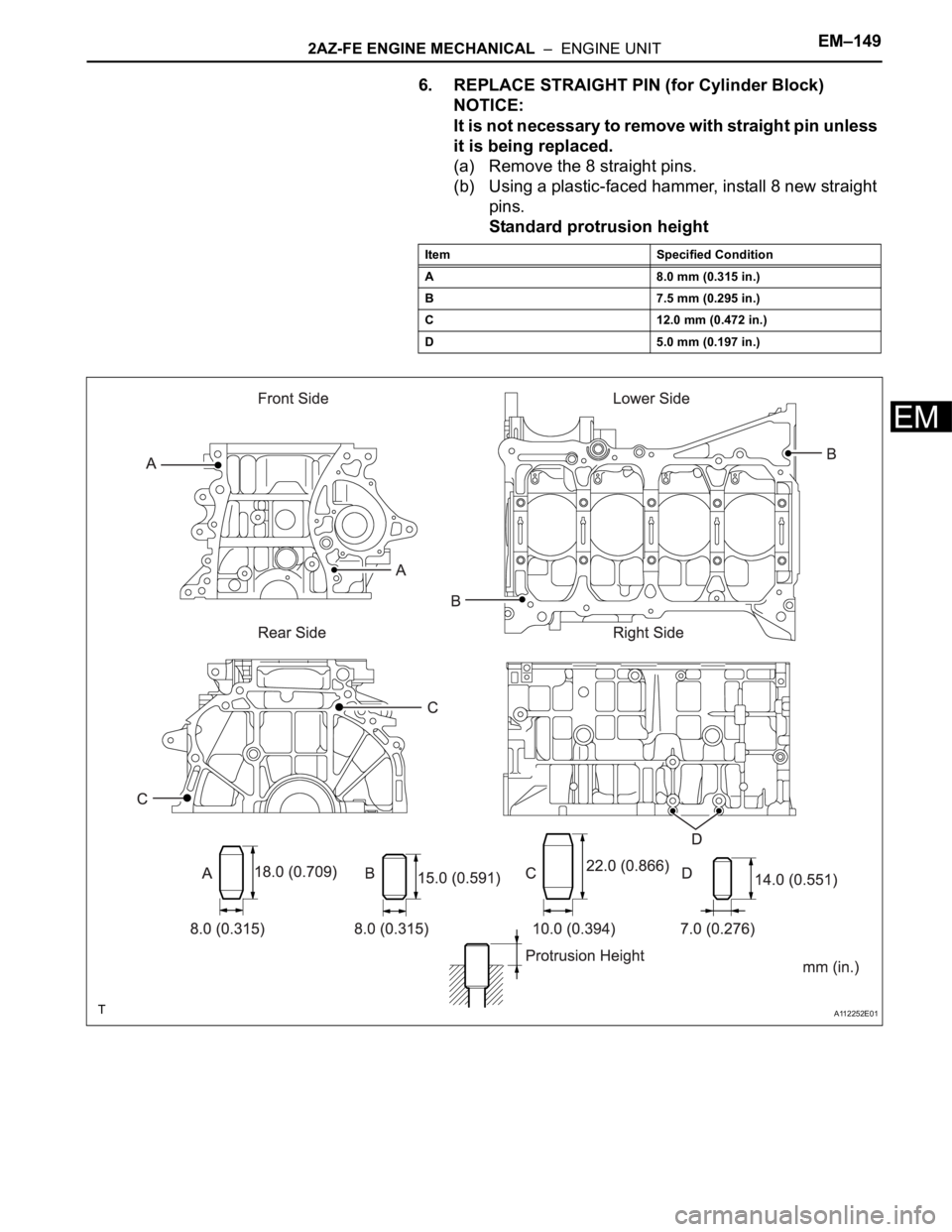

6. REPLACE STRAIGHT PIN (for Cylinder Block)

NOTICE:

It is not necessary to remove with straight pin unless

it is being replaced.

(a) Remove the 8 straight pins.

(b) Using a plastic-faced hammer, install 8 new straight

pins.

Standard protrusion height

Item Specified Condition

A 8.0 mm (0.315 in.)

B 7.5 mm (0.295 in.)

C 12.0 mm (0.472 in.)

D 5.0 mm (0.197 in.)

A112252E01

Page 677 of 2000

2GR-FE ENGINE MECHANICAL – ENGINE ASSEMBLYEM–31

EM

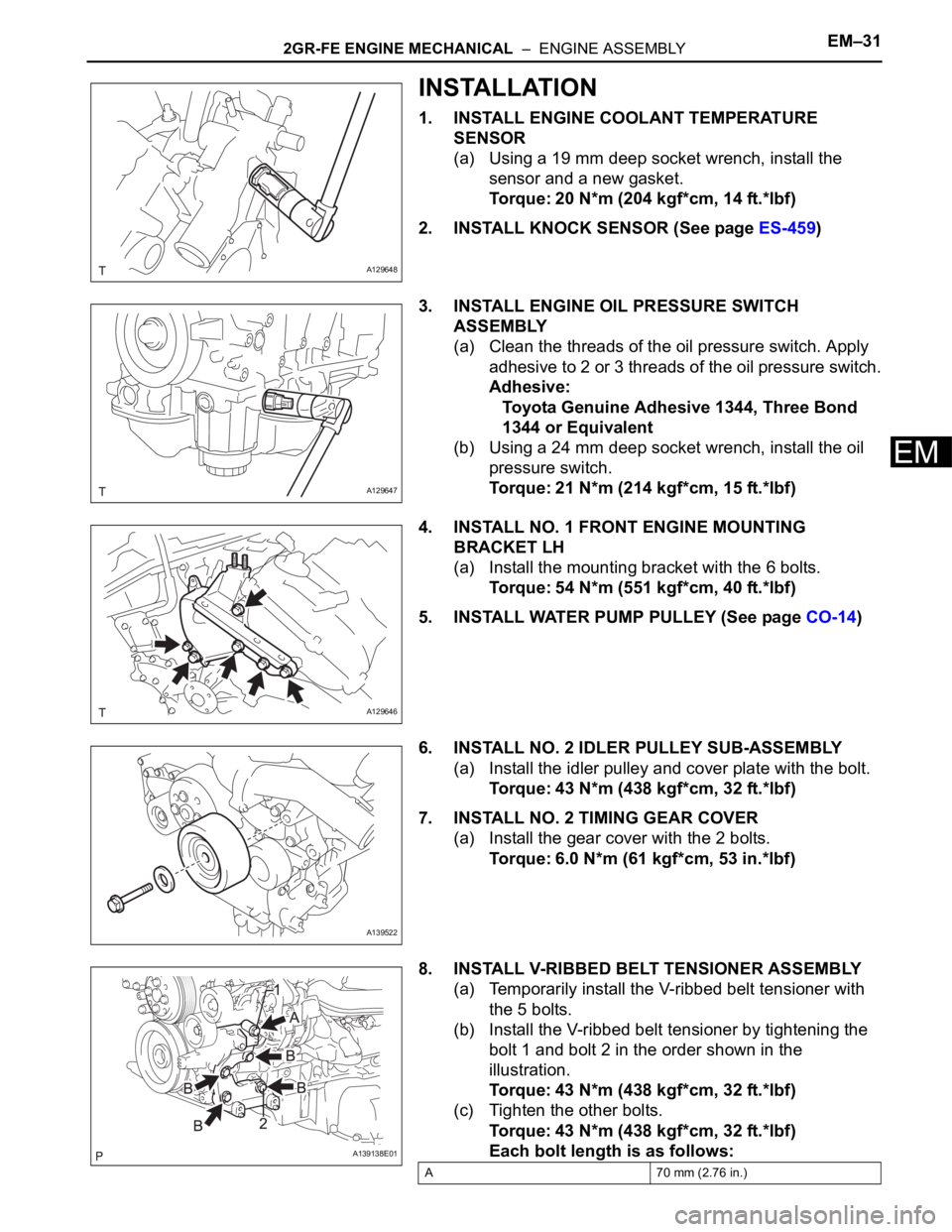

INSTALLATION

1. INSTALL ENGINE COOLANT TEMPERATURE

SENSOR

(a) Using a 19 mm deep socket wrench, install the

sensor and a new gasket.

Torque: 20 N*m (204 kgf*cm, 14 ft.*lbf)

2. INSTALL KNOCK SENSOR (See page ES-459)

3. INSTALL ENGINE OIL PRESSURE SWITCH

ASSEMBLY

(a) Clean the threads of the oil pressure switch. Apply

adhesive to 2 or 3 threads of the oil pressure switch.

Adhesive:

Toyota Genuine Adhesive 1344, Three Bond

1344 or Equivalent

(b) Using a 24 mm deep socket wrench, install the oil

pressure switch.

Torque: 21 N*m (214 kgf*cm, 15 ft.*lbf)

4. INSTALL NO. 1 FRONT ENGINE MOUNTING

BRACKET LH

(a) Install the mounting bracket with the 6 bolts.

Torque: 54 N*m (551 kgf*cm, 40 ft.*lbf)

5. INSTALL WATER PUMP PULLEY (See page CO-14)

6. INSTALL NO. 2 IDLER PULLEY SUB-ASSEMBLY

(a) Install the idler pulley and cover plate with the bolt.

Torque: 43 N*m (438 kgf*cm, 32 ft.*lbf)

7. INSTALL NO. 2 TIMING GEAR COVER

(a) Install the gear cover with the 2 bolts.

Torque: 6.0 N*m (61 kgf*cm, 53 in.*lbf)

8. INSTALL V-RIBBED BELT TENSIONER ASSEMBLY

(a) Temporarily install the V-ribbed belt tensioner with

the 5 bolts.

(b) Install the V-ribbed belt tensioner by tightening the

bolt 1 and bolt 2 in the order shown in the

illustration.

Torque: 43 N*m (438 kgf*cm, 32 ft.*lbf)

(c) Tighten the other bolts.

Torque: 43 N*m (438 kgf*cm, 32 ft.*lbf)

Each bolt length is as follows:

A129648

A129647

A129646

A139522

A139138E01

A 70 mm (2.76 in.)

Page 678 of 2000

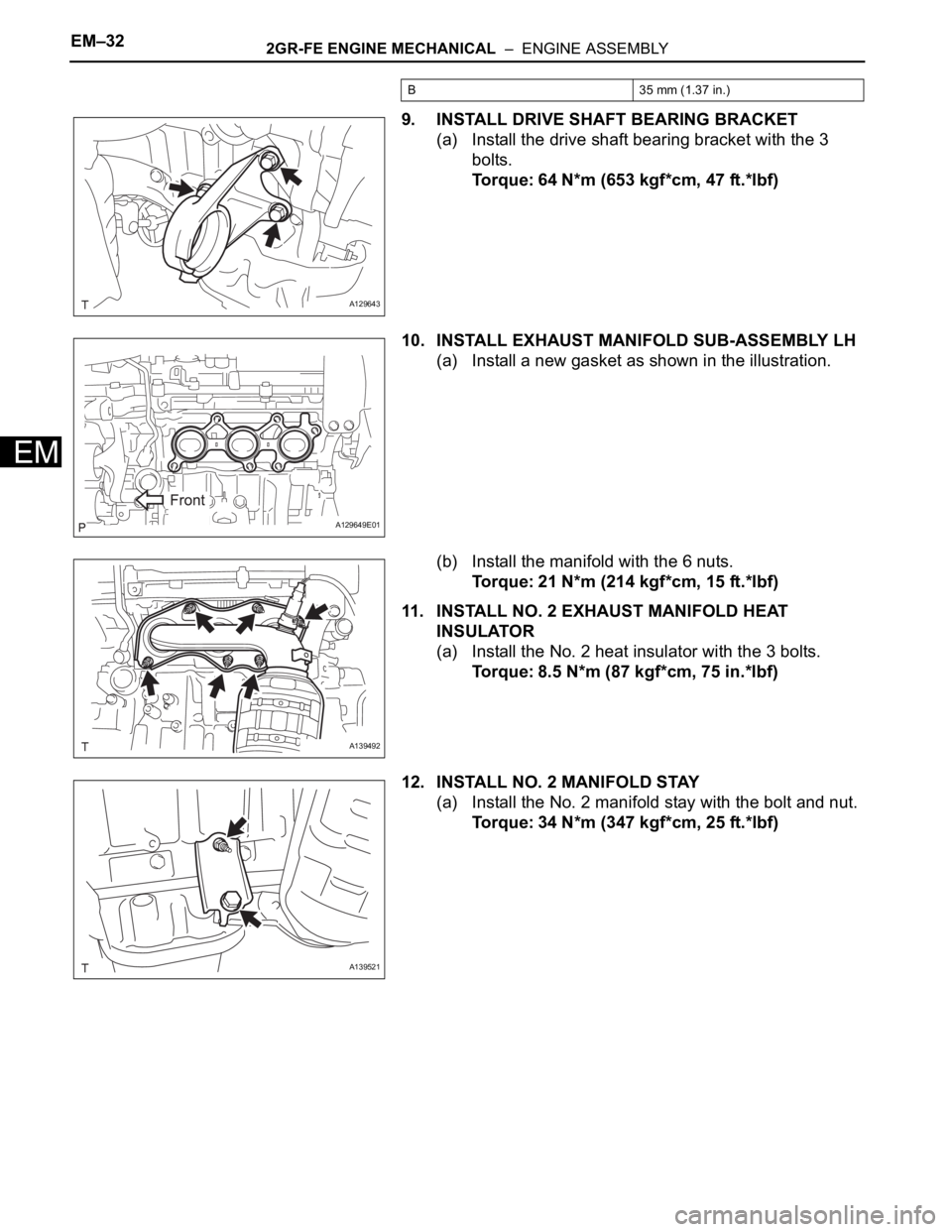

EM–322GR-FE ENGINE MECHANICAL – ENGINE ASSEMBLY

EM

9. INSTALL DRIVE SHAFT BEARING BRACKET

(a) Install the drive shaft bearing bracket with the 3

bolts.

Torque: 64 N*m (653 kgf*cm, 47 ft.*lbf)

10. INSTALL EXHAUST MANIFOLD SUB-ASSEMBLY LH

(a) Install a new gasket as shown in the illustration.

(b) Install the manifold with the 6 nuts.

Torque: 21 N*m (214 kgf*cm, 15 ft.*lbf)

11. INSTALL NO. 2 EXHAUST MANIFOLD HEAT

INSULATOR

(a) Install the No. 2 heat insulator with the 3 bolts.

Torque: 8.5 N*m (87 kgf*cm, 75 in.*lbf)

12. INSTALL NO. 2 MANIFOLD STAY

(a) Install the No. 2 manifold stay with the bolt and nut.

Torque: 34 N*m (347 kgf*cm, 25 ft.*lbf)

B 35 mm (1.37 in.)

A129643

A129649E01

A139492

A139521

Page 679 of 2000

2GR-FE ENGINE MECHANICAL – ENGINE ASSEMBLYEM–33

EM

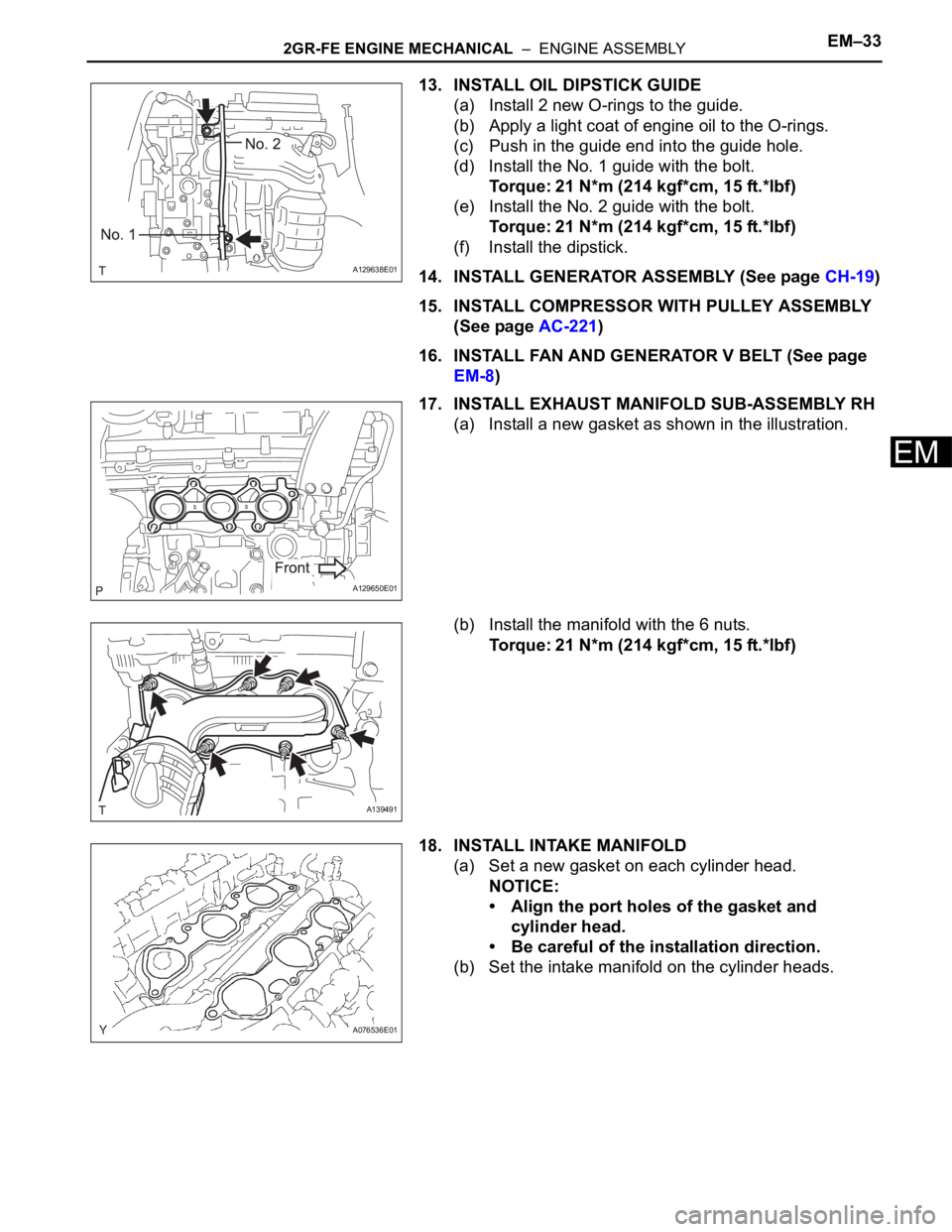

13. INSTALL OIL DIPSTICK GUIDE

(a) Install 2 new O-rings to the guide.

(b) Apply a light coat of engine oil to the O-rings.

(c) Push in the guide end into the guide hole.

(d) Install the No. 1 guide with the bolt.

Torque: 21 N*m (214 kgf*cm, 15 ft.*lbf)

(e) Install the No. 2 guide with the bolt.

Torque: 21 N*m (214 kgf*cm, 15 ft.*lbf)

(f) Install the dipstick.

14. INSTALL GENERATOR ASSEMBLY (See page CH-19)

15. INSTALL COMPRESSOR WITH PULLEY ASSEMBLY

(See page AC-221)

16. INSTALL FAN AND GENERATOR V BELT (See page

EM-8)

17. INSTALL EXHAUST MANIFOLD SUB-ASSEMBLY RH

(a) Install a new gasket as shown in the illustration.

(b) Install the manifold with the 6 nuts.

Torque: 21 N*m (214 kgf*cm, 15 ft.*lbf)

18. INSTALL INTAKE MANIFOLD

(a) Set a new gasket on each cylinder head.

NOTICE:

• Align the port holes of the gasket and

cylinder head.

• Be careful of the installation direction.

(b) Set the intake manifold on the cylinder heads.

A129638E01

A129650E01

A139491

A076536E01

Page 680 of 2000

EM–342GR-FE ENGINE MECHANICAL – ENGINE ASSEMBLY

EM

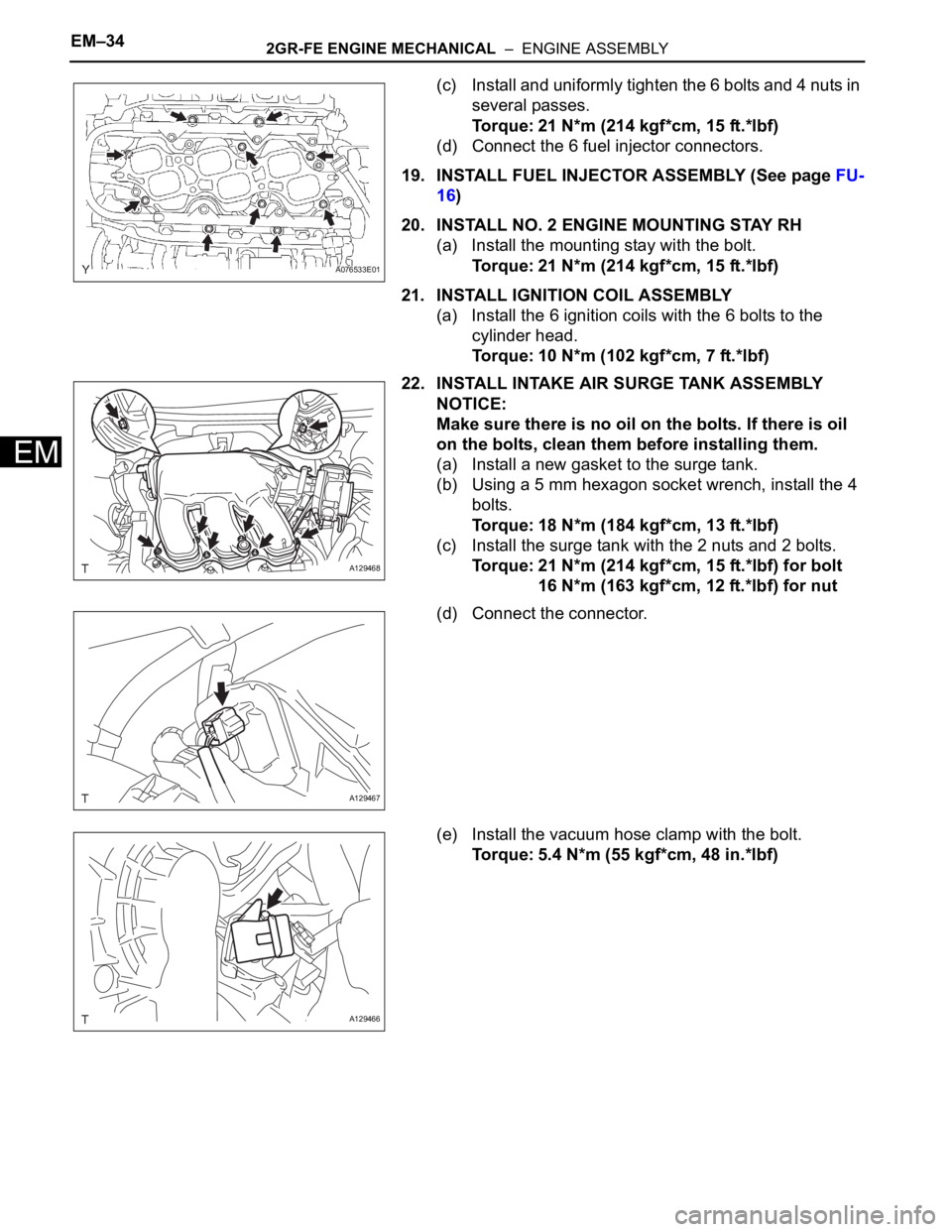

(c) Install and uniformly tighten the 6 bolts and 4 nuts in

several passes.

Torque: 21 N*m (214 kgf*cm, 15 ft.*lbf)

(d) Connect the 6 fuel injector connectors.

19. INSTALL FUEL INJECTOR ASSEMBLY (See page FU-

16)

20. INSTALL NO. 2 ENGINE MOUNTING STAY RH

(a) Install the mounting stay with the bolt.

Torque: 21 N*m (214 kgf*cm, 15 ft.*lbf)

21. INSTALL IGNITION COIL ASSEMBLY

(a) Install the 6 ignition coils with the 6 bolts to the

cylinder head.

Torque: 10 N*m (102 kgf*cm, 7 ft.*lbf)

22. INSTALL INTAKE AIR SURGE TANK ASSEMBLY

NOTICE:

Make sure there is no oil on the bolts. If there is oil

on the bolts, clean them before installing them.

(a) Install a new gasket to the surge tank.

(b) Using a 5 mm hexagon socket wrench, install the 4

bolts.

Torque: 18 N*m (184 kgf*cm, 13 ft.*lbf)

(c) Install the surge tank with the 2 nuts and 2 bolts.

Torque: 21 N*m (214 kgf*cm, 15 ft.*lbf) for bolt

16 N*m (163 kgf*cm, 12 ft.*lbf) for nut

(d) Connect the connector.

(e) Install the vacuum hose clamp with the bolt.

Torque: 5.4 N*m (55 kgf*cm, 48 in.*lbf)

A076533E01

A129468

A129467

A129466