TOYOTA RAV4 2006 Service Repair Manual

Manufacturer: TOYOTA, Model Year: 2006, Model line: RAV4, Model: TOYOTA RAV4 2006Pages: 2000, PDF Size: 45.84 MB

Page 651 of 2000

EM–1242AZ-FE ENGINE MECHANICAL – ENGINE UNIT

EM

20. REMOVE SPARK PLUG

21. REMOVE OIL FILLER CAP SUB-ASSEMBLY

22. REMOVE OIL FILLER CAP GASKET

23. REMOVE VENTILATION VALVE SUB-ASSEMBLY

(See page EC-18)

24. REMOVE CYLINDER HEAD COVER SUB-ASSEMBLY

(See page EM-24)

25. REMOVE CYLINDER HEAD COVER GASKET

26. REMOVE OIL FILTER SUB-ASSEMBLY (See page LU-

4)

27. REMOVE OIL FILTER UNION

(a) Using a 12 mm hexagon wrench, remove the oil

filter union.

28. REMOVE CRANKSHAFT POSITION SENSOR (See

page ES-402)

29. REMOVE WATER PUMP PULLEY (See page CO-11)

30. REMOVE WATER PUMP ASSEMBLY (See page CO-

11)

A132575

A128158

A128159

A128166

A126912E01

Page 652 of 2000

2AZ-FE ENGINE MECHANICAL – ENGINE UNITEM–125

EM

31. REMOVE OIL PAN DRAIN PLUG

(a) Remove the oil pan drain plug and gasket.

32. REMOVE OIL PAN SUB-ASSEMBLY (See page EM-

24)

33. REMOVE CRANKSHAFT PULLEY (See page EM-25)

34. REMOVE NO. 1 CHAIN TENSIONER ASSEMBLY (See

page EM-26)

35. REMOVE TIMING CHAIN COVER SUB-ASSEMBLY

(See page EM-26)

36. REMOVE NO. 1 CRANKSHAFT POSITION SENSOR

PLATE

37. REMOVE TIMING CHAIN GUIDE (See page EM-28)

38. REMOVE CHAIN TENSIONER SLIPPER (See page

EM-28)

39. REMOVE NO. 1 CHAIN VIBRATION DAMPER (See

page EM-28)

40. REMOVE CHAIN SUB-ASSEMBLY

41. REMOVE CRANKSHAFT TIMING SPROCKET

42. REMOVE NO. 2 CHAIN SUB-ASSEMBLY (See page

EM-29)

43. REMOVE OIL PUMP DRIVE GEAR

44. REMOVE OIL PUMP ASSEMBLY (See page LU-12)

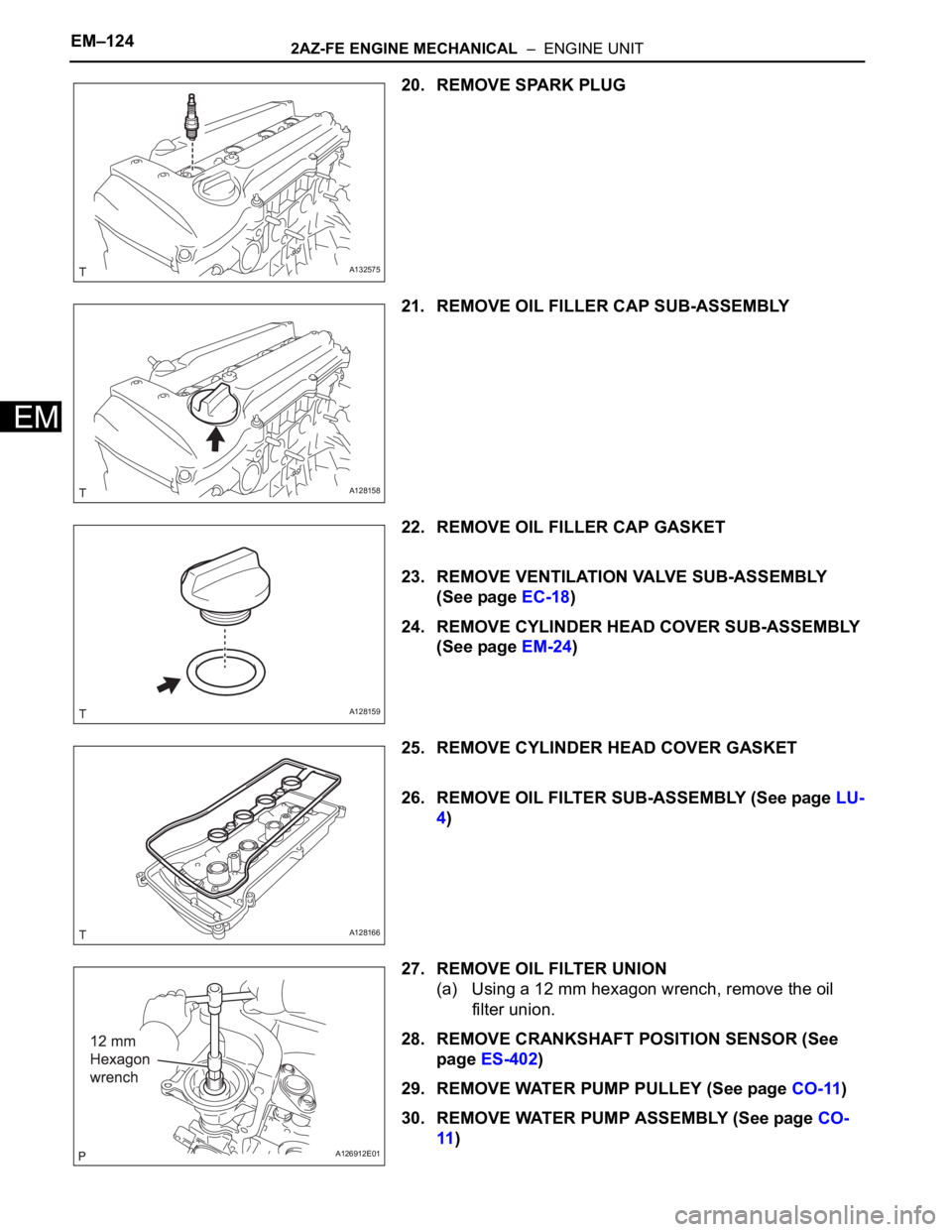

45. REMOVE CAMSHAFT

(a) Using several steps, uniformly loosen and remove

the 20 bearing cap bolts in the sequence shown in

the illustration.

(b) Remove the 10 bearing caps, then remove the

camshaft and No. 2 camshaft.

46. REMOVE CYLINDER HEAD SUB-ASSEMBLY (See

page EM-62)

A128176

A132571

A128185

A128186

F050596E02

Page 653 of 2000

EM–1262AZ-FE ENGINE MECHANICAL – ENGINE UNIT

EM

47. REMOVE CYLINDER HEAD GASKET

48. REMOVE CYLINDER BLOCK WATER JACKET

SPACER

(a) Using needle-nose pliers, remove the cylinder block

water jacket spacer from the water jacket.

NOTICE:

Before turning the cylinder block upside down,

make sure that the water jacket spacer is

removed, as it will fall out.

49. REMOVE CYLINDER BLOCK WATER DRAIN COCK

SUB-ASSEMBLY

50. REMOVE OIL CONTROL VALVE FILTER

(a) Using a 6 mm socket hexagon wrench, remove the

plug and gasket.

(b) Remove the oil control valve filter.

51. INSPECT BALANCE SHAFT THRUST CLEARANCE

(a) Using a dial indicator, measure the thrust clearance

while moving the balance shaft back and forth.

Standard thrust clearance:

0.05 to 0.09 mm (0.0020 to 0.0035 in.)

Maximum thrust clearance:

0.09 mm (0.0035 in.)

If the thrust clearance is greater than the maximum,

replace the balance shaft housing and bearings. If

necessary, replace the balance shaft.

A126929

A128208

A128209

A128210

A128196

Page 654 of 2000

2AZ-FE ENGINE MECHANICAL – ENGINE UNITEM–127

EM

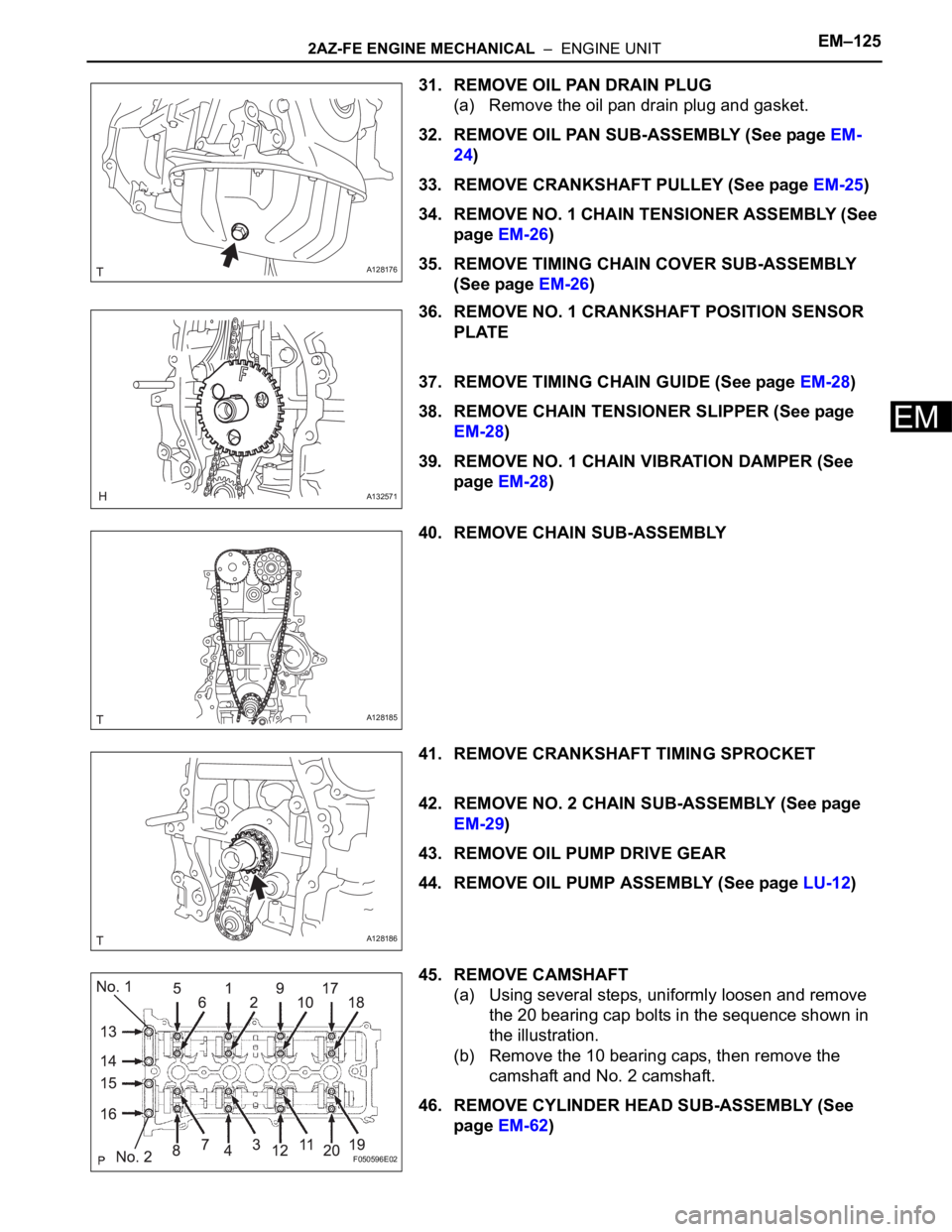

52. INSPECT BALANCE SHAFT OIL CLEARANCE

(a) Using several steps, uniformly loosen and remove

the 8 bolts in the sequence shown in the illustration.

(b) Remove the balance shaft housing from the

crankcase.

HINT:

Keep the lower bearing and balance shaft housing

together.

(c) Lift out the No. 1 and No. 2 balance shafts.

HINT:

Keep the upper bearing with the crankcase.

(d) Clean each bearing and journal.

(e) Check each bearing and journal for pitting and

scratches.

If a bearing or journal is damaged, replace the

bearings. If necessary, replace the balance shaft.

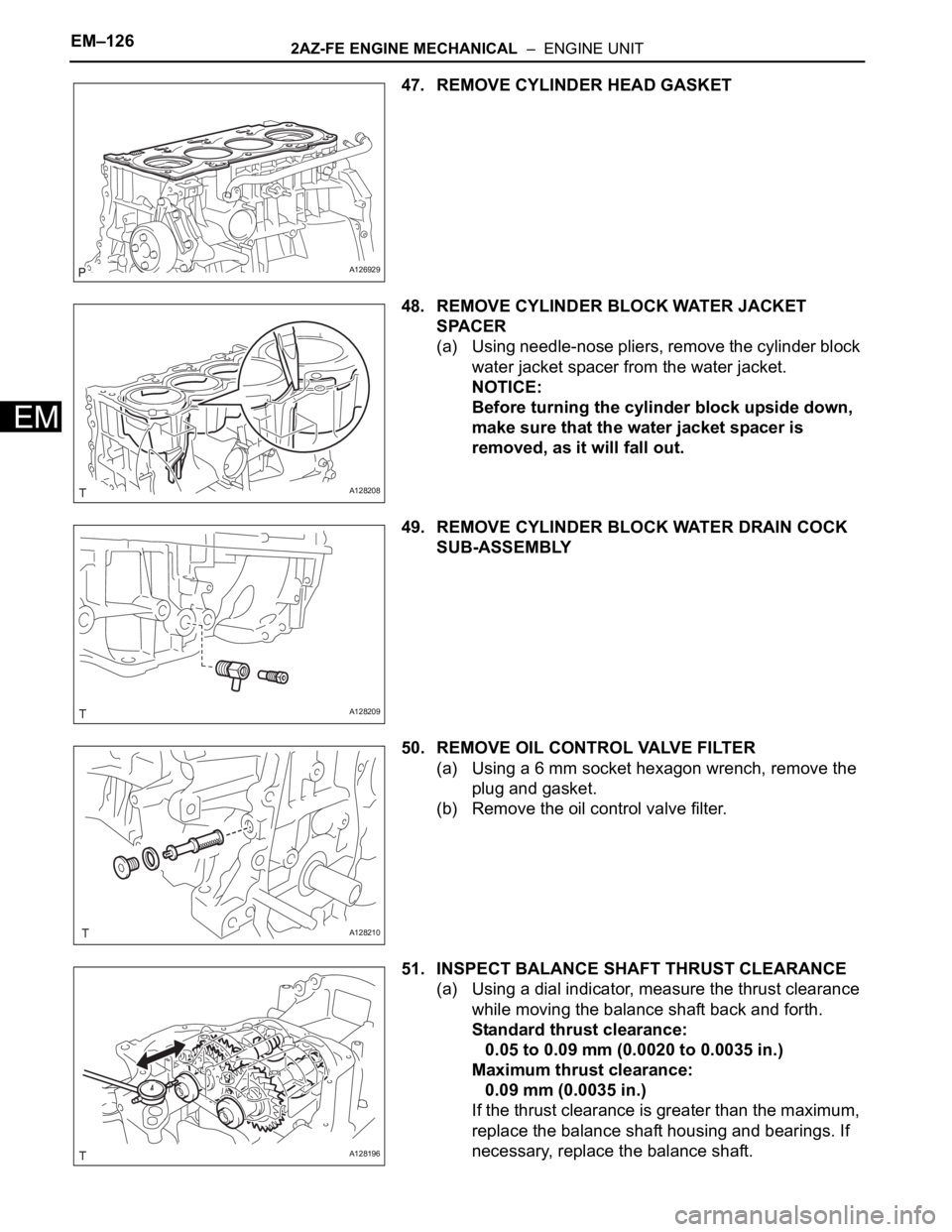

(f) Inspect the balance shaft housing bolt.

(1) Using a vernier caliper, measure the length of

the bolts from the seat to the end.

Standard bolt length:

58.3 to 59.7 mm (2.295 to 2.350 in.)

Maximum bolt length:

60.3 mm (2.374 in.)

If the bolt length is greater than the maximum,

replace the balance shaft bolt.

(g) Place the No. 1 and No. 2 balance shafts onto the

crankcase.

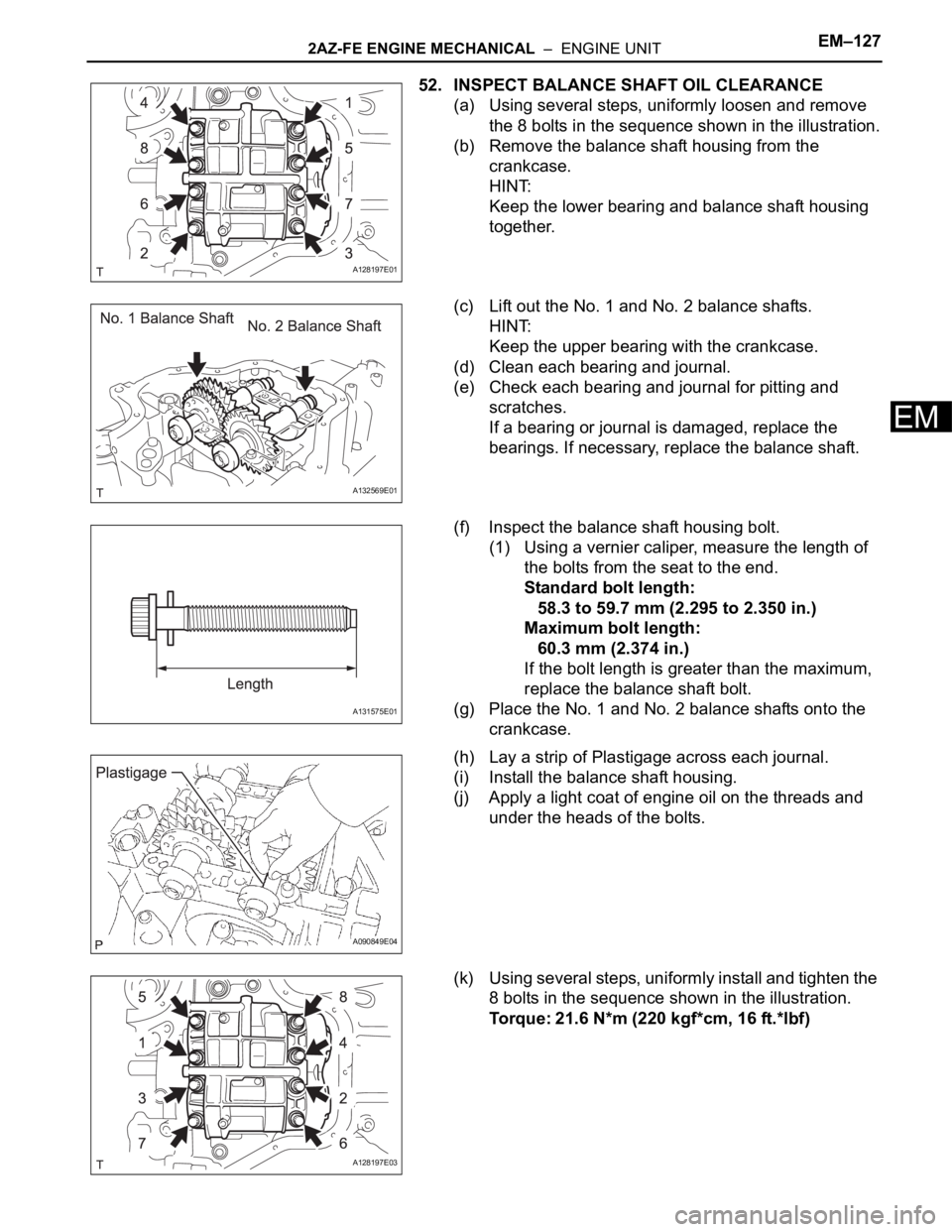

(h) Lay a strip of Plastigage across each journal.

(i) Install the balance shaft housing.

(j) Apply a light coat of engine oil on the threads and

under the heads of the bolts.

(k) Using several steps, uniformly install and tighten the

8 bolts in the sequence shown in the illustration.

Torque: 21.6 N*m (220 kgf*cm, 16 ft.*lbf)

A128197E01

A132569E01

A131575E01

A090849E04

A128197E03

Page 655 of 2000

EM–1282AZ-FE ENGINE MECHANICAL – ENGINE UNIT

EM

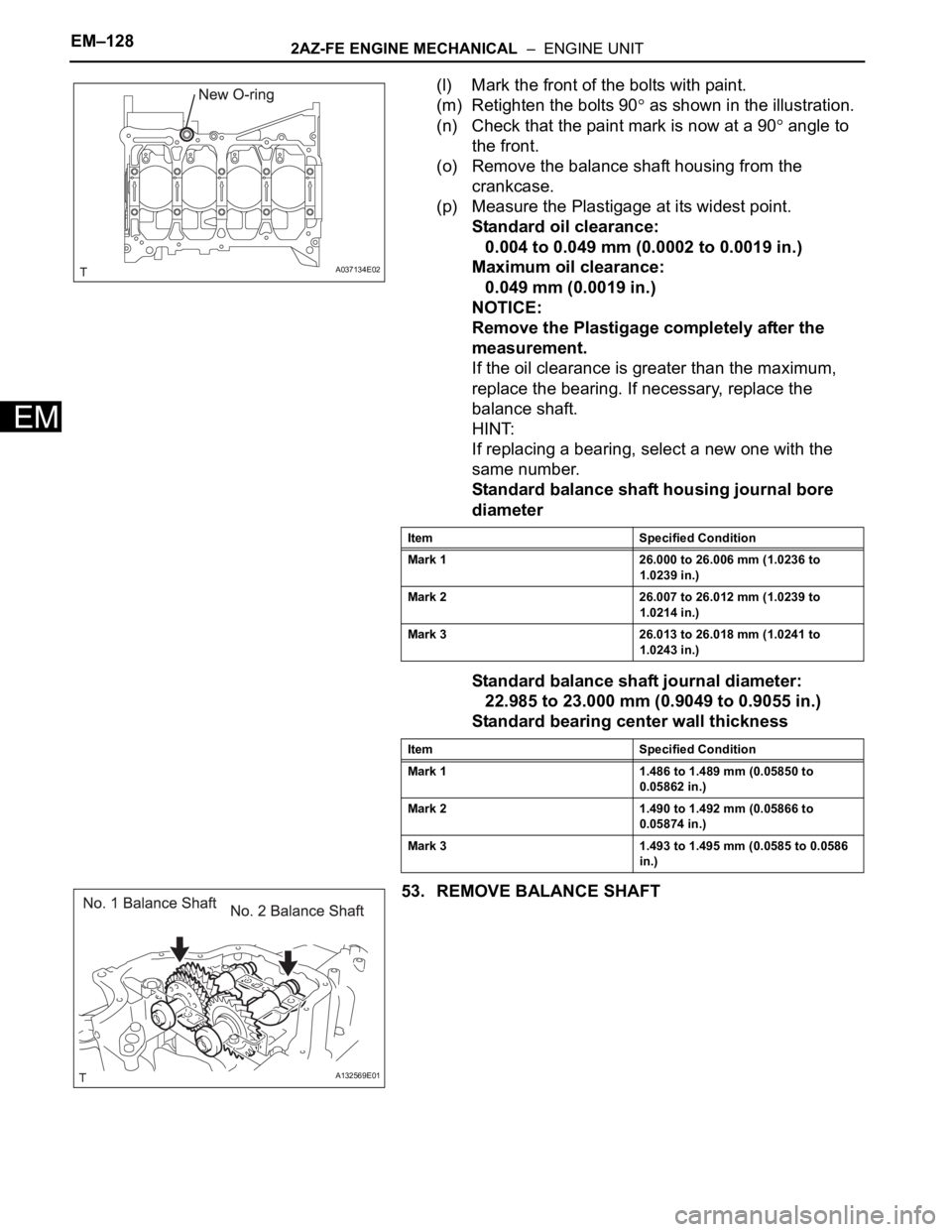

(l) Mark the front of the bolts with paint.

(m) Retighten the bolts 90

as shown in the illustration.

(n) Check that the paint mark is now at a 90

angle to

the front.

(o) Remove the balance shaft housing from the

crankcase.

(p) Measure the Plastigage at its widest point.

Standard oil clearance:

0.004 to 0.049 mm (0.0002 to 0.0019 in.)

Maximum oil clearance:

0.049 mm (0.0019 in.)

NOTICE:

Remove the Plastigage completely after the

measurement.

If the oil clearance is greater than the maximum,

replace the bearing. If necessary, replace the

balance shaft.

HINT:

If replacing a bearing, select a new one with the

same number.

Standard balance shaft housing journal bore

diameter

Standard balance shaft journal diameter:

22.985 to 23.000 mm (0.9049 to 0.9055 in.)

Standard bearing center wall thickness

53. REMOVE BALANCE SHAFT

A037134E02

Item Specified Condition

Mark 1 26.000 to 26.006 mm (1.0236 to

1.0239 in.)

Mark 2 26.007 to 26.012 mm (1.0239 to

1.0214 in.)

Mark 3 26.013 to 26.018 mm (1.0241 to

1.0243 in.)

Item Specified Condition

Mark 1 1.486 to 1.489 mm (0.05850 to

0.05862 in.)

Mark 2 1.490 to 1.492 mm (0.05866 to

0.05874 in.)

Mark 3 1.493 to 1.495 mm (0.0585 to 0.0586

in.)

A132569E01

Page 656 of 2000

2AZ-FE ENGINE MECHANICAL – ENGINE UNITEM–129

EM

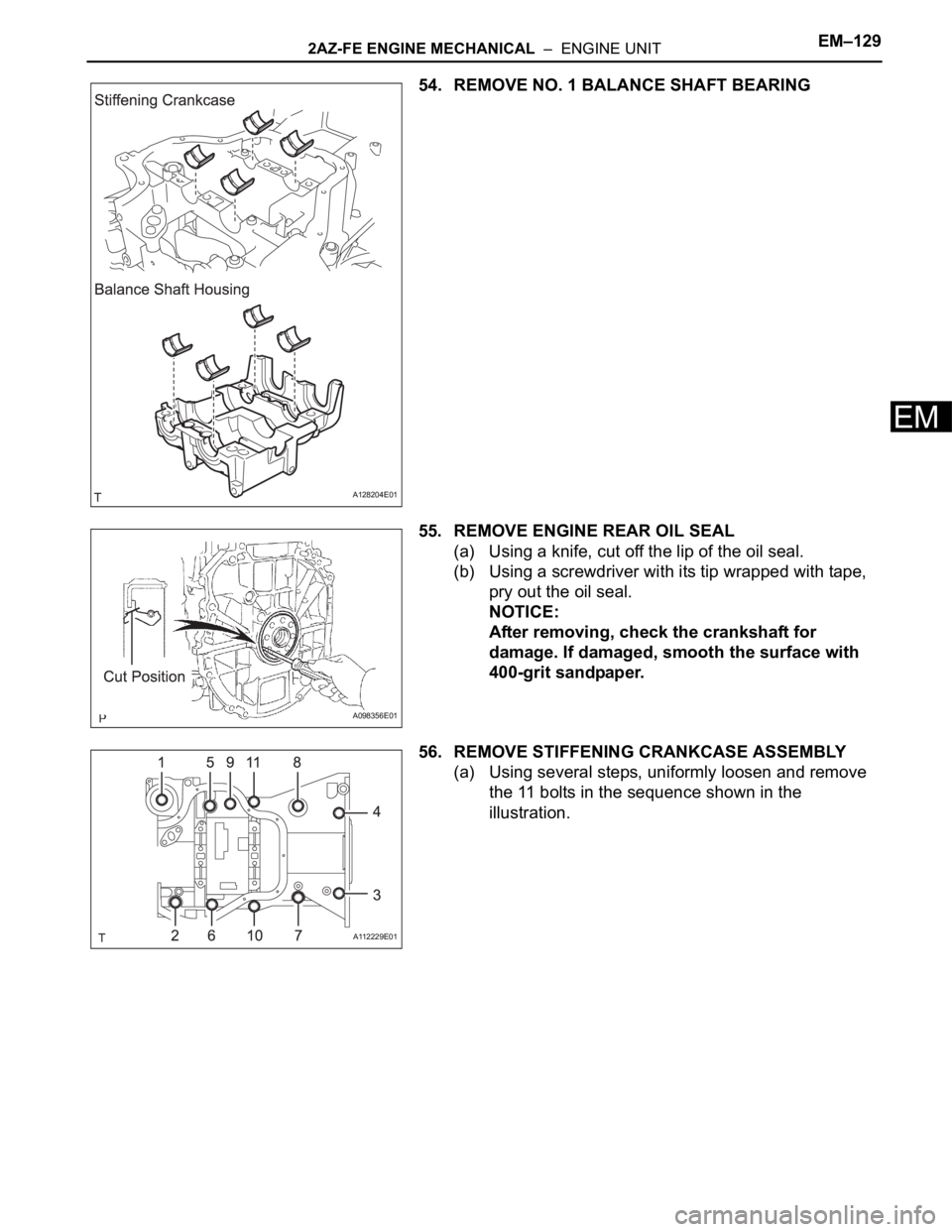

54. REMOVE NO. 1 BALANCE SHAFT BEARING

55. REMOVE ENGINE REAR OIL SEAL

(a) Using a knife, cut off the lip of the oil seal.

(b) Using a screwdriver with its tip wrapped with tape,

pry out the oil seal.

NOTICE:

After removing, check the crankshaft for

damage. If damaged, smooth the surface with

400-grit sandpaper.

56. REMOVE STIFFENING CRANKCASE ASSEMBLY

(a) Using several steps, uniformly loosen and remove

the 11 bolts in the sequence shown in the

illustration.

A128204E01

A098356E01

A112229E01

Page 657 of 2000

EM–1302AZ-FE ENGINE MECHANICAL – ENGINE UNIT

EM

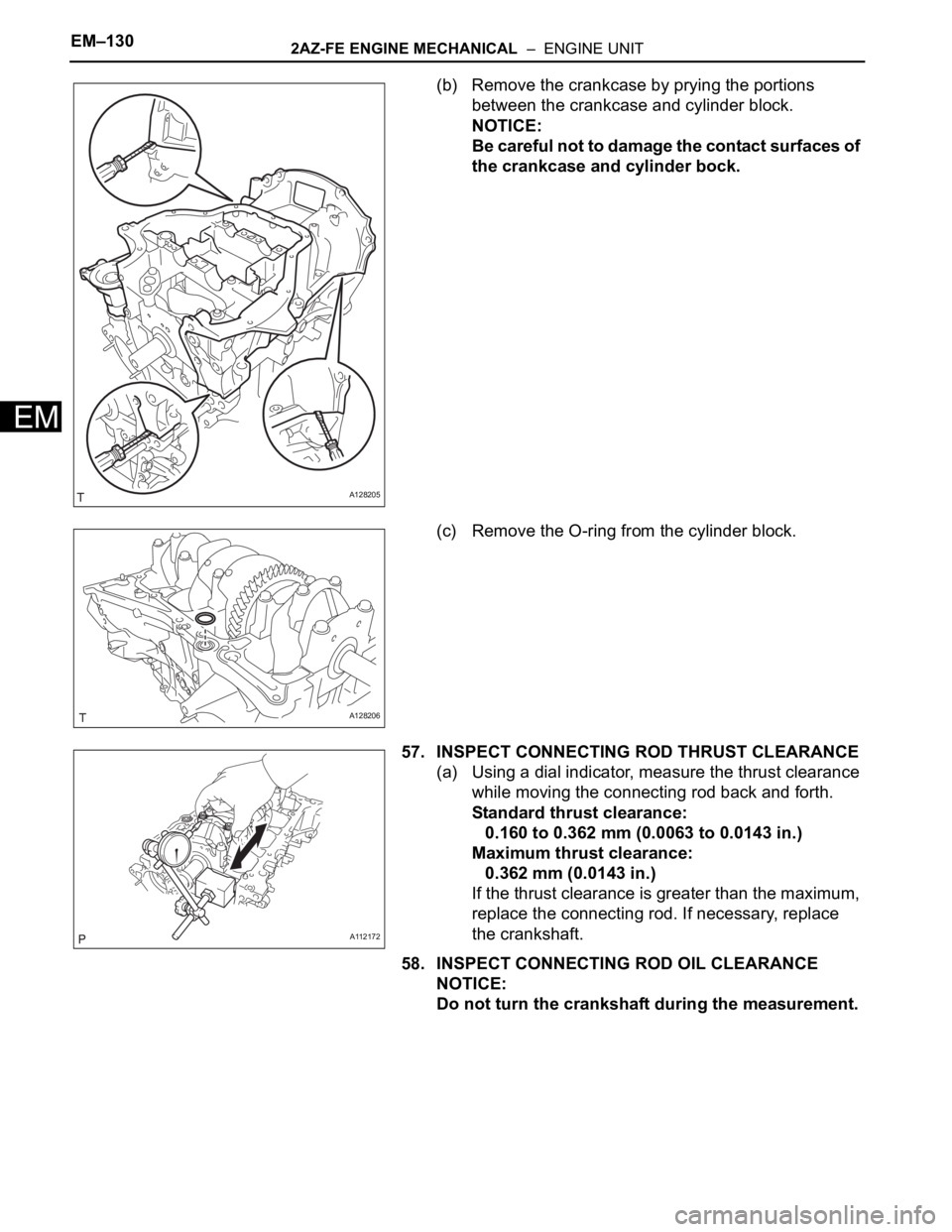

(b) Remove the crankcase by prying the portions

between the crankcase and cylinder block.

NOTICE:

Be careful not to damage the contact surfaces of

the crankcase and cylinder bock.

(c) Remove the O-ring from the cylinder block.

57. INSPECT CONNECTING ROD THRUST CLEARANCE

(a) Using a dial indicator, measure the thrust clearance

while moving the connecting rod back and forth.

Standard thrust clearance:

0.160 to 0.362 mm (0.0063 to 0.0143 in.)

Maximum thrust clearance:

0.362 mm (0.0143 in.)

If the thrust clearance is greater than the maximum,

replace the connecting rod. If necessary, replace

the crankshaft.

58. INSPECT CONNECTING ROD OIL CLEARANCE

NOTICE:

Do not turn the crankshaft during the measurement.

A128205

A128206

A112172

Page 658 of 2000

2AZ-FE ENGINE MECHANICAL – ENGINE UNITEM–131

EM

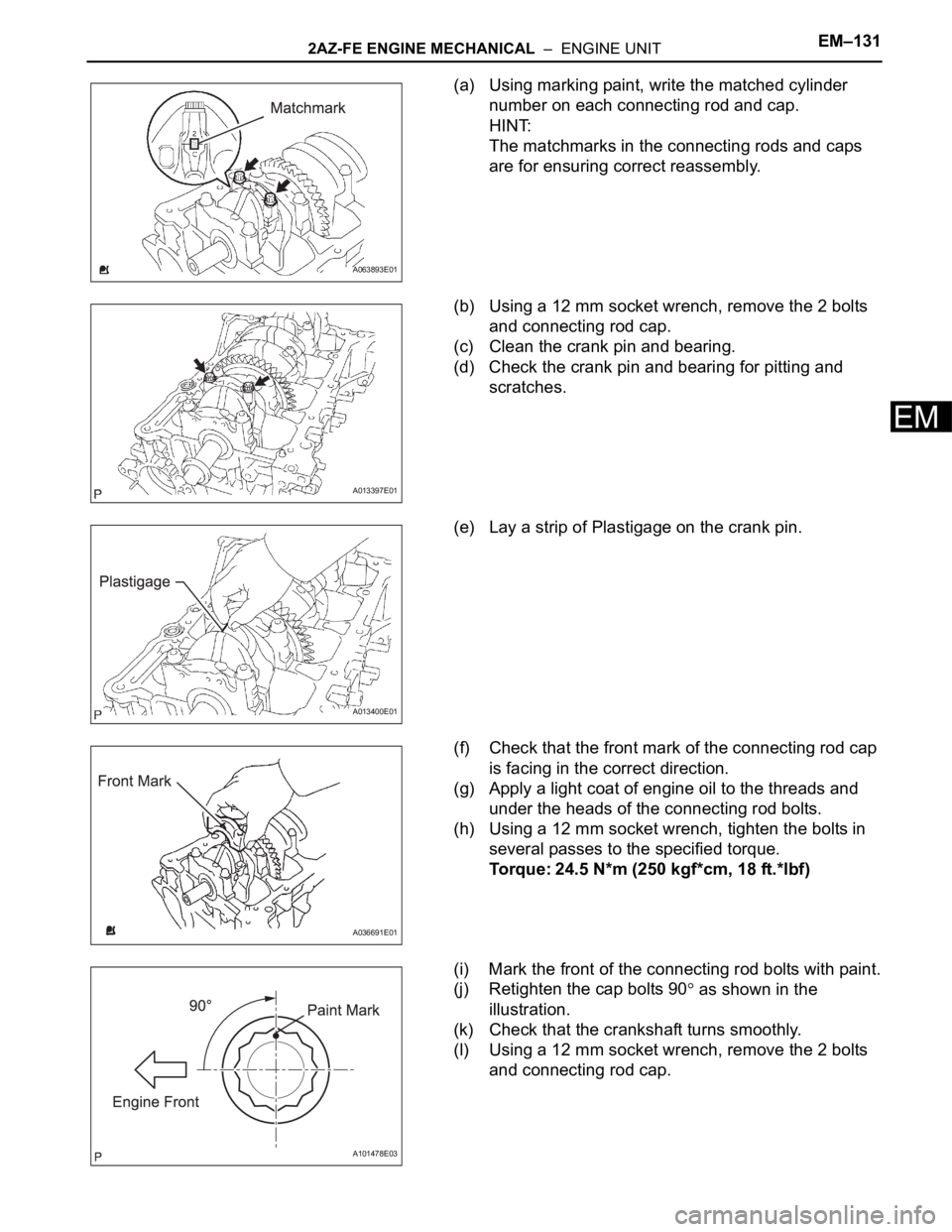

(a) Using marking paint, write the matched cylinder

number on each connecting rod and cap.

HINT:

The matchmarks in the connecting rods and caps

are for ensuring correct reassembly.

(b) Using a 12 mm socket wrench, remove the 2 bolts

and connecting rod cap.

(c) Clean the crank pin and bearing.

(d) Check the crank pin and bearing for pitting and

scratches.

(e) Lay a strip of Plastigage on the crank pin.

(f) Check that the front mark of the connecting rod cap

is facing in the correct direction.

(g) Apply a light coat of engine oil to the threads and

under the heads of the connecting rod bolts.

(h) Using a 12 mm socket wrench, tighten the bolts in

several passes to the specified torque.

Torque: 24.5 N*m (250 kgf*cm, 18 ft.*lbf)

(i) Mark the front of the connecting rod bolts with paint.

(j) Retighten the cap bolts 90

as shown in the

illustration.

(k) Check that the crankshaft turns smoothly.

(l) Using a 12 mm socket wrench, remove the 2 bolts

and connecting rod cap.

A063893E01

A013397E01

A013400E01

A036691E01

A101478E03

Page 659 of 2000

EM–1322AZ-FE ENGINE MECHANICAL – ENGINE UNIT

EM

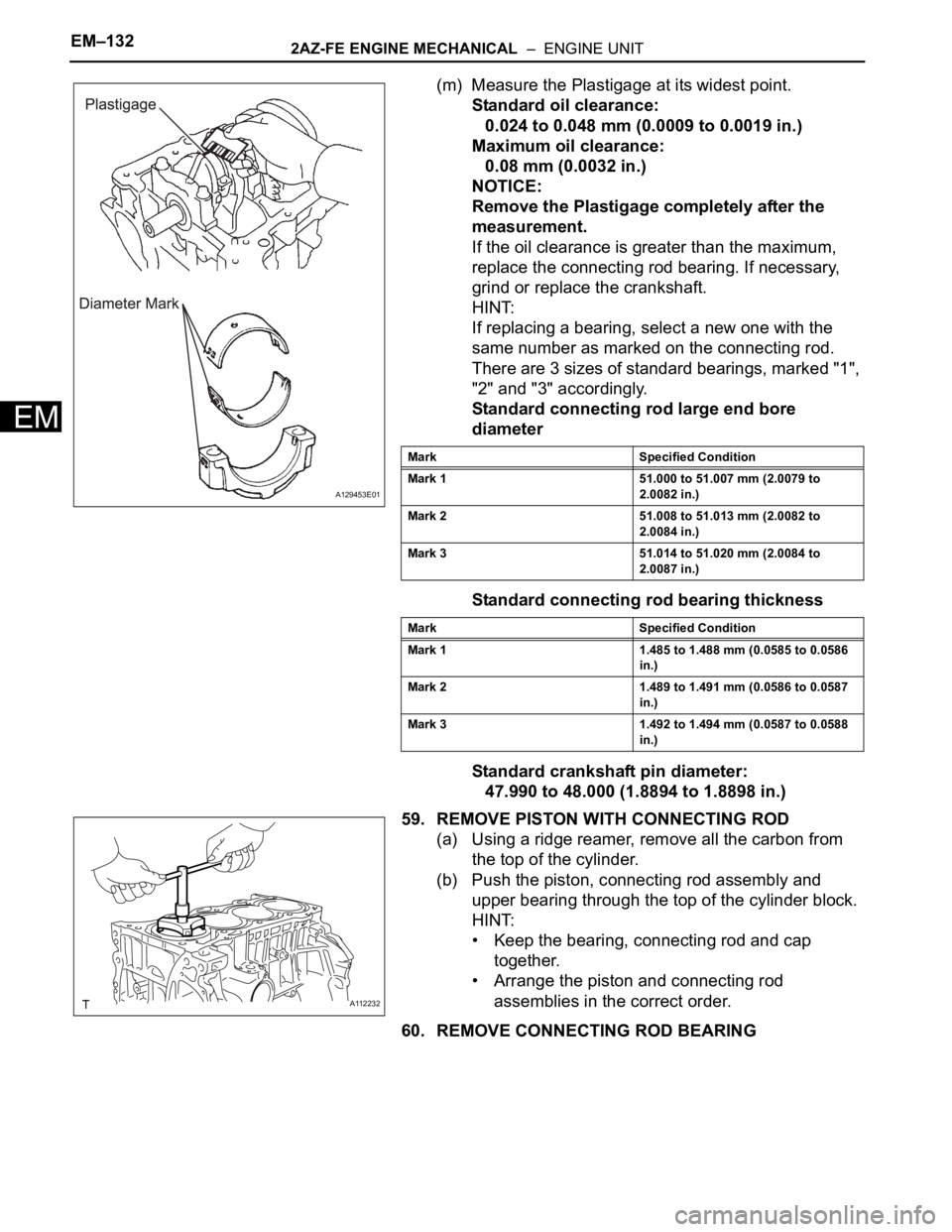

(m) Measure the Plastigage at its widest point.

Standard oil clearance:

0.024 to 0.048 mm (0.0009 to 0.0019 in.)

Maximum oil clearance:

0.08 mm (0.0032 in.)

NOTICE:

Remove the Plastigage completely after the

measurement.

If the oil clearance is greater than the maximum,

replace the connecting rod bearing. If necessary,

grind or replace the crankshaft.

HINT:

If replacing a bearing, select a new one with the

same number as marked on the connecting rod.

There are 3 sizes of standard bearings, marked "1",

"2" and "3" accordingly.

Standard connecting rod large end bore

diameter

Standard connecting rod bearing thickness

Standard crankshaft pin diameter:

47.990 to 48.000 (1.8894 to 1.8898 in.)

59. REMOVE PISTON WITH CONNECTING ROD

(a) Using a ridge reamer, remove all the carbon from

the top of the cylinder.

(b) Push the piston, connecting rod assembly and

upper bearing through the top of the cylinder block.

HINT:

• Keep the bearing, connecting rod and cap

together.

• Arrange the piston and connecting rod

assemblies in the correct order.

60. REMOVE CONNECTING ROD BEARING

A129453E01

Mark Specified Condition

Mark 1 51.000 to 51.007 mm (2.0079 to

2.0082 in.)

Mark 2 51.008 to 51.013 mm (2.0082 to

2.0084 in.)

Mark 3 51.014 to 51.020 mm (2.0084 to

2.0087 in.)

Mark Specified Condition

Mark 1 1.485 to 1.488 mm (0.0585 to 0.0586

in.)

Mark 2 1.489 to 1.491 mm (0.0586 to 0.0587

in.)

Mark 3 1.492 to 1.494 mm (0.0587 to 0.0588

in.)

A112232

Page 660 of 2000

2AZ-FE ENGINE MECHANICAL – ENGINE UNITEM–133

EM

61. REMOVE PISTON RING SET

(a) Using a piston ring expander, remove the 2

compression rings.

(b) Remove the oil ring and expander by hand.

62. REMOVE PISTON PIN HOLE SNAP RING

(a) Using a small screwdriver, pry out the 2 snap rings.

63. REMOVE PISTON

(a) Gradually heat the piston up to 80 to 90

C (176 to

194

F).

(b) Using a plastic-faced hammer and brass bar, lightly

tap out the piston pin, then remove the connecting

rod.

HINT:

• The piston and pin are a matched set.

• Arrange the piston, pin, ring, connecting rod and

bearings in the correct order.

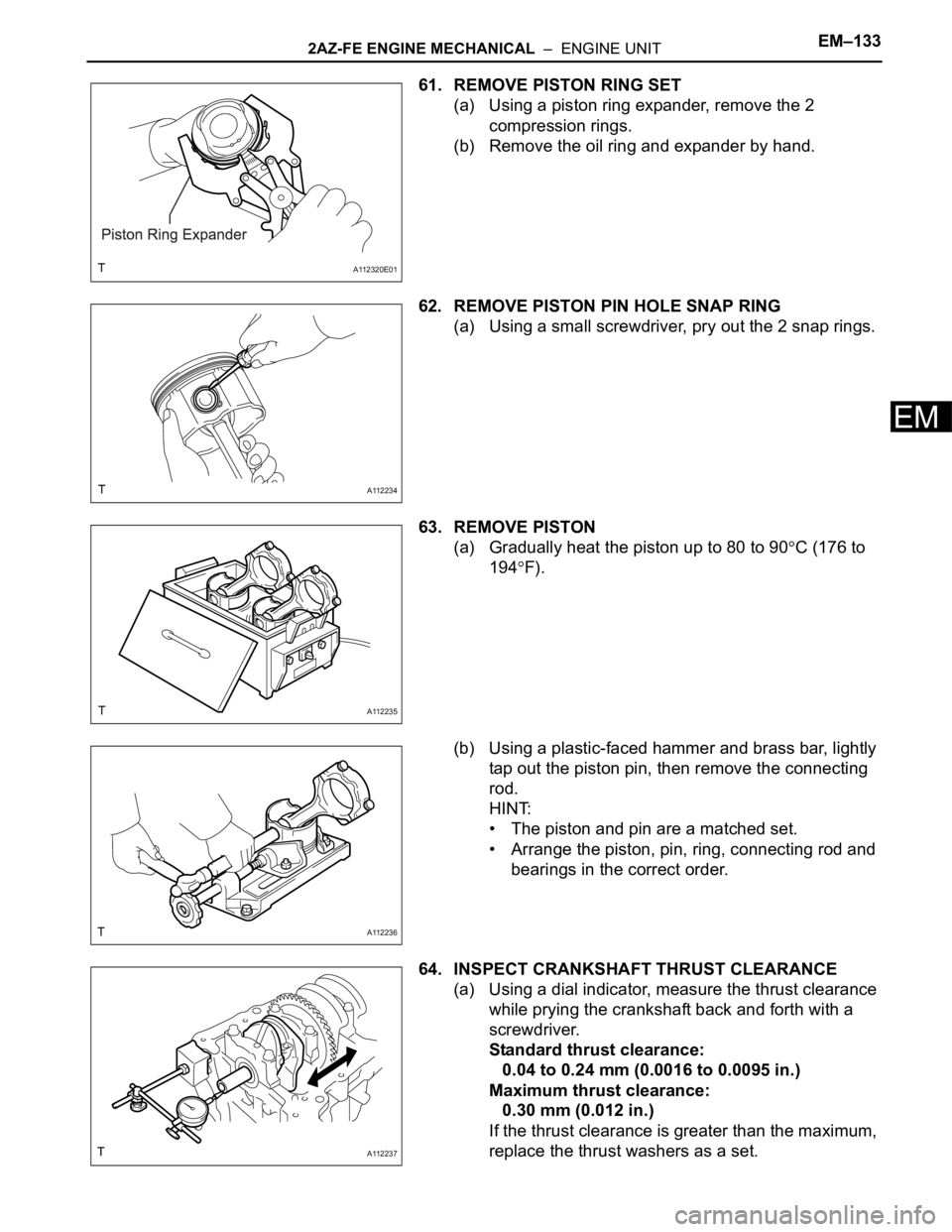

64. INSPECT CRANKSHAFT THRUST CLEARANCE

(a) Using a dial indicator, measure the thrust clearance

while prying the crankshaft back and forth with a

screwdriver.

Standard thrust clearance:

0.04 to 0.24 mm (0.0016 to 0.0095 in.)

Maximum thrust clearance:

0.30 mm (0.012 in.)

If the thrust clearance is greater than the maximum,

replace the thrust washers as a set.

A112320E01

A112234

A112235

A112236

A112237